Preparation method of thermo-sensitive graphene oxide with improved replacement rate by triggering polymerization through advanced modification

A temperature-sensitive, oxidized stone technology, applied in the direction of medical preparations and pharmaceutical formulas of non-active ingredients, can solve the problems of difficult reaction, low substitution rate, harsh reaction conditions, etc., achieve excellent performance, increase substitution rate, and react easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

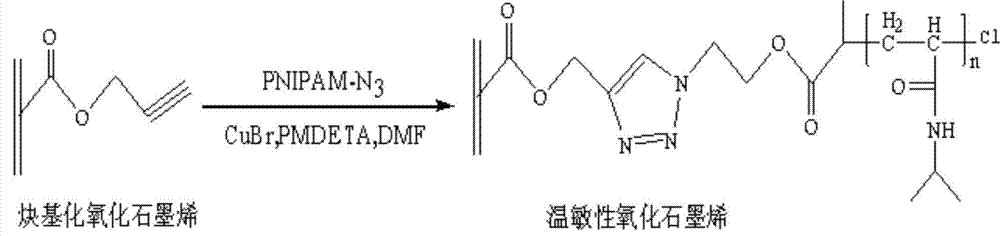

[0007] The specific scheme of the method for preparing temperature-sensitive graphene oxide that first modifies and initiates polymerization to increase the substitution rate of the present invention is as follows.

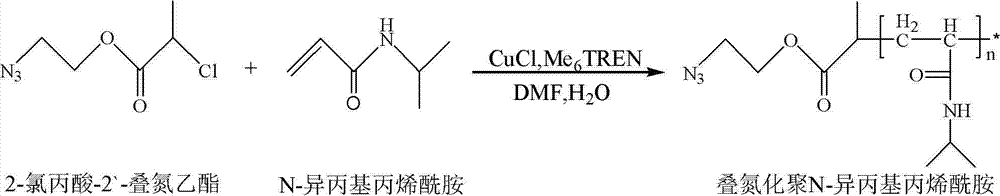

[0008] Firstly, the polymerization of NIPAM was initiated by ATRP initiator with azide group at the end to obtain the polymer PNIPAM with azide group at the end. The NIPAM has been purified; the ATRP initiator with an azide group at the end is CPAE, that is, 2-chloropropionic acid-2'-azidoethyl ester. The details are as follows: Put CPAE and NIPAM into one end of the W-shaped tube according to the ratio of the amount of substances (ratio n of mass m to relative molecular weight M) at a ratio of 1:100, and dissolve them in DMF (N,N-dimethylacetamide) , the concentration of CPAE was 12 mg / mL. Then add the same amount of CuCl as the CPAE substance to the middle tube of the W-shaped tube, and dissolve it in a mixed solution of DMF and water with a volume ratio of 1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com