Preparation method of high-purity tungsten powder

A high-purity, tungsten powder technology, applied in the field of preparation of high-purity tungsten powder, can solve the problems of small reduction furnace, high cost and long process of quartz furnace tube, so as to save the calcination step, increase the output and reduce the introduction volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

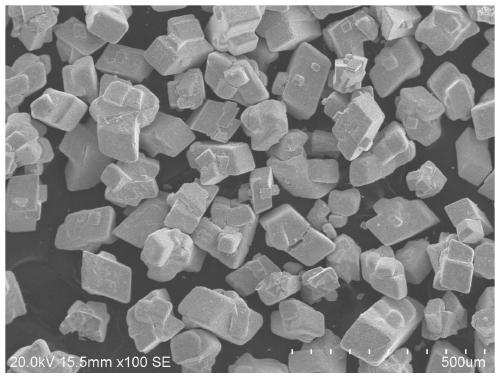

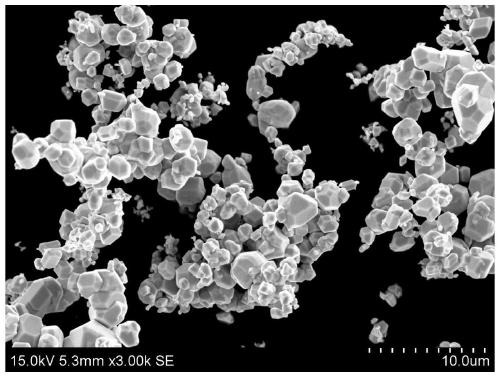

Image

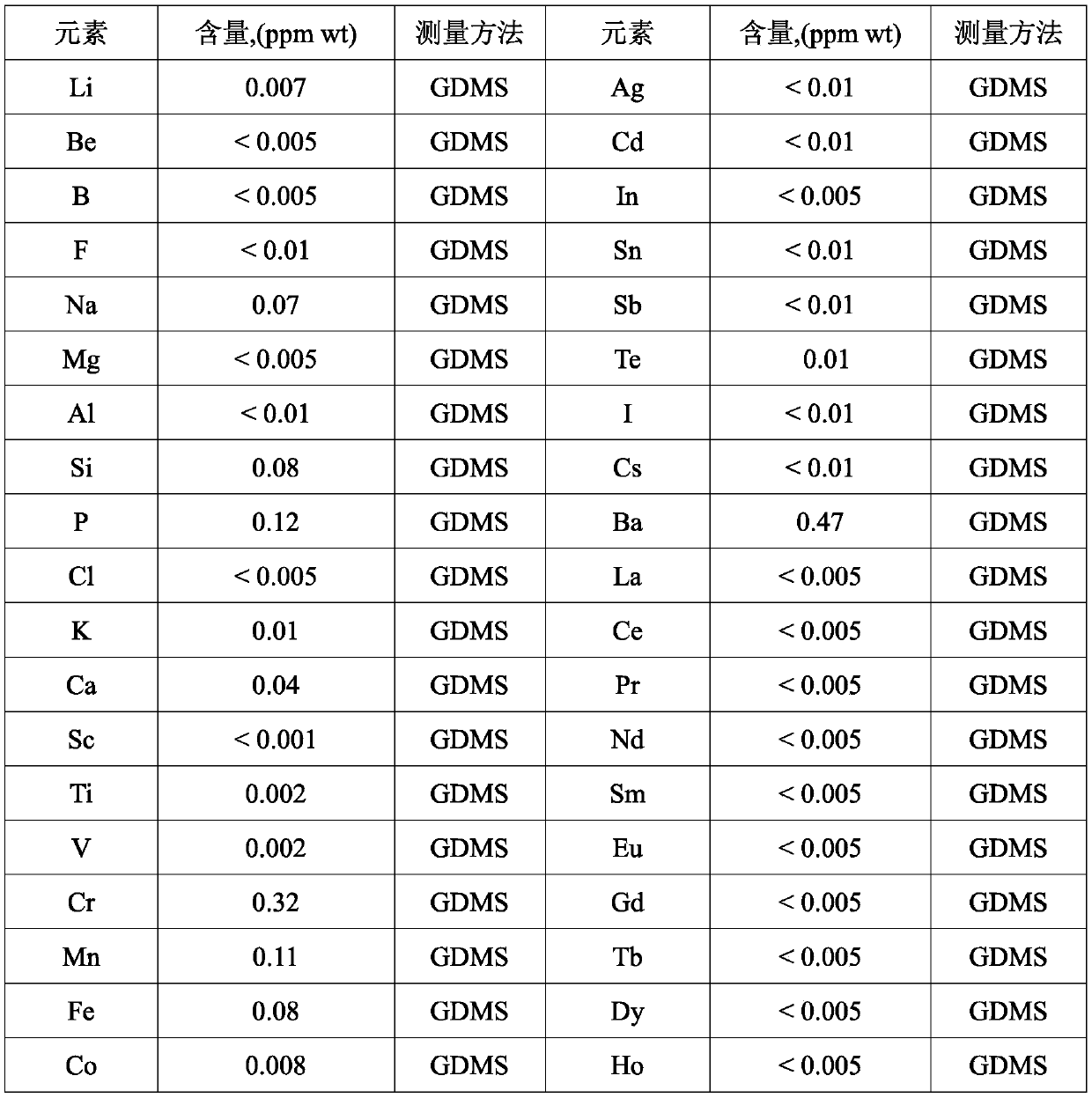

Examples

Embodiment 1

[0032] A preparation method of high-purity tungsten powder, comprising the steps of:

[0033] (1) Dissolving 1000kg of commercial grade 0 ammonium paratungstate ammonium paratungstate at 70-90°C in a 10wt% ammonia solution (the dissolution time is 4-8h, and the dissolved tungstic acid concentration is 300g / L), and Filter to remove the alkaline insoluble residues of iron, calcium and other elements to obtain ammonium tungstate solution with pH=9-11;

[0034] (2) Evaporate and crystallize the ammonium tungstate solution obtained in step (1) in the reaction kettle under the conditions that the internal pressure is lower than one atmospheric pressure, pH=7-8 and temperature is 95-105°C, and the tungsten in the mother liquor to be crystallized When the acid concentration reached 20g / L, the crystallization was stopped, and the crystallization rate at this moment reached 92%, and the material containing the mother liquor of crystallization was obtained;

[0035] (3) Filter the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com