Low-temperature copper-based brazing filler metal for high-temperature resistance clean steel and preparation method thereof

A copper-based brazing filler metal and clean steel technology, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems that cannot meet the requirements of clean steel brazing, the influence of the base metal structure, and the high impurity content, and the cost is low. , Excellent brazing performance and the effect of reducing the introduction of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

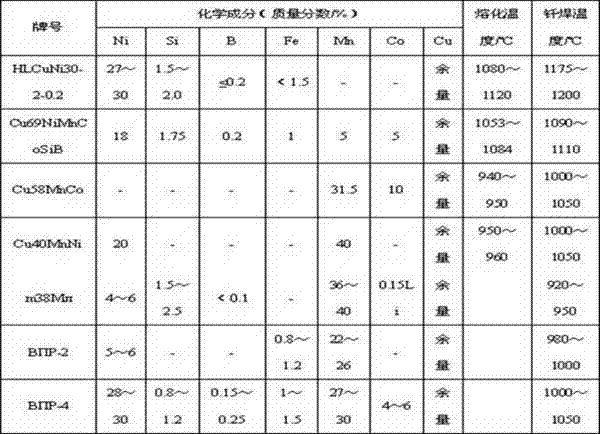

Image

Examples

Embodiment 1

[0020] a, by weight percentage: Cu84.68%, Ni4%, Mn10%, Zr0.2%, Hf0.2%, B0.02%, Ti0.1%, Ge0.8%;

[0021] b. The high melting point elements Ni, Zr, Hf are smelted with copper respectively to form master alloys A1, A2, A3; the master alloy A1 is composed of Cu:Ni=90:30 in weight ratio; the master alloy A2 is composed of Composition of Cu:Zr=91:9 in weight ratio; the master alloy A3 is composed of Cu:Hf=90:20 in weight ratio;

[0022] c, smelting easily oxidizable elements boron B, Ti, Ge and copper in a vacuum furnace respectively to form master alloys B1, B2, B3; said master alloy B1 is made up of Ni:B=86:14 in weight ratio; said The master alloy B2 is composed of Cu:Ti=80:20 in weight ratio; the master alloy B3 is composed of Cu:Ge=88:12 in weight ratio;

[0023] d. Put the remaining amount of copper and master alloy A1 in an induction furnace protected by argon gas, raise the temperature to 500-600°C at a speed of 30°C / min, and then raise the temperature to 1100-1300°C at a ...

Embodiment 2

[0026] a, by weight percentage: Cu52.25%, Ni10%, Mn30%, Zr1.8%, Hf3.5%, B0.2%, Ti0.25%, Ge2.0%;

[0027] b. The high melting point elements Ni, Zr, Hf are smelted with copper respectively to form master alloys A1, A2, A3; the master alloy A1 is composed of Cu:Ni=90:30 in weight ratio; the master alloy A2 is composed of Composition of Cu:Zr=91:9 in weight ratio; the master alloy A3 is composed of Cu:Hf=90:20 in weight ratio;

[0028] c, smelting easily oxidizable elements boron B, Ti, Ge and copper in a vacuum furnace respectively to form master alloys B1, B2, B3; said master alloy B1 is made up of Ni:B=86:14 in weight ratio; said The master alloy B2 is composed of Cu:Ti=80:20 in weight ratio; the master alloy B3 is composed of Cu:Ge=88:12 in weight ratio;

[0029] d. Put the remaining amount of copper and master alloy A1 in an induction furnace protected by argon gas, raise the temperature to 500-600°C at a speed of 30°C / min, and then raise the temperature to 1100-1300°C at a...

Embodiment 3

[0032] a, by weight percentage: Cu72.48, Ni5%, Mn20%, Zr0.5%, Hf 0.2%, W0.2%, Co0.5%, Ti 0.2%, B0.02%, Ge0.8%, Li0.1%;

[0033] b. The high melting point elements Ni, Zr, Hf, W, Co are smelted with copper respectively to form master alloys A1, A2, A3, A4, A5; the master alloy A1 is composed of Cu:Ni=90:30 by weight ; The master alloy A2 is composed of Cu:Zr=91:9 in weight ratio; the master alloy A3 is composed of Cu:Hf=90:20 in weight ratio; the master alloy A4 is composed of Cu in weight ratio : W=98:2 composition; the master alloy A5 is composed of Cu:Co=95:5 in weight ratio;

[0034] b. The easily oxidizable elements boron B, Ti, Ge, Li are smelted with copper in a vacuum furnace respectively to form master alloys B1, B2, B3, B4; the master alloy B1 is composed of Ni:B=86:14 in weight ratio Composition; the master alloy B2 is composed of Cu:Ti=80:20 by weight ratio; the master alloy B3 is composed of Cu:Ge=88:12 by weight ratio; the master alloy B4 is composed of Cu:Ge=88...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com