Light energy-saving wall board capable of preventing joint from disintegrating as well as installation method thereof

A wallboard, light-weight technology, applied in the direction of walls, building components, sustainable waste treatment, etc., can solve the problems of small butt joint gaps between wallboards, less bonding and grouting, and more molds, so as to prevent joint cracking , enhance the bonding strength, and the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The weight ratio of each component raw material in the slurry of the wallboard can be: 30 parts of magnesium sulfate or magnesium chloride, 80 parts of magnesium oxide, 30 parts of coal ash, 50 parts of crumb plant fiber, 10 parts of short glass fiber, modified 0.6 parts of agent and 120 parts of water, wherein the modifying agent is prepared from the following raw materials in parts by weight: 10 parts of ferrous sulfate, 30 parts of waterproofing agent, and 10 parts of water-repelling agent.

Embodiment 2

[0028] The weight ratio of each component raw material in the slurry of the wallboard can be: 35 parts of magnesium sulfate or magnesium chloride, 90 parts of magnesium oxide, 40 parts of coal ash, 55 parts of crumb plant fiber, 12 parts of short glass fiber, modified 0.8 parts of agent and 140 parts of water, wherein the modifier is prepared from the following raw materials in parts by weight: 30 parts of ferrous sulfate, 105 parts of waterproofing agent, 30 parts of water-resistant agent,

Embodiment 3

[0030] The weight ratio of each component raw material in the slurry of the wallboard can be: 40 parts of magnesium sulfate or magnesium chloride, 100 parts of magnesium oxide, 50 parts of coal ash, 60 parts of crumb plant fiber, 15 parts of short glass fiber, modified 1 part of agent and 160 parts of water, wherein the modifying agent is prepared from the following raw materials in parts by weight: 50 parts of ferrous sulfate, 160 parts of waterproofing agent, and 50 parts of water-repelling agent.

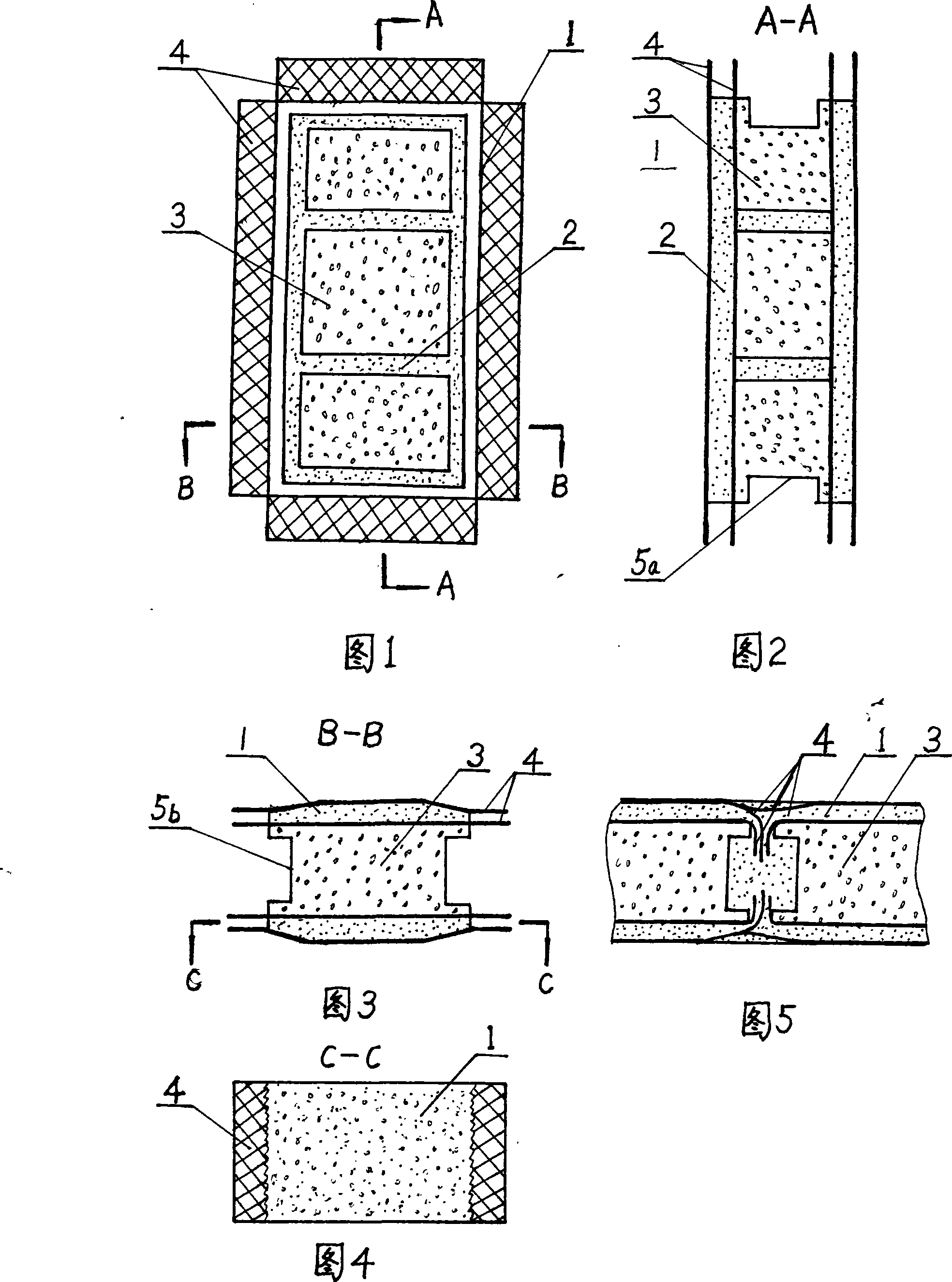

[0031] Referring to Fig. 5, when the wallboard of the present invention is installed, first make the installation adhesive slurry for standby according to the formula for making the wallboard surface layer slurry layer, and then use the installation adhesive slurry to seal the groove of the upper installation edge of the wallboard. 5a is filled and installed close to the ceiling or top beam of the room, and the fiber fabric overlapping adhesive layers 4 on both sides are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com