Automatic laser soldering machine

A soldering machine and automatic welding technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems affecting the properties of thermal elements, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

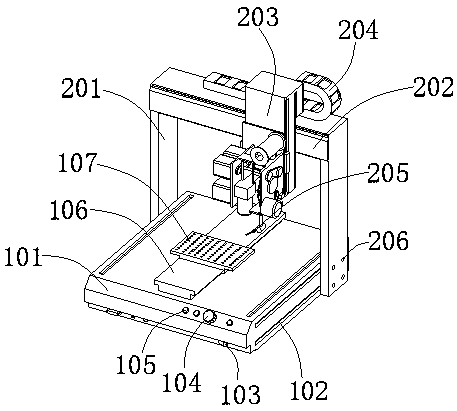

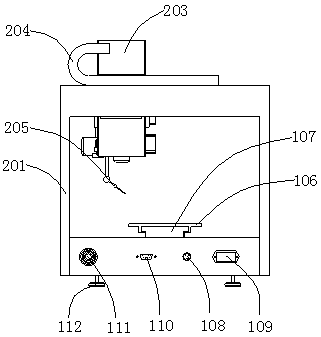

[0024] see Figure 1-3 , an automatic laser soldering machine, including a console device 1 and a soldering device 2, the top of the console device 1 is fixedly installed with the soldering device 2.

[0025] The operating table device 1 includes a soldering machine operating table 101, and both sides of the soldering machine operating table 101 are fixedly installed with connecting bosses 102, and a switch 103 is fixedly installed on the front surface of the soldering machine operating table 101, and a switch 103 is fixedly installed above the switch 103. Adjusting knob 104, the left and right sides of adjusting knob 104 are all fixedly installed with several operating buttons 105, and adjusting knob 104 and operating buttons 105 are all fixedly installed on the front surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com