Generative fuel produced by using industrial solid waste and preparation method thereof

A solid waste and renewable fuel technology, applied in the direction of solid fuel, waste fuel, fuel, etc., can solve the problems of general hazards of raw materials, not very prominent environmental protection benefits, etc., and achieve good flammability, easy molding and consolidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

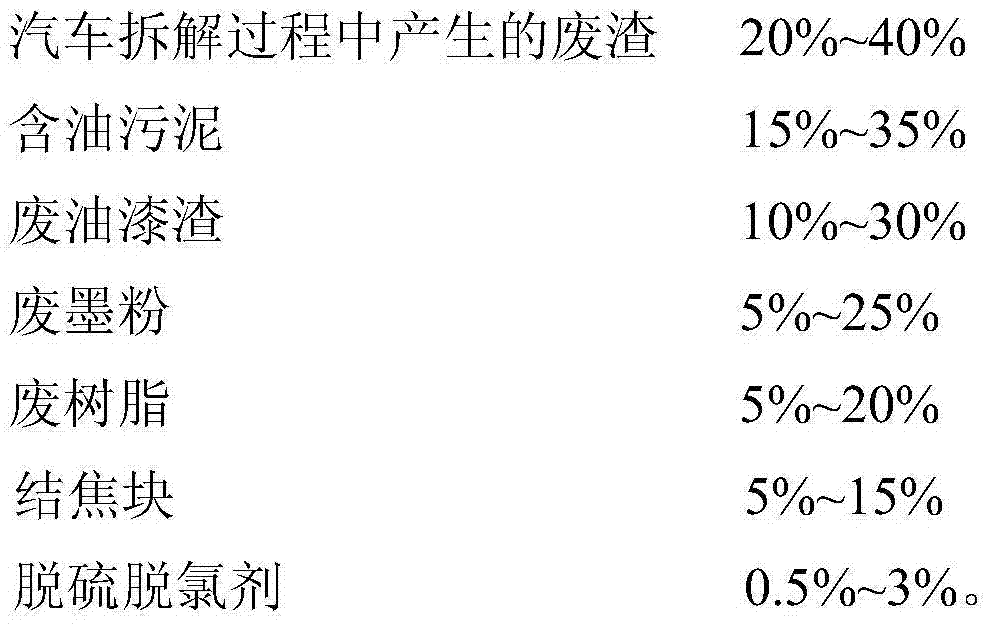

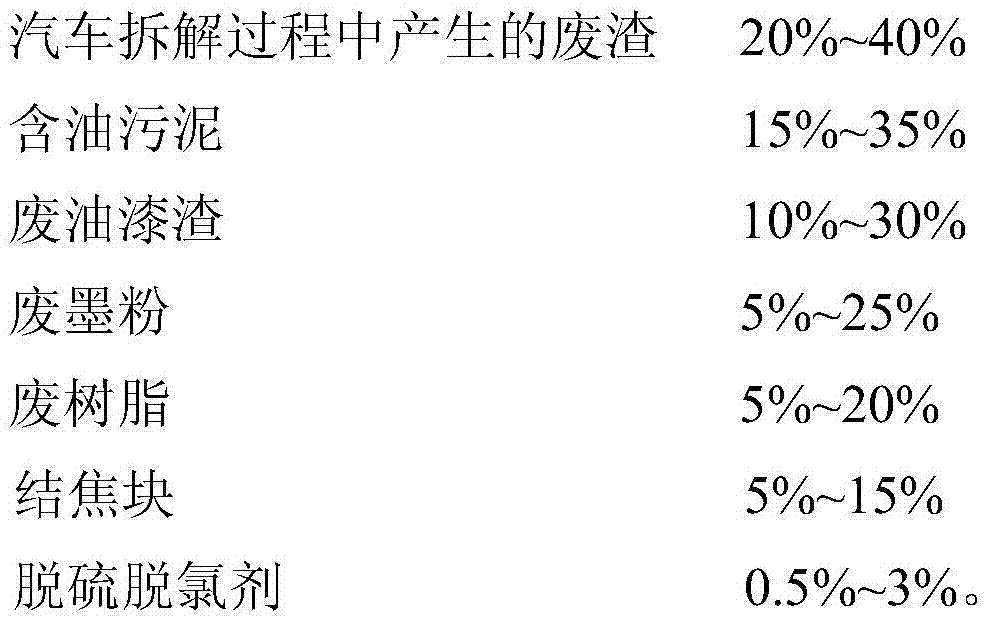

Method used

Image

Examples

Embodiment 1

[0025] The ratio of renewable fuel is 30% of waste residue generated during the dismantling process of automobiles, 20% of oily sludge, 20% of waste paint residue, 10% of waste toner, 10% of waste resin, 9% of coking blocks, and 1% of desulfurization and dechlorination agent CaO . After mixing the above, stir evenly, place in a fuel sphere forming machine for compression molding, dry and consolidate to a moisture content of 14%, and obtain fuel spheres.

[0026] The calorific value of the fuel bulb was measured to be 4306kcal / kg, the sulfur fixation rate was 71.6%, and the chlorine fixation rate was 71.2%.

Embodiment 2

[0028] The ratio of renewable fuel is 40% of waste residue generated during the dismantling of automobiles, 25% of oily sludge, 15% of waste paint residue, 5% of waste toner, 5% of waste resin, 9.5% of coke, and desulfurization and dechlorination agent CaO0. 5%. The treatment method was the same as in Example 1, and fuel spheres with a water content of 10% were obtained.

[0029] The calorific value of the fuel bulb is 4257kcal / kg, the sulfur fixation rate is 69.4%, and the chlorine fixation rate is 70.4%.

Embodiment 3

[0031] The proportion of renewable fuel is 20% of waste residue generated during the dismantling process of automobiles, 15% of oily sludge, 30% of waste paint residue, 15% of waste toner, 10% of waste resin, 7% of coking blocks, and 3% of desulfurization and dechlorination agent CaO . The treatment method was the same as in Example 1, and fuel spheres with a water content of 5% were obtained.

[0032] The calorific value of the fuel bulb is 4681kcal / kg, the sulfur fixation rate is 80.3%, and the chlorine fixation rate is 81.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com