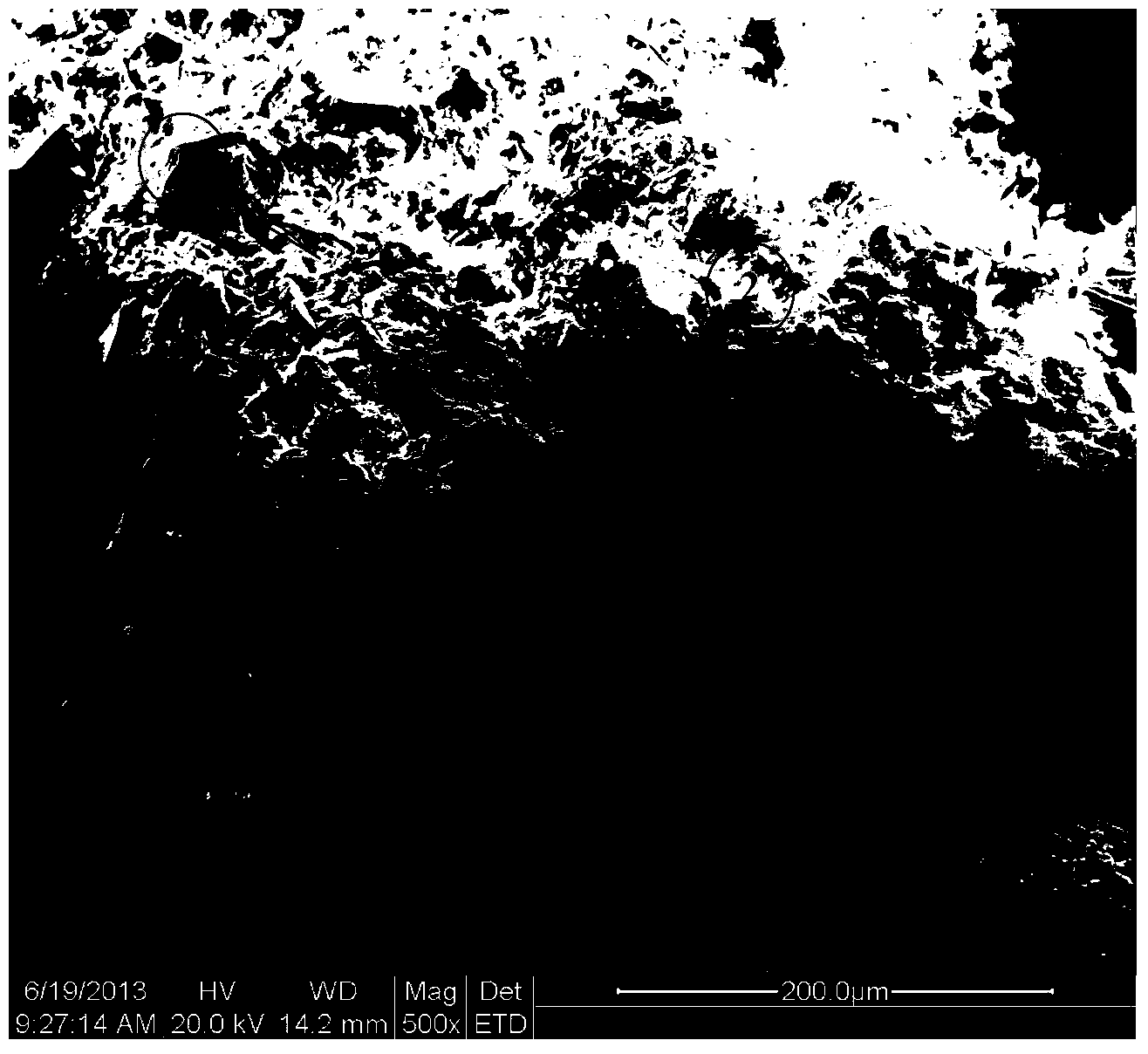

Magnesium phosphate cement recycled aggregate structure concrete and preparation method thereof

A technology of magnesium phosphate cement and recycled aggregate, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of low replacement rate of recycled aggregate, poor interface bonding performance, poor durability, etc. Achieve the effects of improving mechanical properties and durability, enhancing interfacial bonding performance, and stabilizing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

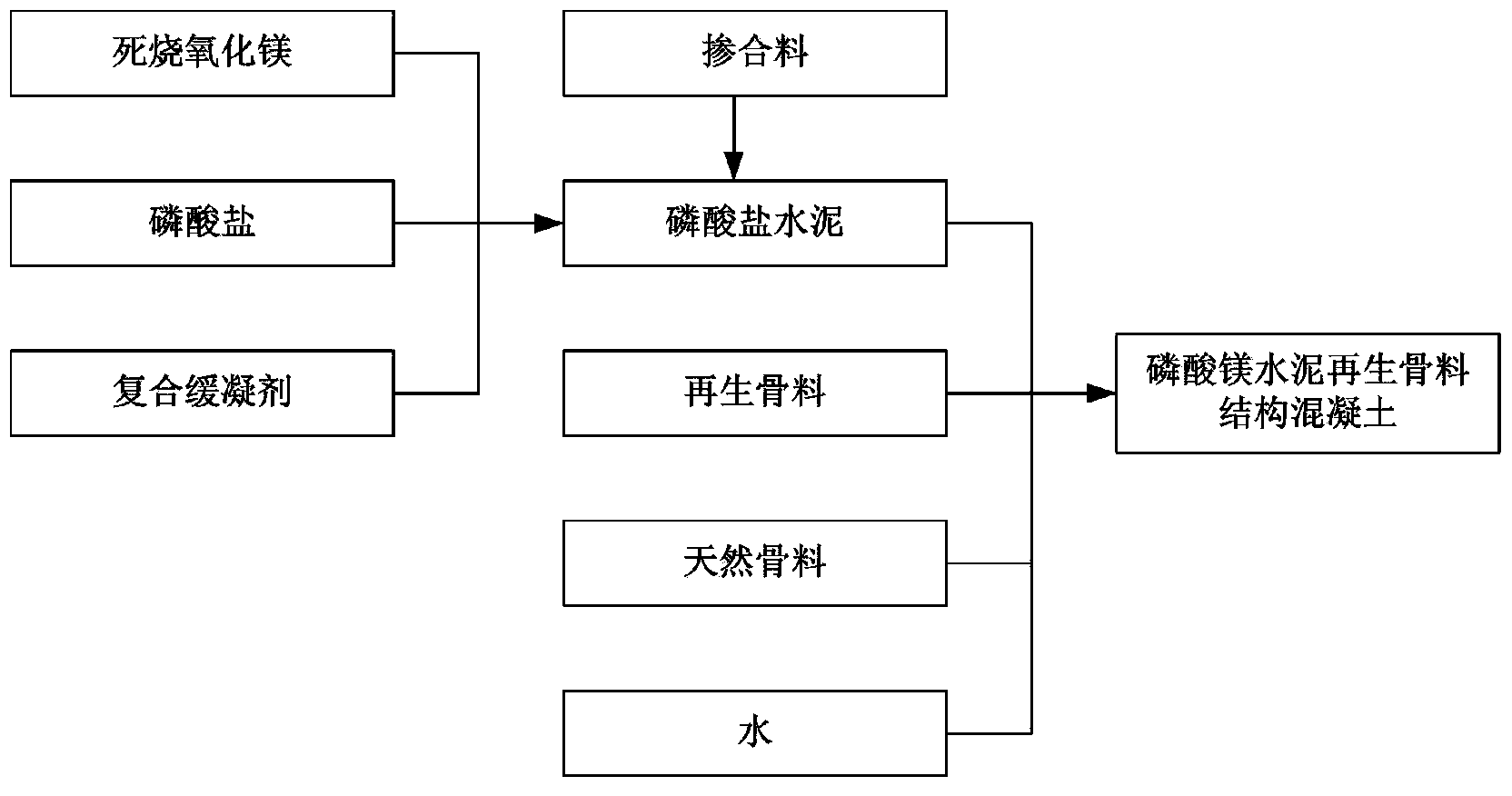

Method used

Image

Examples

Embodiment 1

[0030] The percentages by weight of the components of the magnesium phosphate cement recycled aggregate structure concrete in this example are: magnesium oxide 18.6%, potassium dihydrogen phosphate 5.4%, sodium dihydrogen phosphate 2.5%, composite retarder 2.4%, admixture pulverized coal Ash 2.8%, limestone powder 2.8%, recycled fine aggregate 13.3%, sand 13.3%, recycled coarse aggregate 15.1%, crushed stone 15.1%, water 7.9%; among them, the mass ratio of composite retarder is sodium tetraborate: 12 Disodium hydrogen phosphate hydrate: inorganic chloride salt = 2: 6: 3;

[0031] Mix magnesium oxide, phosphate, composite retarder, and admixture evenly according to the above ratio to obtain phosphate cement base material; wet the inner surface of the mixer, add regenerated coarse and fine aggregates and a part of water, and stir for 2-3 Minutes; After the recycled aggregate absorbs water, add the phosphate cement base material, natural aggregate and the rest of the water and st...

Embodiment 2

[0033] The percentage by weight of each component of the magnesium phosphate cement recycled aggregate structure concrete in this embodiment is: magnesia 18.5%, potassium dihydrogen phosphate 7.9%, composite retarder 2.4%, admixture fly ash 2.7%, limestone powder 2.7% %, recycled fine aggregate 21.3%, sand 5.3%, recycled coarse aggregate 24.2%, crushed stone 6.1%, water 8.9%; among them, the mass ratio of composite retarder is sodium tetraborate: sodium hydrogen phosphate dodecahydrate: inorganic Chlorine salt=2:6:3;

[0034] Mix magnesium oxide, phosphate, composite retarder, and admixture evenly according to the above ratio to obtain phosphate cement base material; wet the inner surface of the mixer, add regenerated coarse and fine aggregates and a part of water, and stir for 2-3 Minutes; After the recycled aggregate absorbs water, add the phosphate cement base material, natural aggregate and the rest of the water and stir evenly, and form the phosphate recycled aggregate st...

Embodiment 3

[0036] The percentage by weight of each component of the magnesium phosphate cement recycled aggregate structure concrete in this embodiment is: magnesia 18.5%, potassium dihydrogen phosphate 7.9%, composite retarder 2.4%, admixture fly ash 2.7%, limestone powder 2.7% %, recycled fine aggregate 26.6%, recycled coarse aggregate 30.2%, water 8.9%; among them, the mass ratio of composite retarder is sodium tetraborate: disodium hydrogen phosphate dodecahydrate: inorganic chloride = 2: 6: 3 ;

[0037] Mix magnesium oxide, phosphate, composite retarder, and admixture evenly according to the above ratio to obtain phosphate cement base material; wet the inner surface of the mixer, add regenerated coarse and fine aggregates and a part of water, and stir for 2-3 Minutes; After the recycled aggregate absorbs water, add the phosphate cement base material, natural aggregate and the rest of the water and stir evenly, and form the phosphate recycled aggregate structure concrete after harden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com