Patents

Literature

182results about How to "Increase replacement rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

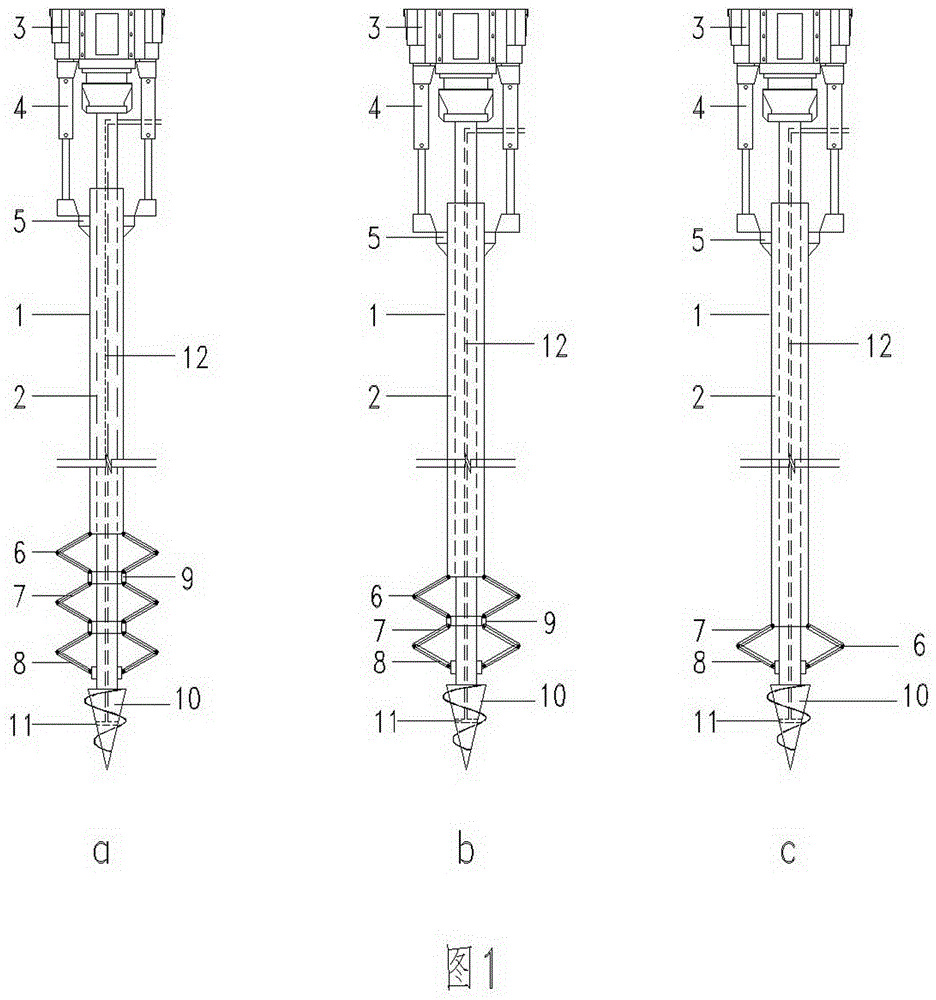

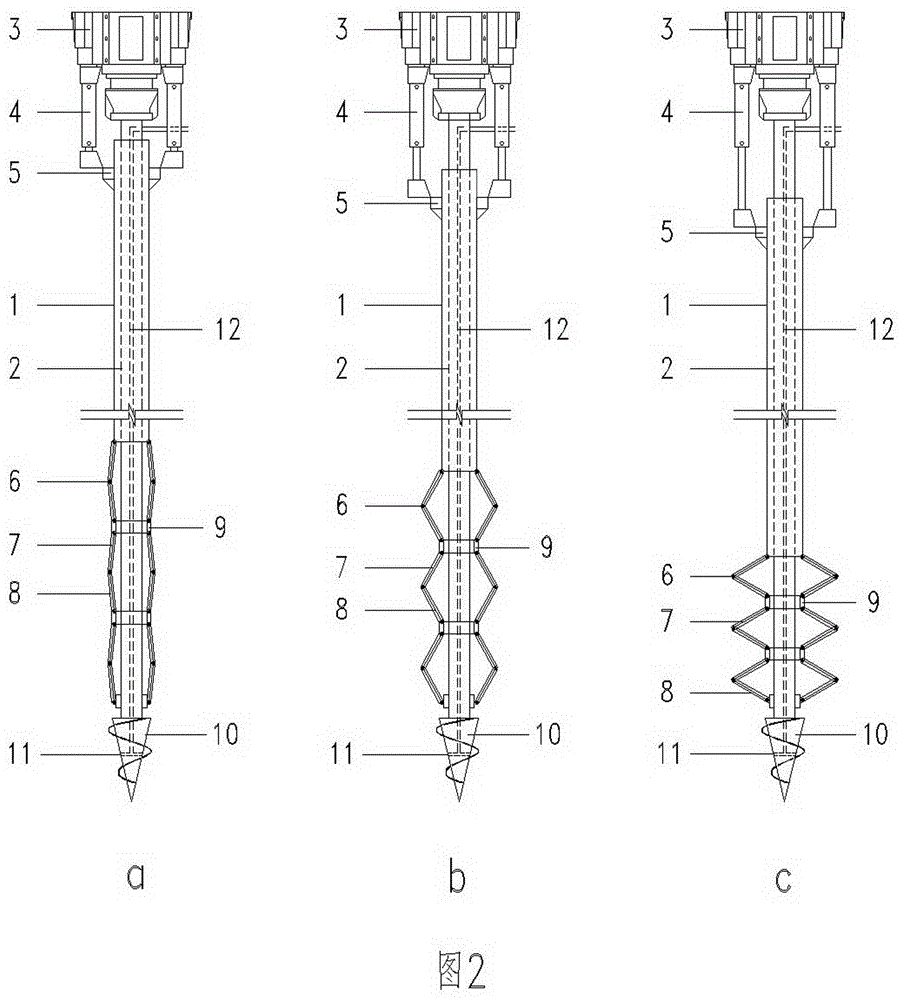

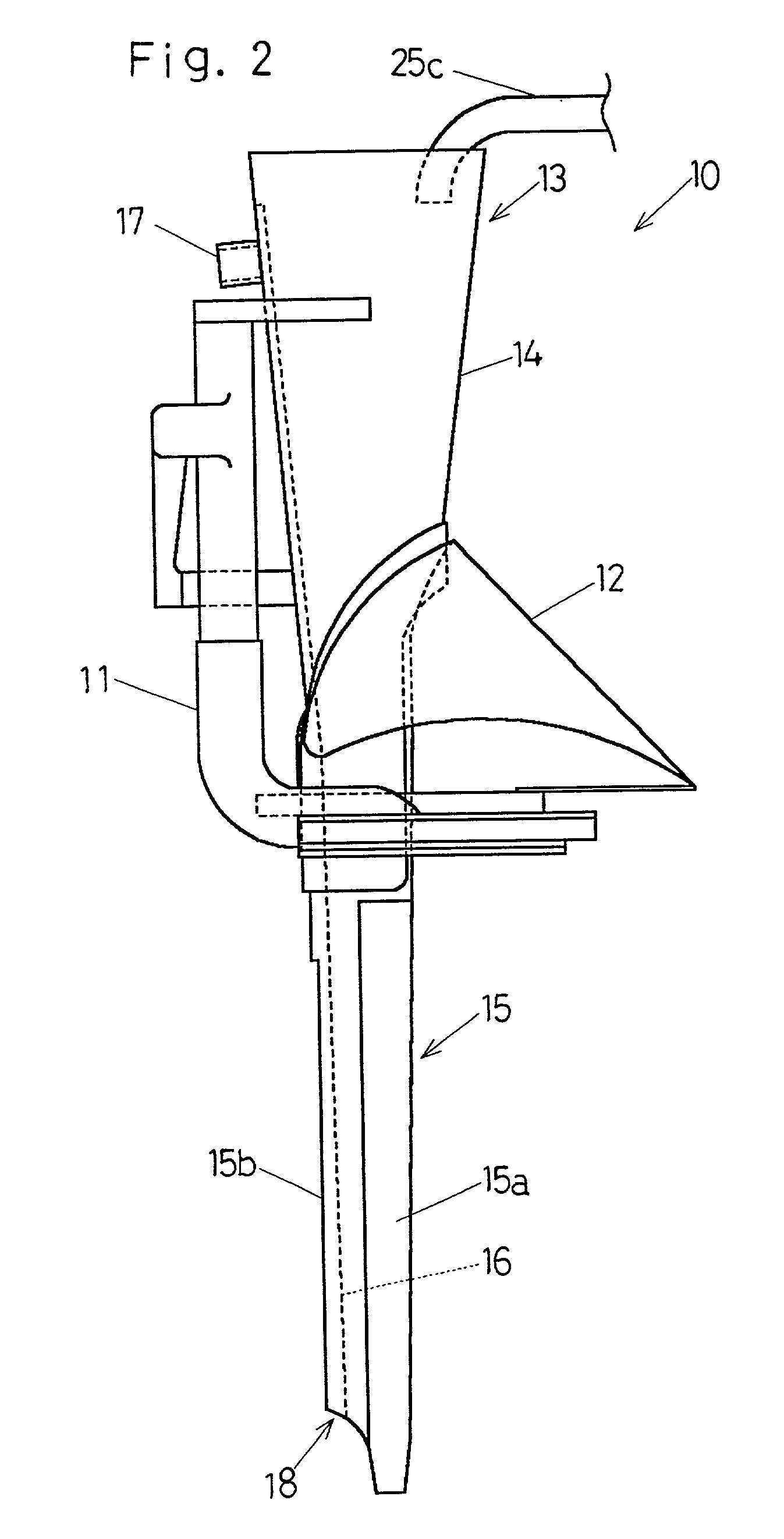

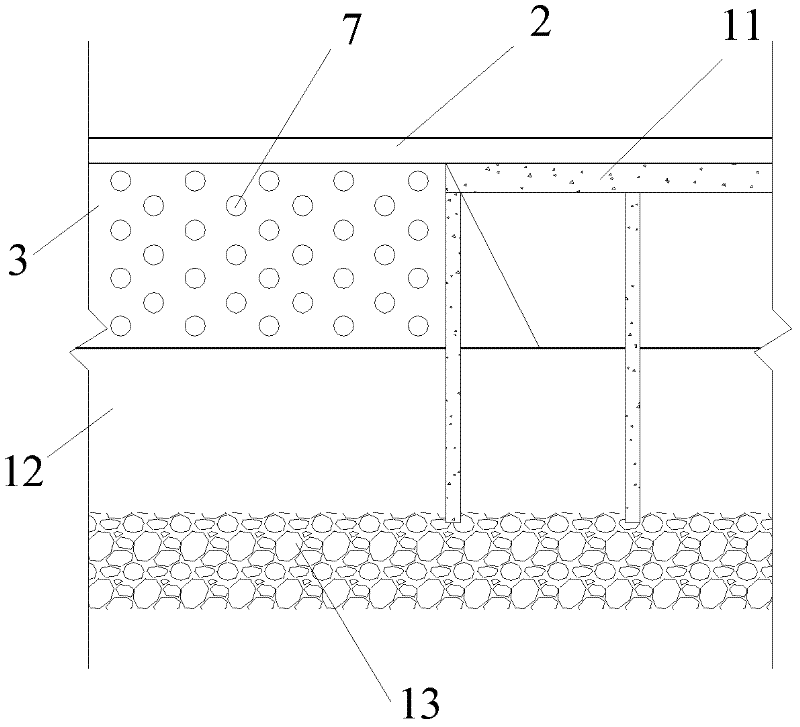

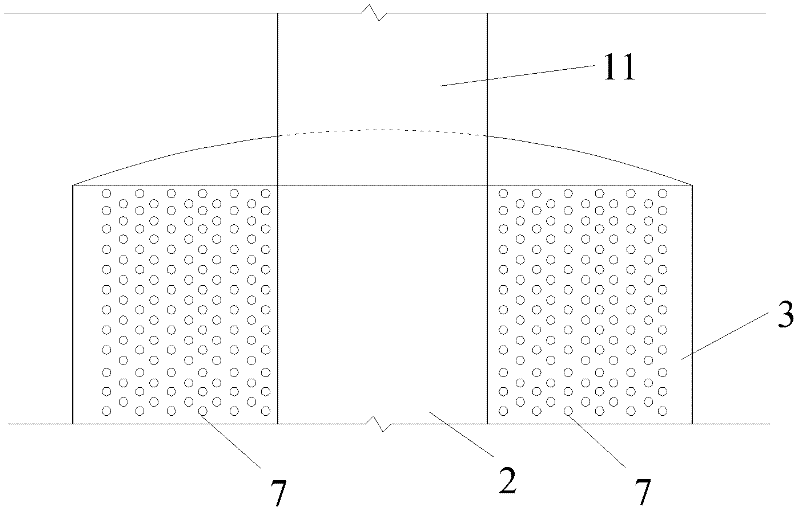

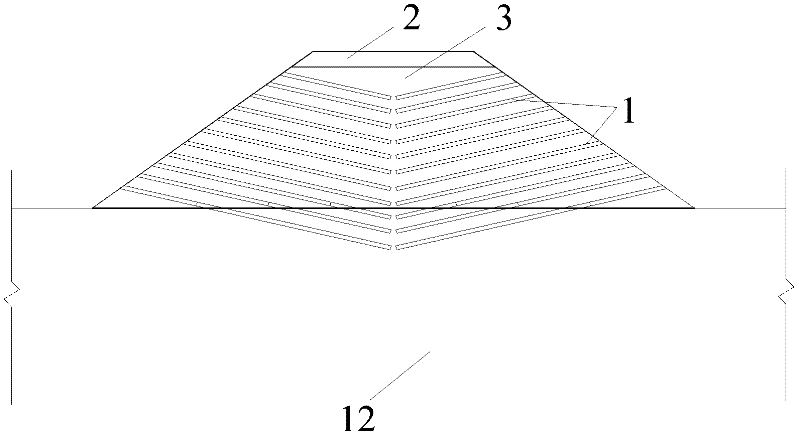

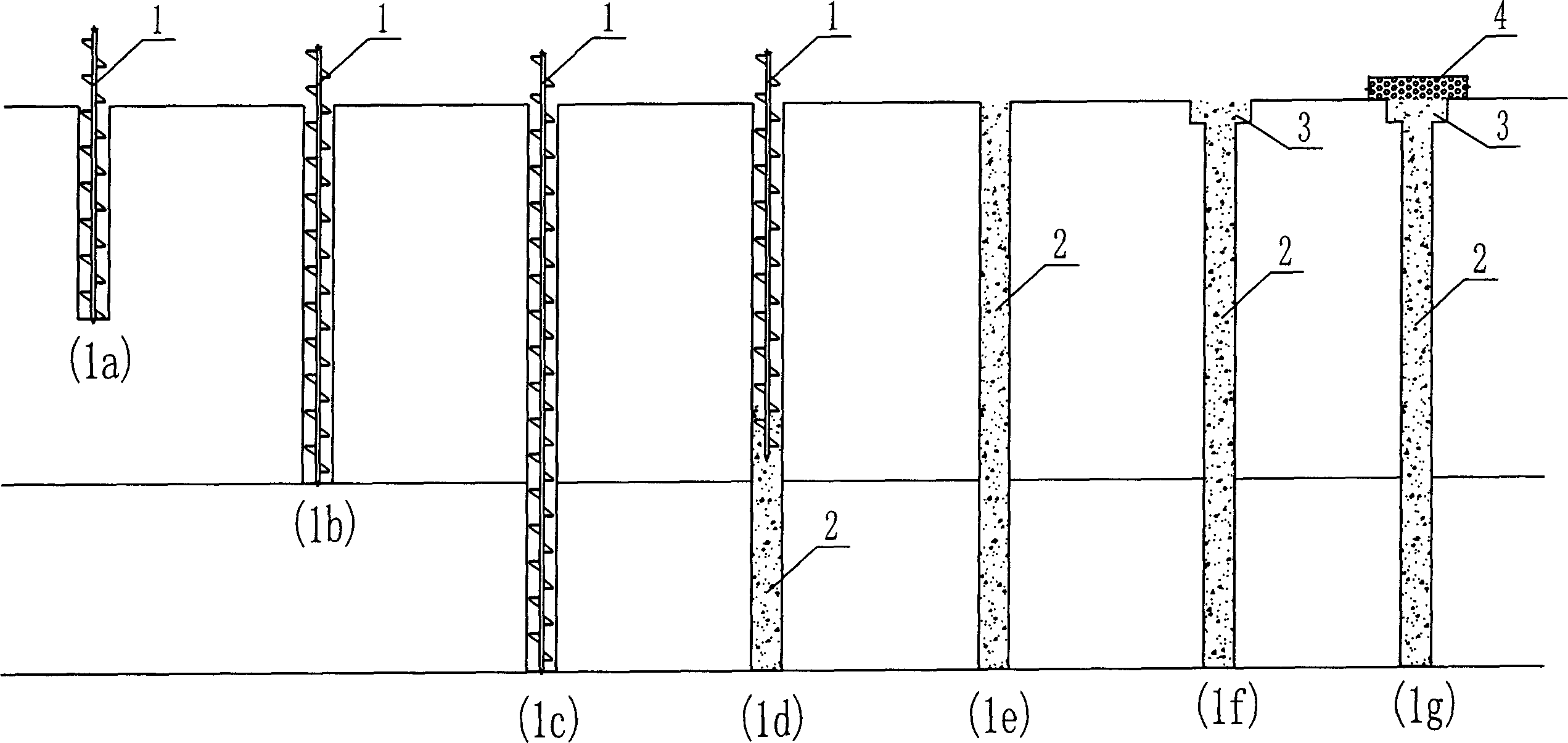

Construction device and construction method for stirring and spraying expanded reinforcement pile

ActiveCN106087999AIncrease resistance to horizontal thrustIncrease end resistanceBulkheads/pilesDrilling machines and methodsSpray nozzleHigh pressure

The invention provides a construction device and construction method for a stirring and spraying expanded reinforcement pile. The construction device is characterized in that a drill pipe is formed by coaxially overlapping an outer pipe body and an inner pipe body in a sleeving mode and provided with a rotary power mechanism, a lifting device and a variable-diameter telescopic stirring arm; the inner pipe body is provided with a spiral drill bit and a spraying nozzle, and high-pressure ejection, forced stirring, improvement on the drilling speed and adjustment of the specifications of a pile body and an expanded body are realized through the operations of arm folding, arm unfolding, rotating, high-pressure grouting and the like. The construction method is characterized in that the setting parameters and design scheme of the pile body and the expanded body of the reinforcement pile are designed in advance. The method includes the particular construction steps that (1) pile positions are aligned; (2) the expanded body and the pile body of the reinforcement pile are constructed in a mode A (from top to bottom) or mode B (from bottom to top) according to the advanced design; (3) the stirring and spraying expanded reinforcement pile which accords with the advanced design and is provided with the expanded body is formed; and (4) subsequent construction is carried out through multiple methods and includes manufacturing of a reinforcement body pile body and pile end carriers and laying of a cushion layer.

Owner:北京波森特岩土工程有限公司

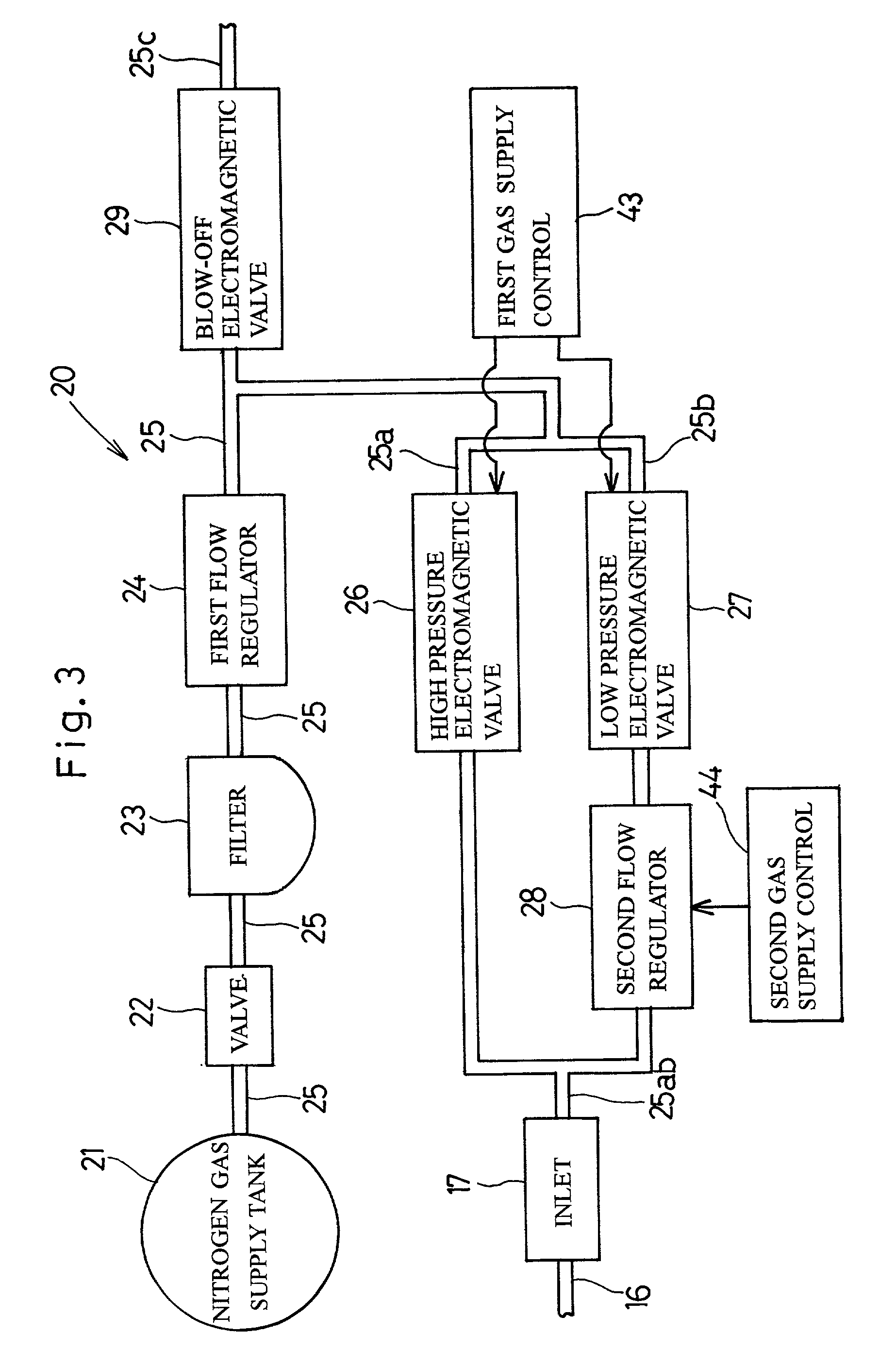

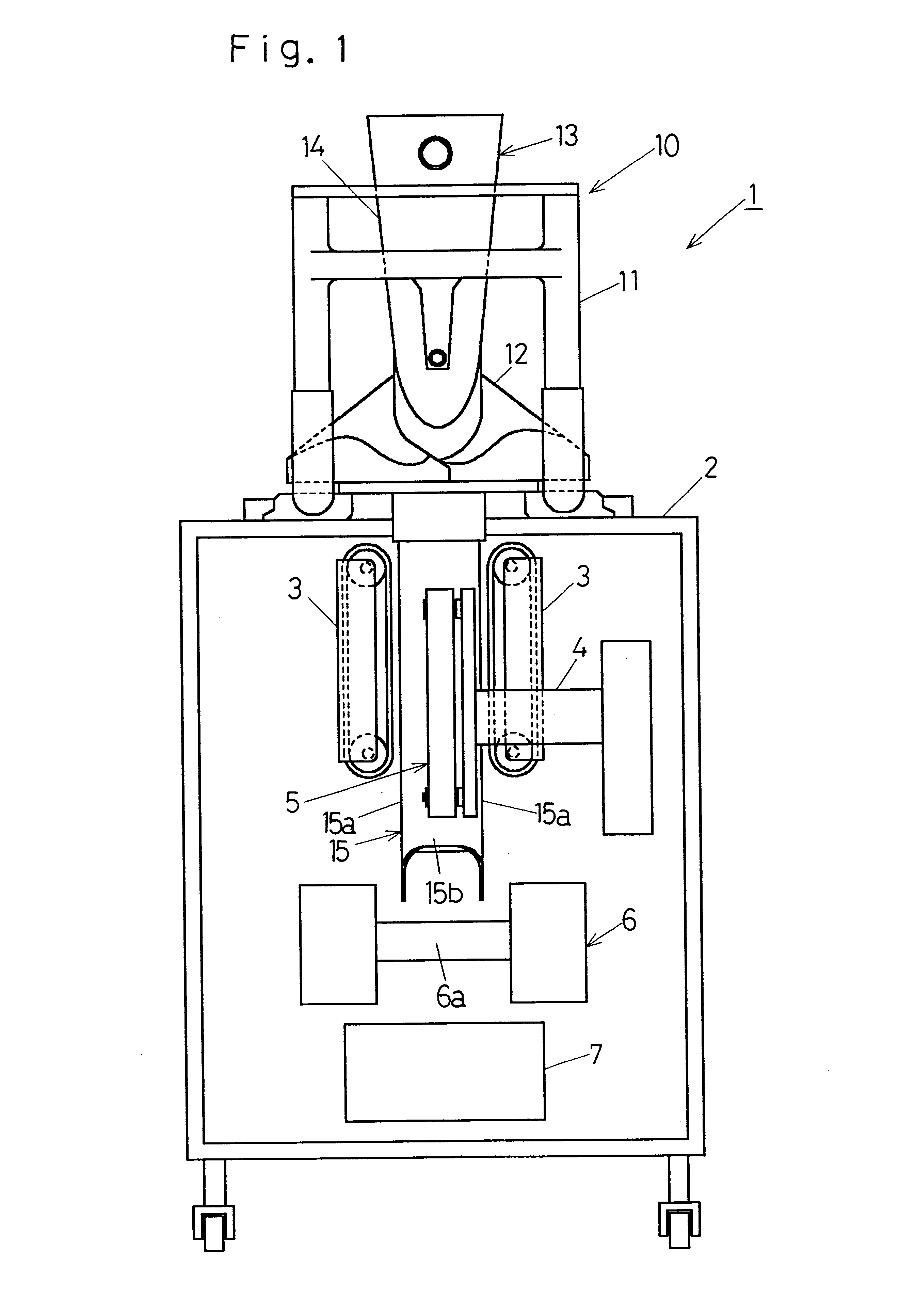

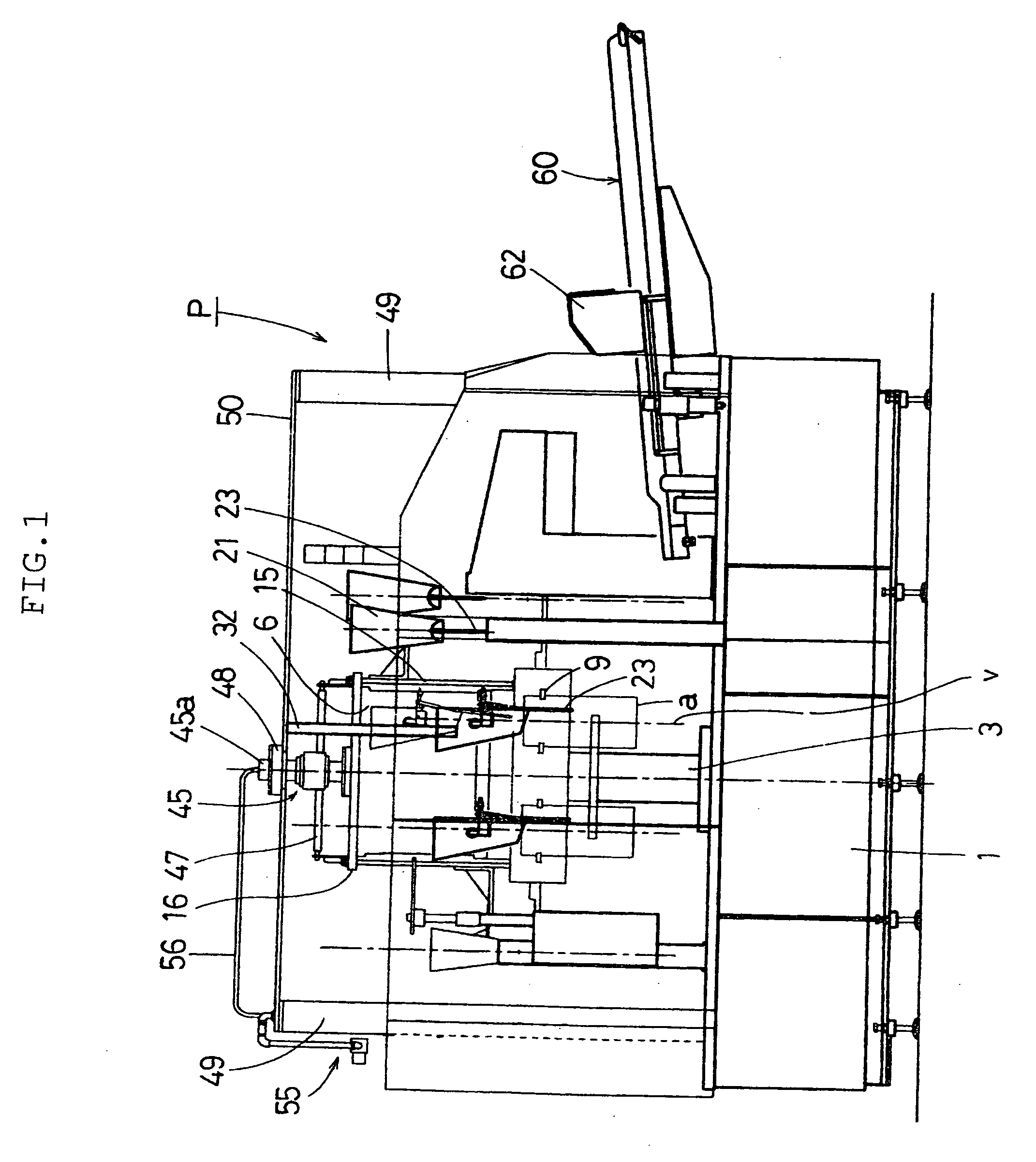

Bagging and packaging machine capable of filling a proper quantity of inert gas into bags

InactiveUS20010005974A1Lightweight productionReduce replacement rateCapsCapping machinery safety/controlProduct gasProcess engineering

A bagging and packaging machine for forming a bag from a strip of bag material and introducing an article into the bag includes a gas supply unit for supplying an inert gas into the bag to substitute for air contained in the bag and a gas supply control means for controlling supply of the inert gas by the gas supply means into the bag. The bagging and packaging machine is designed to allow the inert gas to be supplied under high pressure at a flow rate sufficient to increase the gas replacement rate in the bag when the machine is started, to be supplied under low pressure at a flow rate lower than the high pressure flow rate during a bagging and packaging operation subsequent to the start of the machine. Should the machine is temporarily brought to a halt, the length of time T passing from the timing at which the machine is temporarily brought to a halt is counted by a timer without the supply of the inert gas being interrupted, so that the supply of the inert gas can be interrupted at a timing the counted length of time exceeds a low pressure gas supply time T2. In this way, without the bag being bitten during bagging and / or the bagging and packaging speed being lowered, not only can the inert gas be sufficiently filled in the bag to achieve a high gas replacement rate, but the amount of the inert gas supplied can also be suppressed.

Owner:ISHIDA CO LTD

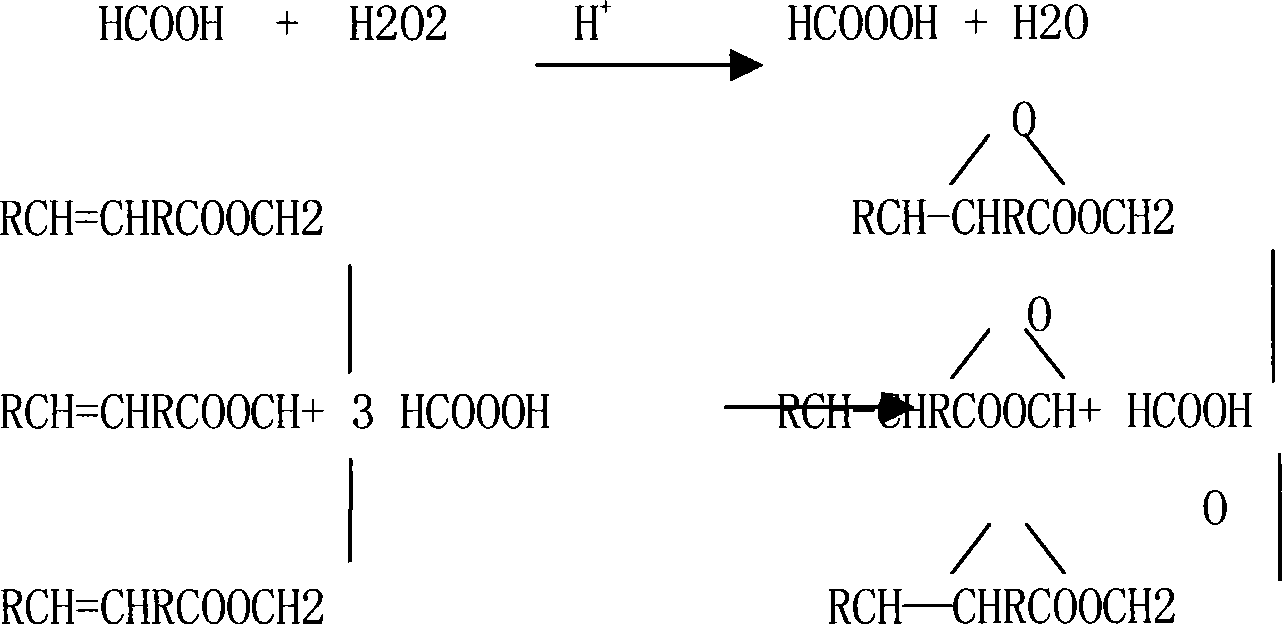

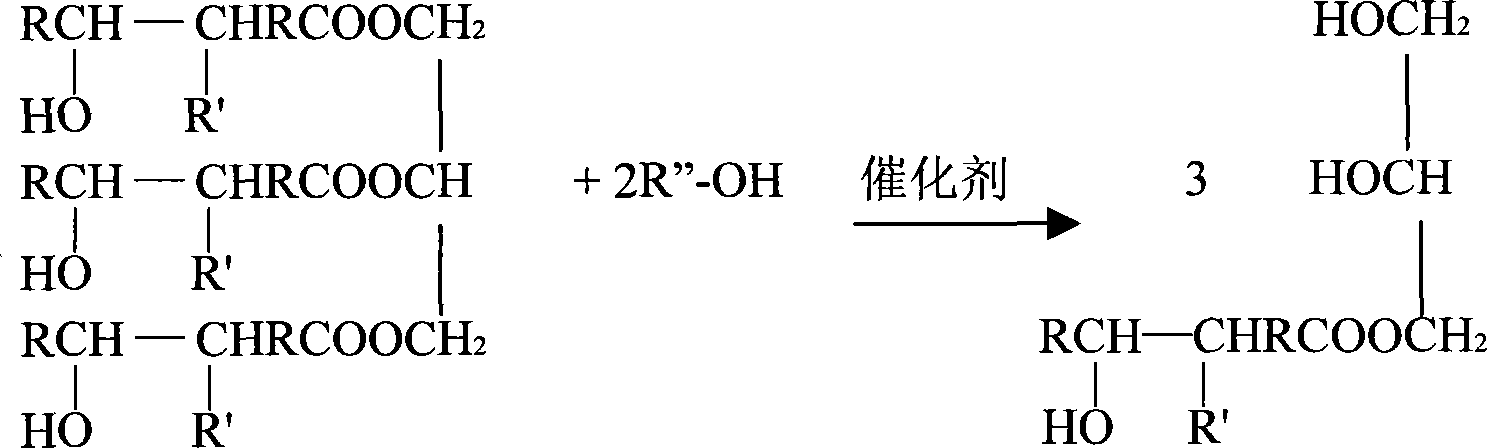

Polyurethane foam plastic prepared from barbadosnut oil

InactiveCN101125912AAbundant sources of raw materialsIncrease replacement rateFatty acid esterificationIsocyanatePolymer chemistry

The invention relates to a polyurethane foam plastic prepared by little tung oil. The biologic group polylol is prepared by epoxidation, ring cleavage, alcoholysis and addition of the tung oil, then the biologic group polylol and polyether glycol are used as basic raw materials to prepare compound materials with assistant agent; finally the compound materials are mixed evenly with blowing catalyst, then react with polyisocyanate with the yield of effervescence, thus obtaining the polyurethane foam plastic. The invention has the advantages that: 1. the little tung oil of the raw material of the biologic group polylol is renewable resource and the little tung is abundant with low cost and is unnecessary to get resources from people; 2. the preparation technique of the biologic group polylol has simple operation, good adjustability of product functionality, comparatively good property and high rate of petrified polyether glycol substation reducing dependence to petrified products; 3. the biologic degradability of polyurethane foam plastic prepared by the little tung oil and biologic group polylol is comparatively good and friendly to environment.

Owner:HONGBAOLI GRP CO LTD

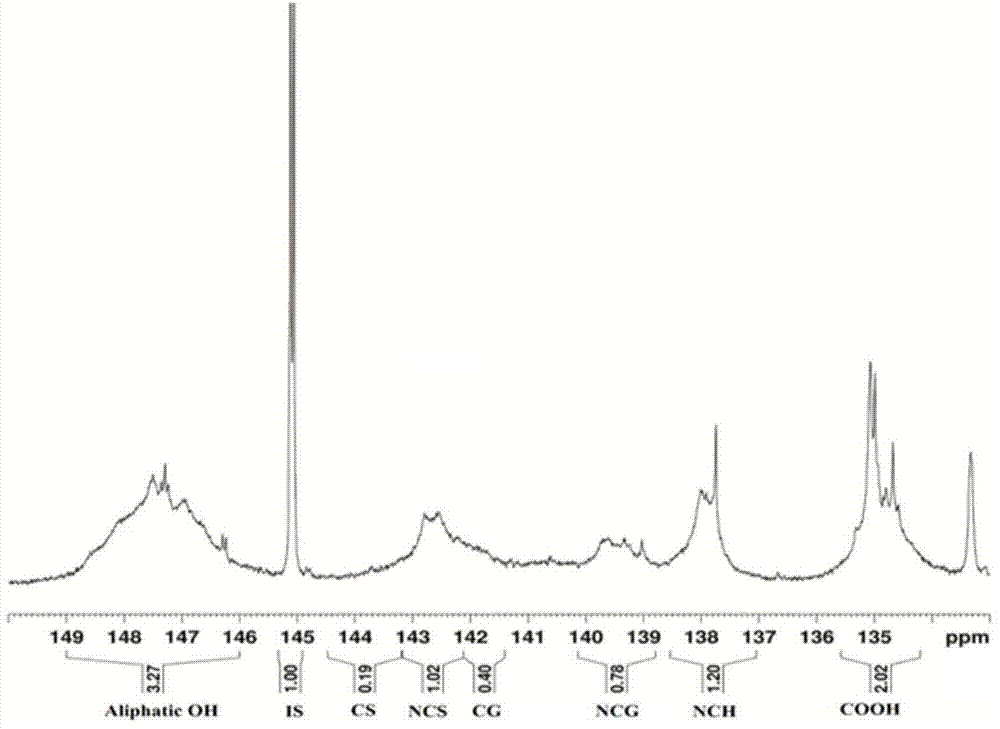

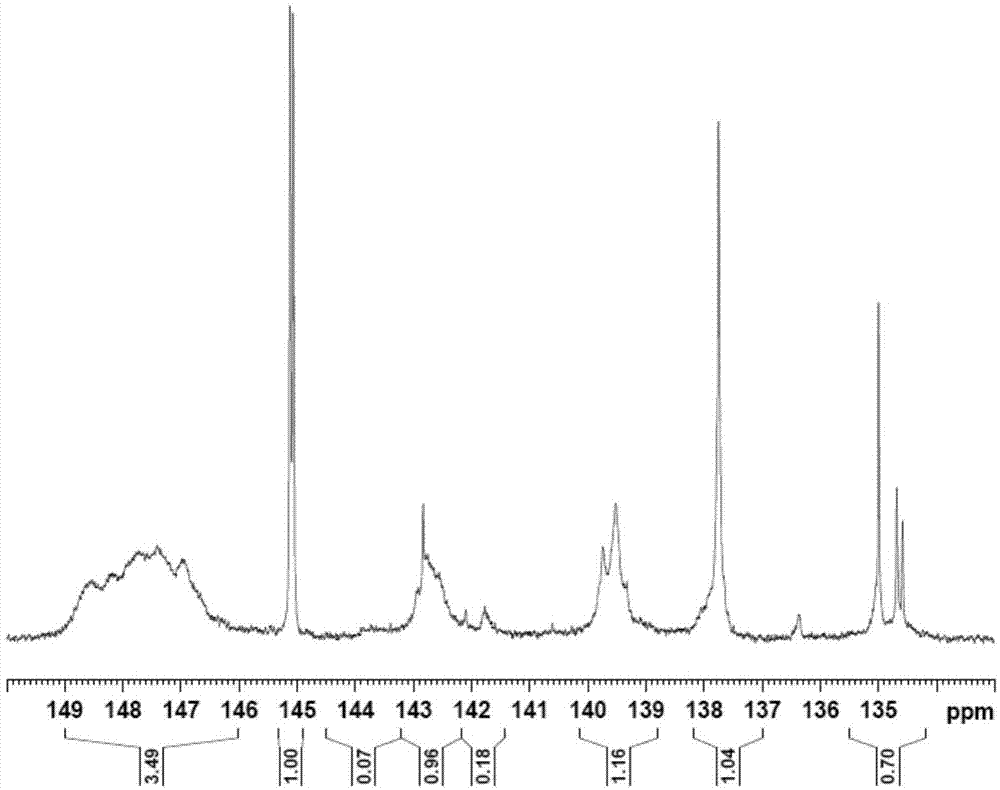

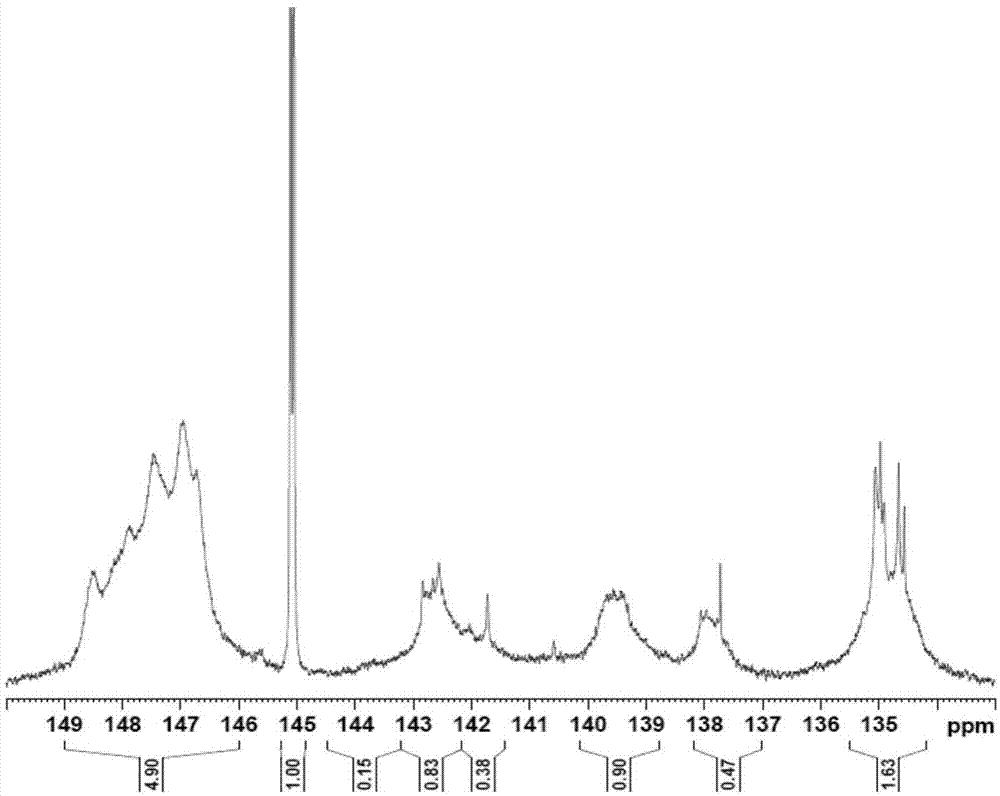

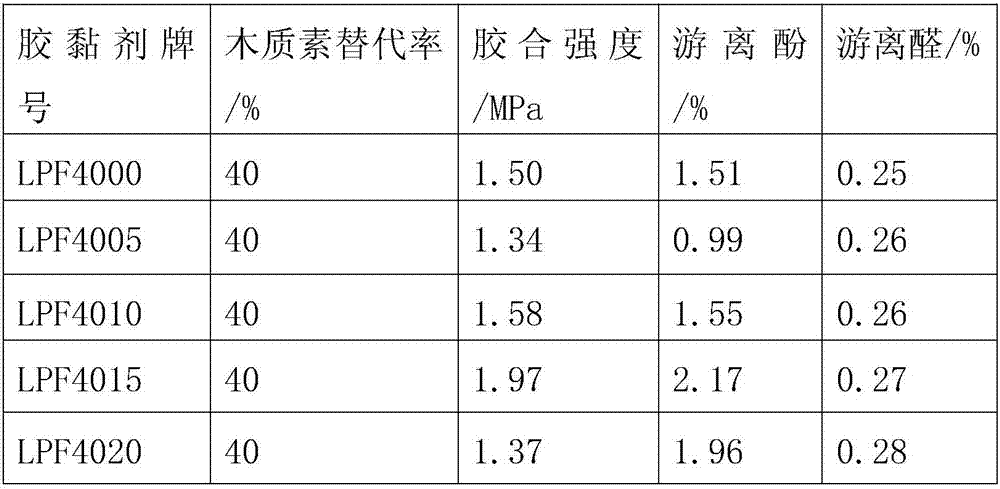

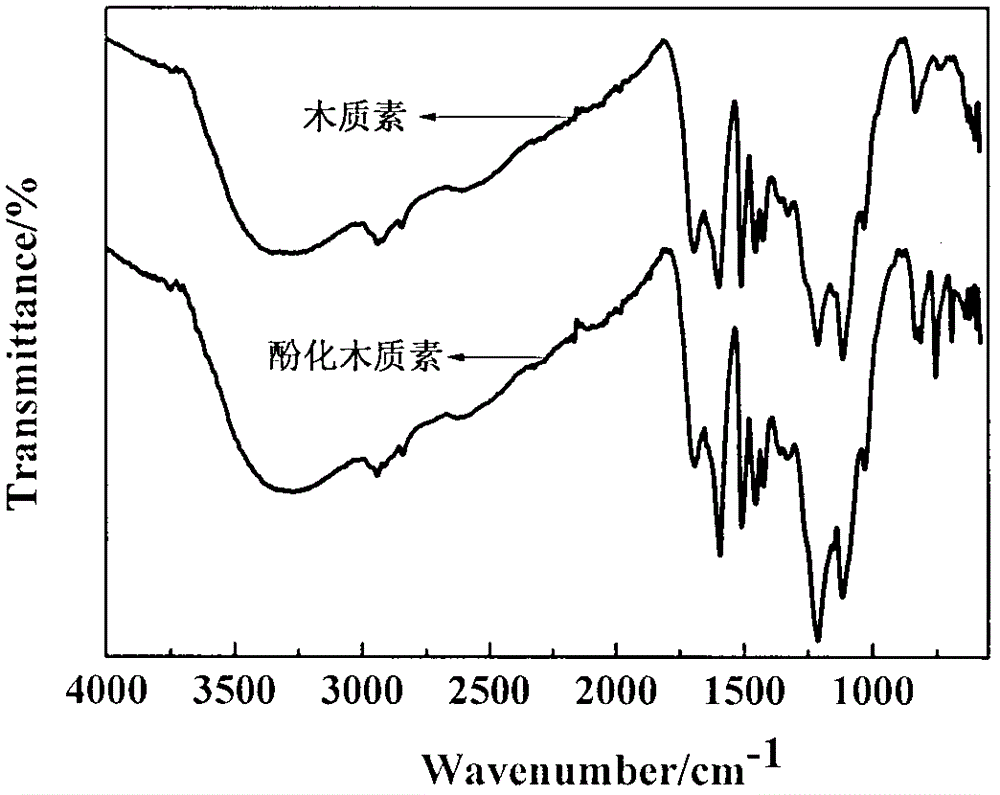

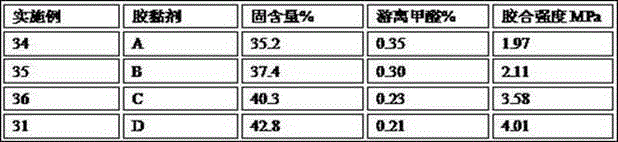

Method for preparing lignin-based environment-friendly phenolic resin adhesive

ActiveCN103804618AAvoid excessive releaseAdaptableAldehyde/ketone condensation polymer adhesivesAlcoholNMR - Nuclear magnetic resonance

The invention discloses a method for preparing a lignin-based environment-friendly phenolic resin adhesive. The method comprises the following steps: 1, carrying out quantitative analysis on hydroxyl of a lignin material by using a quantitative phosphorus spectrum of nuclear magnetic resonance technology, and obtaining the quantity of active site points in unit mass of lignin material when reacting with formaldehyde by calculating the quantity of phenolic hydroxyl groups and alcoholic hydroxyl groups; 2, mixing the lignin material with phenol to form a material mixture, wherein the mass ratio of the lignin material to the phenol is (1:9)-(8:2) in the mixing process; 3, calculating the gross of formaldehyde; 4, mixing the material mixture obtained in the step 2 with formaldehyde and aqueous alkali for reaction, so as to prepare the lignin-based environment-friendly phenolic resin adhesive. The biomass refined by-product lignin is utilized at high value on the basis that the problems of expensive product and formaldehyde pollution of the traditional lignin-based phenolic resin adhesive are solved, and the method has great economic significance and social significance.

Owner:HUNAN FORESTECH NEW MATERIALS CO LTD

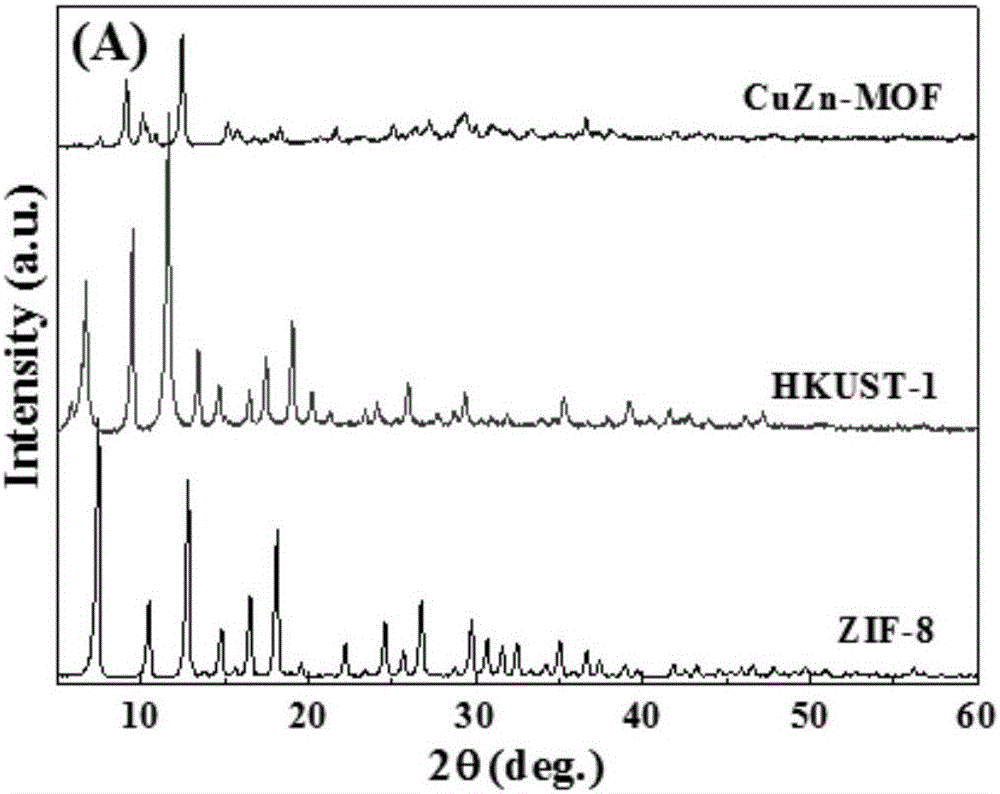

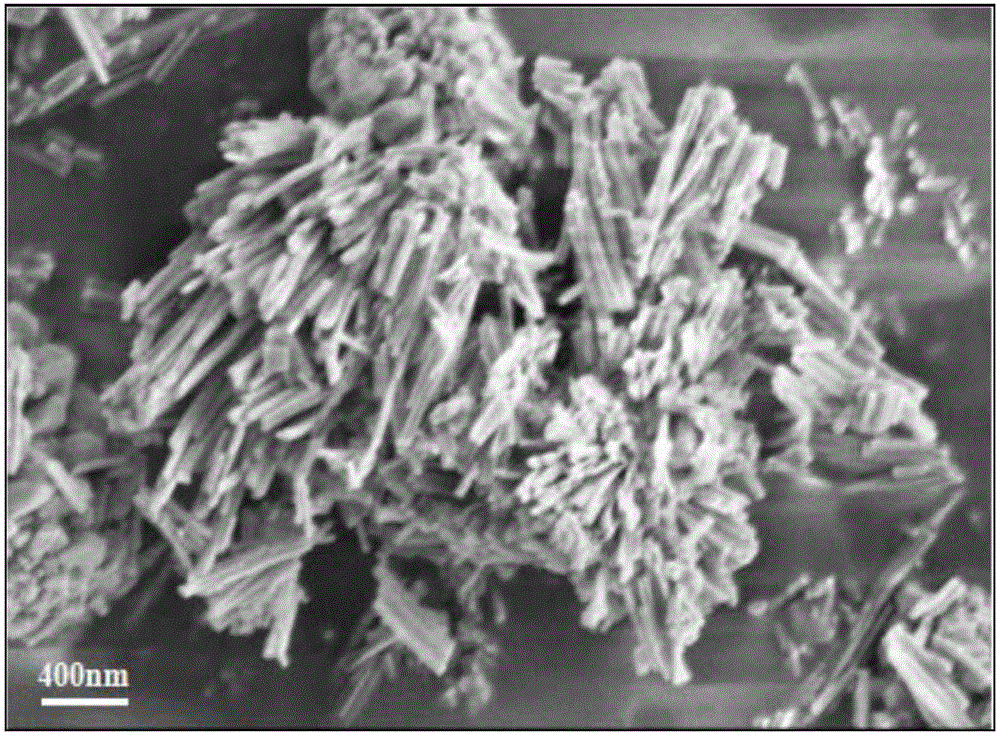

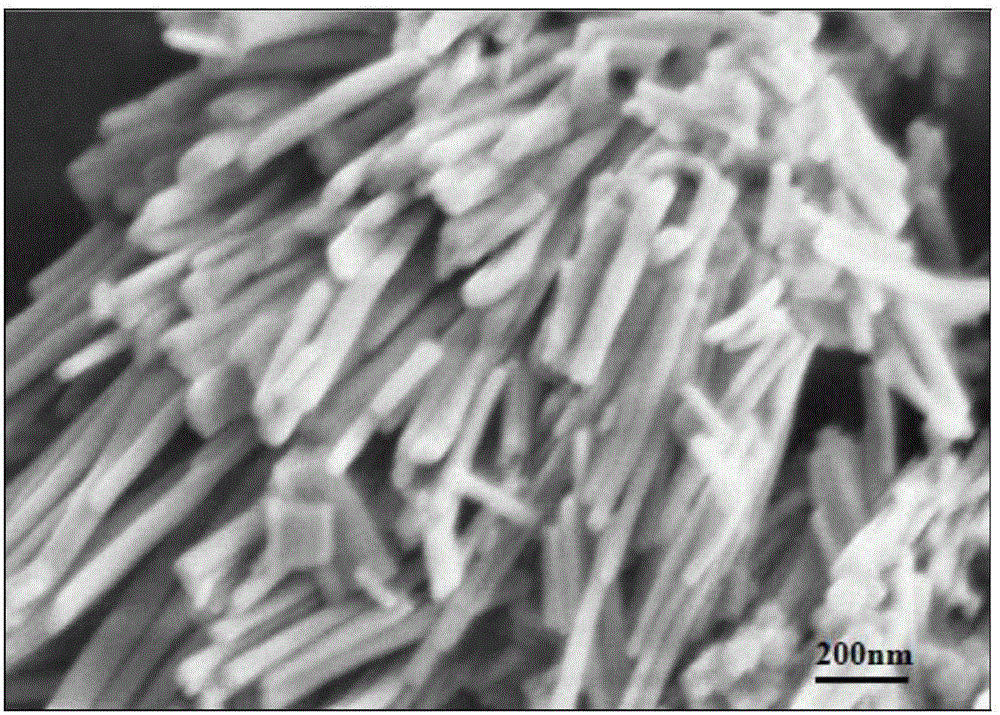

CuZn bi-metal organic framework material and preparing method thereof

The invention discloses a CuZn bi-metal organic framework material and a preparing method thereof.The metal organic framework material ZIF-8 containing metal Zn and soluble copper salt are dissolved in a mixed solvent containing H2O, ethyl alcohol and N,N-dimethylformamide, and then 1,3,5-benzene tricarboxylic acid is added for hydrothermal crystallization, separation, washing and drying, so that the CuZn bi-metal organic framework material is obtained.Different from traditional bi-metal MOF preparing methods, the preparing method has the advantages that preparing time is short, replacement rate is high, and the crystal structure of the product varies.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Bagging and packaging machine capable of filling a proper quantity of inert gas into bags

InactiveUS6735928B2Lightweight productionReduce replacement rateCapsCapping machinery safety/controlProcess engineeringProduct gas

A bagging and packaging machine for forming a bag from a strip of bag material and introducing an article into the bag includes a gas supply unit for supplying an inert gas into the bag to substitute for air contained in the bag and a gas supply control means for controlling supply of the inert gas by the gas supply means into the bag. The bagging and packaging machine is designed to allow the inert gas to be supplied under high pressure at a flow rate sufficient to increase the gas replacement rate in the bag when the machine is started, to be supplied under low pressure at a flow rate lower than the high pressure flow rate during a bagging and packaging operation subsequent to the start of the machine. Should the machine is temporarily brought to a halt, the length of time T passing from the timing at which the machine is temporarily brought to a halt is counted by a timer without the supply of the inert gas being interrupted, so that the supply of the inert gas can be interrupted at a timing the counted length of time exceeds a low pressure gas supply time T2. In this way, without the bag being bitten during bagging and / or the bagging and packaging speed being lowered, not only can the inert gas be sufficiently filled in the bag to achieve a high gas replacement rate, but the amount of the inert gas supplied can also be suppressed.

Owner:ISHIDA CO LTD

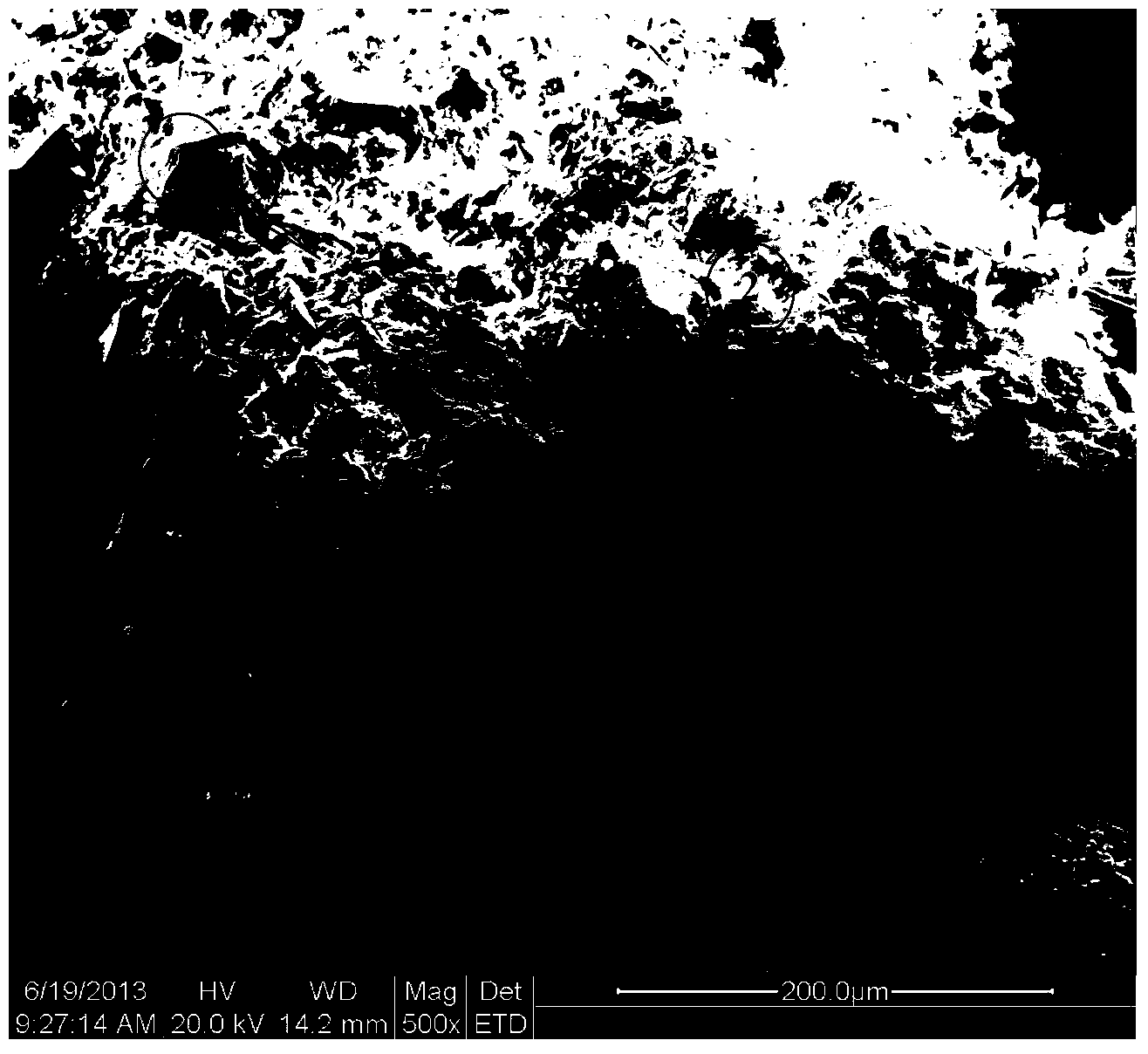

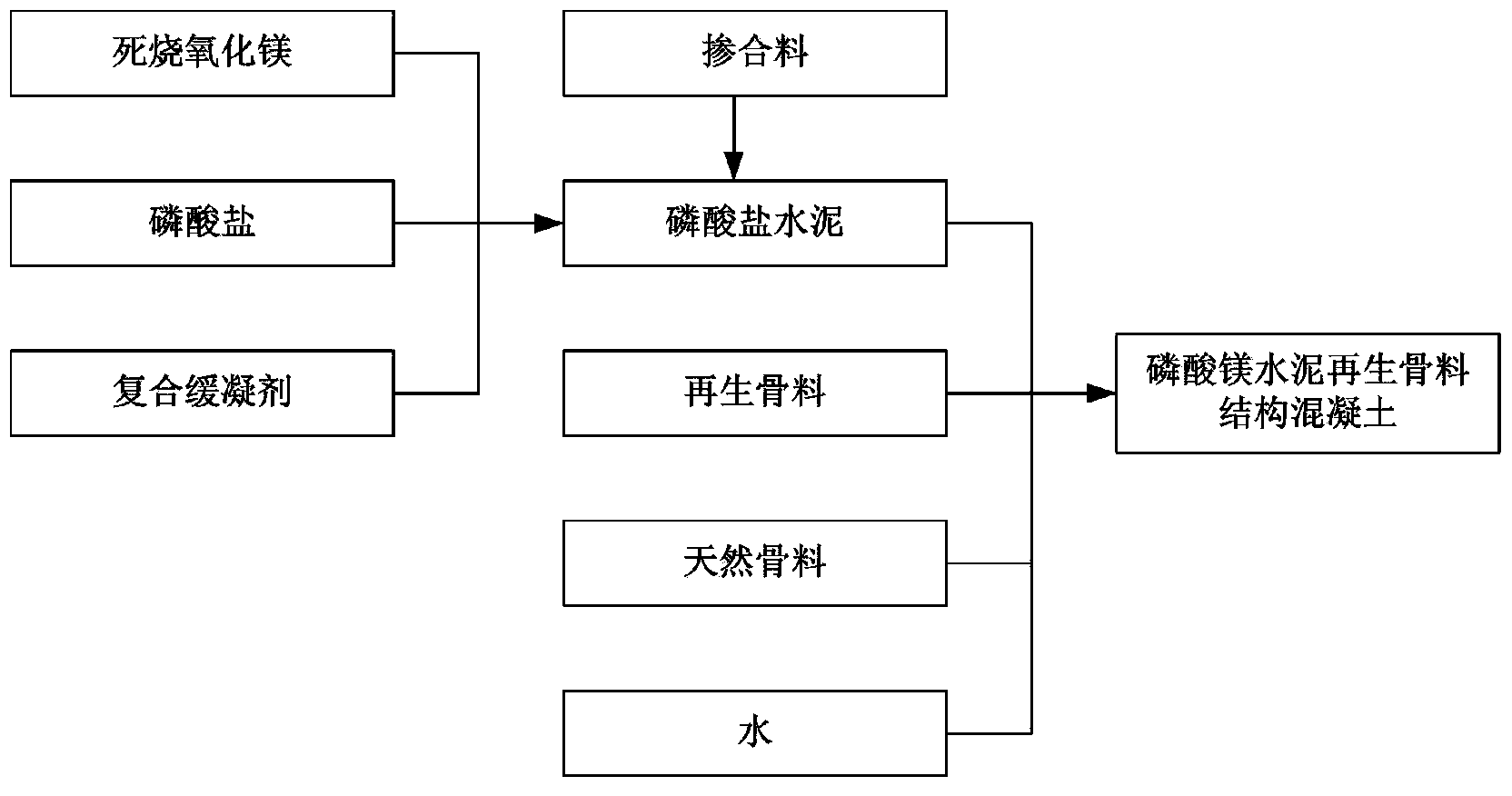

Magnesium phosphate cement recycled aggregate structure concrete and preparation method thereof

InactiveCN104072091AEarly hardening fastHigh strengthSolid waste managementAggregate (composite)Magnesium phosphate

The invention discloses magnesium phosphate cement recycled aggregate structure concrete and a preparation method thereof. The magnesium phosphate cement recycled aggregate structure concrete comprises the following components by weight percent: 12-30% of magnesium oxide, 8-20% of phosphate, 2-10% of composite retarder, 5-15% of admixture, 5-20% of recycled fine aggregate, 5-30% of recycled coarse aggregate, 0-10% of natural fine aggregate, 0-15% of natural coarse aggregate, and the balance being water. High early strength, small shrinkage rate, strong adhesive property and good corrosion resistance of the concrete are ensured by the magnesium phosphate cement; stable growth of the strength of the concrete is ensured by the admixture, and the durability and the volume stability are improved. The magnesium phosphate cement recycled aggregate structure concrete has the beneficial effects that the concrete material is applicable to the structure concrete and high-performance recycled aggregate concrete, can be applied to civil engineering in bad environments such as sulphate attack, marine corrosion, high-temperature environment and low-temperature environment, efficient utilization of the waste concrete is achieved, mining of natural gravel is reduced, the construction cost is reduced, and the targets of recycling wastes and protecting environment are achieved.

Owner:YANCHENG INST OF TECH

Method for processing vehicle bump at bridge head of existing highway

InactiveCN102409598AReduce post-construction settlementSolve the jumpRoads maintainenceArchitectural engineeringStructural engineering

The invention discloses a method for processing vehicle bump at a bridge head of an existing highway, and the method comprises the following steps: mixing lightweight materials at a construction site; drilling holes from embankment slopes on both sides of the highway, and automatically discharging soil outward from a threaded opening while rotatably drilling holes; after a designed depth reaches, rotatably and slowly pulling out a drill rod, and starting a booster pump so as to pump the lightweight materials into the obtained drill holes by virtue of a central tube of the drill rod; and jetting the lightweight materials from the central hole of the drill rod so as to gradually fill the hole from bottom to top, thereby replacing the filled soil of an embankment. The drill holes are arranged squarely or quincuncially on the side slope of the embankment, a certain included angle is formed between each drill hole and a horizontal plane, and the elevation of the opening of each hole is positioned below a pavement structure layer and above the underside of the filled soil of the embankment. By using the method disclosed by the invention, the weight of the embankment is greatly reduced, thereby reducing the settlement after construction caused by embankment loads and then effectively solving the problem of vehicle bump at bridge heads. During the construction period, the highway is not required to be closed, therefore, the normal traffic of the highway is not affected. The method disclosed by the invention is simple in construction process, convenient to operate, simple in equipment, economical, and high in efficiency.

Owner:HOHAI UNIV

Preparation method of furfural-modified lignin-based phenolic resin adhesive

ActiveCN107337774ASimple processHigh purityOrganic chemistryAldehyde/ketone condensation polymer adhesivesChemical industryXylose

The invention discloses a preparation method of a furfural-modified lignin-based phenolic resin adhesive and belongs to the technical field of the biomass energy chemical industry. According to the method, a xylose solution is prepared from biomass hemicellulose through hydrolysis under catalysis of diluted acid, furfural is prepared through dehydration of xylose under catalysis of concentrated acid, lignin is extracted under catalysis of alkali, and an alkali lignin solution is obtained; alkali lignin is subjected to phenolation modification with phenol as a phenolation reagent and alkali as a catalyst, phenol is replaced with the modified lignin in different proportions, formaldehyde is replaced with furfural in different proportions, and the lignin-based phenolic resin adhesive is prepared through collaborative copolymerization of lignin, furfural, phenol and formaldehyde. The product furfural prepared through hydrolysis and dehydration of hemicellulose is taken as a crosslinking agent, the industrial application problem that the glue strength of the adhesive is reduced due to the fact that the proportion of lignin replacing phenol is increased in the prior art is solved, and the total replacement rate of chemical products from biomass for phenol and formaldehyde from fossil resources is increased.

Owner:JILIN UNIV

Method for preparing tellurium dioxide from tellurium slag

InactiveCN102390819AMain grade improvedSave resourcesBinary selenium/tellurium compoundsPregnant leach solutionSlag

The invention relates to a method for preparing tellurium dioxide from tellurium slag. According to the technical scheme, the method comprises the following steps of: adding tellurium slag to sulfuric acid solution, stirring at normal temperature, adding 10% oxydol at the temperature of 30-40 DEG C, and then heating to 80-90 DEG C, and leaching under normal pressure; adding copper powder to leachate, carrying out replacement reaction at the temperature of 90-95 DEG C for 2 hours, and carrying out solid-liquid separation to obtain copper telluride slag; adding copper telluride slag to sulfuricacid solution, adding 10% oxydol, stirring at the temperature of 90 DEG C for 1 hour, and filtering; adding sodium carbonate to filtrate for neutralizing the filtrate till pH of the filtrate is 3, and filtering; adding NaOH to filter residue, carrying out alkali leaching and stirring at the temperature of 85-95 DEG C for 1 hour, and filtering; and adding H2SO4 to filtrate for neutralizing the filtrate till pH of the filtrate is 6-7, filtering, washing and drying to obtain a product. The method has the characteristics that: low-grade tellurium-containing material discarded by a copper anode mud production enterprise is used as a raw material to produce high-purity tellurium dioxide, the process is reasonable and pollution-free, and the recovery rate of tellurium is high.

Owner:LIAONING UNIVERSITY

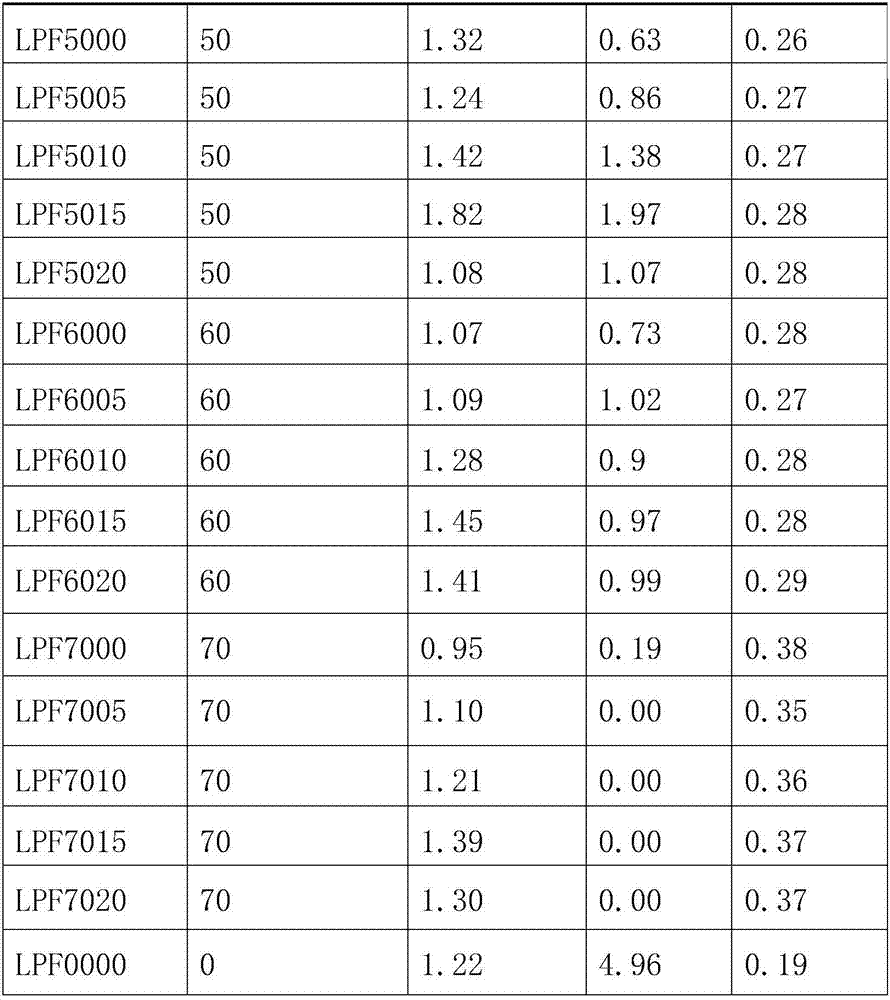

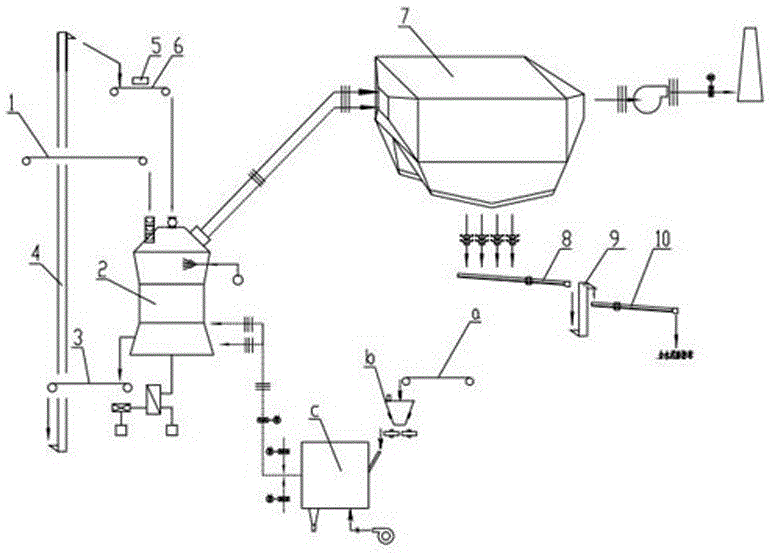

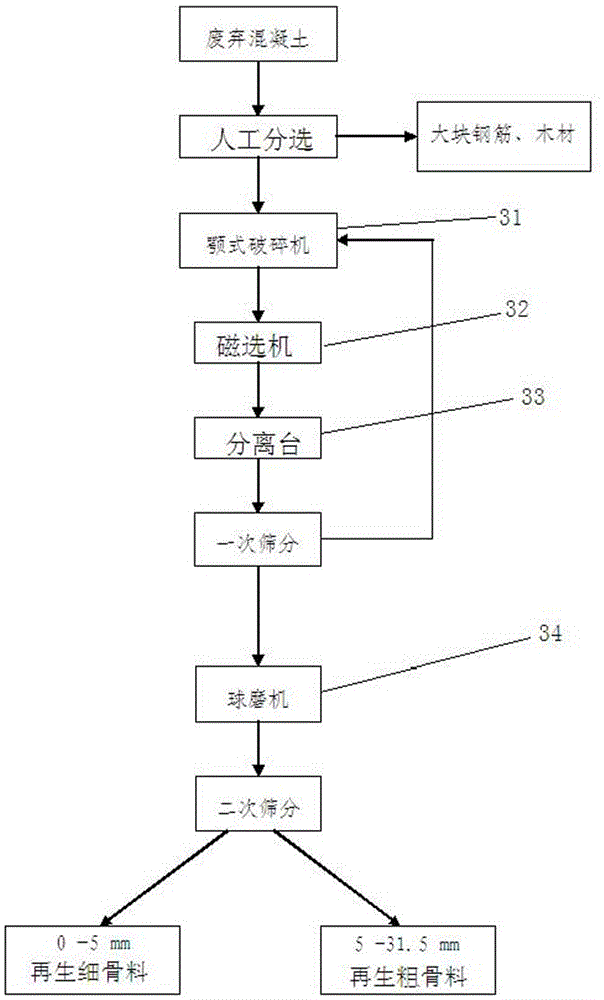

Process for preparing high-performance composite concrete from mineral powder, machine-made sand and waste concrete

The invention discloses a process for preparing high-performance composite concrete from mineral powder, machine-made sand and waste concrete. The process comprises the following steps of 1, the process of preparing the mineral powder, wherein the mineral powder is dried and pulverized through a vertical mill; 2, preparation of the machine-made sand, wherein incoming main raw materials broken stone or stone chips with the particle size smaller than or equal to 40 mm are placed in a piling shed for natural air drying, then sent to a feeding grade-level funnel, fed through a feeding valve and elevated through a belt conveyor and a belt-bucket elevator to enter a sand-making tower, the broken stone or stone chips pass through a sand-making shaping machine, a powerful air sieve and a graduation adjusting machine from top to bottom, a centralized pulse cloth bag type dust collector is adopted, discharging is conducted, so that a finished product, namely the machine-made sand, is obtained, and remaining aggregate returns to the belt-bucket elevator for re-circulation treatment; 3, the process of preparing regenerated aggregate from the waste concrete, wherein the waste concrete is subjected to artificial sorting, simple crushing, separation, sieving and reinforcing, so that the regenerated aggregate is obtained. The process has the advantages that discharging and piling of waste are reduced, and the treatment site is saved.

Owner:GUANGXI YUFENG CONCRETE CO LTD

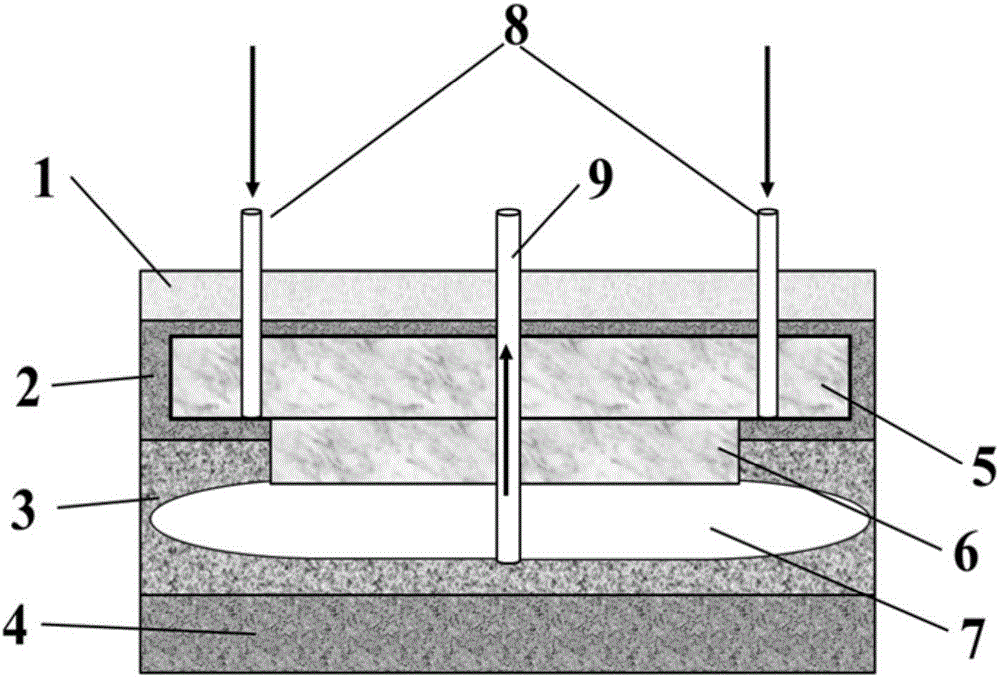

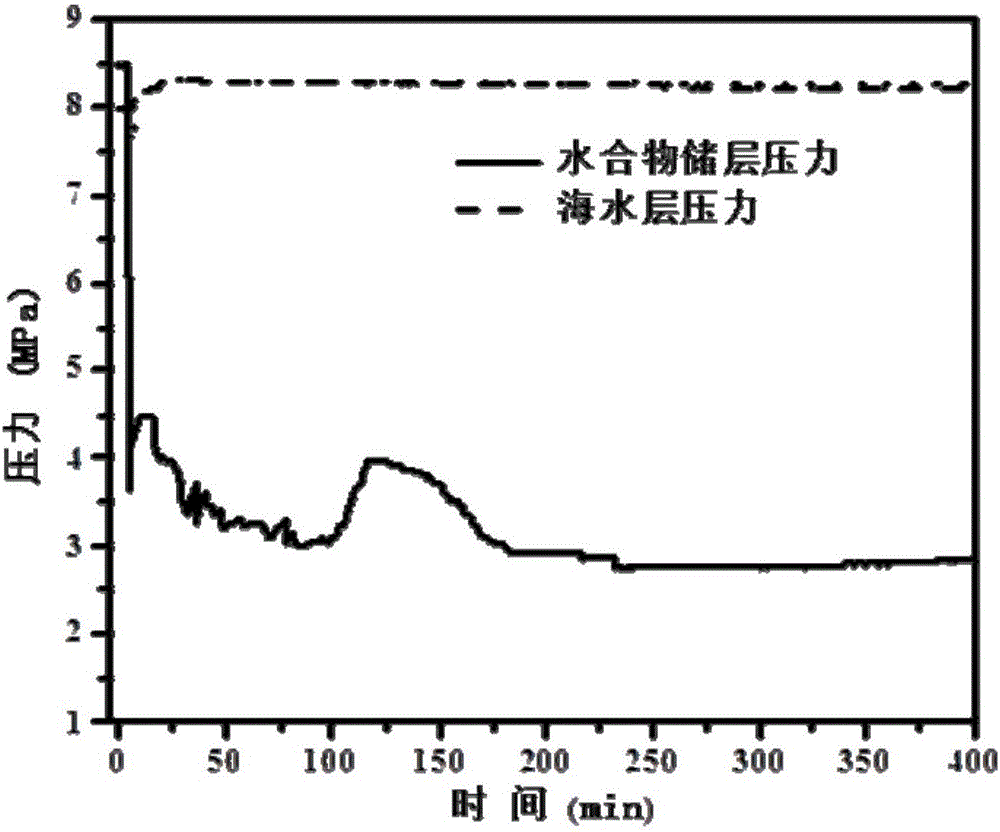

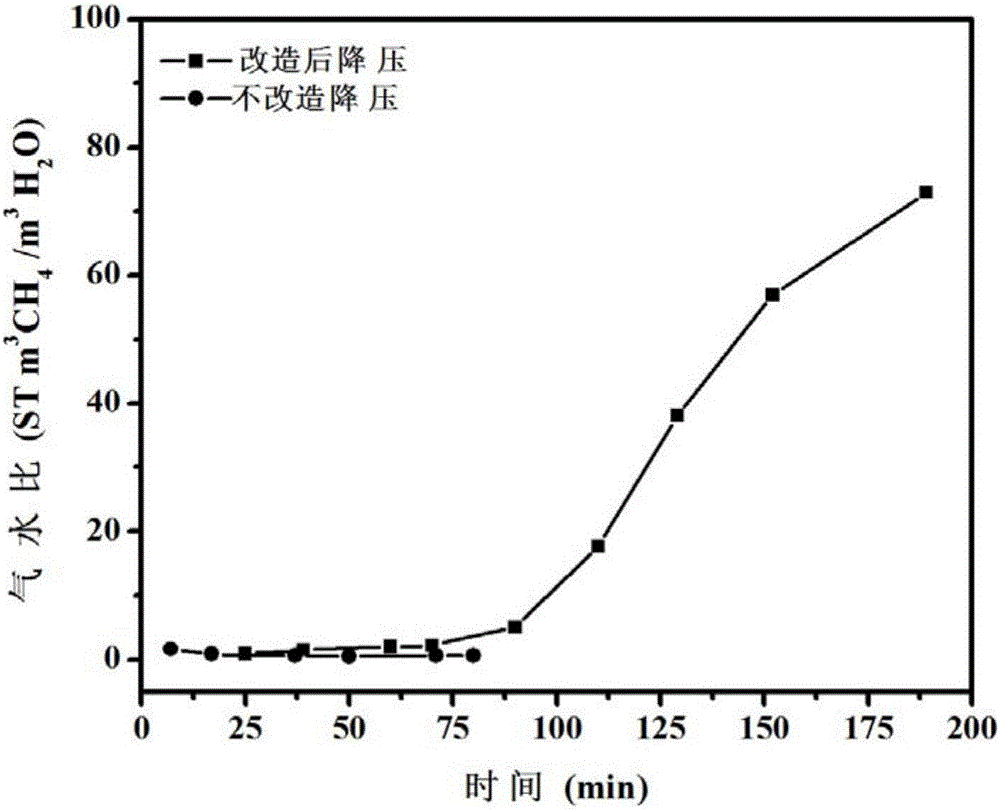

Method of reforming and exploiting marine natural gas hydrate reservoir

ActiveCN106761589AImprove efficiencyImprove securityConstructionsFluid removalProduction rateMechanical stability

The invention provides a method of reforming and exploiting a marine natural gas hydrate reservoir; the method comprises: arranging a production well in the natural gas hydrate reservoir, and an injection well in upper cap rock of the natural gas hydrate reservoir; injecting CO2 into the injection well, and stopping the injection of CO2 when the CO2 covers the upper cap rock of the natural gas hydrate reservoir; when CO2 hydrate in the deposit of the upper cap rock stops growing or after average saturation of the CO2 hydrate is greater than 30%, exploiting by means of depressurizing production; when the molar content of the CO2 in produced gas is greater than 90%, stopping exploitation, closing the production well, and completing reforming and exploiting of the marine natural gas hydrate reservoir. The method has the advantages that uncontrollable escape of natural gas and immersion of the reservoir by sea water can be prevented, water restraint effect is relieved, gas production rate is increased, and mechanical stability of a stratum is maintained.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

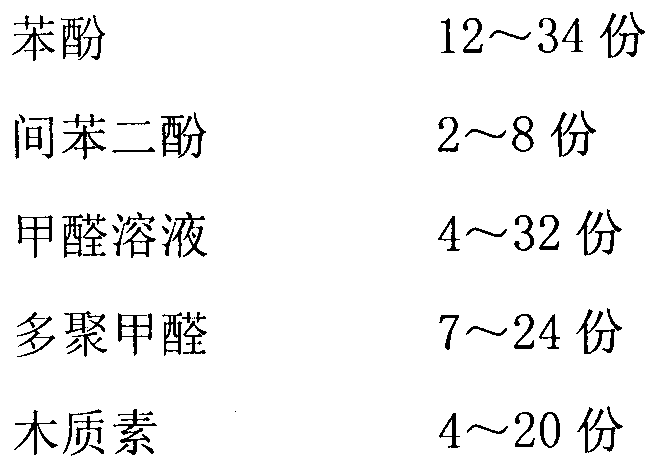

Phenolated lignin modified expandable resorcinol-phenol-formaldehyde resin and preparation method thereof

The invention discloses modified expandable resorcinol-phenol-formaldehyde resin and a preparation method thereof. The preparation method comprises the following steps: adding lignin, phenol and a basic catalyst into a reactor for phenolate and degradation of lignin; adding a formaldehyde solution for condensation reaction with phenolated lignin and phenol; adding paraformaldehyde for further condensation reaction with the basic catalyst; adding resorcinol for condensation polymerization, so as to obtain the phenolated lignin modified expandable resorcinol-phenol-formaldehyde resin. As phenolate and degradation of lignin are carried out in advance, the phenolic hydroxyl group content of lignin is improved. Moreover, high-activity resorcinol is added, so that the prepared lignin-based phenolic resin is high in activity; a foam material made of the modified resin through solidification is high in mechanical properties, and low in scaling off rate. The compression strength of lignin modified phenolic foam is 172.1 kPa, and the bending strength of lignin modified phenolic foam is 254.6 kPa, which are respectively 10.5 percent and 22.1 percent higher than those of foam which is not added with lignin; the scaling off rate of the lignin modified phenolic foam is 19.1 percent, which is 22.8 percent lower than that of the form which is not added with lignin.

Owner:重庆集凯科技服务有限公司

Preparation method of low-grade activated coal ash composite material

InactiveCN102718423ASlow down excessive consumptionLow costCement productionIndustrial wasteAdverse effect

The invention relates to a preparation method of a low-grade activated coal ash composite material applied to cement and concrete. The low-grade activated coal ash composite material is prepared by taking the low-grade coal ash as a main raw material and slag, red mud, and other industrial waste residues, limestone powder and semi-hydrated gypsum as auxiliary materials through the combined action of physical milling and activating and chemical excitation. In the process of mixing concrete materials, 30% by weight of the activated coal ash composite material is used to replace PO52.5, PO42.5 or PO32.5 silicate cement; under the circumstance that other mixing materials remain the same, a great amount of cost can be saved for mixing the concrete per cube meter; the strength of the mixed concrete at all ages is equal to or higher than that of contrast concrete; the newly mixed concrete has the characteristics of high workability, low slump loss, low heat of hydration, good transitive performance of long-term strength, high resistance to sulfate attack, high chemical resistance, high durability, and the like; and the added coal ash composite material has no adverse effect on the performance of the concrete.

Owner:CHINA UNIV OF MINING & TECH

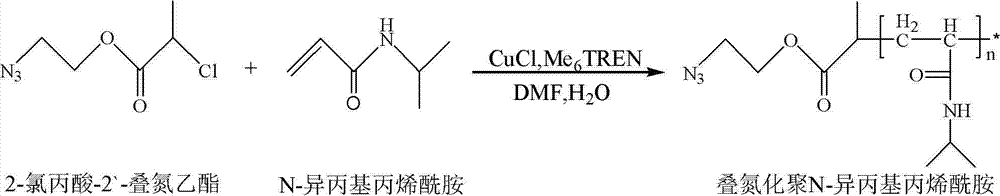

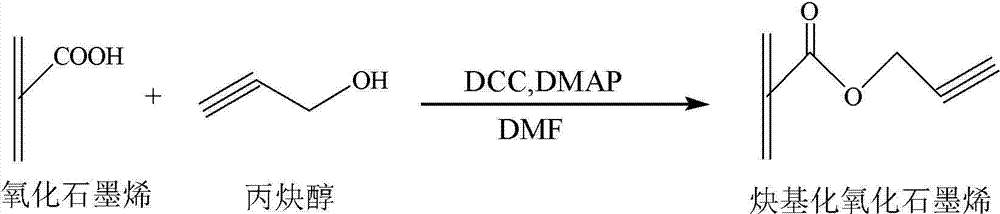

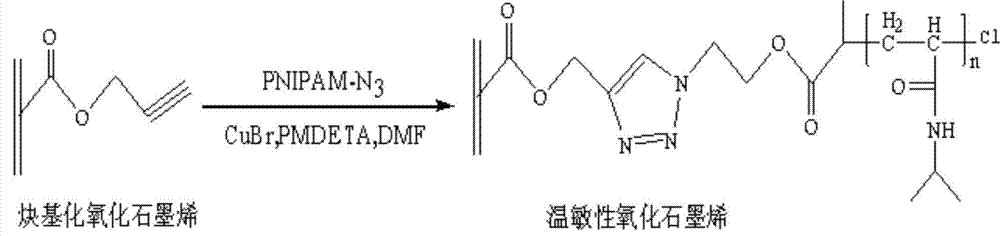

Preparation method of thermo-sensitive graphene oxide with improved replacement rate by triggering polymerization through advanced modification

InactiveCN103044688AIncrease contentHas fluorescent labeling propertiesPharmaceutical non-active ingredientsChemical reactionAtom-transfer radical-polymerization

The invention discloses a preparation method of thermo-sensitive graphene oxide with improved replacement rate by initializing polymerization through advanced modification. Graphene oxide with a medicine carrying property and a PNIPAM (Poly N-Isopropyl Acryl Amide) with thermo-sensitivity are synthesized into a thermo-sensitive medicine carrying composite material through click chemical reaction, belonging to the technical field of macromolecule medicinal materials. An azide group in the prior art is low in replacement rate, and an obtained thermo-sensitive graphene oxide is difficult to further modify. The preparation method is characterized by comprising the following steps of firstly, initializing the NIPAM to be polymerized by using an ATRP (Atom Transfer Radical Polymerization) initiator with an azide group at the tail end of the initiator, so as to obtain the PNIPAM with the azide group at the tail end; secondly, reacting alkynyl molecules with the graphene oxide so as to obtain alkynyl graphene oxide; and finally, combining the PNIPAM with the azide group at the tail end with the alkynyl graphene oxide by using a click chemical reaction method so as to obtain the thermo-sensitive graphene oxide. Due to polymerization initialization through advanced modification, the azide group is high in replacement rate, and the other end of a PNIPAM chain after stem grafting is halogen, so that the thermo-sensitive graphene oxide can be further modified.

Owner:CHANGCHUN UNIV OF SCI & TECH

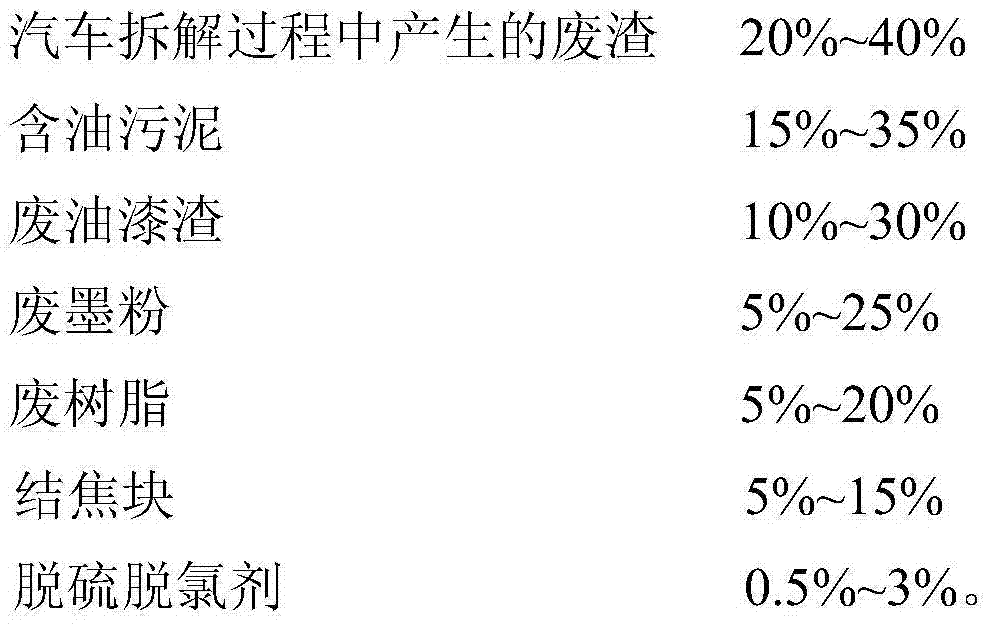

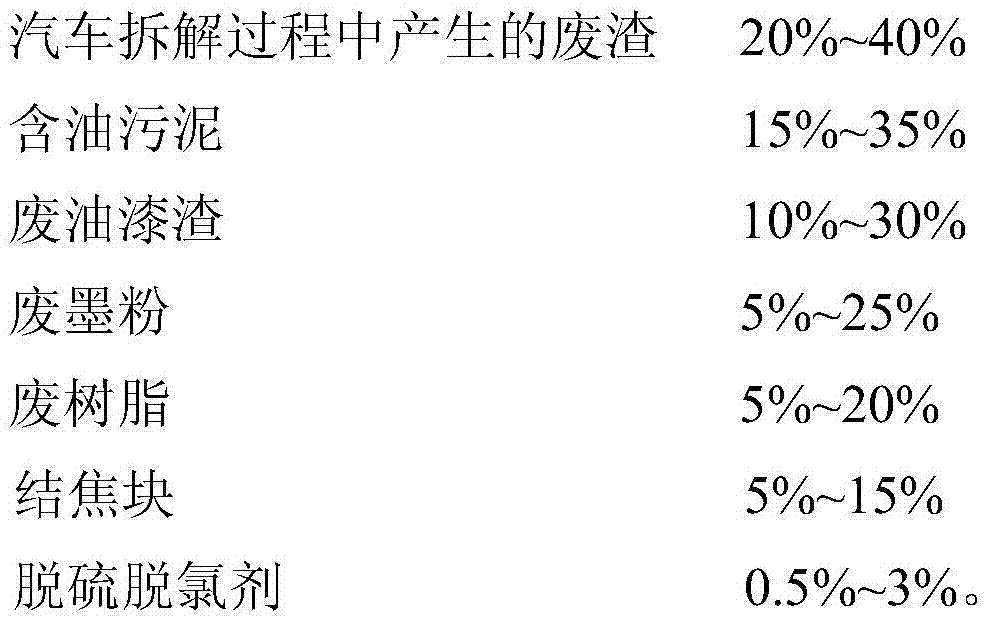

Generative fuel produced by using industrial solid waste and preparation method thereof

ActiveCN103756750AImprove adhesionBonding EfficientSolid fuelsWaste based fuelAlternative fuelsCombustion

The invention discloses a generative fuel produced by using an industrial solid waste and a preparation method thereof. The method comprises the following steps: taking industrial solid wastes such as waste residues, oily sludge, waste paint slags, waste powdered ink, waste resin, coking blocks and the like generated in a car dismantling process as calorific value components; adding a desulfurization and dechlorination agent as an auxiliary component; evenly mixing, pressing and molding, and drying, so as to obtain the generative fuel. The heat value of the generative fuel disclosed by the invention is over 4,000kcal / kg, the generative fuel can be used as an alternative fuel for a cement plant and a power plant, and is good in inflammability, and free of any combustion improver; the burnt ash content is below 20%, the fire coal substitution rate can be up to 80%, the sulfur fixation efficiency is 69.4-80.3%, the chlorine fixation efficiency is 70.4-81.1%, the content of hazardous substances (based on S and Cl) in the combustion tail gas is reduced by 70-80%. The generative fuel and the preparation method thereof provided by the invention have outstanding environmental benefits.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

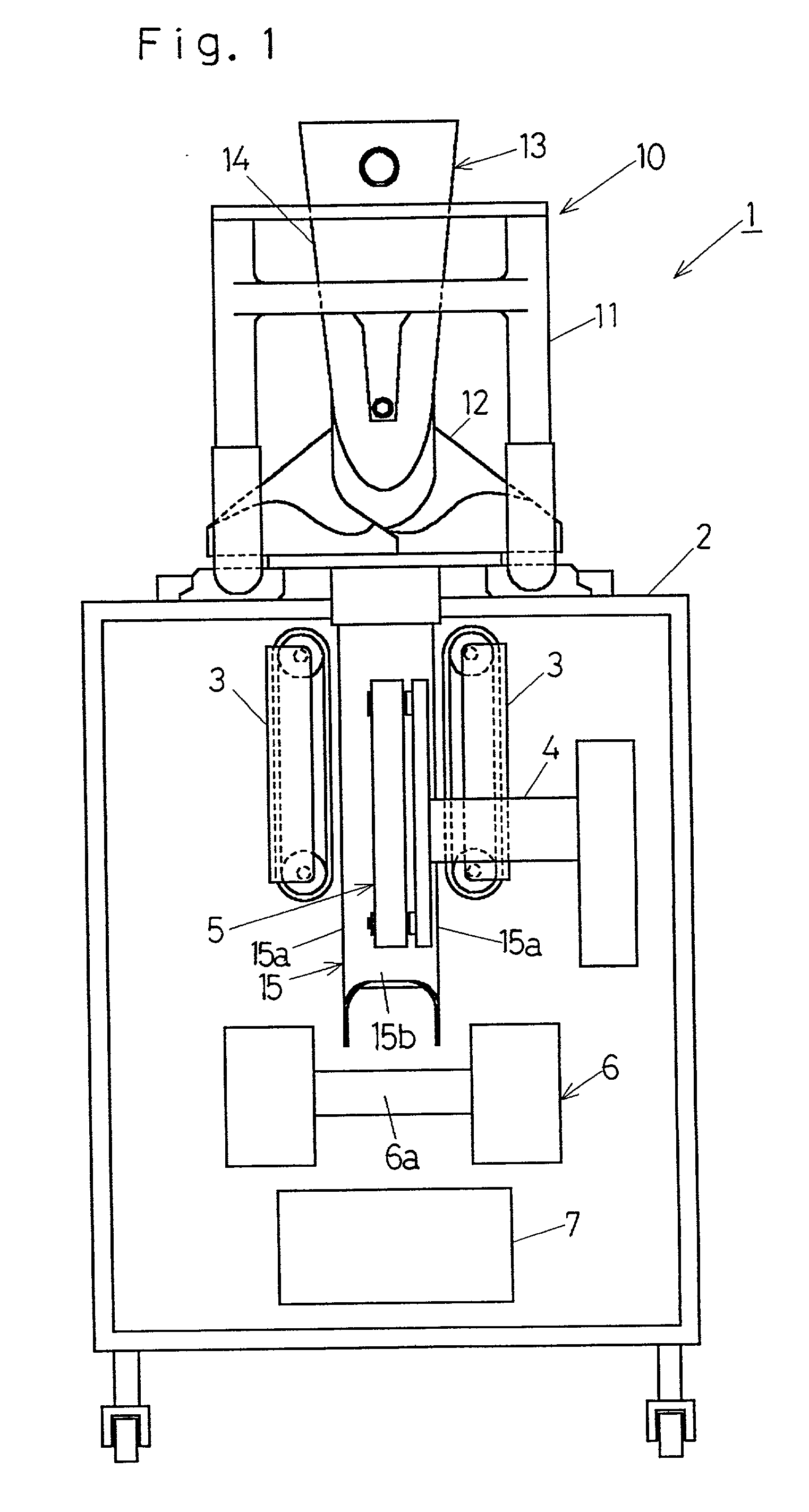

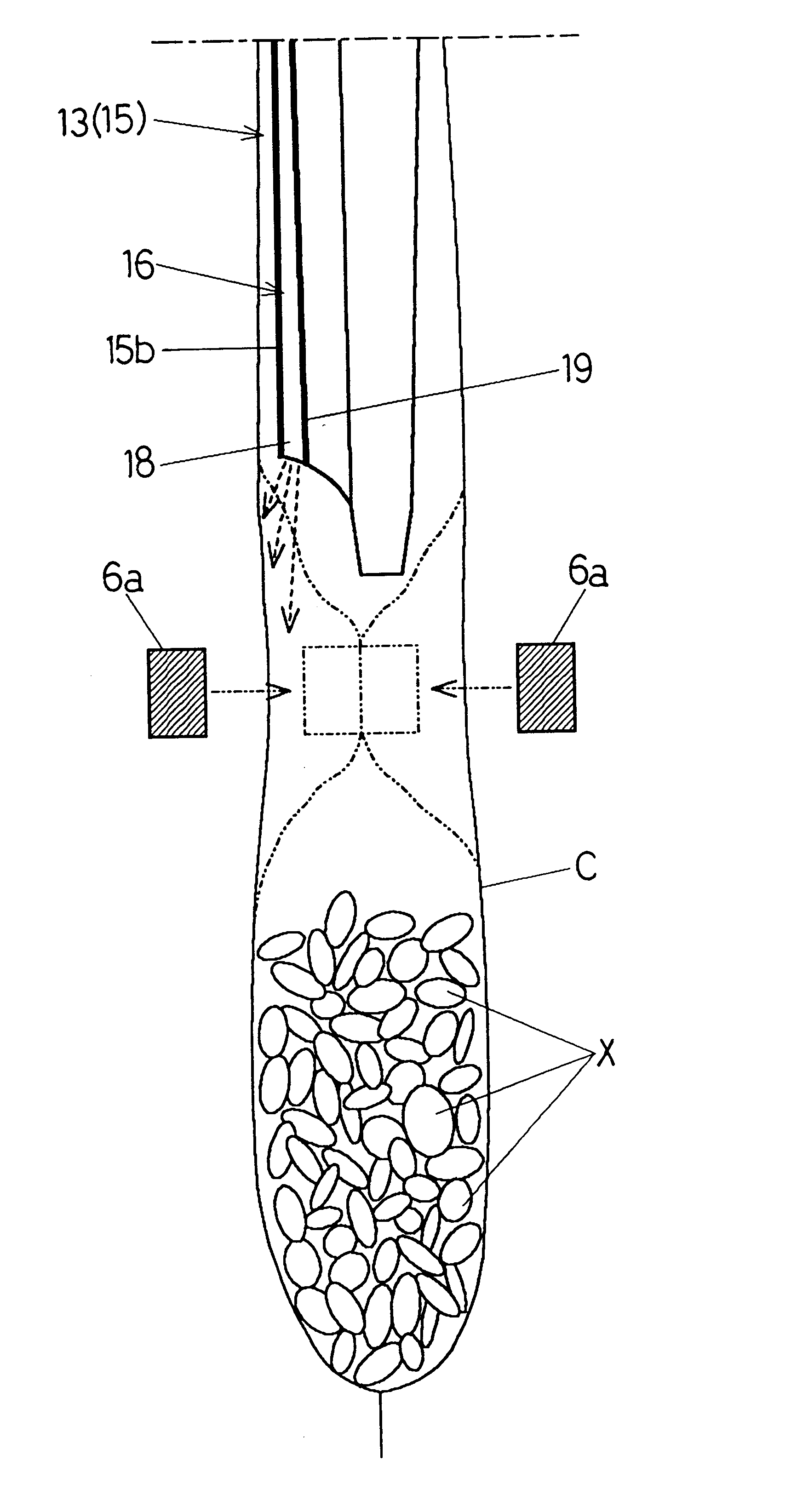

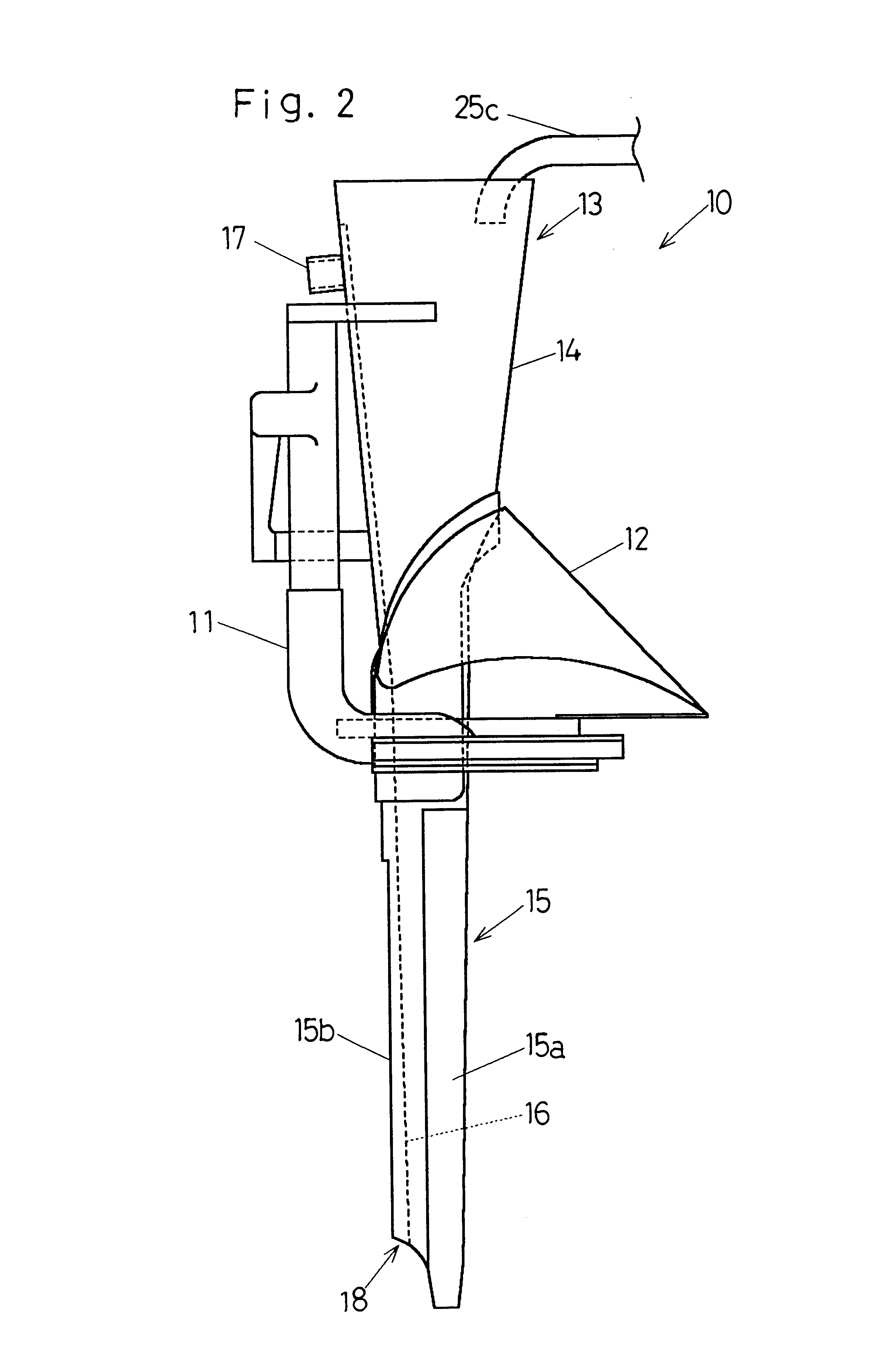

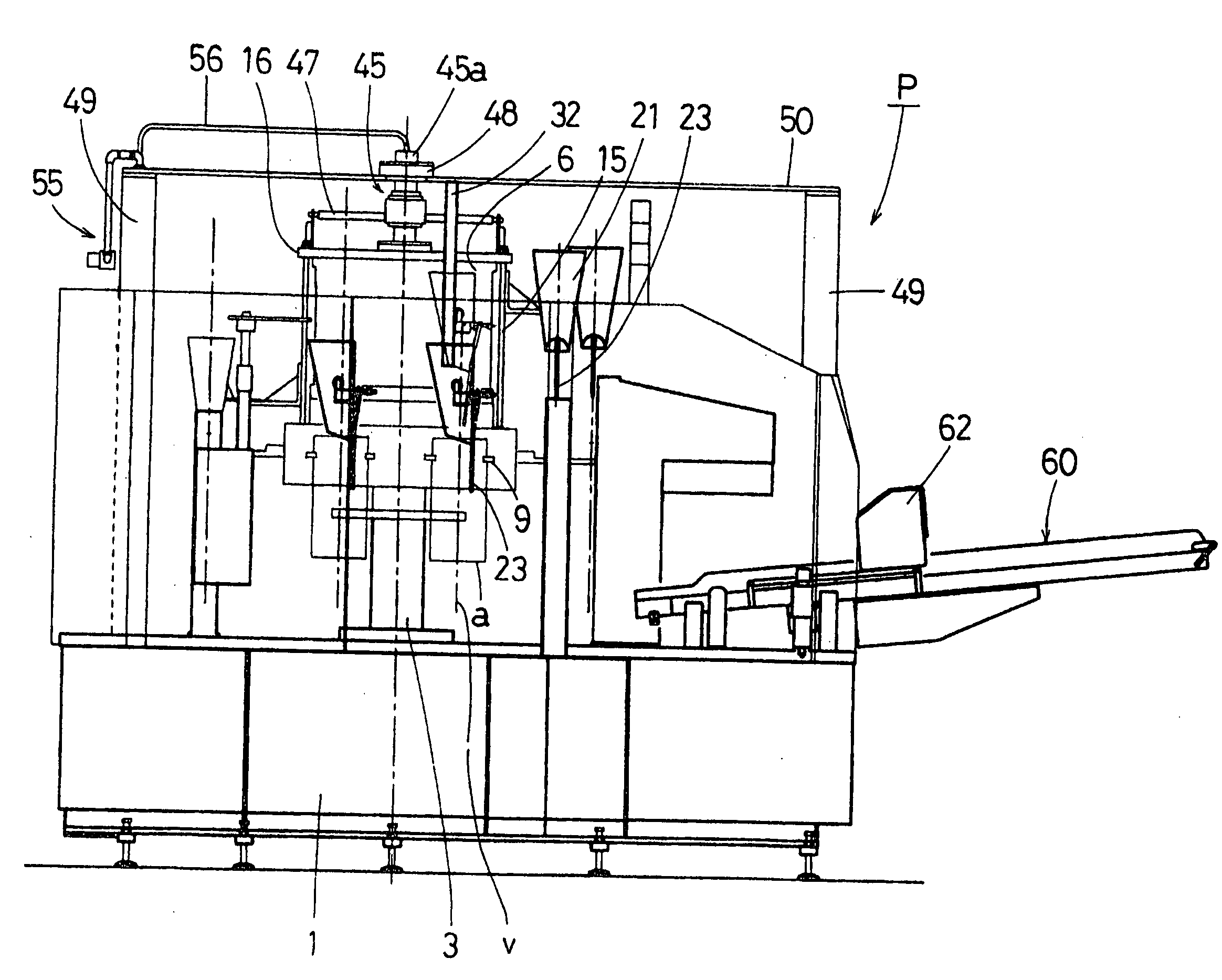

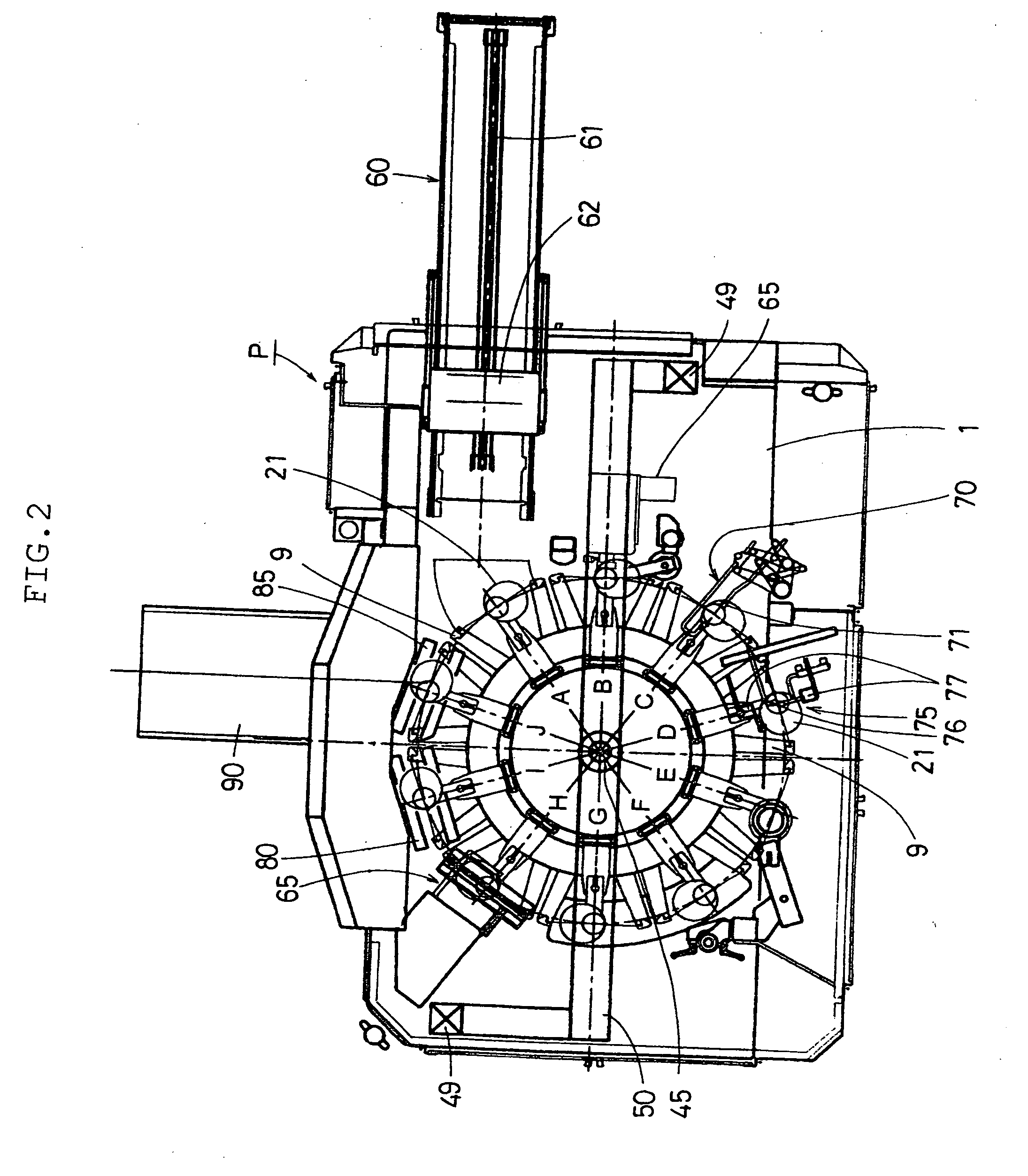

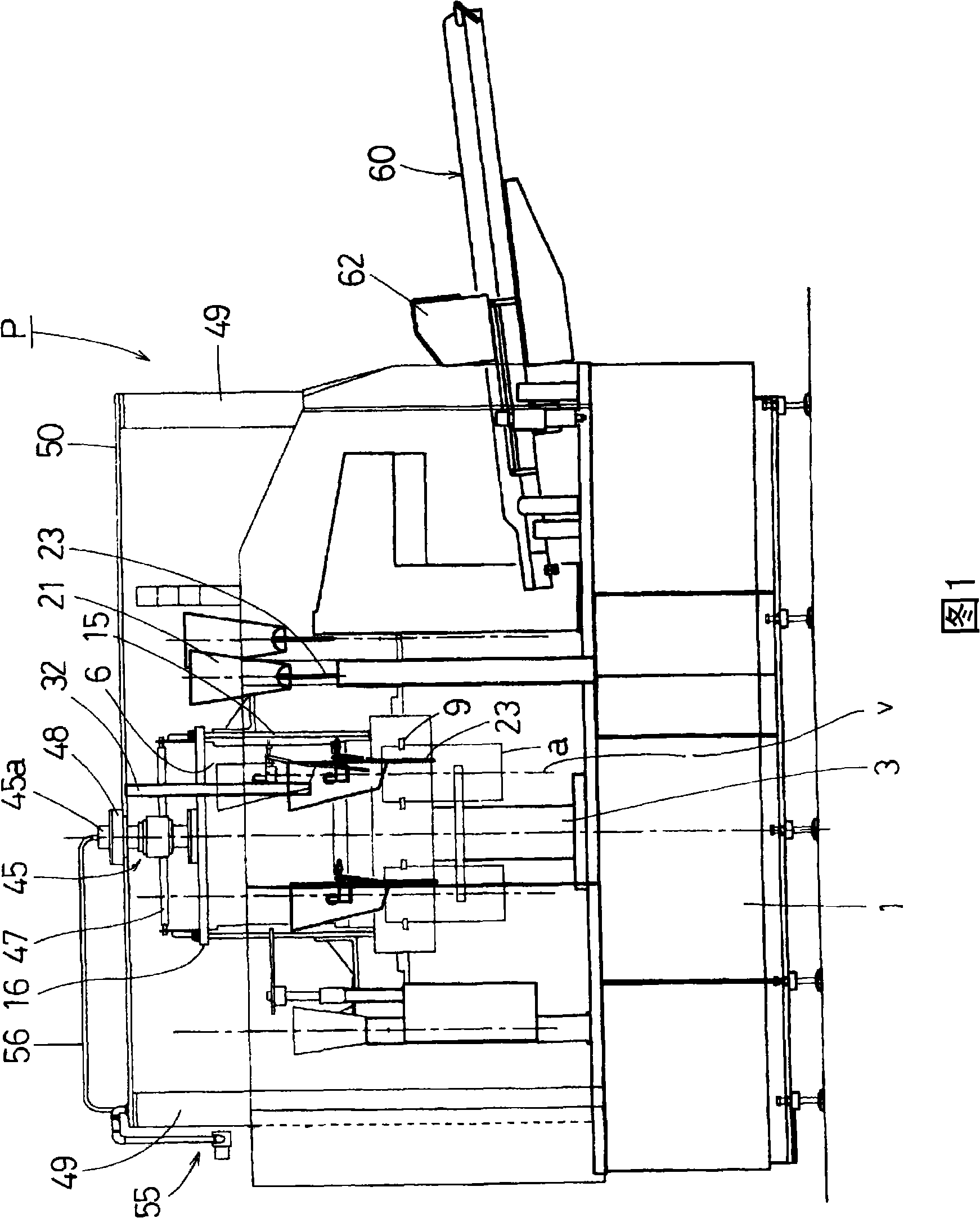

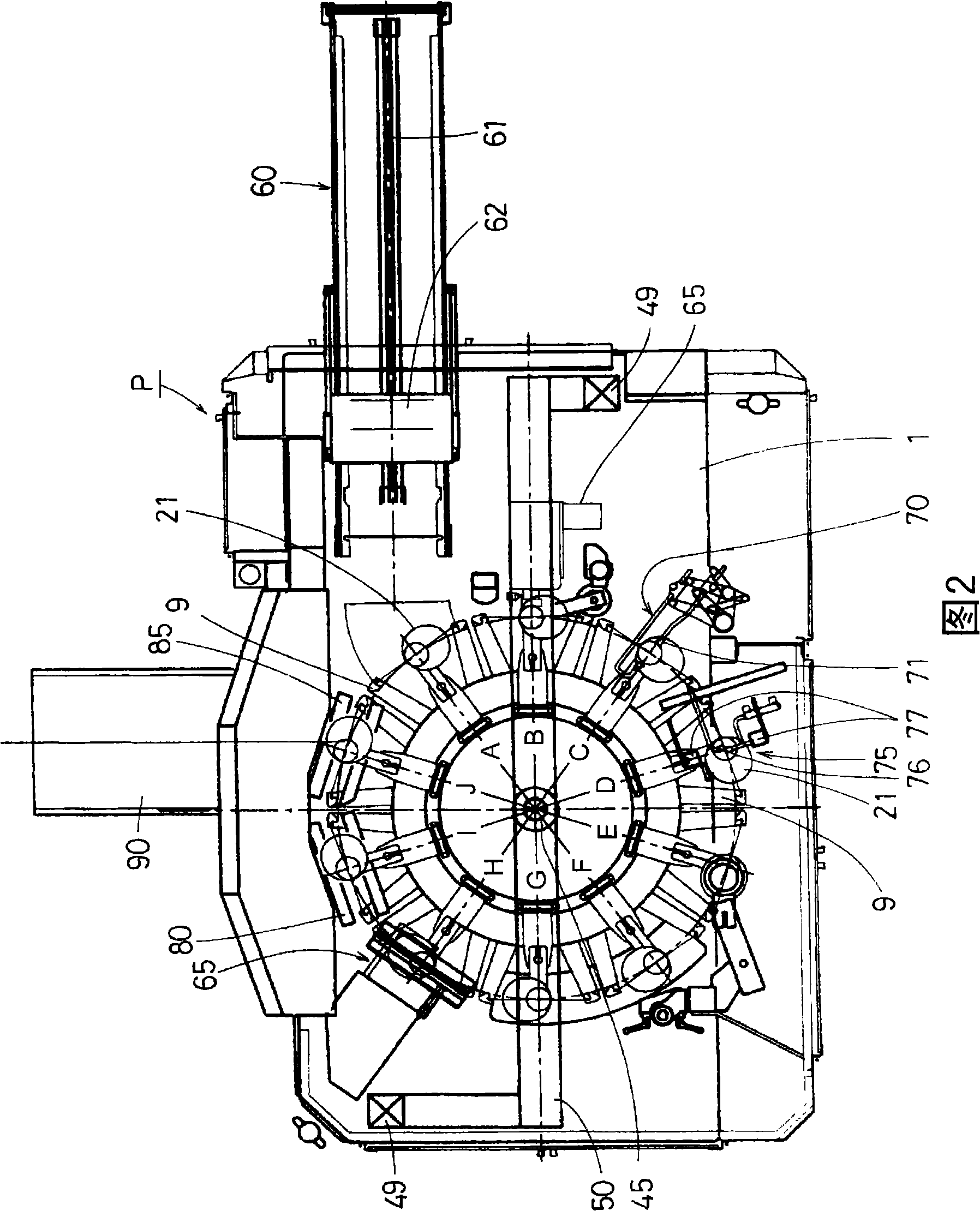

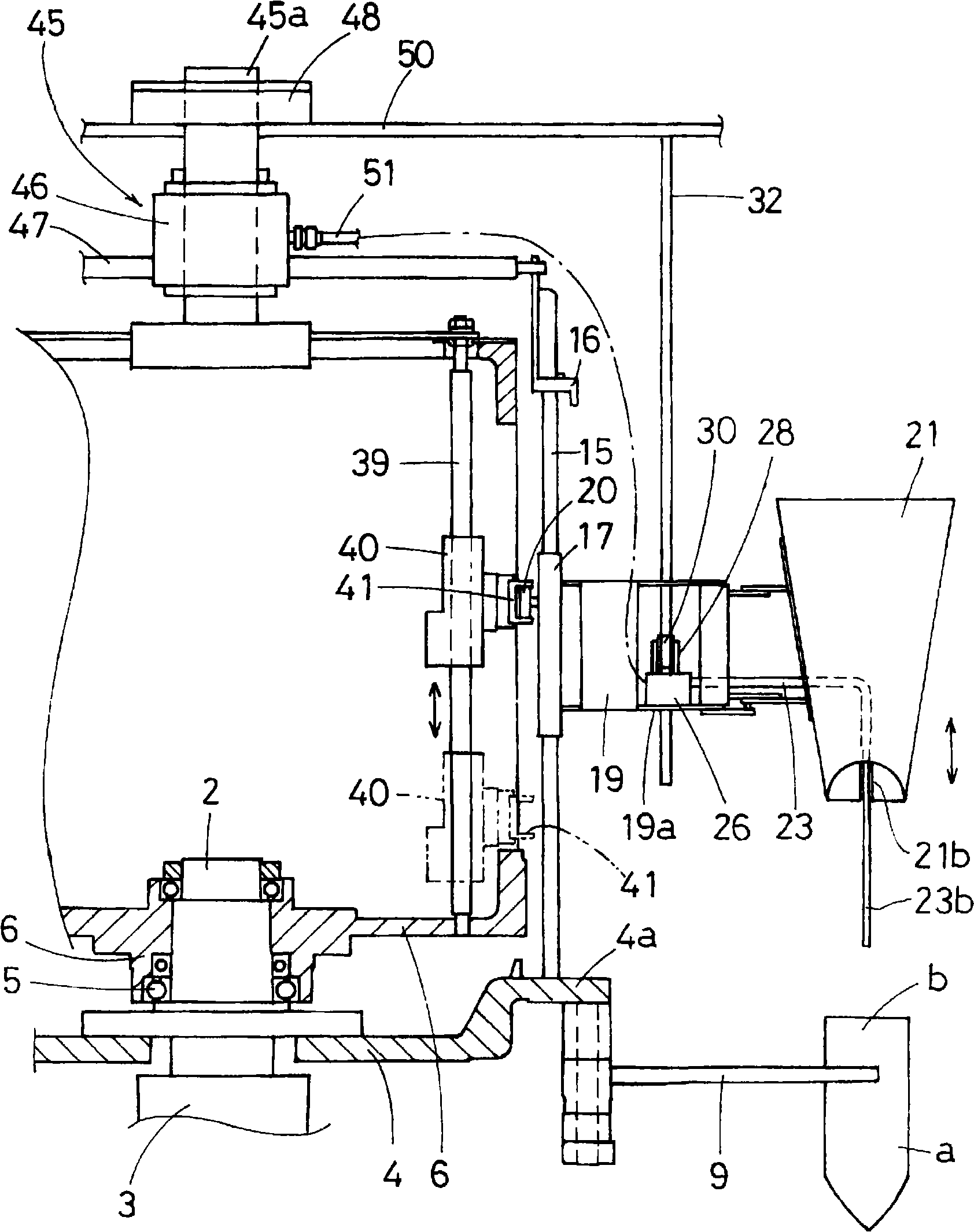

Method for Placing Inert Gas in Gas-Filling Packaging Machine

ActiveUS20090223172A1Increase replacement rateAvoid stickingCapsCap application using vaccuumAttitude controlProduct gas

[PROBLEMS] To provide an inert gas placing method for a gas-filling and packaging machine, in which troubles occurring when a gas-filling nozzle is inserted into a packaging bag are eliminated and in which a gas replacement rate is increased.[MEANS FOR OVERCOMING PROBLEMS] A gas-filling nozzle (23) is provided at a filling funnel (21) in correspondence with each grip (9) of a rotating body, and the gas-filling nozzle (23) has a forward end (23b) controlled by a nozzle attitude control unit (25) so as to approach or recede from an imaginary normal line v passing through the center of the drop opening of the filling funnel. In the process preceding a filling process, the drop opening of the filling funnel and the forward end of the gas-filling nozzle brought close to the normal line v are inserted from the opened bag opening b into a package bag a, and at the same time, the forward end is separated from the normal line v and moved toward a corner of the package bag. In the process following the filling process, inert gas jetted from the gas filling nozzle and air in the package bag are replaced with each other, and in a postprocess on the downstream side, the replacement action between the inert gas and the air is promoted with the bag opening b substantially closed by a shutter unit (65).

Owner:GENERAL PACKER

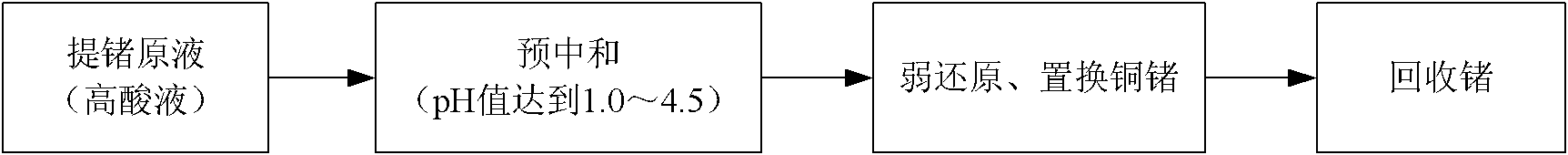

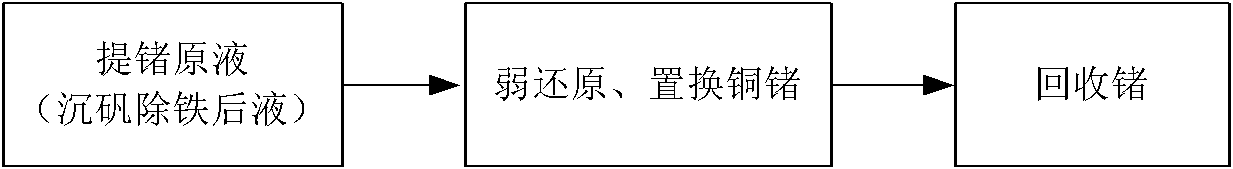

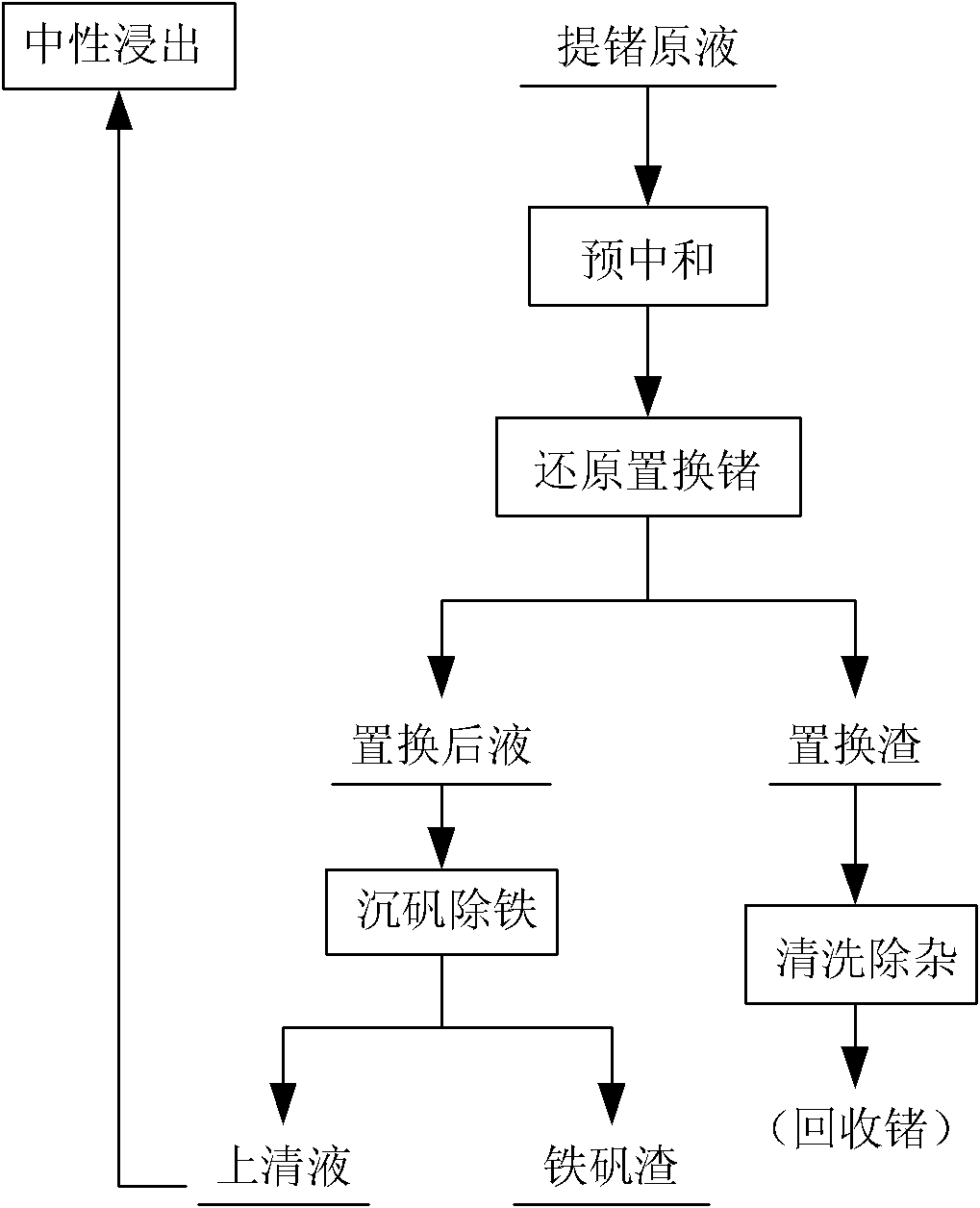

Method for enriching germanium from wet process zinc smelting system

ActiveCN102031371AShort processIncrease replacement rateProcess efficiency improvementIron removalZinc smelting

The invention discloses a method for enriching germanium from a wet process zinc smelting system. The method comprises the following process steps of: pre-neutralizing germanium extracting stock solution; weakly reducing; replacing reduced germanium; cleaning replacement residue; extracting germanium; opening a path and removing iron and the like. The method comprises the following specific steps of: firstly, pre-neutralizing pickle liquor (or liquid obtained from iron removal by jarosite process) with high germanium content by using a small amount of neutralizing agent and controlling the pH of a reaction final point to be between 1.0 and 4.5; secondly, adding a slightly excess amount of reducing agent such as zinc powder or scrap iron to replace germanium; and lastly, after reaction, separating excessive zinc powder or the scrap iron, separating solid from liquid to obtain copper germanium residue with high germanium grade and extracting germanium. Germanium replacement rate is high, and germanium residue has high grade and is easy to treat; moreover, the method is easy to operate, has easily-controllable process condition and low cost and is suitable for the requirement of industrial production.

Owner:CENT SOUTH UNIV +1

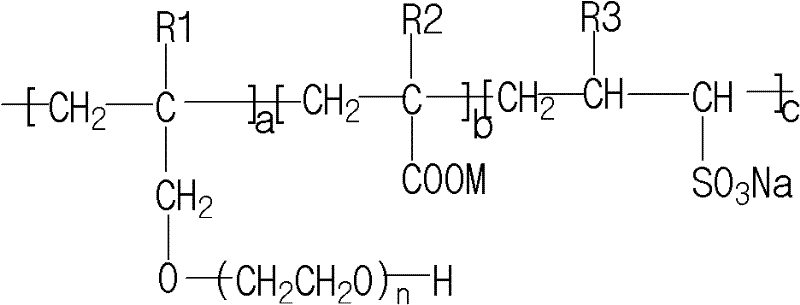

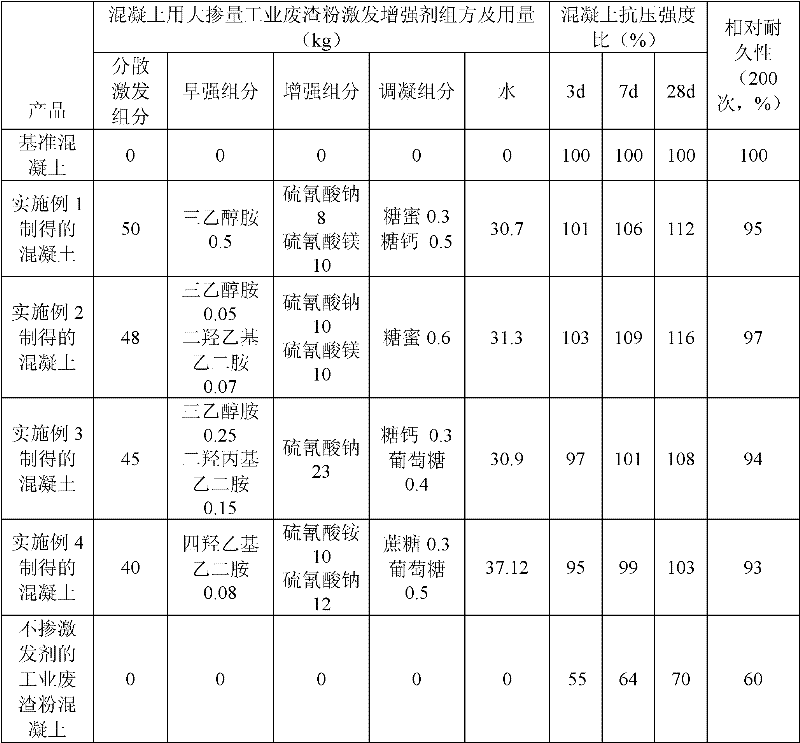

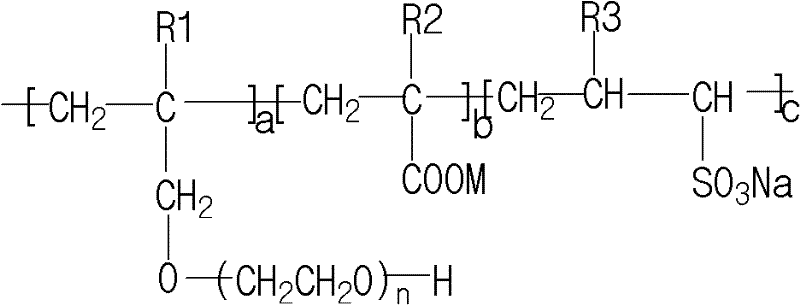

Stimulation reinforcer with high volume industrial waste residue powder used for concrete and its preparation method

InactiveCN102344256ASimple production processAdvanced production equipmentCement productionAdditive ingredientDissolution

The invention belongs to the concrete preparation technical field, and relates to a stimulation reinforcer with high volume industrial waste residue powder used for concrete. The stimulation reinforcer comprises the following raw materials by mass percentage: 30-60% of dispersed stimulation ingredient, 0.01-1% of early strength ingredient, 10-30% of reinforcement ingredient, 0.01-1% of set-regulating ingredient and the balance of water. A preparation method comprises the following steps: successively adding water, the dispersed stimulation ingredient, the early strength ingredient, the reinforcement ingredient and the set-regulating ingredient, stirring for 20-30 minutes until complete dissolution. The prepared stimulation reinforcer is capable of stimulating the activity of the industrial waste residue powder, under the premise of ensuring each performance of the concrete, the industrial waste residue powder is a substitution of the cement, the method has simple and reasonable preparation and is easy for production, the prepared concrete has the advantages of high compression strength and good durability.

Owner:山东华伟银凯建材科技股份有限公司

Method for preparing concrete from industrial waste residue fine aggregate

ActiveCN104072028AHigh replacement rateHigh strengthSolid waste managementIndustrial wasteConstruction aggregate

The invention provides a method for preparing concrete from industrial waste residue fine aggregate, which belongs to preparation methods for concrete. According to the method, a standard mix ratio of common concrete is adjusted and fine industrial waste residue and cobblestone are used together to equivalently replace a part of fine aggregate and cement so as to improve physical and mechanical properties of concrete and reduce material cost; in mixing of concrete materials, fine industrial waste residue is used to equivalently replace 10 to 15% of fine aggregate and fine industrial waste residue and cobblestone are used together to equivalently replace 20 wt% of cement on the basis of the standard mix ratio of common concrete, other mixing materials are maintained unchanged, so cost for each cubic of concrete can be decreased by 10 to 20 Yuan, and the mixed concrete has strength equivalent to or higher than the strength of concrete prepared based on the standard mix ratio in every stage and has the characteristics of good workability, small slump loss, low heat of hydration, good later strength deferment, resistance to sulfate erosion, strong resistance to chemical attack, good durability, no unfavorable influence on concrete performance, etc.

Owner:徐州经济技术开发区诚意商品混凝土有限公司

Method for placing inert gas in gas-filling and packaging machine

InactiveCN101258074AIncrease replacement rateResolve staggered insertion errorsPackaging by pressurising/gasifyingAttitude controlEngineering

The present invention provides an inert gas placing method for a gas- filling and packaging machine, in which troubles occurring when a gas-filling nozzle is inserted into a packaging bag are eliminated and in which a gas replacement rate is increased. A gas-filling nozzle (23) is provided at a filling funnel (21) in correspondence with each grip (9) of a rotating body, and the gas-filling nozzle (23) has a forward end (23b) controlled by a nozzle attitude control means (25) so as to approach or recede from an imaginary normal line v passing through the center of the drop opening of the filling funnel. In the process preceding a filling process, the drop opening of the filling funnel and the forward end of the gas-filling nozzle brought close to the normal line v are inserted from the opened bag opening b into a package bag a, and at the same time, the forward end is separated from the normal line v and moved toward a corner of the package bag. In the process following the filling process, inert gas jetted from the gas filling nozzle and air in the package bag are replaced with each other, and in a postprocess on the downstream side, the replacement action between the inert gas and the air is promoted with the bag opening b substantially closed by a shutter means (65).

Owner:GENERAL PACKER

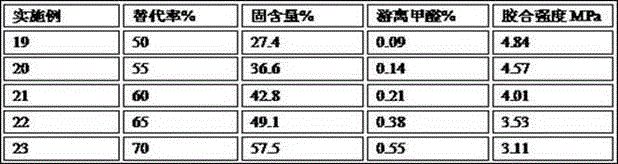

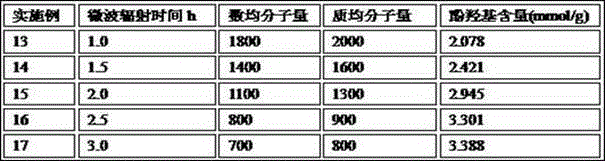

Method for preparing lignin phenolic resin adhesive by using microwave-CuO to treat papermaking waste liquid

ActiveCN104910341AHigh activityIncrease replacement rateAldehyde/ketone condensation polymer adhesivesPhenol formaldehyde resinPhenolic aldehyde

The invention discloses a preparation method for preparing a lignin phenolic resin adhesive by using activated lignin to replace part of phenol to react with formaldehyde. The preparation method comprises the following steps: treating papermaking waste liquid with microwave and CuO, then filtering, adjusting the pH value to be about 2-3 by using hydrochloric acid, putting into a drying oven, standing for a period of time at a set temperature, filtering while the liquid is hot, washing to be neutral, and drying to obtain acidified lignin for later use; and taking the dried lignin to replace part of phenol, and performing phenolization, hydroxymethylation and phenolic reaction to prepare the lignin phenolic resin adhesive. By using the method disclosed by the invention, the replacement rate of phenol by lignin is improved, the cost is reduced, the pollution to the environment is reduced, the adhesive is high in bonding strength and low in free formaldehyde content, and various properties of the adhesive accord with national standards.

Owner:湖南恒旺新材料科技有限公司

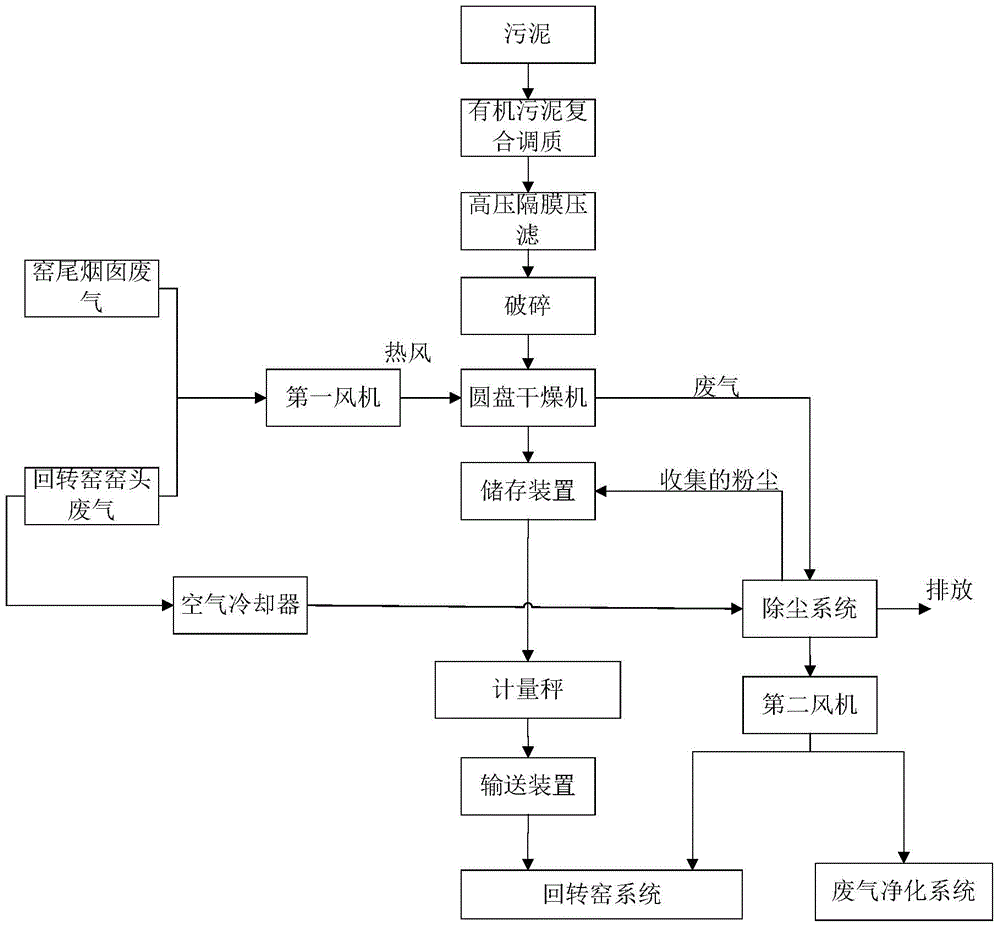

Deep sludge dewatering method and cement kiln comprehensive utilization method using same

ActiveCN103819069AReduce outputReduce the amount of introductionSludge treatment by de-watering/drying/thickeningCross-linkSludge cake

The invention relates to a deep sludge dewatering method and a cement kiln comprehensive utilization method using the same. Ferric trichloride is added and serve as an inorganic ferric salt coagulant, the uniformly stirred sludge mixed liquor is conveyed by a screw pump to a high pressure membrane plate-and-frame filter press for filter pressing, polyacrylamide is added to serve as an organic polymer flocculant while the sludge is fed, a sludge cake with the moisture content of 50-61.33% is finally obtained, and the sludge cake is subjected to dried with waste heat and is comprehensively utilized for a cement kiln after dewatered. The adsorption charge neutrality and the adsorption bridging action of cationic polyacrylamide are used to flocculate the sludge particles, meanwhile, as the selected polyacrylamide has a special branch chain cross-linked structure, the formed floc is small and pressuerproof, and is good for improving the dewatering degree of the sludge. Compared with the tradition, the dosage is reduced greatly, the yield of the cake and the introduction of a harmful element Cl are reduced, the equipment processing efficiency is increased, the heat value of the sludge is kept to the greatest extent, the treatment of the waste gas in a kiln head is taken into comprehensive consideration with a cement kiln system, the capital investment is saved, and the operation cost is lowered.

Owner:华新环境工程有限公司 +1

Double-network hydrogel material containing antibacterial nano calcium phosphate particle filling material and preparation method thereof

The invention discloses a double-network hydrogel material containing an antibacterial nano calcium phosphate particle filling material and a preparation method thereof. The method comprises the following steps: -poly(glutamic acid) modified copper-doped nano-calcium phosphate is prepared into an aqueous suspension, and then an initiator ammonium persulfate and a crosslinking agent N,N'-methylenebisacrylamide are added to adjust the pH to 5.0-6.5, the sodium alginate is added and stirred evenly, then tetramethylethylenediamine is added, and stirred for a reaction, and the material is washed and dried to obtain the double-network hydrogel material containing the antibacterial nano-calcium phosphate particle filling material. The copper-doped calcium phosphate is modified by poly(glutamic acid), which not only improves the replacement rate of copper ions in calcium phosphate, but also strengthens the bonding, effectively slows the overflow of the copper ions, and slows down the cell toxicity at an initial release stage on the basis of antibacterial action. The antibacterial calcium phosphate particles are nanospheres, and the particle size is mainly between 10 nm and 70 nm.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY

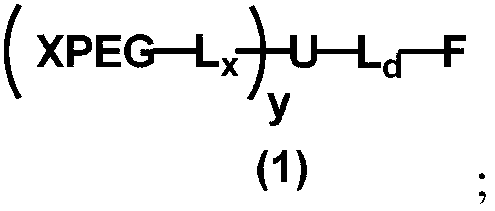

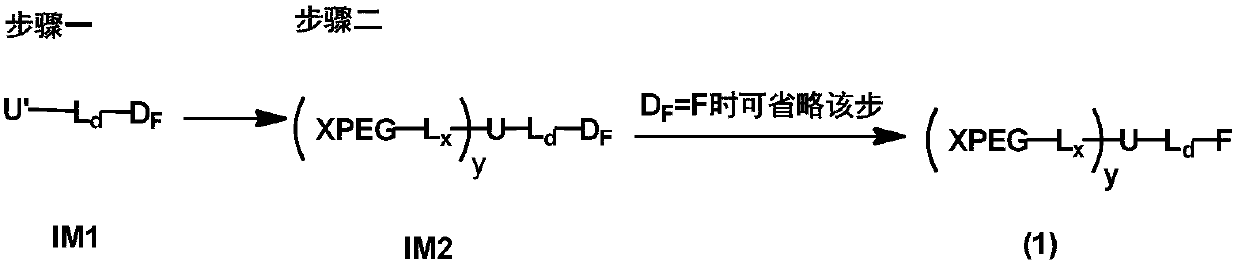

Preparation method of monofunctionalized nonlinear polyethylene glycol

The invention discloses a preparation method of monofunctionalized nonlinear polyethylene glycol. The monofunctionalized nonlinear polyethylene glycol has a nonlinear multivalent group U, one side ofthe nonlinear multivalent group is connected with a single functional end group, and the other side of the nonlinear multivalent group is connected with at least two linear polyethylene glycol chains.The preparation method includes the steps, first, a low molecular weight intermediate IM1 is obtained first, and the single functional end group or a microvariant form is introduced; and the step only refers to an organic reaction between low molecular weight reagents, the controllability is good, the structure can be precisely controlled, selectable segregation patterns are diverse, and a high-purity intermediate can be obtained; and second, then a polyethylene glycol component is introduced, and the monofunctional nonlinear polyethylene glycol with a high substitution rate can be obtained directly or by simple chemical modification of a terminal. When the monofunctionalized nonlinear polyethylene glycol continues functionalized modification or is used as a reaction raw material to construct a multistage branched nonlinear structure, the reaction steric hindrance is small, and a relatively high substitution rate or a relatively high grafting rate can also be obtained.

Owner:XIAMEN SINOPEG BIOTECH

Bored pile foundation bearing stratum reinforcing and strengthening construction method

The invention relates to a bored pile foundation bearing stratum reinforcing and strengthening construction method. The bored pile foundation bearing stratum reinforcing and strengthening constructionmethod comprises the following steps that step one, grouting holes are drilled; step two, the grouting holes are cleaned; step three, grouts are prepared; step four, grouting is carried out; and stepfive, grouting hole openings are closed. Hole flushing carried out by adopting double-pipe high-pressure jet grouting is a key strengthening process, through high-pressure water flushing and cutting,soil in sediments, argillaceous contents in pile body separation segments and argillaceous contents in pile bottom fragmental intense weathering and weak intercalated layers can be flushed clean, andthe groutability of the grouts and the quality of induration are further improved, so that the bearing capacity of a sediment segment, pile bottom rock stratum fragments and weak intercalated layersis further improved; and in the grouting process, floral tubes are inserted into the grouting holes in a mode of floral tube grouting after rotary jet grouting is completed, and the problem that in the grouting hole forming, the pile tip soil body strength is reduced due to disturbance of soil around piles and the problem that water softening by soaking exacerbates the pile tip soil body strengthto be reduced during grouting hole cleaning are solved.

Owner:湖南化工地质工程勘察院有限责任公司

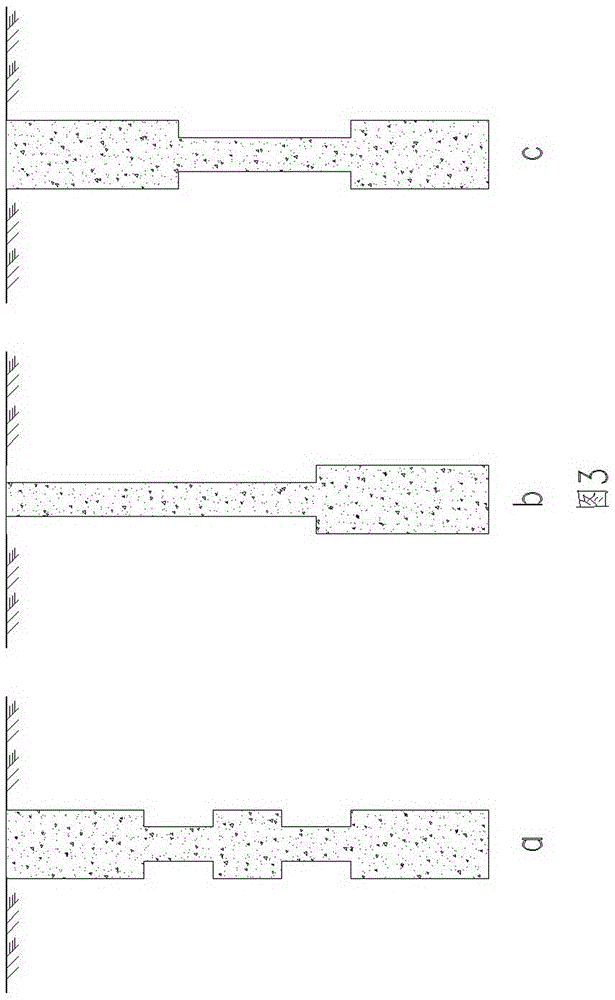

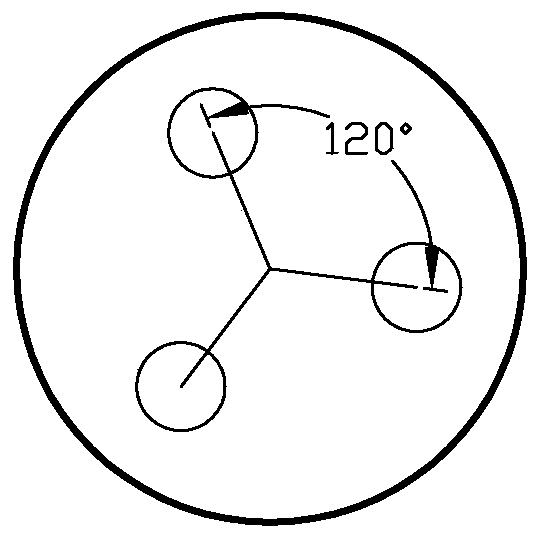

Composite foundation construction method

ActiveCN1641112AIncrease replacement rateGet twice the result with half the effortBulkheads/pilesEarth surfaceDrill

The purpose of the invention is to provide a kind of construction method to reinforce foundation, we could get the compound foundation through that method quickly and simply, raise the displacement frequency of the common CFG stake consumedly through the increment the expanding parts of stake crest, to reduce the quantity of the stake, economize the engineering expenditure significantly, economize the material, simplified the construction. The construction method includes following steps:1) prepare the drill machine, helix drill a hole to the destined depth in foundation at the place of stake;2) send the water rigidity admixture filler using the pump simultaneously, simultaneously, form a body of stake through raising the drilling pole to the earth's surface;3) the form locates to the coping of stake, for the used of increment of interface of mat layer at the expanding parts of stake crest;4)Build the mat layer at the superficial of expanding parts of stake crest foundation at the peak surface and surface of groundwork.

Owner:北京波森特岩土工程有限公司

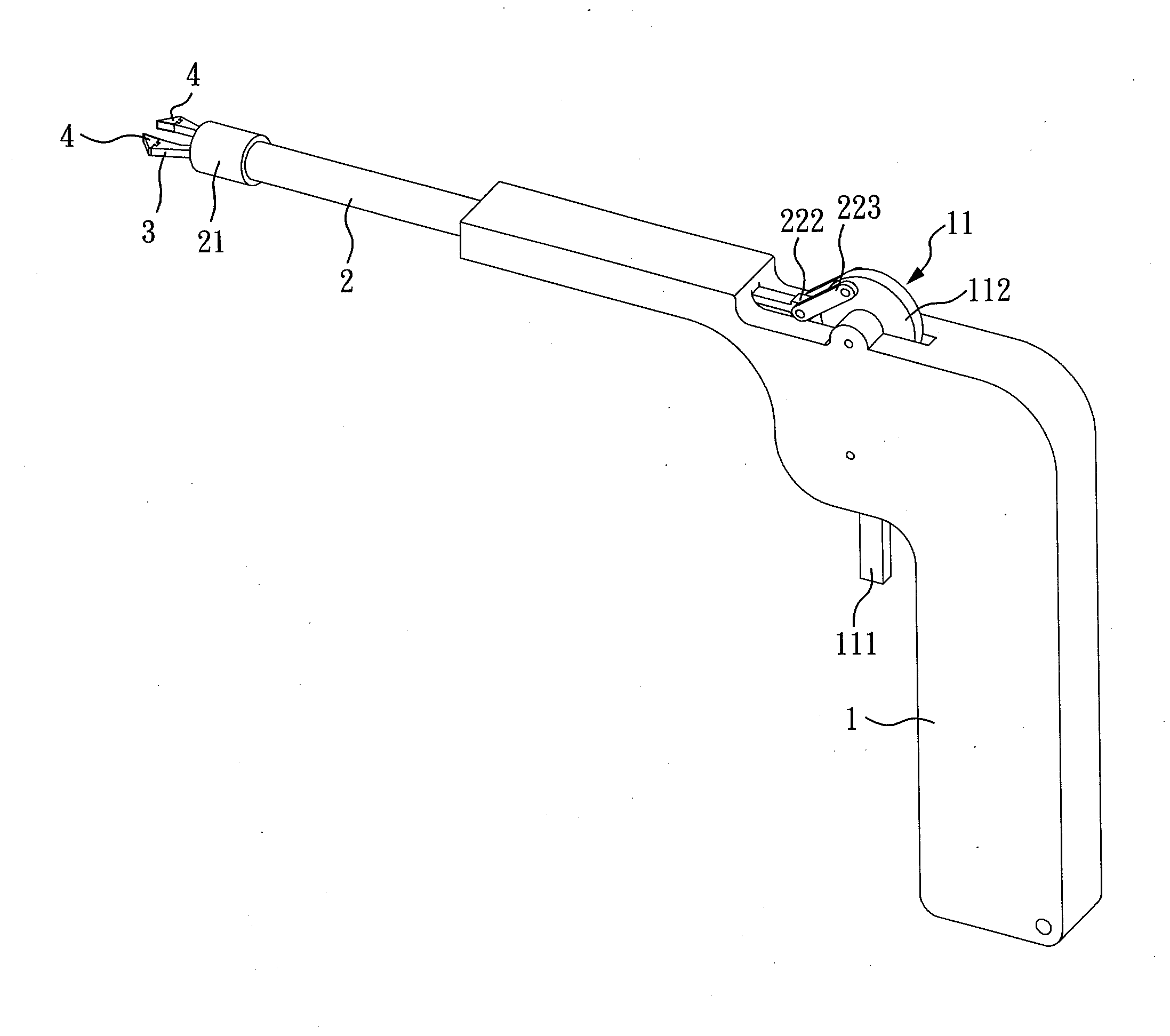

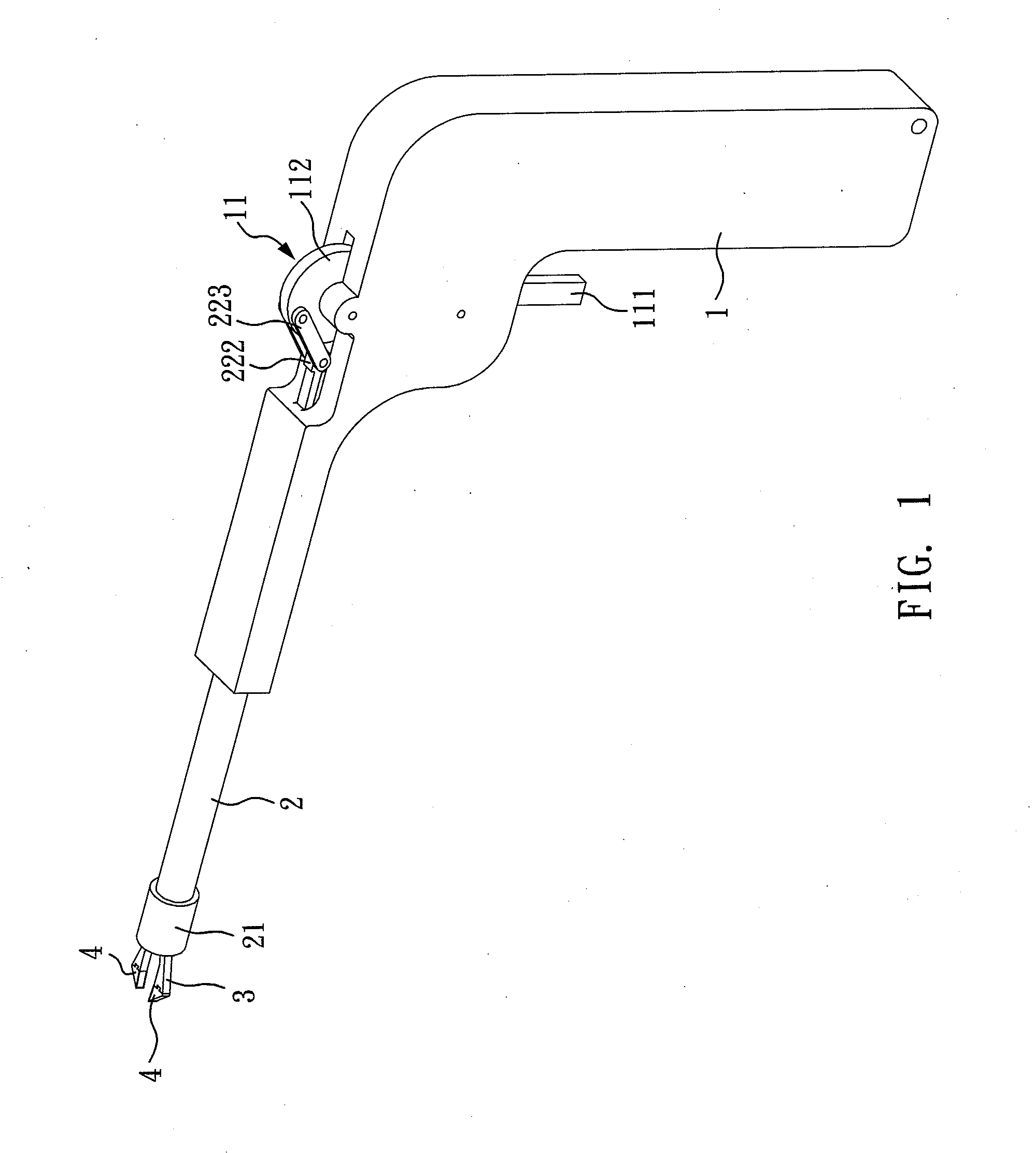

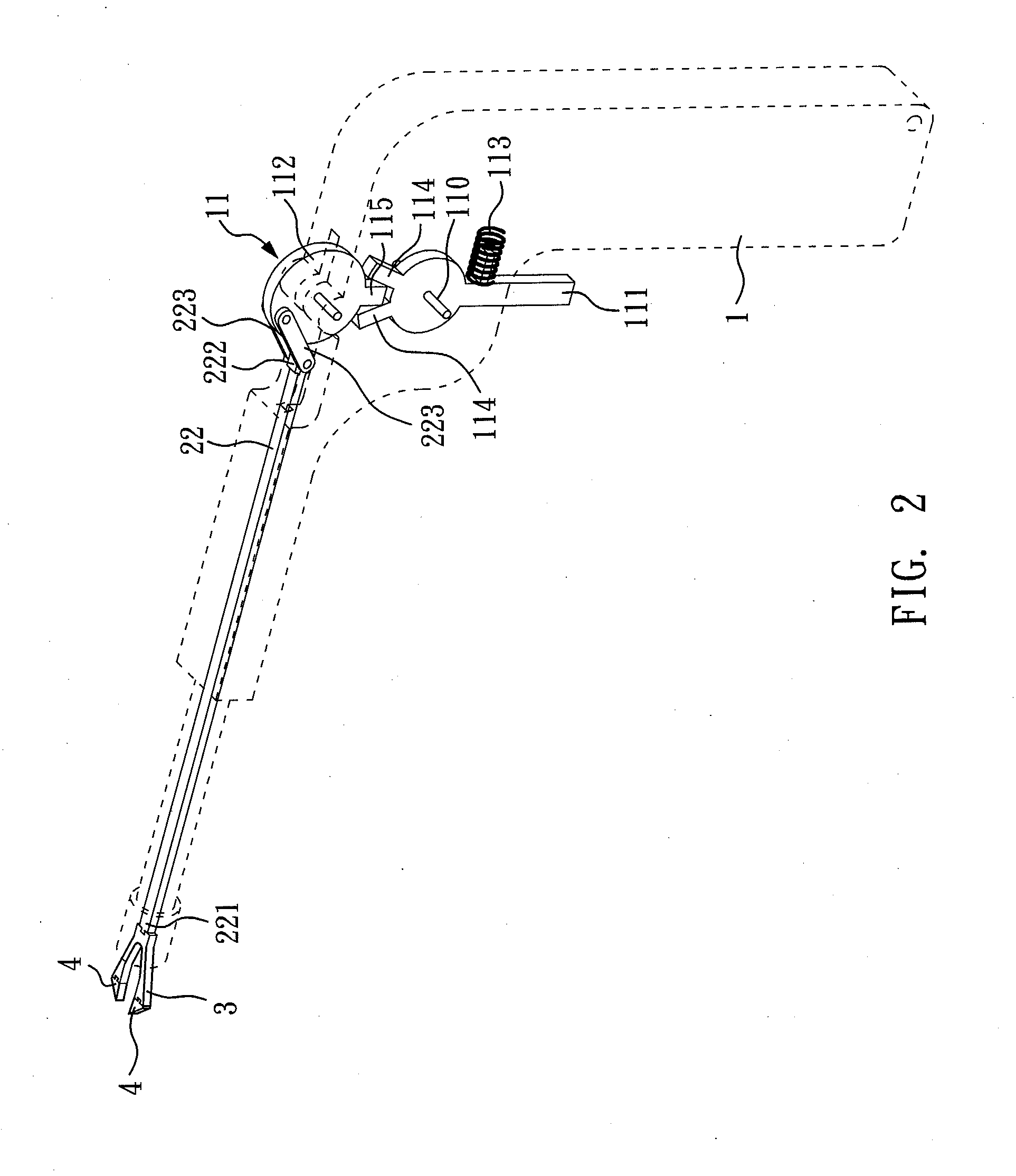

Replaceable micro-surgical instrument

InactiveUS20130325049A1Easy to disassembleReduce instrument costSurgical pincettesEndoscopic cutting instrumentsEngineeringSurgical device

The present invention provides a replaceable micro-surgical instrument which comprises a pull structure and a hollow tube attached to a grip. The hollow tube has a sleeve at one end with a U-type elastic element sliding in. The U-type elastic element includes a spring tension section and two opposite extending arms and the outer edge of each arm is against the inner wall of the sleeve. Two arms could move according to the pull structure to selectively extend out of the sleeve to be opened or pull back into the sleeve to be clip together. Particularly, there is a replaceable micro-surgical element set in the front-end of each arm, so when the micro-surgical element becomes blunt or broken, the doctor could only replace the micro-surgical element without replace a whole new instrument in order to reduce instrument cost, increase replacement rate, and maintain the quality of medical surgery.

Owner:NAT CENT UNIV

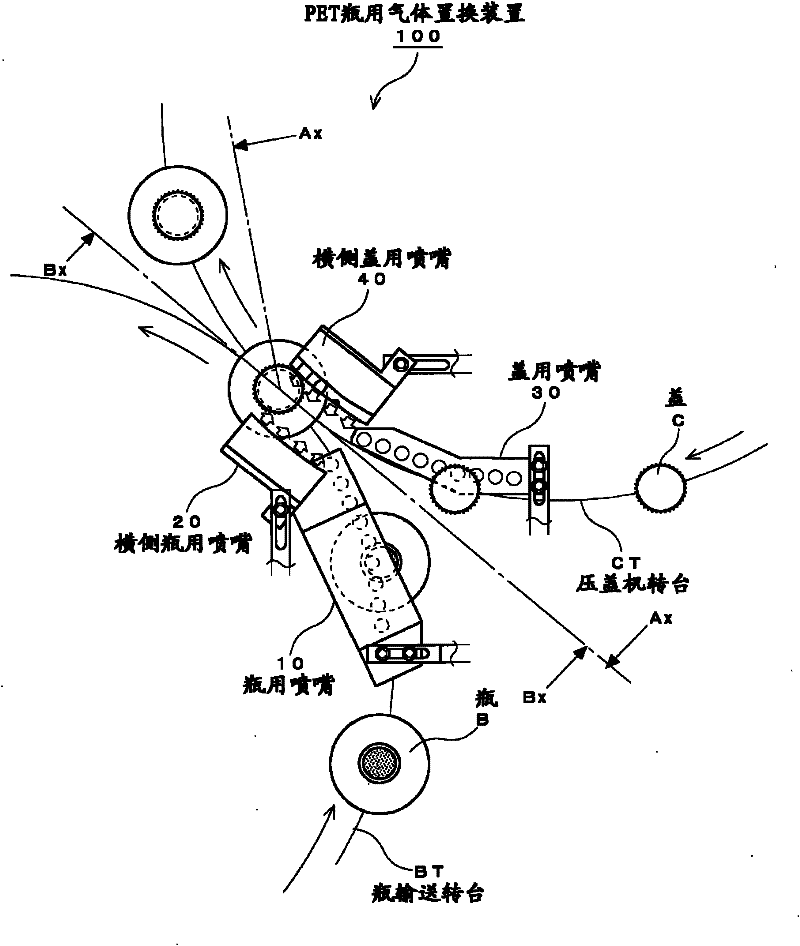

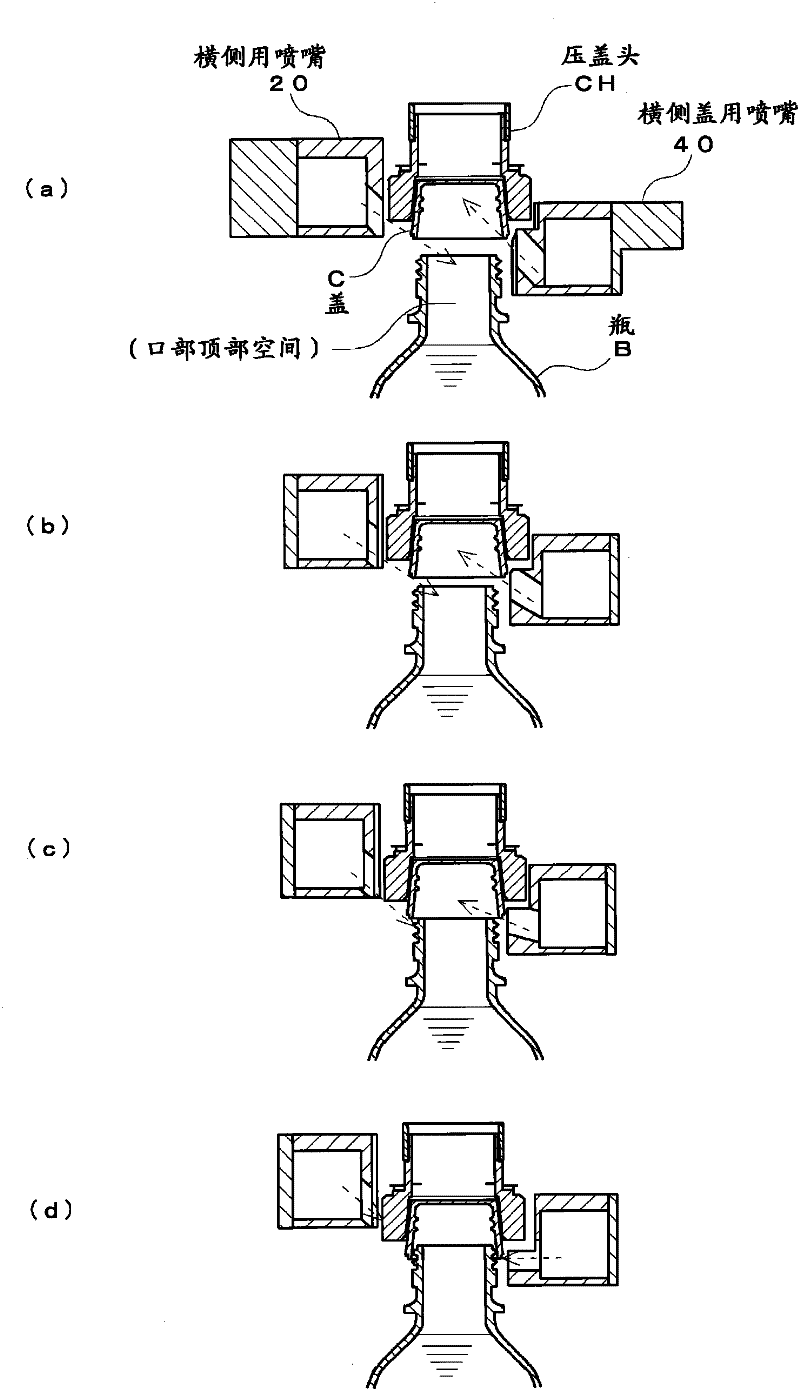

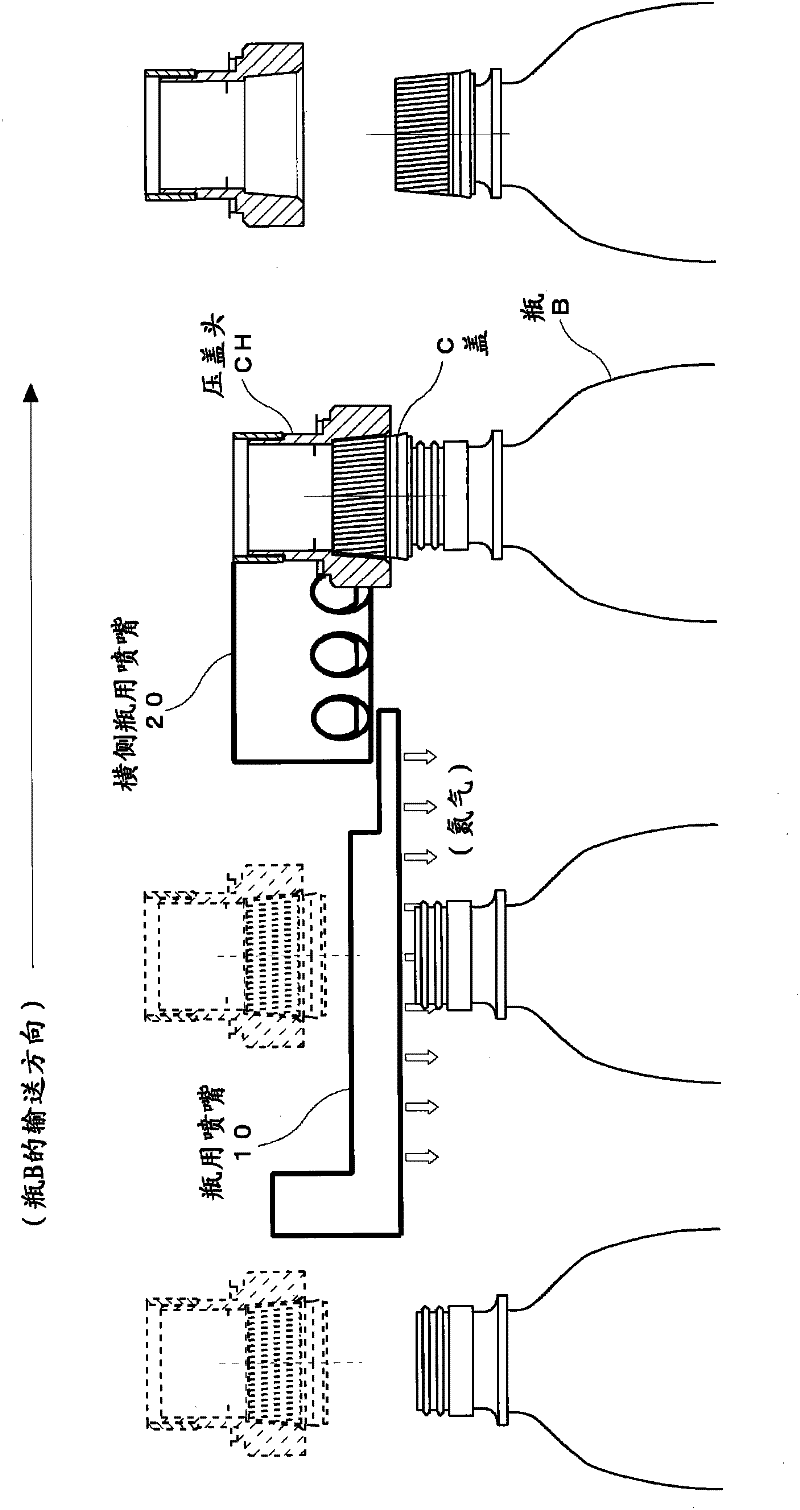

Gas replacement method and device for container

ActiveCN102292265AAppropriate implementation of gas displacement methodsImplement the Gas Replacement MethodPackaging by pressurising/gasifyingLiquid bottlingNitrogenEngineering

Provided are a method for gas replacement of a container capable of obtaining a high replacement effect using a smaller amount of an inert gas, without spilling foam or content liquid at the time of gas replacement in a head space of the container, and an apparatus therefor. A bottle nozzle (10), which is arranged in a range wherein it does not interfere with a capper head (CH) introduces nitrogen gas from above into a mouth of bottle (B) which has been conveyed, and a lateral-side bottle nozzle (20) arranged to avoid interference with the bottle (B) and the capper head (CH) introduces nitrogen gas from an obliquely upward direction into the mouth of the bottle (B) until just before the bottle (B) is fitted with the cap (C); while a cap nozzle (30), which is arranged in a range wherein itdoes not interfere with the bottle (B) introduces nitrogen gas from below into an inside of the cap (C) which has been conveyed, and a lateral-side cap nozzle (40) arranged to avoid interference withthe bottle (B) and the capper head (CH) introduces nitrogen from an obliquely downward direction into the inside of the cap (C) until just before the cap (C) is fitted with the bottle (B).

Owner:TOYO SEIKAN KAISHA LTD

Cement-slag powder gel system with desulfurized gypsum as excitant

InactiveCN101343161AHigh degree of greeningAffect the engineering processSolid waste managementSulfateSlag

The invention relates to a cement-slag powder cementing material system which adopts the desulfurization gypsum as an activator, belonging to the technical field of the building materials. The cement-slag powder cementing material system is composed of cement, slag powder and desulfurization gypsum. With the cement-slag powder cementing material system adopted, on the condition that the proportion of the slag powder is 60 percent to 90 percent, the early mechanical properties can reach the standard of the cement of P.O 42.5 grade, and the later strength develops stably. The cement-slag powder cementing material system can be used to prepare a cementing system of very high green degree, and can effectively avoid the problem that the early strength of the high-blending slag powder cementing system develops slowly, for the problem affects the process and the quality of the project. The cement-slag powder cementing material system is applicable to being used as the raw material in the commercial concrete mixing station and the commercial mortar mixing station, and is more suitable for preparing the marine concrete and the sulfate resistant mortar in the project.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com