Y-type zeolite with intracrystalline hierarchical pores and preparation method and application thereof

A multi-level pore and zeolite technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, chemical instruments and methods, etc., can solve hydrothermal stability and weak acidity, mesopore and macropore volume Not rich enough, not widely used in the oil refining industry, etc., to achieve the effect of high silicon-aluminum ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

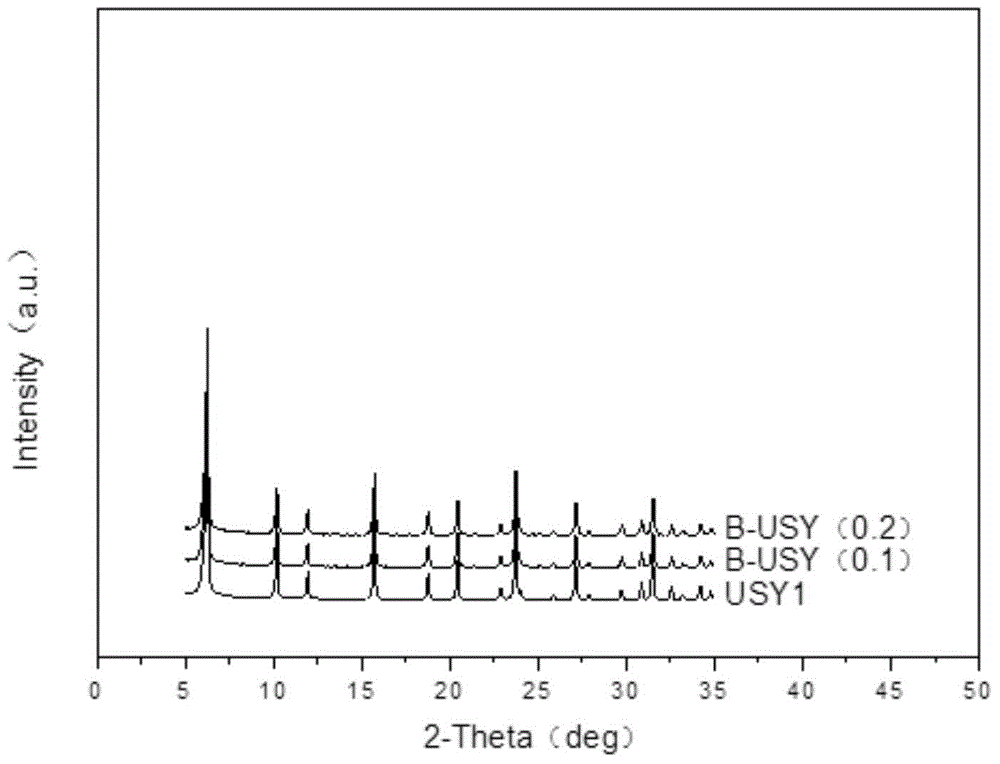

Embodiment 1

[0041] This embodiment provides a Y-type zeolite with intracrystalline hierarchical pores, which is prepared by the following preparation method:

[0042] Ammonium exchange process: the ratio of boron to aluminum (in B 2 o 3 , Al 2 o 3 The molar ratio of the B-NaY zeolite is 0.1 and 0.2 respectively, and then the B-NaY zeolite, ammonium salt and water with a mass ratio of 1:0.5:5 are mixed evenly to obtain a mixture, and the mixture is continuously stirred, and the concentration is 0.5mol / L hydrochloric acid solution to adjust the pH of the mixture to 2.3, raise the temperature to 30°C, stir for 1 hour while maintaining the constant pH value, filter, wash with deionized water until neutral, and dry at 120°C to obtain the ammonium form Y zeolite containing boron;

[0043] Hydrothermal treatment process: Put the obtained ammonium-type boron-containing Y zeolite into a hydrothermal device, heat up to 500°C, and pass 40% steam for 3 hours;

[0044] The above-mentioned ammoni...

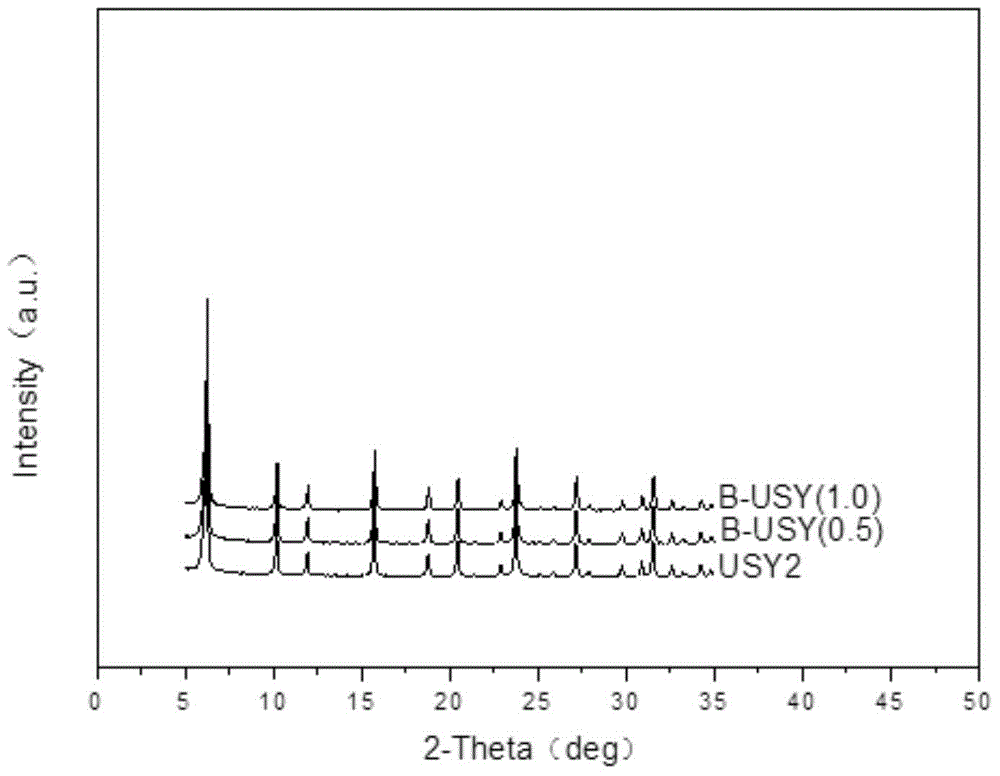

Embodiment 2

[0055] This embodiment provides a Y-type zeolite with intracrystalline hierarchical pores, which is prepared by the following preparation method:

[0056] Ammonium exchange process: the ratio of boron to aluminum (in B 2 o 3 , Al 2 o 3 The molar ratio of boron-containing NaY zeolite) is 0.5 and 1 respectively, and then B-NaY zeolite, ammonium salt and water with a mass ratio of 1:1:10 are mixed evenly to obtain a mixture, and the mixture is continuously stirred, and the concentration is 0.5 mol / L hydrochloric acid solution to adjust the pH of the mixture to 3.3, raise the temperature to 50°C, stir for 1.5h while maintaining a constant pH value, filter, wash with deionized water until neutral, and dry at 120°C to obtain Boron-containing Y zeolite in the ammonium form;

[0057] Hydrothermal treatment process: Put the obtained ammonium-type boron-containing Y zeolite into a hydrothermal device, heat up to 550°C, and pass 80% steam for 2 hours;

[0058] The above-mentioned am...

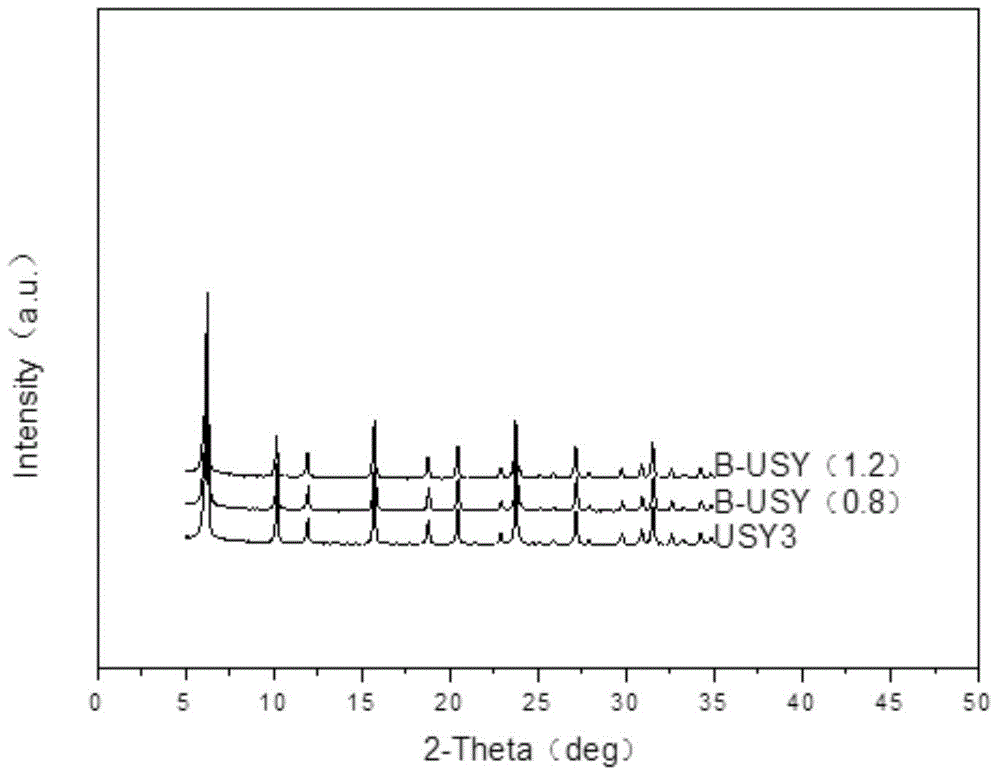

Embodiment 3

[0069] This embodiment provides a Y-type zeolite containing intracrystalline hierarchical pores, which is prepared by the following preparation method:

[0070] Ammonium exchange process: the ratio of boron to aluminum (in B 2 o 3 , Al 2 o 3 The molar ratio of boron-containing NaY zeolite) is 0.8 and 1.2 respectively, and then the B-NaY zeolite, ammonium salt and water with a mass ratio of 1:1.5:15 are mixed evenly to obtain a mixture, and the mixture is continuously stirred, and the concentration is 0.5 mol / L hydrochloric acid solution to adjust the pH of the mixture to 4.3, raise the temperature to 70°C, stir for 2 hours while maintaining a constant pH value, filter, wash with deionized water until neutral, and dry at 120°C to obtain Boron-containing Y zeolite in the ammonium form;

[0071] Hydrothermal treatment process: Put the obtained ammonium-type boron-containing Y zeolite into a hydrothermal device, heat up to 650°C, and pass 100% steam for 1 hour;

[0072] The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com