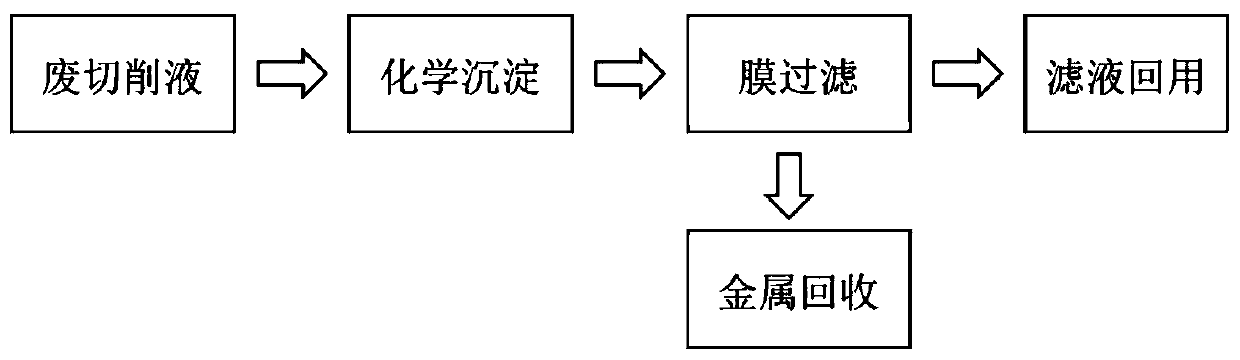

Cyclic utilization method of cutting fluid containing copper and nickel

A technology of cutting fluid and copper-nickel, which is applied in the field of recycling of cutting fluid, can solve the problems of complex cutting fluid treatment process and high treatment cost, and achieve the effect of small impact, high metal content and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

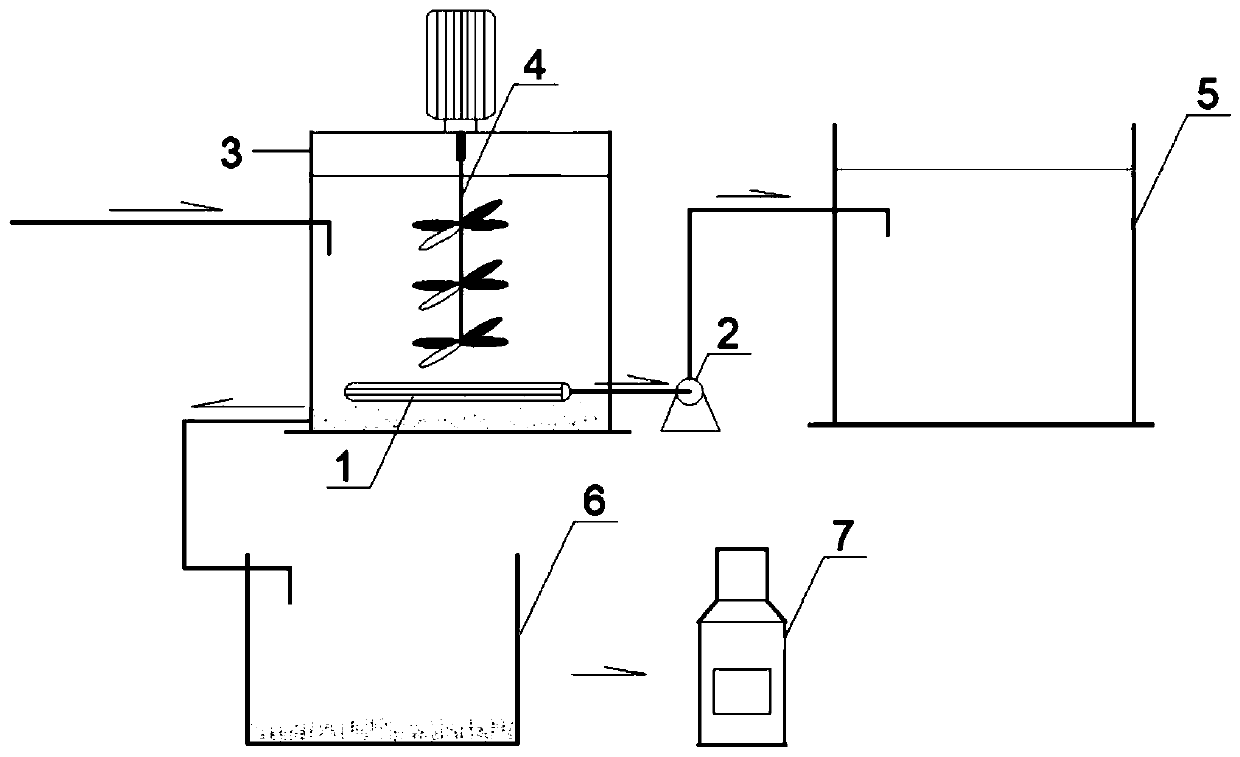

[0015] Specific embodiment one: present embodiment is a kind of recycling method of copper-nickel cutting fluid, specifically carries out according to the following steps:

[0016] 1. Fix the membrane filter on the inner bottom of the reaction tank. The membrane filter is connected to the water inlet of the self-priming centrifugal pump through the water pipe, and the water outlet of the self-priming centrifugal pump is connected to the collection tank; the cutting fluid to be treated is added to the reaction tank and then add sodium sulfide or organic sulfide polymer chelating agent. After adding, the concentration of sodium sulfide or organic sulfide polymer hydrating agent in the reaction tank is 1g / L~3g / L, and then put it into the reaction tank Add polyacrylamide aqueous solution, the concentration of polyacrylamide in the reaction tank after adding is 10mg / L~15mg / L, turn on the stirrer in the reaction tank, the stirrer speed is 200r / min~400r / min, and the stirring time is ...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the membrane filter described in step 1 is an ultrafiltration membrane, a microporous membrane, a nanofiltration membrane, a microfiltration membrane, a hollow fiber ultrafiltration membrane or Ceramic Membrane. Others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 2 in that: the pore diameter of the membrane wall of the membrane filter described in step 1 is 0.1 μm˜1 μm. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com