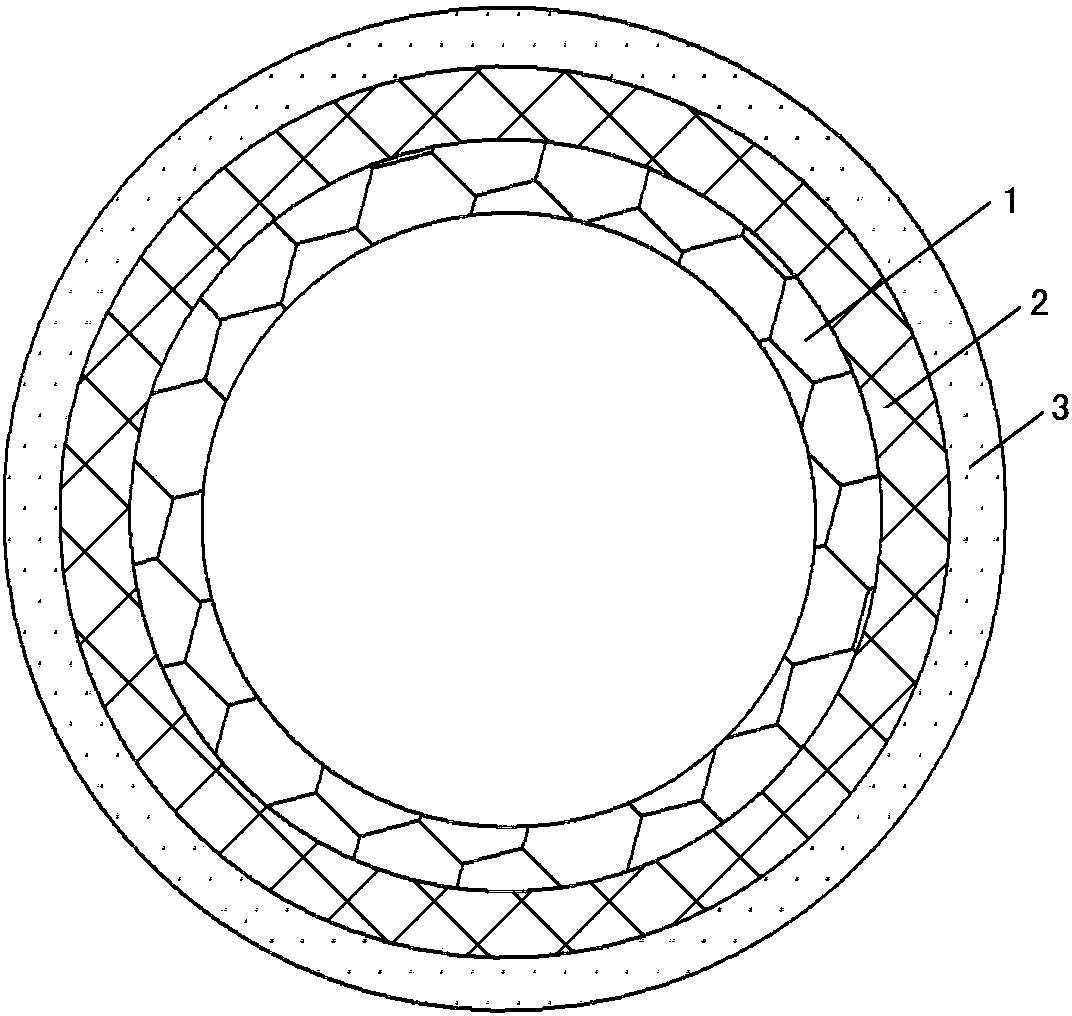

Household fuel gas rubber hose and preparation method thereof

A rubber hose, gas technology, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of hose aging and hardening, airtight performance decline, gas leakage and other problems, and achieve the effect of excellent joint strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] components Inner glue middle glue Outer glue Chlorine rubber 90.0 Nitrile rubber 10.0 100.0 Neoprene 80.0 Chlorinated polyethylene 20.0 Zinc stearate 2.0 stearic acid 2.0 0.5 Silica 20.0 15.0 acid absorber 7.0 Zinc oxide 5.0 5.0 5.0 magnesium oxide 3.0 8.0 Clay 40.0 40.0 30.0 Antiaging agent 2.0 2.5 4.0 plasticizer 10.0 20.0 20.0 Accelerator 1.2 1.2 1.8 sulfur 1.0 1.8 2.0 carbon black 70.0 calcium carbonate 40.0 60.0 2-thiol imidazoline 2.0 2.5 Colorant 15.0

[0024] First, mix the synthetic rubber, filling reinforcing agent, plasticizer, etc. with an internal mixer, and then add a vulcanizing agent and an accelerator to the open mixer to obtain a mixed rubber, which is extruded with an extruder and vulcanized. Medium vulcanization, the vulcanization temperatu...

Embodiment 2

[0026] components Inner glue middle glue Outer glue Chlorine rubber 70.0 Nitrile rubber 30.0 100.0 Neoprene 70.0 Chlorinated polyethylene 30.0 Zinc stearate 2.0 stearic acid 2.0 0.5 Silica 20.0 15.0 acid absorber 6.0 Zinc oxide 5.0 5.0 5.0 magnesium oxide 3.0 8.0 Clay 40.0 60.0 30.0 Antiaging agent 2.0 2.5 4.0 plasticizer 10.0 20.0 20.0 Accelerator 1.7 1.2 1.7 sulfur 1.5 1.8 1.8 carbon black 50.0 calcium carbonate 40.0 60.0 2-thiol imidazoline 2.0 2.5 Colorant 15.0

[0027] First, mix the synthetic rubber, filling reinforcing agent, plasticizer, etc. with an internal mixer, and then add a vulcanizing agent and an accelerator to the open mixer to obtain a mixed rubber, which is extruded with an extruder and vulcanized. Medium vulcanization, the vulcanization temperature i...

Embodiment 3

[0029] components Inner glue middle glue Outer glue Chlorine rubber 80.0 Nitrile rubber 20.0 100.0 Neoprene 60.0 Chlorinated polyethylene 40.0 Zinc stearate 2.0 stearic acid 2.0 0.5 Silica 20.0 15.0 acid absorber 6.0 Zinc oxide 5.0 5.0 4.5 magnesium oxide 3.0 8.0 Clay 40.0 70.0 30.0 Antiaging agent 2.0 2.5 4.0 plasticizer 10.0 20.0 20.0 Accelerator 1.5 1.2 1.5 sulfur 1.2 1.8 1.6 carbon black 60.0 calcium carbonate 40.0 60.0 2-thiol imidazoline 2.0 2.5 Colorant 15.0

[0030] First, mix the synthetic rubber, filling reinforcing agent, plasticizer, etc. with an internal mixer, and then add a vulcanizing agent and an accelerator to the open mixer to obtain a mixed rubber, which is extruded with an extruder and vulcanized. Medium vulcanization, the vulcanization temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com