Occlusion degassing type circuit packaging method

A circuit packaging and degassing technology, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve problems such as hidden dangers of electrical safety, moisture resistance, reduced electrical insulation performance, and integrated circuit manufacturing failures, and reduce porosity. Defects, the effect of improving strength and electrical insulation, improving packing density and flowability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

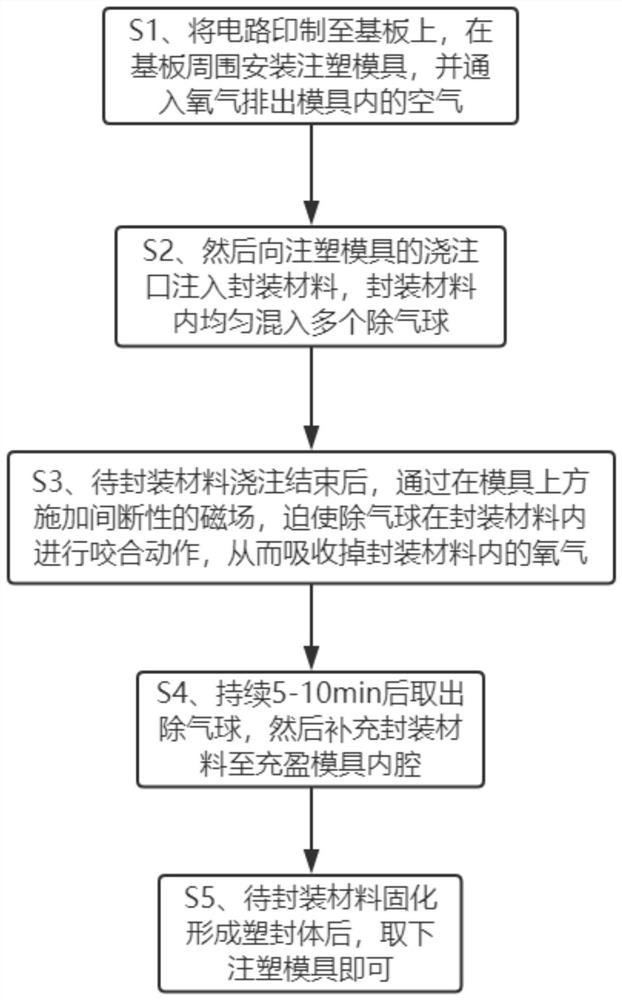

[0046] See Figure 1-2 A biting and devilular circuit packaging method, including the following steps:

[0047] S1, print the circuit to the substrate, mount the injection mold around the substrate, and enter the air in the oxygen discharge mold;

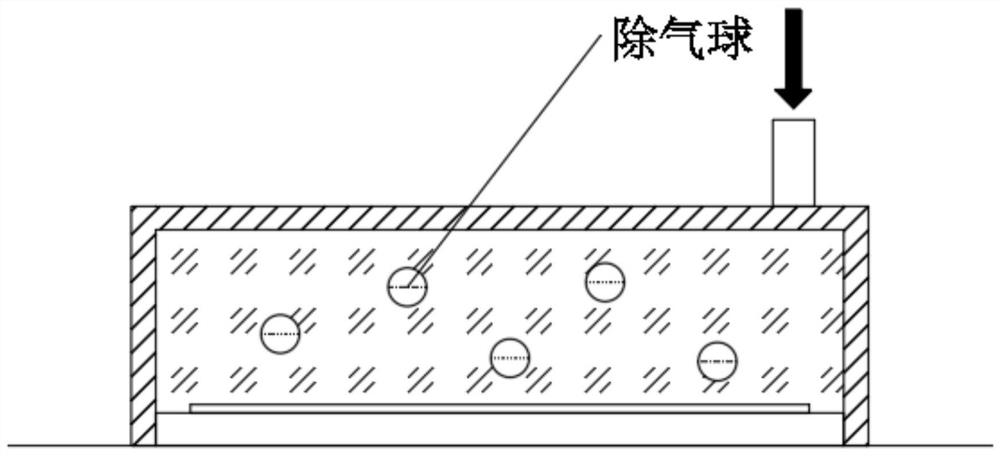

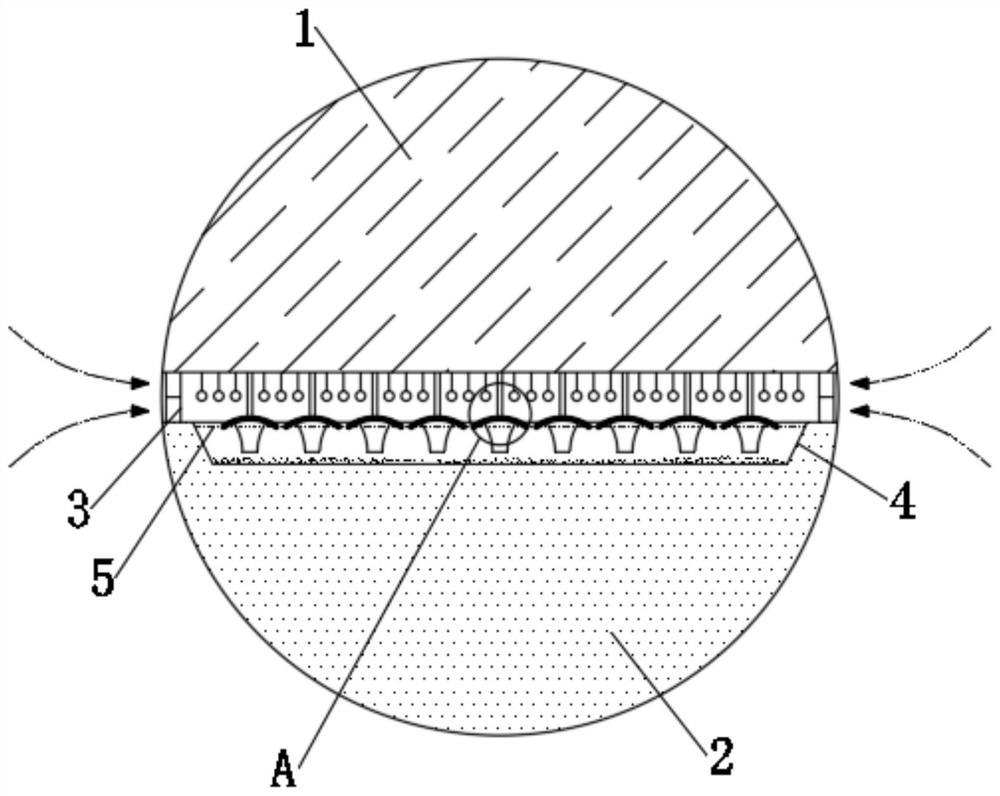

[0048] S2, then inject the packaging material into the casting of the injection mold, evenly mixing the ball in the package material;

[0049] S3, after the pouring of the package material is completed, by applying an intermittent magnetic field above the mold, the balloon is forced to perform a bite operation in the package material, thereby absorbing the oxygen in the package material;

[0050] S4, after 5-10min, remove the balloon, then supplement the packaging material to the inner cavity of the filling mold;

[0051] S5, after the material to be encapsulated materials, after forming a plastic seal, remove the injection mold.

[0052] The substrate uses an alumina substrate, a glass fiber enhanced epoxy resin plate or a glass substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com