Sludge solidification in-situ test method

A technology for in-situ testing and silting, applied in measurement devices, climate sustainability, instruments, etc., can solve problems such as excessive soil damage, unsuitable layout, etc., and achieve accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

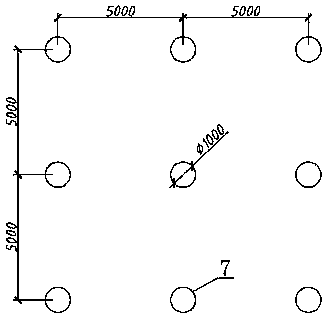

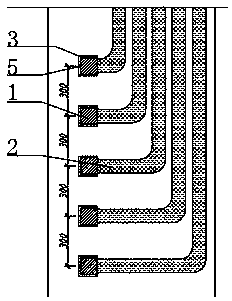

[0031] Such as figure 1 and figure 2 As shown, the in-situ curing test method of this embodiment is a multi-point parallel test method, and the measuring holes 7 are arranged at equal intervals in the vertical depth of the solidified soil, and the internal measuring points are connected by the piezoelectric solidified soil 1 through the conductive solidified soil 2 and the data The collector is connected; the piezoelectric solidified soil 1 is composed of in-situ silt and self-sensing silt solidifying agent, and the conductive solidified soil is composed of in-situ silt and conductive solidifying agent.

[0032] The self-sensing sludge curing agent is composed of cement, fly ash, piezoelectric ceramic particles and conductive medium according to the volume ratio of 32:18:40:10, and the conductive curing agent is composed of cement, fly ash, sand and conductive medium according to the volume ratio Mixing ratio of 32:18:40:10;

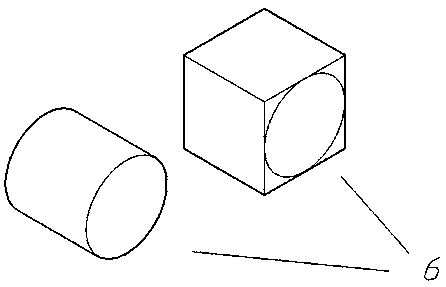

[0033] Such as image 3 As shown, the shape of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com