Phosphate aerated concrete bonding agent

A technology of air-entrained concrete and phosphate, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems affecting the service life of air-entrained concrete, hindering the promotion and application, etc. Good anti-corrosion performance and the effect of reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The composition and proportion of the phosphate air-entrained concrete interface agent in this example are: 100 parts of ammonium dihydrogen phosphate; 400 parts of dead-burned magnesium; 48 parts of borax; and 65 parts of water, in parts by weight. Mix dead-burned magnesium, ammonium dihydrogen phosphate and borax evenly according to the above ratio, add stirring water and stir fully in a mixer to obtain a phosphate air-entrained concrete interface agent.

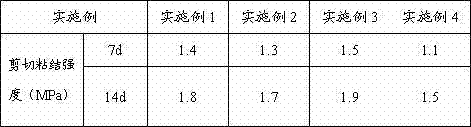

[0023]

Embodiment 2

[0025] The components of the phosphate air-entrained concrete interface agent in this embodiment and the ratio of use are: 100 parts of potassium dihydrogen phosphate; 200 parts of dead-burned magnesium; 60 parts of fly ash; 40 parts of borax; 3 parts of methyl cellulose; made in parts by weight. Mix dead-burned magnesium, potassium dihydrogen phosphate, borax, fly ash and methyl cellulose evenly according to the above ratio, add stirring water and stir fully in a mixer to obtain a phosphate aerated concrete interface agent.

[0026]

Embodiment 3

[0028] The components of the interface agent for phosphate air-entrained concrete in this embodiment and the ratio of use are: 100 parts of ammonium dihydrogen phosphate; 400 parts of dead-burned magnesium; 50 parts of fly ash; 50 parts of ground slag; 5 parts of sodium cellulose; 120 parts of water, in parts by weight. Mix dead-burned magnesium, ammonium dihydrogen phosphate, borax, fly ash, finely ground slag and sodium carboxymethyl cellulose evenly according to the above ratio, add stirring water and stir fully in a mixer to obtain a phosphate aerated concrete interface agent.

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com