Preparation method of furfural-modified lignin-based phenolic resin adhesive

A phenolic resin glue, lignin-based technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of decreased bonding strength of adhesives and inability to achieve high proportion replacement, etc. To achieve the effect of improving the bonding strength, improving the product purity and increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

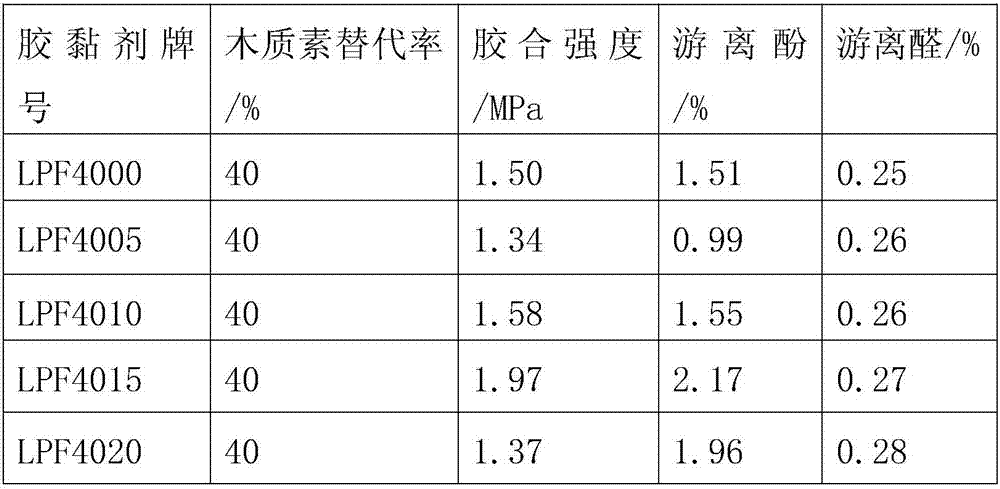

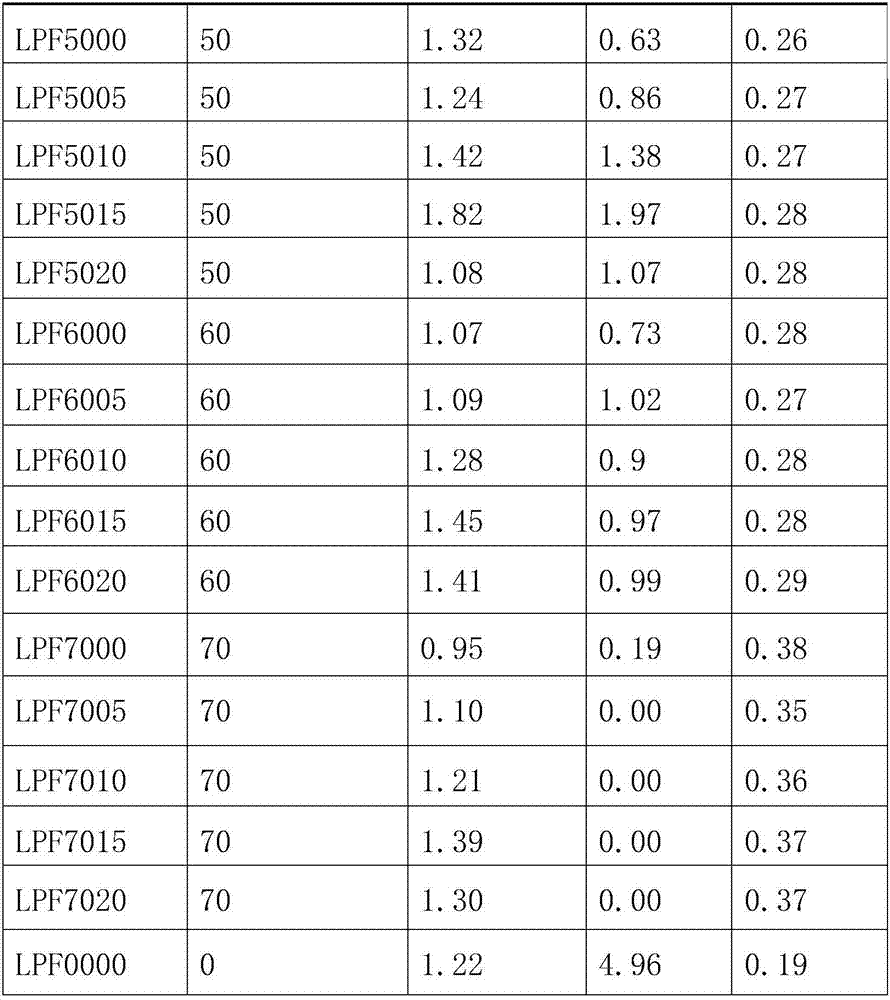

Examples

Embodiment 1

[0042] Step 1, preparation of xylose solution

[0043] 1. Mix the biomass with a sulfuric acid solution with a concentration of 2wt% according to a solid-to-liquid ratio of 1Kg:10L, heat and reflux for 2h to 4h, cool down and filter, and obtain a hydrolyzed solution and hydrolyzed slag with a xylose concentration of 6.5wt%;

[0044] ② adjust the concentration of sulfuric acid in the hydrolyzate in ① to be 2wt% with a sulfuric acid solution with a concentration of 3wt%, add biomass by solid-liquid ratio 1Kg:10L, heat and reflux for 3h, cool down and filter, and obtain xylose concentration of 10wt%. Hydrolyzate and hydrolyzed slag;

[0045] ③Adjust the sulfuric acid concentration in the hydrolyzate in ② with a sulfuric acid solution with a concentration of 3wt% to be 2wt%, add biomass according to the solid-to-liquid ratio of 1Kg:10L, heat and reflux for 2h to 4h, cool down and filter, and obtain the xylose concentration of the hydrolyzate 15.6wt% xylose solution and hydrolyzed...

Embodiment 2

[0049] ① Concentrate the hydrolyzed slag in Step 1 of Example 1, wash until neutral, mix it with a sodium hydroxide solution with a concentration of 5wt% at a solid-to-liquid ratio of 1Kg:8L, heat and reflux for 4 hours, drop to room temperature, filter, Obtain alkali lignin solution and crude cellulose;

[0050] ②Add the alkali lignin solution, phenol and alkali catalyst obtained in ① into the reaction device, raise the temperature to 80°C-100°C, and reflux for 0.5h-2h to obtain a phenolic modified alkali lignin solution;

[0051] The mass of lignin in the alkali lignin solution accounts for 40% of the total mass of lignin and phenol, the alkali catalyst is a sodium hydroxide solution, and the mass of active ingredients in the alkali catalyst is 5% of the total mass of lignin and phenol;

[0052] ③ Add formaldehyde solution with a concentration of 37% in batches to the phenolic modified alkali lignin solution obtained in ②, and add 80% of the total amount of formaldehyde solu...

Embodiment 3

[0055] The mass of lignin accounted for 40% of the total mass of lignin and phenol, and the mass of furfural accounted for 10% of the total mass of furfural and formaldehyde. Other conditions were the same as in Example 2, and lignin-based phenolic resin adhesive LPF4010 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com