Preparation method of high-silica-alumina-ratio Y-type molecular sieve

A high silicon-aluminum ratio, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

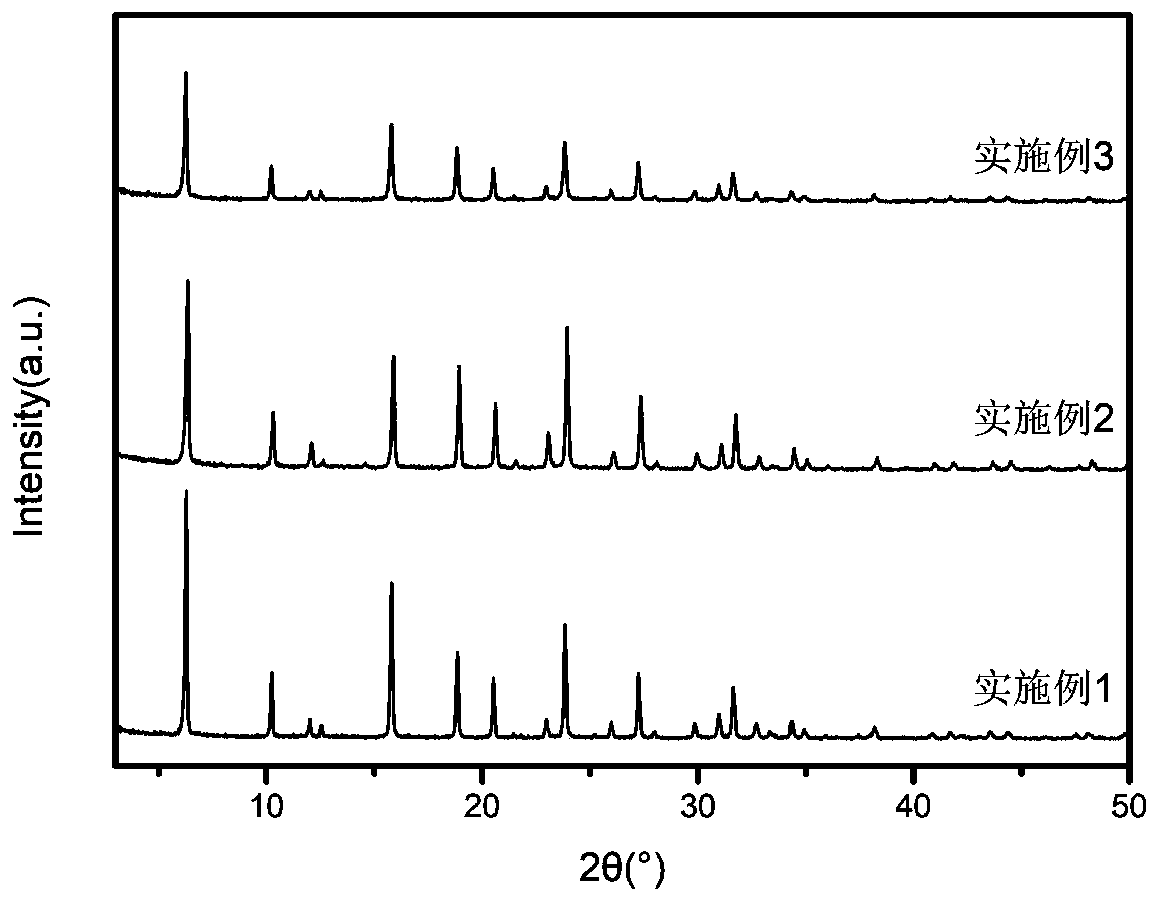

Embodiment 1

[0049] Take 6.495g of tetrabutylammonium hydroxide and 0.014g of tetramethylammonium hydroxide, add 31.542g of deionized water, mix well to obtain a dual template solution, wherein the mass percentage of tetrabutylammonium hydroxide is 17.07%, tetramethyl The mass percentage concentration of ammonium hydroxide is 0.037%. Add 0.425g of sodium metaaluminate and 0.776g of sodium hydroxide to the dual template agent solution for stirring and dissolving to obtain the first mixed solution. Add 7.510g of silica sol to the first mixed solution at a dropping rate of 1 drop / s ( Content 40.0wt.%), stir evenly, add 0.07g Tosoh Y molecular sieve (SiO 2 / Al 2 O 3 =115) As a seed crystal, a second mixed solution is obtained.

[0050] The second mixed solution was stirred at 25°C for 15h for aging treatment. After the aging treatment was completed, the aging treatment solution was transferred to the reactor, and the reactor was placed in an oven for static crystallization at 100°C for 8d. After...

Embodiment 2

[0052] Take 8.145g of tetrapropylammonium hydroxide and 0.685g of tetramethylammonium hydroxide, add 27.036g of deionized water, and mix evenly to obtain a dual template solution, wherein the mass percentage concentration of tetrapropylammonium hydroxide is 22.71% , The mass percentage concentration of tetramethylammonium hydroxide is 1.91%. Add 1.168 g of aluminum sulfate and 0.991 g of potassium hydroxide to the dual template agent solution for stirring and dissolving to obtain the first mixed solution. Add 3.004 g of fumed silica to the first mixed solution, stir well, and finally add 0.042 g of Tosoh Y molecular sieve (SiO 2 / Al 2 O 3 =115) As a seed crystal, a second mixed solution is obtained.

[0053] The second mixed solution was stirred for 8 hours at 25°C for aging treatment. After the aging treatment was completed, the aging treatment solution was transferred to the reactor, and the reactor was placed in an oven for static crystallization at 120°C for 10 days. After t...

Embodiment 3

[0055] Take 2.034 g of tetrapropyl ammonium hydroxide and 0.237 tetramethyl ammonium hydroxide, add 14.400 g of deionized water, mix well to obtain a dual template solution, wherein the mass percentage concentration of tetrapropyl ammonium hydroxide is 12.20%, The mass percentage concentration of tetramethylammonium hydroxide is 1.42%. 0.340g of sodium metaaluminate and 0.460g of sodium hydroxide were added to the dual template agent solution for stirring and dissolving to obtain the first mixed solution, and 3.000g of silica sol was added dropwise to the first mixed solution at a dropping rate of 1 drop / s ( Content 40.0wt.%), stir evenly, add 0.070g Tosoh Y molecular sieve (SiO 2 / Al 2 O 3 =115) As a seed crystal, a second mixed solution is obtained.

[0056] The second mixed solution was stirred at 25°C for 24h for aging treatment. After the aging treatment was completed, the aging treatment solution was transferred to the reactor, and the reactor was placed in an oven for stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com