Water-soluble non-formaldehyde wood adhesive and method for preparing same

A wood adhesive, water-soluble technology, applied in the direction of adhesives, wood processing appliances, wood veneer bonding, etc. The effect of high strength, fast strength building, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Preparation of water-soluble formaldehyde-free wood adhesive

[0022] Utilize the present invention to prepare water-soluble formaldehyde-free wood adhesive, first weigh raw materials according to the following parts by weight: starch 300, distilled water 860, acrylamide 80, glutaraldehyde 35, p-toluenesulfonic acid 1, azobisisobutyronitrile 30 .

[0023] All raw materials used in the present invention can be purchased commercially.

[0024] Mix the above raw materials evenly to obtain the prepared adhesive mother liquor, which is added into a three-necked flask. Heat in an oil bath, control the temperature at 80°C, stir mechanically, and react for 2 hours to obtain a water-soluble formaldehyde-free wood adhesive.

Embodiment 2

[0025] Embodiment 2 prepares water-soluble formaldehyde-free wood adhesive

[0026] Using the present invention to prepare water-soluble formaldehyde-free wood adhesive, firstly weigh the raw materials according to the following parts by weight: starch 300, distilled water 860, acrylamide 70, glutaraldehyde 35, p-toluenesulfonic acid 1, cerium ammonium nitrate 30.

[0027] Mix the above raw materials evenly to obtain the prepared adhesive mother liquor, which is added into a three-necked flask. Heat in an oil bath, control the temperature at 80°C, stir mechanically, and react for 1 hour to obtain a water-soluble formaldehyde-free wood adhesive.

Embodiment 3

[0028] Example 3 Preparation of water-soluble formaldehyde-free wood adhesive

[0029] Using the present invention to prepare water-soluble formaldehyde-free wood adhesive, firstly weigh the raw materials according to the following parts by weight: starch 400, distilled water 860, acrylamide 60, glutaraldehyde 35, p-toluenesulfonic acid 1, ammonium persulfate 30.

[0030] Mix the above raw materials evenly to obtain the prepared adhesive mother liquor, which is added into a three-necked flask. Heat in an oil bath, control the temperature at 60°C, stir mechanically, and react for 2 hours to obtain a water-soluble formaldehyde-free wood adhesive.

PUM

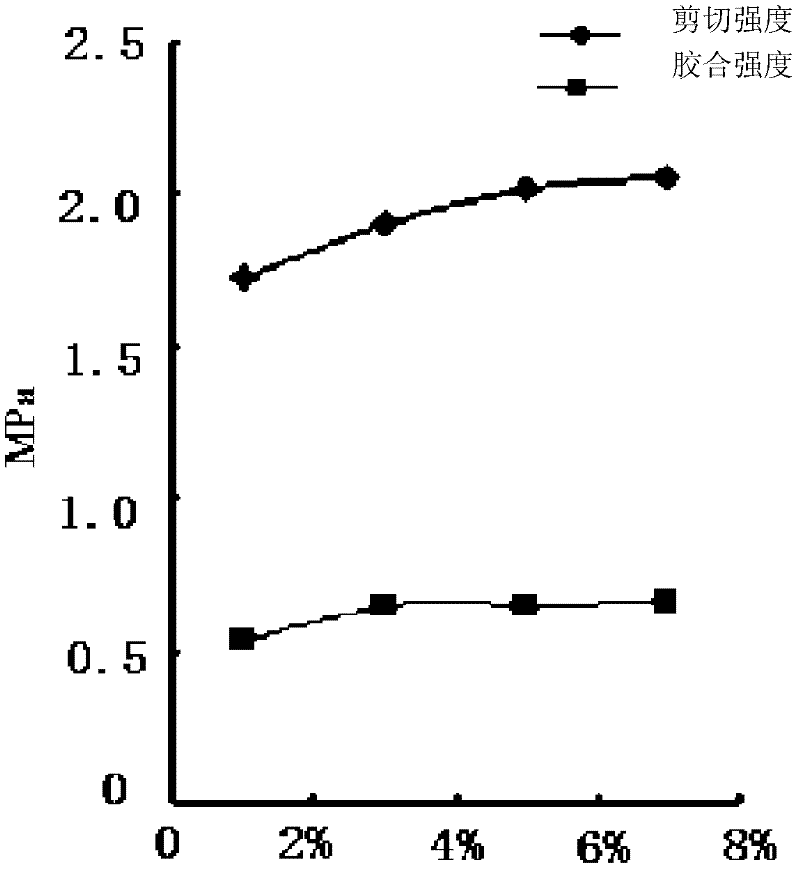

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Bonding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com