A kind of mud solidification in-situ test method

A technology of in-situ testing and silt, applied in the direction of measuring devices, climate sustainability, instruments, etc., can solve problems such as excessive soil damage, limited number of measuring points, etc., and achieve accurate measurement results and high density of measuring points Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

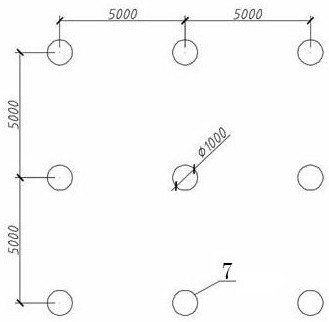

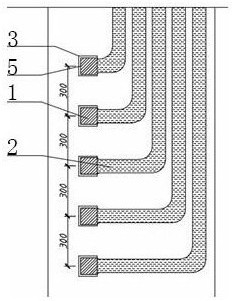

[0031] like figure 1 and figure 2 As shown, the in-situ solidification test method of this embodiment is a multi-point parallel test method, measuring holes 7 are arranged at equal intervals in the vertical depth of the solidified soil, and the internal measuring points are composed of piezoelectric solidified soil 1 through conductive solidified soil 2 and data. The collector is connected; the piezoelectric solidified soil 1 is composed of in-situ sludge and self-sensing sludge curing agent, and the conductive solidified soil is composed of in-situ sludge and conductive curing agent.

[0032] The self-sensing sludge curing agent is mixed by cement, fly ash, piezoelectric ceramic particles and conductive medium in a volume ratio of 32:18:40:10, and the conductive curing agent is composed of cement, fly ash, sand and conductive medium by volume. Mix in a ratio of 32:18:40:10;

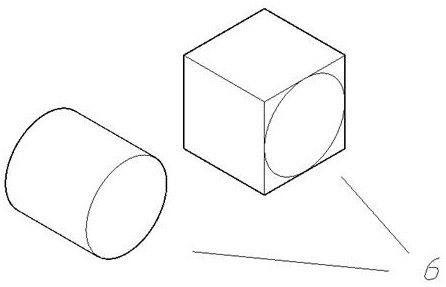

[0033] like image 3 As shown, the shape of the measuring point can be a cylinder or a cube. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com