Raw oil dewatering and desalting process

A crude oil dehydration and process technology, which is applied in the field of crude oil dehydration and desalination, can solve the problems of failing to meet the corresponding technical standards and requirements, and achieve the effects of saving energy, avoiding mutual interference, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

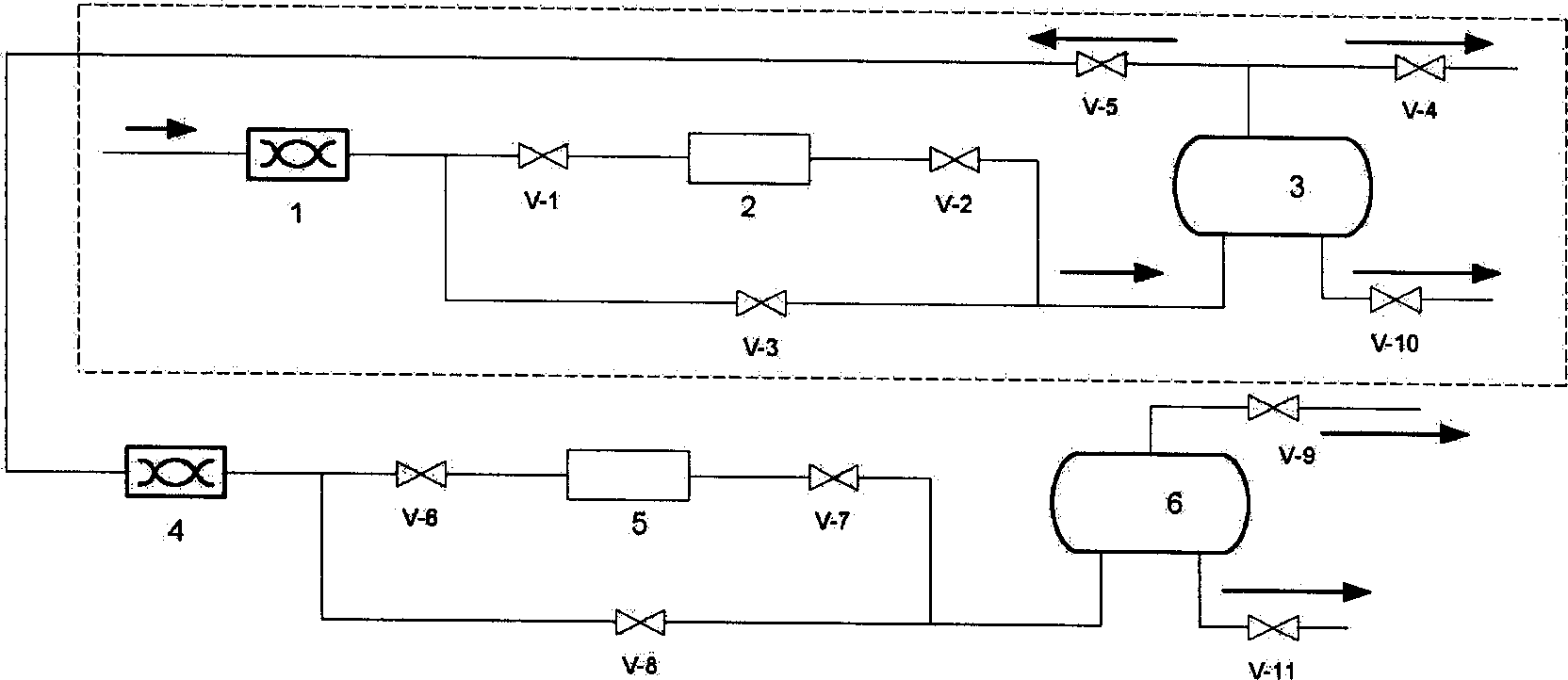

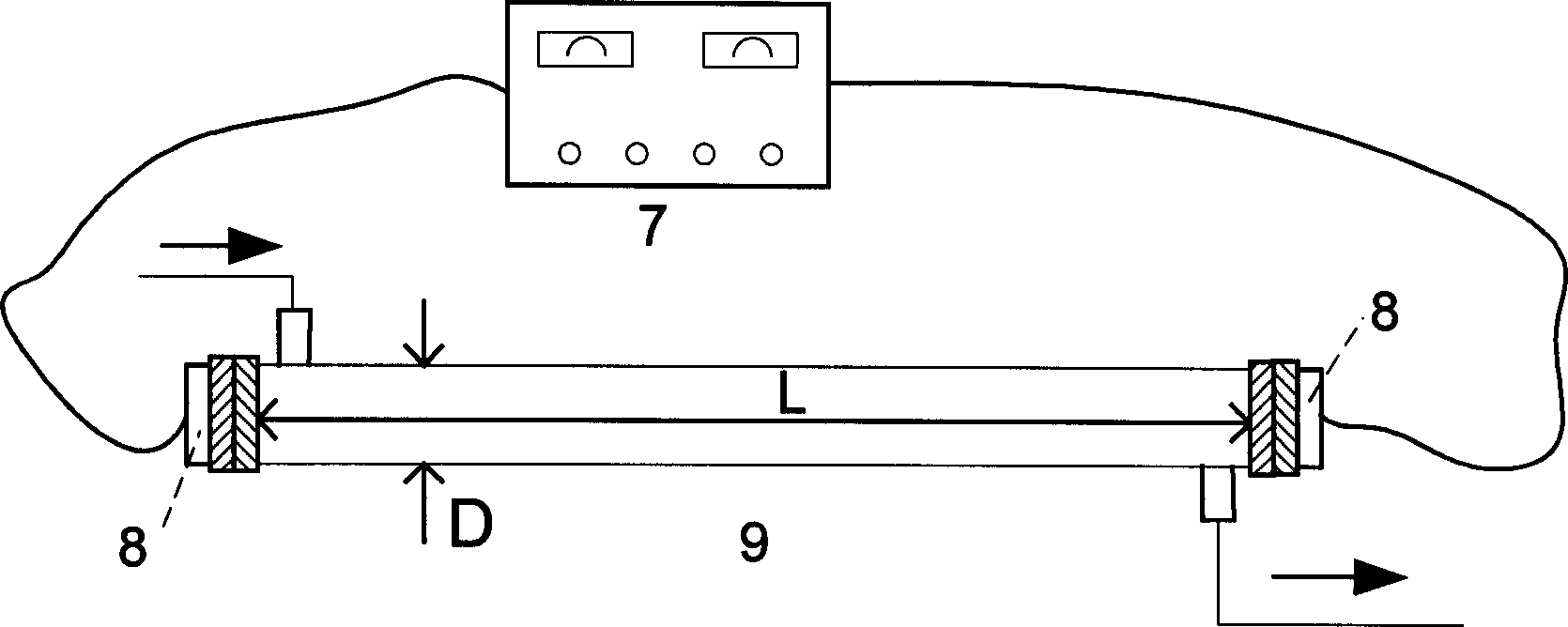

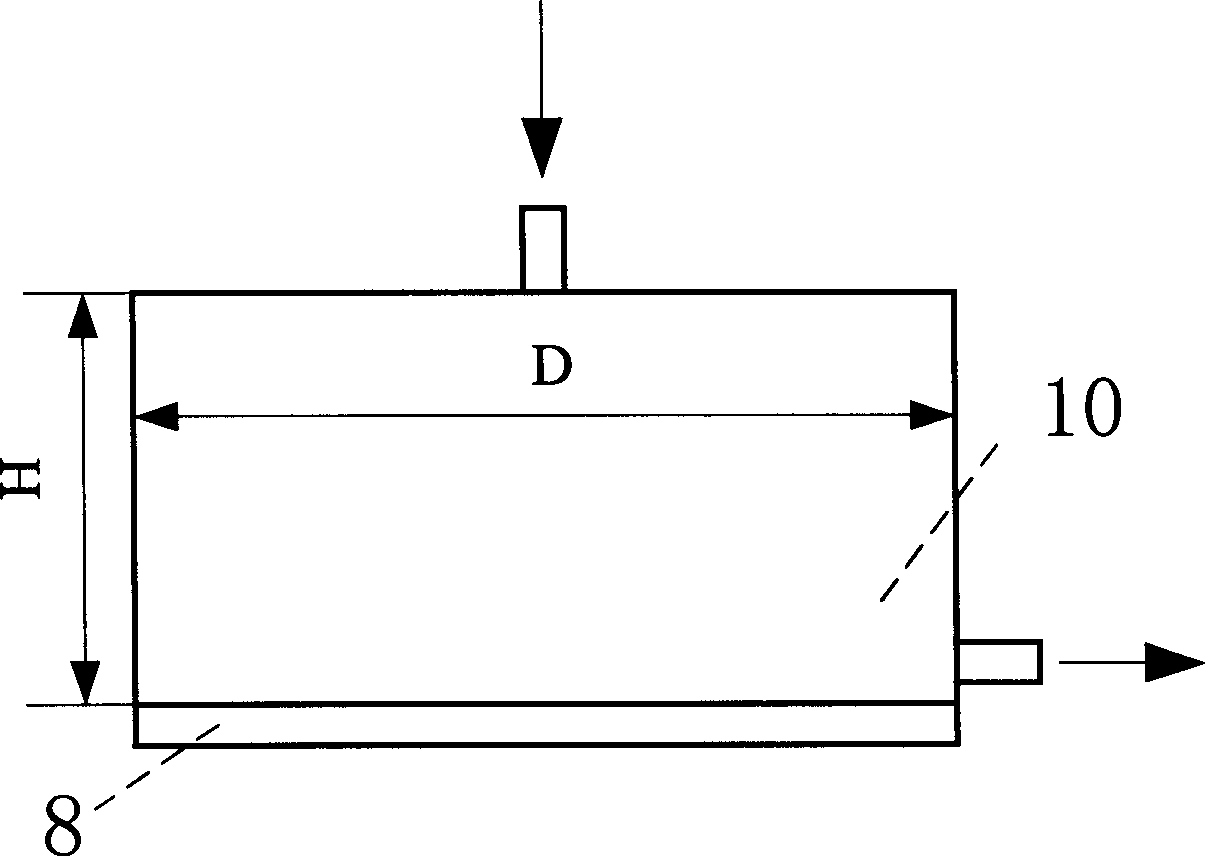

Method used

Image

Examples

Embodiment 1

[0021] This process is used to dehydrate and desalt Luning crude oil. The treatment temperature is 70-90°C, the ultrasonic frequency is 10kHz, the magnetostrictive transducer is used, the residence time is 7.5min, the initial water content is less than 0.4%, and the salt content before removal is 39.5mgNaCl / L, water injection is about 5.0%. After a single standing wave ultrasonic-electric field combined action, the water content of crude oil after dehydration is 0.13%, and the desalt content of crude oil is 2.2mgNaCl / L.

Embodiment 2

[0023] This process is used to dehydrate and desalt Luning crude oil. The treatment temperature is 70-90°C, the ultrasonic frequency is 20kHz, the piezoelectric ceramic transducer is used, the residence time is 5min, the initial water content is less than 0.4%, and the salt content before desalination is 39.5mgNaCl / L, about 5.0% water injection, after a single standing wave ultrasonic-electric field combined action, the water content of the crude oil after dehydration is 0.28%, and the desalt content of the crude oil is 3.5mgNaCl / L.

Embodiment 3

[0025] This process is used to dehydrate and desalt Luning crude oil, the treatment temperature is 70-90°C, the ultrasonic frequency is 10kHz, the magnetostrictive transducer, the residence time is 9.4min, the initial water content is less than 0.4%, and the salt content before desalination is 39.5mgNaCl / L, water injection is about 4.0%. After a single standing wave ultrasonic-electric field combined action, the water content of crude oil after dehydration is 0.12%, and the desalt content of crude oil is 2.5mgNaCl / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com