Patents

Literature

152results about How to "Improve bonding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

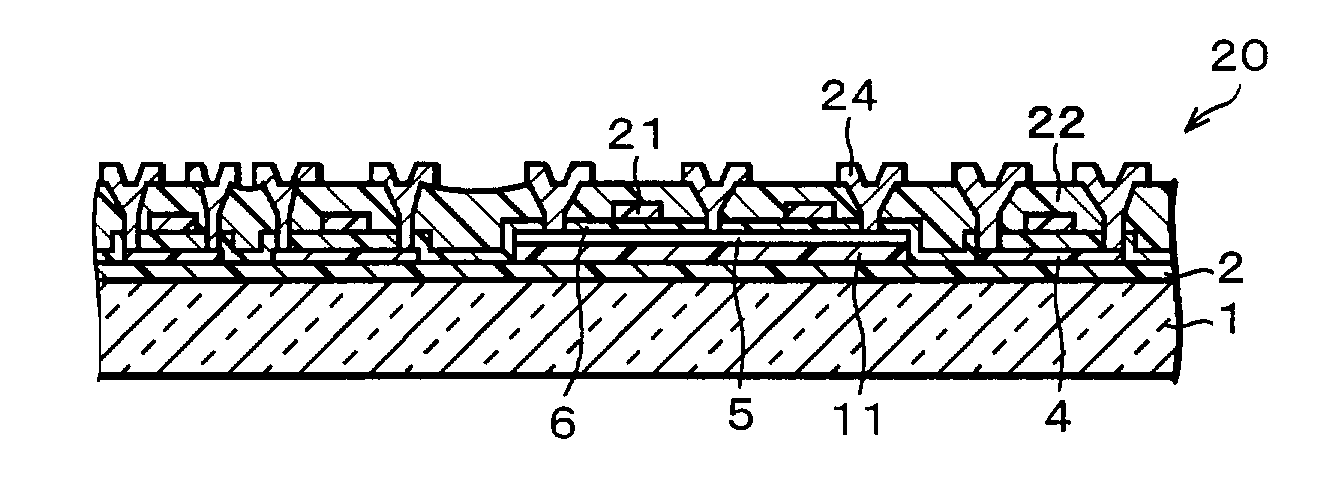

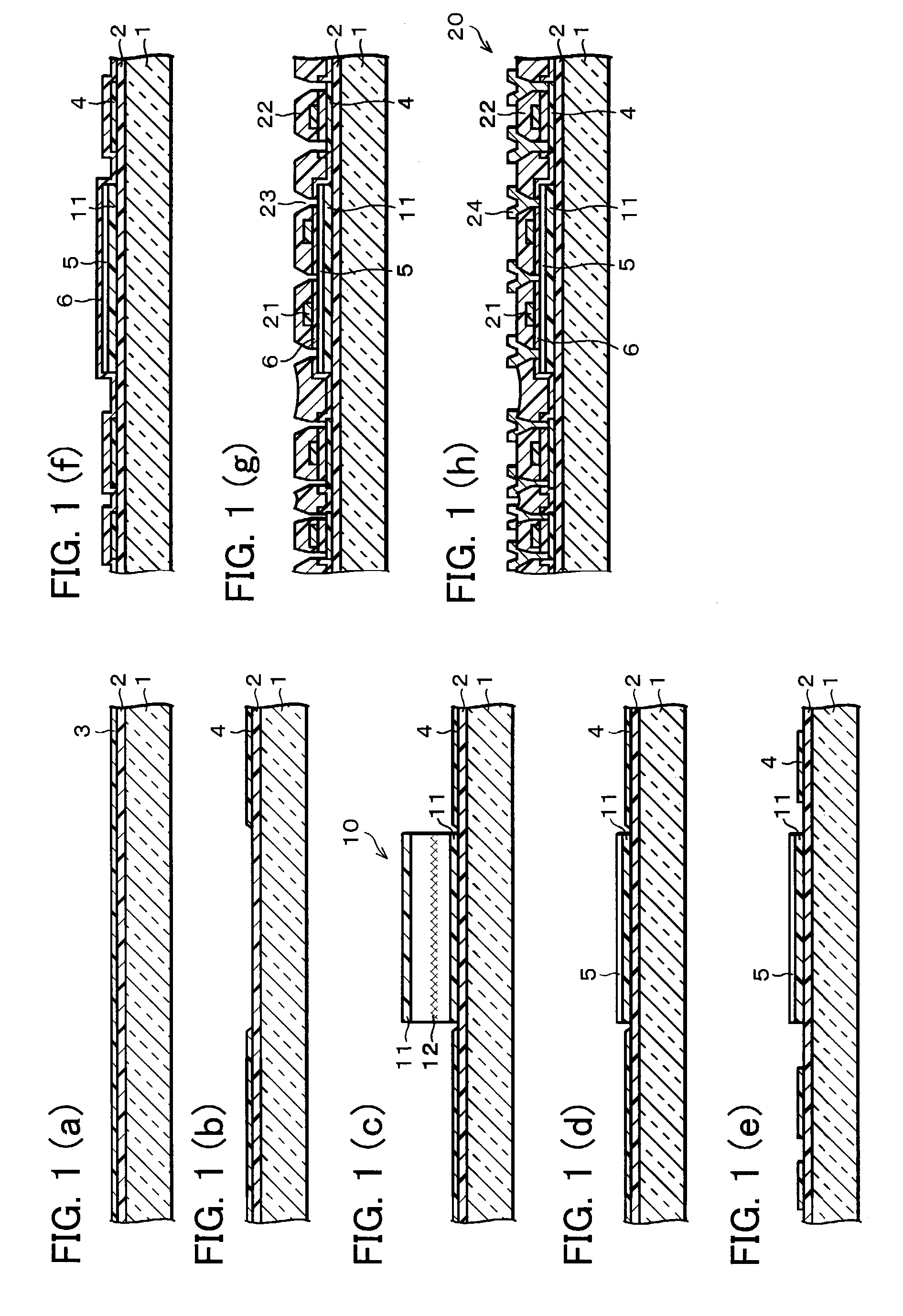

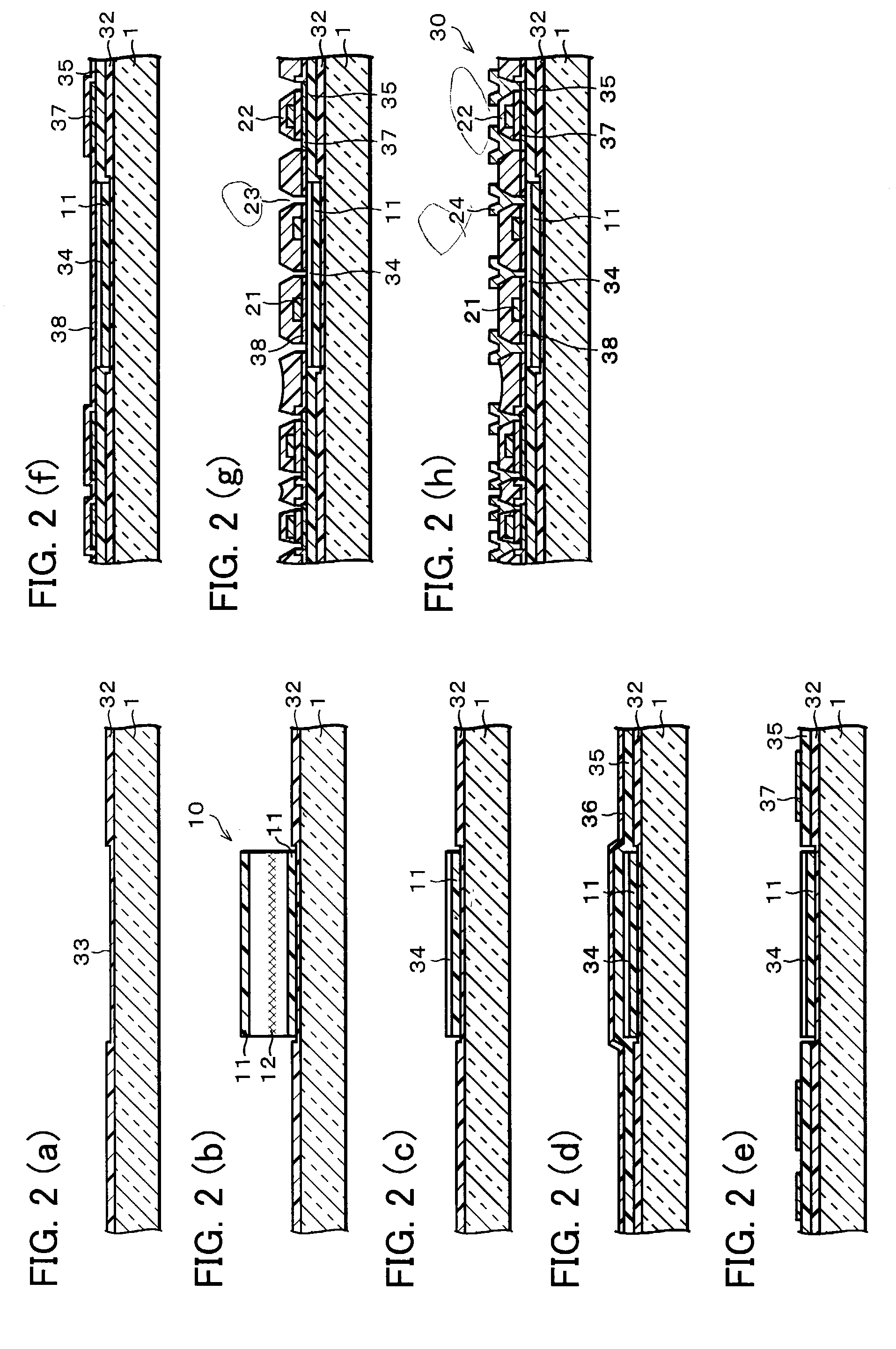

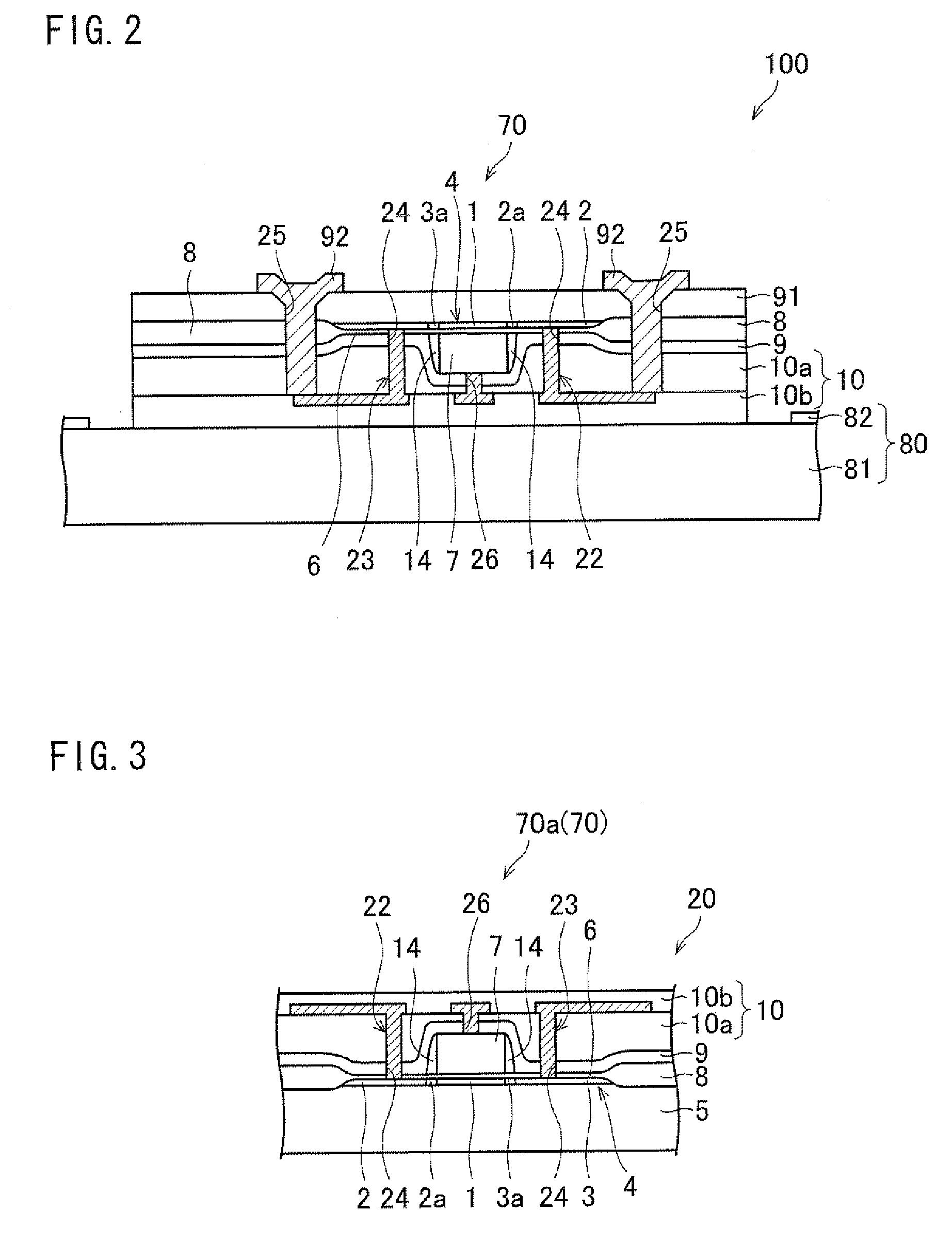

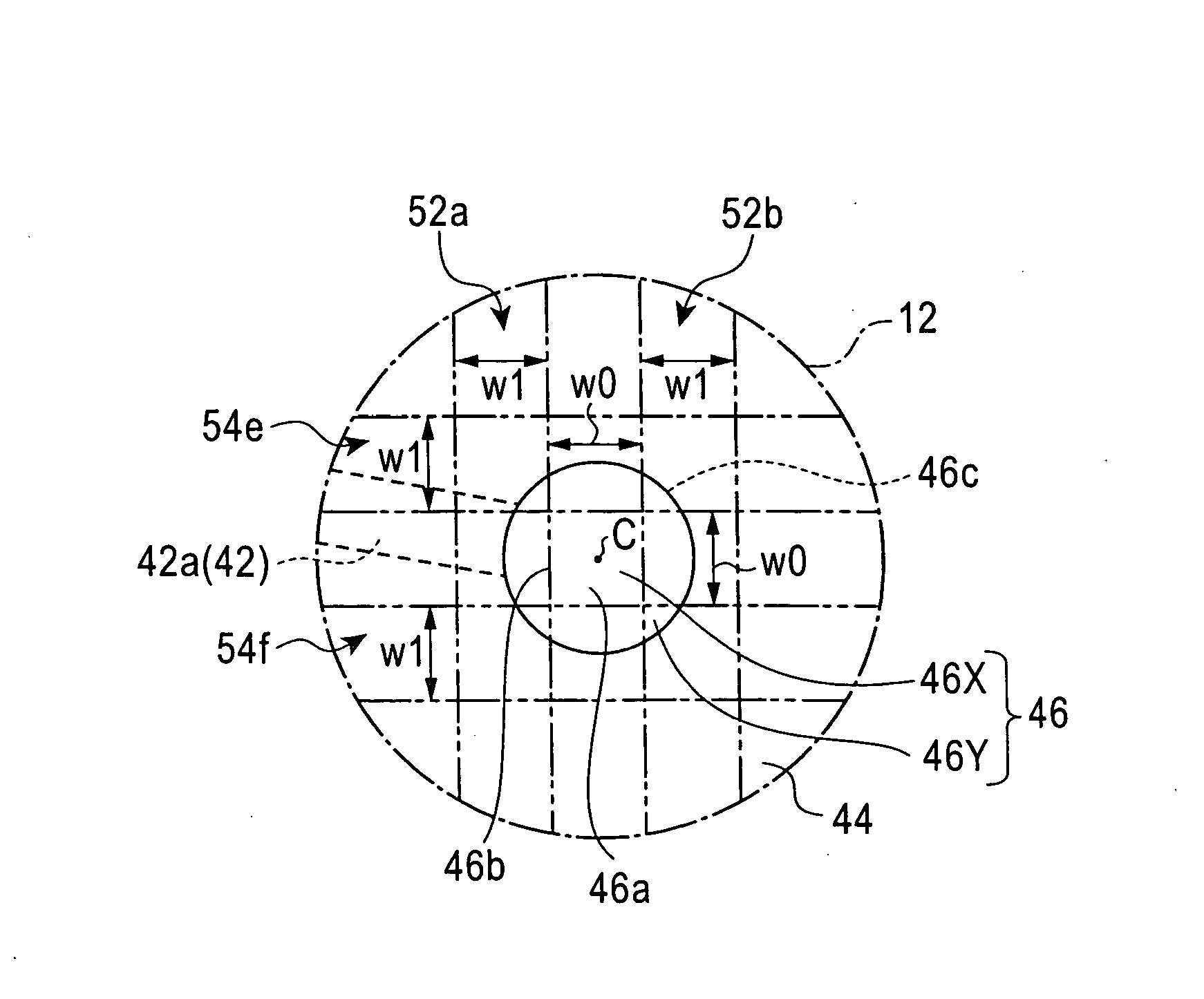

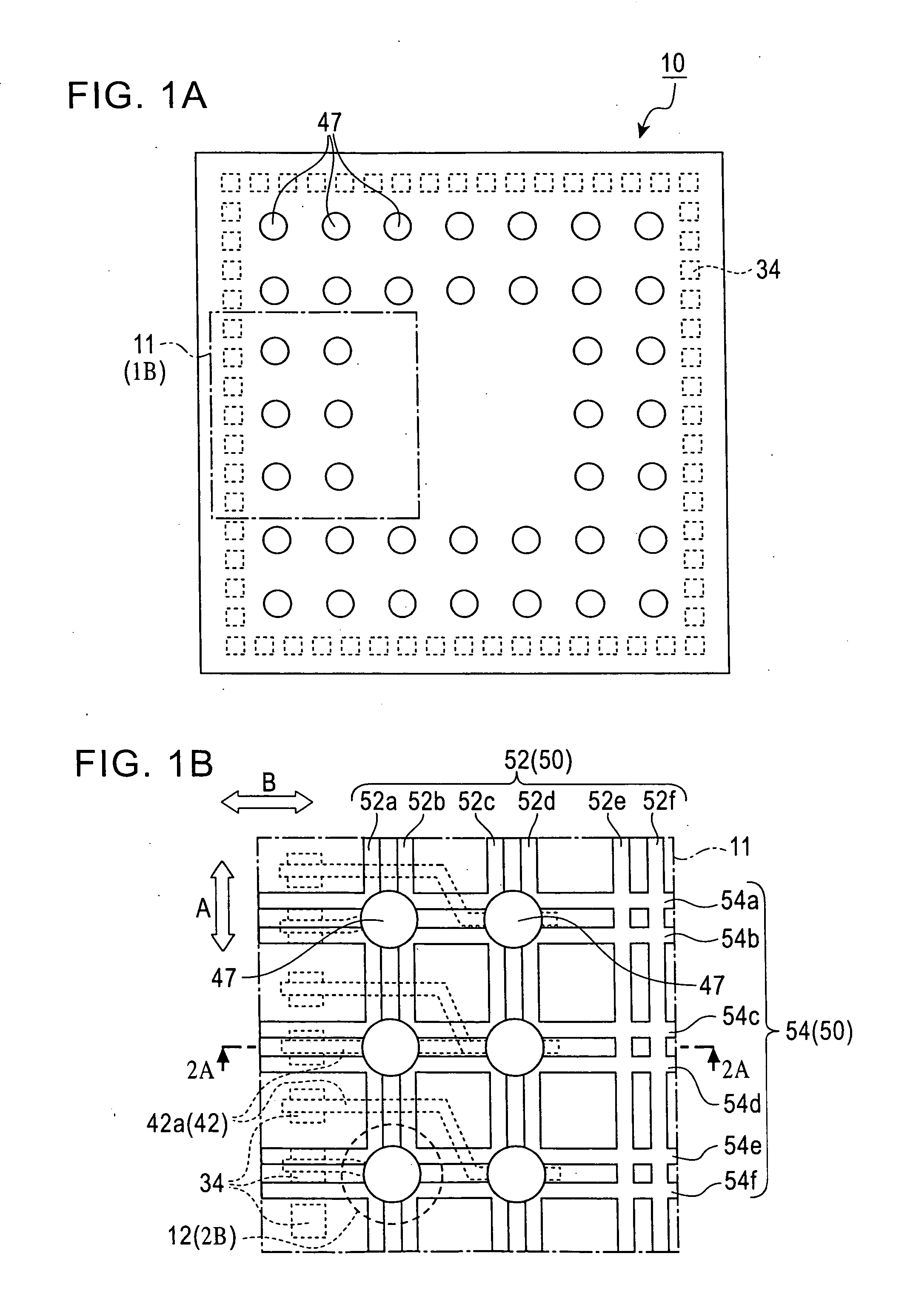

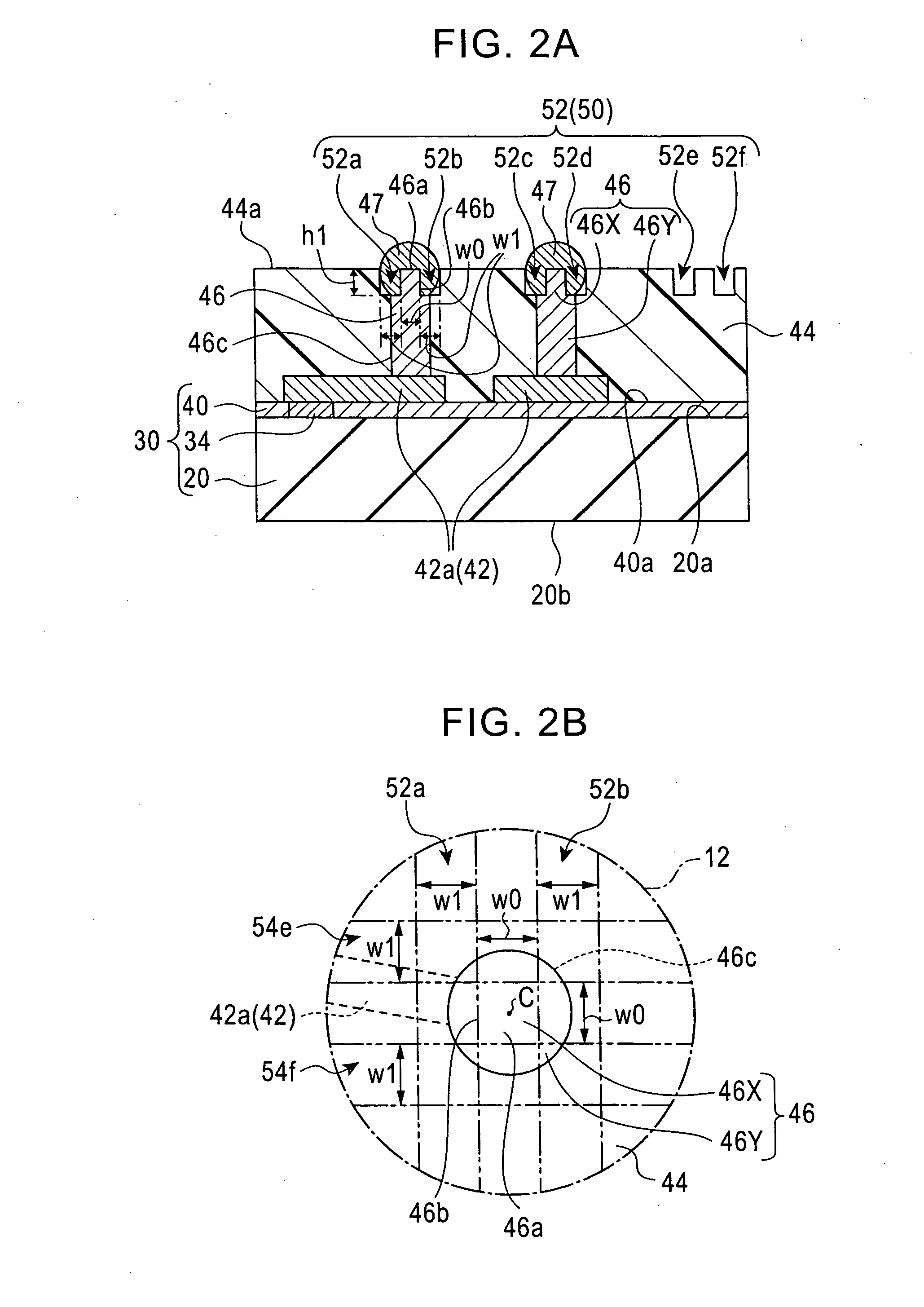

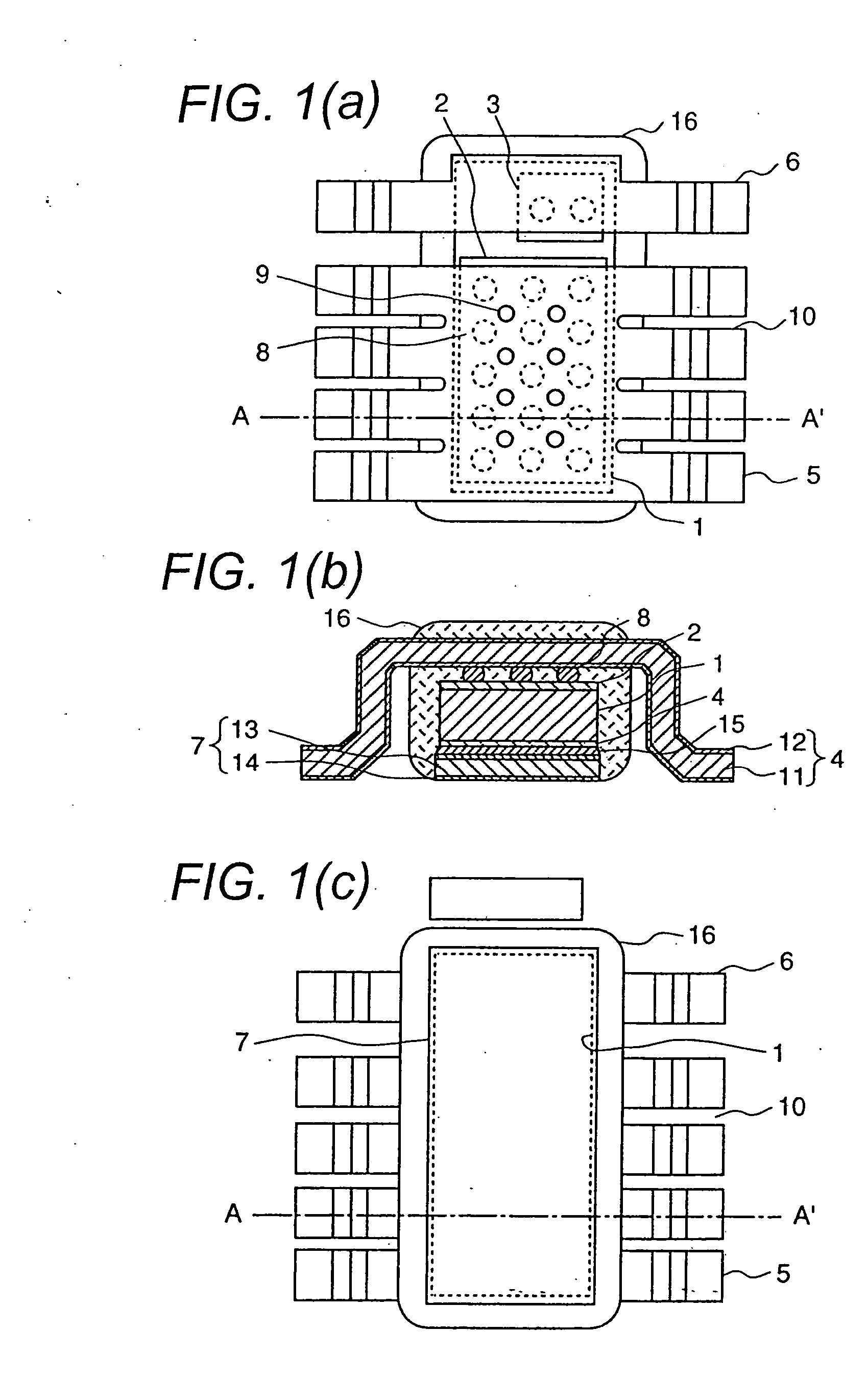

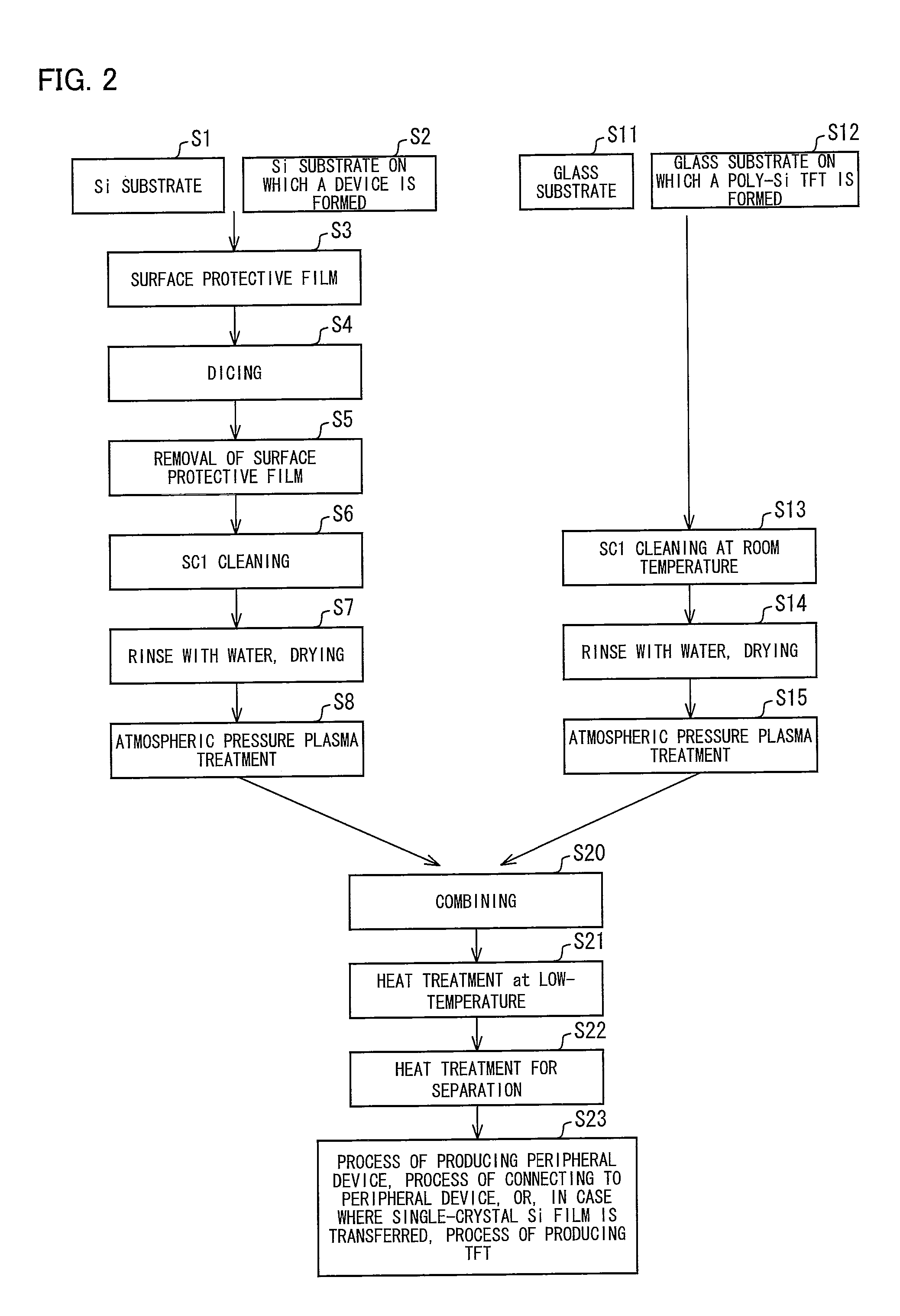

Semiconductor device and manufacturing method thereof, SOI substrate and display device using the same, and manufacturing method of the SOI substrate

InactiveUS7119365B2Improve bonding strengthDrop mobilityTransistorSolid-state devicesPolycrystalline siliconSingle crystal

A polycrystalline Si thin film and a single crystal Si thin film are formed on an SiO2 film deposited on an insulating substrate. A polycrystalline Si layer is grown by thermally crystallizing an amorphous Si thin film so as to form the polycrystalline Si thin film. A single crystal Si substrate, having (a) an SiO2 film thereon and (b) a hydrogen ion implantation portion therein, is bonded to an area of the polycrystalline Si thin film that has been subjected to etching removal, and is subjected to a heating process. Then, the single crystal Si substrate is divided at the hydrogen ion implantation portion in an exfoliating manner, so as to form the single crystal Si thin film. As a result, it is possible to provide a large-size semiconductor device, having the single crystal Si thin film, whose property is stable, at a low cost.

Owner:SHARP KK

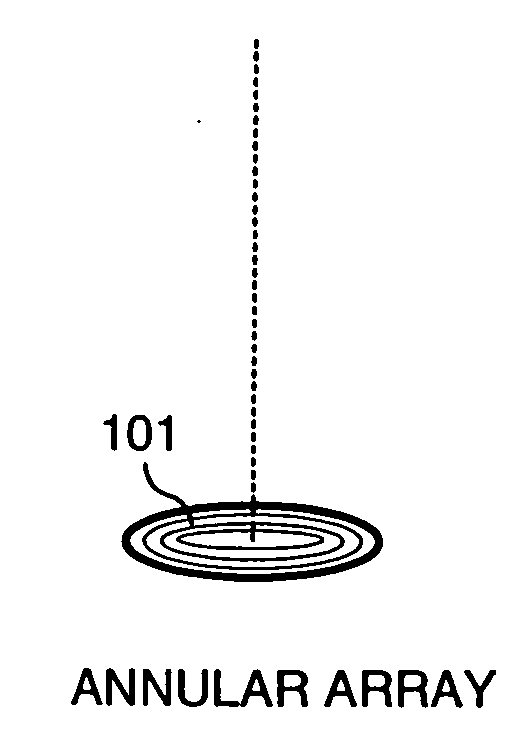

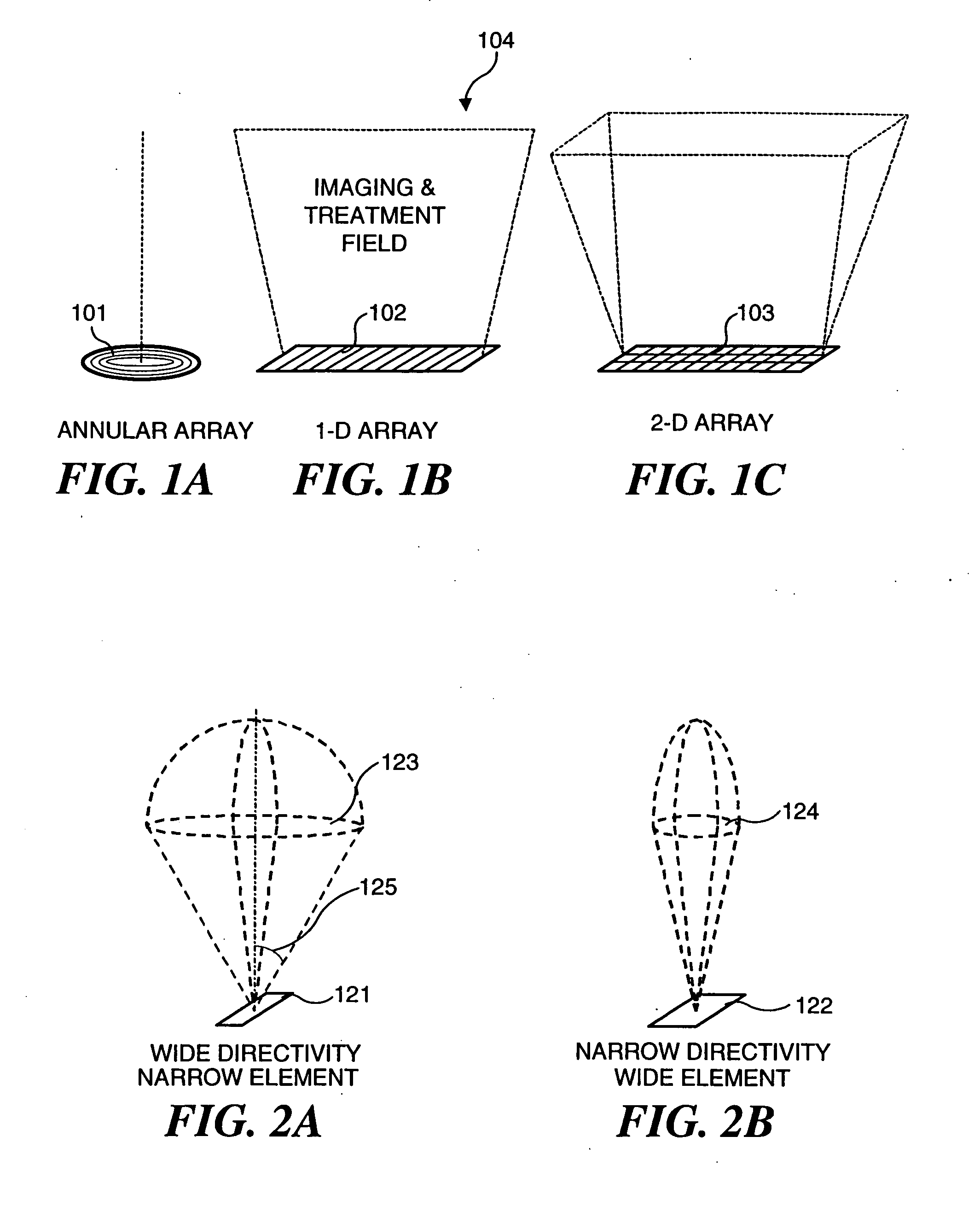

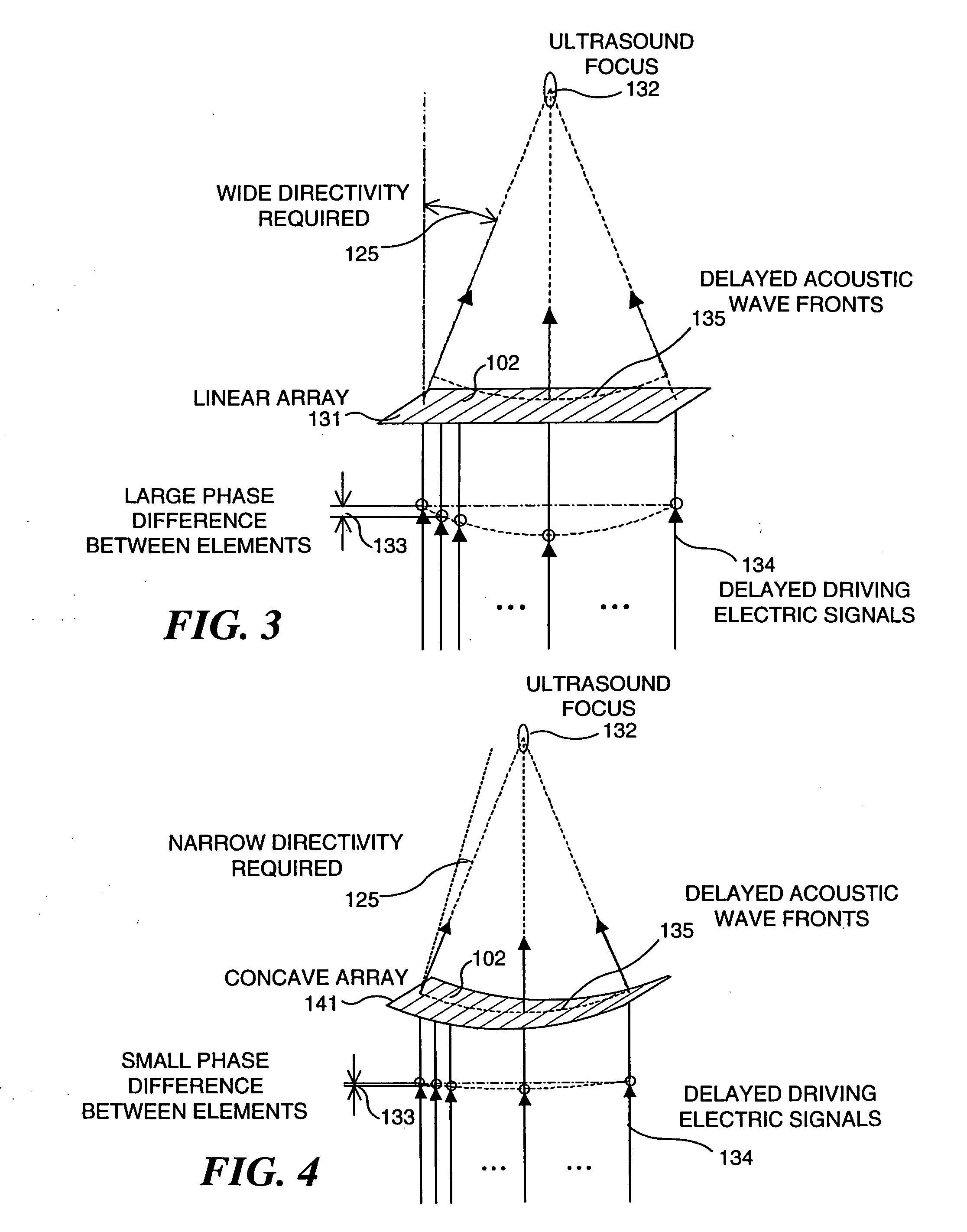

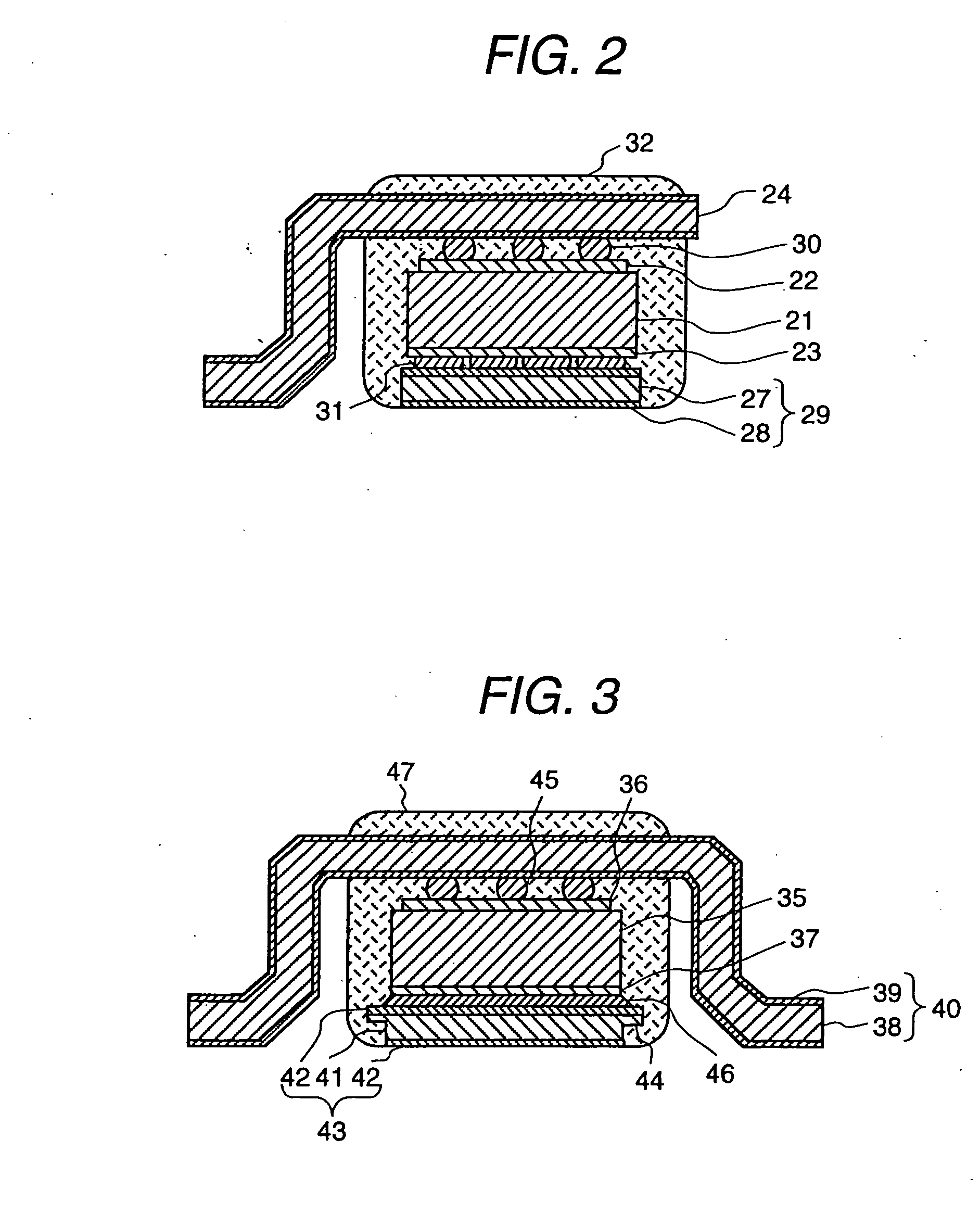

Ultrasound transducers for imaging and therapy

InactiveUS20050096542A1Improve likelihoodImprove bonding strengthUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationUltrasonic beam

Ultrasound applicators able to both image a treatment site and administer ultrasound therapy include an array of transducer elements that can be focused. In several embodiments, an electronically phased array is used for controlling the focal point of an ultrasound beam. The ultrasound beam produced thereby can also be electronically steered. To reduce the quality factor or Q of the array when the array is used for imaging, an electronic switch is selectively closed, placing a resistance in parallel with each of the array elements. A flexible array is employed in several embodiments and is selectively bent or flexed to vary its radius of curvature and thus control the focal point and / or a direction of focus of the array. In another embodiment, each of the transducer elements comprising the array are individually mechanically pivotable to steer the ultrasonic beam produced by the transducer elements.

Owner:OTSUKA MEDICAL DEVICES

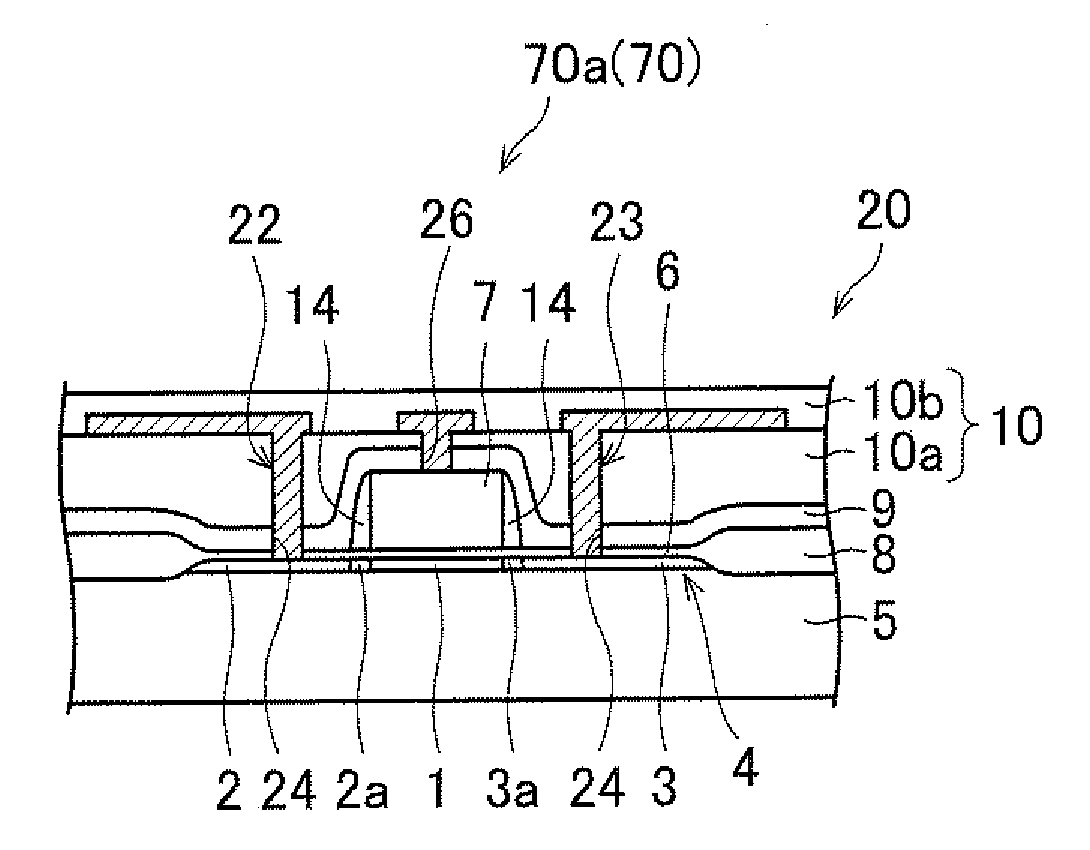

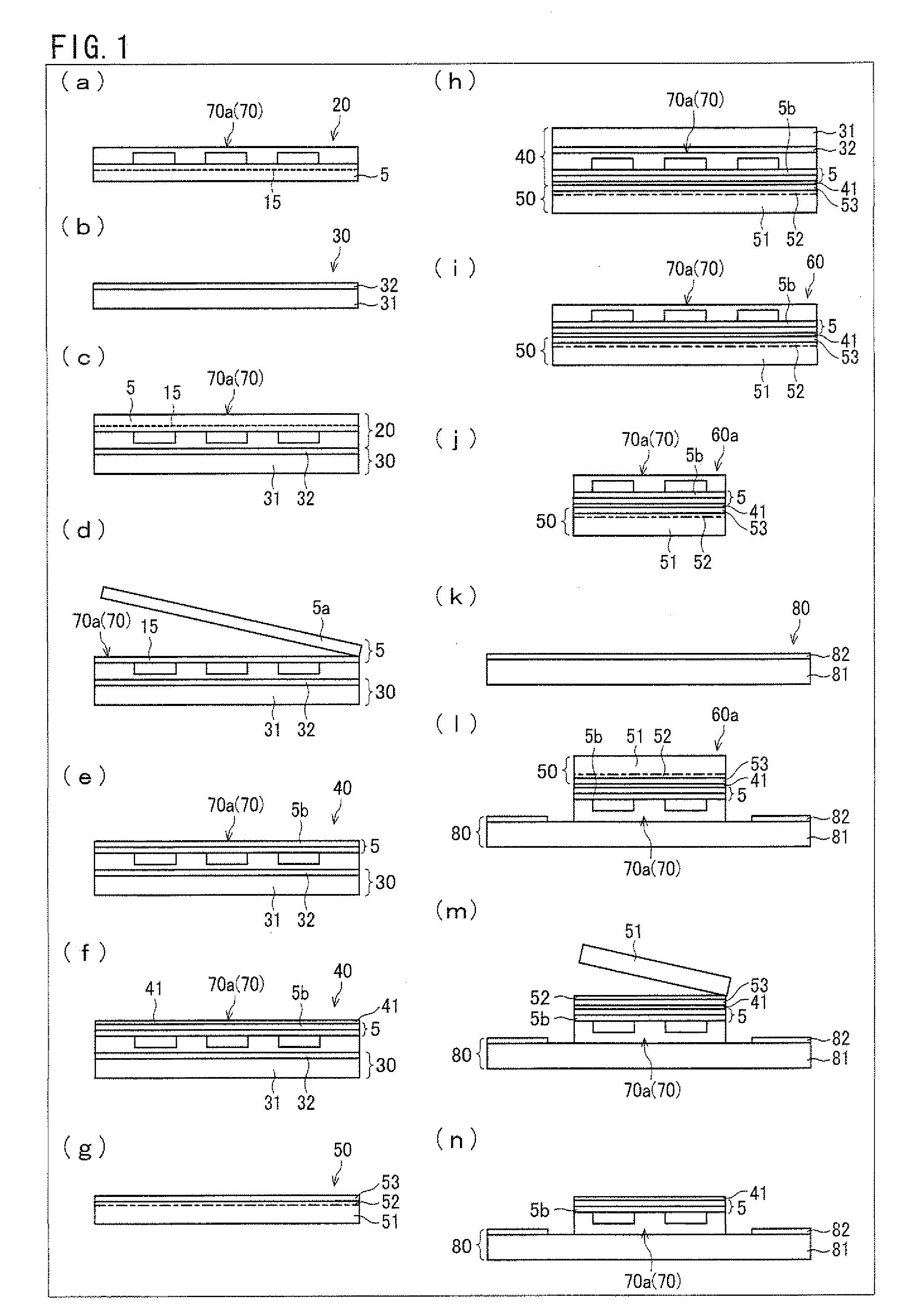

Method for Transferring Semiconductor Element, Method for Manufacturing Semiconductor Device, and Semiconductor Device

ActiveUS20090001504A1Improve bonding strengthLow pour pointSolid-state devicesSemiconductor/solid-state device manufacturingTransistor channelMonocrystalline silicon

A transistor formed on a monocrystalline Si wafer is temporarily transferred onto a first temporary supporting substrate. The first temporarily supporting substrate is heat-treated at high heat so as to repair crystal defects generated in a transistor channel of the monocrystalline Si wafer when transferring the transistor. The transistor is then made into a chip and transferred onto a TFT substrate. In order to transfer the transistor which has been once separated from the monocrystalline Si wafer, a different method from a stripping method utilizing ion doping is employed.

Owner:SHARP KK

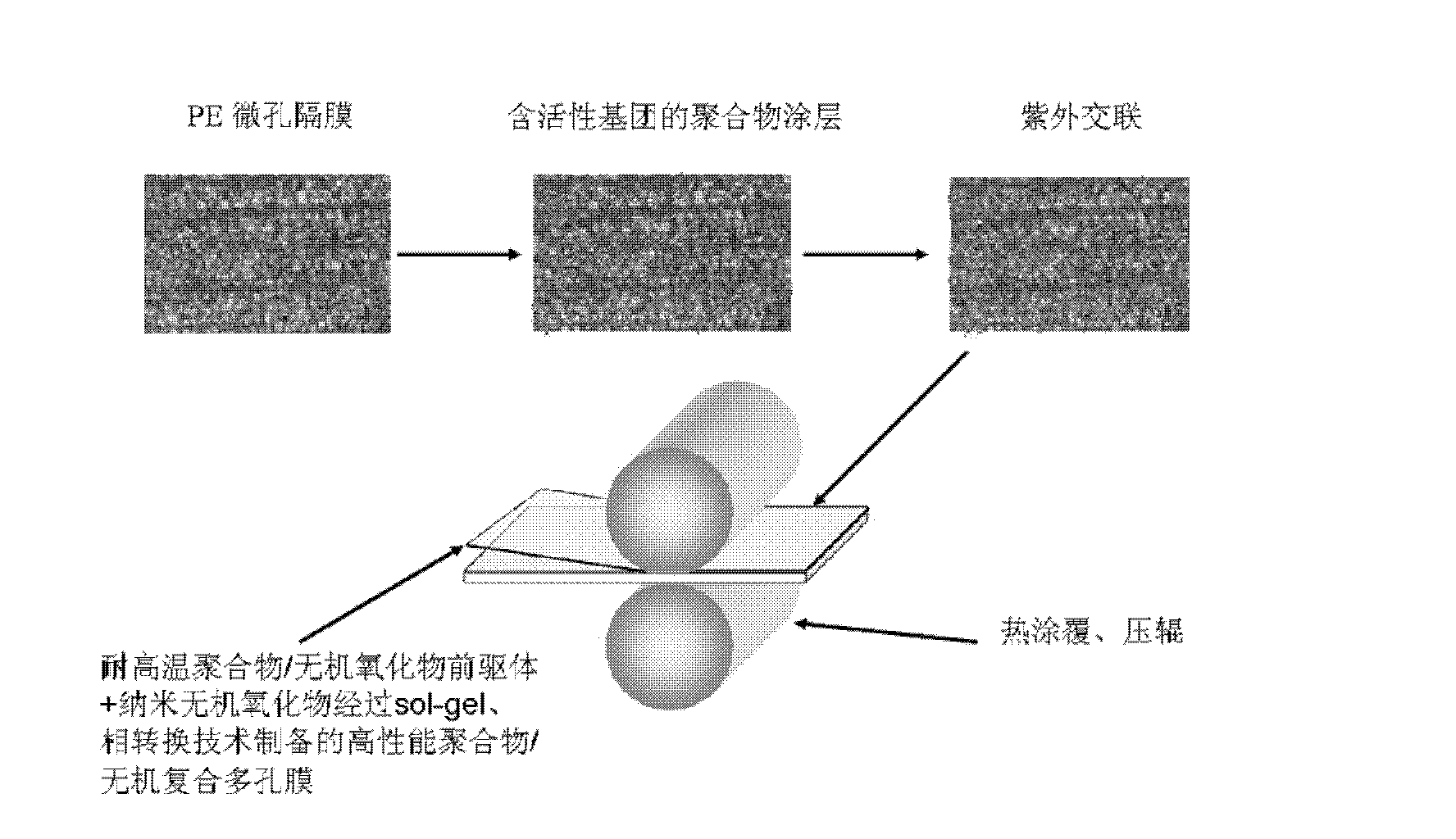

Composite microporous membrane used as lithium ion battery diaphragm as well as preparation method and application thereof

ActiveCN102122704AImprove bonding strengthEasy to prepareCell component detailsPolyolefinHigh performance polymer

The invention discloses a composite microporous membrane used as a lithium ion battery diaphragm as well as a preparation method and application thereof. The composite microporous membrane is prepared by the following steps of: steeping a polyolefin porous framework membrane in a modified liquid a and carrying out radiation crosslinking to obtain a modified framework membrane; preparing a modified liquid b, steeping the modified framework membrane in the modified liquid b and adding a sol-gel reaction catalytic agent to carry out a sol-gel condensation reaction; and immersing the modified membrane in a phase transforming agent solution, carrying out phase conversion to form a membrane and then drying to obtain a high-performance polymer / inorganic composite microporous membrane. In the invention, the preparation process is simple and the industrialization is easy to realize; the obtained composite microporous membrane has high air permeability, good electrolyte-favoring performance andhigh temperature resistance, a composite layer and the framework polyolefin membrane have good adhesion strength and cannot be separated when being placed in a lithium ion electrolyte solution with very good adhesion and without power-dropping and shedding. By means of the product of the invention, a series of defects in the prior art can be overcome.

Owner:河南惠强新能源材料科技股份有限公司

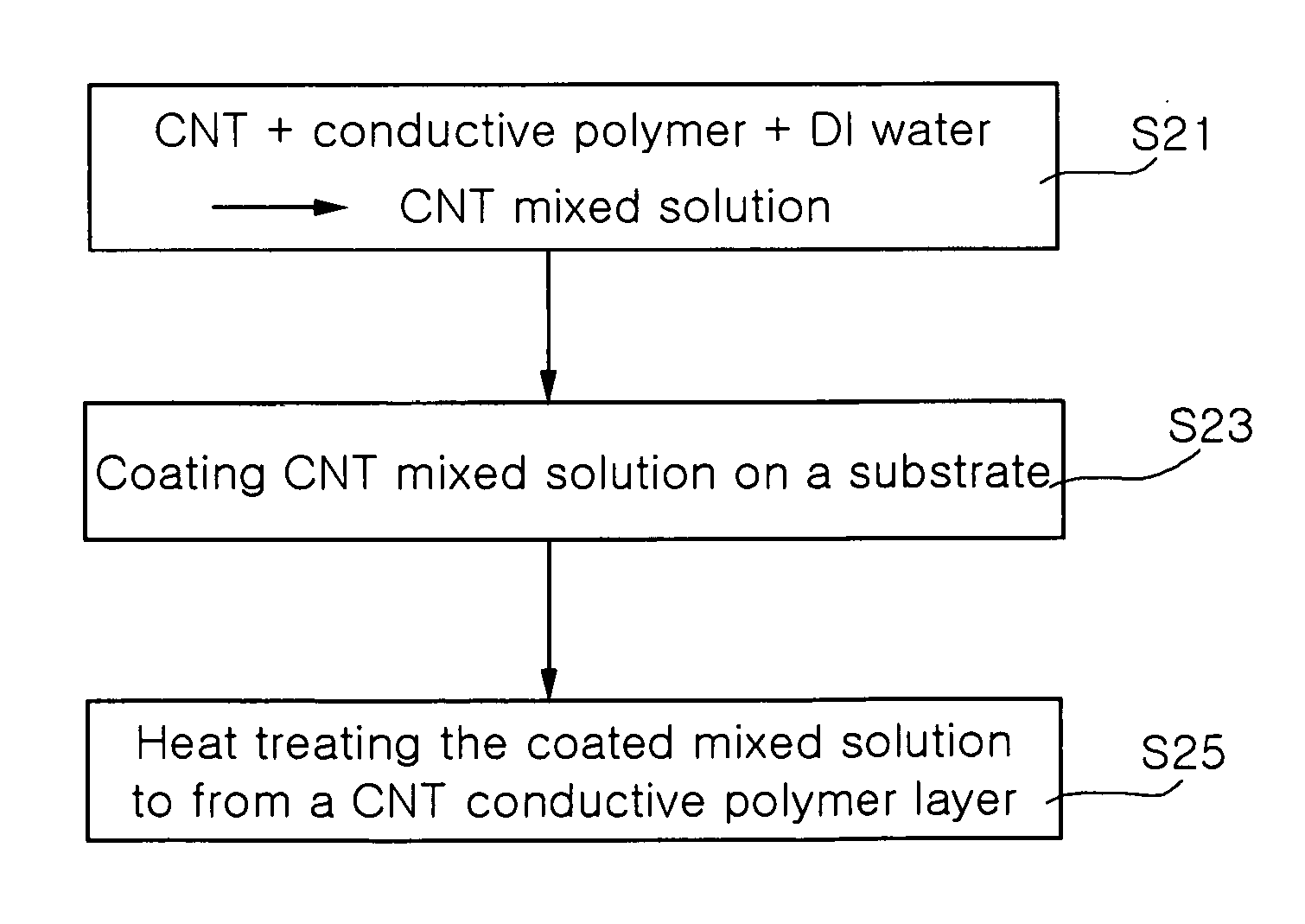

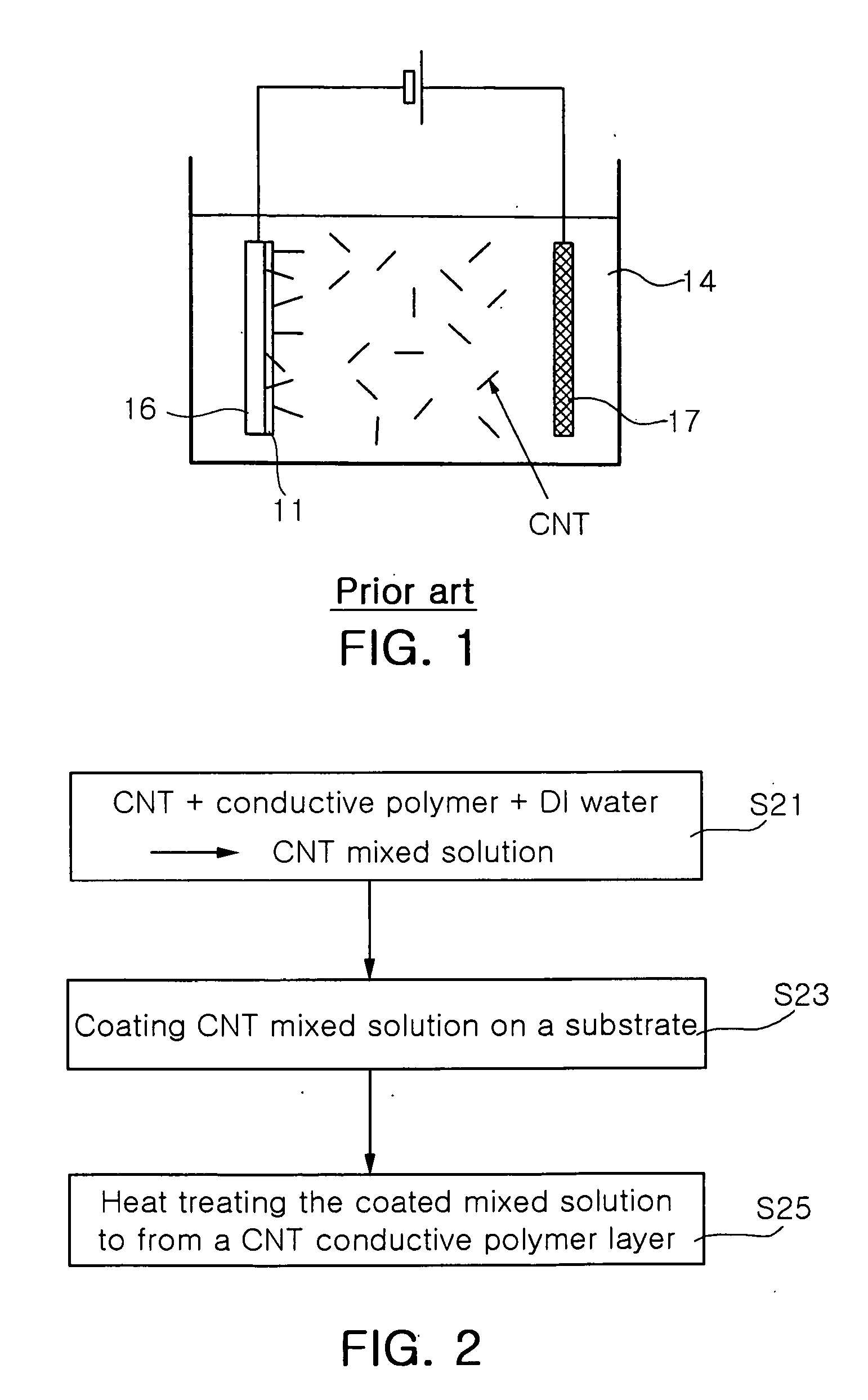

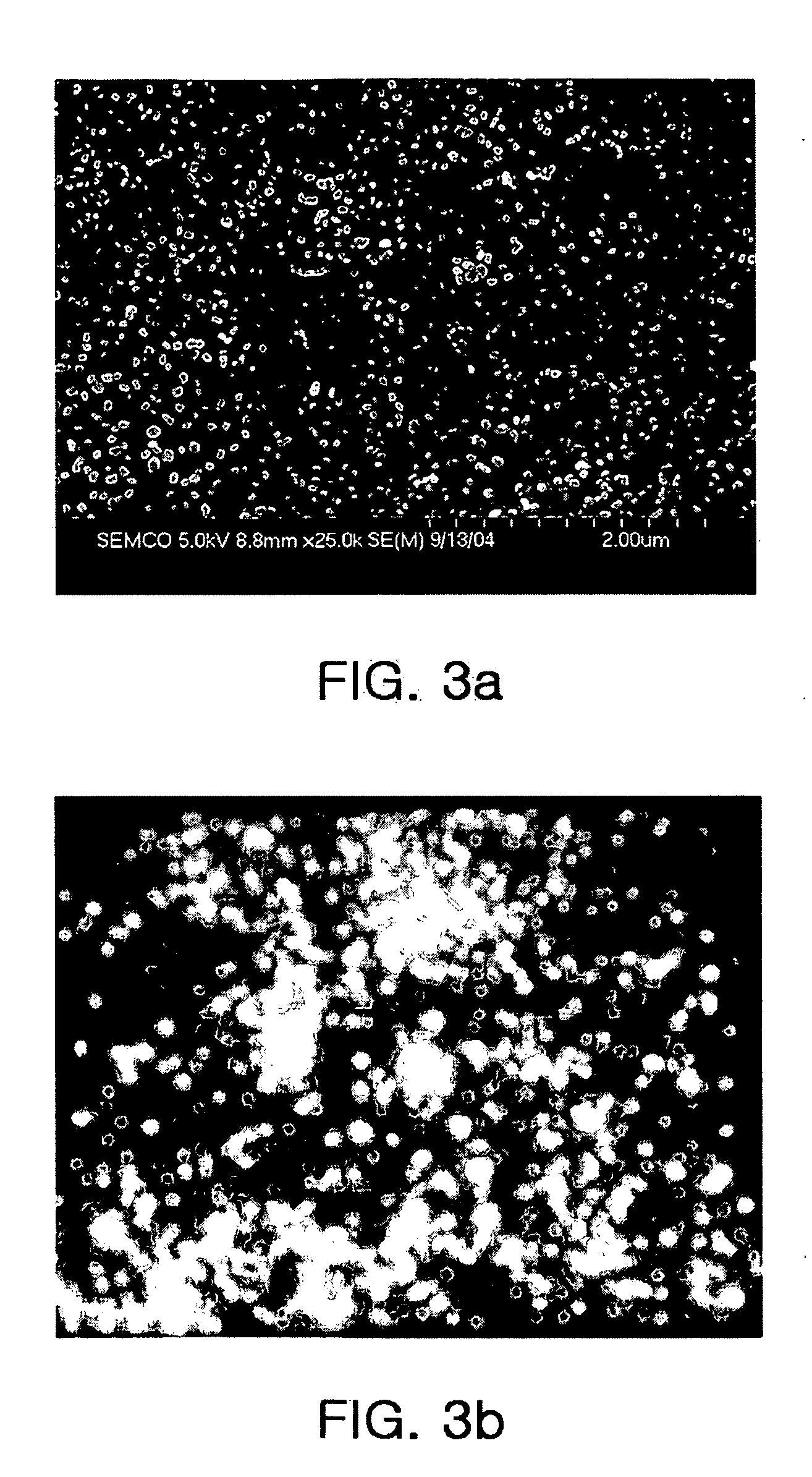

Fabrication method of field emitter electrode

InactiveUS20060057927A1Improve bonding strengthSimplify processElectric discharge tubesNanoinformaticsIonConductive polymer

The present invention provides a process for fabricating a field emitter electrode, comprising dispersing carbon nanotubes and a conductive polymer in DI (deionized) water to prepare a carbon nanotube mixture having a viscosity of 50 to 100 cps; applying the carbon nanotube mixture to a substrate; and heat treating the carbon nanotube mixture to form a conductive polymer layer including carbon nanotubes.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

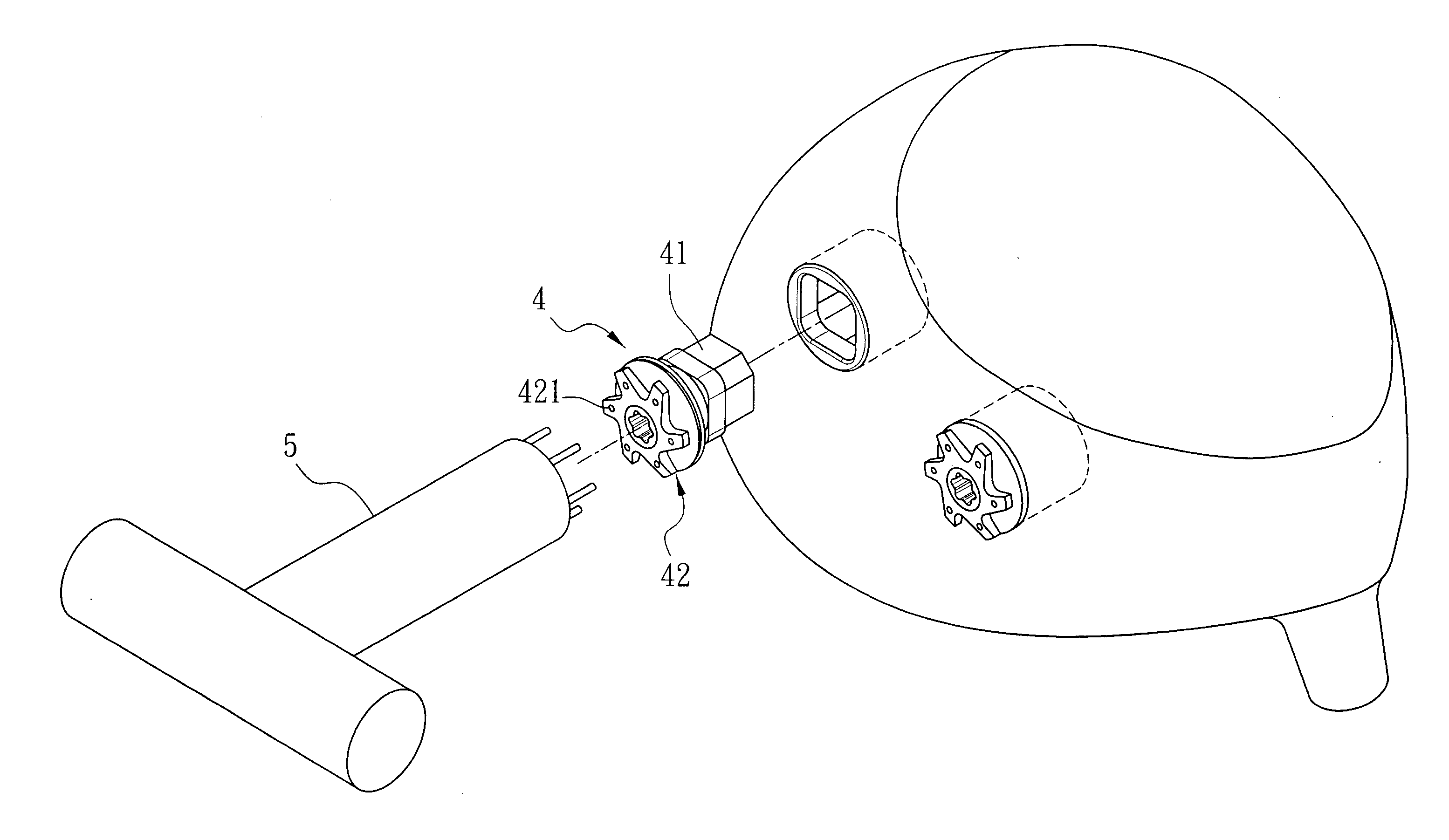

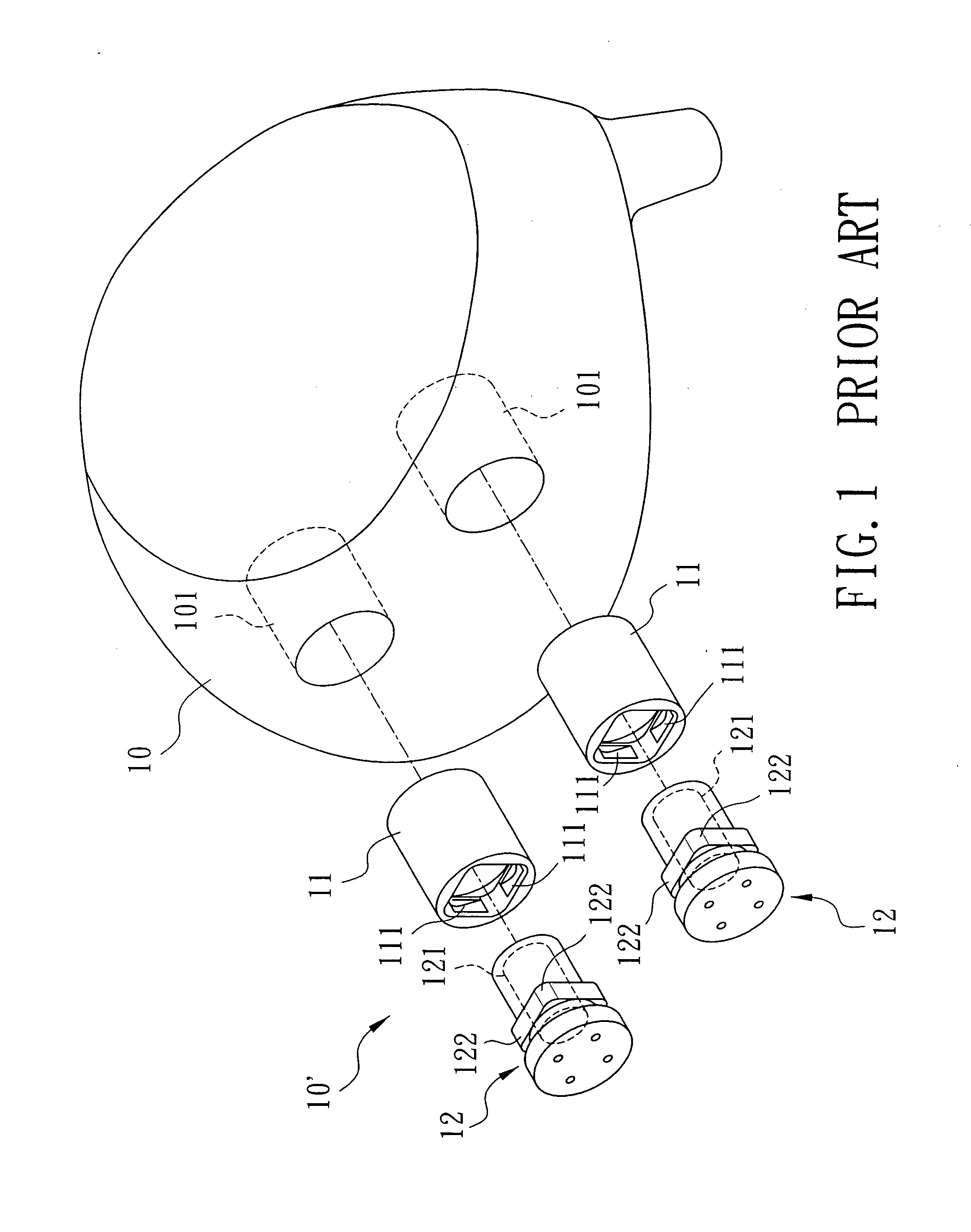

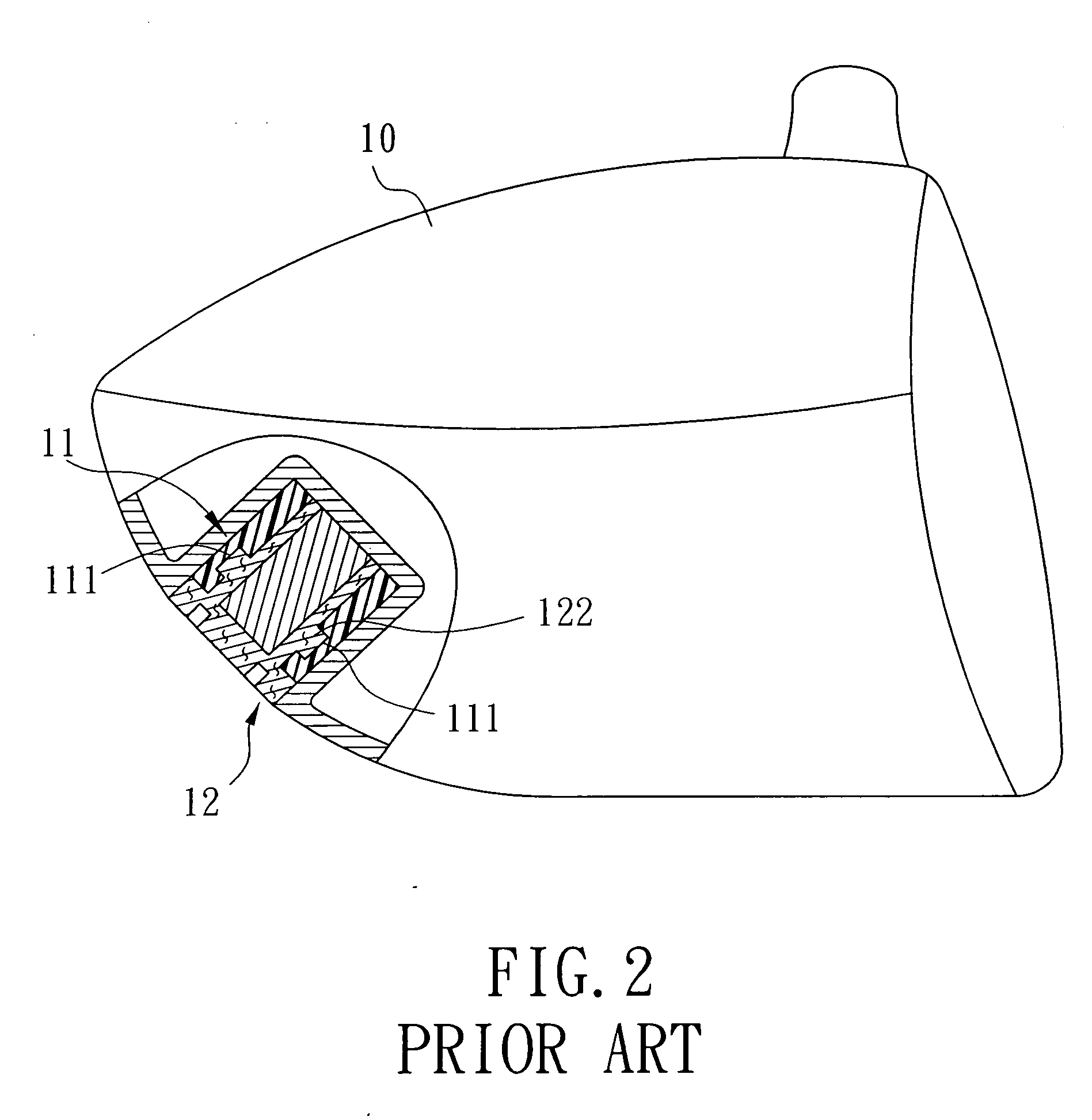

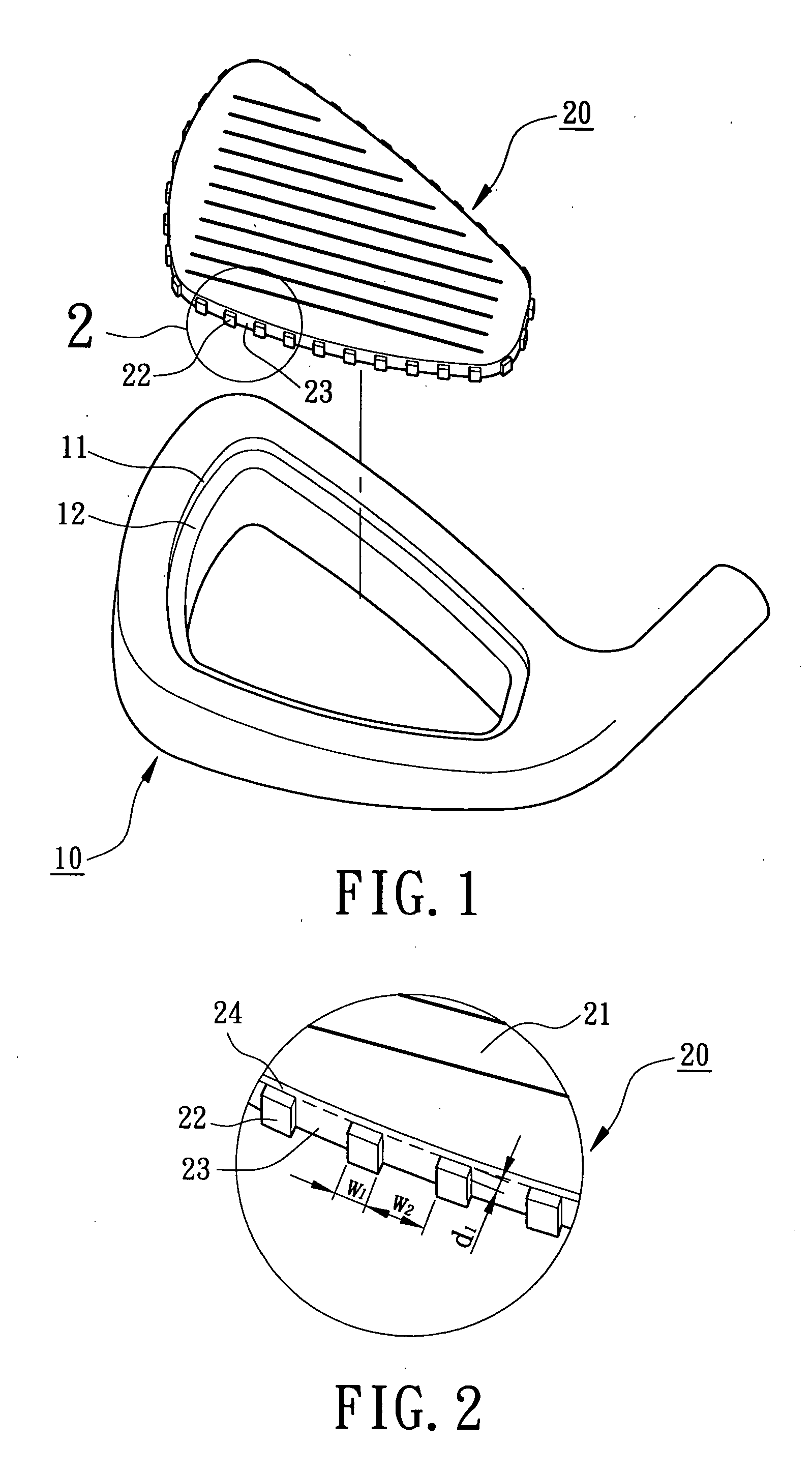

Golf club head

InactiveUS20090131200A1Easily assembleImprove bonding strengthNutsRail fastenersEngineeringGolf club

A golf club head includes a head body formed with a cavity, and a counterweight unit fitted in the cavity and including a sleeve body and an insert body. The sleeve body has a first end face, a second end face, first and second cavities, and first and second inner walls. The first inner wall has at least one first corner. The second inner wall has at least one second corner out of alignment with the first corner. The sleeve body further has at least one shoulder face formed at a junction of the first and second cavities. The insert body includes an insert portion removably inserted into the sleeve body, and an abutting portion extending outward from the sleeve body and abutting against the first end face. The insert portion has at least one flange engaging the second corner and having a stop face abutting against the shoulder face.

Owner:ADVANCED INT MULTITECH CO LTD

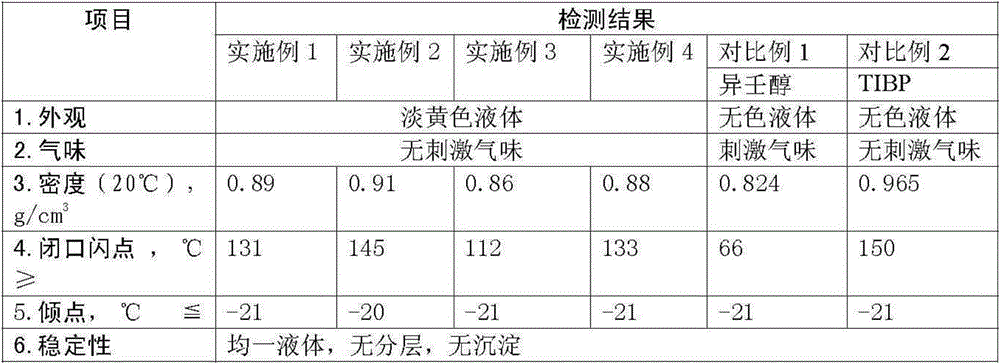

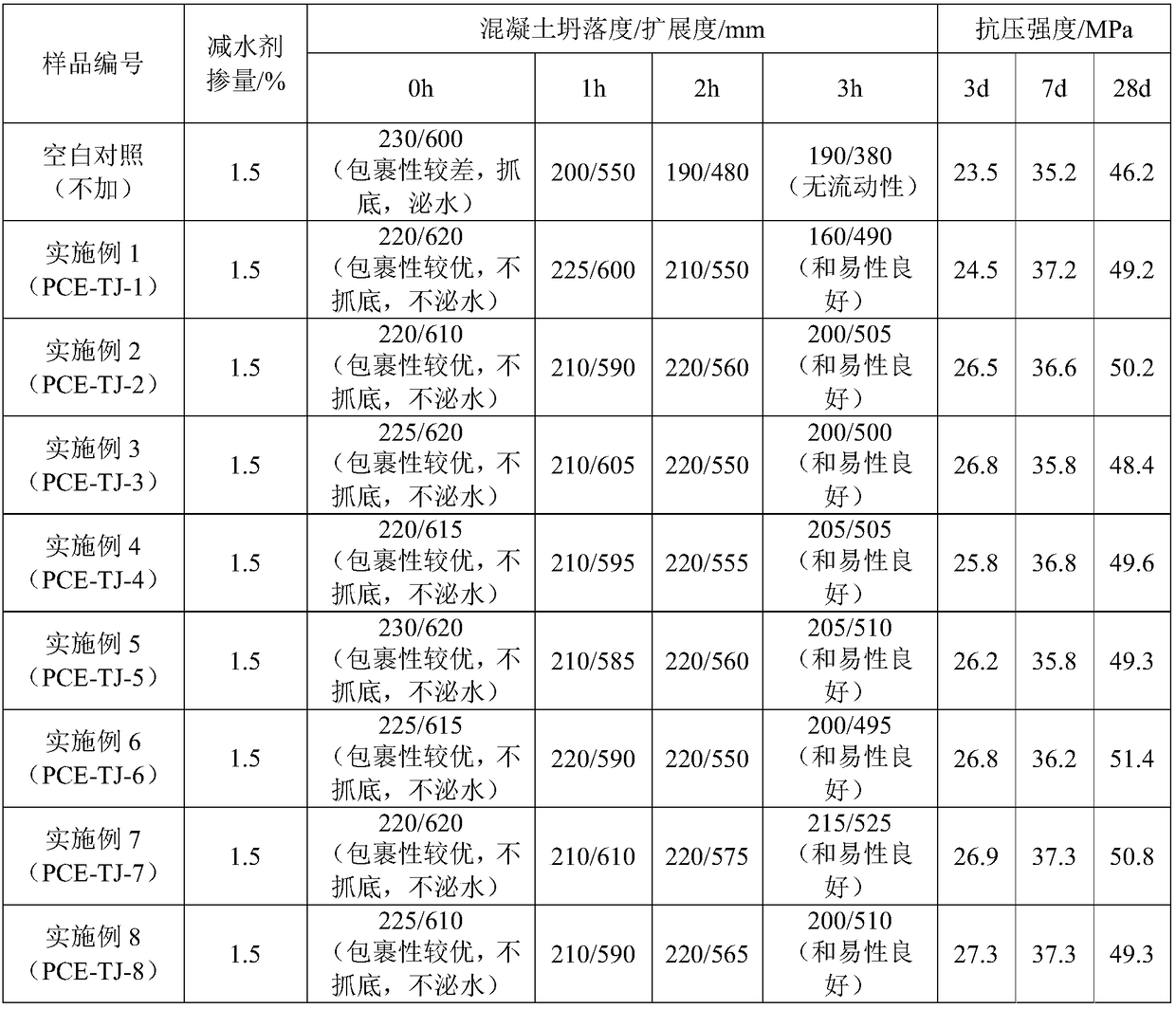

Alkali-free chloride-free liquid concrete enhancer and preparation method thereof

The invention relates to an alkali-free chloride-free liquid concrete enhancer and a preparation method thereof, wherein the enhancer mainly comprises the following materials according to weight percentages: 20-80% of anhydrous aluminum sulfate, 5-20% of triethanolamine, 0-0.2% of stabilizer, and 15-60% of water. The concrete enhancer is lower in cost, the preparation process is simple, the production of the ettringite in the early stage is increased when the concrete enhancer is added into a concrete mixture, so that more chemical bonds with stronger binding forces are produced among cement hydration particles, the Van der Waals' force is replaced the binding force of a cementing material is increased, the strength of the cement and concrete is reached, the quality and the property of the concrete material are improved, and the amount of consumed concrete cement is reduced.

Owner:LUOYANG INST OF SCI & TECH

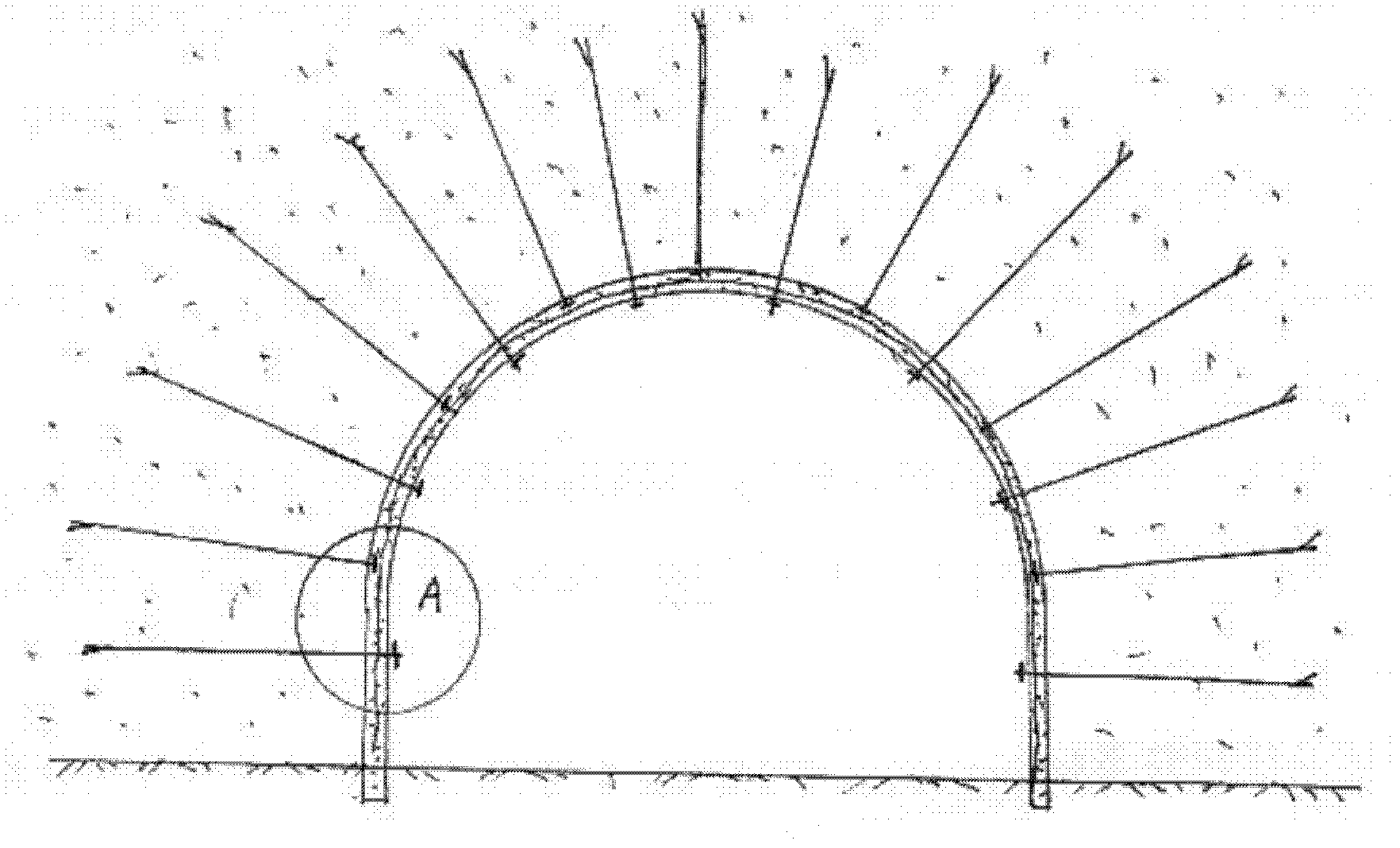

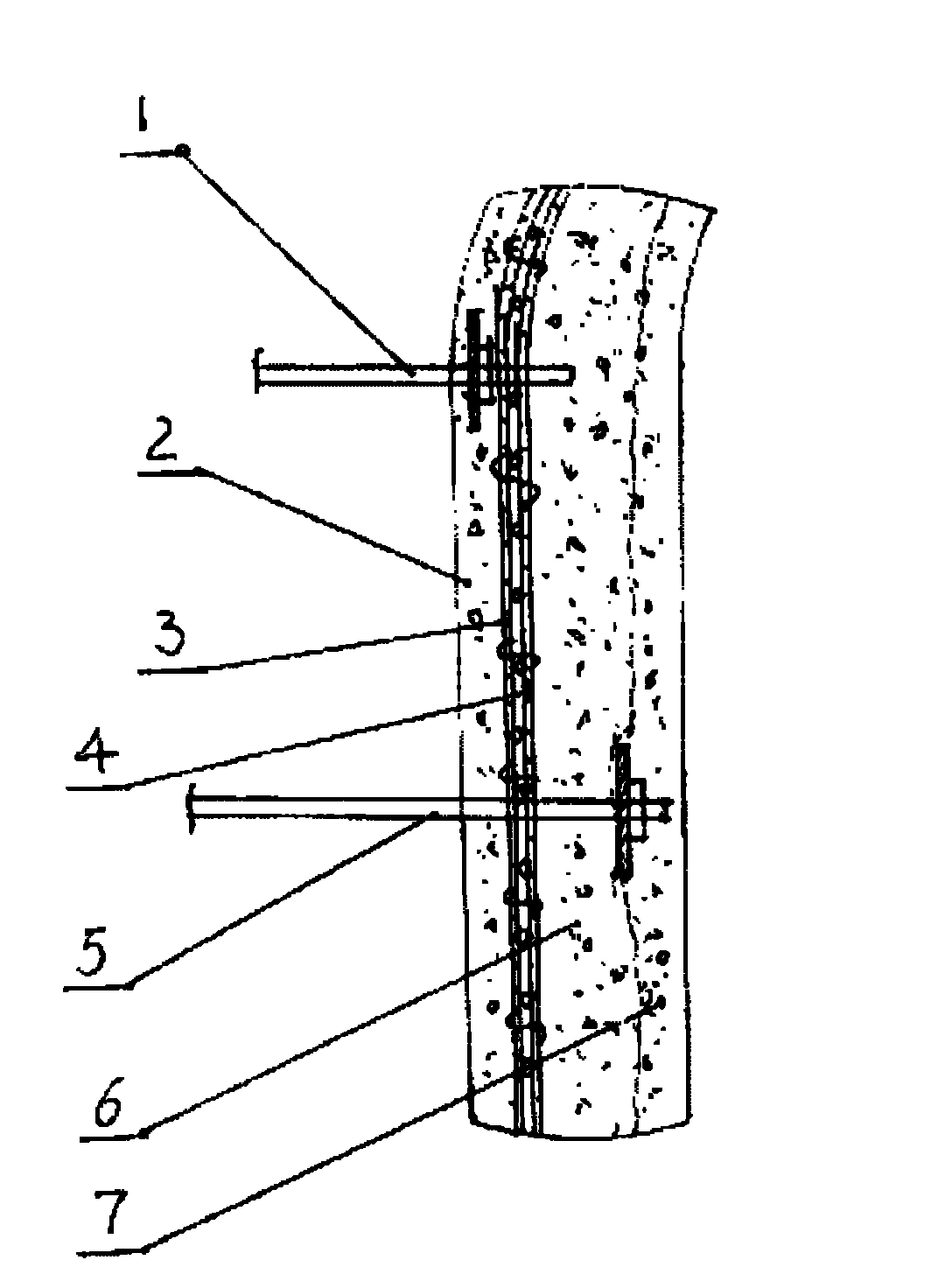

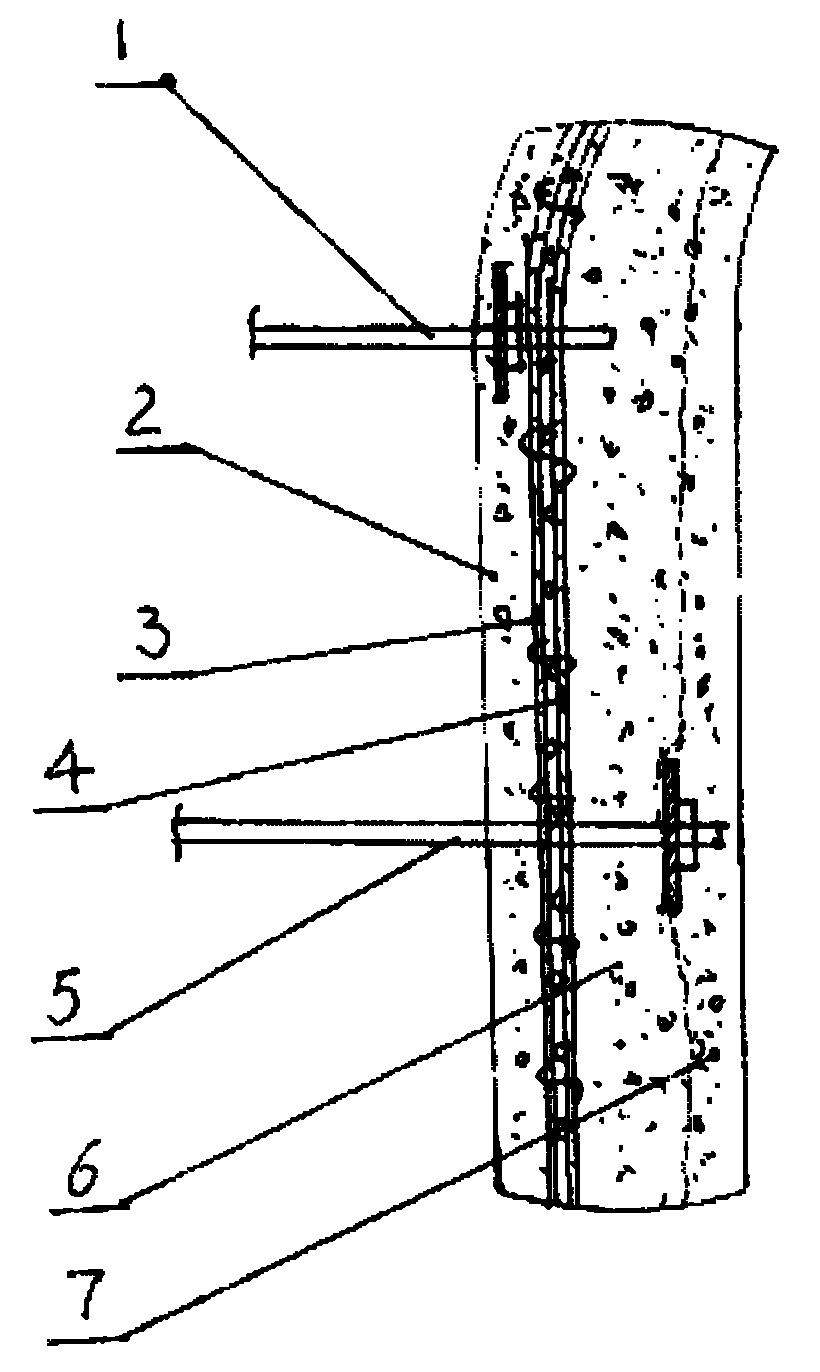

Tensile reinforcement concrete spray body supporting method for deep soft roadway

InactiveCN102635377AIncrease frictionImprove bonding strengthUnderground chambersTunnel liningReinforced concreteEngineering

The invention discloses a tensile reinforcement concrete spray body supporting method for a deep soft roadway. The method includes preliminarily spraying a first layer of concrete on a surrounding rock of the roadway after blasting and punching a hole to mount a primary supporting anchor rod; hanging two layers of reinforcement screens on a head of the reserved primary supporting anchor rod; secondarily spraying concrete on the roadway after the screens are hung on the roadway, punching a hole to mount a secondary supporting anchor rod after secondary concrete spraying, and leading the secondary supporting anchor rod and the primary supporting anchor rod to be in quincunx staggered arrangement; and finally spraying concrete for the third time to cover an exposed portion of the secondary supporting anchor rod. On the basis of sufficiently researching and analyzing breakage forms and mechanisms of the roadway with the broken surrounding rock, tensile reinforcement concrete spray body supporting technology is provided. Repeated practices in fields prove that the technology effectively increases supporting strength of the roadway, and the difficulty about supporting of the deep soft roadway is resolved.

Owner:新汶矿业集团有限责任公司协庄煤矿

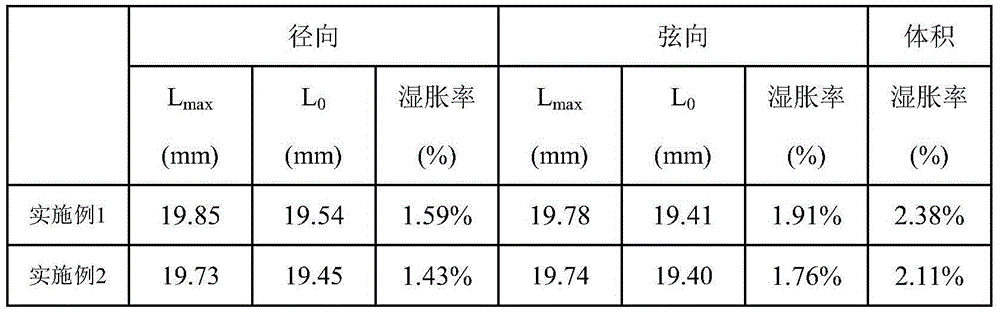

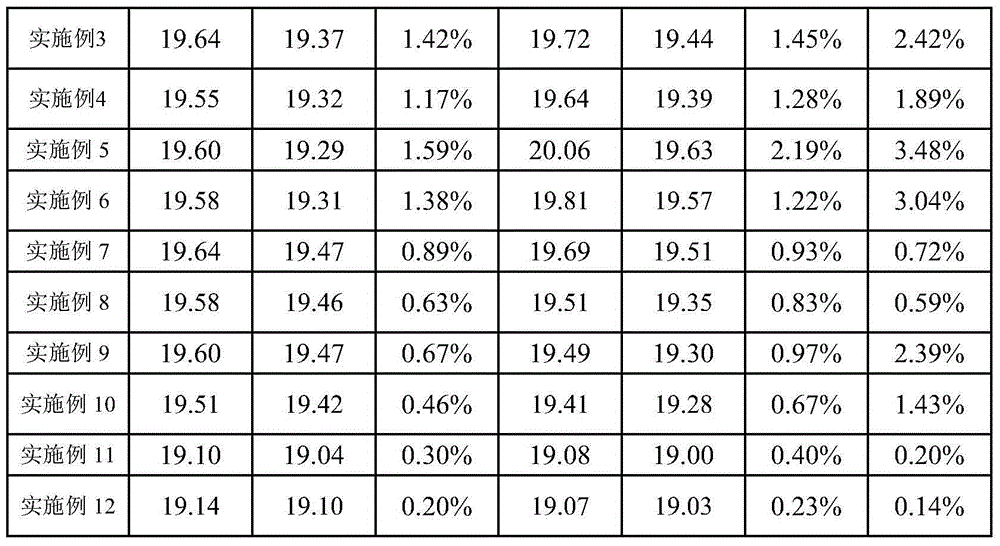

Method for improving dimensional stabilization of wood

InactiveCN105082282AGood dimensional stabilityEven contactWood impregnation detailsWaxProcess conditions

The invention discloses a method for improving the dimensional stabilization of wood. The method comprises the steps of soaking wood in petroleum wax, carrying out soaking process on the wood and making wood absorbing petroleum wax to obtain wood with good dimensional stabilization. According to the method, wax injection process is carried out on the wood in the normal pressure condition, and the petroleum wax is injected into the wood on the premise without damaging performance of the wood. Thus, redundant moisture in the wood can be drained out. Meanwhile, pipe holes of the wood and gaps between cells can be sealed, and the purpose of improving the dimensional stabilization of the wood is achieved. Furthermore, the method is simple in equipment, convenient to operate, controllable in processing condition and suitable for processing various kinds of wood.

Owner:BEIJING FORESTRY UNIVERSITY

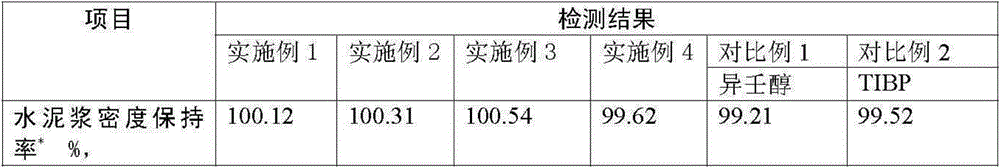

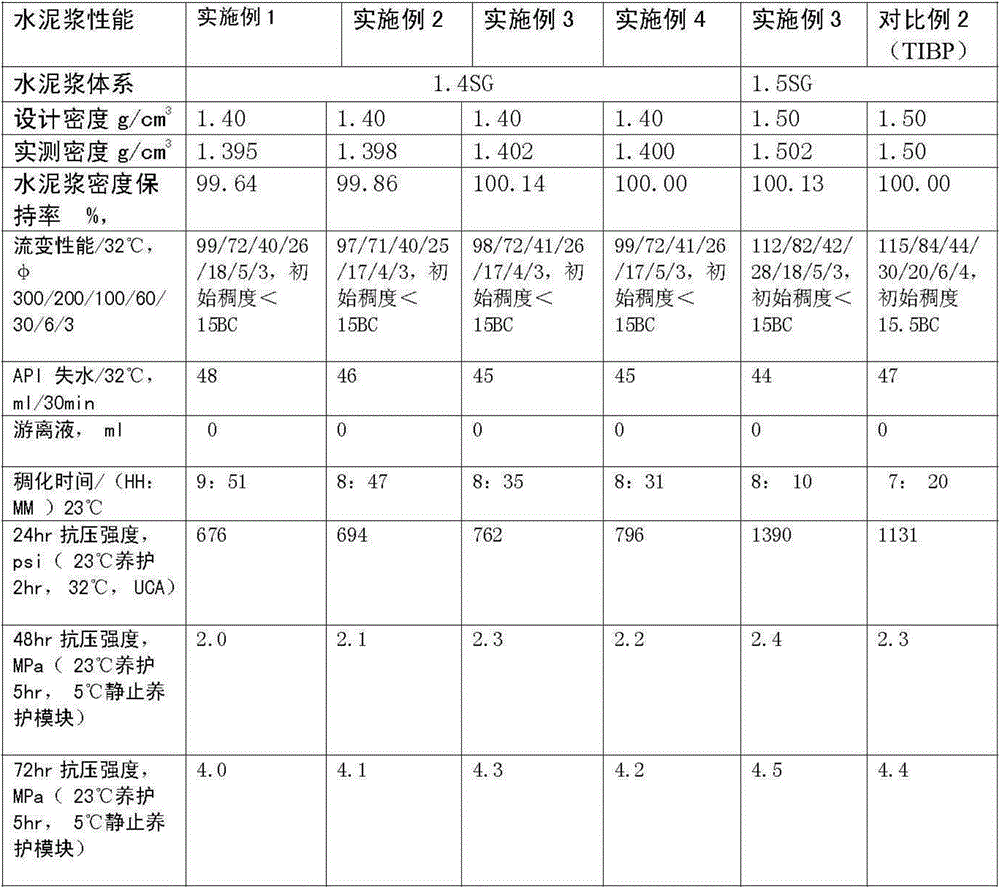

Efficient composite defoaming agent for oil well cement and preparation method thereof

The invention discloses an efficient composite defoaming agent for oil well cement and a preparation method thereof. The defoaming agent is applied to the defoaming and foam inhibition of various admixtures containing cement paste for well cementation in the processes of high-speed shearing and mixing. The defoaming agent comprises the following components in percentage by mass: 15-59.5% of mineral oil, 40-84.5% of polyol fatty acid ester, 0-15% of polyacid fatty alcohol ester and 0.5-15% of a defoaming auxiliary component, wherein the defoaming auxiliary component contains one or two of polyether and tri-isobutyl phosphate. The preparation method of the defoaming agent comprises the following steps: under the condition of stirring at room temperature, sequentially adding the mineral oil, the polyol fatty acid ester, the polyacid fatty alcohol ester and the defoaming auxiliary component into a batching kettle; mixing for 0.5-2.0 hours; filtering the obtained mixture, and discharging the obtained object; and carrying out measurement packing on the obtained product. Compared with common defoaming agents for oil well cement, the defoaming agent disclosed by the invention is low in cost and simple in manufacturing process, products are uniform and stable, and the defoaming agent concurrently has the functions of defoaming and foam inhibition, and does not affect the rheological property and thickening property of cement paste and the compressive strength and the like of cement.

Owner:NANJING YUNYUE NEW MATERIAL TECH CO LTD

Semiconductor device and fabrication method thereof

InactiveUS20070085182A1Increase pinImprove bonding strengthSemiconductor/solid-state device detailsSolid-state devicesSolder ballDevice material

A semiconductor device includes a semiconductor chip having a plurality of electrode pads, and a rewiring pattern having a plurality of interconnects which are connected to the electrode pads and extend over an insulation film. The semiconductor device also includes a plurality of columnar electrodes each of which has a main body section and a protrusion section, and a sealing section which has a top face having a height the same as the top faces of the protrusion sections. The semiconductor device also includes solder balls formed on the protrusion sections. The semiconductor device also has a plurality of trenches in the sealing section. Each trench has a depth which reaches the boundary between the main body and protrusion of the electrode. The side faces of the protrusion section are exposed face defined by the trenches. Each solder ball is electrically connected to the top face and side faces of the protrusion section of each electrode.

Owner:LAPIS SEMICON CO LTD

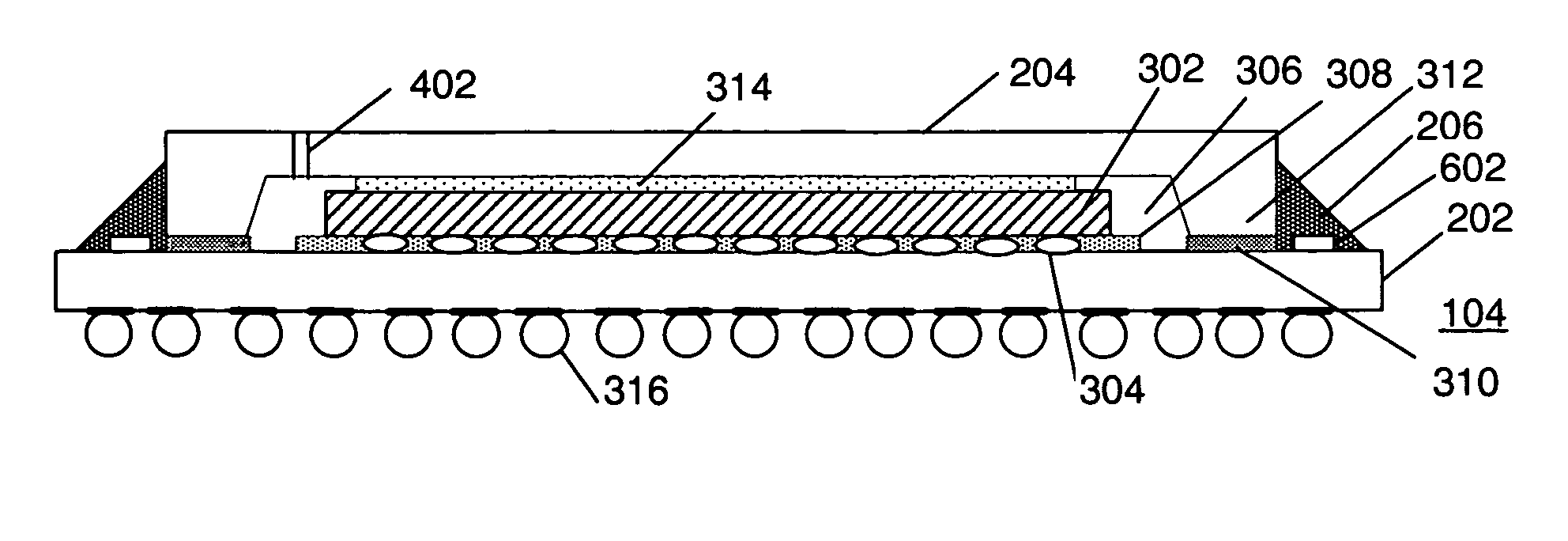

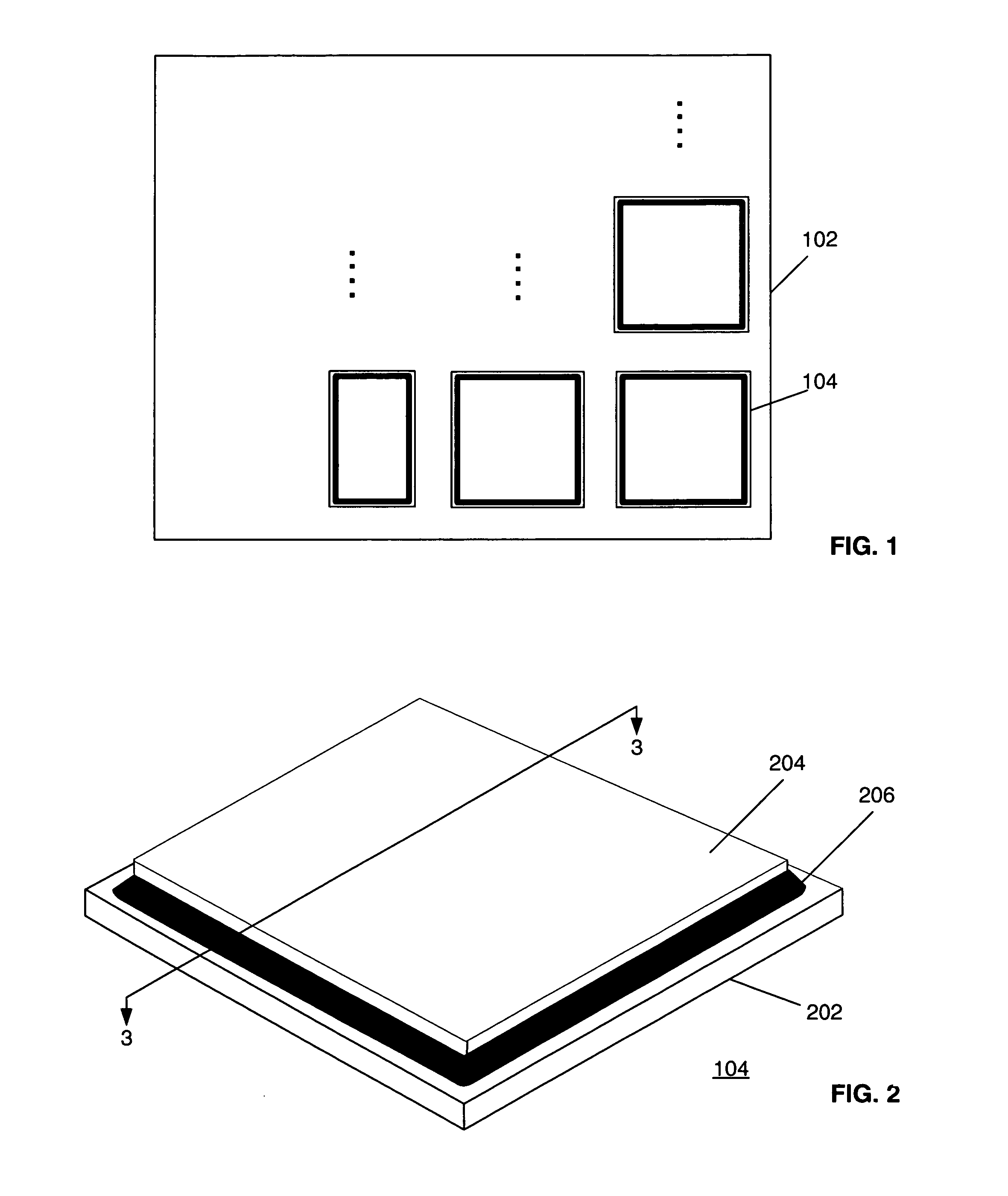

Integrated circuit having a lid and method of employing a lid on an integrated circuit

ActiveUS7187077B1Improve bonding strengthHigh bonding strengthSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuit

Owner:XILINX INC

Method for producing uniform-density bamboo shaving board

InactiveCN102198685ALow costSave on energy costsWood working apparatusFlat articlesEngineeringVolumetric Mass Density

The invention relates to a machining process for an artificial board, in particular to a method for producing a uniform-density bamboo shaving board. The invention is realized through the following technical scheme: the method for producing the uniform-density bamboo shaving board is characterized by sequentially comprising the following steps of: (1) selecting materials; (2) first screening; (3) first drying; (4) second screening; (5) second drying; (6) sizing; (7) hot-pressing; and (8) refrigerating. The uniform-density bamboo shaving board has the advantages of density uniformity, high dimensional stability and high static bending strength.

Owner:浙江安吉强裕人造板有限公司

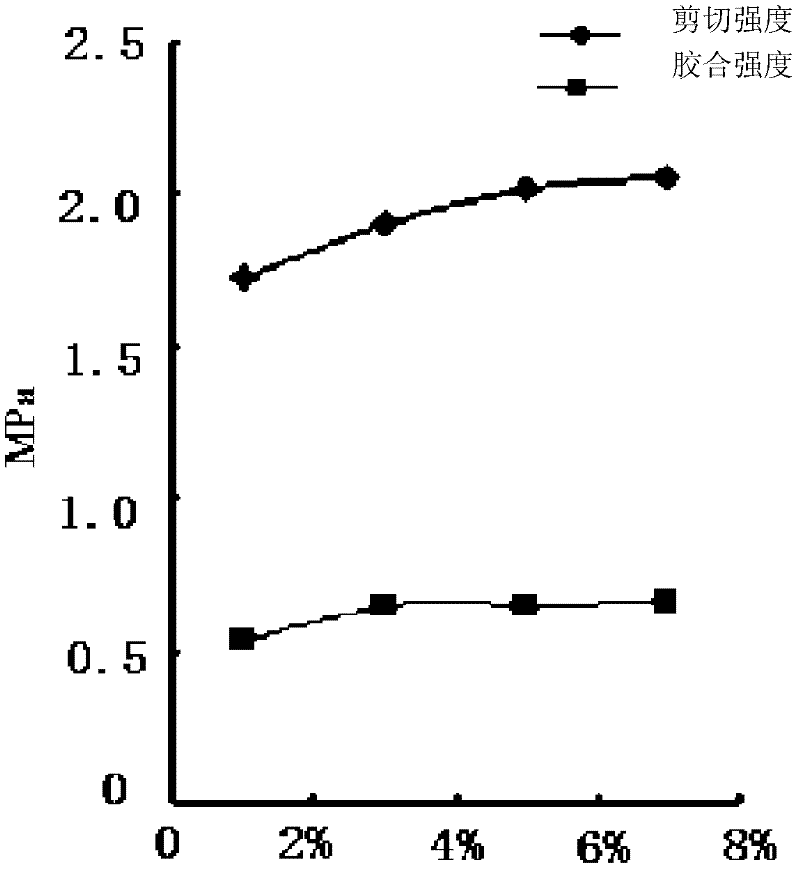

Concrete anti-bleeding inhibitor with water reducing function and preparation method thereof

The invention discloses a concrete anti-bleeding inhibitor with a water reducing function and a preparation method thereof. The anti-bleeding inhibitor is mainly prepared by subjecting polyether largemonomer, unsaturated carboxylic acid, unsaturated amide, unsaturated sulfonic acid or sulfonate, a cross-linking agent, an oxidizing agent, a reducing agent, a chain transfer agent and deionized water to free radical polymerization at 15-30 DEG C through an aqueous solution, adding a sodium hydroxide solution to adjust a pH value and then supplementing water. According to the preparation method,production is conducted at normal temperature, no heat sources are needed, the equipment is simple, no pollution is generated, the production efficiency is high, and the anti-bleeding inhibitor can effectively solve the problems that existing polycarboxylic acid water reducers are poor in water retention and water absorption performance and workability, and bleeding and bottom holding are easy tooccur; the inhibitor has excellent thickening and water retention performance, and the degree of construction difficulty can be greatly reduced.

Owner:SICHUAN TONGZHOU CHEM TECH

Wind prevention, sand fixation and water retention afforestation method

ActiveCN105918056AStrong molecular adsorptionExcellent adhesionClimate change adaptationAfforestationSoil sciencePlastic mulch

The invention discloses a wind prevention, sand fixation and water retention afforestation method and belongs to the technical field of environmental protection engineering. The method comprises steps as follows: a curing agent is prepared from sodium carboxymethylcellulose, anionic polyacrylamide, ferrous chloride and water; the curing agent and sand are blended to form cured sand; deep holes for tree planting and shallow trenches for grass planting are dug in the sand land, water collecting hoppers are drilled in the deep holes, the deep holes and the shallow trenches are filled with the cured sand, and the cured sand form deep hole sand fixation and water absorption layers in the deep holes and form shallow trench sand fixation and water absorption layers in the shallow trenches; saplings are planted in the deep holes, the roots of the saplings extend into the mouth parts of the water collecting hoppers, and grass seeds are scattered in the deep holes and the shallow trenches; the grass seeds are covered with a mulching film for maintenance, and small ventilation holes are formed in the mulching film. The curing agent and the sand soil are blended, inside gaps of soil particles can be filled with the blended curing agent and sand soil, the cured sand particles don't easily disperse and jump, sufficient water can be continuously provided for plants, and the long-time wind prevention, sand fixation and water retention effects are achieved.

Owner:裴向军 +1

Water-soluble non-formaldehyde wood adhesive and method for preparing same

InactiveCN102653667AImprove bonding strengthEasy to prepareWood veneer joiningGraft polymer adhesivesPara-toluenesulfonic acidWater soluble

The invention provides a water-soluble non-formaldehyde wood adhesive which is prepared from raw materials according to weight by part as follows: 200-600 parts of starch, 500-1000 parts of distilled water, 20-400 parts of water-soluble olefin grafting monomer, 10-200 parts of cross-linking agent, 1-2 parts of para-toluenesulfonic acid, and 10-70 parts of polymerization reaction catalyst. The invention also discloses a method for preparing the adhesive, specifically comprising the following steps of: weighing all of the raw materials according to the proportions, mixing the raw materials together evenly, and in the mechanical stirring state, causing the mixture to continuously react for 1-2 h at 60-80 DEG C, thereby obtaining the water-soluble non-formaldehyde wood adhesive. The adhesive disclosed by the invention is a water-soluble adhesive free of formaldehyde; the water-soluble olefin monomer is used for grafting, and the bonding of wood materials can be achieved through grafting and cross-linking on the surface of wood powder; the bonding strength is high; the bonding can be strengthened through microwaves or heating; the preparation method is simple; the adhesive has excellent properties such as good storage stability and quick strength building; and the adhesive can be widely applied to the fields of wood joining, artificial plate and the like.

Owner:BEIJING FORESTRY UNIVERSITY

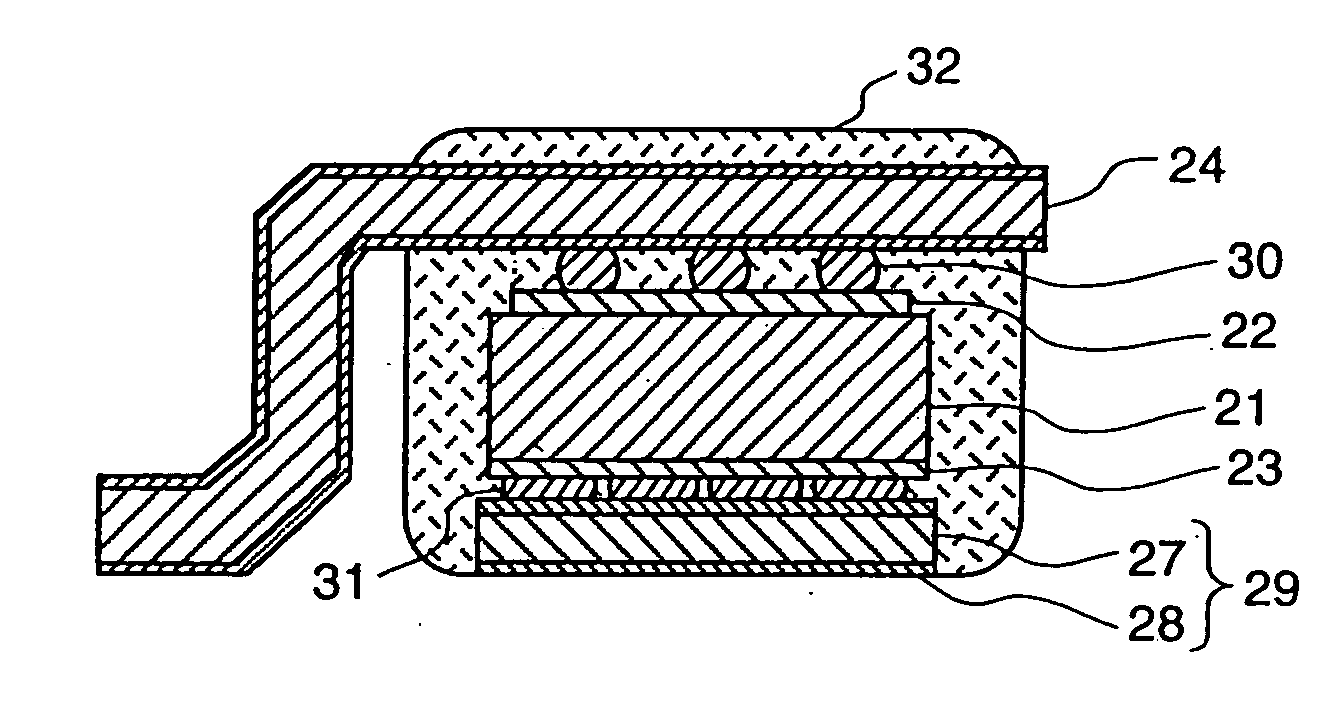

Semiconductor device

InactiveUS20060197200A1Characteristic be lowImprove bonding strengthSemiconductor/solid-state device detailsSolid-state devicesSemiconductor componentsPrecious metal

A semiconductor device, wherein a first metallic member is bonded to a first electrode of a semiconductor element via a first metallic body containing a first precious metal, and a second metallic member is bonded to a second electrode via a second metallic body containing a second precious metal.

Owner:RENESAS SEMICON PACKAGE & TEST SOLUTIONS +1

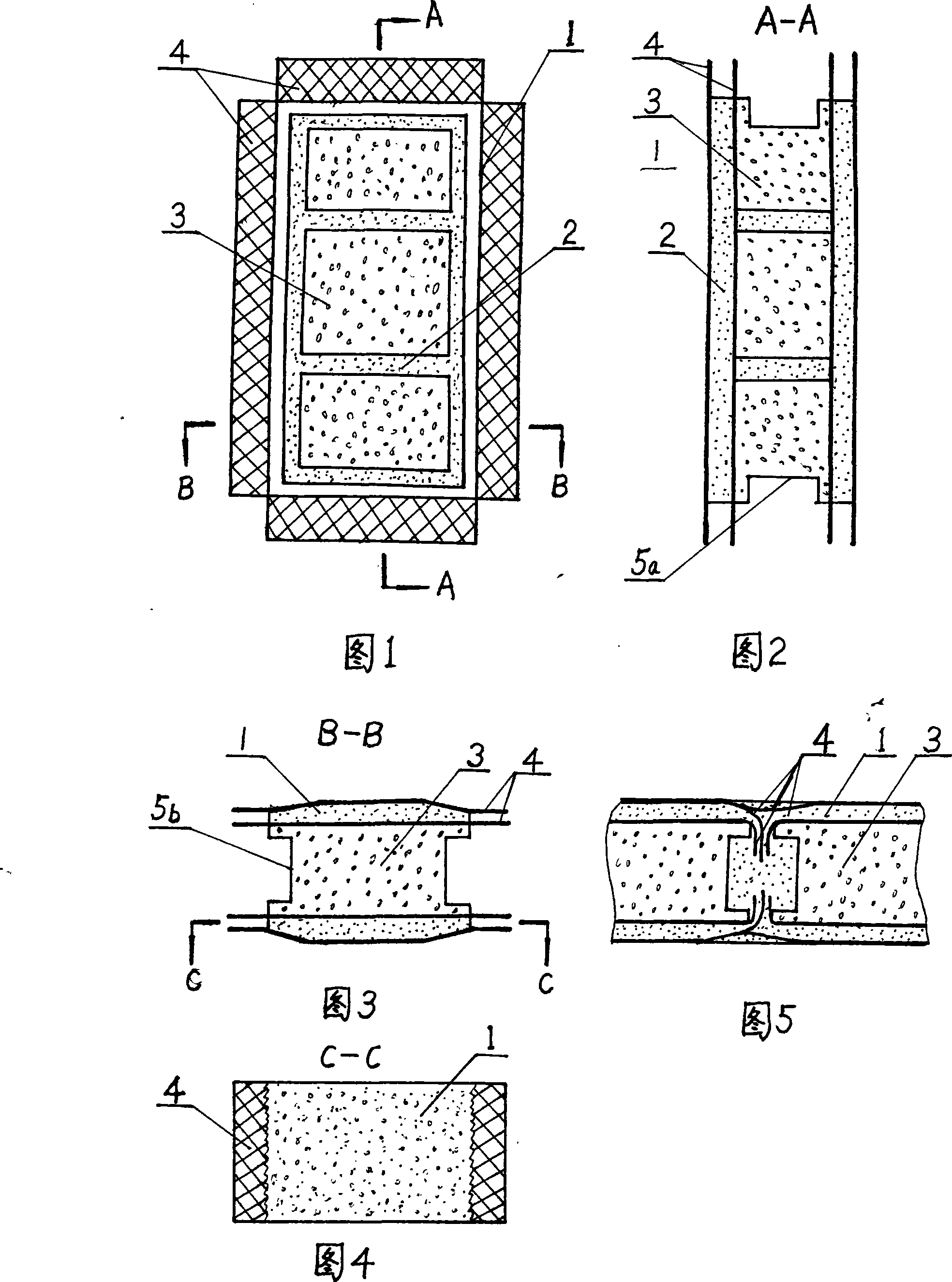

Light energy-saving wall board capable of preventing joint from disintegrating as well as installation method thereof

InactiveCN101250925AReasonable structural designImprove bonding strengthConstruction materialSolid waste managementScrapMagnesium

The invention relates to a light energy-saving seam split-preventing wallboard, wherein the upper mounting plate and the lower mounting plate and both side butt-joint edges of the wallboard are provided with grooves used for butt joint; the surface layer of the wallboard consists of a slurry layer and more than one layer of fabric layer; the fabric layer extends out of a face plate to form a mounting lapping conglutination layer; the slurry layer is prepared from raw materials according to the following part by weight: 30 to 40 portions of magnesium sulphate or magnesium chloride, 80 to 100 portions of magnesium oxide, 30 to 50 portions of coal ash, 50 to 60 portions of scrap plant fiber, 10 to 15 staple glass fiber, 0.6 to 1 portions of modifier and 120 to 160 portions of water. The wallboard which has reasonable structural design can greatly increase the cohesive force of the wallboard during butt joint; meanwhile, when installed through adopting the method of the invention, the wallboard can completely eliminate the seam split phenomenon of a wall body during use. Moreover, the wallboard has the advantages of light weight, high strength, no crushing and good thermal-insulation effect and good inflaming retarding effect, etc.

Owner:邢思银

Preparation method of lithium battery negative pole material

ActiveCN106410200AIncrease spacingSmall peeling forceMaterial nanotechnologyCell electrodesNano siliconFreeze-drying

The invention discloses a preparation method of a lithium battery negative pole material. The preparation method comprises the following steps: 1) preparing graphene nanoplatelets: stirring and mixing H2SO4 and (NH4)2S2O8, adding graphite powder after (NH4)2S2O8 is dissolved, further stirring, dropwisely adding H2O2, standing to obtain expanded graphene aggregate, washing with water to neutral, and drying; and adding the dried graphene aggregate into an N-methylpyrrolidone solution, pulverizing to obtain a graphene solution, centrifuging, washing with water, and freeze-drying to obtain graphene nanoplatelet powder; and 2) adding the graphene nanoplatelet powder prepared in the step 1) together with nano silicon powder, polyacrylonitrile and artificial graphite into a container containing dimethylformamide, performing ultrasonic dispersion, freeze-drying to obtain a graphene / nano silicon powder / polyacrylonitrile / artificial graphite mixture, calcining the mixture to obtain a graphene / nano silicon powder / cyclized polyacrylonitrile / artificial graphite compound, and crushing the compound to obtain the graphene / nano silicon powder / cyclized polyacrylonitrile / artificial graphite mixed negative pole material.

Owner:ZHEJIANG JILI POWER NEW ENERGY

Heat-insulating plastering gypsum for building interior wall and preparation method thereof

The invention discloses heat-insulating plastering gypsum for a building interior wall and a preparation method thereof and relates to the technical field of plastering gypsum. The heat-insulating plastering gypsum comprises 55-75 parts of desulfurized gypsum, 20-30 parts of natural gypsum, 15-20 parts of cement, 15-20 parts of heat-insulating filler, 10-15 parts of modified heavy calcium carbonate, 10-15 parts of plant source additive, 5-10 parts of rubber powder, 5-10 parts of modified expandable graphite and 7-12 parts of auxiliary. The preparation method includes: pretreating the natural gypsum. The heat-insulating plastering gypsum is used for being brushed on the building interior wall, is excellent in heat-insulating performance and has high adhesiveness, and a coating is free of shrinking and cracking and less prone to shedding.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Fabrication method of anti-corrosive and wear-resistant pipeline for delivering minerals

ActiveCN103276282AEvenly distributedHigh hardnessCorrosion preventionPipe protection against corrosion/incrustationTemperingNanocomposite coating

The invention relates to a fabrication method of an anti-corrosive and wear-resistant pipeline for delivering minerals. The method comprises the steps that a wear-resistant pipeline body is fabricated by centrifugal casting; quenching, high temperature tempering, solid solution strengthening heat treatment and a double tempering dispersion hardening heat treatment technology are performed; an outer wall of the pipeline is coated with a water glass nano composite coating subjected to test configuration; high temperature solidifying and then cooling are performed; a high-temperature-resistant, oxidized and anti-corrosive filming inner layer is obtained; and finally an inner wall of the pipeline is coated with a wear-resistant coating. The fabricated metal pipeline has higher hardness and wear-resistant property; the anti-corrosive outer coating of the pipeline has excellent water resistance, anti-fouling effect and high-temperature-resistant property; and the anti-corrosive inner coating of the pipeline has excellent wear-resistant property.

Owner:JIANGSU JINSHENGYUAN SPECIAL VALVE

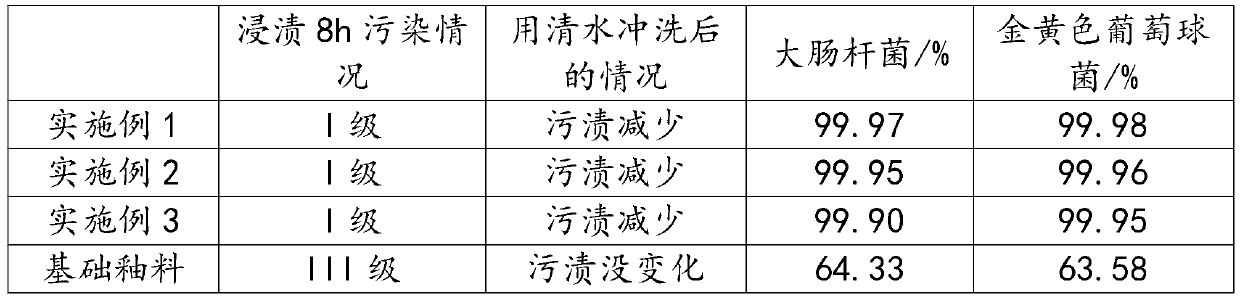

Antifouling antibacterial ceramic glaze and preparation method thereof

The invention discloses an antifouling antibacterial ceramic glaze, which is prepared from, by weight, 50-60 parts of basic glaze slurry, 7-9 parts of calcium oxide, 3-5 parts of calcium carbonate, 4-6 parts of aluminum hydroxide, 4-5 parts of an antibacterial agent, 5-7 parts of nano zinc oxide, 2-3 parts of sodium hexametaphosphate, 8-10 parts of a phosphoric acid aqueous solution and 2-3 partsof an yttrium nitrate aqueous solution. The invention further discloses a preparation method of the antifouling antibacterial ceramic glaze. By the adoption of the antifouling antibacterial ceramic glaze and the preparation method thereof, the antibacterial agent is added into basic glaze, the antibacterial agent can be uniformly distributed in the glaze, and sintered ceramic can continuously andslowly release silver ions in water, so that a continuous antibacterial effect is achieved; the phosphoric acid aqueous solution and the yttrium nitrate aqueous solution are adopted in the glaze, so that the ceramic sintered by the glaze has good hydrophobicity, dirt cannot be firmly attached to the surface of the coating, the dirt can be washed away when water drops flow past a surface layer, andan antifouling effect is achieved; and a preparation process is simple, the conditions are easy to control, and production cost is low.

Owner:潮州市华利达陶瓷制作有限公司

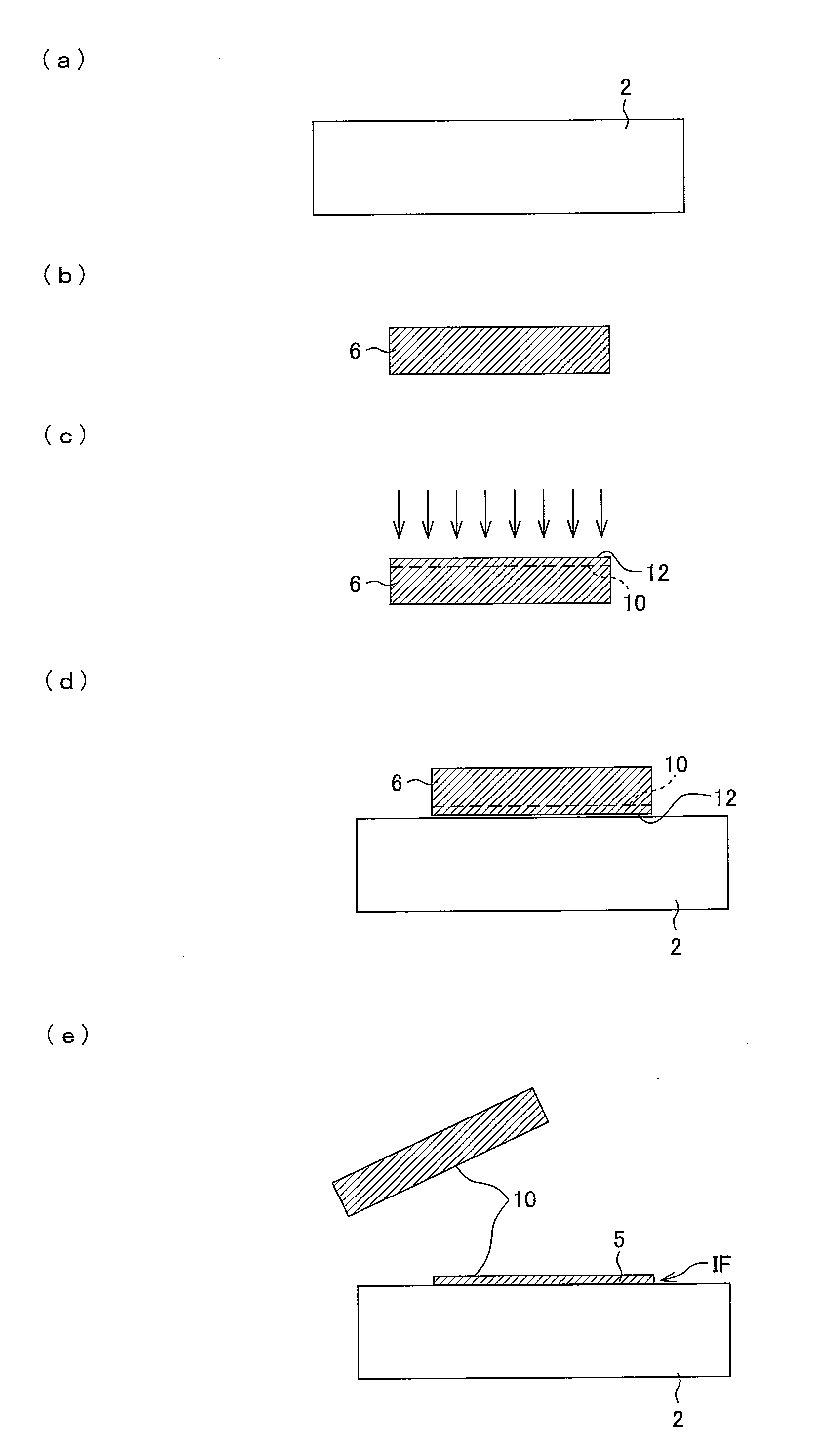

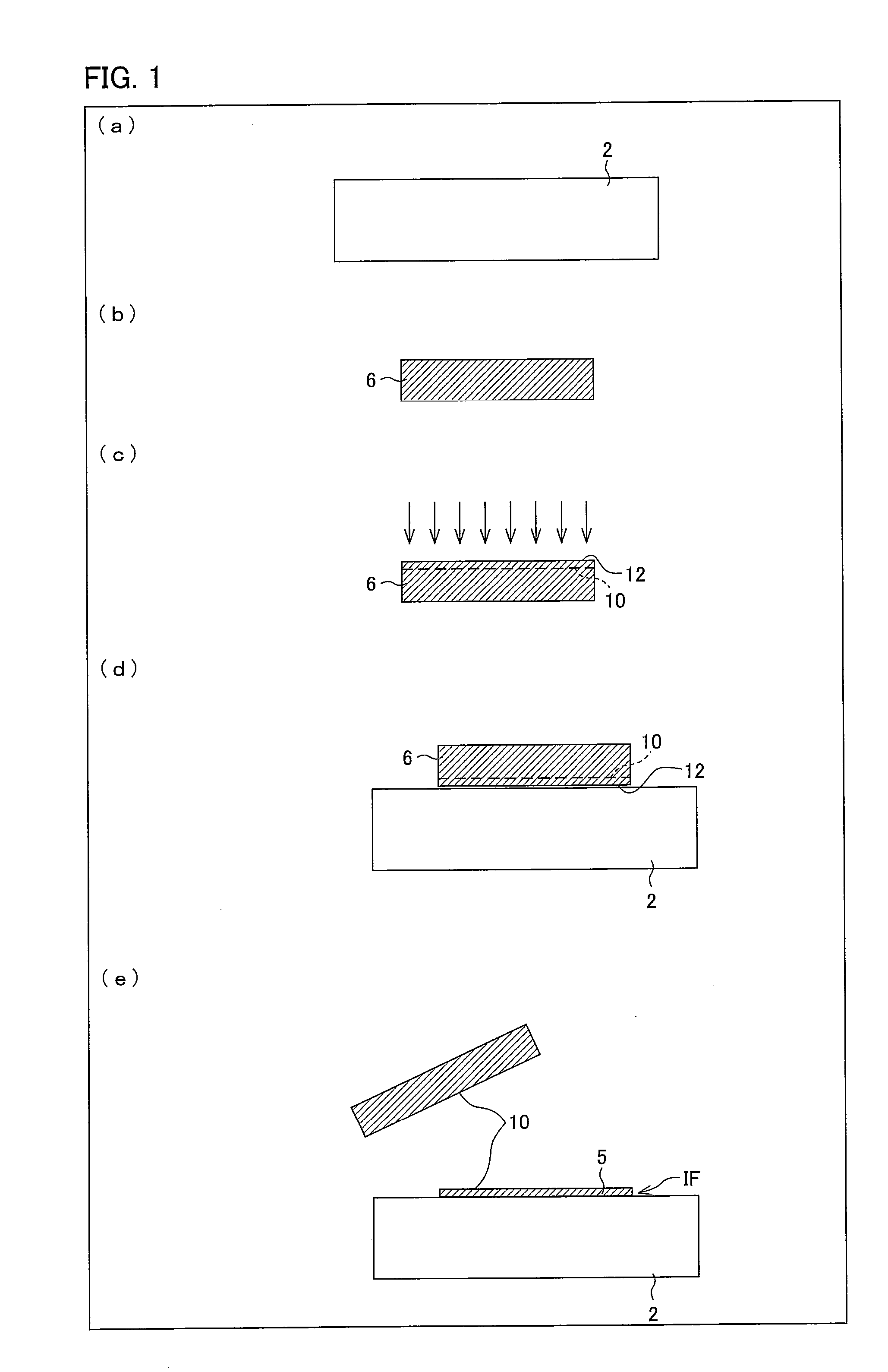

Method for producing semiconductor device and semiconductor device produced by same method

InactiveUS20100207212A1Improve bonding strengthMore timeTransistorSolid-state devicesEngineeringSemiconductor

To prevent bubbles from occurring along a transfer interface, the present method includes the steps of: forming a peeled layer 10 in a transferred member 6 by implanting a peeled-layer forming substance into the transferred member 6; forming a planar surface in the transferred member 6 by planarizing a surface of the transferred member 6; forming a composite including the transferred member 6 and a glass substrate 2 by directly combining the transferred member 6 via the planar surface with a surface of the glass substrate 2; and peeling a part of the transferred member 6 from the composite along the peeled layer 10 serving as an interface by heat-treating the composite.

Owner:SHARP KK

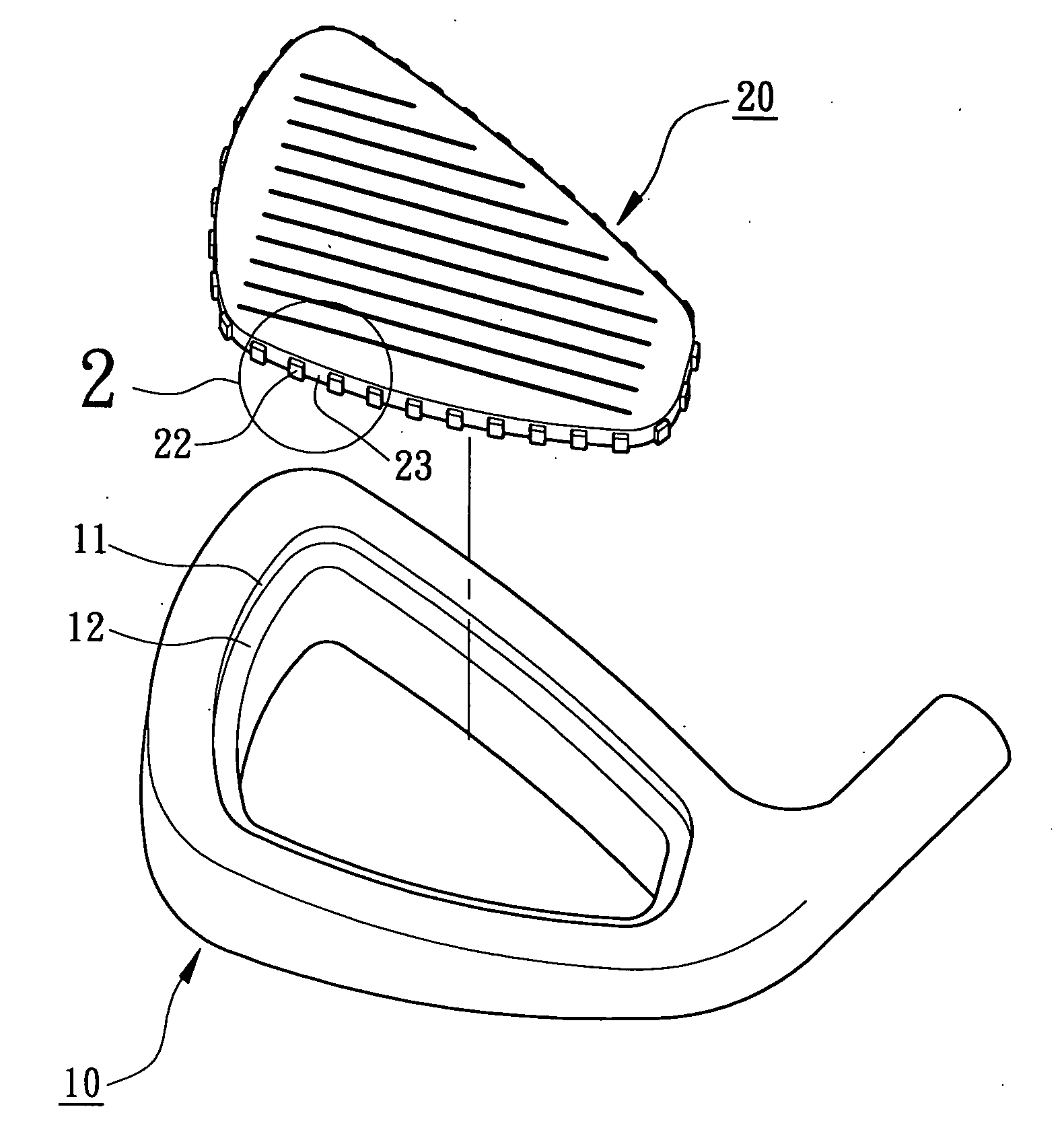

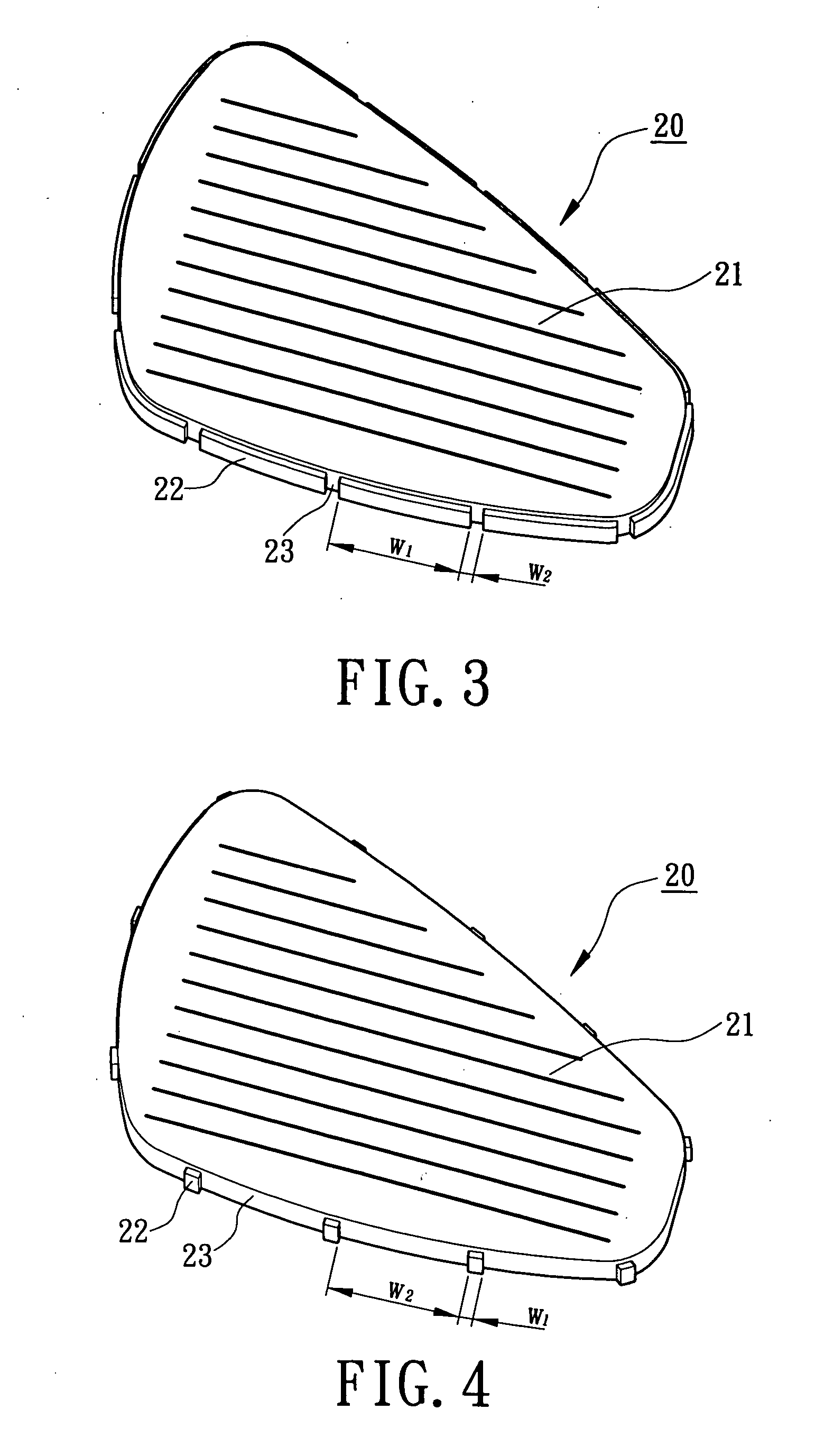

Connecting structure for a striking plate of a golf club head

InactiveUS20050181890A1Improve bonding strengthManufacturing cost be reduceGolf clubsRacket sportsEngineeringGolf club

A golf club head includes a body and a striking plate. The body includes a recess in a front side thereof. A plurality of positioning protrusions project from a perimeter of the striking plate. When the striking plate is inserted into the recess of the body, the positioning protrusions plastically deform and engage with an inner perimeter delimiting the recess, thereby positioning the striking plate in the recess and simplifying assembling and positioning for a subsequent welding procedure. In another embodiment, the positioning protrusions project from the inner perimeter delimiting the recess, and when the striking plate is inserted into the recess of the body, the positioning protrusions plastically deform and engage with the perimeter of the striking plate.

Owner:FUSHENG IND CO LTD

Ceramic adhesive and preparation method thereof

InactiveCN107353872AImprove adhesionMaterials are readily availableMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAdhesiveHigh carbon

The invention relates to a ceramic adhesive and a preparation method thereof. The ceramic adhesive is prepared from raw materials in parts by weight as follows: 20-35 parts of quartz sand, 10-13 parts of synthetic resin, 10-15 parts of butanediol, 5-9 parts of amino resin, 3-6 parts of phenolic resin, 6-8 parts of a polyvinyl acetate emulsion, 8-11 parts of butyl p-hydroxybenzoate, 5-10 parts of high-carbon alcohol aliphatic ester composition and 3-5 parts of titanium dioxide. The materials are easy to obtain, the preparation method is simple, the ceramic adhesive is low in cost, small in density, light in mass, high in adhesion, high in bonding force, good in permeability, waterproof, moisture-proof and high-temperature resistant, has certain fireproof effect and insulativity and good defoaming or non-foaming effect, realizes rapid drying, can effectively bond hard materials such as ceramic, metal and the like and is wide in application range, safe, non-poisonous and good in environment-friendly effect.

Owner:方碧水

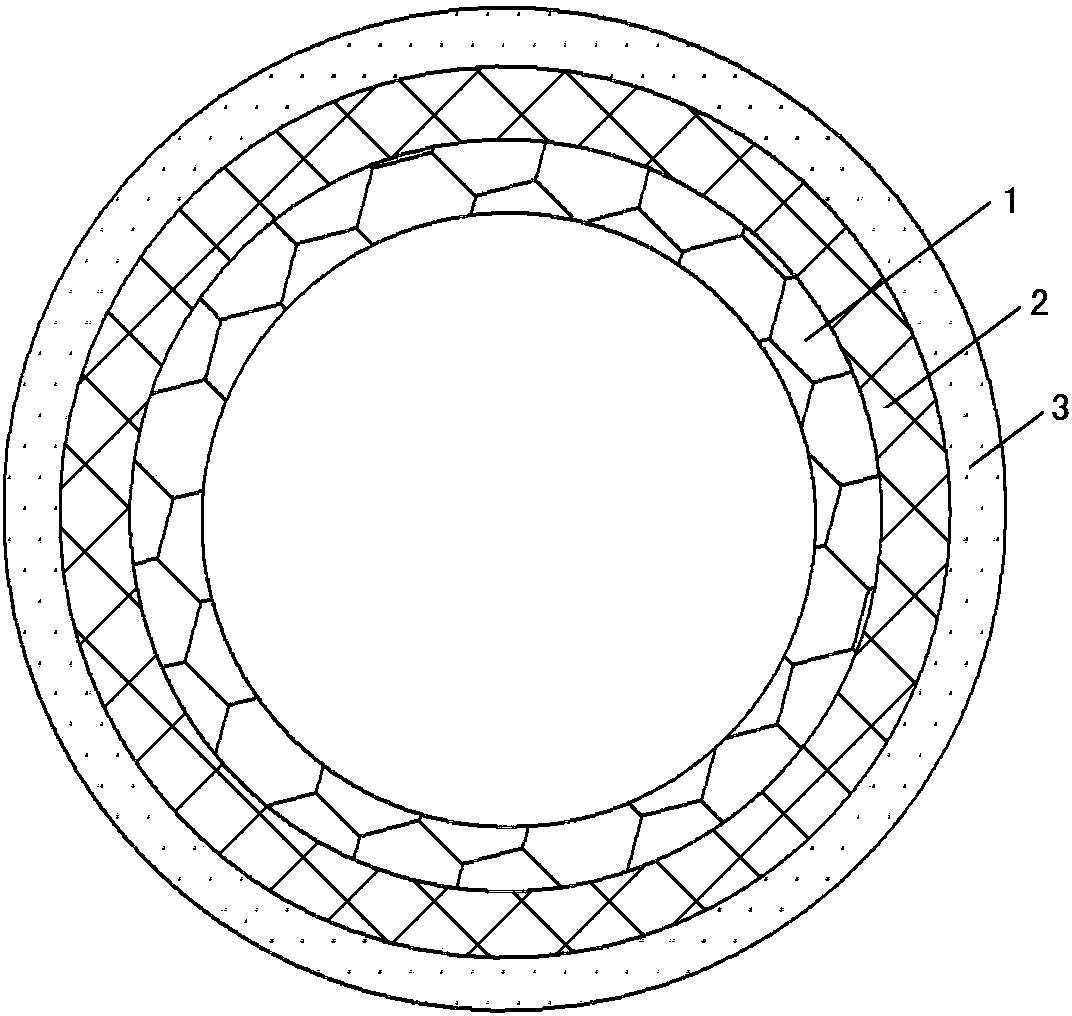

Household fuel gas rubber hose and preparation method thereof

The invention relates to the field of manufacturing anindoor hose in a household natural gas pipeline, in particular to a preparation method of a rubber hose non-metal material used in anti-solvent type (methane type) medium. The novel household fuel gas hose has a multilayer composite structure which consists of an inner layer (1), a middle layer (2) and an outer layer (3), the three layers are respectively formed by mixing the following compositions in parts by weight: the inner layer (1): 30-100 parts of epichloro-hydrin rubber, 0-70 parts of nitrile butadiene rubber, 10-200 parts of filling reinforcing agent, 0.5-40 parts of vulcanizing agent, 0.5-20 parts of accelerant, and other processing aids; the middle layer (2): 100 parts of nitrile butadiene rubber, 10-200 parts of filling reinforcing agent, 0.5-20 parts of vulcanizing agent, 0.5-20 parts of accelerant, and other processing aids; the outer layer (3): 10-100 parts of chloroprene rubber, 0-90 parts of chlorinated polyethylene, 10-200 parts of filling reinforcing agent, 0.5-20 parts of vulcanizing agent, 0.5-20 parts of accelerant, and other processing aids. The obtained rubber hose is good in physical and mechanical properties, good in airtight property, and good in fuel gas corrosion resistance, pressure resistance and thermal stability, and the service life of the rubber hose can be prolonged.

Owner:BEIJING GAS GRP +2

Premixed colored pervious concrete

Disclosed premixed colored pervious concrete is prepared from the following components in parts by weight: 289 to 306 parts of cement, 51 to 54 parts of fly ash, 15 to 25 parts of a reinforcing agent, 1450 to 1550 parts of coarse aggregate, 3.4 to 3.6 parts of a water reducing agent, 90 to 120 parts of mixing water, 0.51 to 0.54 part of a tackifier and 10 to 15 parts of a coloring agent. The cement is adopted as a main cementing material, the coal ash improves the workability and durability, the reinforcing agent improves the strength of the premixed colored pervious concrete and inhibits surface efflorescence, the tackifier improves the bonding force between slurry and an aggregate interface, and the inorganic coloring agent ensures that the color of a surface layer of the premixed colored pervious concrete is durable and does not fade. In the premixed colored pervious concrete, the slurry can uniformly wrap the aggregate and is clustered by hand holding, the cementing force of the slurry and the aggregate is strong, stones do not fall off for a long time, the permeable rate after hardening is high, the strength is not lower than C20, the color is lasting and does not fade, saltpetering is avoided, and the durability is good.

Owner:陕西建工集团混凝土有限公司

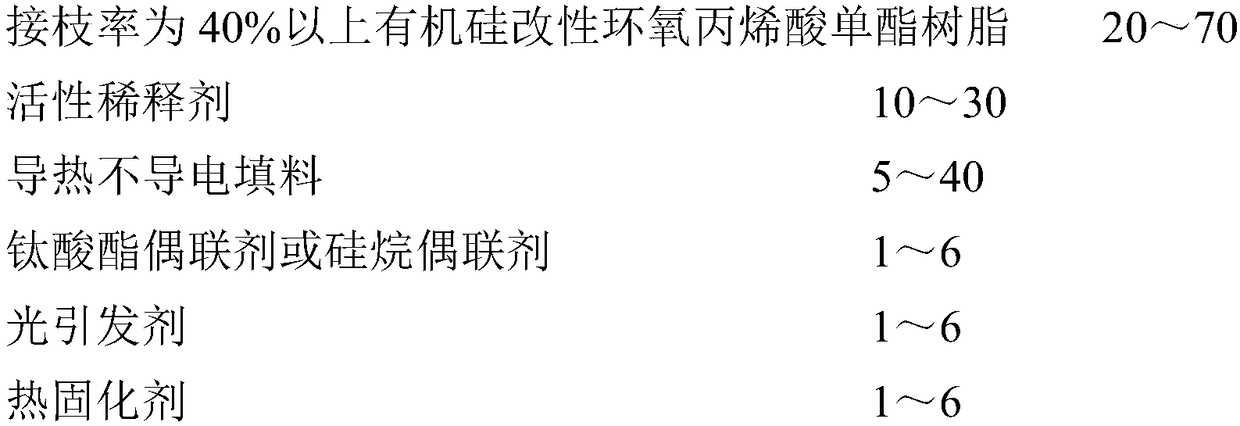

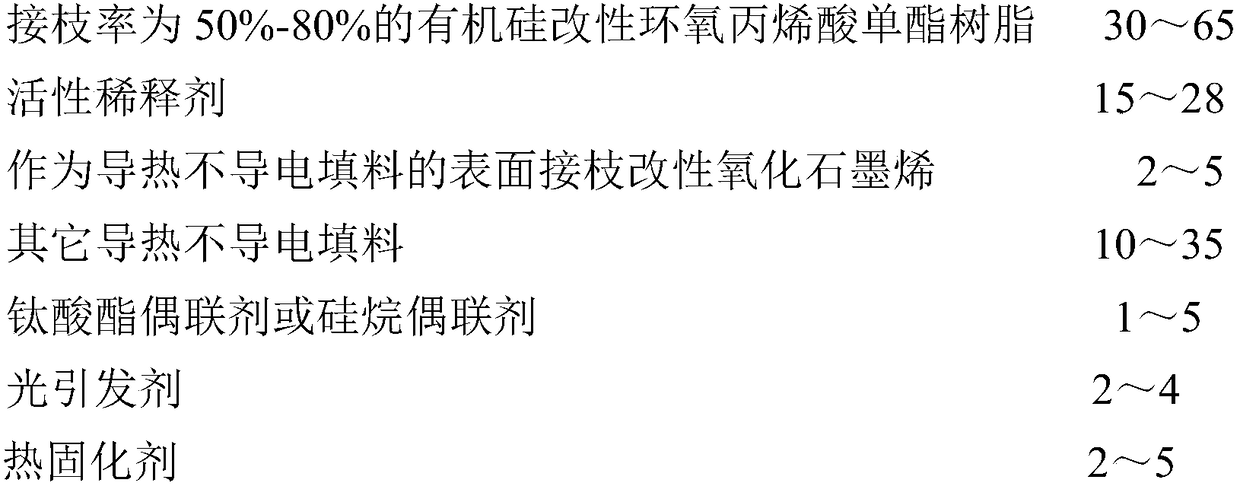

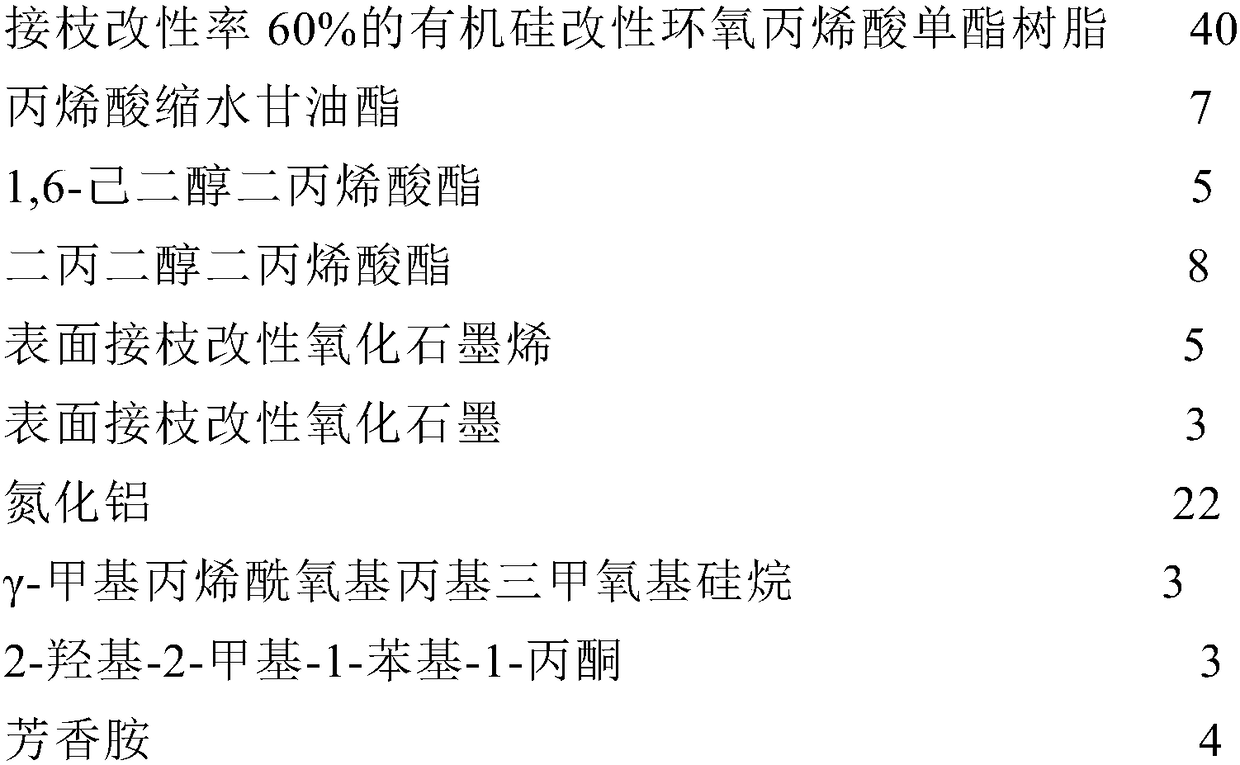

Ultraviolet light hybrid curing packaging adhesive composition

ActiveCN109337638AImprove bonding strengthDouble bond density decreasesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPhotoinitiatorOmega

The invention discloses an ultraviolet light hybrid curing packaging adhesive composition. The composition consists of organosilicone modification epoxy acrylic resin, a thinner, a photoinitiator, a heat curing agent, a heat conduction non-conductive fiber, a coupling agent and the like, wherein the heat conduction non-conductive fiber comprises surface grafted modified oxidized graphene / graphite.The adhesive strength of the composition is greater than 1.3 MPa, the heat-resistance temperature exceeds 190 DEG C, the thermal conductivity is greater than 1.21 W / m.K, the volume resistivity is greater than 1013 omega.m, the packaging requirement of some components and parts in electron industry can be met, and the composition can be applied to the adhesive fixation of radiating devices.

Owner:SHENZHEN POLYTECHNIC

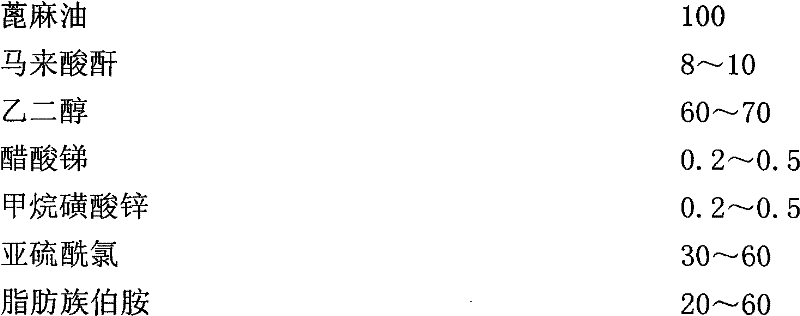

Amino polyester polyether castor oil, preparation method and application thereof

InactiveCN102604064AFast curingImprove bonding strengthPolyureas/polyurethane adhesivesMaleic anhydrideIsocyanate

The invention relates to amino polyester polyether castor oil, a preparation method and application of the amino polyester polyether castor oil. The amino polyester polyether castor oil is prepared from castor oil, maleic anhydride, glycol, composite catalyst, thionyl chloride and primaryaliphaticamine. When in use, the amino polyester polyether castor oil is mixed with polyaryl polymethylene isocyanate (PAPI) according to mass ratio of 1:1, and the mixture is evenly coated on the surface of bonded material by an automatic continuous forming machine or intermittent-type process route, whereinthe glue application dosage is 0.5kg / m<2>.

Owner:UNIV OF JINAN

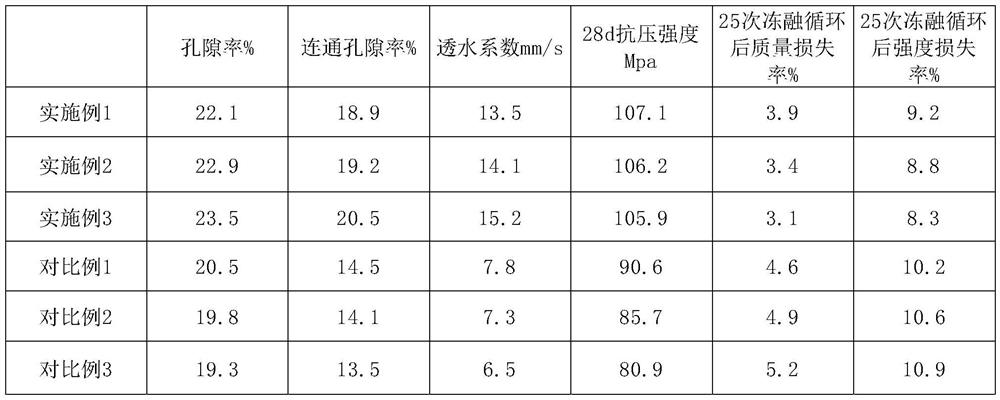

Recycled aggregate pervious concrete and preparation method thereof

The invention discloses recycled aggregate pervious concrete and a preparation method thereof, and belongs to the technical field of concrete. The pervious concrete is prepared from the following raw materials: cement, pretreated recycled aggregate, superfine slag powder, fly ash, toughened modified polypropylene fibers, redispersible latex powder, a silane coupling agent, hydroxypropyl methyl cellulose, a water reducing agent and water. According to the invention, the recycled aggregate is pretreated by chitosan, and then the toughening modified polypropylene fiber is modified by nano silicon dioxide and cetyltrimethylammonium chloride, so that the bonding force between the fiber and recycled aggregate particles is improved, and the strength of the material is greatly improved on the whole. The raw materials are scientifically proportioned, recycled aggregate is used for preparing the pervious concrete, recycling of waste resources is achieved, and the obtained recycled aggregate pervious concrete is high in compressive strength, high in water permeability, high in frost resistance and high in adaptability to the environment and has wide economic benefits and social benefits.

Owner:日照联汇建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com