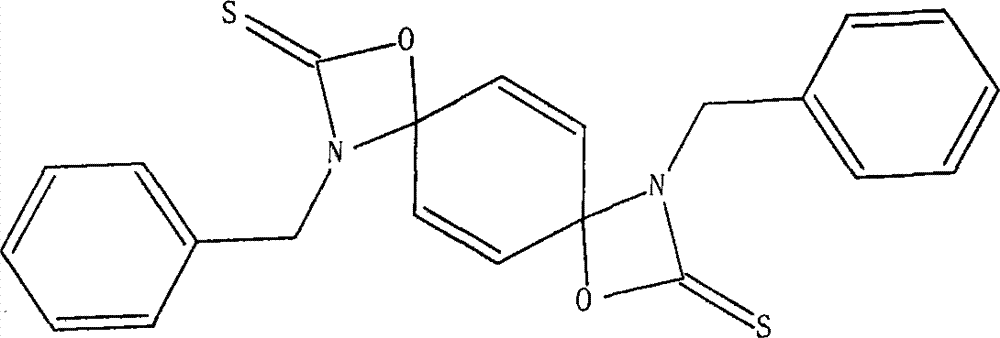

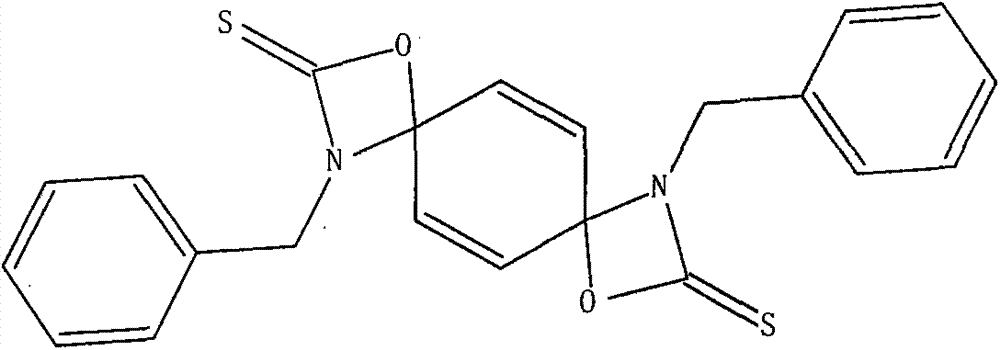

Method for extracting pterigospermin from moringa root

A technology of moringa and its roots, which is applied in the field of separation and purification of natural products, can solve the problems that do not involve the extraction of moringa bioactive substances, and achieve the effects of lowering temperature, improving utilization rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

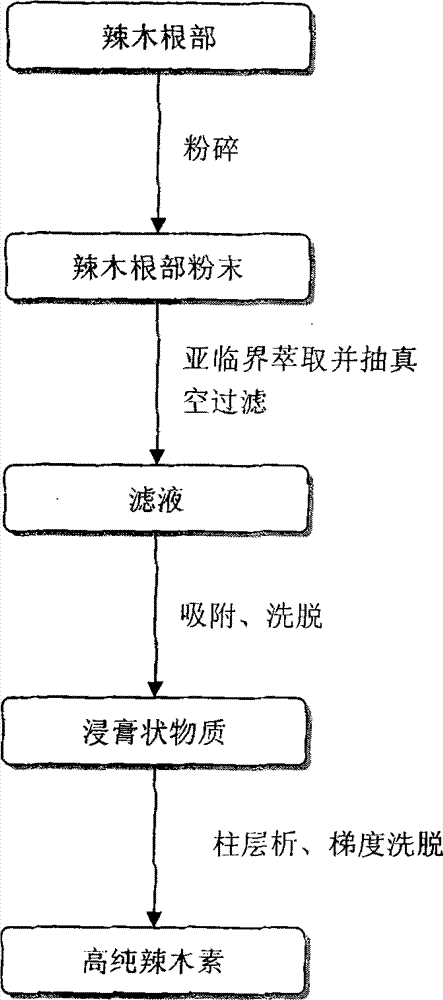

Method used

Image

Examples

Embodiment 1

[0030] Take 150g of Moringa oleifera root powder and place it in an extractor, add 750ml of alcohol to raise the temperature to 50°C and keep it at a constant temperature, and extract with intermittent stirring for 3h. After extraction, filter out the extract, add 750ml of new alcohol to the material, and continue to keep stirring at 50°C for 3 hours. Filter and collect the filtrate. Take again 20g of bamboo-based activated carbon and place it in a beaker, add 100ml of filtrate and stir to make it adsorb, then add 150ml of sherwood oil to elute the activated carbon, obtain 10.95mg of product after methanol recrystallization, and the content is 84.2%.

Embodiment 2

[0032] Get Moringa oleifera root powder 150g, put into filter basket, drop into subcritical extraction kettle, add volume fraction and be 750ml of ethanol of 75%, adjust vacuum degree to be 0.08Mpa, be warming up to 100 ℃, extract twice, each time is 3h, Each time the obtained extract is put into a solvent recovery kettle, and the solvent is recovered under reduced pressure to obtain a black-green leachate. Take again 20g of bamboo-based activated carbon and place it in a beaker, add 100ml of filtrate and stir to make it adsorb, then add 150ml of sherwood oil to elute the activated carbon, obtain product 11.53mg after recrystallization with methanol, and the content is 91.5%.

Embodiment 3

[0034] Get Moringa oleifera root powder 150g, put into filter basket, drop into subcritical extraction kettle, add volume fraction and be 750ml of ethanol of 75%, adjust vacuum degree to be 0.08Mpa, be warming up to 100 ℃, extract twice, each time is 3h, Each time the obtained extract is put into a solvent recovery kettle, and the solvent is recovered under reduced pressure to obtain a black-green leachate. Then take by weighing 20g of bamboo-based activated carbon and place it in a beaker, add 100ml of filtrate and stir to make it adsorb, then add 150ml of sherwood oil to elute the activated carbon to obtain an extract-like substance. Take an appropriate amount of the extract and put it on a silica gel column with a column volume of 1.5L and a diameter-to-height ratio of 1:9, and use dichloromethane-ethanol for gradient elution from small to large polarity, and obtain when the dichloromethane-methanol volume ratio is appropriate. Off-white solid, recrystallized twice with met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com