Method for producing uniform-density bamboo shaving board

A production method and particleboard technology, which are applied to wood processing appliances, household components, flat products, etc., can solve the problems of poor dimensional stability, warped moisture content, uneven density of bamboo particleboard, etc., and achieve high dimensional stability and moisture content. The effect of increasing rate and excellent elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

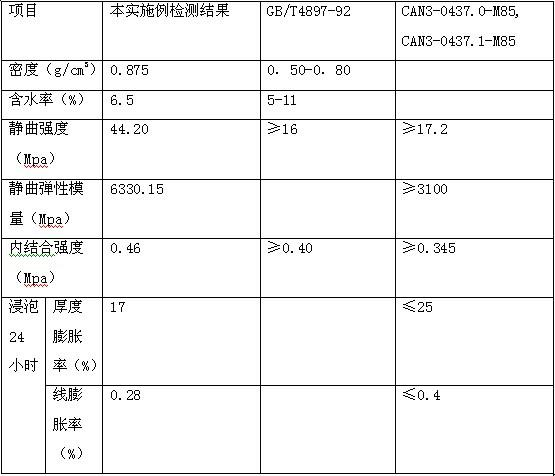

Embodiment 1

[0036] Embodiment 1: a kind of average density bamboo particle board production method, it comprises the following steps successively:

[0037] (1) Material selection, the raw material is scraps from the production process of bamboo products, such as bamboo scraps produced during the production of bamboo mats;

[0038] (2) For the first screening, use a drum type screening machine to screen the above scraps to remove impurities such as stones and metal particles in the scraps, leaving only bamboo debris;

[0039] (3) For the first drying, place the bamboo chips obtained through the first screening in an oven, control the temperature in the oven to 80°C, and adjust the moisture content of the bamboo chips to 15%;

[0040] (4) The second screening is to re-screen the bamboo debris obtained through the first drying to obtain bamboo debris with a particle size of less than 0.9cm, and the screening machine used is a vibrating screening machine;

[0041] (5) For the second drying, ...

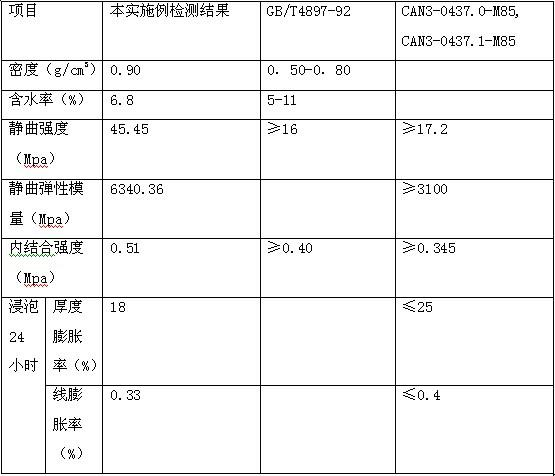

Embodiment 2

[0054] Embodiment 2: a kind of uniform density bamboo particleboard production method, it comprises the following steps successively:

[0055] (1) Material selection, the raw material is scraps from the production process of bamboo products, such as bamboo scraps produced during the production of bamboo mats;

[0056] (2) For the first screening, use a drum type screening machine to screen the above scraps to remove impurities such as stones and metal particles in the scraps, leaving only bamboo debris;

[0057] (3) For the first drying, place the bamboo chips obtained through the first screening in an oven, control the temperature in the oven to 90°C, and adjust the moisture content of the bamboo chips to 14%;

[0058] (4) The second screening is to re-screen the bamboo debris obtained through the first drying to obtain bamboo debris with a particle size of less than 0.9cm, and the screening machine used is a vibrating screening machine;

[0059] (5) For the second drying, p...

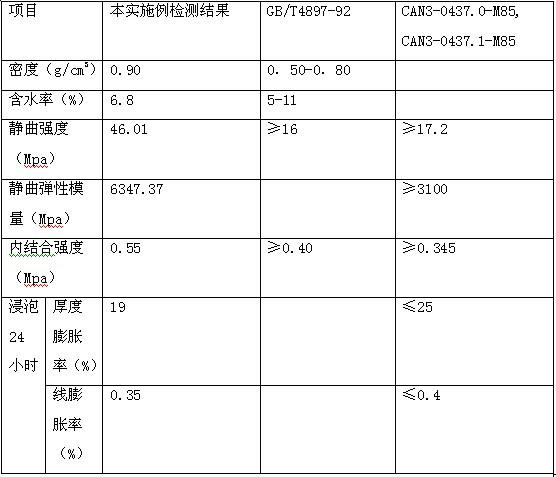

Embodiment 3

[0072] Embodiment 3: a kind of uniform density bamboo particle board production method, it comprises the following steps successively:

[0073] (1) Material selection, the raw material is scraps from the production process of bamboo products, such as bamboo scraps produced during the production of bamboo mats;

[0074] (2) For the first screening, use a drum type screening machine to screen the above scraps to remove impurities such as stones and metal particles in the scraps, leaving only bamboo debris;

[0075] (3) For the first drying, place the bamboo chips obtained through the first screening in an oven, control the temperature in the oven to 110°C, and adjust the moisture content of the bamboo chips to 13%;

[0076] (4) The second screening is to re-screen the bamboo debris obtained through the first drying to obtain bamboo debris with a particle size of less than 0.9cm, and the screening machine used is a vibrating screening machine;

[0077] (5) For the second drying,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com