Method for complexing hydrothermal synthesis of uniform flower-like MoS2 nanospheres

A hydrothermal synthesis, nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of small specific surface, low activity, large, mostly at the micron level, etc., to reduce The effect of agglomeration, high reactivity and many active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

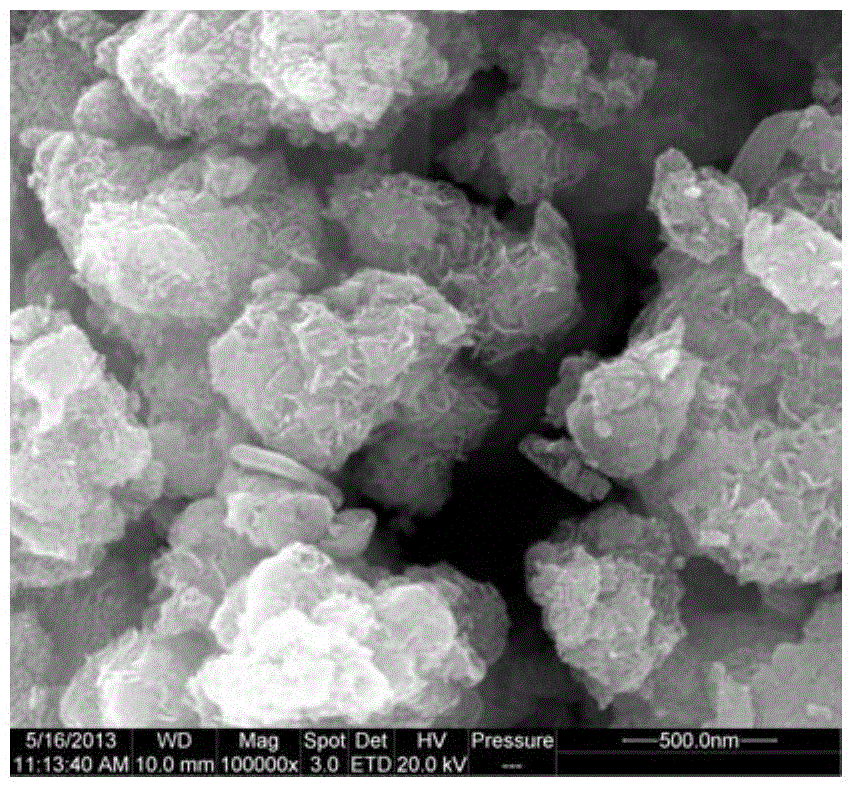

[0026] Dissolve 5mmol of sodium molybdate in 50ml of deionized water to form a 0.1M solution, add 20mmol of potassium sulfide, and stir evenly. Then 12 mmol of oxalic acid was added. After fully stirring, transfer the solution to a 100ml hydrothermal kettle, react at 120°C for 24 hours, naturally cool to room temperature, filter with suction, wash the precipitate with deionized water and absolute ethanol, dry it under vacuum at 70°C overnight, and collect MoS 2 sample. The samples were characterized by SEM, and the SEM results showed that the obtained product was nano-curds with a particle size of about 200nm, and the curds were formed by a large number of lamellar structures with good dispersion.

Embodiment 2

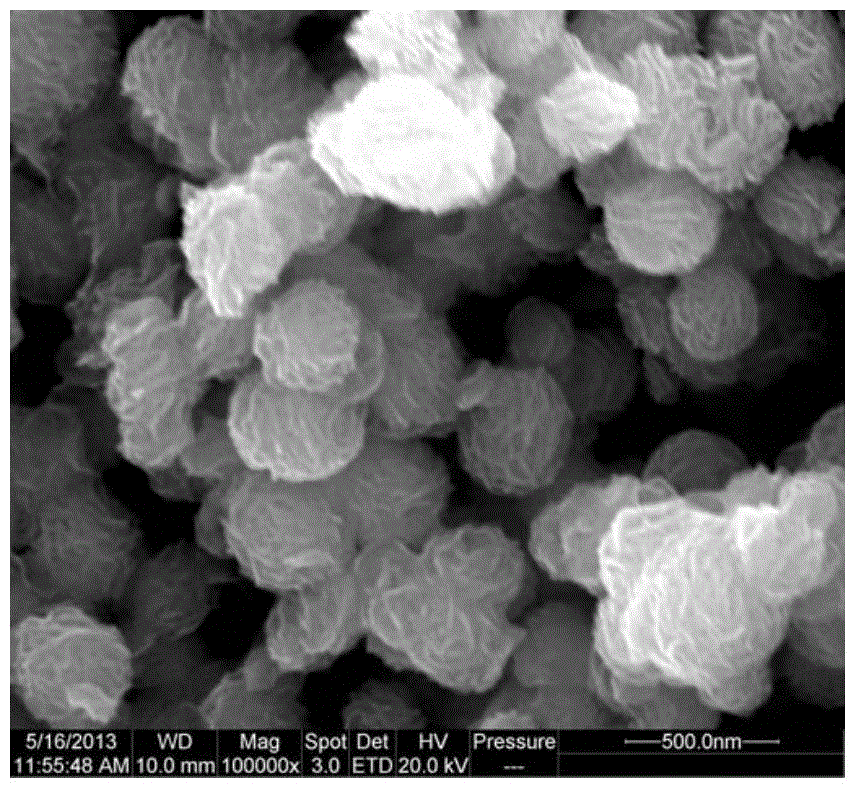

[0028] Dissolve 3.5mmol of sodium molybdate in 50ml of deionized water to form a 0.07M solution, add 12mmol of ammonium sulfide, and stir evenly. Then 8.3 mmol of oxalic acid was added. After fully stirring, transfer the solution to a 100ml hydrothermal kettle, react at 140°C for 36 hours, naturally cool to room temperature, filter with suction, wash the precipitate with deionized water and absolute ethanol, dry it under vacuum at 70°C overnight, and collect MoS 2 sample. The samples were characterized by SEM, and the SEM results showed that the obtained product was nano-curds with a particle size of about 300nm, and the curds were formed by lamellar structures with good dispersion.

Embodiment 3

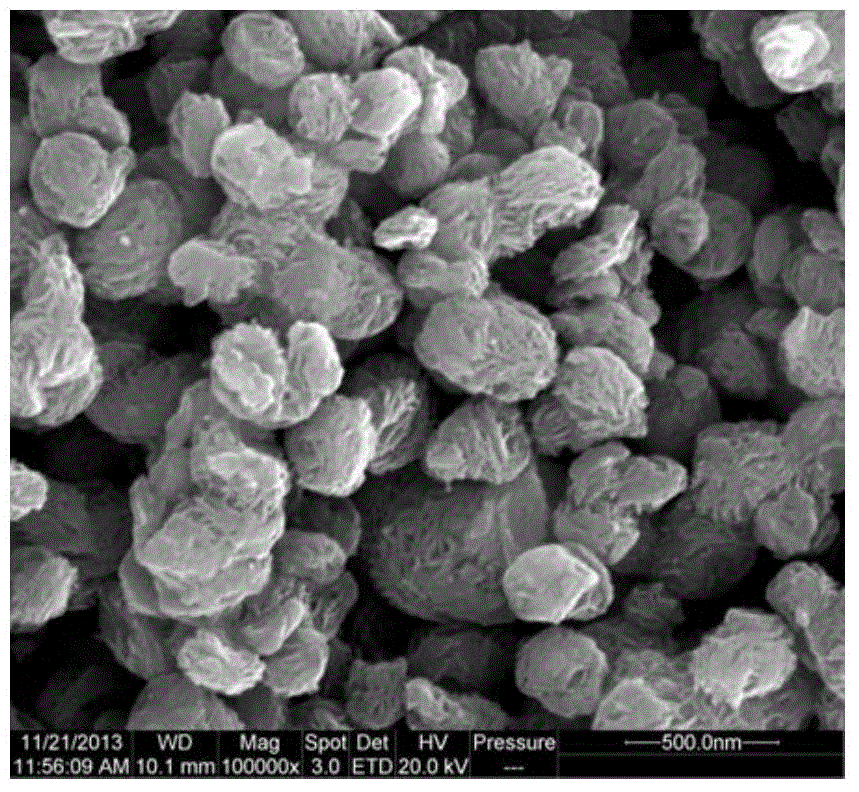

[0030] Dissolve 2.5mmol of ammonium molybdate in 50ml of deionized water to form a 0.05M solution, add 10mmol of ammonium sulfide, and stir evenly. Then 7.5 mmol of oxalic acid was added. After fully stirring, transfer the solution to a 100ml hydrothermal kettle, react at 160°C for 48 hours, naturally cool to room temperature, filter with suction, wash the precipitate with deionized water and absolute ethanol, dry it under vacuum at 70°C overnight, and collect MoS 2 sample. The samples were characterized by SEM, and the SEM results showed that the obtained product was nano-curds with a particle size of about 200-300nm, and the curds were formed by stacking lamellar structures with good dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com