Deep sludge dewatering method and cement kiln comprehensive utilization method using same

A deep dewatering and cement kiln technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of reducing equipment processing capacity, affecting resource utilization, reducing the calorific value of mud cake, etc., to reduce operating costs, increase The effect of equipment processing efficiency and high replacement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

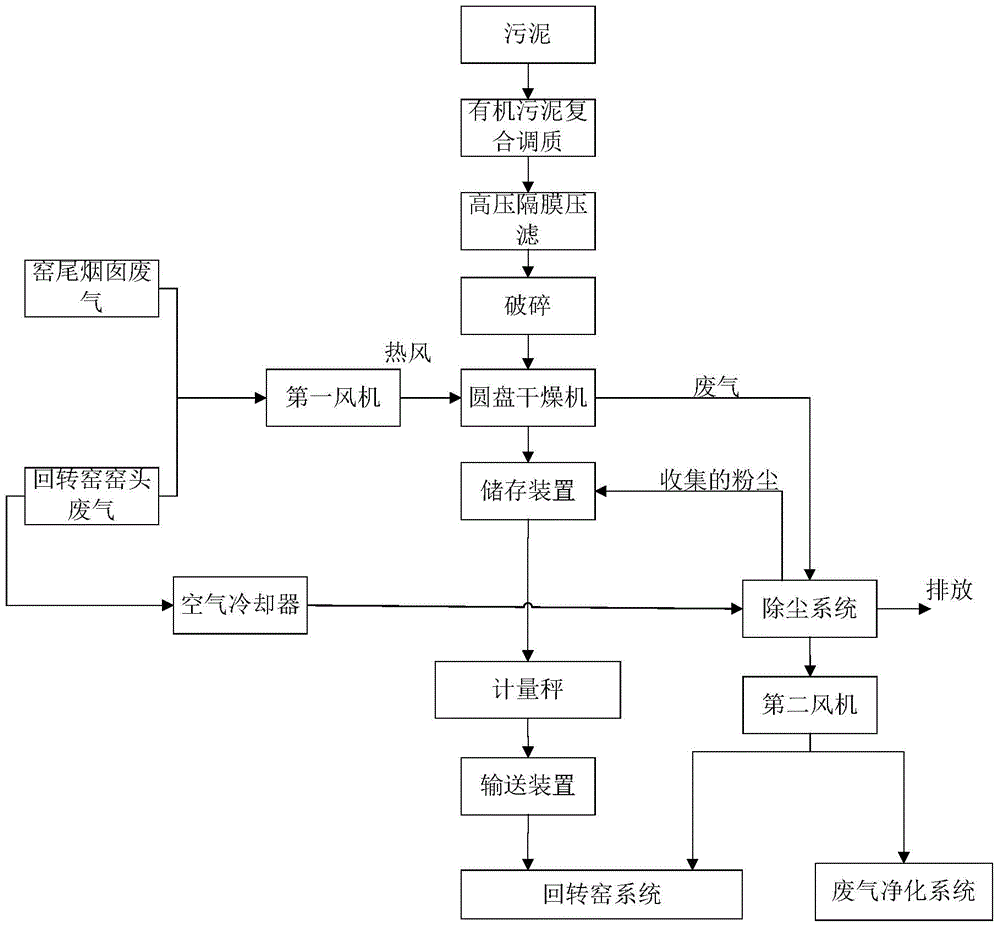

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of sludge deep dehydration process: specific steps:

[0027] Step A1: Dilute the wet sludge with a water content of about 80% from the sewage plant to a water content of 92-94%;

[0028] Step A2: Add ferric chloride as an inorganic iron salt coagulant, the dosage is controlled at 20-30kg / ton of wet sludge, and fully stirred for 5-10 minutes;

[0029] Step A3: Transport the evenly stirred sludge mixture to a high-pressure diaphragm plate-and-frame filter press through a screw pump, and add polyacrylamide as an organic macromolecule flocculant through pipelines while feeding the sludge. The mass concentration of acrylamide is diluted to about 1‰, and the dosage is 1.5-3kg / ton of wet sludge. The moisture content of the obtained mud cake is about 60%, that is, the moisture content is ±60%.

[0030] In the above technical solution, the polyacrylamide used in step A3 is cationic polyacrylamide.

[0031] In the above technical solution, in step A3: trans...

Embodiment 2

[0047] Transport the wet sludge with a moisture content of about 80% to the sludge conditioning and mixing tank, add water to dilute to a moisture content of 94%, and first add ferric chloride solution with a concentration of 38% to the sludge and fully stir for 10 minutes. The dosage of ferric chloride solution is 2.2% of the wet sludge mass, and then the sludge is transported to the high-pressure diaphragm plate and frame filter press through the screw pump, and polyacrylamide is added through the pipeline dosing method while transporting the sludge , the dosage of polyacrylamide is 2.2‰ of the mass of wet sludge. After the feed filtration and secondary pressing of the high-pressure diaphragm plate and frame filter, the sludge particles are trapped in the filter chamber and gradually form a filter cake. The moisture content of the final filter cake is 58.9%.

Embodiment 3

[0049] Transport the wet sludge with a moisture content of about 80% to the sludge conditioning and mixing tank, add water to dilute to a moisture content of 93%, and first add ferric chloride solution with a concentration of 38% to the sludge and fully stir for 10 minutes. The dosage of ferric chloride solution is 2.7% of the mass of wet sludge, and then the sludge is transported to the high-pressure diaphragm plate and frame filter press through the screw pump, and polyacrylamide is added through the pipeline dosing method while transporting the sludge , the dosage of polyacrylamide is 2.1‰ of the mass of wet sludge. After the feed filtration and secondary pressing of the high-pressure diaphragm plate and frame press, the sludge particles are trapped in the filter chamber and gradually form a filter cake. The final moisture content of the filter cake is 59.86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com