Preparation method of oxide dispersion strengthening steel spherical powder for 3D printing

A dispersion-strengthened, spherical powder technology, applied in the field of 3D printing, can solve the problems of nano-oxide particle growth, difficulty in large-scale production, and limited application, and achieve simple preparation process, low production cost, and less introduction of impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

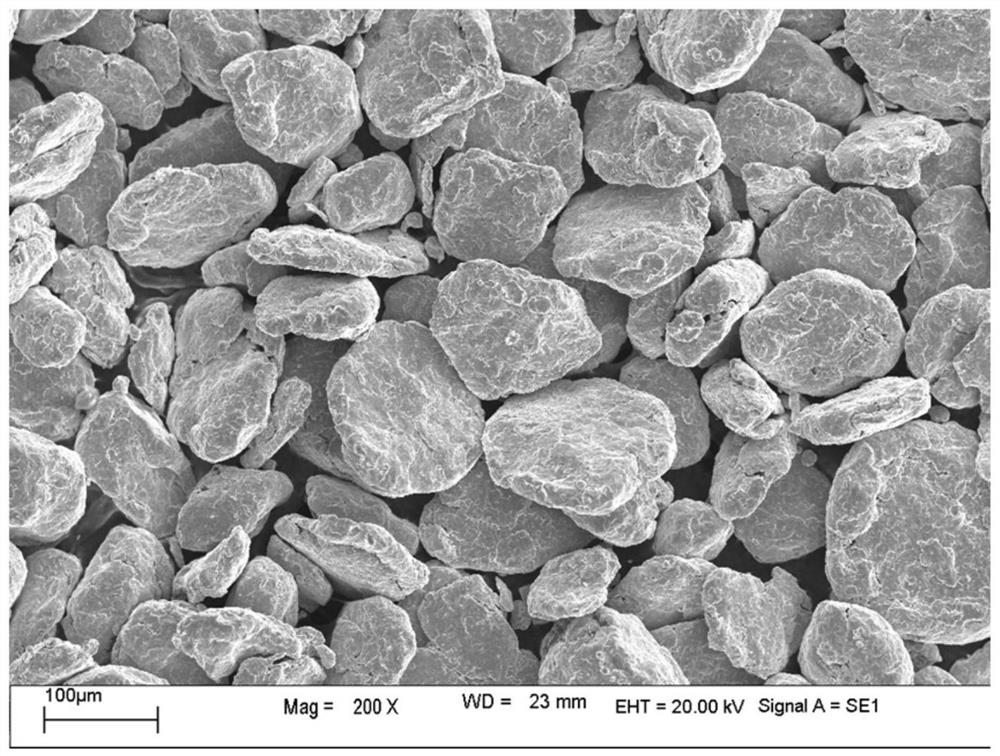

[0067] The oxide dispersion strengthened steel powder whose composition is Fe-16Cr-0.5Ti-0.5Y is selected as the raw material, which is obtained by high-energy ball milling according to the formula, and its SEM image is as follows figure 1 As shown, it can be found that the powder is irregular and flat, with extremely poor sphericity and fluidity, and cannot be directly 3D printed.

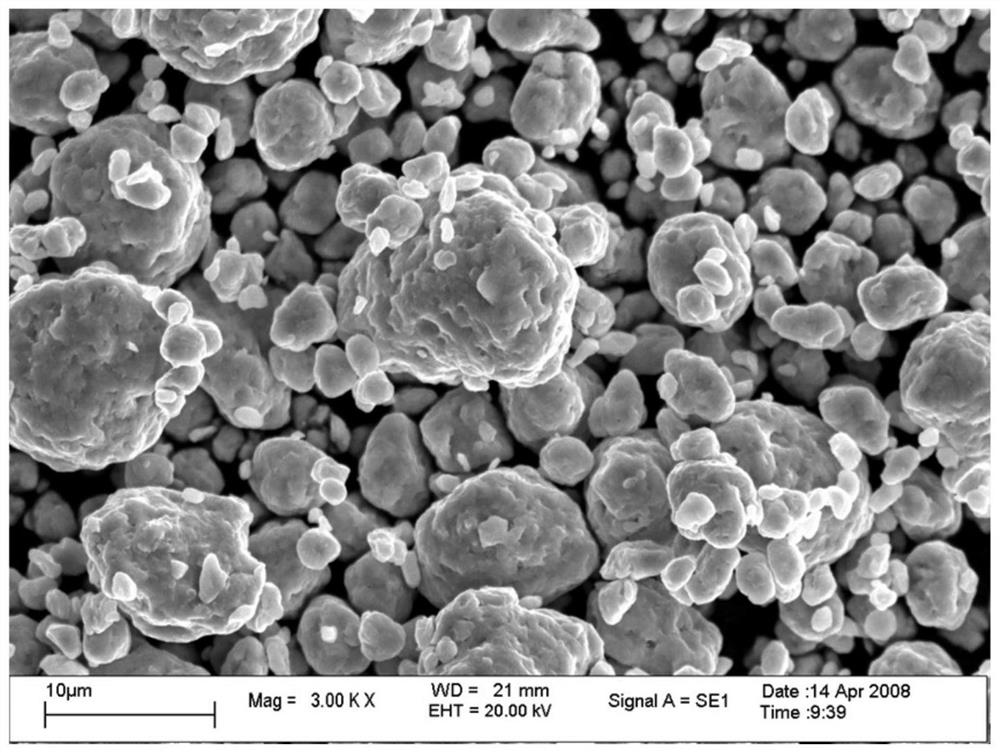

[0068] Weigh 100g of powder raw material and add it to the fluidized bed. Zirconia ceramic particles with a particle size range of 125-250μm are used as the auxiliary medium of the jet mill. Weigh 10g of the zirconia powder and add it to the fluidized bed, and pass through the argon gas to discharge the fluidized bed. Inner air, the gas velocity is 0.6m / min, and the time is 60min. Put the fluidized bed into the resistance furnace to ensure that the powder raw material flow area is located in the heating constant temperature area and the gas inlet / outlet is far away from the heating area. After 5 m...

Embodiment 2

[0072] The difference between Example 2 and Example 1 is that the composition of the oxide dispersion strengthened steel powder in Example 1 is changed from Fe-16Cr-0.5Ti-0.5Y ferrite to Fe-18Cr-8Ni- For 0.5Ti-0.5Y austenite, the jet milling time was reduced from 60min to 15min, the experimental temperature was increased from 600°C to 850°C, and other experimental conditions remained unchanged.

[0073] The powder sphericity measured by SEM is 76 (d1 / da), the fluidity measured by Hall flow meter is 19.8s / 50g, and the oxygen increment is 1800ppm. It shows that the change of the oxide dispersion strengthened steel powder matrix and composition will not significantly affect the feasibility of the method. Although reducing the jet milling time will shorten the spheroidization time of the powder, the increase in temperature can promote the metal powder. Softening effect, reducing hardness, thereby strengthening the effect of powder spheroidization treatment.

Embodiment 3

[0075] The difference between this Example 2 and Example 1 is that the jet mill auxiliary medium in Example 1 is changed from zirconia ceramic particles to tungsten carbide ceramic particles, and 100 g of oxide dispersion strengthened steel powder raw materials are weighed, and tungsten carbide ceramic particles are weighed. Since the particle is larger than the zirconia powder, 20g is weighed, and the oxide dispersion strengthened steel powder raw material and tungsten carbide ceramic particles are added to the fluidized bed at the same time.

[0076] The powder sphericity measured by SEM is 81 (d1 / da), the fluidity measured by Hall flow meter is 18.8s / 50g, and the oxygen increment is 400ppm. Since tungsten carbide has a higher hardness than zirconia, it has a better effect when assisting jet milling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com