Amino polyester polyether castor oil, preparation method and application thereof

A technology of amino polyester polyether and polyester polyether, which is applied in the field of polymer synthesis chemistry, can solve the problems of poor compatibility of polystyrene interface and low bonding strength of two-phase interface, and achieve faster curing speed and better adhesion strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

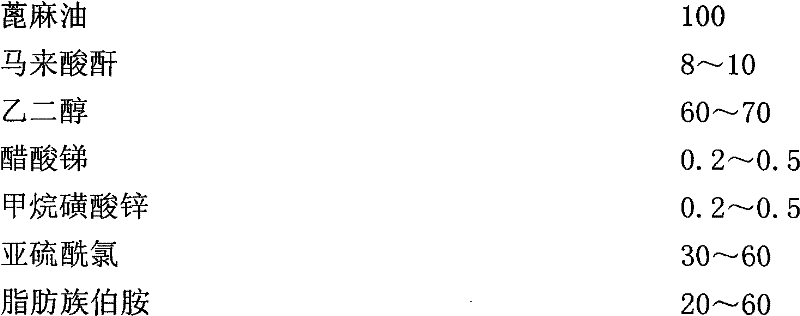

Embodiment 1

[0035] In a flask equipped with a fractionation device, add 300g of industrial grade castor oil and 24g of maleic anhydride in sequence, raise the temperature to 170°C, stir and react for 30min, then add 180g of ethylene glycol, 0.6g of catalyst antimony acetate and 1.5g of zinc methanesulfonate , continue to keep the temperature at 170°C, control the temperature at the top of the fractionation column at 105°C, when no water is distilled out, dehydrate under reduced pressure, and remove unreacted ethylene glycol; then lower the temperature to 0-5°C, Add 90 g of thionyl chloride dropwise within 30 minutes, and after reacting for 1 hour, remove unreacted thionyl chloride under reduced pressure; add 60 g of methylamine, heat to reflux for 5 hours, cool to room temperature, add dilute NaOH aqueous solution to neutralize, filter with suction, and dry to obtain Amino polyether polyester castor oil.

[0036] The amino polyester polyether castor oil described above is a light yellow t...

Embodiment 2

[0038]In a flask equipped with a fractionation device, add 300g of industrial grade castor oil and 30g of maleic anhydride in sequence, raise the temperature to 180°C, stir and react for 30min, then add 210g of ethylene glycol, 1.5g of catalyst antimony acetate and 0.6g of zinc methanesulfonate , continue to keep the temperature at 180°C, control the temperature at the top of the fractionating column at 105°C, when no water is distilled out, dehydrate under reduced pressure, and remove unreacted ethylene glycol; then lower the temperature to 0-5°C, Add 170g of thionyl chloride dropwise within 40min. After reacting for 1h, remove unreacted thionyl chloride under reduced pressure; add 170g of butylamine, heat to reflux for 5-6h, cool to room temperature, add dilute NaOH aqueous solution to neutralize, suction filter, and dry , to obtain amino polyether polyester castor oil.

[0039] The above-mentioned amino polyester polyether castor oil is a light yellow transparent liquid wit...

Embodiment 3

[0041] In a flask equipped with a fractionation device, add 300g of industrial grade castor oil and 27g of maleic anhydride in sequence, raise the temperature to 175°C, stir and react for 30min, then add 200g of ethylene glycol, 1.0g of catalyst antimony acetate and 1.0g of zinc methanesulfonate , continue to keep the temperature at 175°C, control the temperature at the top of the fractionation column at 105°C, when no water is distilled out, dehydrate under reduced pressure, and remove unreacted ethylene glycol; then lower the temperature to 0-5°C, Add 110 g of thionyl chloride dropwise within 35 minutes. After reacting for 1 hour, remove unreacted thionyl chloride under reduced pressure; add 110 g of propylamine, heat to reflux for 5.5 hours, cool to room temperature, add dilute NaOH aqueous solution to neutralize, filter with suction, and dry to obtain Amino polyether polyester castor oil.

[0042] The amino polyester polyether castor oil described above is a light yellow t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com