Fault detection method and sampler for oil overflow of oil-filled high-pressure casing

A high-voltage bushing and fault detection technology, which is applied to sampling, sampling devices, and through detecting the appearance of fluid at leakage points, can solve problems such as seal damage, insignificant phenomena, and complicated causes of oil overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

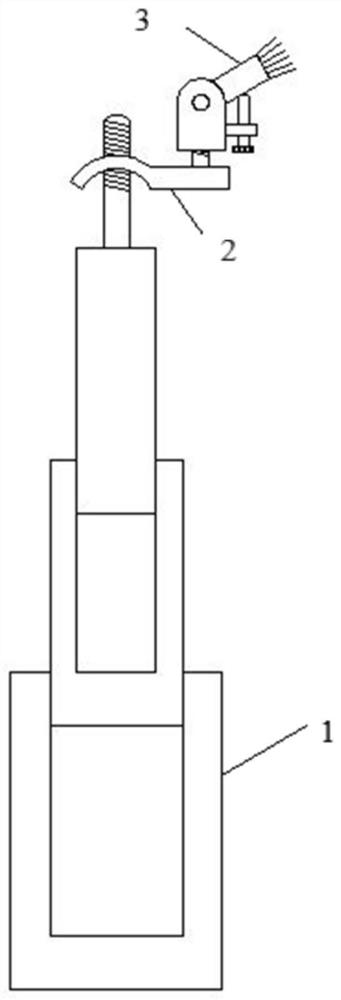

Image

Examples

Embodiment 1

[0027] Embodiment 1 is specifically to adopt the reddish brown test paper soaked in the carbon tetrachloride solution of bromine and air-dried as the detection test paper to the detection of oil-filled high-pressure casing oil flow overflow, and will be obtained from the surface sampling of the oil-filled high-pressure casing to be tested Smear the sample on the test paper, and judge whether the oil-filled high-pressure bushing to be tested has an oil overflow failure according to whether the test paper has faded;

[0028] Among them, the method for sampling the surface of the oil-filled high-pressure bushing to be tested is specifically to wipe the end of the oil-filled high-pressure bushing to be tested in all directions, thereby ensuring complete sampling of the oil-filled high-pressure bushing to avoid missed detection and improve detection accuracy.

[0029] In this embodiment, the carbon tetrachloride solution of bromine is formed by mixing liquid bromine and carbon tetra...

Embodiment 2

[0035] Embodiment 2 is specifically to adopt the potassium permanganate aqueous ethanol solution as the detection reagent to the detection of oil-filled high-pressure casing oil overflow, or to further use the detection reagent to soak test paper and dry it to make the detection test paper; The sample taken from the surface of the oil-filled high-pressure bushing is smeared on the test paper, and whether the oil-filled high-pressure bushing to be tested has an oil overflow failure is determined according to whether the test paper has faded;

[0036]In this embodiment, the aqueous ethanol solution of potassium permanganate is formed by dissolving potassium permanganate in aqueous ethanol with a concentration of about 85% to 95% (adding about 5% to 15% of water in the ethanol), and at this concentration , the unsaturated carbon-carbon bond has good binding with the detection reagent, and the reaction speed is fast. When the unsaturated carbon-carbon bond is detected, the phenomen...

Embodiment 3

[0038] Embodiment 3 is to detect oil-filled high-pressure casing oil overflow failure, is on the basis of embodiment 2, adds chemical tracer in potassium permanganate aqueous ethanol solution to make detection agent, and further adopts this detection agent Soak the test paper and dry it to make a test paper; apply the sample taken from the surface of the oil-filled high-pressure bushing to be tested to the test paper, and judge whether the oil-filled high-pressure bushing to be tested has an oil overflow fault according to whether the test paper has faded. ; If the color fades, it is determined that the oil-filled high-pressure bushing has an oil overflow failure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com