Device and method for preparing texture-controllable gradient nanometer structure

A technology of nanostructure and ladder structure, applied in the field of gradient nanostructure materials, can solve the problems of complex equipment, complex process, cumbersome pretreatment, etc., and achieve the effect of simple equipment, low processing temperature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

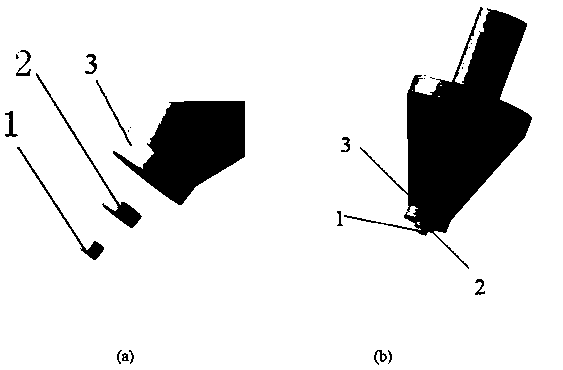

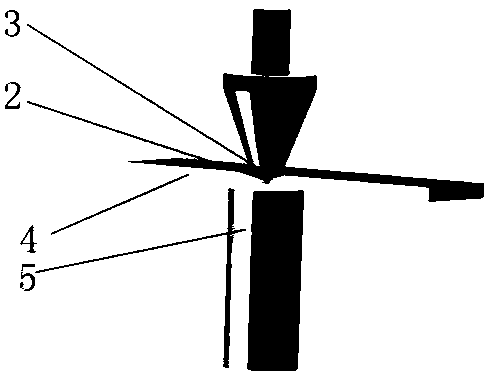

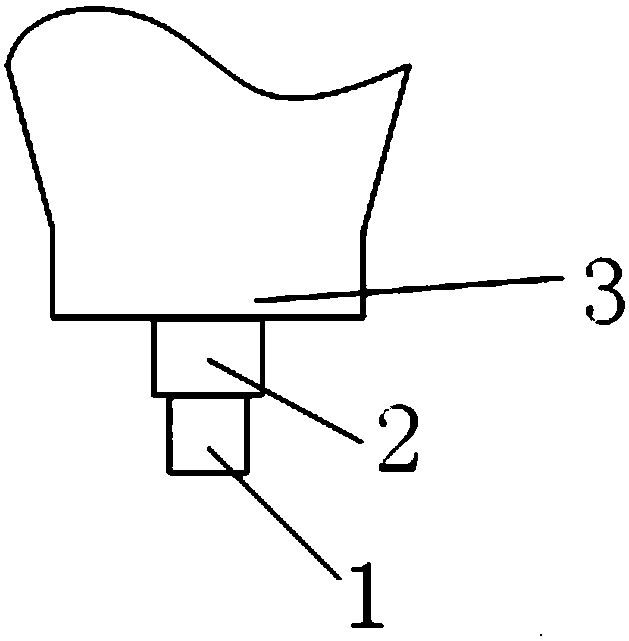

[0046] A device for preparing tissue-controllable gradient nanostructures, see the front plan view figure 1 , See the 3D view figure 2 ,among them, figure 2 The left view (a) is an exploded view, and the right view (b) is a three-dimensional view. The device is an assemblable variable cross-section stirring tool. The tool includes a blessing area, a shoulder 3 and two stirring needles with different diameters under the shoulder. The two stirring needles form a stepped structure. According to the diameter of the stirring needle, the smallest diameter The largest diameter is the first stirring needle and the second stirring needle. The diameter of the second stirring needle is twice the diameter of the first stirring needle. The sum of the length of the first stirring needle and the length of the second stirring needle is 2.7mm.

[0047] In the device for preparing tissue-controllable gradient nanostructures, the connection mode of the first stirring needle and the second stirrin...

Embodiment 2

[0060] A device for preparing tissue-controllable gradient nanostructures is the same as in Example 1.

[0061] A method for preparing a tissue-controllable gradient nanostructure, same as Example 1, except that in step 2, the assemblable variable cross-section stirring tool is inserted into the aluminum plate to be processed at a speed of 2500rad / min 4.

Embodiment 3

[0063] A device for preparing tissue-controllable gradient nanostructures is the same as in Example 1.

[0064] A method for preparing tissue-controllable gradient nanostructures is the same as Example 1, except that in step 2, the ultrasonic tool head 5 performs continuous ultrasound, and the parameters of the ultrasound are as follows: the frequency is 10 kHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com