Ultraviolet light hybrid curing packaging adhesive composition

A hybrid curing and composition technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., to achieve the effect of improving bond strength, enhancing bond strength, and reducing double bond density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

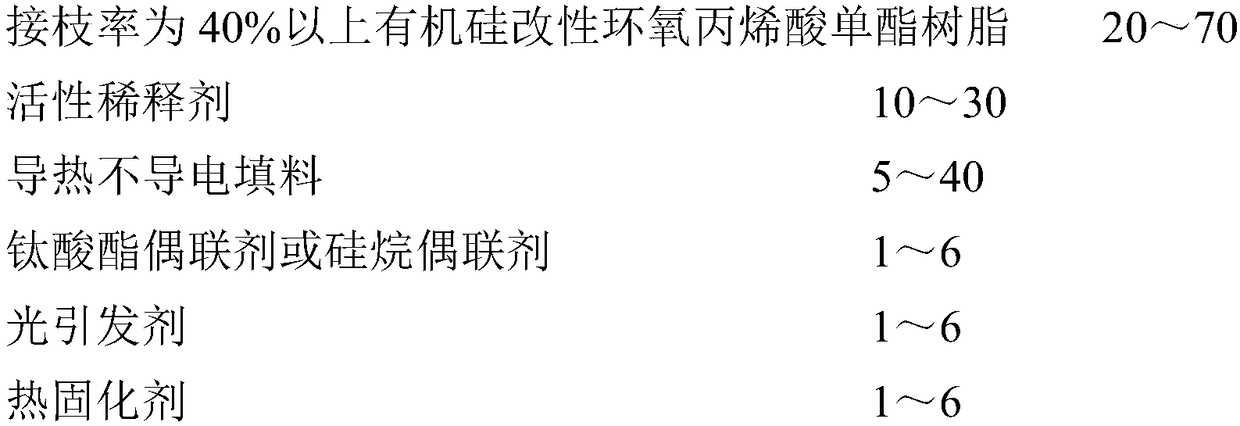

[0047] An ultraviolet light hybrid curing thermally conductive and non-conductive encapsulant, which contains the following components and parts by weight:

[0048]

[0049] The preparation method of the organosilicon-modified epoxy acrylate monoester resin of described graft modification rate 60% is:

[0050] In the first step, add 250g of naphthalene-based epoxy to a 1000mL three-necked flask, take an oil bath to 110°C, stir, and add 0.4% of the total mass to the measured acrylic acid (the molar ratio of epoxy group to acrylic acid is 2:1). The catalyst triethylbenzyl ammonium chloride and 0.3% polymerization inhibitor p-hydroxyanisole are added dropwise into the epoxy resin, and the acid value of the system is less than 3mgKOH / g after 4.5 hours of reaction, that is, the epoxy acrylate monoester ①;

[0051] The second step, in the there-necked flask of 1000mL, add the diphenylmethane diisocyanate (MDI) of 1mol, be heated to 60 ℃, dibutyltin dilaurate joins the hydroxyl si...

Embodiment 2

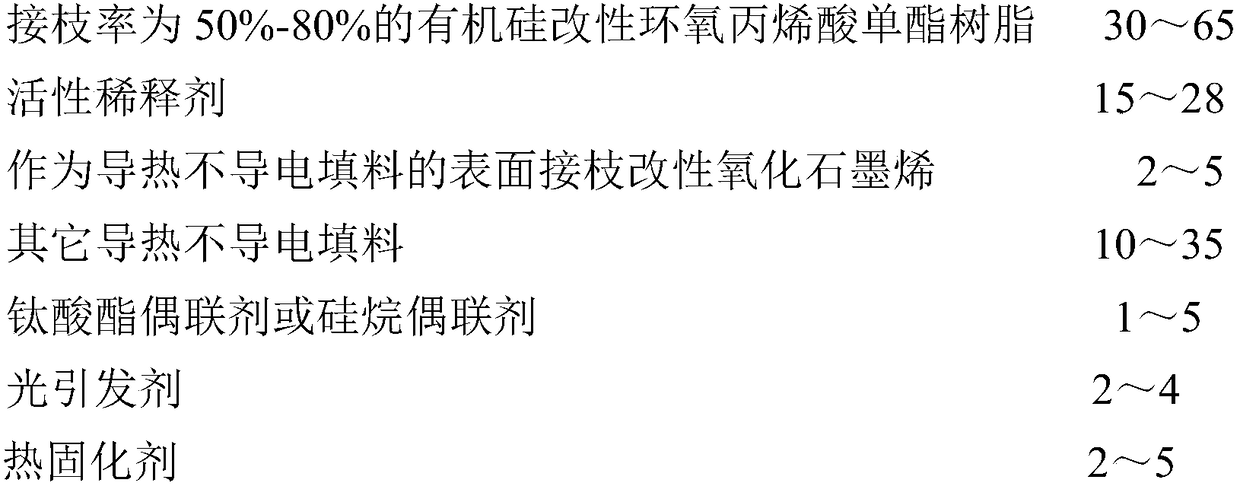

[0059] An ultraviolet light hybrid curing thermally conductive and non-conductive encapsulant, which contains the following components and parts by weight:

[0060]

[0061] The preparation method of the organosilicon-modified epoxy acrylate monoester resin with a graft modification rate of 70% is:

[0062] In the first step, add 500g novolac epoxy resin to a 1000mL three-necked flask, heat the oil bath to 90°C, stir, and add 0.5% of the total mass to the measured acrylic acid (the molar ratio of epoxy group to acrylic acid is 2:1). The catalyst tris(acetylacetonate) complex iron (Ⅲ) and 0.5% polymerization inhibitor p-hydroxyanisole are added dropwise to the epoxy resin, and after 6 hours of reaction, the acid value of the system is less than 3mgKOH / g, that is, the epoxy acrylate monoester① ;

[0063] Second step, add 1mol hexamethylene diisocyanate (HDI) in the there-necked flask of 1000mL, heat to 80 ℃, dibutyltin dilaurate joins the hydroxyl silicone oil containing 1mo...

Embodiment 3

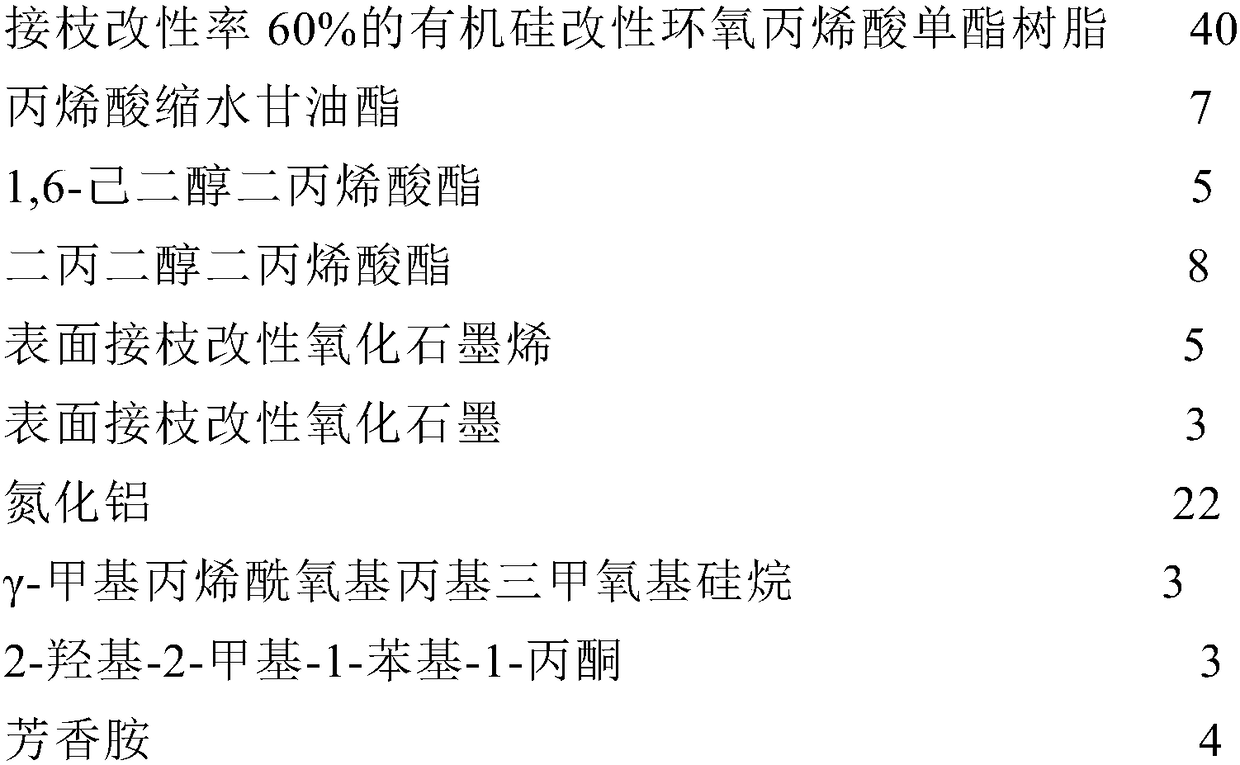

[0071] An ultraviolet light hybrid curing thermally conductive and non-conductive encapsulant, which contains the following components and parts by weight:

[0072]

[0073]

[0074] The preparation method of the organosilicon-modified epoxy acrylate monoester resin with a graft modification rate of 80% is:

[0075] In the first step, add 500g of bisphenol F epoxy resin into a 1000mL three-necked flask, heat the oil bath to 110°C, stir, and add the total mass Add 0.8% catalyst triethanolamine and 0.8% polymerization inhibitor p-hydroxyanisole dropwise into the epoxy resin, and after 4 hours of reaction, the acid value of the system is less than 3mgKOH / g, that is, epoxy acrylate monoester ①;

[0076] In the second step, add 1mol of isophorone diisocyanate (IPDI) in a three-necked flask of 1000mL, heat to 80°C, and dibutyltin dilaurate is added to the hydroxyl silicone oil containing 1mol of hydroxyl by 0.6% of the total mass ( Hydroxyl content 6%), add dropwise in isopho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com