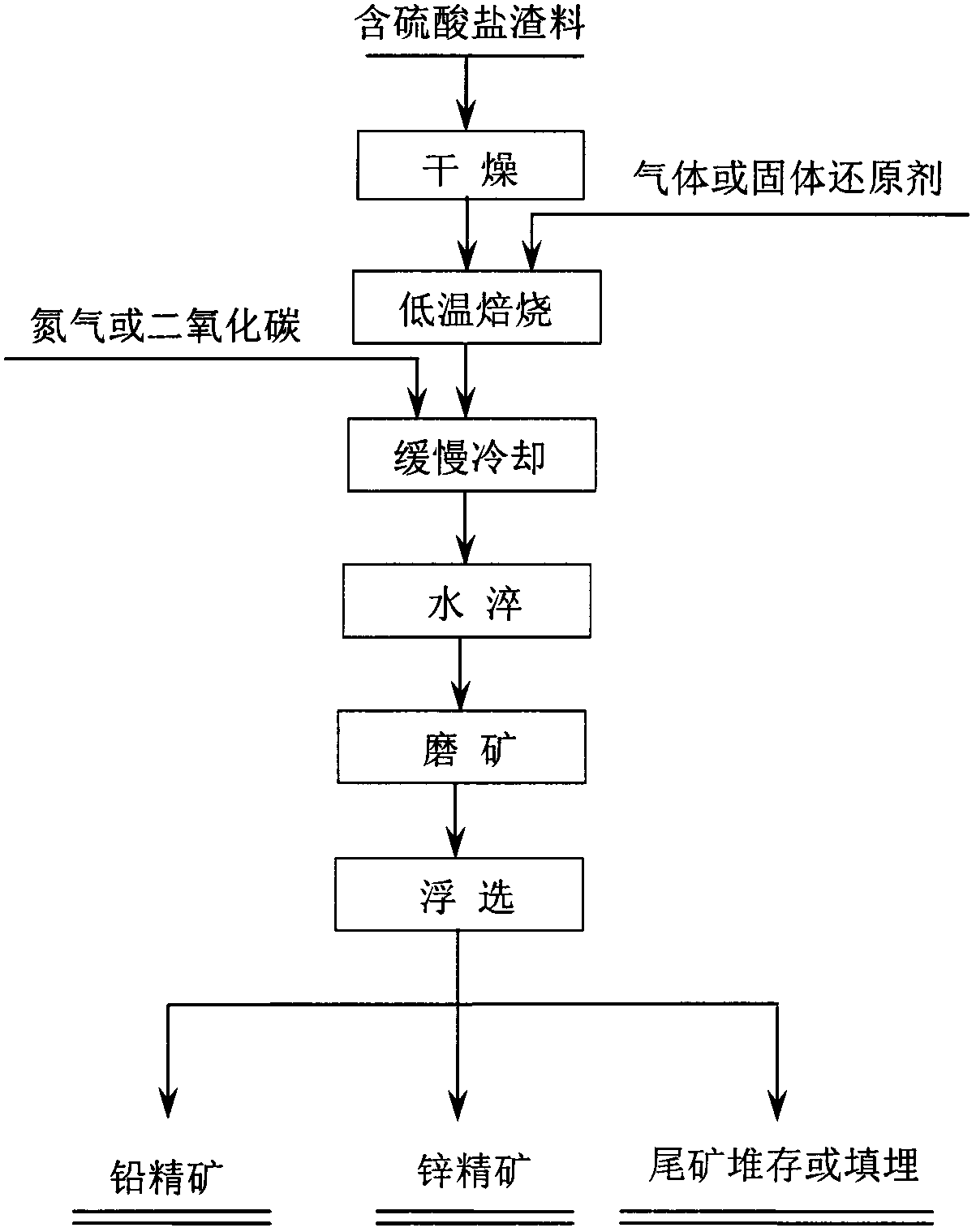

Dressing-smelting combined treatment method for sulfate-containing lead-zinc smelting slags

A combination technology of sulfate lead-zinc and dressing and smelting, which is applied in the field of dressing and smelting, can solve the problems of high recycling cost, difficult recycling, and environmental pollution by wet or pyrotechnic methods, and achieve no heavy metal pollution, stable flotation system, and high production efficiency. Chen Benlow's effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Treatment object: Lead-containing slag in the conventional hydrometallurgy process.

[0050] The lead-containing slag in the conventional hydrometallurgy process is the residue after the leaching of zinc oxide soot. Its main chemical composition (mass percentage) is: Pb35%, Zn8%, Fe10%, and the chemical phase of lead (mass percentage) is: PbSO 4 30%, PbS4%, other 1%, the chemical phase (mass percentage) of zinc is: ZnSO 4 7%, ZnFe2O 4 1%.

[0051] Take 200g of the slag to carry out the reduction test of carbon monoxide. Firstly, the temperature is heated to 700°C under the protection of nitrogen, and then the flow rate is 3.0L / min with a volume fraction of 10% of carbon monoxide and 6.0L / min of carbon dioxide. The holding time is 1.5h. After the end, use nitrogen as a protective gas for slow cooling, and start water quenching when the temperature drops below 200 °C. The water-quenched material was ground to -74μm, and then subjected to flotation tests to finally obt...

Embodiment 2

[0053] Treatment object: lead-silver slag produced in hot acid leaching.

[0054] The lead-silver slag produced in hot acid leaching is the residue after hot acid leaching concentration and separation, and its main chemical components (mass percentage) are: Pb40%, Zn6%, Fe28%, SiO 2 10%, the chemical phase (mass percentage) of lead is: PbSO 4 32%, PbS6%, other 2%, the chemical phase (mass percentage) of zinc is: ZnSO 4 5%, ZnFe 2 o 4 1%.

[0055] Take 200g of the slag material for carbon powder reduction test, fully mix 5% coke powder and mineral powder, start to heat up after covering, start timing when the temperature rises to 600°C, hold time for 2.0h, follow the furnace after roasting Cool slowly, and start water quenching when the temperature drops below 200°C. The water-quenched material was ground to -74μm, and then subjected to flotation tests to finally obtain lead concentrate with a lead grade of 65% and a recovery rate of 85% and a zinc concentrate with a zinc ...

Embodiment 3

[0057] Treatment object: lead-containing slag after extraction of valuable metals from copper smelting soot.

[0058] The lead-containing slag after the extraction of valuable metals from copper smelting soot is the by-product of the comprehensive utilization of copper smelting soot to extract valuable metals such as bismuth, zinc, cadmium, and copper. Its main chemical components (mass percentage) are: Pb38%, Zn4%, Fe12%, Ag: 200g / t, lead chemical phase (mass percentage): PbSO 4 32%, PbS6%, zinc is mainly zinc sulfate.

[0059] Take 200g of the slag material for carbon powder reduction test, fully mix 7% coke powder and mineral powder, start to heat up after covering, and start timing when the temperature rises to 700°C, and the holding time is 3.0h. The furnace is cooled slowly, and water quenching is started when the temperature drops below 200°C. Water-quenched materials were ground to -74μm, and then flotation tests were carried out to obtain lead concentrates with a le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com