Patents

Literature

96results about How to "Reduce the amount of introduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of making a thin film transistor using laser annealing

InactiveUS6809012B2Activation can be moreRecovery can be moreTransistorSolid-state devicesNoble gasLaser light

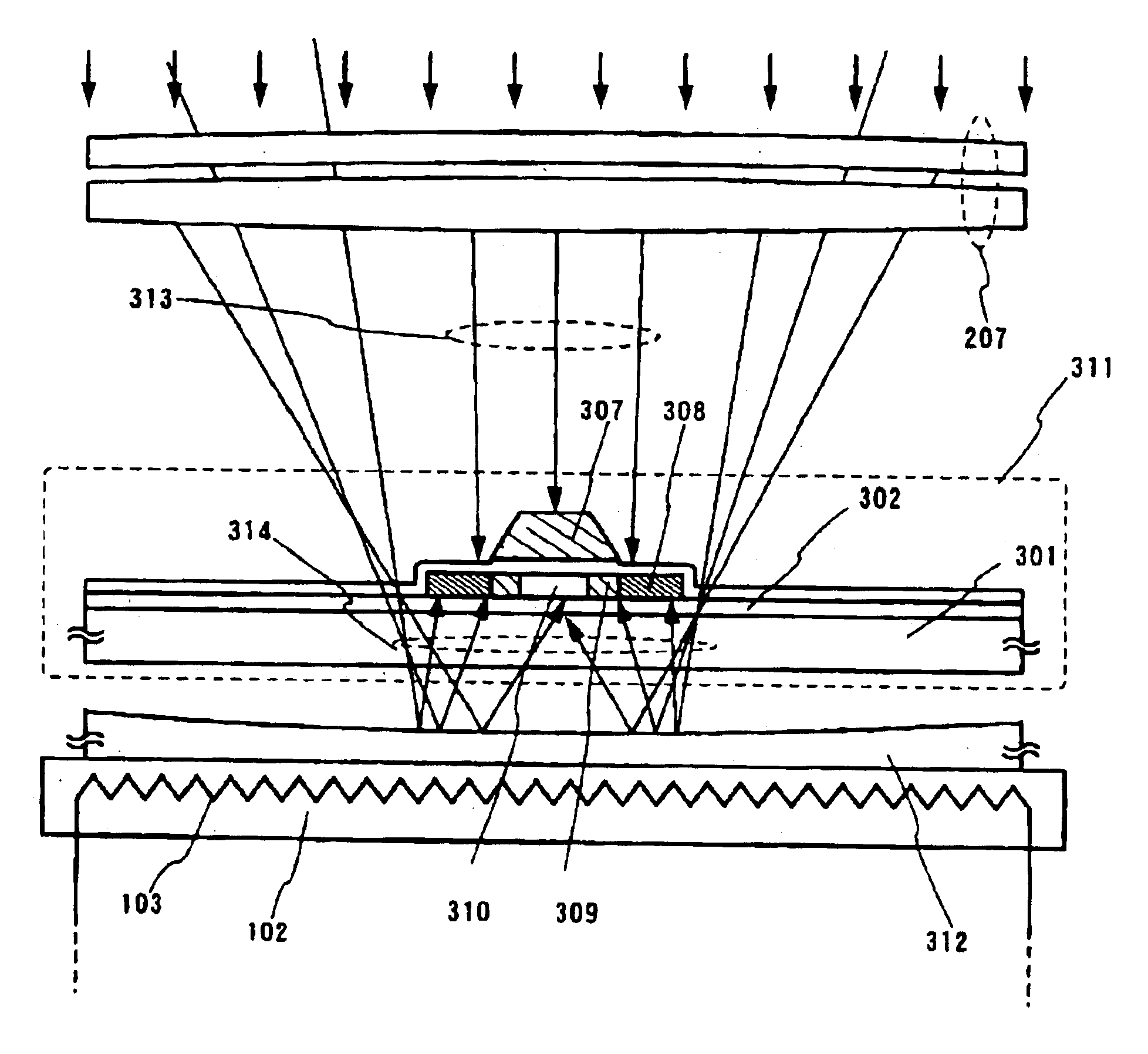

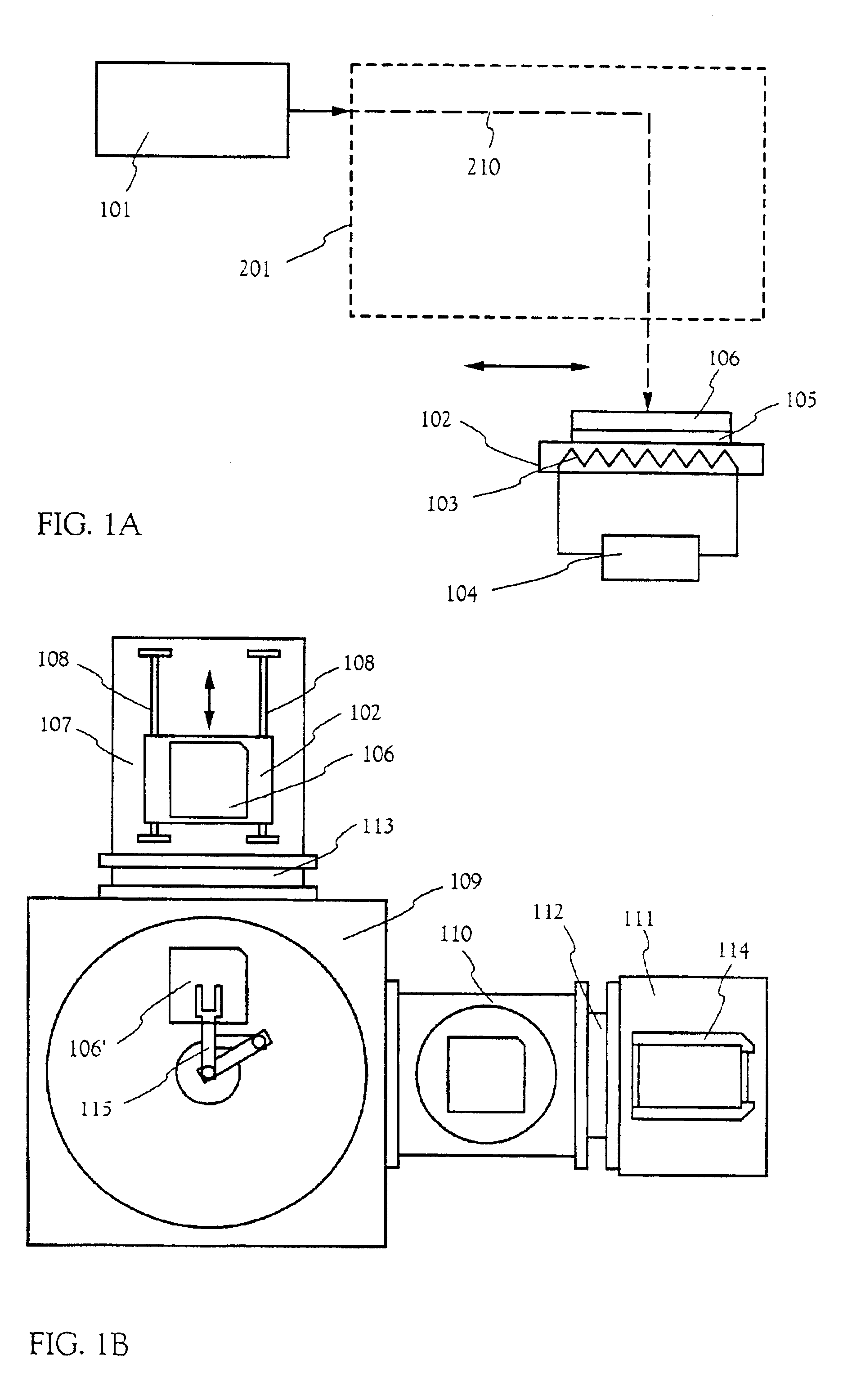

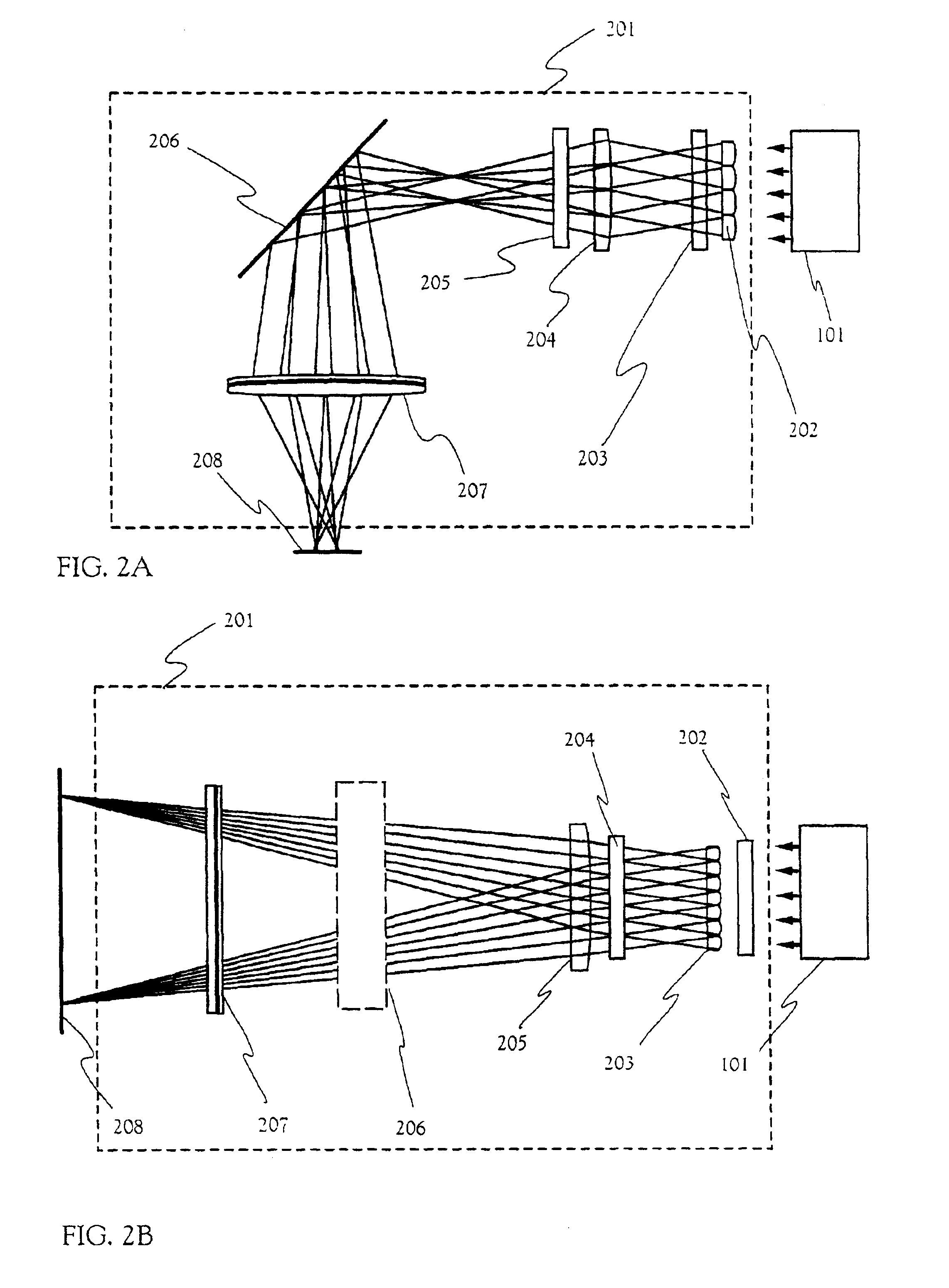

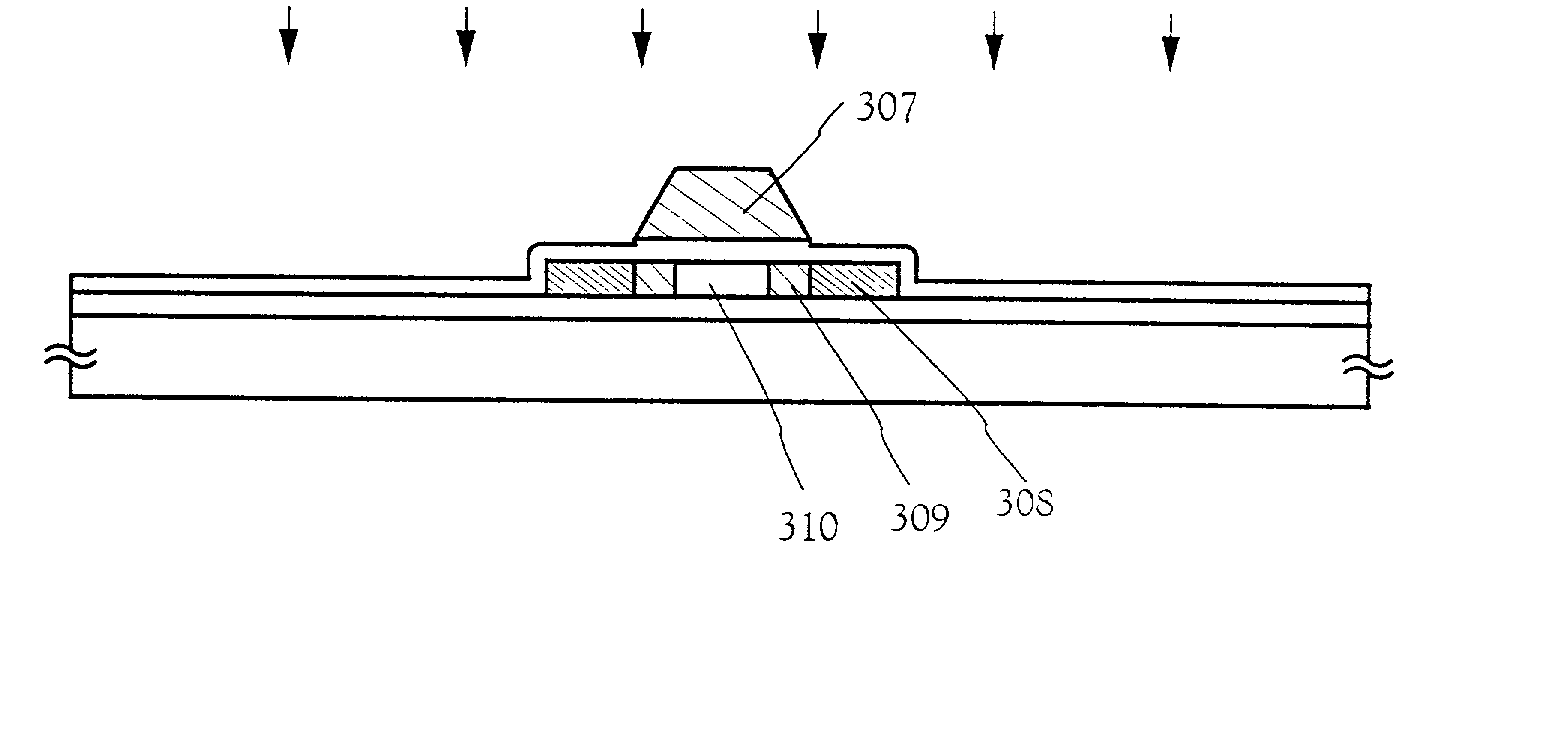

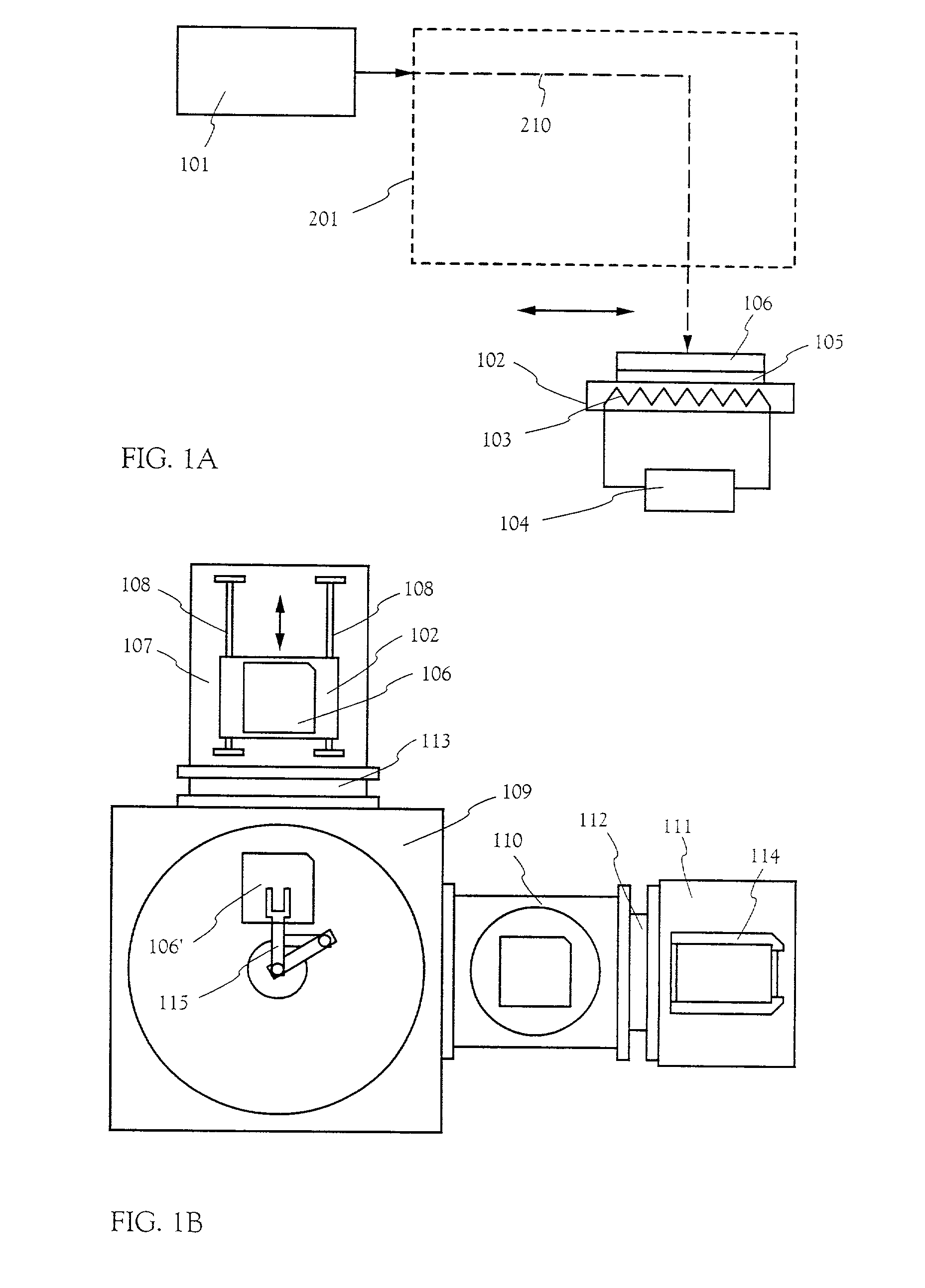

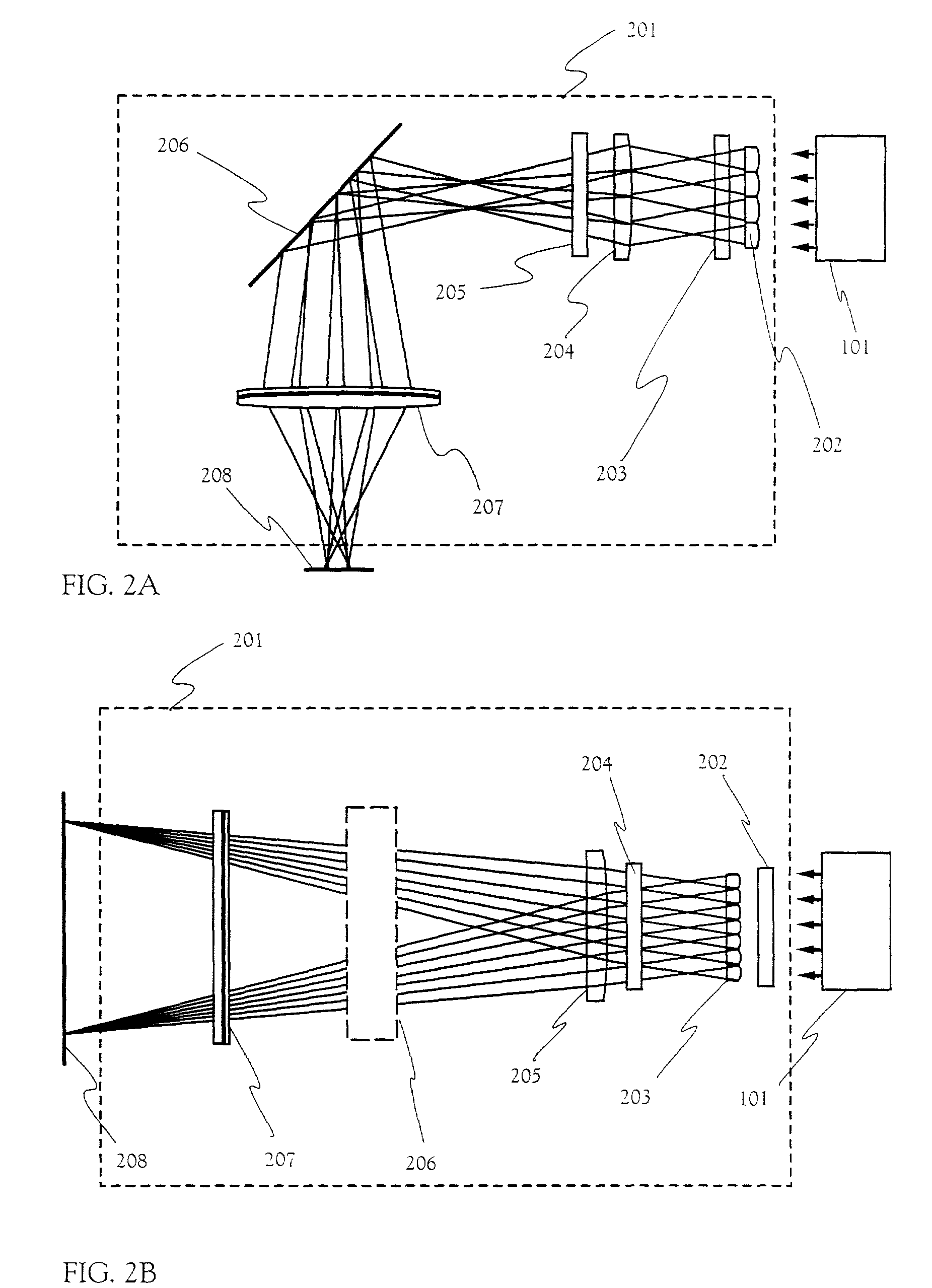

The present invention is characterized in that gettering is performed such that impurity regions to which a noble gas element is added are formed in a semiconductor film and the metallic element included in the semiconductor film is segregated into the impurity regions by laser annealing. Also, a reflector is provided under a substrate on which a semiconductor film is formed. When laser light transmitted through the semiconductor film substrate is irradiated from the front side of the substrate, the laser beam is reflected by the reflector and thus the laser light can be irradiated to the semiconductor film from the read side thereof. Laser light can be also irradiated to low concentration impurity regions overlapped with a portion the gate electrode. Thus, an effective energy density in the semiconductor film is increased to thereby effect recovery of crystallinity and activation of the impurity element.

Owner:SEMICON ENERGY LAB CO LTD

Method of manufacturing semiconductor device

InactiveUS20020094613A1Activation can be moreRecovery can be moreTransistorSolid-state devicesLaser lightLaser annealing

The present invention is characterized in that gettering is performed such that impurity regions to which a noble gas element is added are formed in a semiconductor film and the metallic element included in the semiconductor film is segregated into the impurity regions by laser annealing. Also, a reflector is provided under a substrate on which a semiconductor film is formed. When laser light transmitted through the semiconductor film substrate is irradiated from the front side of the substrate, the laser beam is reflected by the reflector and thus the laser light can be irradiated to the semiconductor film from the read side thereof. Laser light can be also irradiated to low concentration impurity regions overlapped with a portion the gate electrode. Thus, an effective energy density in the semiconductor film is increased to thereby effect recovery of crystallinity and activation of the impurity element.

Owner:SEMICON ENERGY LAB CO LTD

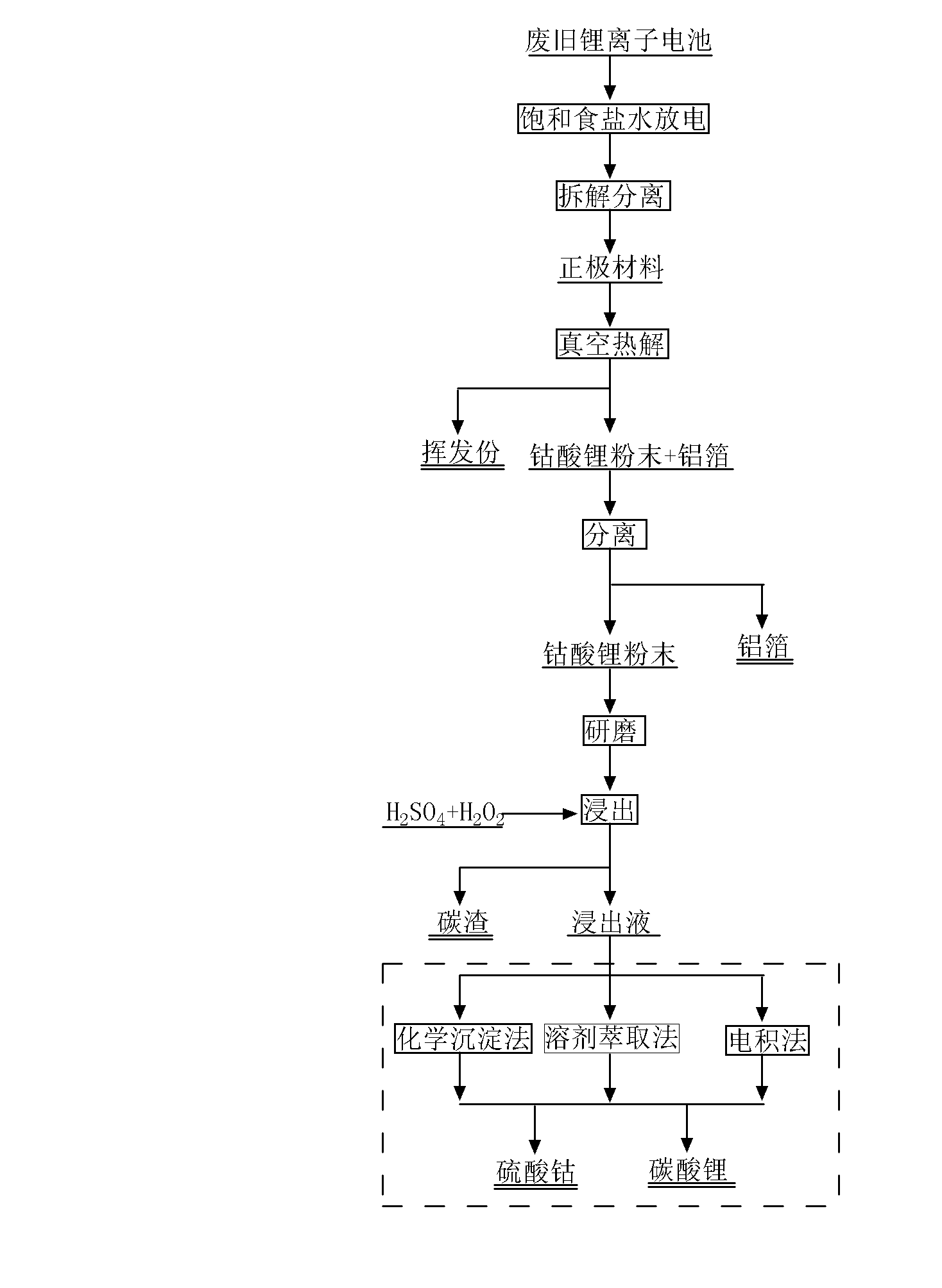

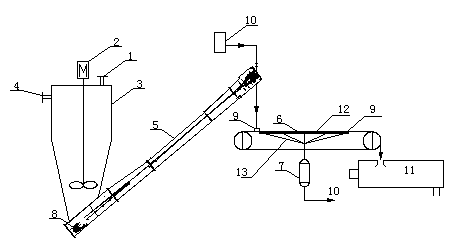

Pretreatment method for recovering valuable metal from anode material of waste lithium ion battery

InactiveCN101969148AEfficient separationEfficient removalWaste accumulators reclaimingBattery recyclingPretreatment methodSlag

The invention provides a pretreatment method for recovering valuable metal from the anode material of a waste lithium ion battery, which comprises the following steps: (1) treating an anode piece of the lithium ion battery under a vacuum pyrolysis condition; (2) separating; (3) heating and leaching lithium cobalt oxide slag falling off in a sulfuric acid and hydrogen peroxide system; and (4) soaking separated aluminum foil in a leach solution. The invention is simple, feasible, low in cost and environment friendly, the recovery rates of the valuable metal cobalt and lithium are both above 99%, and the invention is suitable for pretreatment for large-scale recovery of waste lithium ion batteries.

Owner:CENT SOUTH UNIV

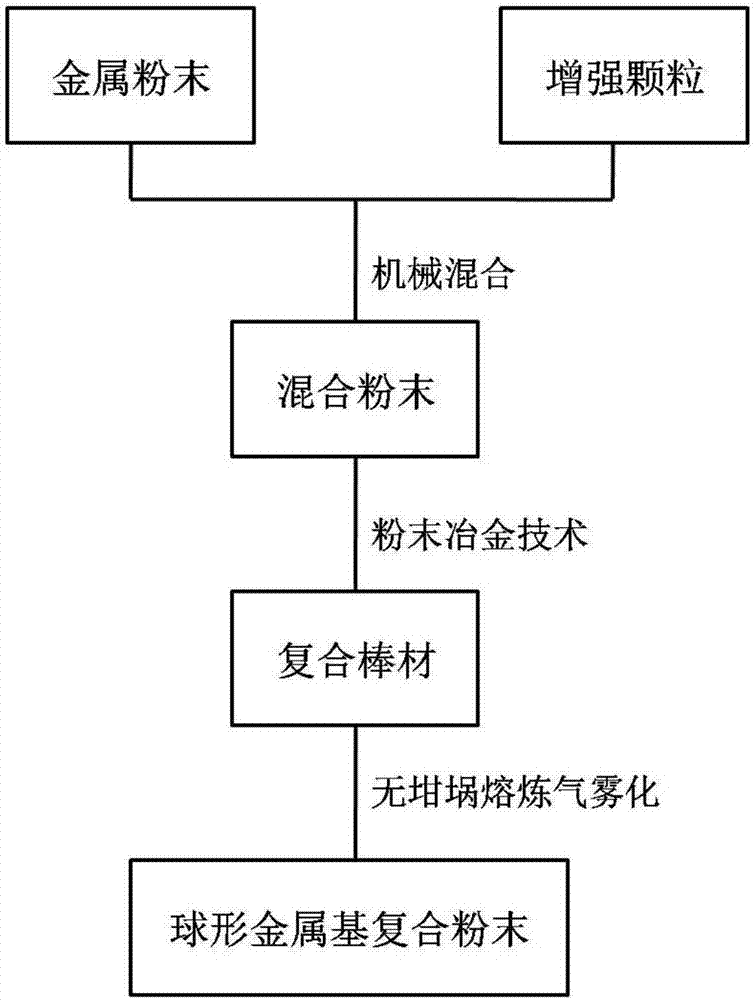

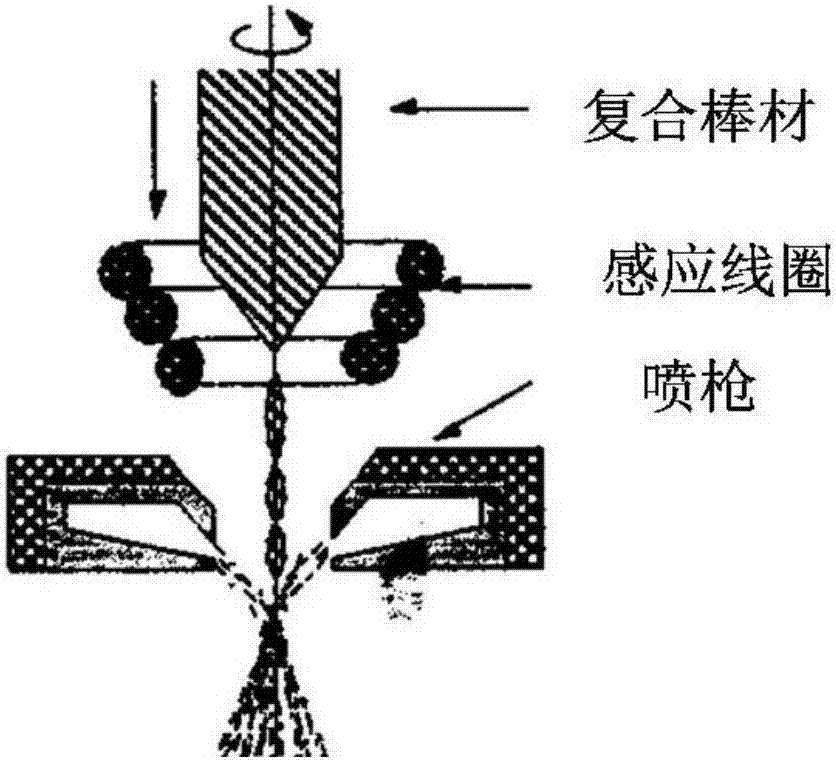

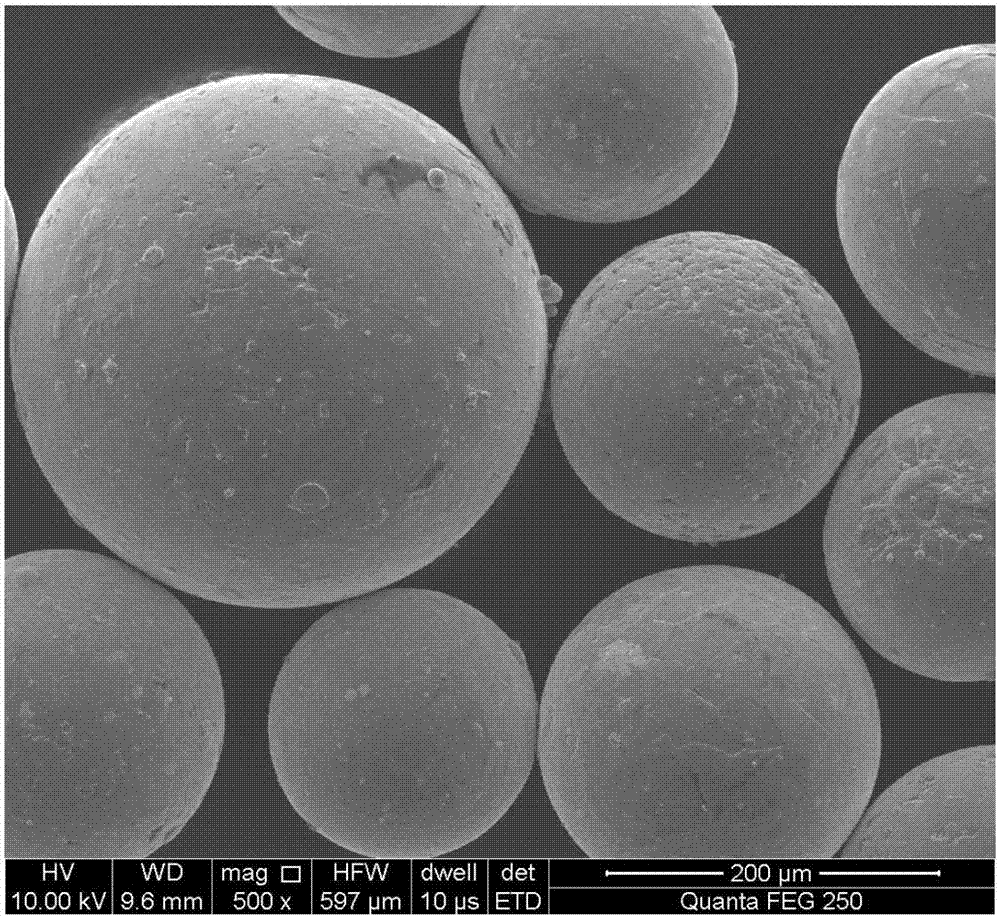

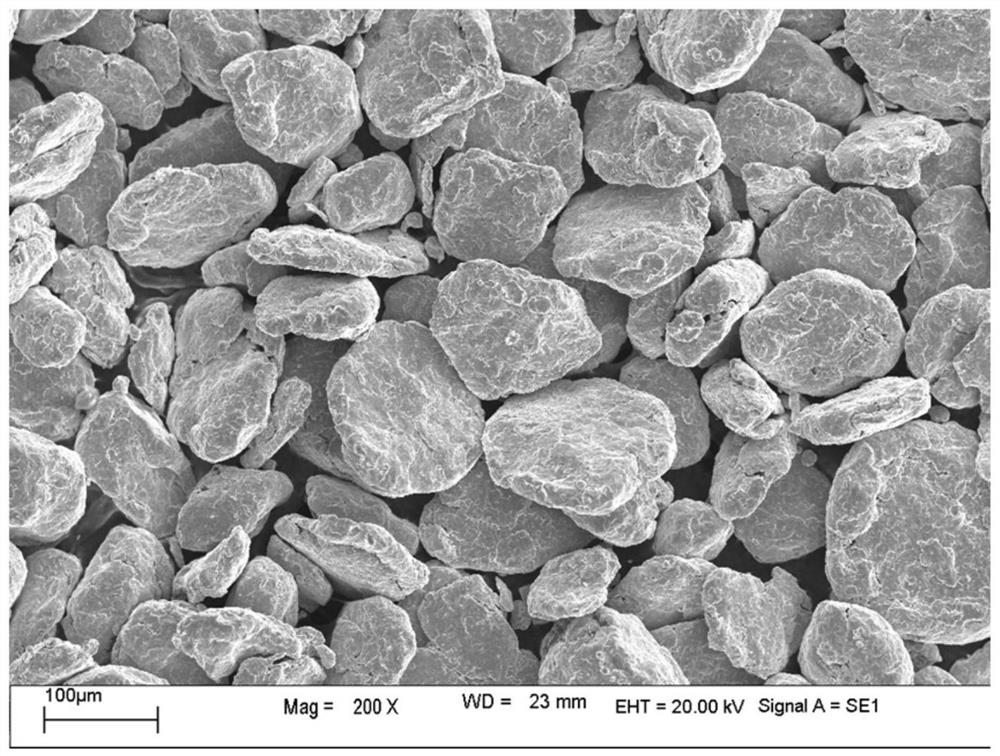

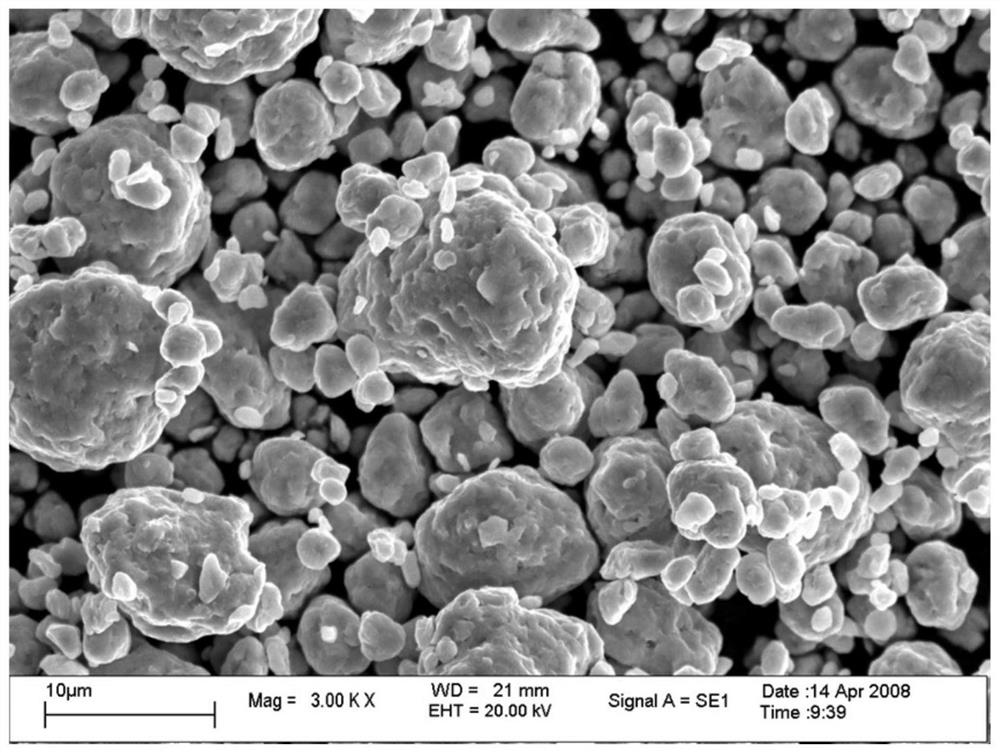

Preparation method for particle reinforced metal-based composite spherical powder material with uniform reinforcing phase distribution

ActiveCN107262729AHigh purityReduce the amount of introductionTransportation and packagingMetal-working apparatusApparent densityCrucible

The invention discloses a preparation method for a particle reinforced metal-based composite spherical powder material with uniform reinforcing phase distribution. According to the preparation method, after metal powder and reinforced phase powder are mechanically mixed, the mixture is molded through a powder metallurgy technology and sintered to form composite bars, and the composite rods are used for preparing the particle reinforced metal-based composite spherical powder material with uniform reinforcing phase distribution by utilizing a crucible-free smelting gas atomization technology. The composite powder prepared by the method has few impurities and uniform reinforcing phase distribution, is spherical or near-spherical, has excellent fluidity and high apparent density, has unique advantages and irreplaceability when used as raw materials for powder metallurgy, injection molding, 3D printing and the like, and can form a device with excellent comprehensive performance.

Owner:CENT SOUTH UNIV

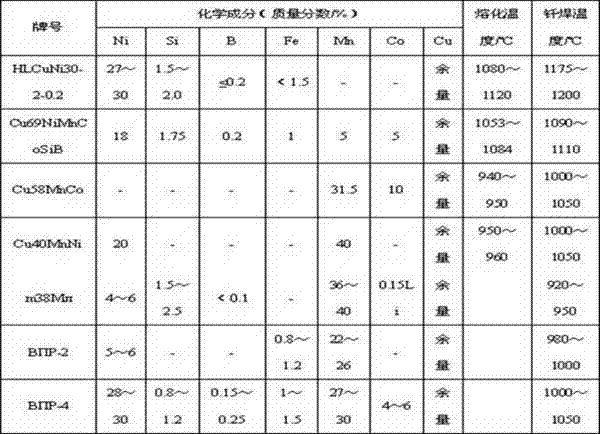

Low-temperature copper-based brazing filler metal for high-temperature resistance clean steel and preparation method thereof

ActiveCN102773632AEasy to useImprove cleanlinessWelding/cutting media/materialsSoldering mediaCopperTemperature resistance

The invention provides a low-temperature copper-based brazing filler metal for high-temperature resistance clean steel and a preparation method thereof. The low-temperature copper-based brazing filler metal is prepared by raw materials in percentage by weight as follows: 4-10% of Ni, 10-30% of Mn, 0.2-1.8% of Zr, 0.2-3.5% of Hf, 0-1% of W, 0-1% of Co, 0.1-0.25% of Ti, 0.02-0.2% of B, 0.8-2.0% of Ge, 0-0.5% of Li and a residual amount of Cu. According to the low-temperature copper-based brazing filler metal provided by the invention, various trace elements are added in copper, so that the using property of the brazing filler metal is improved; a melting process is protected by using gas, a high-temperature resistant quartz glass tube is inserted into molten brazing filler metal alloy after being vacuumized to be in a negative pressure state, so that filament welding strips with different diameters can be directly obtained; techniques of later-stage squeezing, drawing in a reducing manner and the like can be cancelled; the introduction amount of impurities in a production process of the brazing filler metal can be reduced; the cleanliness of the brazing filler metal is improved; the brazing filler metal does not contain an easily-volatile element Zn and can be applicable to vacuum brazing; the brazing filler metal does not contain silver and does not contain any toxic elements; and the brazing filler metal has the advantages of low cost, no pollution, good brazing property and the like.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

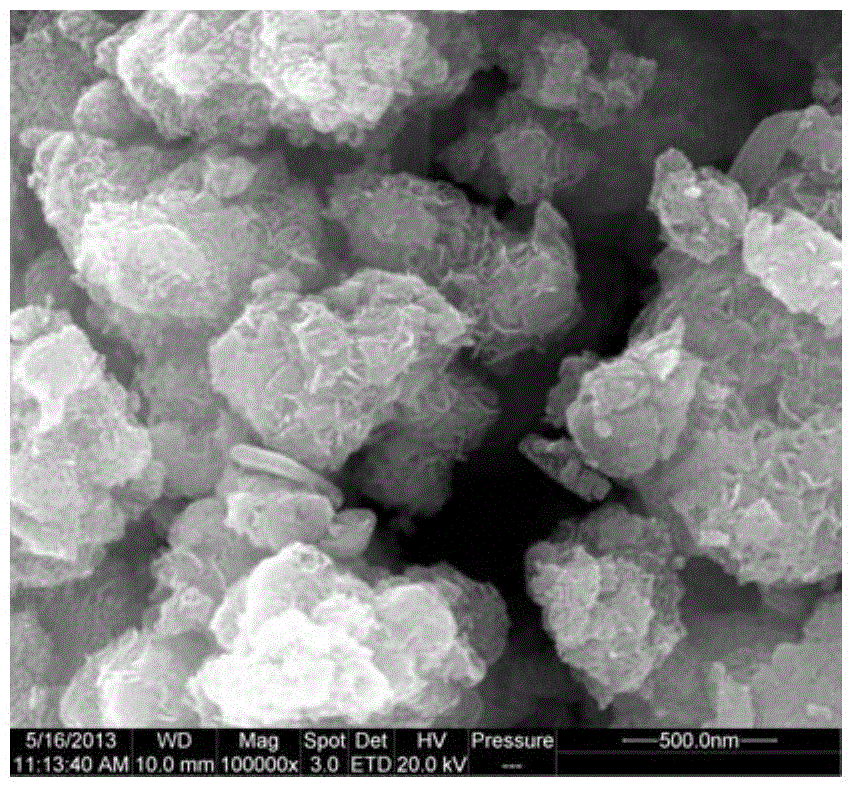

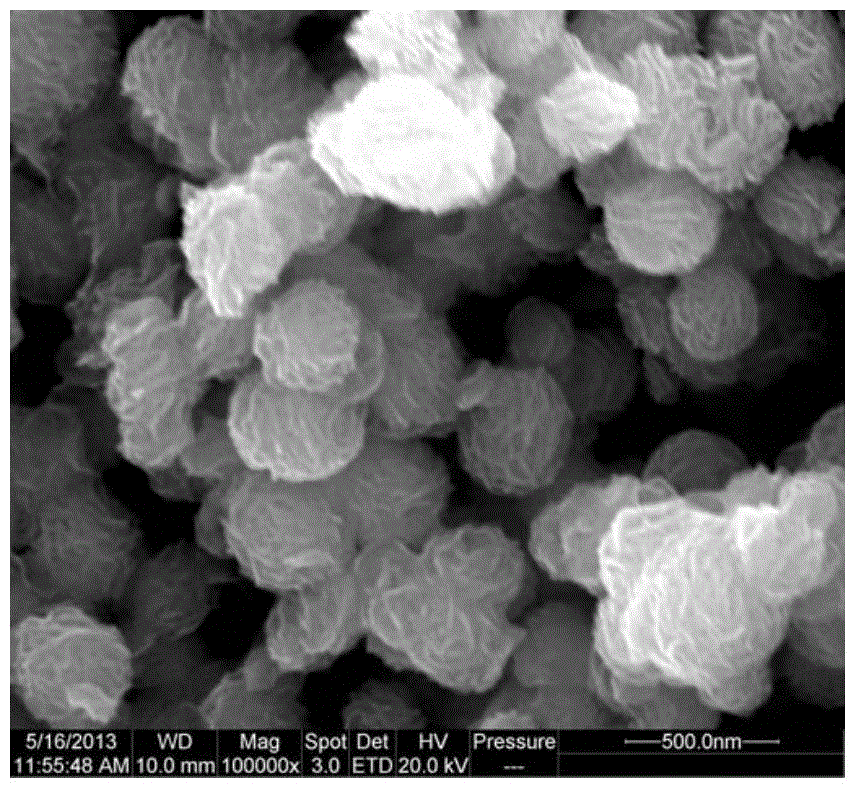

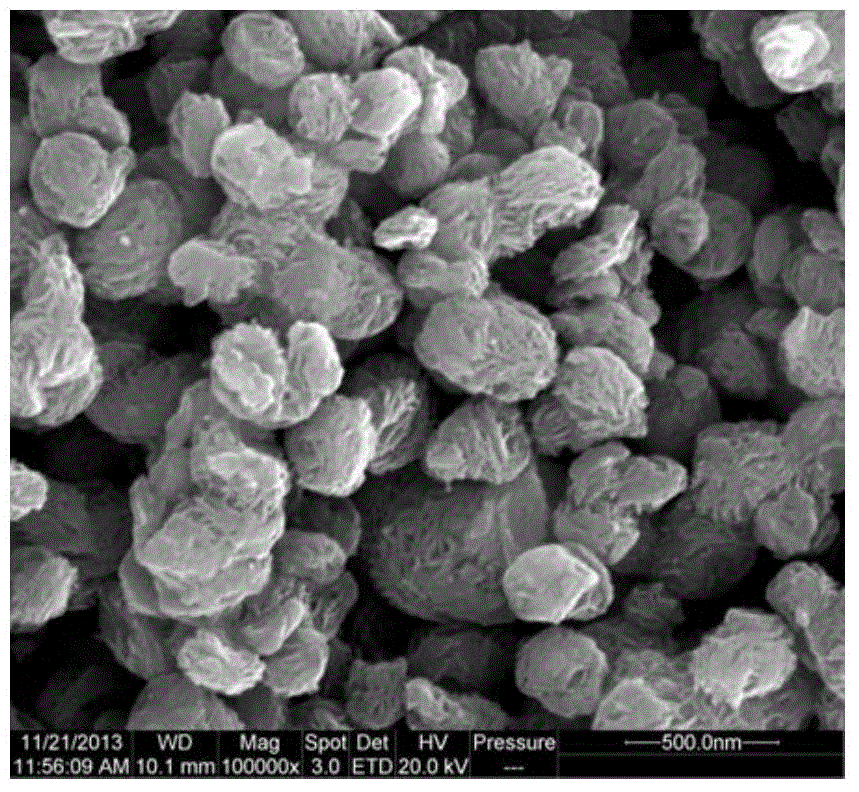

Method for complexing hydrothermal synthesis of uniform flower-like MoS2 nanospheres

InactiveCN105417581AReduce the amount of introductionMild conditionsMaterial nanotechnologyMolybdenum sulfidesFlower likeFiltration

The present invention discloses a method for complexing hydrothermal synthesis of uniform flower-like MoS2 nanospheres. The method comprises: sequentially dissolving a certain amount of a molybdenum source, a sulfur source and a complexing agent in deionized water to form a solution, regulating the molybdenum source concentration to 0.04-0.16 M, regulating a molar ratio of the sulfur source to the molybdenum source to 2:7-4:1, and regulating a molar ratio of the complexing agent to the molybdenum source to 2-6; placing the prepared solution in a closed hydrothermal reaction kettle, controlling the reaction temperature at 120-200 DEG C, and controlling the reaction time at 24-72 h; and after completing the reaction, cooling, carrying out suction filtration, washing, and drying to obtain the flower-like MoS2 nanospheres. According to the present invention, the synthesis method has advantages of mild condition, simple operation, uniform product morphology and particle size, good product dispersion property, and high yield; and the synthesized flower-like MoS2 nanospheres adopted as oil product hydrogenation catalysts, electrode materials, solid lubricants and the like have wide applications.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

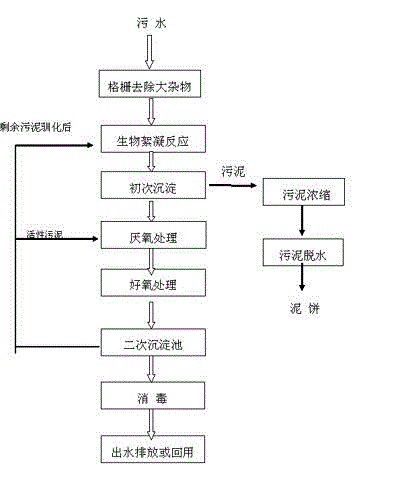

Sewage treatment method

InactiveCN102718358AReduce inputReduce the amount of introductionMultistage water/sewage treatmentWater treatmentMicroorganism

Owner:ZHENGZHOU MENGXI ENVIRONMENTAL PROTECTION TECH

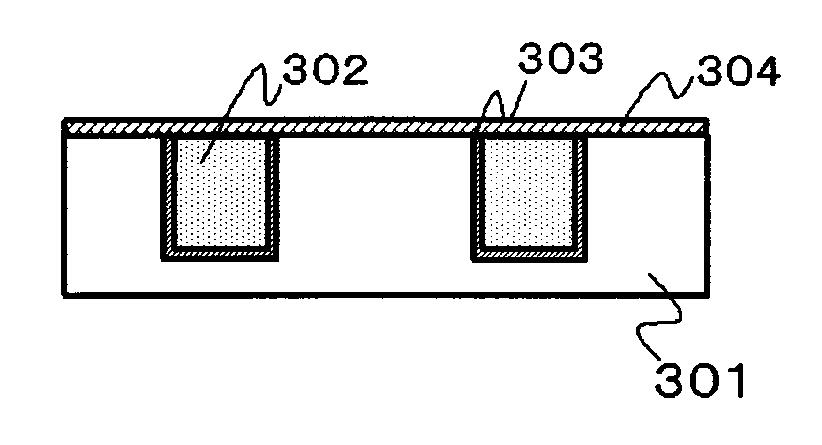

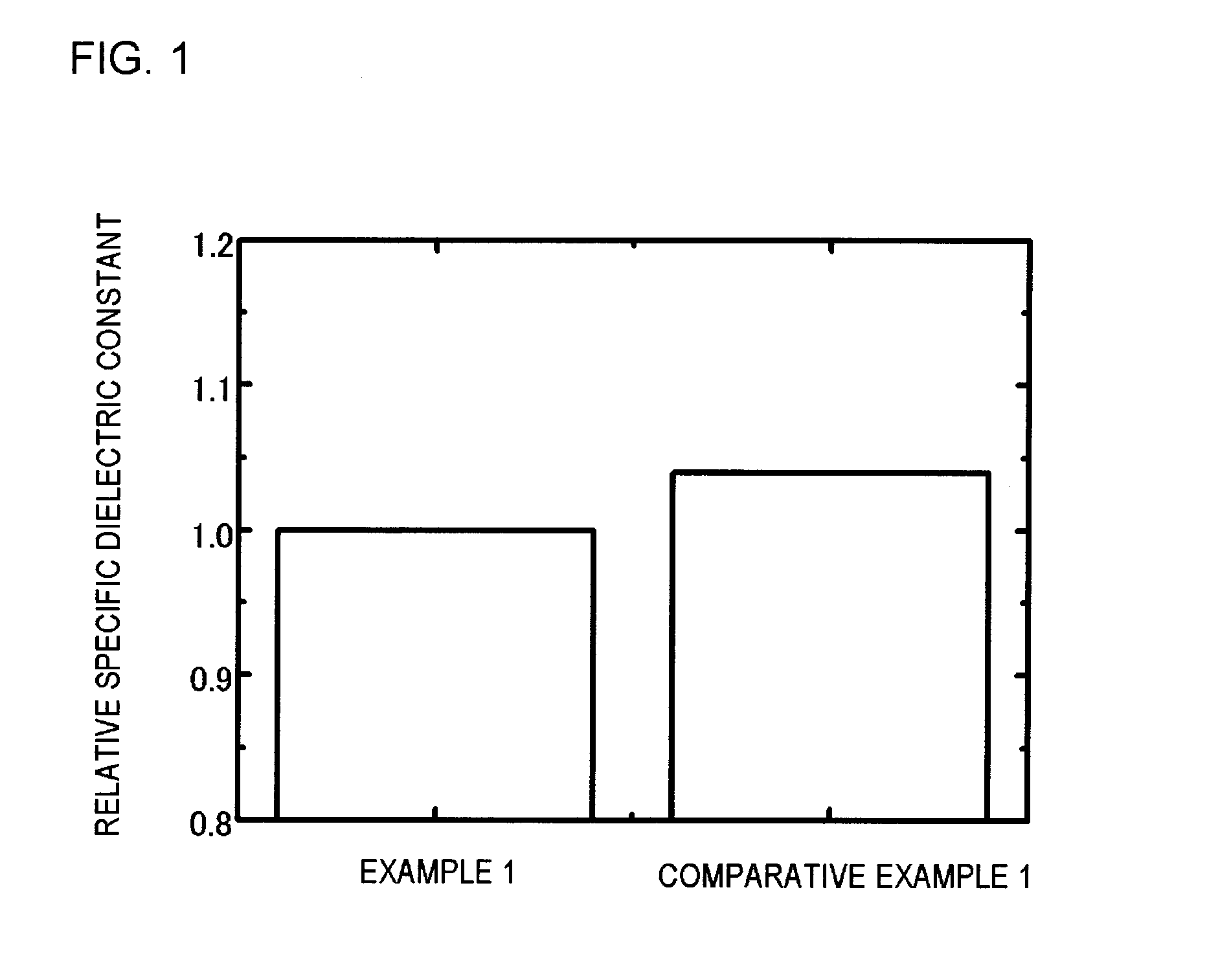

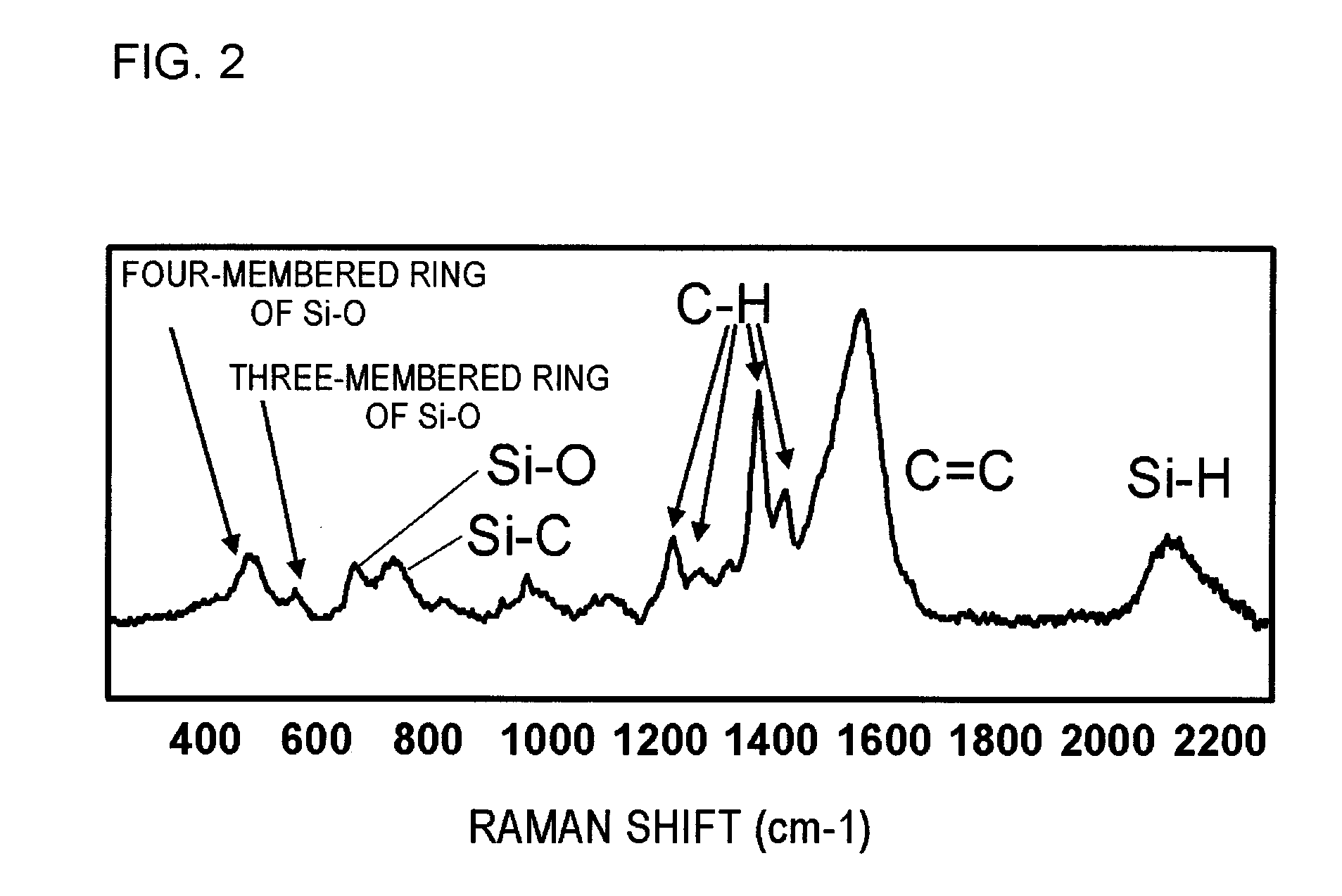

Method for producing semiconductor device and semiconductor device

InactiveUS20110201212A1Easily and sufficiently loweredReduce contentSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialSemiconductor

In a method for producing a semiconductor device, two or more kinds of organic siloxane compound materials each having a cyclic SiO structure as a main skeleton and having different structures are mixed and thereafter vaporized. Alternatively, those two or more kinds of organic siloxane compound materials are mixed and vaporized simultaneously to produce a vaporized gas. Then, the vaporized gas is transported to a reaction furnace together with a carrier gas. Then, in the reaction furnace, a porous insulating layer is formed by the plasma CVD method or the plasma polymerization method using the vaporized gas.

Owner:RENESAS ELECTRONICS CORP

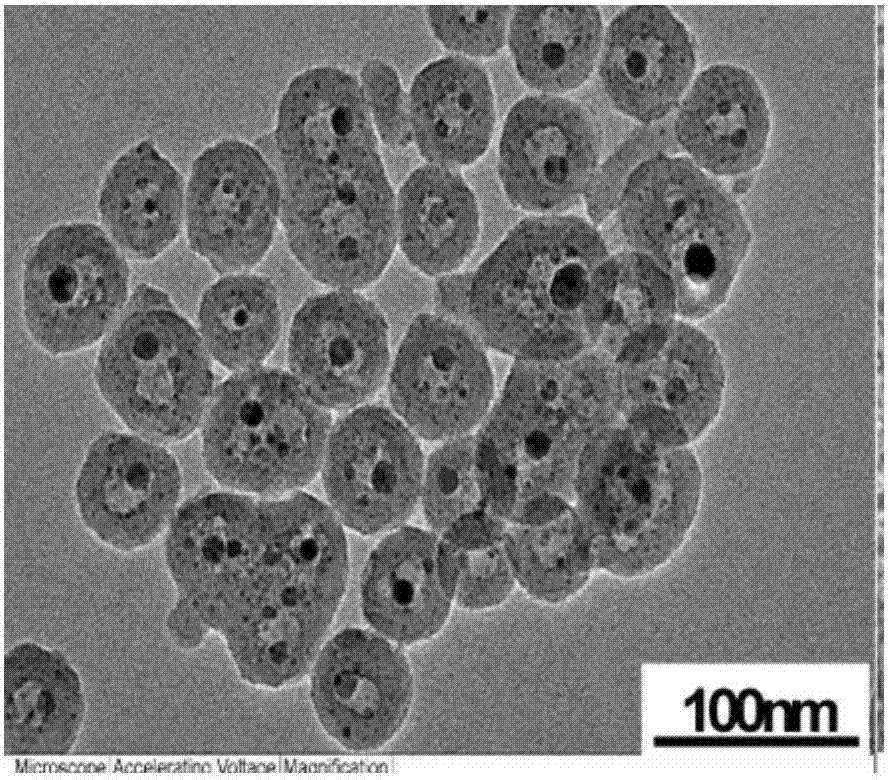

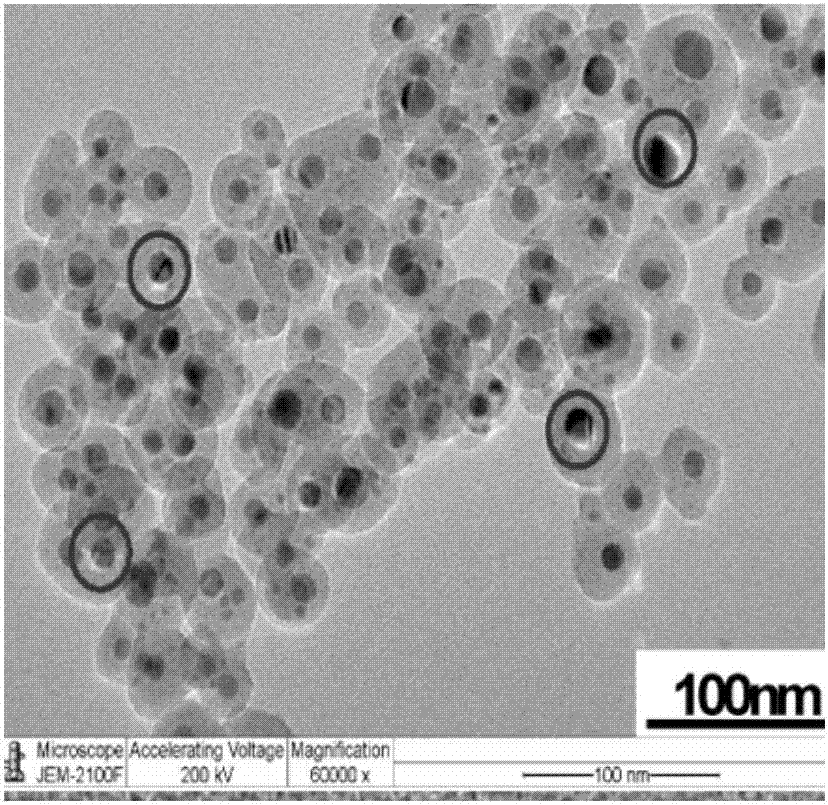

Sulfur-tolerant methanation catalyst and preparation method thereof as well as magnesium aluminate spinel composite carrier and preparation method thereof

ActiveCN107398262AReduce manufacturing costReduce the amount of introductionCatalyst carriersGaseous fuelsMagnesium AluminateChemistry

The invention relates to the field of catalysts, and discloses a sulfur-tolerant methanation catalyst and a preparation method thereof as well as a magnesium aluminate spinel composite carrier and a preparation method thereof. The sulfur-tolerant methanation catalyst comprises a magnesium aluminate spinel composite carrier, a catalyst active component and an optional catalyst aid, wherein the catalyst active component is loaded by the magnesium aluminate spinel composite carrier; the magnesium aluminate spinel composite carrier is a carrier of a core-shell structure formed by a carrier modifier as a shell layer and magnesium aluminate spinel as a core layer; and relative to 100 parts by weight of the magnesium aluminate spinel, the amount of the catalyst aid is 0-20 parts by weight, the amount of the catalyst active component is 5-30 parts by weight, and the amount of the carrier modifier is 2-15 parts by weight. By adopting the sulfur-tolerant methanation catalyst disclosed by the invention, the CO (Carbon Monoxide) transformation rate is increased, the methane selectivity is improved, the reaction stability and the high-temperature catalysis property stability are also improved, the service life of the catalyst is prolonged, and meanwhile the amount of the carrier modifier and the production cost of the catalyst are reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A fast recovery diode and a manufacturing method thereof

ActiveCN103618006AIncreased avalanche toleranceReduce the amount of introductionSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceEngineering

The invention relates to a power semiconductor device and a manufacturing method thereof and specifically to a fast recovery diode and a manufacturing method thereof. A junction pushing is performed in an active region in order to form a P+ region and a P region. A junction forming process comprises: firstly performing boron injection in order to push a junction one to ten [mu]m; secondly performing phosphorus compensative injection, wherein a phosphorus injection condition requires that the amount of injected phosphorus only decreases the concentration of the P region close to the silicon surface but not reverses a junction; and performing active region compensative injection to form the P region with low surface concentration. Therefore, the amount of hole injection of the P region in forward conduction is decreased while the concentration on the two sides of a PN junction is guaranteed. When minority carrier lifetime control is used, excessive recombination centers are not required to be generated. Therefore, a series of parameters are optimized. The fast recovery diode and the manufacturing method thereof perform phosphorus compensative injection on the P region so as to achieve the decrease in the surface concentration of the P region. Therefore, the decrease in the number of the hole injection in forward conduction is actually achieved.

Owner:STATE GRID CORP OF CHINA +2

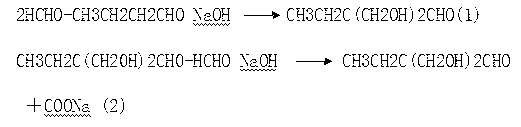

20000-ton-annual-yield production technique of trimethylolpropane by calcium method

ActiveCN102795964AReduce settingsPrevent the occurrenceOrganic compound preparationCarboxylic acid salt preparationCalcium formateEvaporation

The invention discloses a 20000-ton-annual-yield production technique of trimethylolpropane by a calcium method, which is divided into condensation, filtration, evaporation, calcium separation and rectification. The production technique is characterized by comprising the following steps: by using n-butyl aldehyde and formaldehyde as raw materials and industrial calcium hydroxide as an alkaline catalyst, carrying out condensation and formic acid neutralization reaction to obtain a trimethylolpropane crude product reaction solution containing byproducts ditrimethylolpropane and calcium formate;in the filtration process, separating out solid-phase residues from the reaction solution in a horizontal spiral centrifugal filtration mode; evaporating with a climbing-film evaporator, and sending the evaporative condensate back to the condensation technique; after entering the settling tank, continuously scraping calcium formate from the bottom of the settling tank, and recycling the calcium formate with a band filter; and carrying out rectification to obtain the trimethylolpropane product, wherein rectification column uses column refluxing and climbing film heating techniques, the deflector plate in the column is controlled, and meanwhile, a gas-liquid separator is mounted on a vacuum tube of the rectification column. The invention has the advantages of simple technical process, high labor rate, low production cost, energy saving and emission reduction.

Owner:江西高信前沿科技有限公司

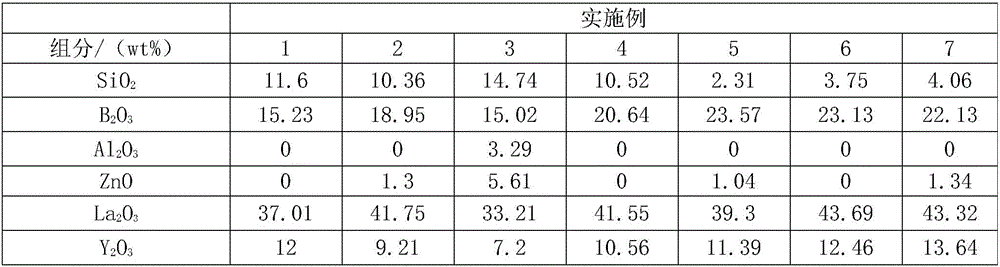

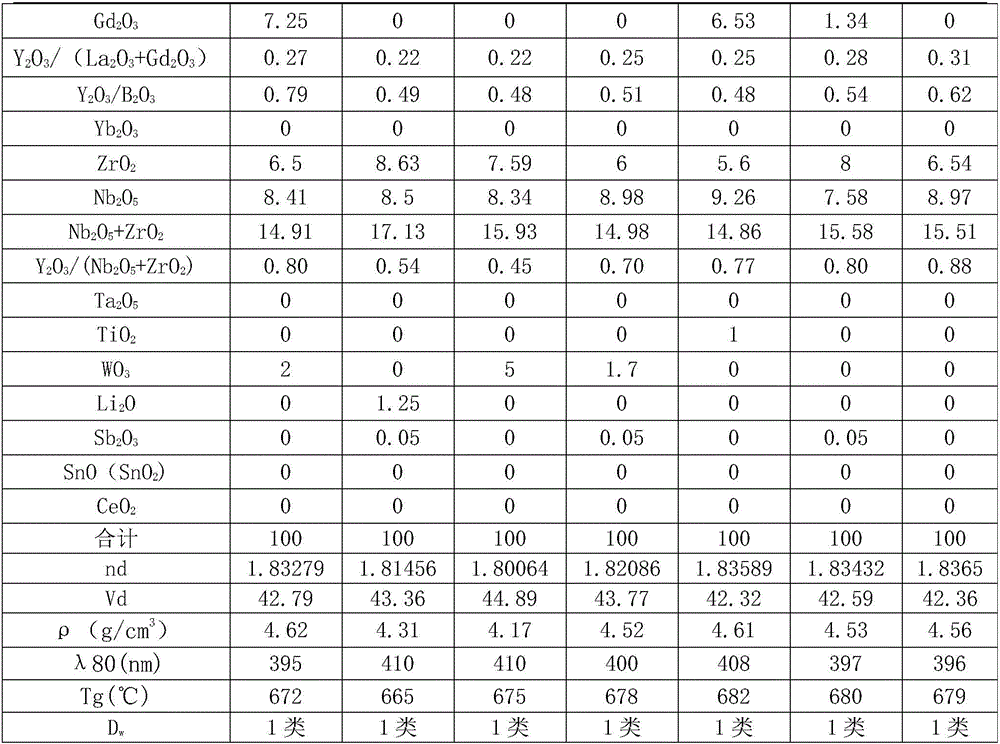

Optical glass

The invention provides optical glass which is low in density, high in transmittance, high inrefractive index and low in chromatic dispersion, the refractive index of the glass is 1.80-1.85, and the abbe number is 40-45. The optical glass comprises B2O3, La2O3, Y2O3, Nb2O5 and ZrO2, and according to the weight percentage, Y2O3 / (Nb2O5+ZrO2) is 0.43-1.4. The introducing amount of Ta2O5 is reduced in the glass components, the appropriate amount of La2O3, Gd2O3, Y2O3, Yb2O3 and rare earth oxide components with the high refractive index and low chromatic dispersion are introduced, Nb2O5 and ZrO2 of an appropriate ratio are introduced, the component compatibility is optimized, the high-refractive-index and low-chromatic-dispersion optical glass which is low in density, high in transmittance and free of devitrification, and a glass prefabricated member and optical element made of the optical glass are obtained.

Owner:CDGM OPTICAL GLASS

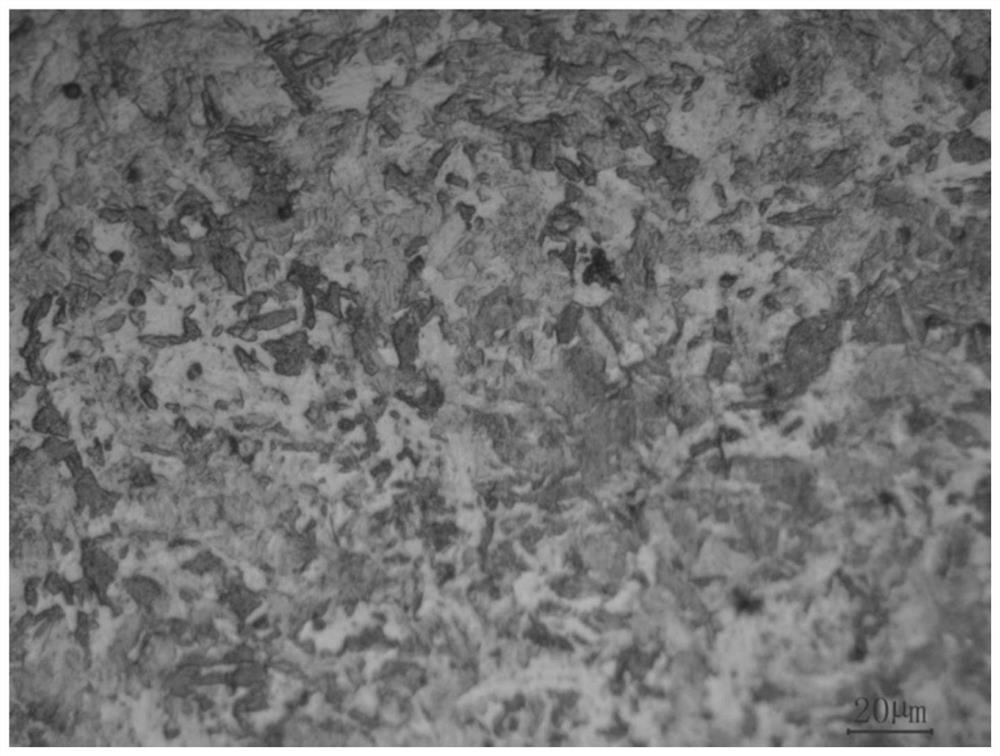

Method for producing sintering brown fused alumina

The invention discloses a method used to manufacture sintering brown alumina. The sintering brown alumina adopts high-alumina bauxite raw ore with a loose structure and aluminum oxide as raw materials and is made through steps such as material proportioning, grinding, forming, drying and burning. Compared with the prior fused brown alumina, the sintering brown alumina has equivalent aluminum content and excellent thermal shock stability, and the cost of the sintering brown alumina is only 37 percent that of the fused brown alumina; moreover, the main crystal phase of the sintering brown alumina is Alpha-Al2O3 and the section of the sintering brown alumina is black; meanwhile, the sintering brown alumina, which has compact texture and regular crystal grain development with most crystal grain more than 10 micron, is a top quality fireproof raw material.

Owner:PUYANG REFRACTORIES GRP CO LTD

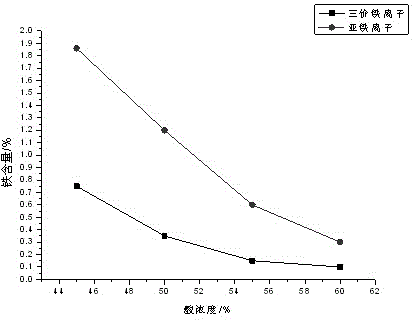

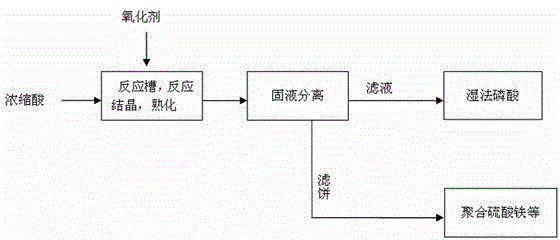

Method for removing iron from titanium dioxide concentrated acid solution

ActiveCN104129816ALower iron levelsReduce the amount of introductionIron sulfatesPhosphoric acidChemical industryPhosphate

A disclosed method for removing iron from a titanium dioxide concentrated acid solution comprises the following steps: (1) collecting the titanium dioxide concentrated sulfuric acid solution with the mass percentage of 45%-55% into a reaction tank; (2) adding an oxidant and a crystal seed into the reaction tank and performing oxidation, crystallization and curing; and (3) performing solid-liquid separation on the slurry obtained in the step (2), and using the separated liquid phase for wet-process phosphoric acid production. The method has the iron-removing rate of 65% or more, helps to effectively reduce the iron content of the titanium dioxide concentrated acid solution and improve the product quality of a phosphate salt, further optimizes sulfur-phosphor-titanium industrial chain and greatly reduces the production cost of phosphorus chemical industry and titanium chemical industry, and is substantial in economic benefit. The method has no waste and byproduct discharge in the whole process, is extremely small in investment, extremely low in production cost and simple in operation, has important meaning on resource recycling and green production, and has wide popularization application prospect.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD +1

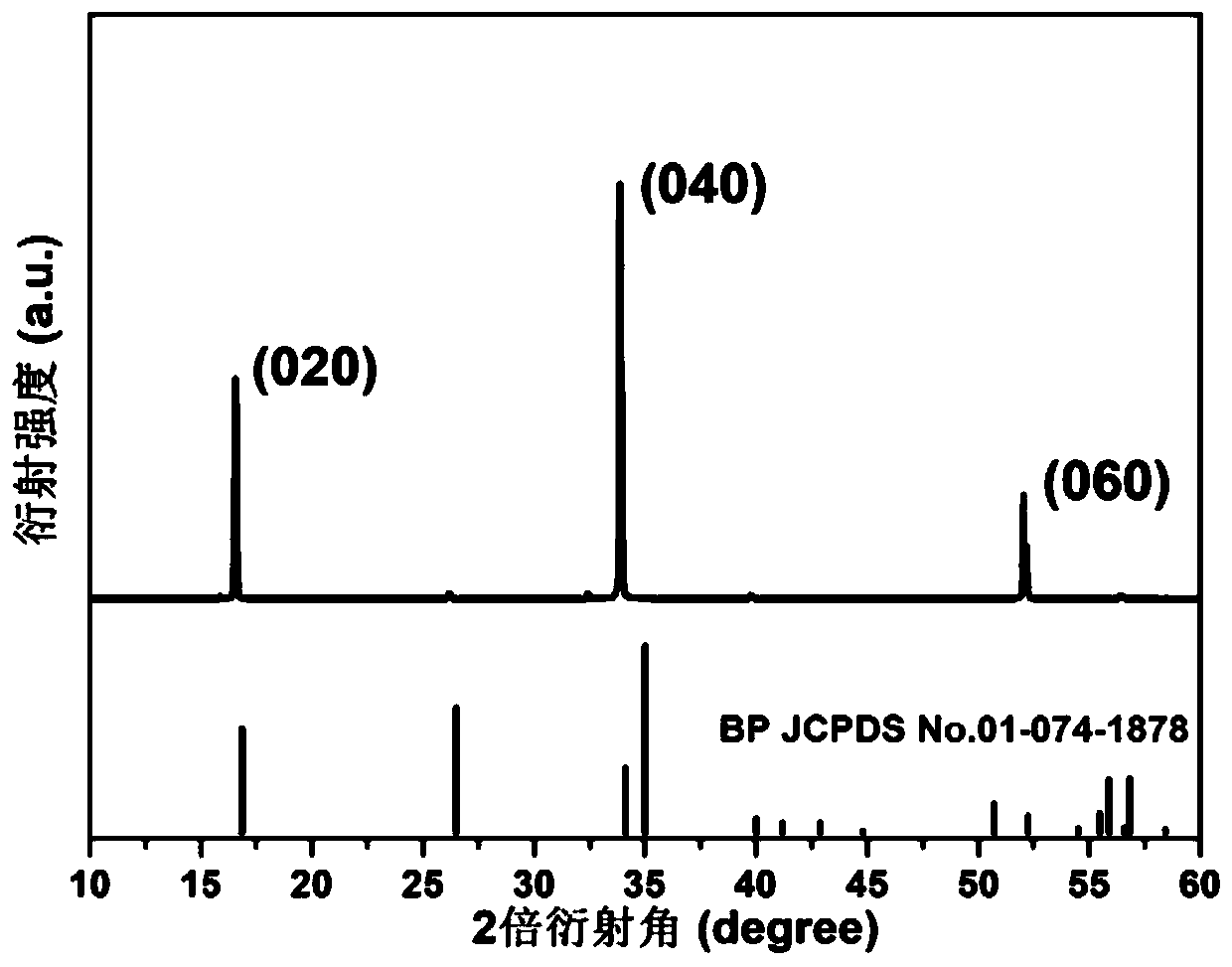

Method for rapidly preparing high-quality two-dimensional black phosphorus crystals through seed crystal induction

InactiveCN110878425AReduce the amount of introductionLower nucleation barrierPolycrystalline material growthPhosphorusCrystallographyPtru catalyst

The invention discloses a method for rapidly preparing high-quality two-dimensional black phosphorus crystals through seed crystal induction. The method comprises the following steps: a red phosphorusraw material, a catalyst and a transport agent are weighed and are placed at the bottom (a raw material end and a hot end) of a single-head sealed quartz tube in an inert atmosphere, the internal ofthe single-head sealed quartz tube is separated by using a porous gasket, a black phosphorus seed crystal is weighed and is placed at the top (a nucleating end and a cold end) of the single-head sealed quartz tube, and the above reaction raw materials are sealed in the quartz tube by using a vacuum tube sealing system; and then the quartz tube is heated through optimized programmed heating and cooling, and the high-purity and high-quality two-dimensional black phosphorus crystal is finally prepared after the reaction is finished. Compared with a traditional preparation method without using crystal seeds, the method of the invention has the advantages of significant reduction of the reaction temperature and the reaction time in the synthesis process, reduction of the energy consumption, effective reduction of the introduction amounts of the catalyst and the transport agent required by the reaction, and cost saving. The black phosphorus crystals synthesized by the method have the advantages of few impurities, high purity, good quality, and facilitation of industrial large-scale preparation of the black phosphorus crystals.

Owner:深圳市中科墨磷科技有限公司 +1

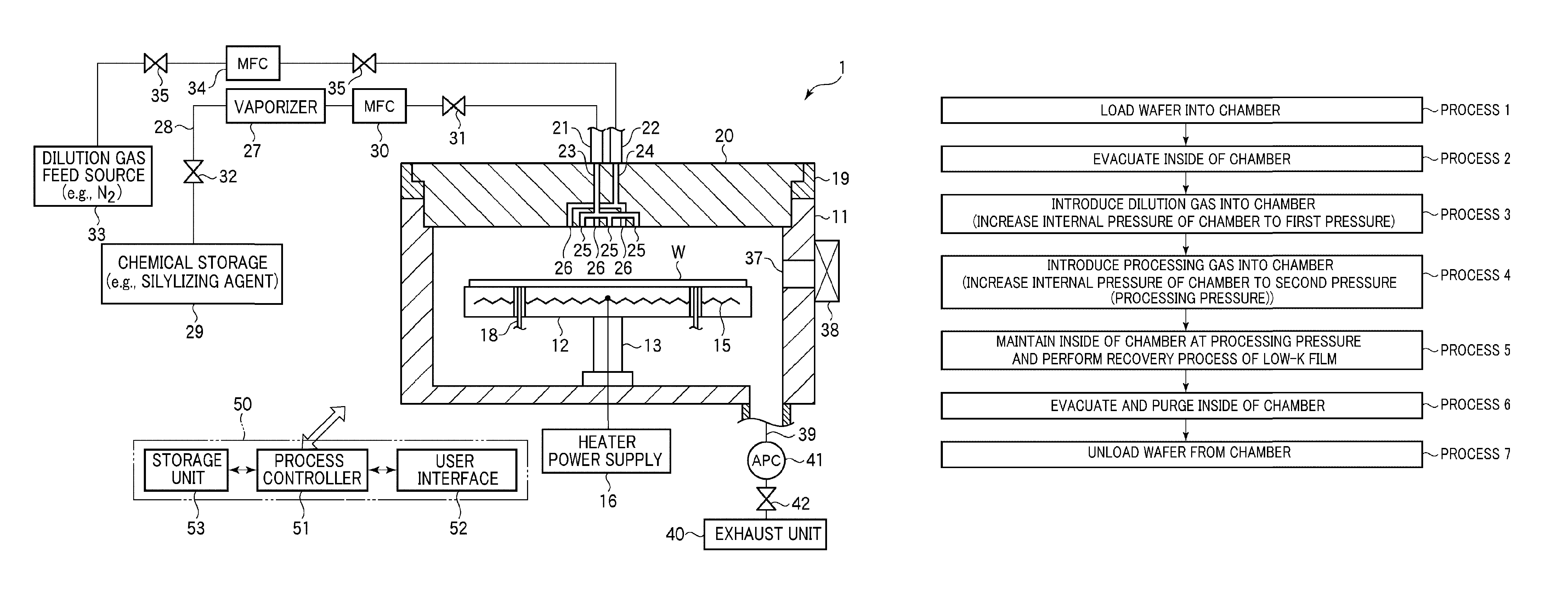

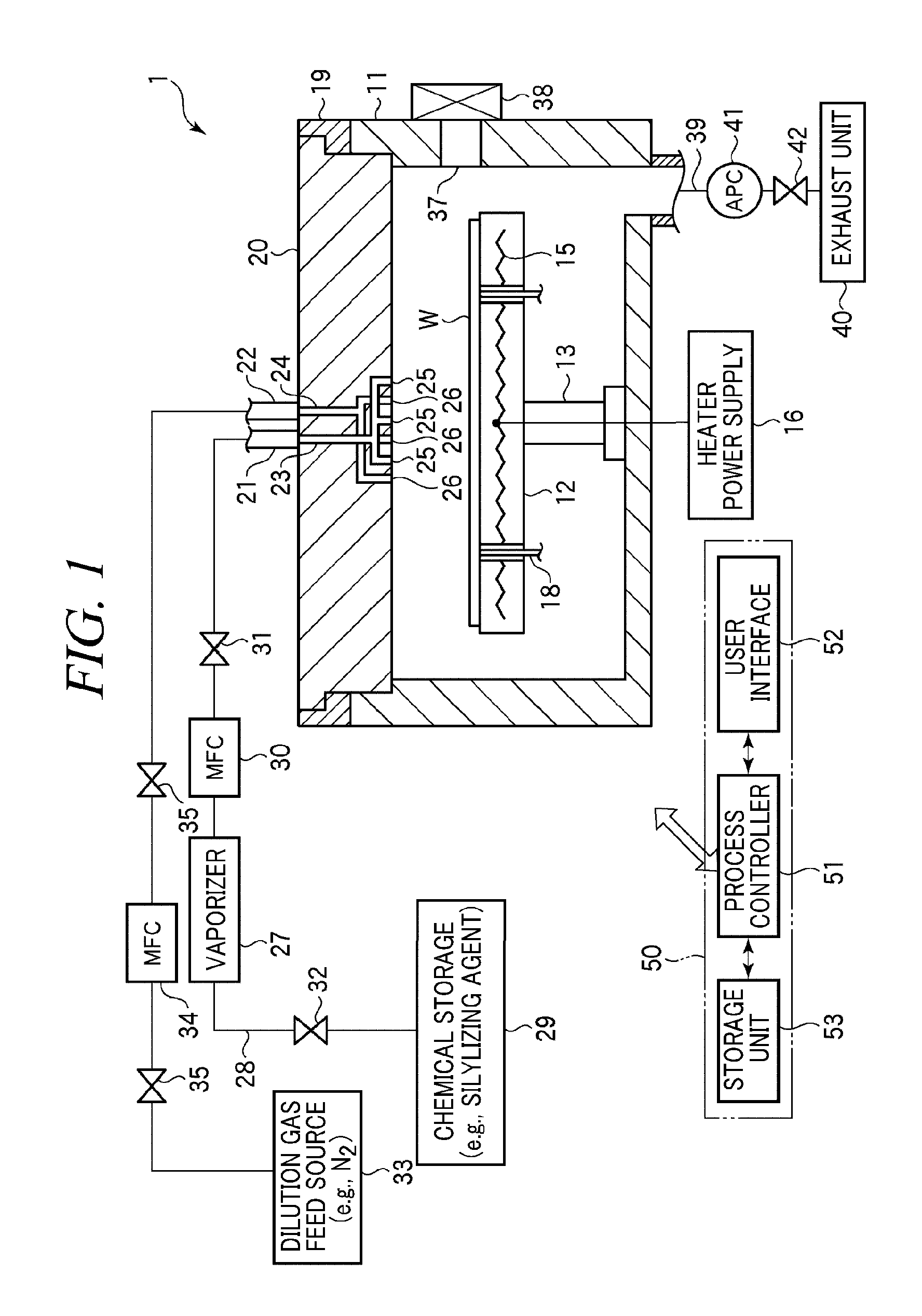

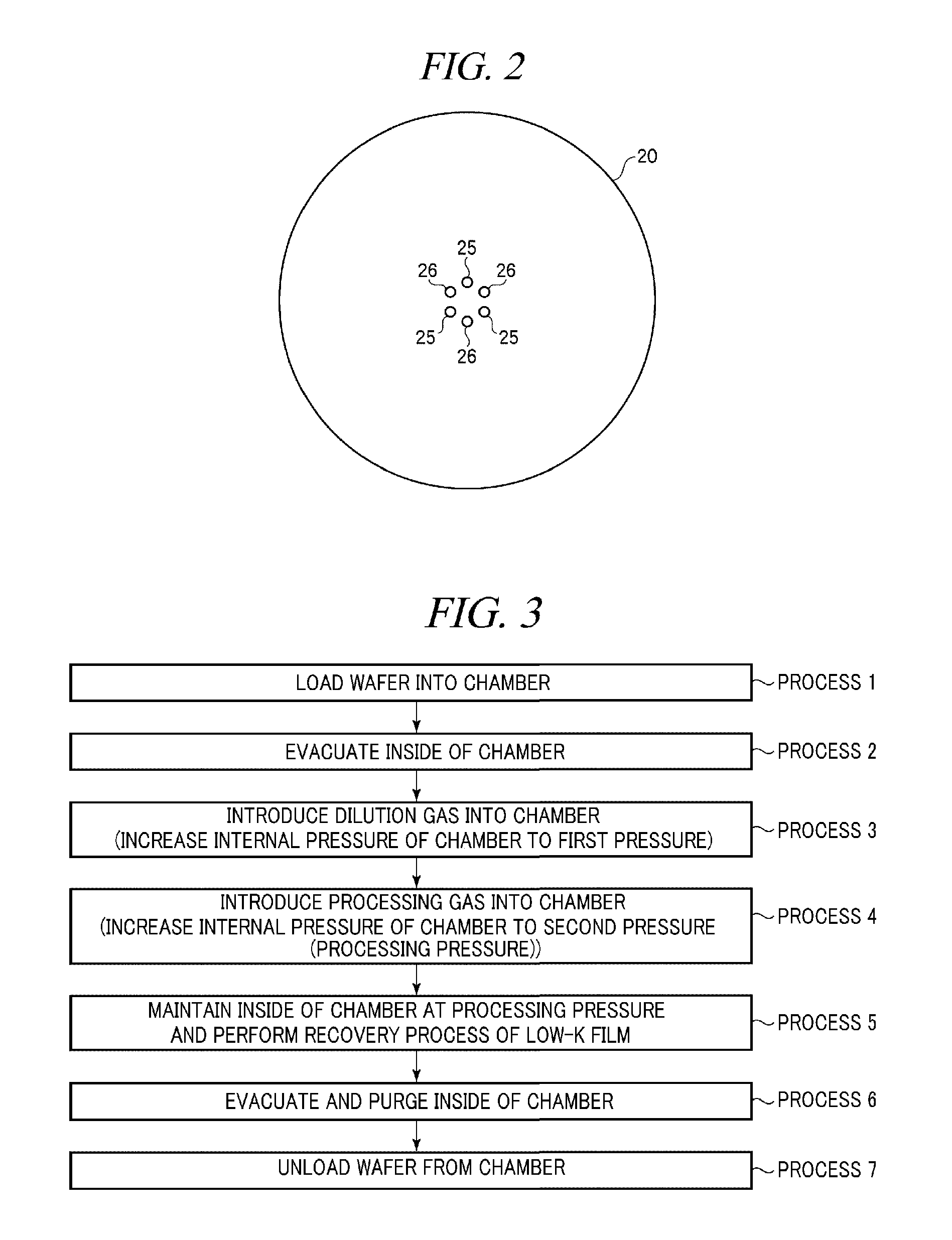

Processing method for recovering a damaged low-k film of a substrate and storage medium

ActiveUS8048687B2Reduce usageSufficient amountSemiconductor/solid-state device manufacturingSemiconductor devicesInternal pressureRecovery procedure

Owner:TOKYO ELECTRON LTD

High-temperature heat-insulation refractory mortar

The invention discloses high-temperature heat-insulation refractory mortar and solves the problem of environmental pollution, short material shelf life, inconvenient construction maintenance or the like due to wrapping of the outer surface of an existing refractory material with a layer of heat preservation material. A preparation method of the high-temperature heat-insulation refractory mortar comprises the following steps: fully mixing aluminum oxide hollow spheres, floating beads, molten quartz powder and bentonite according to a weight part ratio in a sand mixer, adding a proper amount of water, inorganic bonder and foamer, and stirring to obtain the mortar. The high-temperature refractory mortar acts on the surface of the refractory material in a manner of dipping, spraying or coating, and is superior to existing ceramic fibers in linear shrinkage, porosity and thermal conductivity at 1200 DEG C. The high-temperature heat-insulation refractory mortar is simple in preparation process, diverse in construction process, light, environment-friendly and long in shelf life; after acting on the surface of the refractory material, the high-temperature heat-insulation refractory mortar is convenient to maintain, good in heat preservation effect and stable in use performance, and the normal operating temperature exceeds 1200 DEG C.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

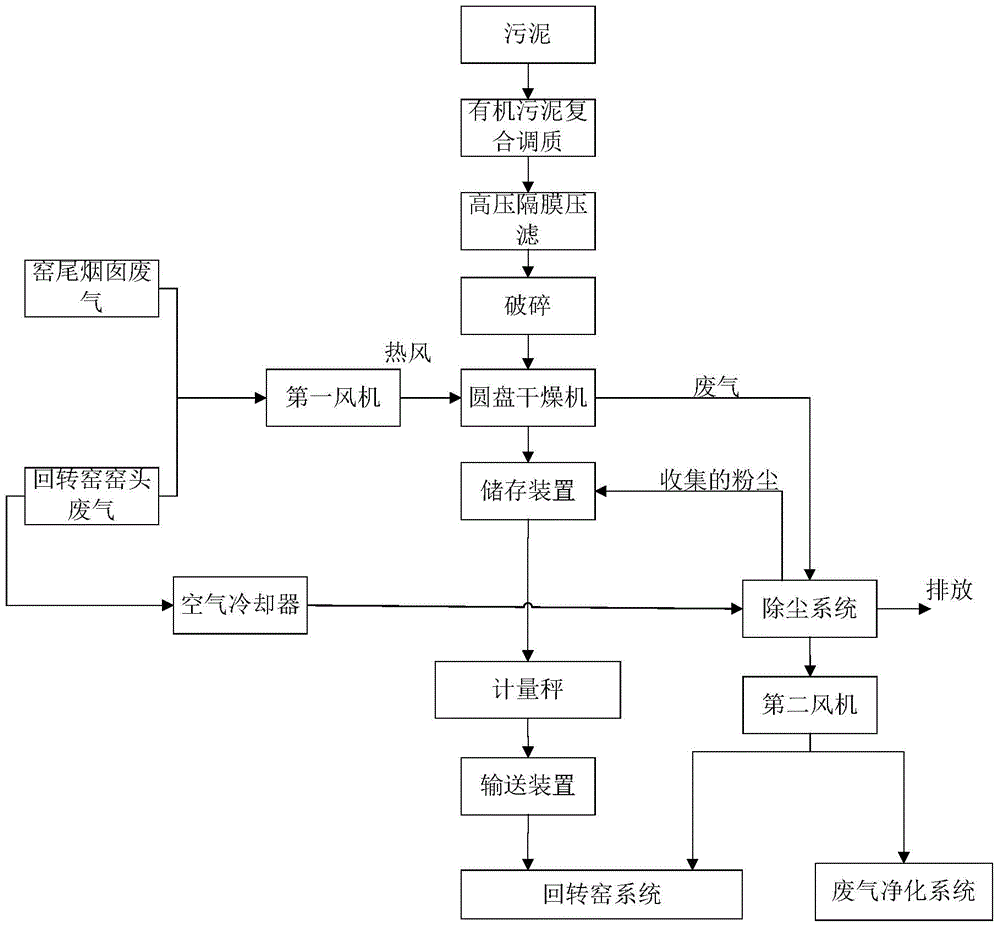

Deep sludge dewatering method and cement kiln comprehensive utilization method using same

ActiveCN103819069AReduce outputReduce the amount of introductionSludge treatment by de-watering/drying/thickeningCross-linkSludge cake

The invention relates to a deep sludge dewatering method and a cement kiln comprehensive utilization method using the same. Ferric trichloride is added and serve as an inorganic ferric salt coagulant, the uniformly stirred sludge mixed liquor is conveyed by a screw pump to a high pressure membrane plate-and-frame filter press for filter pressing, polyacrylamide is added to serve as an organic polymer flocculant while the sludge is fed, a sludge cake with the moisture content of 50-61.33% is finally obtained, and the sludge cake is subjected to dried with waste heat and is comprehensively utilized for a cement kiln after dewatered. The adsorption charge neutrality and the adsorption bridging action of cationic polyacrylamide are used to flocculate the sludge particles, meanwhile, as the selected polyacrylamide has a special branch chain cross-linked structure, the formed floc is small and pressuerproof, and is good for improving the dewatering degree of the sludge. Compared with the tradition, the dosage is reduced greatly, the yield of the cake and the introduction of a harmful element Cl are reduced, the equipment processing efficiency is increased, the heat value of the sludge is kept to the greatest extent, the treatment of the waste gas in a kiln head is taken into comprehensive consideration with a cement kiln system, the capital investment is saved, and the operation cost is lowered.

Owner:华新环境工程有限公司 +1

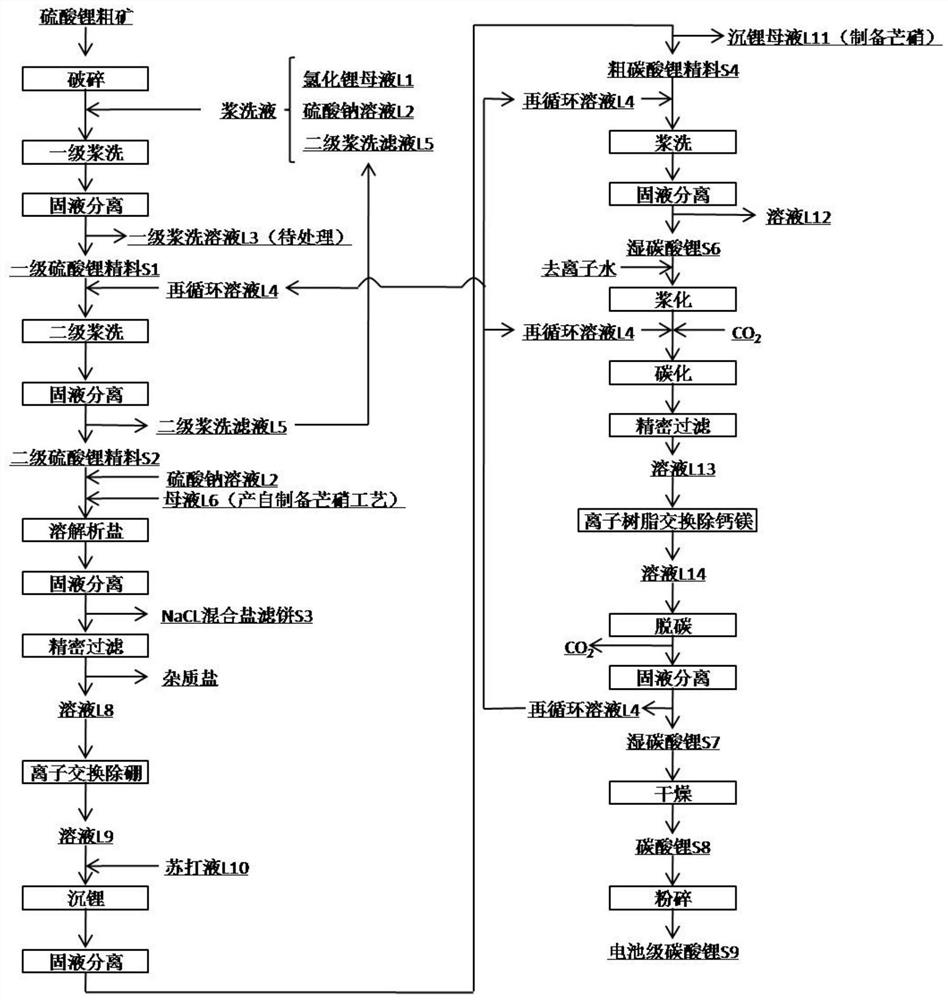

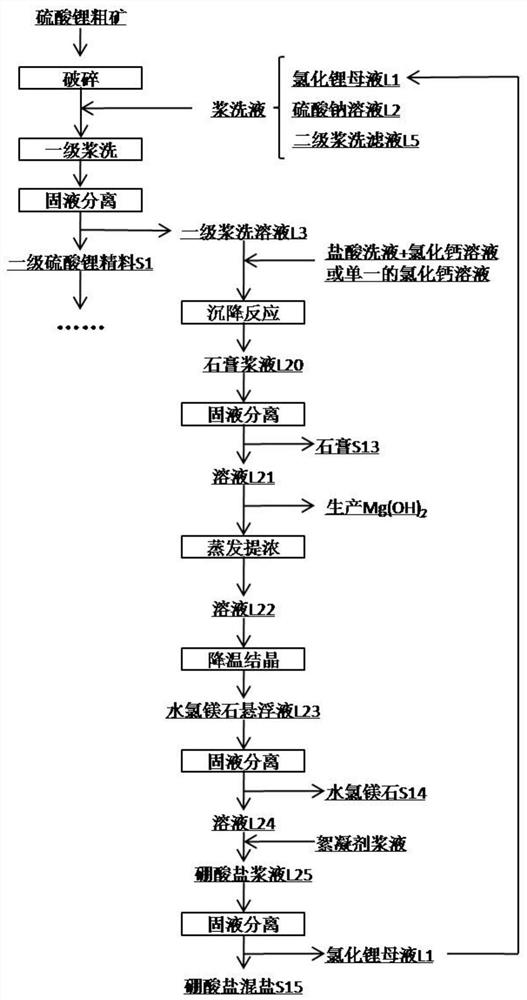

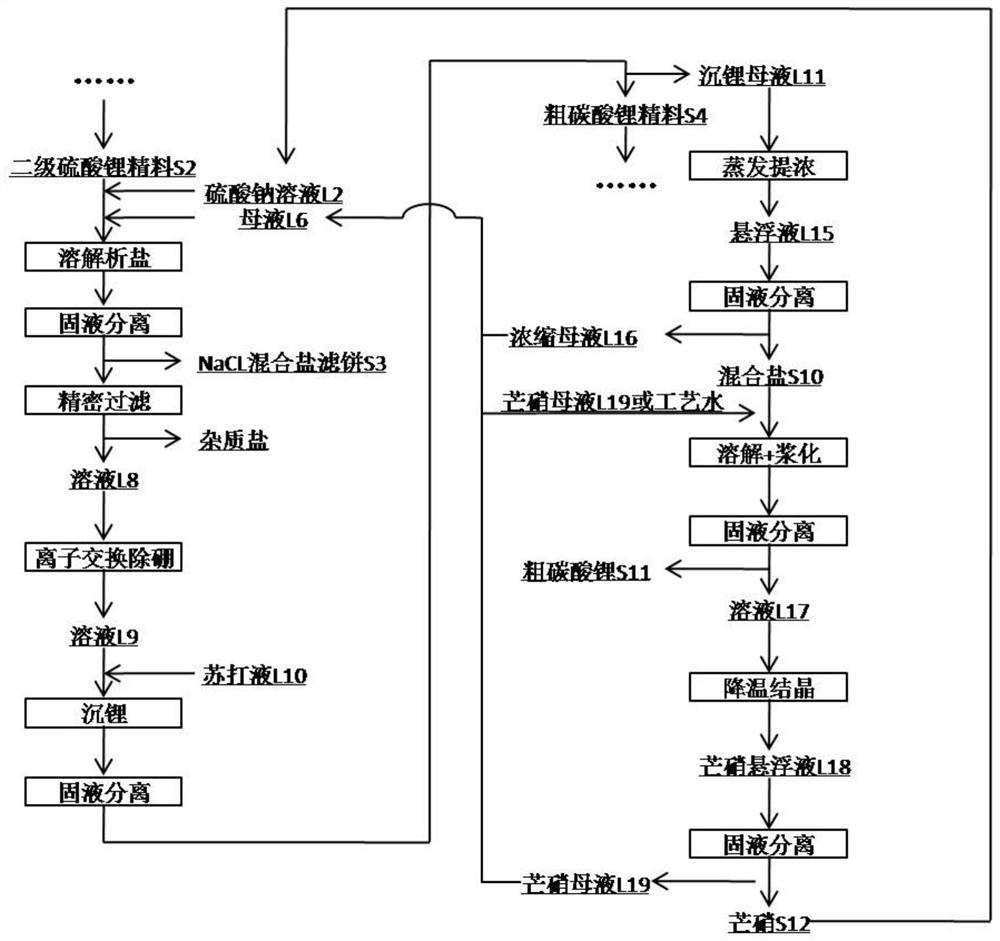

Method for preparing battery-grade lithium carbonate from lithium sulfate crude ores and recovering byproducts

ActiveCN111960445AReduce lossesHigh recovery rateMagnesium chloridesCalcium/strontium/barium sulfatesLithium sulphateLithium chloride

The invention discloses a method for preparing battery-grade lithium carbonate from lithium sulfate crude ores and recovering byproducts. The method comprises the following steps: preparing battery-grade lithium carbonate; preparing mixed salt of gypsum, bischofite and borate; and preparing salt cake. According to the method, lithium chloride mother liquor generated by lithium precipitation and asodium sulfate solution are adopted for primary pulp washing, so that the loss of lithium sulfate can be reduced, and the recovery rate is increased; a recycled solution L4 containing lithium carbonate is taken as a pulp washing solution to carry out secondary pulp washing, soluble calcium and magnesium ions are removed, and lithium in the recycled solution is recovered; the filtrate L5 obtained after solid-liquid separation of the secondary pulp washing contains lithium, and is returned to the primary pulp washing as supplement, the loss of the primary pulp washing is reduced while soluble impurity ions are dissolved; the secondary lithium sulfate concentrate is dissolved by mirabilite preparation mother liquor L6, NaCl mixed salt is separated out in the dissolving process, and lithium isprecipitated. According to the method, the crude lithium carbonate is subjected to pulp washing by adopting the recycling solution containing lithium carbonate, so that the lithium yield can be increased while the system discharge is reduced.

Owner:CINF ENG CO LTD

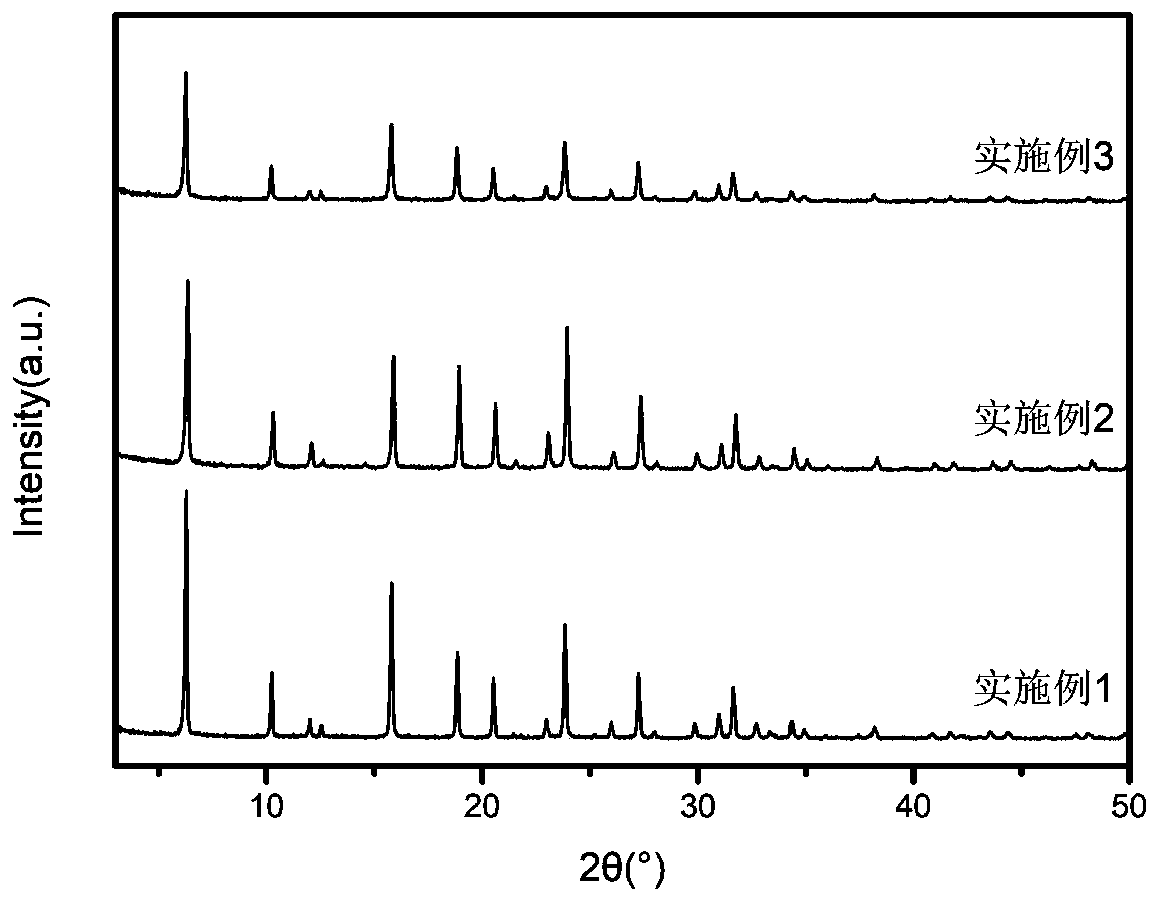

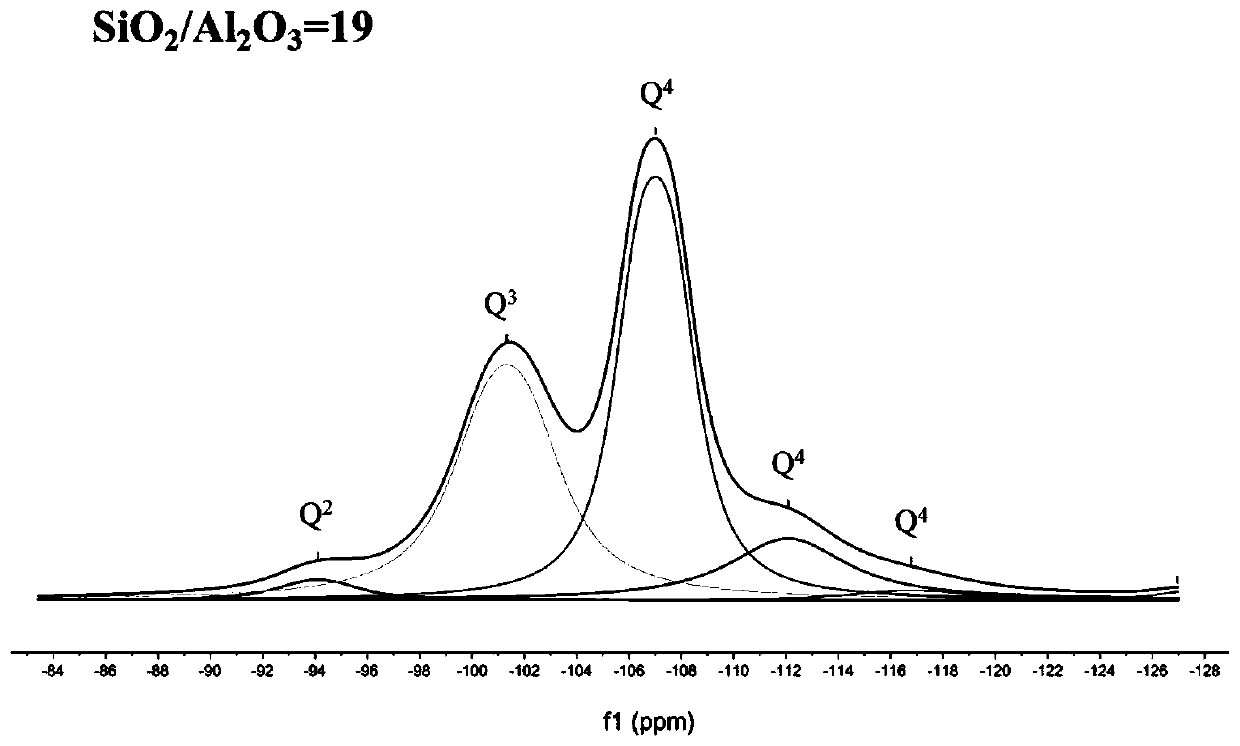

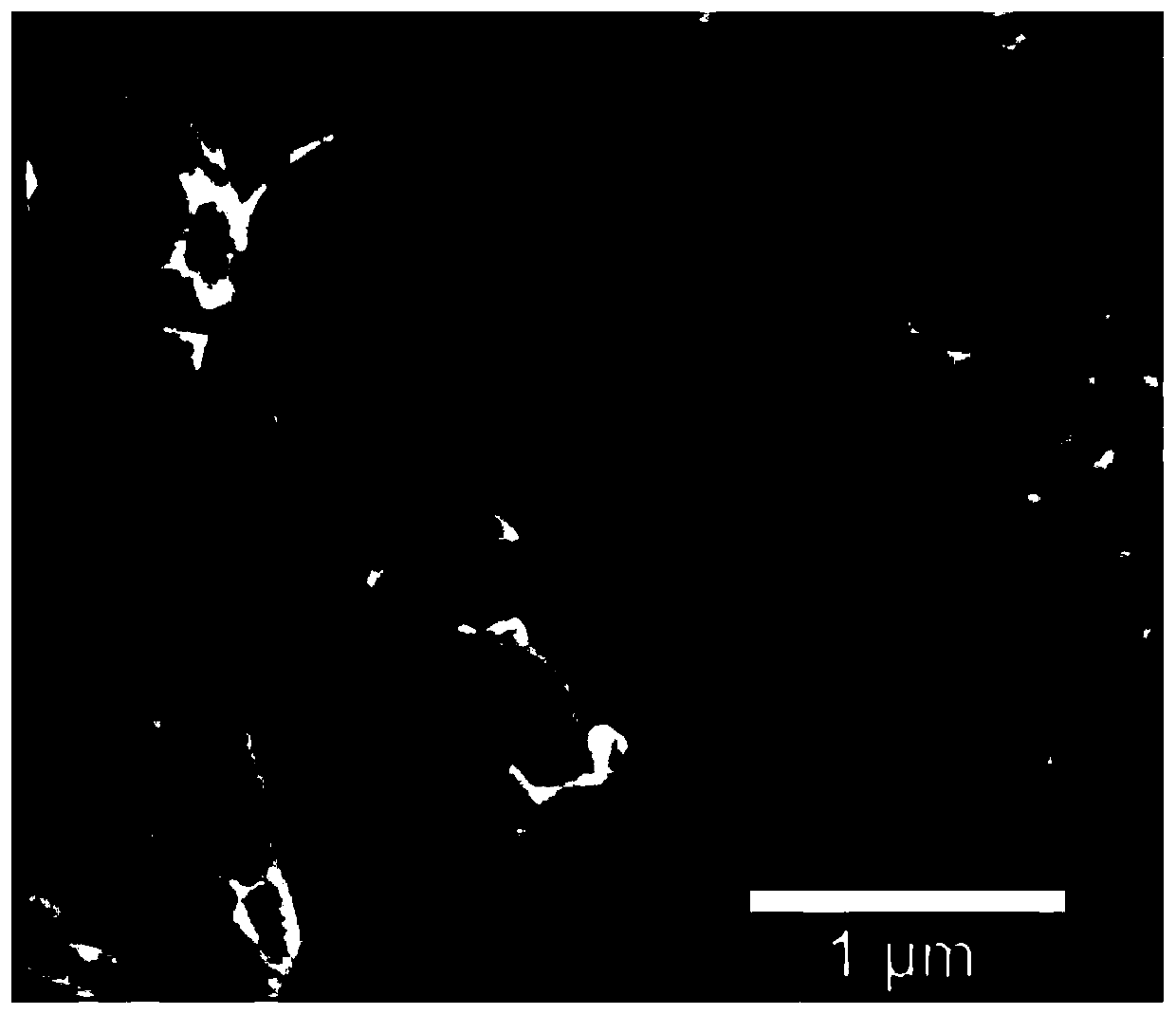

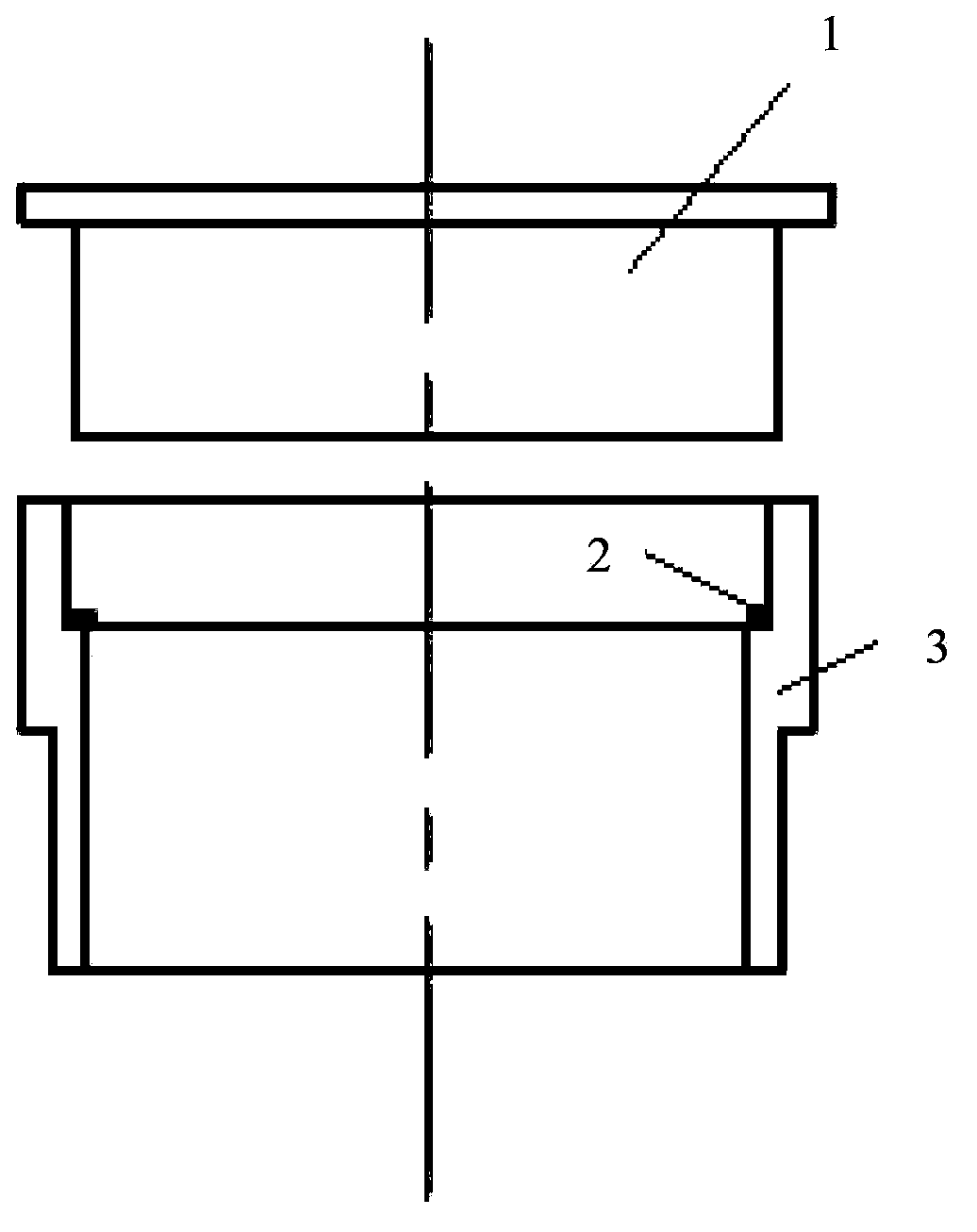

Preparation method of high-silica-alumina-ratio Y-type molecular sieve

ActiveCN110963502AHigh ratio of silicon to aluminumReduce the amount of introductionFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention belongs to the technical field of molecular sieve synthesis and particularly relates to a preparation method of a Y-type molecular sieve with a high silica-alumina ratio. The preparationmethod comprises the following steps: dissolving two template agents, and mixing a double-template-agent solution with an aluminum source and an alkali source to obtain a first mixed solution; mixingthe first mixed solution with a silicon source and a seed crystal to obtain a second mixed solution; and finally, sequentially carrying out aging treatment and hydrothermal crystallization treatmenton the second mixed solution to obtain the Y-type molecular sieve with the high silica-alumina ratio. According to the invention, according to the method of taking the high-silica Y molecular sieve asa seed crystal and synthesizing the Y-type molecular sieve with the high silica-alumina ratio in a double-template system, the Y molecular sieve with the SiO2 / Al2O3 ratio of 6.00-21.352 is synthesized in one step. In addition, the Y-type molecular sieve obtained according to the preparation method is high in crystallinity, the preparation method adopts cheap raw materials, the synthesis method issimple and easy to operate, and the method is suitable for large-scale industrial production.

Owner:JILIN UNIV

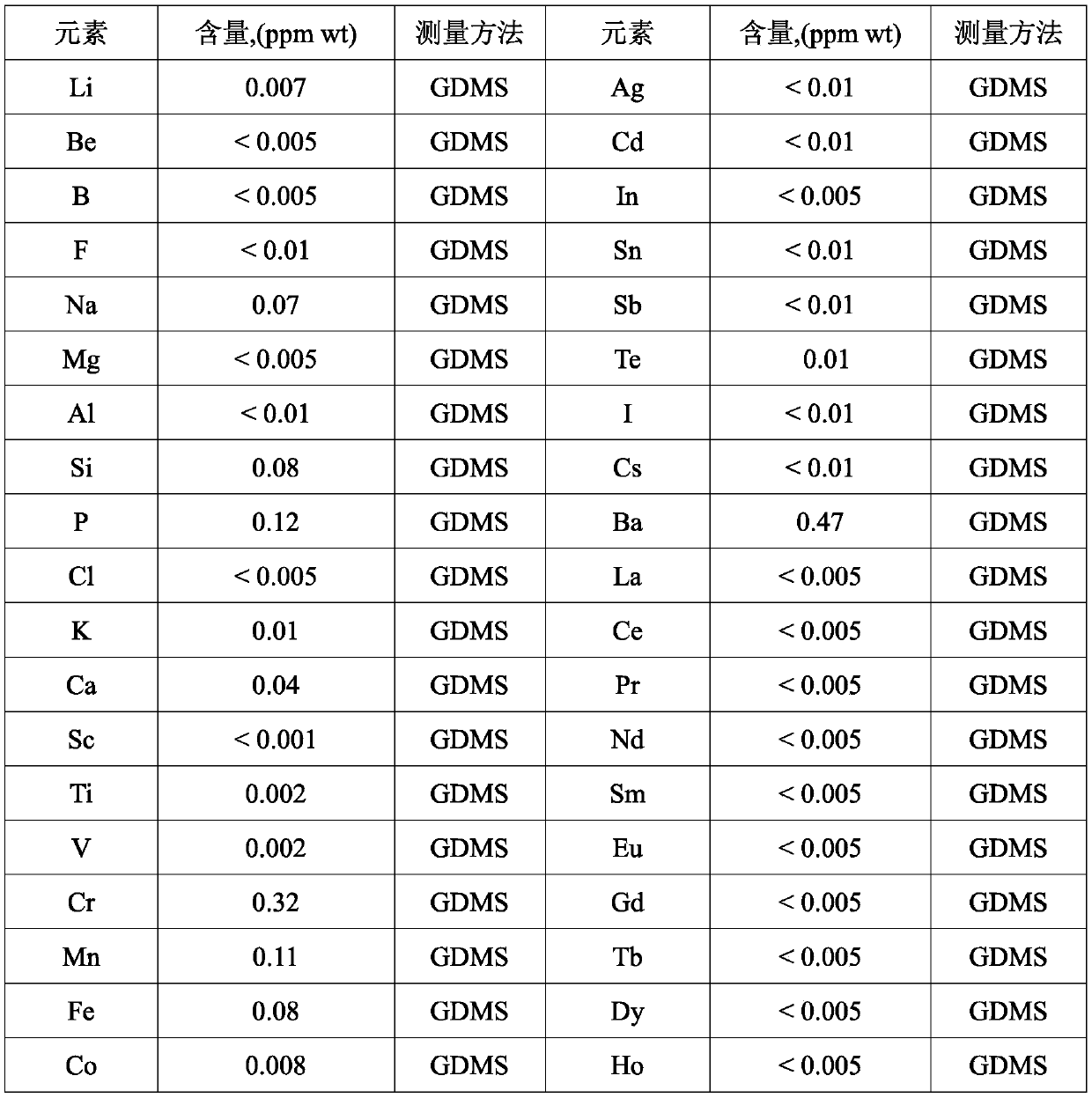

Novel cathode high-temperature brazing material and preparation method thereof

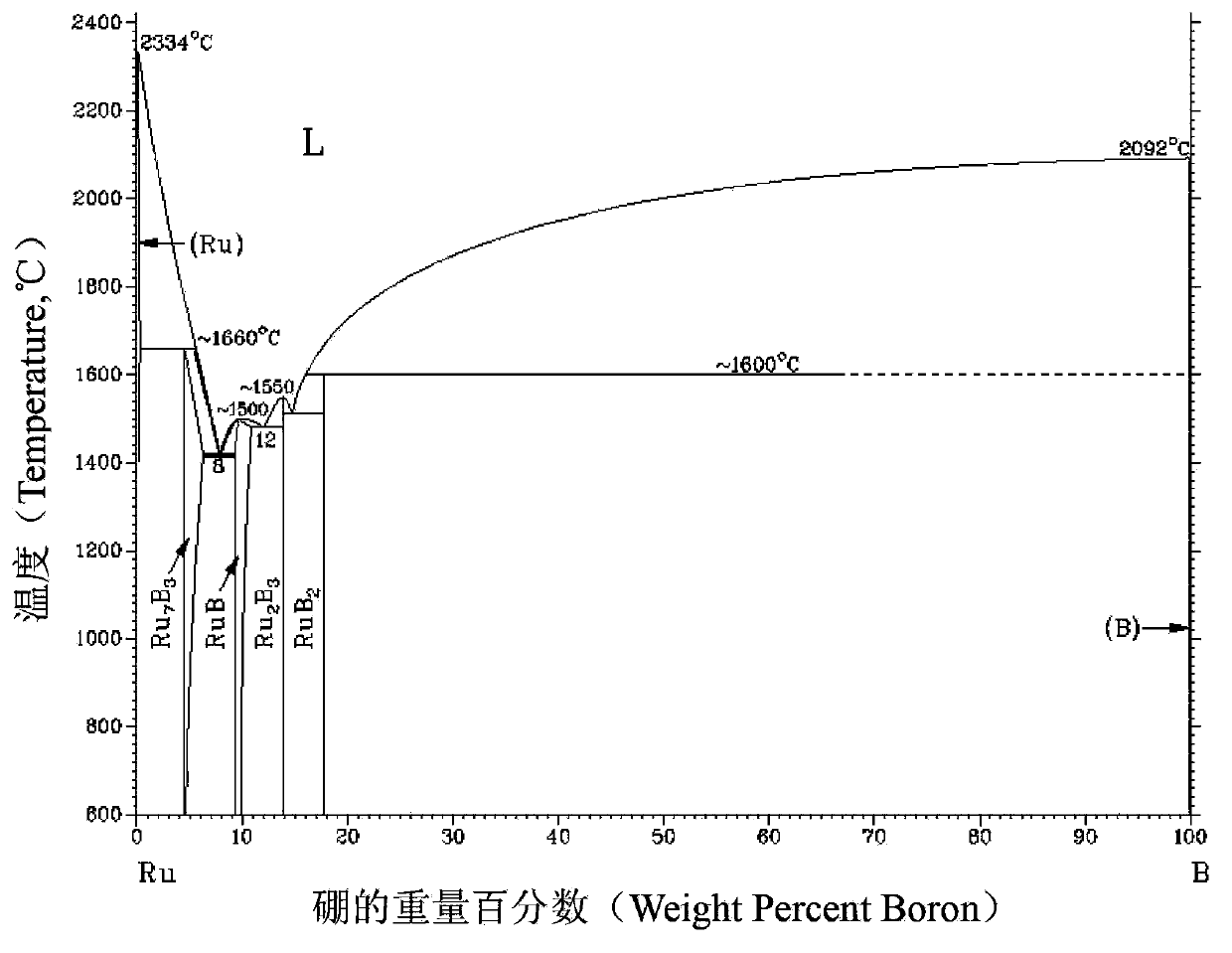

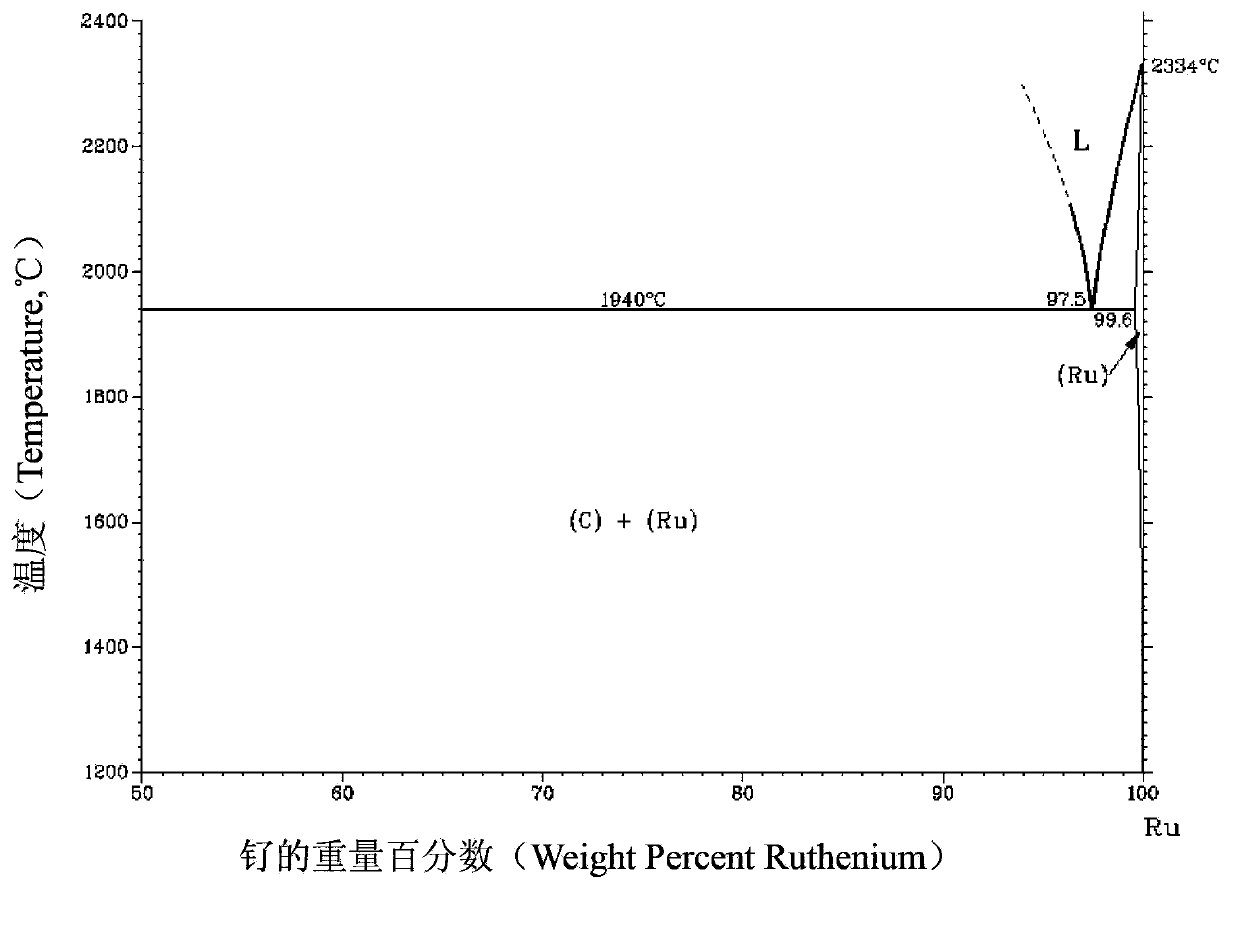

ActiveCN103862190AReduce the amount of introductionSmall particlesWelding/cutting media/materialsSoldering mediaGranularityTemperature difference

The invention relates to a novel cathode high-temperature brazing material and a preparation method thereof, in particular to Ru-B-C alloy component brazing powder and a manufacturing method thereof. The brazing material mainly comprises Ru-B-C alloy powder, in weight percent, 89.0-97.5wt% of Ru, 2.0-10.0wt% of B and 0.5-3.0wt% of C, and the elementary substance content of the Ru, the B and the C is lower than 2wt%. The brazing material is prepared by the aid of an electron beam smelting purification-plasma rotating electrode atomization powder manufacturing-airflow grinding crushing method. Prepared brazing powder particles are fine and uniform in granularity and composition, so that the problems of high welding temperature, composition segregation, large solid-liquid phase line temperature difference, poor welding process and the like of an existing brazing material can be solved.

Owner:GRIMAT ENG INST CO LTD

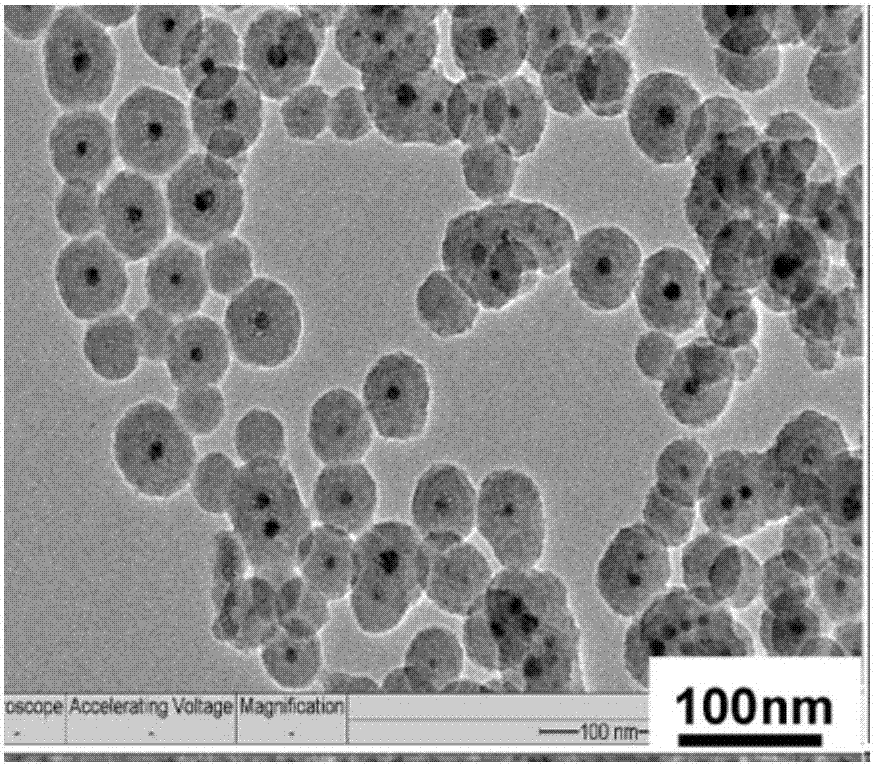

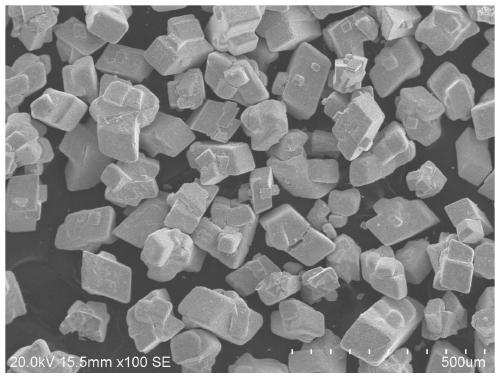

Preparation method of oxide dispersion strengthening steel spherical powder for 3D printing

ActiveCN112453413AReduce the amount of introductionImprove efficiencyTransportation and packagingMetal-working apparatusFluidized bedMixed gas

The invention relates to a preparation method of oxide dispersion strengthening steel spherical powder for 3D printing. The preparation method comprises the following steps of (1) after mixing gas atomization pre-alloyed powder and rare earth oxide powder, and carrying out high-energy ball milling to obtain the oxide dispersion strengthening steel powder; (2) after mixing the obtained oxide dispersion strengthening steel powder with a jet milling medium, adding the mixture into a fluidized bed, and discharging air in the fluidized bed to obtain the material carrying fluidized bed; and (3) heating the obtained material carrying fluidized bed, introducing mixed gas, controlling the flow of the mixed gas after the fluidized state of the powder in the material carrying fluidized bed is stable,and cooling after preset reaction time is reached, thereby obtaining the steel spherical powder from the material carrying fluidized bed. The method has the advantages of simple preparation process,low production cost, high efficiency, small impurity introduction amount, easy realization of engineering amplification and the like, the sphericity degree is greater than 75d1 / da, the granularity is10 microns-100 microns, the fluidity numerical value is less than 20s / 50g, and the oxygen content is less than 3500 ppm.

Owner:中科南京绿色制造产业创新研究院 +1

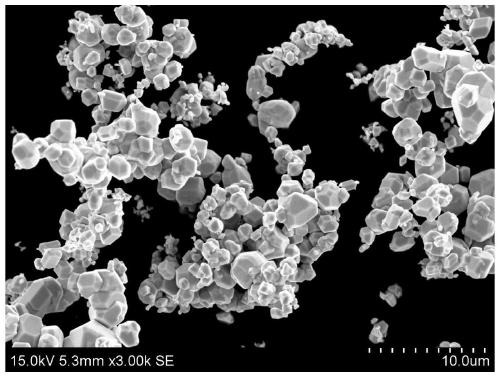

Preparation method of high-purity tungsten powder

The invention discloses a preparation method of high-purity tungsten powder. The high-purity tungsten powder preparation process is short, industrialized batch production can be achieved, and the costis low. Commercial ammonium paratungstate is selected as raw materials and directly subjected to ammonia solution filtering, an ammonium tungstate solution is prepared, after crystallizing, filtering, washing and drying are conducted, ammonium paratungstate is prepared again, then hydrogen gas reduction is conducted in a reduction furnace of a metal furnace tube, and the high-purity tungsten powder is prepared. According to the preparation method of the high-purity tungsten powder, the ammonium paratungstate calcining step is omitted, and the introduced quantities of impurities in the calcining process can be decreased; and general technicians in the field can know that commercial common tungsten powder is obtained through hydrogen gas reduction by taking ammonium paratungstate as the rawmaterials, in the preparation method, a recrystallized product is still ammonium paratungstate, and the high-purity tungsten powder can be conveniently prepared by adopting a common tungsten powder reduction technology.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

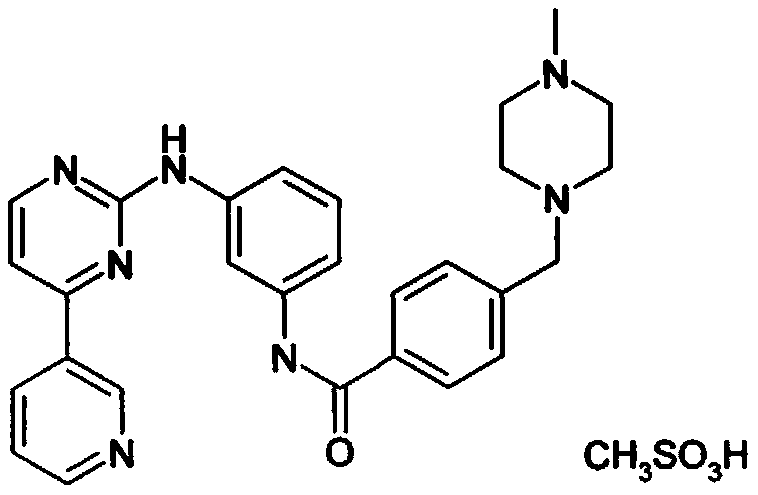

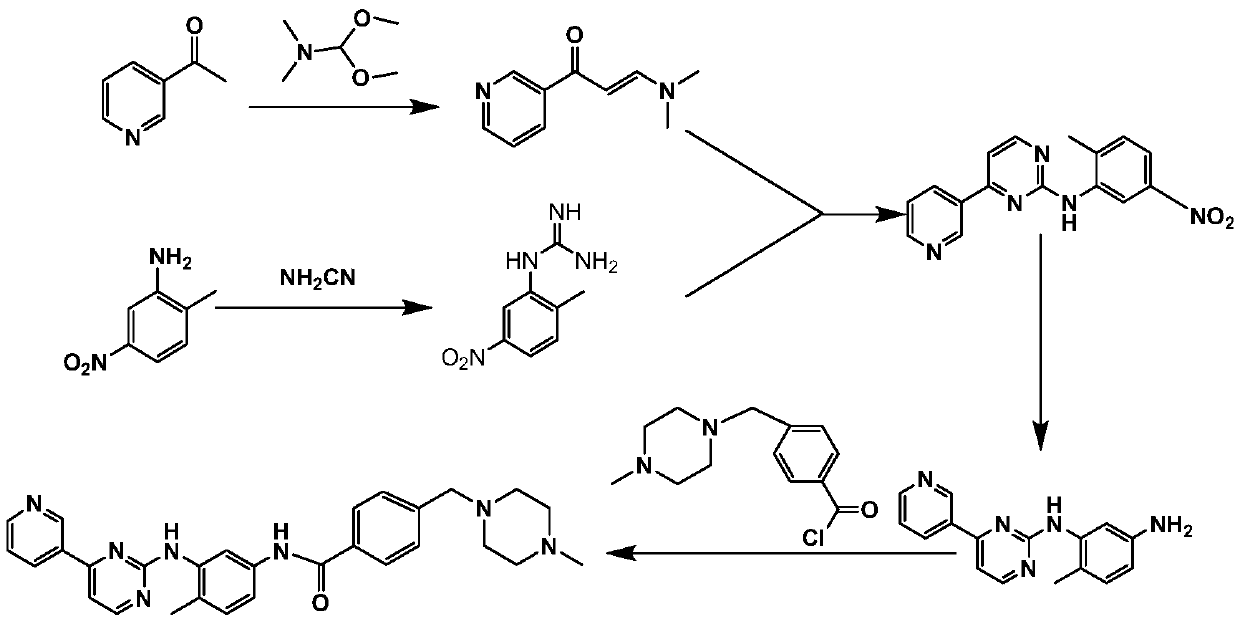

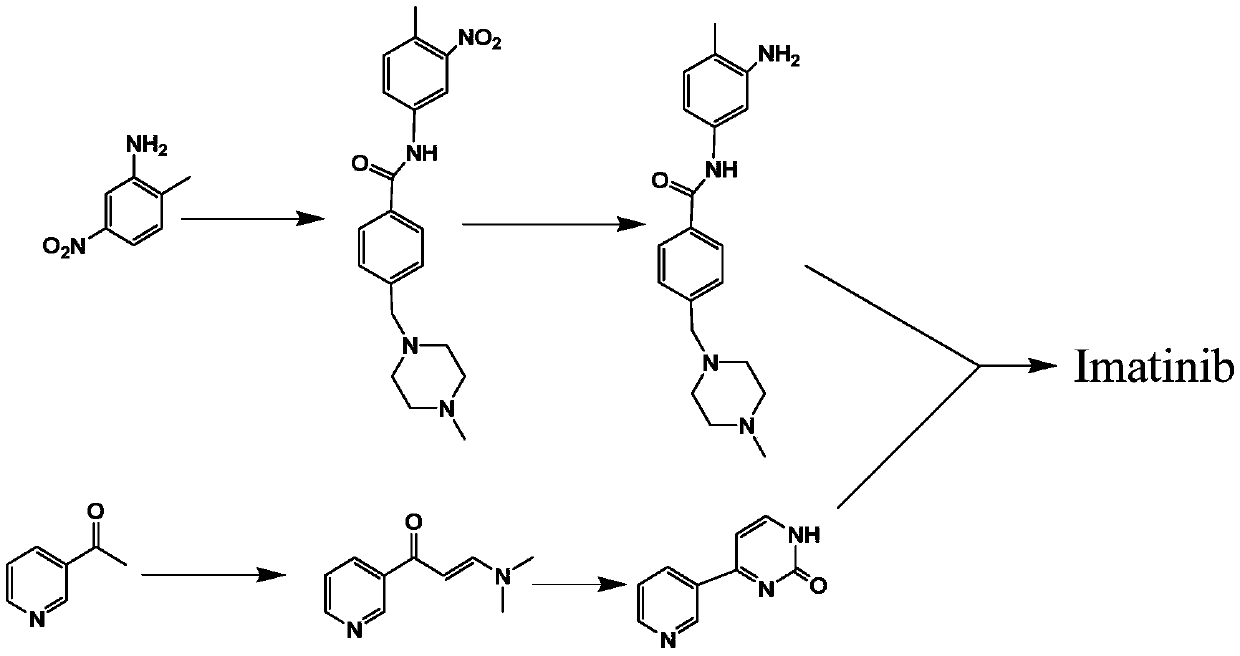

Synthesis method of imatinib and imatinib mesylate

PendingCN111039921AOverall Reaction Time ReducedEasy to operateSulfonic acids salts preparationDimethyl acetalNitro reduction

The invention relates to a synthesis method of imatinib and imatinib mesylate. The method comprises the following steps: condensing 3-acetylpyridine and N,N-dimethylformamide dimethyl acetal which aretaken as initial raw materials to obtain 3-dimethylamino-1-(3-pyridyl)-2-propen-1-one, then reacting with 2-methyl-5-nitrophenylguanidine nitrate to form a pyrimidine ring, performing nitro reductionto obtain N-(5-amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidinamine, amidating the N-(5-amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidinamine and 4-(chloromethyl)benzoyl chloride, performing affinitysubstitution with 1-methylpiperazine to obtain imatinib, and salifying the imatinib and methanesulfonic acid. The products obtained by the method have the advantages of few impurities, simplicity in post-treatment, high total yield, greenness, environmental protection and safety, and is suitable for a production process for large-scale industrial production of imatinib mesylate.

Owner:杭州沧海帆医药科技有限公司

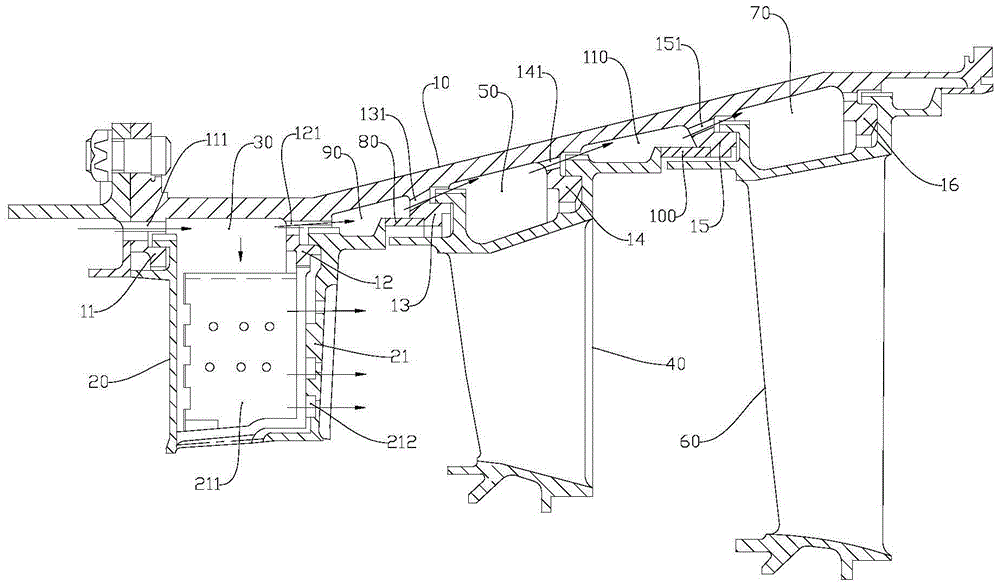

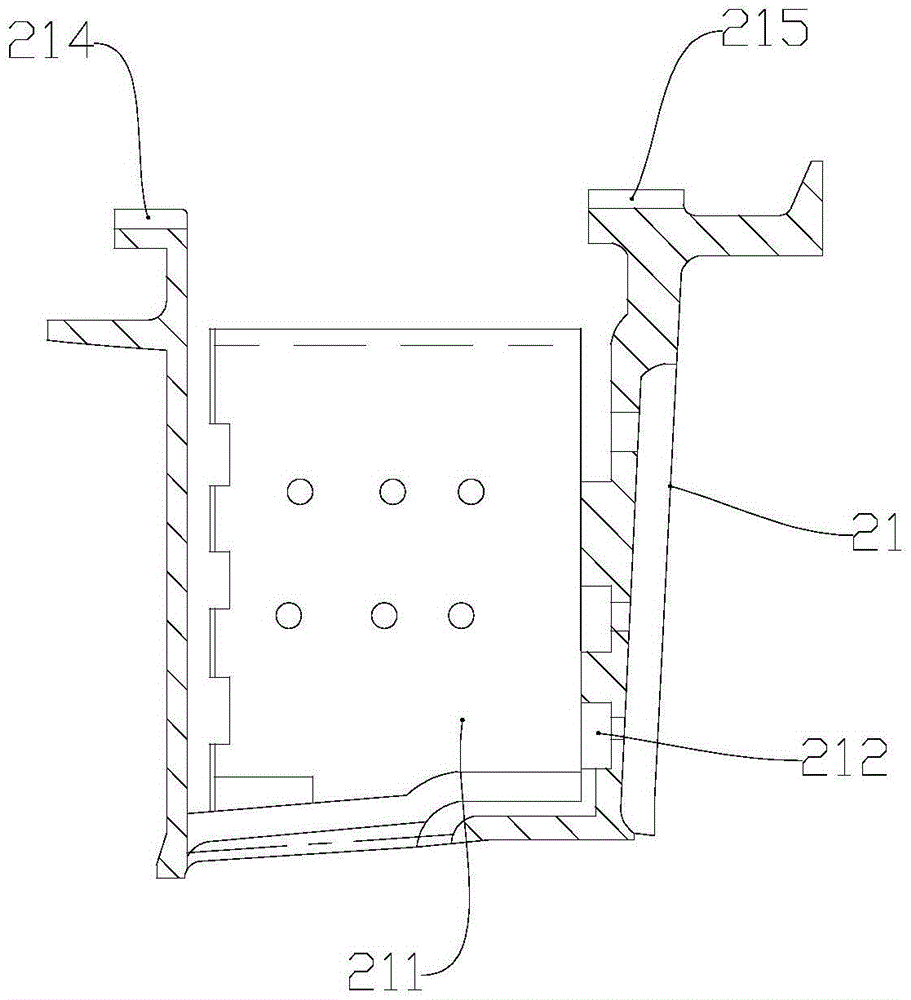

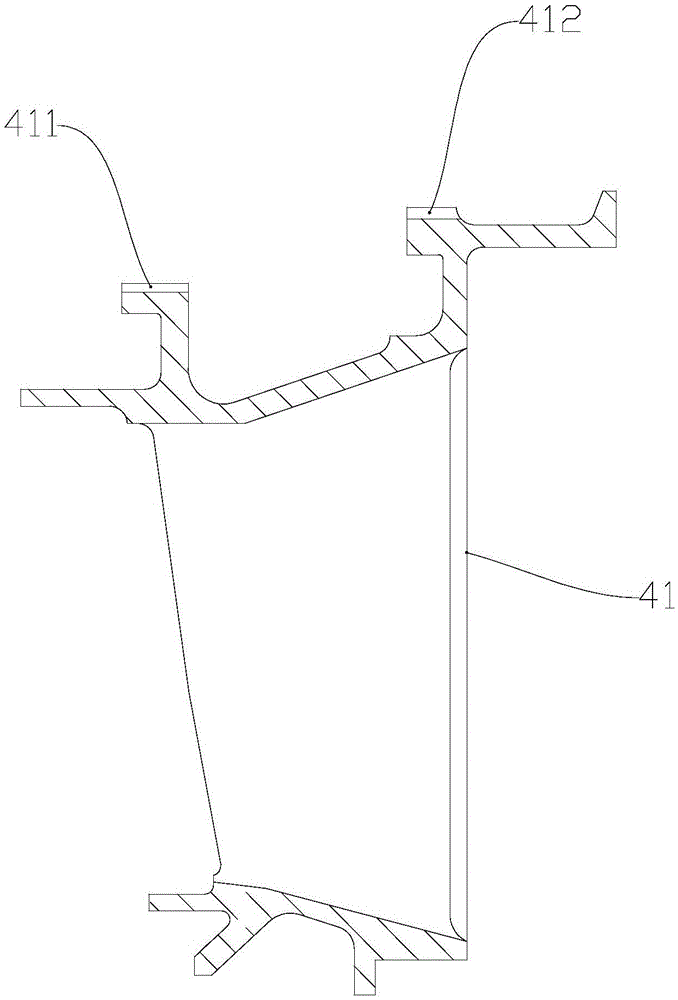

Cooling flow path for stator vanes of turbine engine

The invention discloses a cooling flow path for stator vanes of a turbine engine. A first air hole, through which upstream cooling air is introduced in a first annular passage to cool a turbine engine casing and an upper edge plate of a first-stage stator vane, is formed in a first bearing rib. The first-stage stator vane comprises a plurality of first guiding vanes. An air chamber communicated with the first annular passage is formed in the body of each first-stage guiding vane, and is also communicated with a gas passage in the turbine engine casing so as to enable cooling air to be discharged in the gas passage after the first-stage guiding vanes are cooled with cooling air. The cooling flow path is simple in structure, the first-stage guiding vanes are not deformed or cracked in operation, the parts constituting the cooling flow path are easy to process, and the processing cost can be reduced; and in addition, the quantity of introduced cooling air is smaller, and the power of an engine is not remarkably reduced when a small amount of cooling air is mixed in high-temperature acting gas, so that the requirement on the using power of the engine can be ensured.

Owner:CHINA HANGFA SOUTH IND CO LTD

Preparation method for inorganic antibiosis with copper ion containing silver and preparation method for inorganic antibacterial agent with copper ion containing silver

InactiveCN102642821AReduce silver consumptionReduce raw material costsBiocideDisinfectantsIonAntibiosis

The invention discloses a preparation method for inorganic antibiosis, and particularly relates to a preparation method for inorganic antibiosis with copper ion containing silver and a preparation method for inorganic antibacterial agent with copper ion containing silver, ZrOCl2 8H2O, NaH2PO4 2H2O and Na2C2O4 are mixed to form solution and are reacted to synthetize Na0.64H0.36Zr2(PO4)3 H2O, and is respectively reacted with Cu(NO3)2 and AgNO3. The preparation methods provided by the invention have the functions that: firstly, Cu<2+> is reacted and converted, secondly, Ag<+> is reacted and converted, the antibacterial activity of inorganic antibiosis with copper ion containing silver is enabled to be the same, the introduction amount of Ag<+> is reduced, and the consumption of silver is lowered, the cost of raw materials is obviously lowered, and the stability is greatly increased, meanwhile, since the introduction amount of Cu<2+> is not large, the surface is prevented from changing into a black color caused by oxidization into CuO, and the appearance and the introduction range are also prevented from being affected; additionally, the variation original nature of inorganic antibiosis with copper ion containing silver prepared by the invention is negative, stimulation to skin is zero, and high safety is realized.

Owner:HAINING ZHONGKE NEW MATERIALS CO LTD

Removal of naphthenic acid in oil using composite deacidifying agent

The invention relates to a new method to deprive naphthenic acid from oil product. It adopts alcohols as solvent and thinner, the mixture of alkali organic substance like imidazole and alkylol amine as main deacidification agent and little quantities of inorganic alkali as deacidification additive. The ternary compounding deacidification agent mixes with oil product according 1:1-1:30 under 10-100 degree centigrade to form ion liquid compound to take rapid separation with oil material. The oil material phase would gain qualified oil product after taking refining, and the ion liquid compound could recycle raw naphthenic acid and deacidification agent. The invention could obviously decrease the intake of basic nitrogen, and improve the yield and quality of oil product. And it has simple technology, mild condition, low cost, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

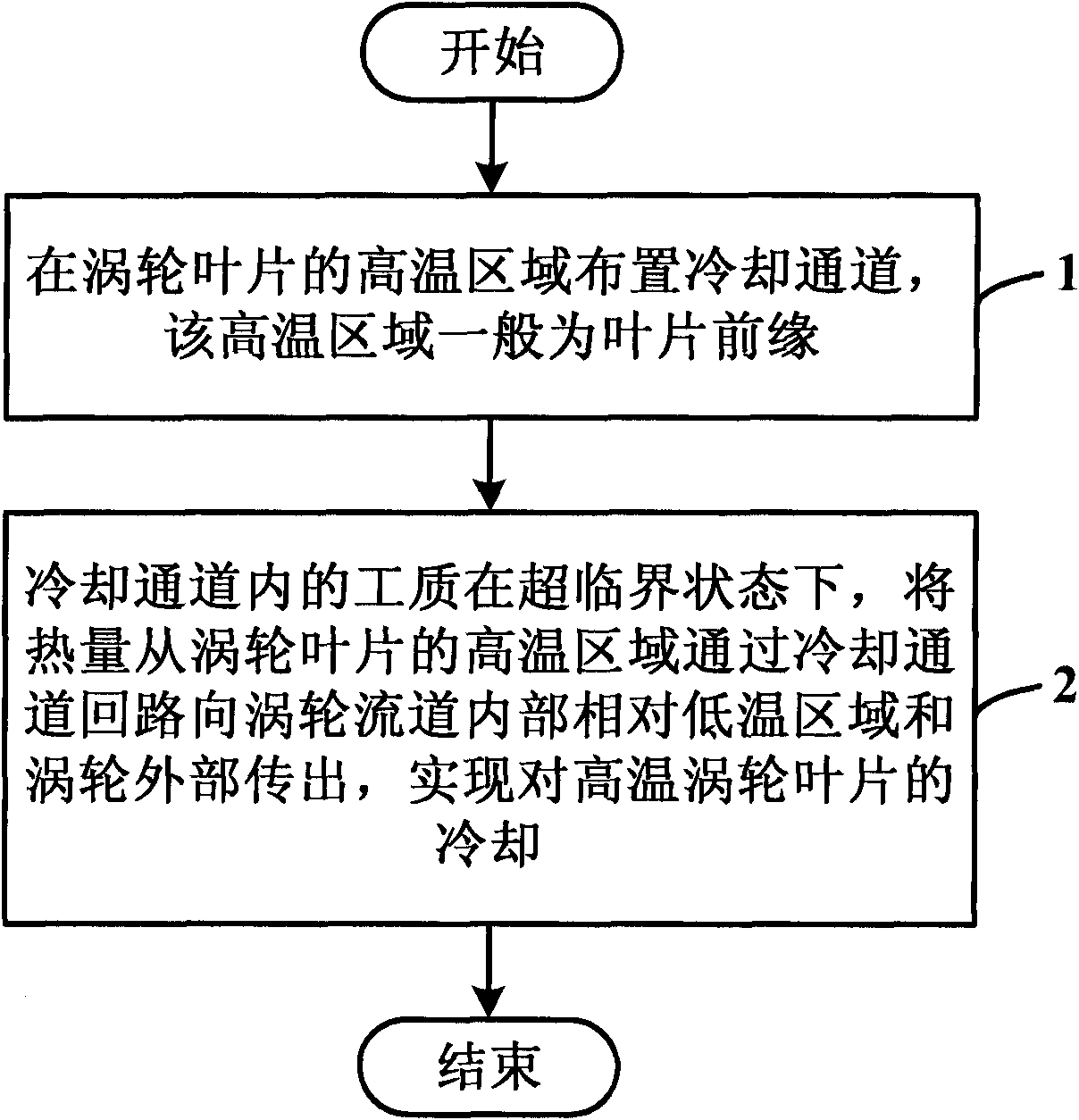

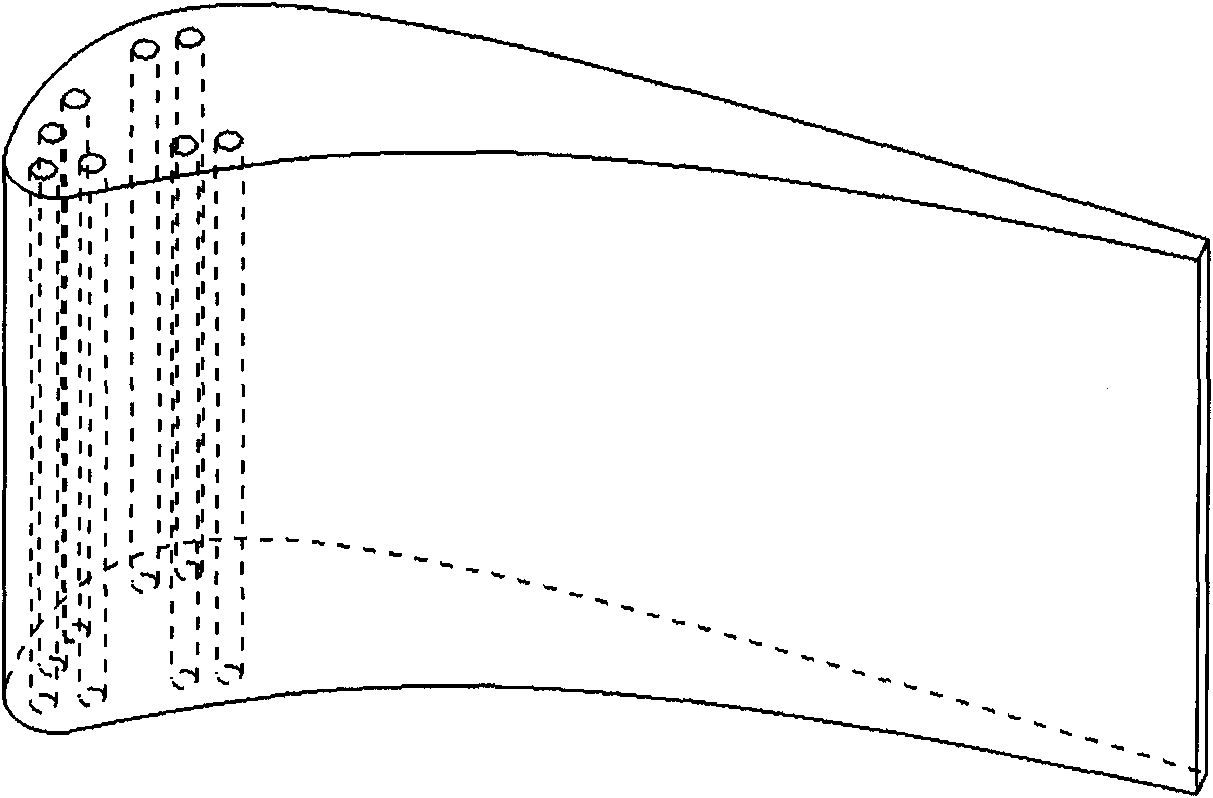

Method for cooling high-temperature turbine blade by utilizing supercritical characteristics of working medium

InactiveCN102146810AImprove cooling effectImprove reliabilityBlade accessoriesMachines/enginesTurbine bladeFront edge

The invention discloses a method for cooling a high-temperature turbine blade by utilizing the characteristics of a working medium under the supercritical state. The method comprises the following steps: step 1, arranging a cooling channel in a high-temperature area of the turbine blade, wherein the high-temperature area generally is the front edge of the blade; step 2, enabling the working medium in the cooling channel to efficiently and quickly transmit heat from the high-temperature area of the turbine blade to a relatively-low temperature area inside a flow channel of a turbine and the outside of the turbine through a cooling channel loop under the supercritical state, thereby providing a novel method for cooling an aircraft engine, a ground gas turbine, a missile engine and other high-temperature turbine blades.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

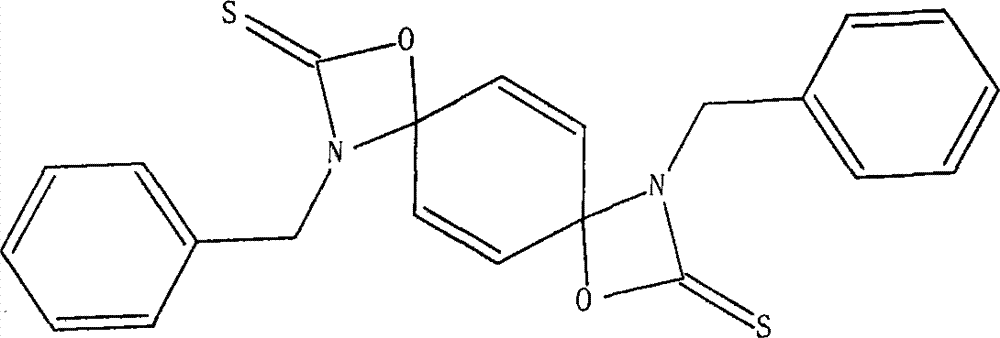

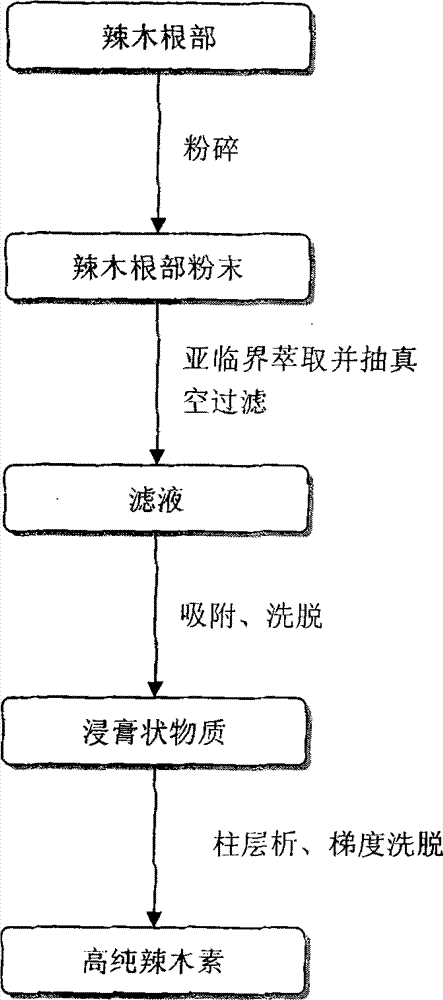

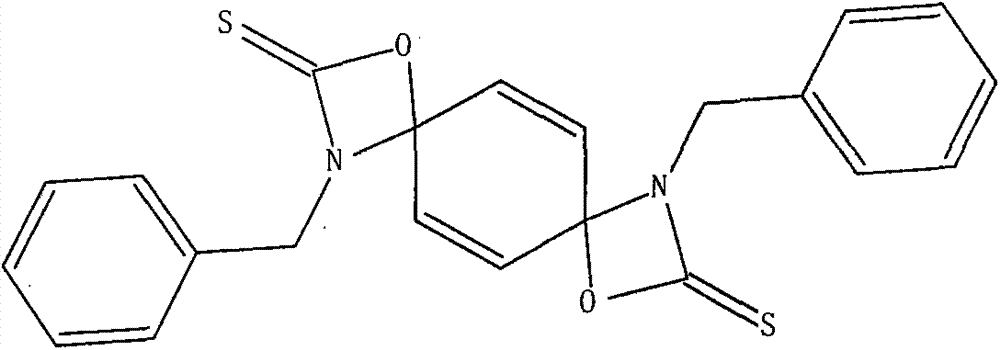

Method for extracting pterigospermin from moringa root

The invention discloses a method for extracting pterigospermin from moringa and belongs to the technical field of natural product extraction. The pterigospermin extraction technology comprises the following steps: step 1, crushing the moringa root; step 2, extracting the moringa root by the subcritical extraction method; step 3, adsorbing the pterigospermin by an adsorbent; step 4, eluting the adsorbent by an elution agent; step 5, removing the elution agent in vacuum; step 6, performing chromatography by a silica-gel column; step 7, eluting by an elution liquid; step 8, re-crystallizing by methanol; and step 9, obtaining the product. The pterigospermin prepared by the invention is high in purity, good in effect, and economical in energy and is applicable to large-scale industrial production.

Owner:刘福利

Method for combined production of high purity crystalline calcium acetate and waterless calcium acetate

InactiveCN105566098AReduce the amount of introductionEfficient removalCarboxylic acid salt preparationThermal insulationSpecific gravity

The invention relates to a method for combined production of high purity crystalline calcium acetate and waterless calcium acetate. The method comprises 1, weighing heavy calcium carbonate, adding acetic acid into the heavy calcium carbonate, heating and dissolving the mixture until CO2 is not escaped, and keeping a temperature of 80 DEG C for 20min, 2, adding a mixed impurity removal agent into the solution according to a ratio of 1: 2-3, controlling pH in a range of 11-12 and carrying out thermal insulation and sedimentation for 1-2h so that the impurities are precipitated in a form of hydroxides, 3, filtering the precipitates, collecting the filtrate, concentrating the filtrate at a temperature of 80-100 DEG C until a concentrating proportion of 1.18-1.30g / cm<3>, carrying out cooling to a temperature of 60 DEG C, filtering the precipitates to obtain a crystalline calcium acetate monohydrate and carrying out drying at a temperature of 60-70 DEG C, and 4, collecting the filtrate, carrying out concentration until the solution is in a viscous solid form so that waterless calcium acetate is obtained, and carrying out drying at a temperature of 90 DEG C. Through use of the mixed impurity removal agent, impurity removal is thorough and all calcium acetate can be produced. The method improves a yield, realizes zero discharge and realizes eco-friendly production.

Owner:TIANJIN GUANGFU TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com