Recycled aggregate pervious concrete and preparation method thereof

A technology of permeable concrete and recycled aggregate, applied in the field of concrete, can solve the problems of increasing the manufacturing cost of recycled aggregate permeable concrete, hindering the recycling of recycled aggregate waste, and failing to achieve water permeability coefficient and strength, so as to enhance ductility and improve Brittleness and good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

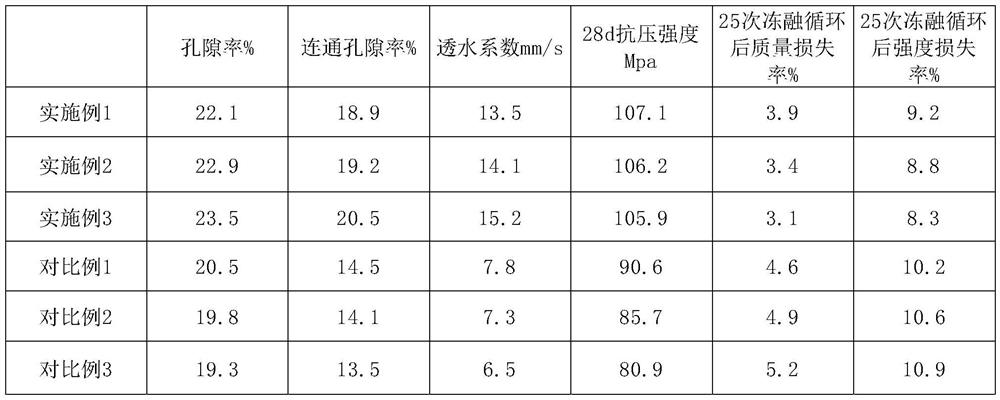

Examples

Embodiment 1

[0027] A recycled aggregate permeable concrete, prepared from the following raw materials in parts by weight: 100 parts of cement, 400 parts of pretreated recycled aggregate, 50 parts of slag micropowder, 30 parts of fly ash, and 10 parts of toughened modified polypropylene fiber , 5 parts of redispersible latex powder, 3 parts of silane coupling agent, 3 parts of hydroxypropyl methylcellulose, 3 parts of water reducer, 30 parts of water.

[0028] The preparation method of the pretreated regenerated aggregate is as follows: add regenerated aggregate particles, chitosan, sodium oleate and sodium hydroxide into a constant speed mixer according to the mass ratio of 10:1:1:0.5 and stir evenly, and then mix according to the solid-liquid Add 30% ethanol solution at a ratio of 1g:100ml, continue stirring for 1 hour, and then dry to obtain pretreated recycled aggregate.

[0029] The specific surface area of the slag micropowder is 200-350m 2 / kg.

[0030] The preparation method of...

Embodiment 2

[0042] A recycled aggregate permeable concrete, prepared from the following raw materials in parts by weight: 120 parts of cement, 500 parts of pretreated recycled aggregate, 70 parts of slag micropowder, 40 parts of fly ash, and 15 parts of toughened modified polypropylene fiber , 10 parts of redispersible latex powder, 5 parts of silane coupling agent, 5 parts of hydroxypropyl methylcellulose, 4 parts of water reducer, and 50 parts of water.

[0043] The preparation method of the pretreated regenerated aggregate is as follows: add regenerated aggregate particles, chitosan, sodium oleate and sodium hydroxide into a constant speed mixer according to the mass ratio of 10:1:1:0.5 and stir evenly, and then mix according to the solid-liquid Add 30% ethanol solution at a ratio of 1g:100ml, continue stirring for 3 hours, and then dry to obtain pretreated recycled aggregate.

[0044] The specific surface area of the slag micropowder is 200-350m 2 / kg.

[0045] The preparation met...

Embodiment 3

[0057] A recycled aggregate permeable concrete, prepared from the following raw materials in parts by weight: 150 parts of cement, 600 parts of pretreated recycled aggregate, 80 parts of slag micropowder, 50 parts of fly ash, and 20 parts of toughened modified polypropylene fiber , 15 parts of redispersible latex powder, 8 parts of silane coupling agent, 7 parts of hydroxypropyl methylcellulose, 5 parts of water reducer, and 80 parts of water.

[0058] The preparation method of the pretreated regenerated aggregate is as follows: add regenerated aggregate particles, chitosan, sodium oleate and sodium hydroxide into a constant speed mixer according to the mass ratio of 10:1:1:0.5 and stir evenly, and then mix according to the solid-liquid Add 30% ethanol solution at a ratio of 1g:100ml, continue stirring for 3 hours, and then dry to obtain pretreated recycled aggregate.

[0059] The specific surface area of the slag micropowder is 200-350m 2 / kg.

[0060] The preparation met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com