Patents

Literature

242 results about "Para-toluenesulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

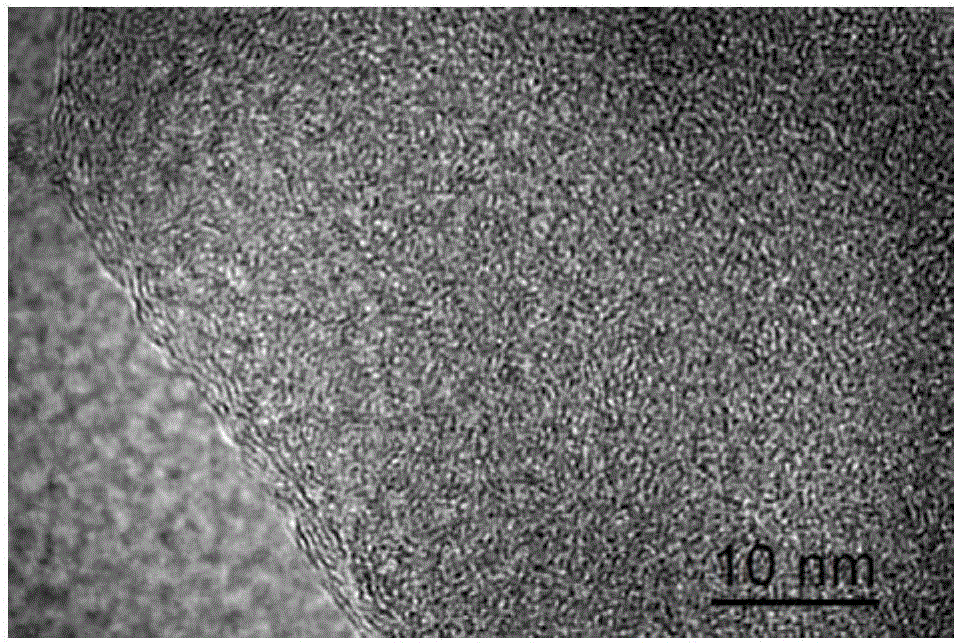

Polypyrrole/graphene nano composite and preparation method thereof

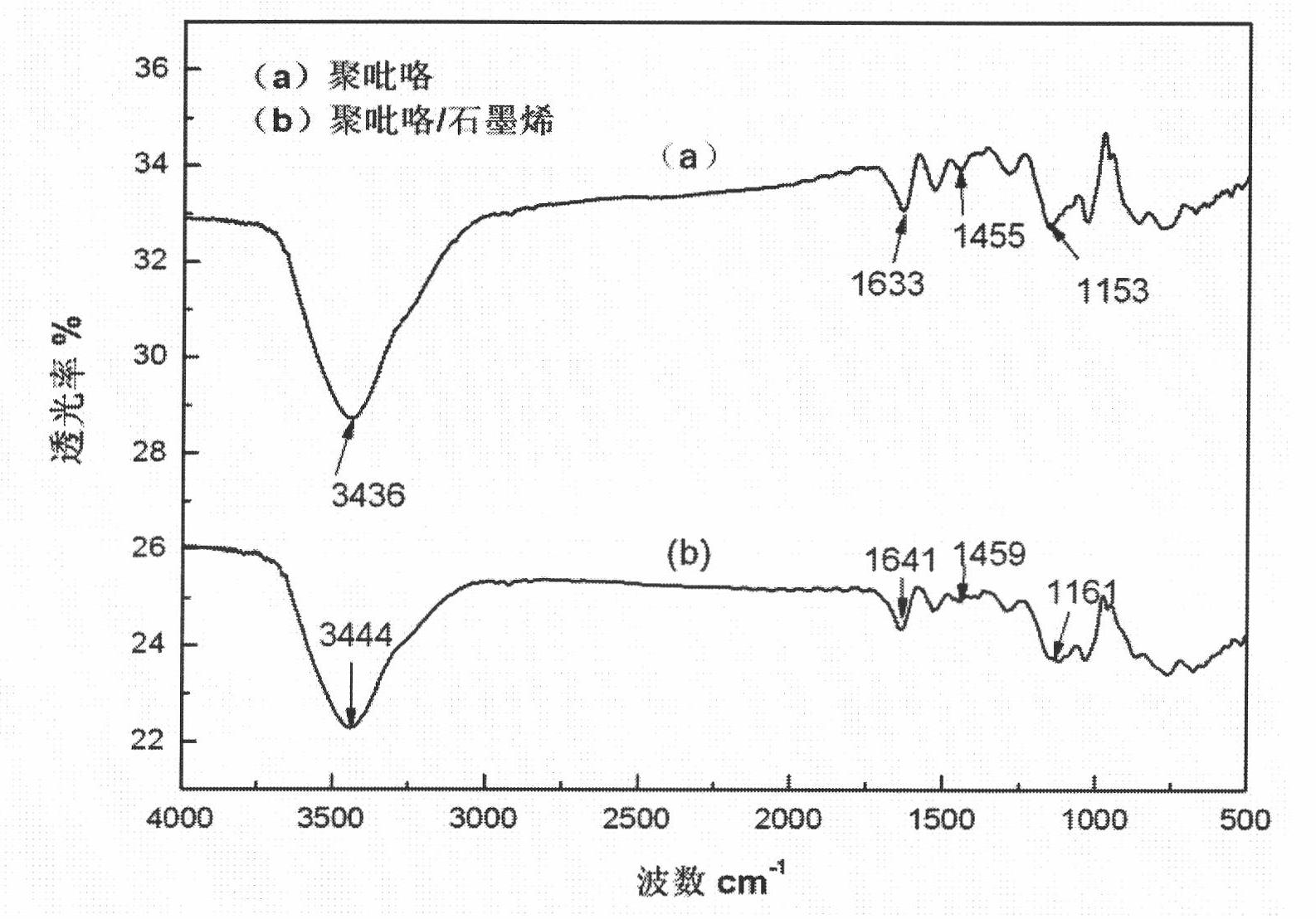

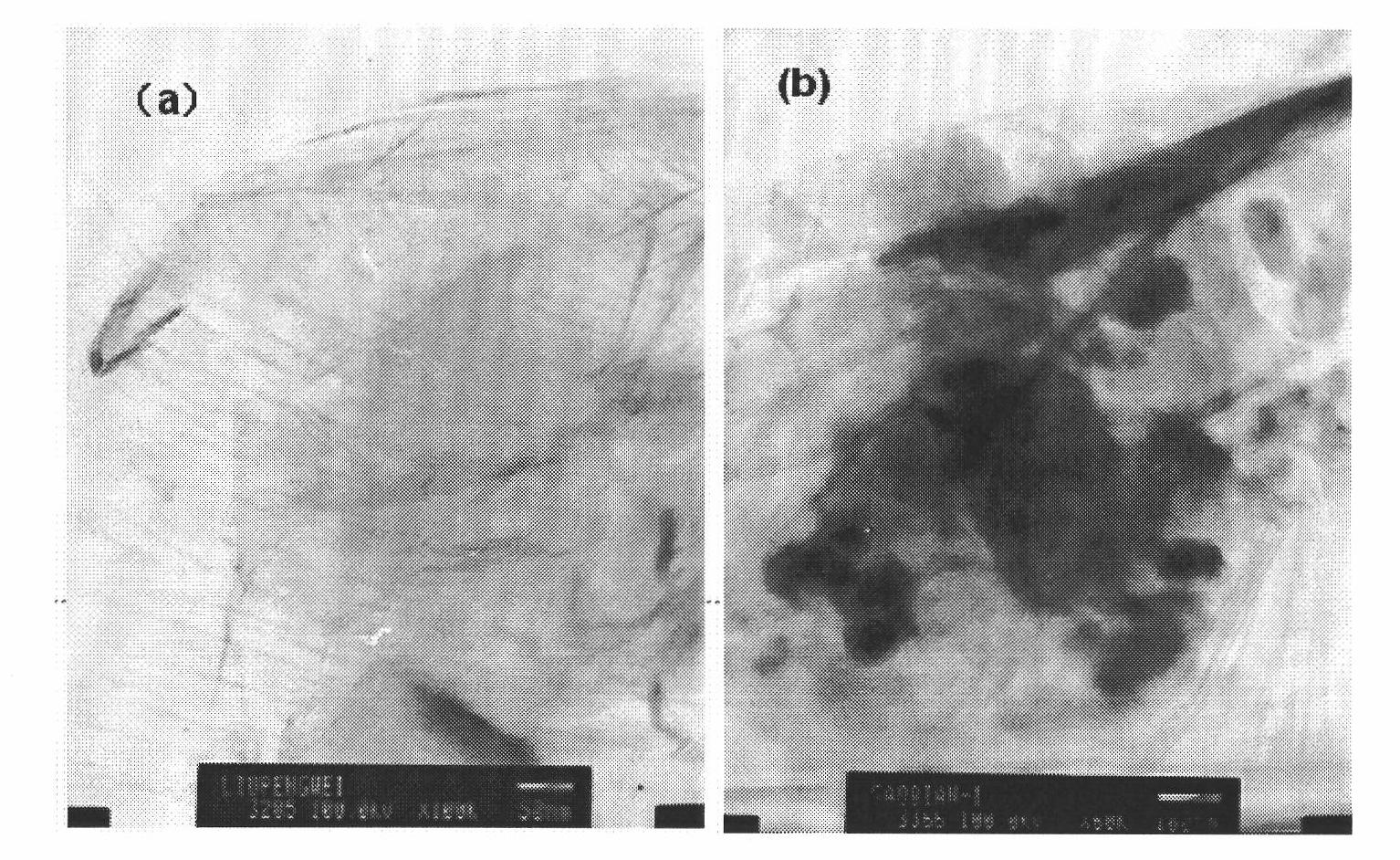

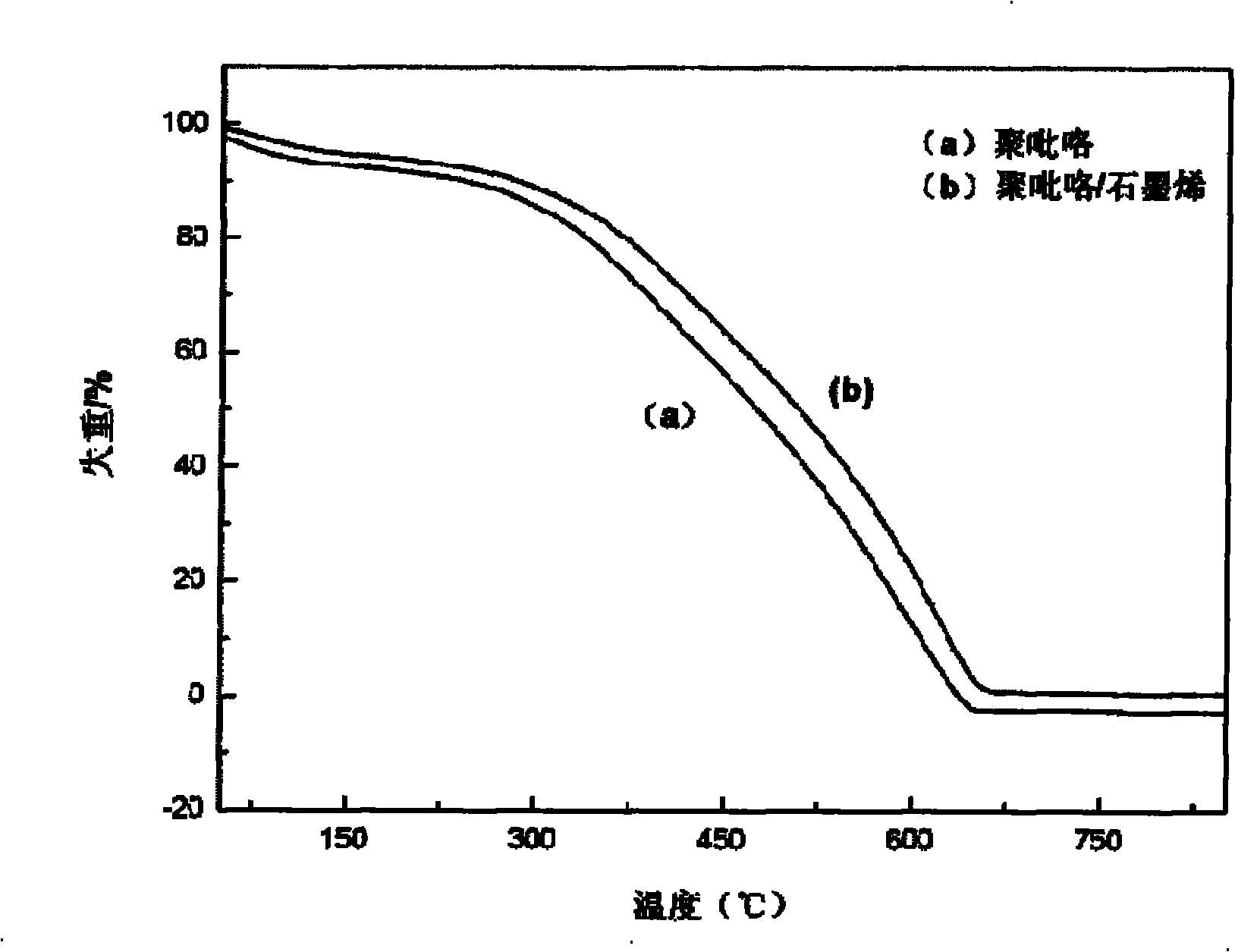

The invention discloses a polypyrrole / graphene nano composite which belongs to the technical field of composites. In the invention, ethanol is taken as a medium, para-toluenesulfonic acid is taken as a surface active agent, polyethylene glycol-400 is taken as phase transfer catalyst, FeCl3*6H2O is taken as an evocating agent, and under ultrasound conditions, pyrrole monomers are polymerized in situ on graphene, so as to obtain the polypyrrole / graphene nano composite. In the composite of the invention, through analysis by electron microscopy, the pyrrole monomers are polymerized in situ and evenly cover the grapheme, and the graphene and the polypyrrole are tightly combined in a nano level; and thermogravimetric analysis and electric conductivity study show that the composite has better heat stability, electric conductivity and processability and can be used in the fields of sensors, electron devices and biomedicine.

Owner:NORTHWEST NORMAL UNIVERSITY

Water body, method for rapidly detecting residue of malachite green and colorless malachite green in aquatic product and detection box therewith

ActiveCN101566574AEasy to operateFew stepsComponent separationMaterial analysis by observing effect on chemical indicatorMalachite greenLead dioxide

The invention relates to a water body, a method for rapidly detecting the residue of malachite green and colorless malachite green in an aquatic product, belonging to the technical field of residue detection in a water body and an aquatic product. The method comprises the following steps: oscillating and mixing a sample to be detected and an extractant I uniformly; adding an extractant II, oscillating and mixing and then standing still; taking and adding an supernatant to an enrichment column; observing color change of a chromogenic reagent on the lowest layer; and determining that the sample contains the malachite green and colorless malachite green if a green circular strap is formed. The extractant I is a mixed solution of acetonitrile, dichloromethane, n-hexane and paratoluenesulfonic acid, the extractant II is a mixture of lead dioxide and acid alumina, and the sample to be detected is a water body sample to be detected or an aquatic product sample to be detected. The invention has the advantages of simple operation and fewer steps, does not need expensive instruments and equipment and can embody the convenience and the flexibility to on-site detection.

Owner:JIANGSU TRIGIANT TECH

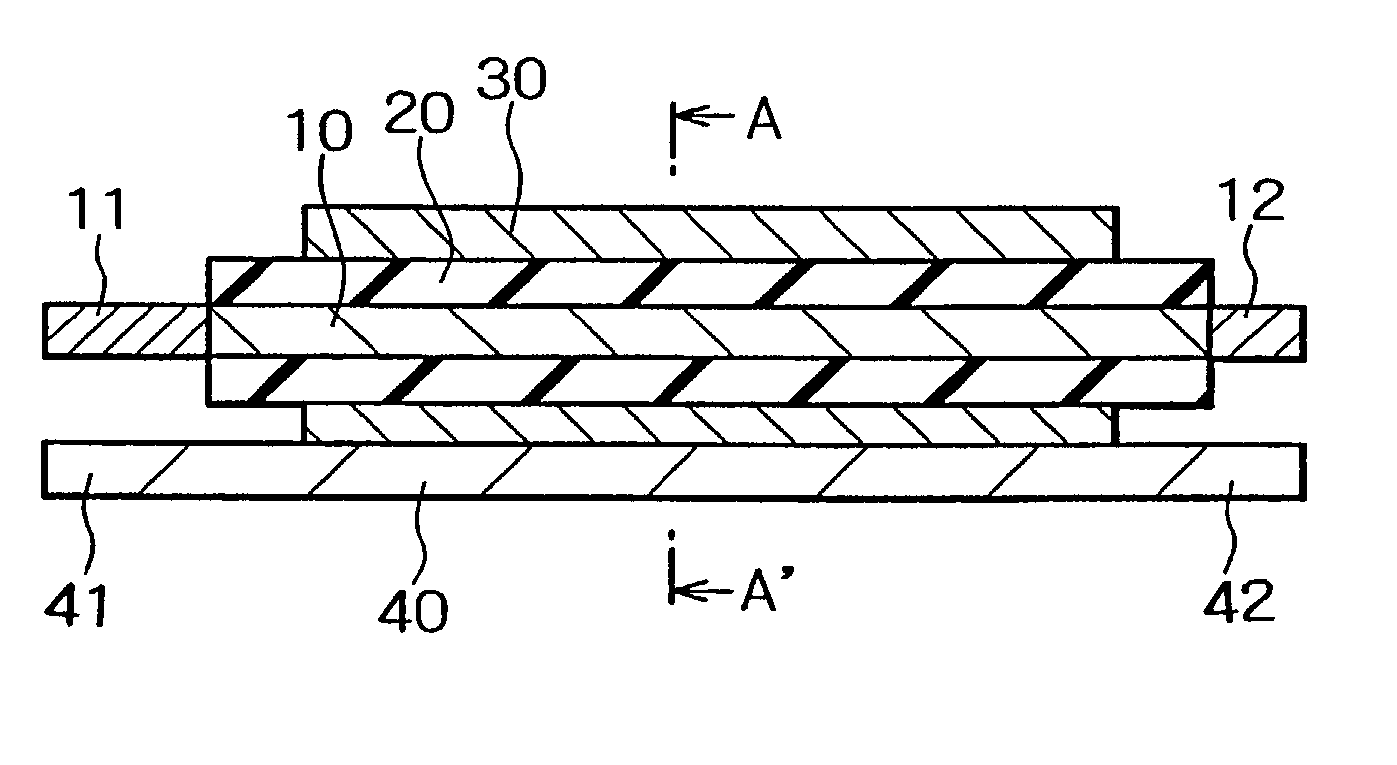

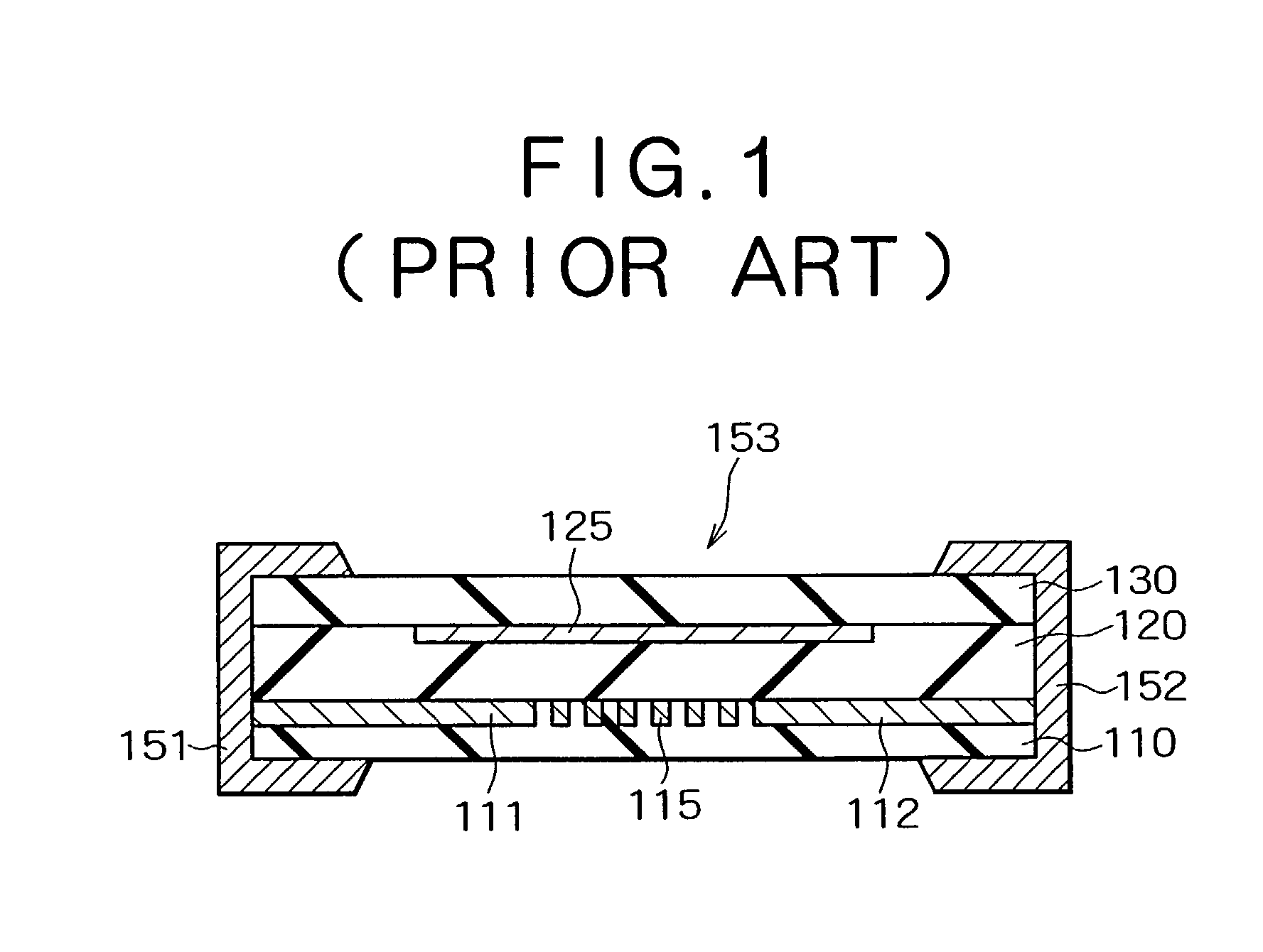

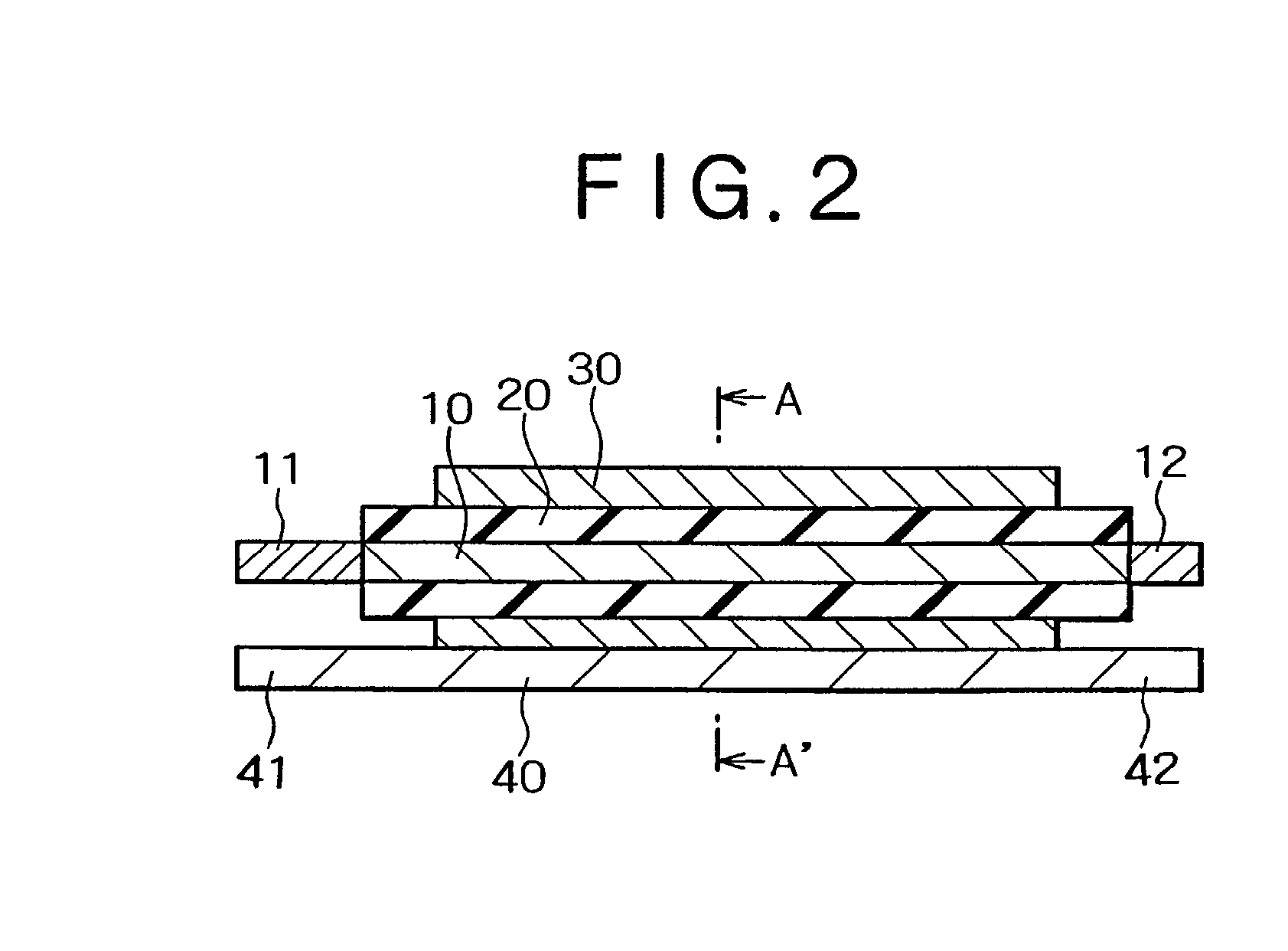

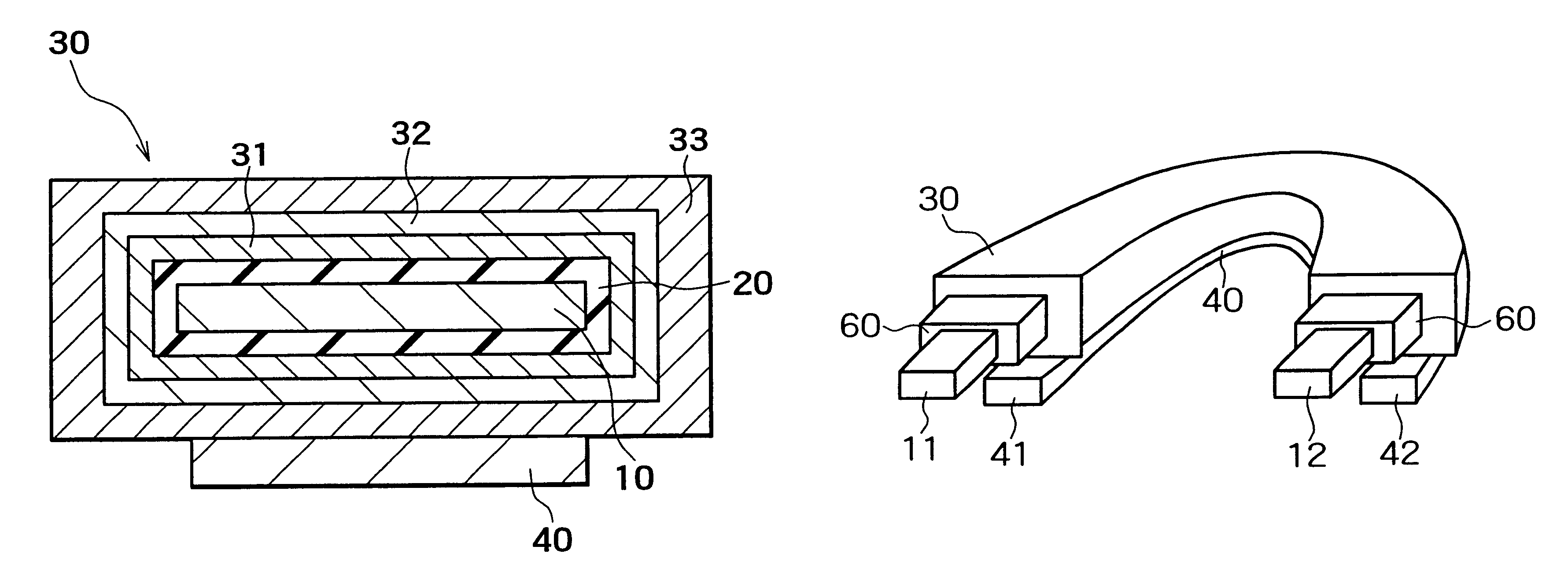

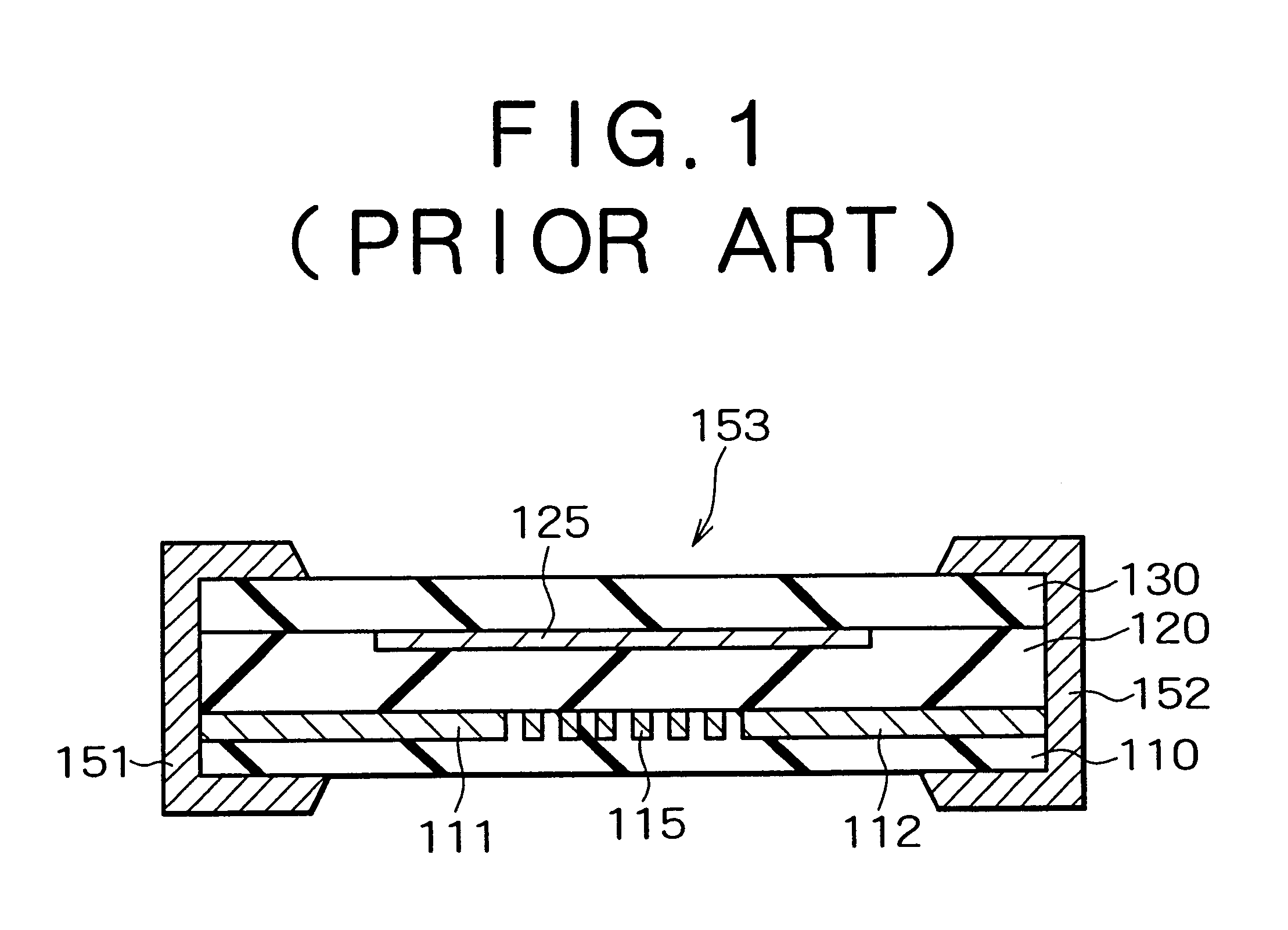

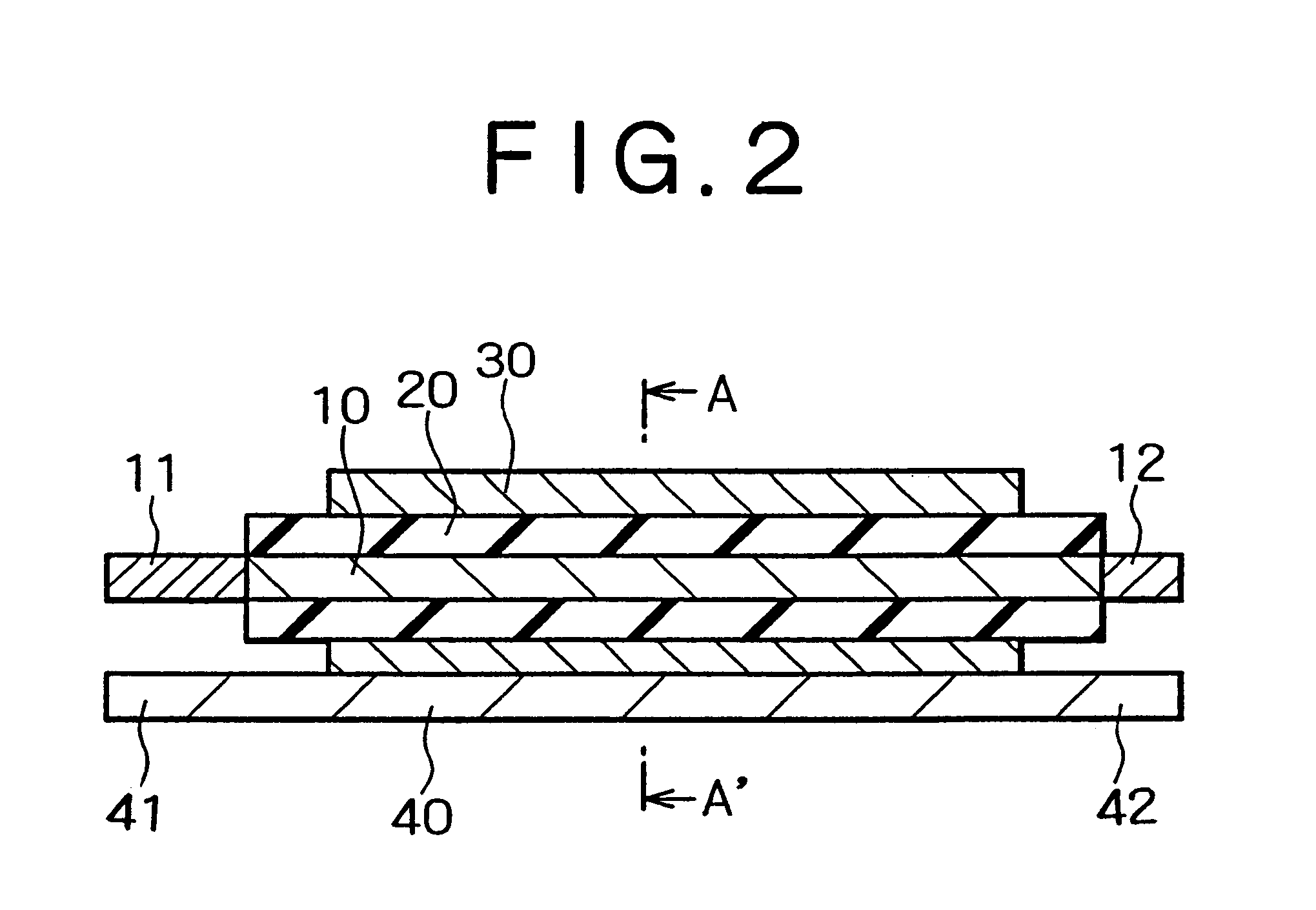

Shielded strip line device and method of manufacture thereof

InactiveUS20030053286A1Lower impedanceIncrease speedImpedence networksSolid electrolytic capacitorsDielectricConductive polymer

A dielectric oxide film is formed on the surface of a valve metal plate formed of aluminum and a conductive polymer layer is provided so as to cover the valve metal plate and the dielectric oxide film. The conductive polymer layer is formed of polyaniline having para-toluenesulfonic acid as a dopant. A conductive carbon paste layer and a silver paste layer are provided at the outer side of the conductive polymer layer and a metal plate, comprising a copper foil, is overlapped onto the silver paste layer. Anode lead terminals are connected to the ends of the valve metal plate and the respective end parts of the metal plate are arranged as cathode lead terminals. A shield strip line device, which is low in impedance, especially in high-frequency ranges of 100 MHz or more, and is favorably adapted to high speed and high frequencies, mainly for use as a bypass device for a noise filter or as a decoupling device, is thus obtained.

Owner:NEC CORP

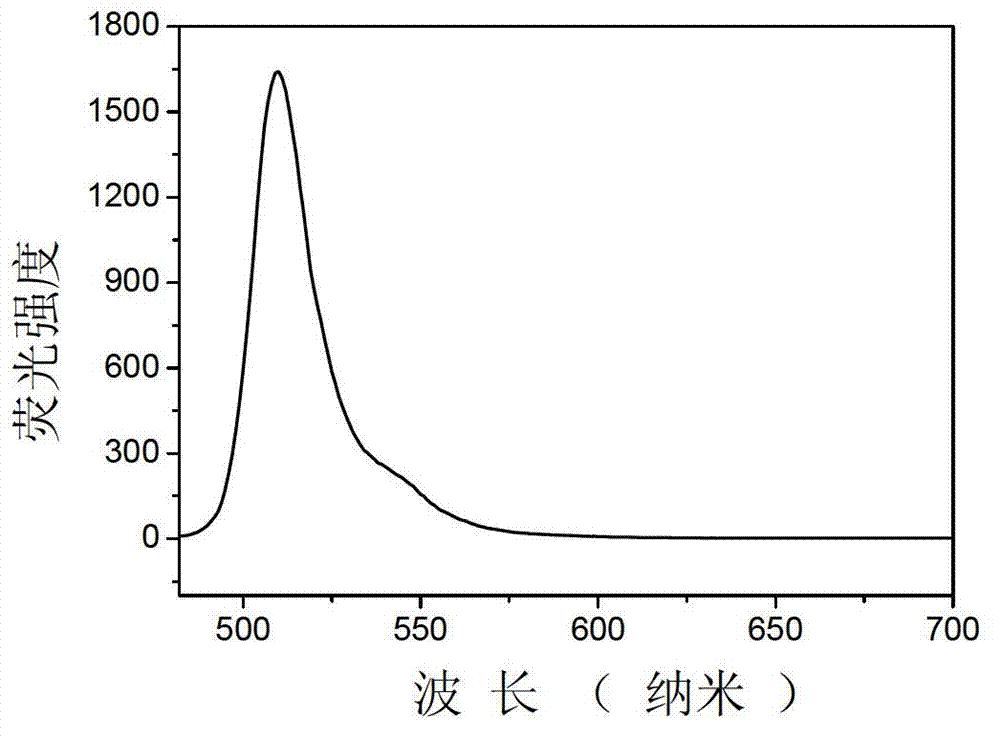

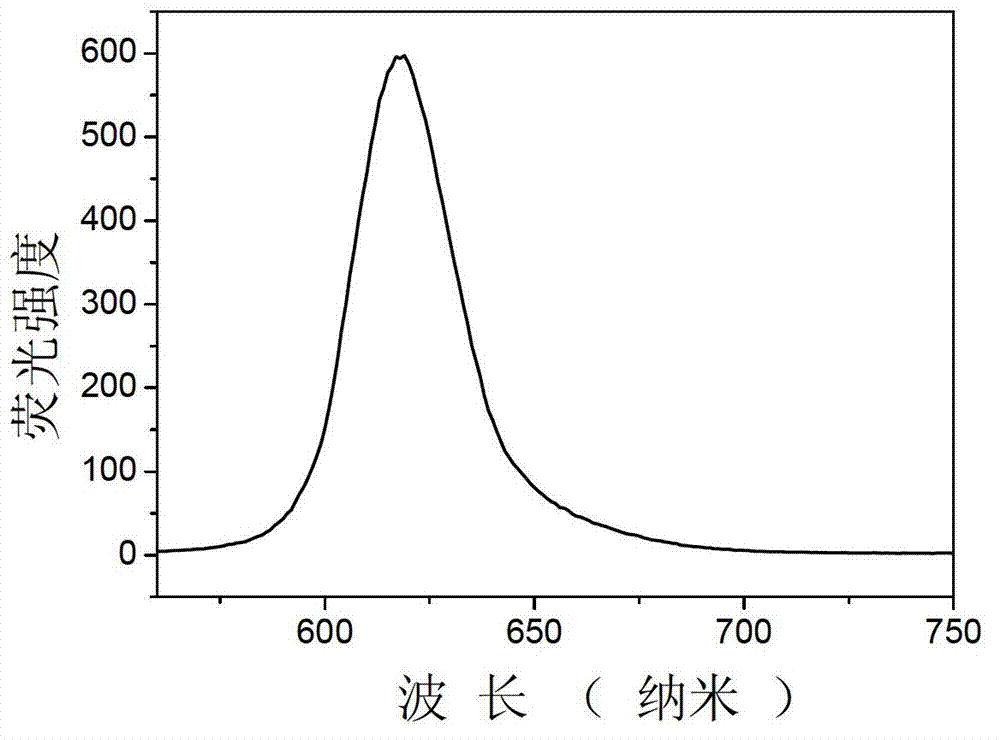

Novel BODIPY flourescent dye with adjustable emission wavelength and preparation method thereof

InactiveCN103194085ASimple molecular structureThe synthesis method is simpleMethine/polymethine dyesBiological testingFluorescence1,4-Benzoquinone

The invention relates to a novel BODIPY flourescent dye with an adjustable emission wavelength. The chemical formula of the novel BODIPY flourescent dye is C15+mH6+nBF7N2+xOy, wherein m, n, x and y are integers from 0 to 100. The preparation method comprises the following steps of: dissolving pentafluorobenzaldehyde into an organic solvent, adding pyrrole with substituent groups R1, R2, R3 in the presence of nitrogen, and reacting by taking trifluoroacetic acid or para-toluenesulfonic acid as a catalyst; then adding 2,3-dichloro-5,6-dicyano-1,4-benzoquinone for oxidative dehydrogenation; and finally adding organic amine and boron trifluoride diethyl etherate solutions for continuous reaction, and concentrating a reaction liquid to obtain a target object by utilizing silica gel column chromatography. The novel BODIPY flourescent dye disclosed by the invention can be used for cell imaging and the like, can be adjusted in emission wavelength from a visible region to a near-infrared region and has the advantages of narrow fluorescence emission spectrum, high fluorescence quantum efficiency, good light stability, simple molecular structure, easiness and convenience for synthetic method and easiness for popularization and application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

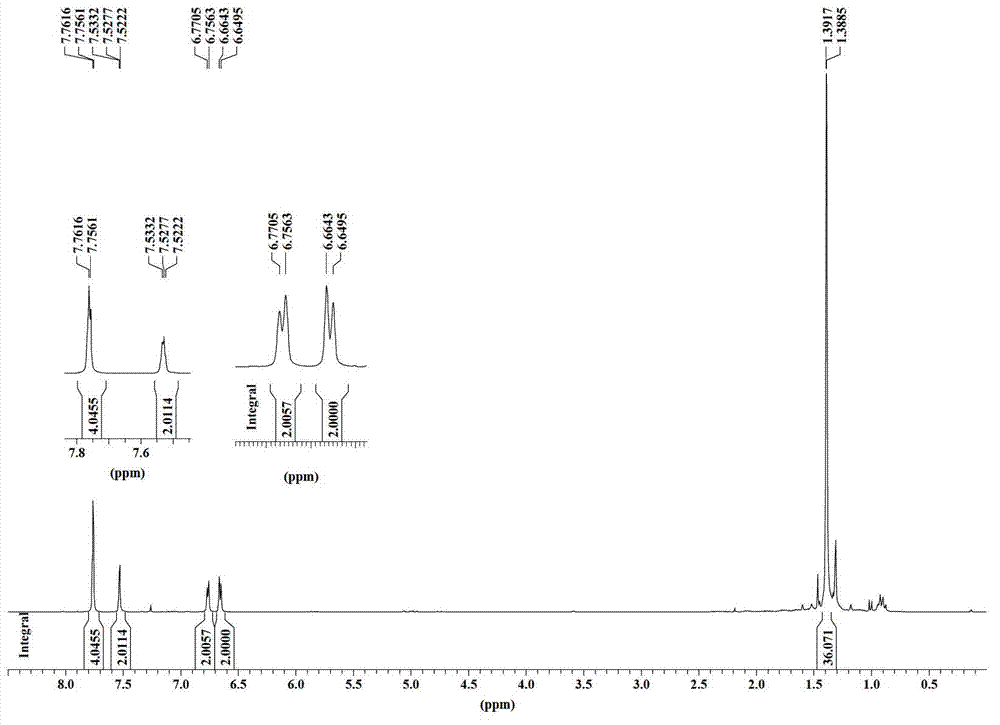

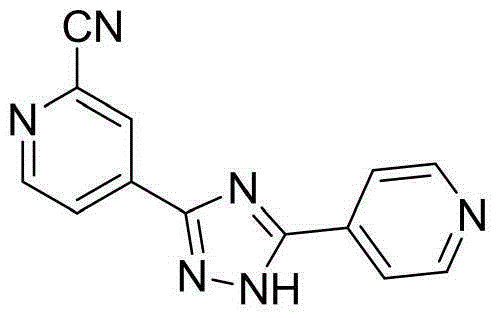

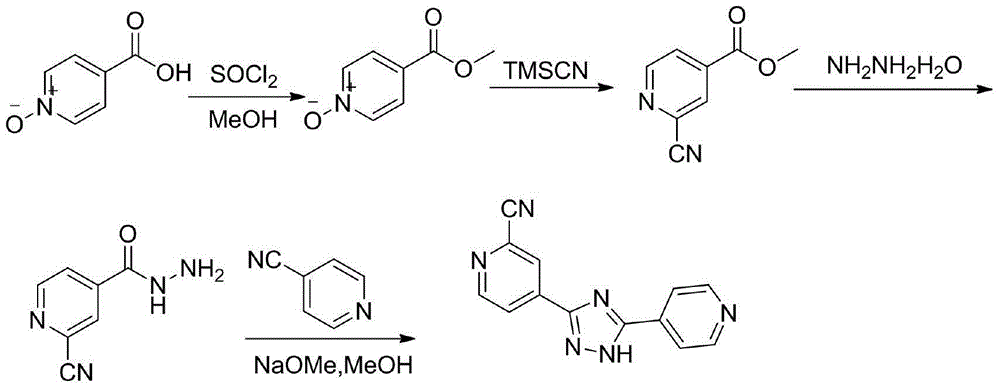

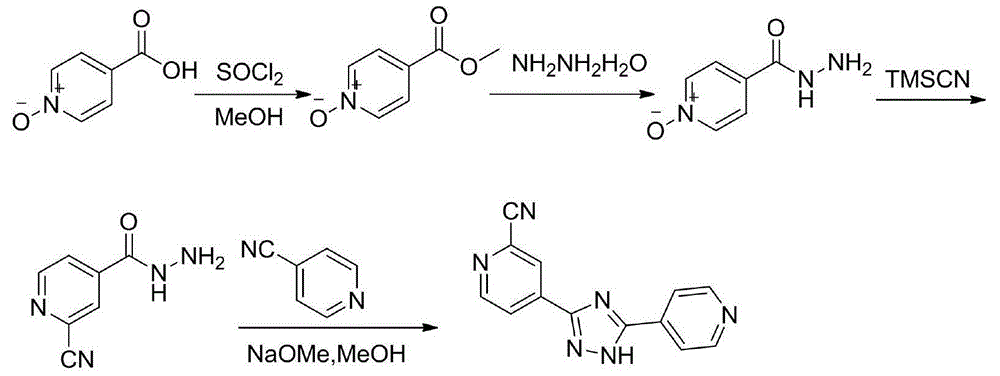

Preparation technology for 5-(2-cyano4-pyridyl)-3-(4-pyridyl)-1,2,4-troazole

InactiveCN105130958ARelieve pressureSimple processOrganic chemistryHydrazine compoundOne-pot synthesis

The invention belongs to the field of medicine and chemical engineering, and particularly discloses a preparation technology for 5-(2-cyano4-pyridyl)-3-(4-pyridyl)-1,2,4-troazole (topiroxostat). The preparation technology is characterized in that methyl isonicotinate serving as a compound II is used as a starting raw material, the compound II, phosphorus oxychloride, N,N-dimethyl formamide, iodine and 28% ammonium hydroxide form a compound III which is 2-cyano methyl isonicotinate in a one-pot synthesis mode, then a compound IV which is 2-cyano isonicotinyi hydrazine is formed through synthesis, a topiroxostat crude product Ia is prepared through condensing the compound IV which is 2-cyano isonicotinyi hydrazine and 4-cyanopyridine, salifying is performed on the crude product Ia and para-toluenesulfonic acid to form topiroxostat tosilate Ib, and finally the topiroxostat finished product I is obtained through desalting in a refined mode. The number of reactions steps is reduced, the yield of the finished product is increased, the reaction process is low in toxin and has small influences on environment, the reaction route is short, the cost is greatly lowered, the product purity is larger than 99.7%, the net contamination is smaller than 0.1%, and standard requirements are met.

Owner:JINAN KANGHE MEDICAL TECH

Shielded strip line device and method of manufacture thereof

InactiveUS6721171B2Lower impedanceIncrease speedSolid electrolytic capacitorsImpedence networksDielectricConductive polymer

Owner:NEC CORP

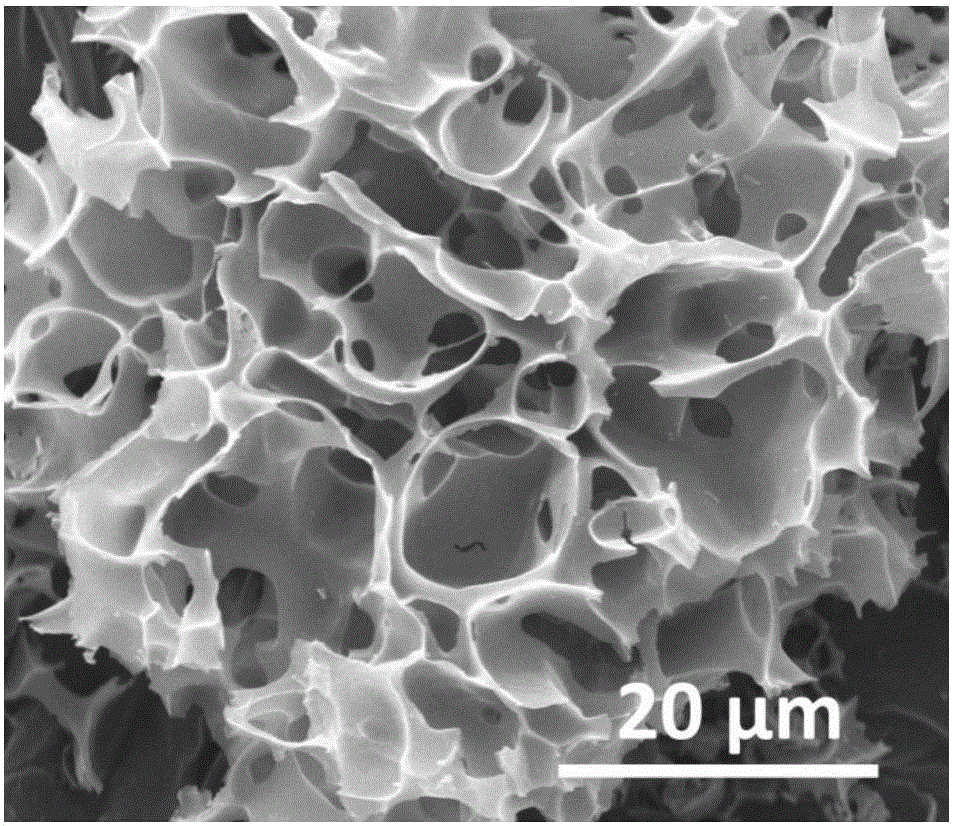

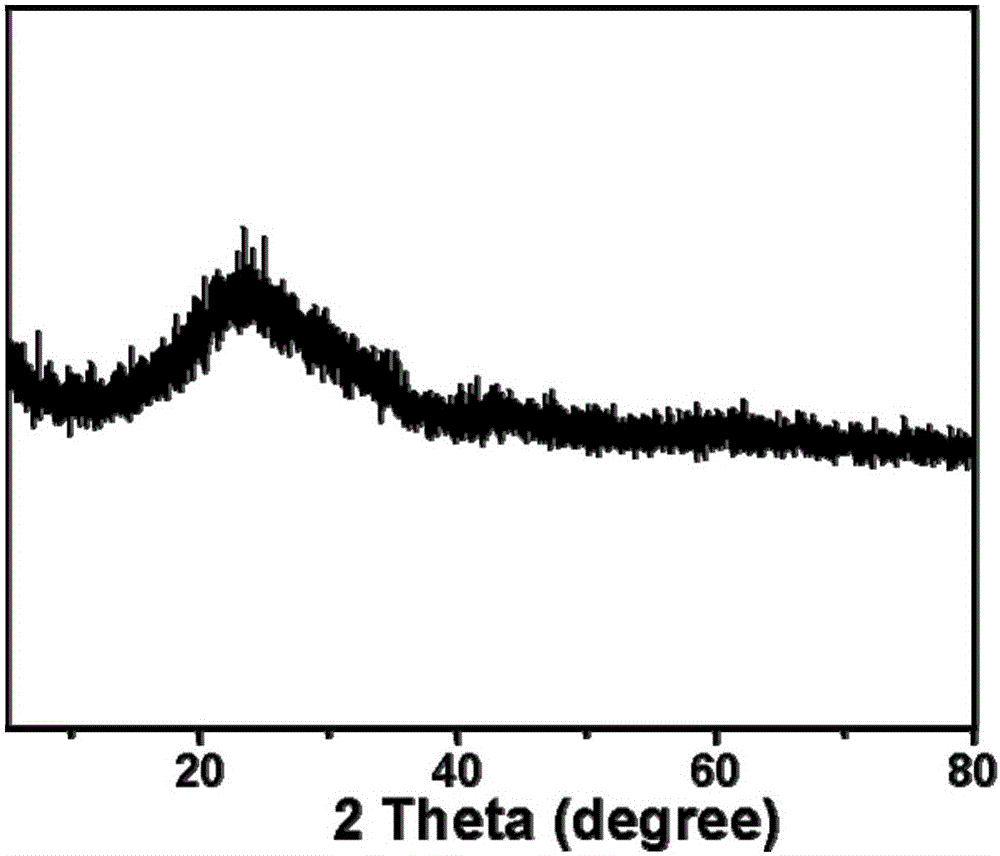

Preparation method and application for pitch-based hard carbon nanosheet

ActiveCN106099109ALow priceHigh reversible sodium storage capacityMaterial nanotechnologyCell electrodesPara-toluenesulfonic acidChemistry

The invention relates to the preparation technical field of a carbon material, and discloses a preparation method and an application for a pitch-based hard carbon nanosheet. The preparation method comprises the following processes of performing a cross-linking reaction by taking medium temperature coal pitch as the raw material, taking terephthalyl alcohol as the cross-linking agent, and taking para-toluenesulfonic acid as the catalyst at a temperature of 100-170 DEG C to prepare hard carbon precursor modified pitch; then carrying out mixing, ball milling and drying on sodium chloride and ethyl alcohol to obtain a micron-level sodium chloride template; and finally dissolving the modified pitch into n-methyl-pyrrolidone, and mixing with the sodium chloride template according to certain proportion, and performing carbonization at a temperature of 650-850 DEG C, and water washing to obtain the pitch-based hard carbon nanosheet which is applied to the negative electrode of a sodium ion battery. The preparation method provided by the invention is simple and feasible; a step of acid washing to remove the template is not required in the preparation process of the carbon nanosheet, so that an effect of green and environment protection is achieved; the sodium chloride template and the n-methyl-pyrrolidone solvent can be recycled, so that the production cost is relatively low; and when the pitch-based hard carbon nanosheet prepared by the invention is used as the negative electrode material of the sodium ion battery, relatively high reversible sodium storage capacity, relatively high rate capability and excellent cycling stability are represented.

Owner:DALIAN UNIV OF TECH

Modified UV photocuring pure acrylic resin and preparation method thereof

InactiveCN101935387AImprove water resistanceImprove performanceEpoxy resin coatingsGlycidyl methacrylateAcrylic resin

The invention discloses modified UV photocuring pure acrylic resin and a preparation method thereof. The modified UV photocuring pure acrylic resin comprises the following raw materials in part by mass: 17 to 23 parts of glycidyl tertcarbonate, 20 to 30 parts of glycidyl methacrylate, 3 to 8 parts of methyl methacrylate, 12 to 18 parts of butyl methacrylate, 3 to 8 parts of butyl acrylate, 10 to 14 parts of methacrylic acid or crylic acid, 8 to 12 parts of methacrylic isobornyl thiocyanoacetate, 10.5 to 13.5 parts of adipic acid, 1.5 to 2.5 parts of para-toluenesulfonic acid, 0.2 to 0.5 part of open-loop catalyst, 0.01 to 0.05 part of polymerization inhibitor and 1.0 to 3.0 parts of initiator. The modified UV photocuring pure acrylic resin has good water resisting property and maintains the excellent performance of pure acrylic resin; simultaneously, the modified UV photocuring pure acrylic resin is used for UV photocureable coatings, and the films have the advantages of low shrinkage rate and excellent combination property.

Owner:JIANGMEN PAINT FACTORY

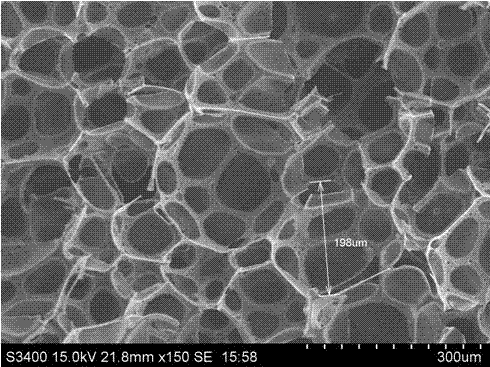

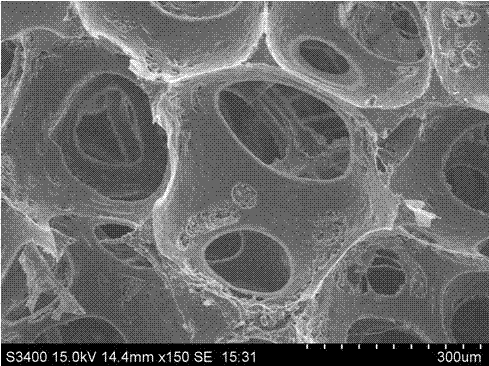

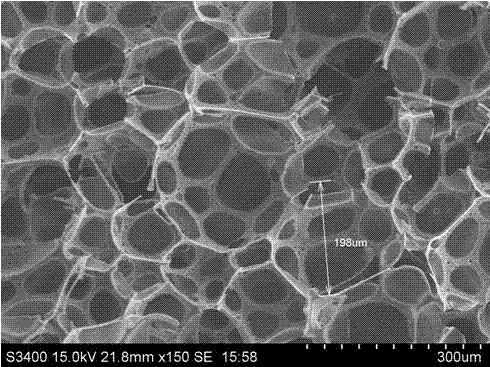

Lignin-based phenolic foam material and preparation method thereof

The invention discloses a lignin-based phenolic heat insulating material and a preparation method thereof. The preparation method comprises the following steps of: uniformly stirring expandable lignin basic phenolic resin with the conventional pH adjusting agent and a surfactant; adding a foaming agent and rapidly and uniformly stirring; adding a curing agent lastly; and uniformly stirring, and rapidly pouring into a specified enclosed container for foaming to the obtain lignin-based phenolic heat insulating material, wherein the used curing agent is a compound curing agent obtained by mixing toluenesulfonic acid and phosphoric acid in the mass ratio of 1.5:1. The foaming multiplying power of the lignin-based phenolic foam material is adjustable, the form hole fineness uniform density is 40-60 kg / m<3>, the compression strength is 0.07-0.45MPa, and the water absorbing rate is 7-15.5 percent.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

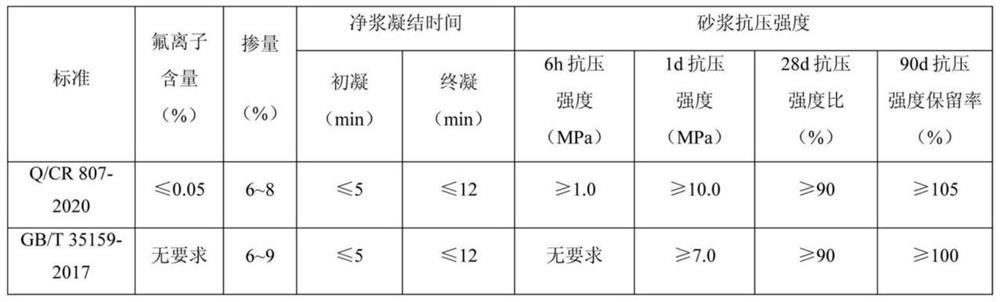

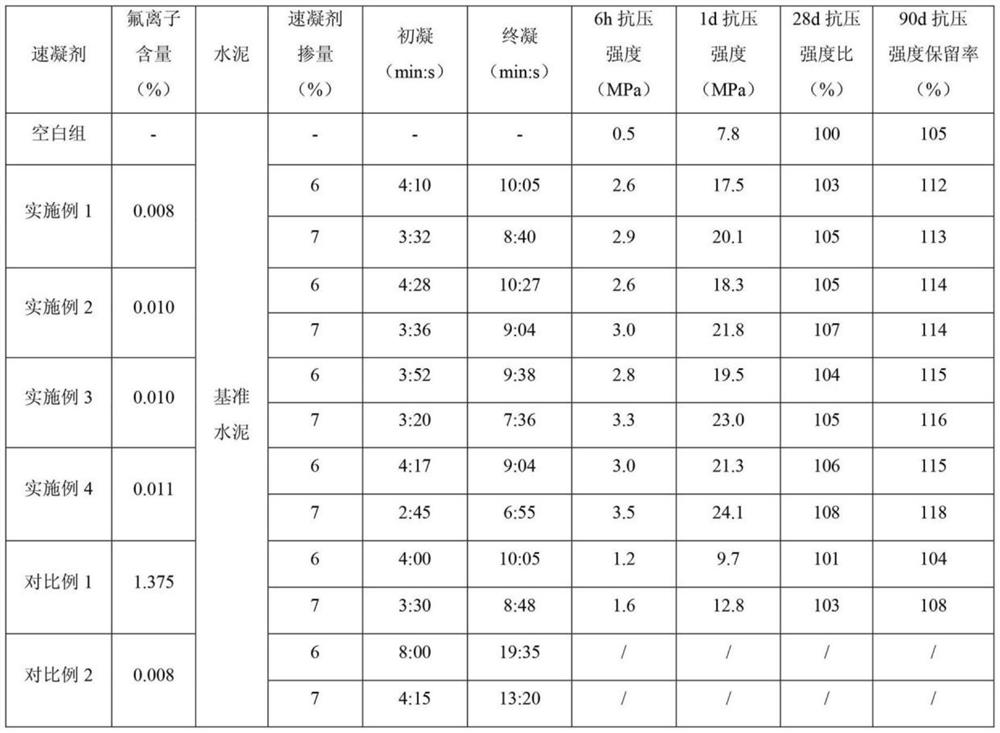

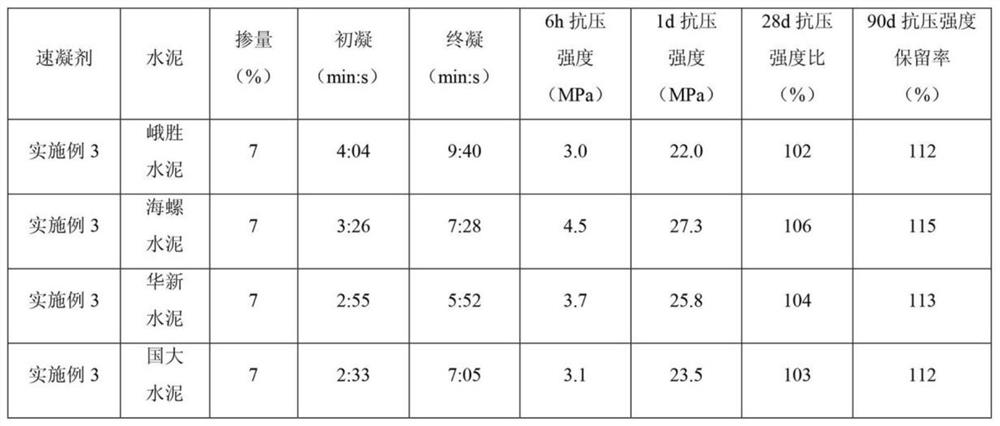

Super-early-strength fluoride-free alkali-free liquid accelerator and preparation method thereof

ActiveCN113603384AHigh aluminum contentAvoid hydrolysisSolid waste managementOXALIC ACID DIHYDRATEDiethylenetriamine

The invention relates to a super-early-strength fluorine-free alkali-free liquid accelerator and a preparation method thereof. The accelerator is prepared from the following raw materials: aluminum sulfate, an organic dissolution promoter, a stabilizer, an early strength agent, a pH regulator and water. The organic dissolution promoter is formed by mixing a component A, a component B and a component C, wherein the component A is monoethanolamine, diethanolamine or triethanolamine; the component B is N-methyldiethanolamine, N,N-dimethylethanolamine or N,N-dimethylformamide; and the component C is diethylenetriamine, triethylene tetramine or tetrahydroxypropyl ethylenediamine. The stabilizer is selected from superfine sepiolite and pseudo-boehmite. The pH regulator is selected from p-toluenesulfonic acid, oxalic acid and formic acid. The early strength agent is selected from lithium sulfate, magnesium sulfate, nanometer silica sol and nanometer aluminum sol. The super-early-strength fluorine-free alkali-free liquid accelerator is good in performance, simple in preparation process, free of fluorine, alkali and chlorine and capable of meeting the performance requirements of various setting accelerator standards for alkali-free accelerators; and according to the liquid accelerator, compressive strength within 6 hours is far larger than 2.5 MPa, compressive strength within 1 day is far larger than 15.0 MPa, a compressive strength retention rate within 90 days is larger than or equal to 110%, and stability exceeds 9 months.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

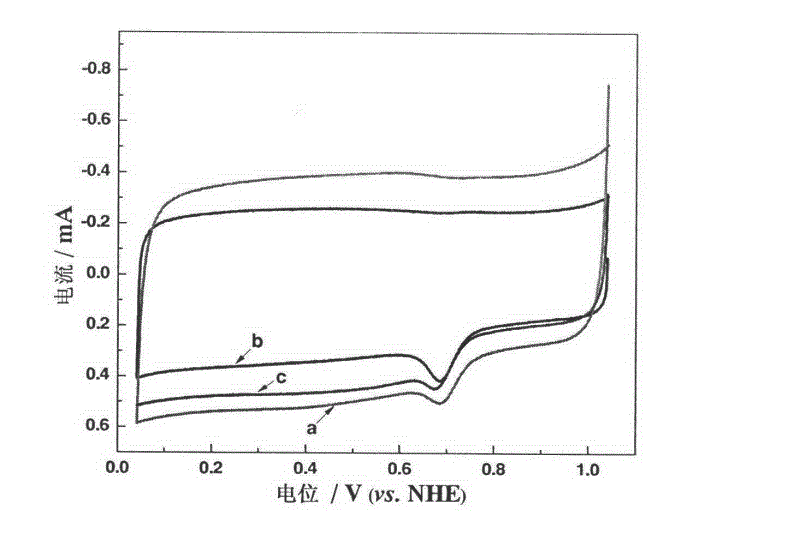

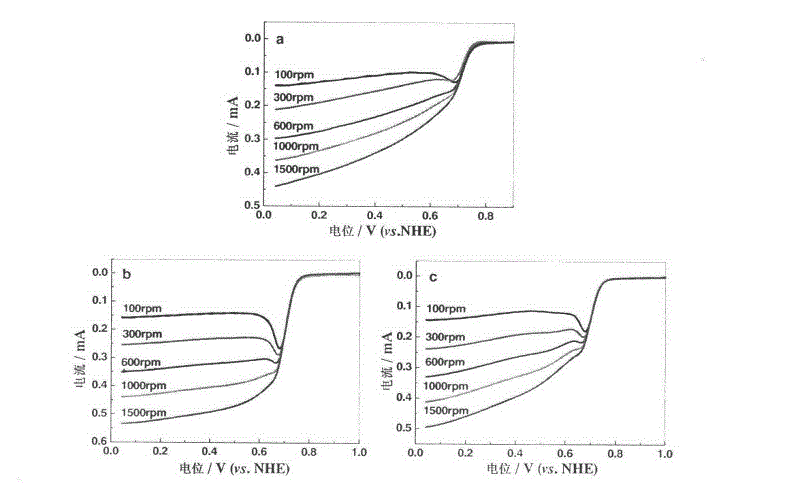

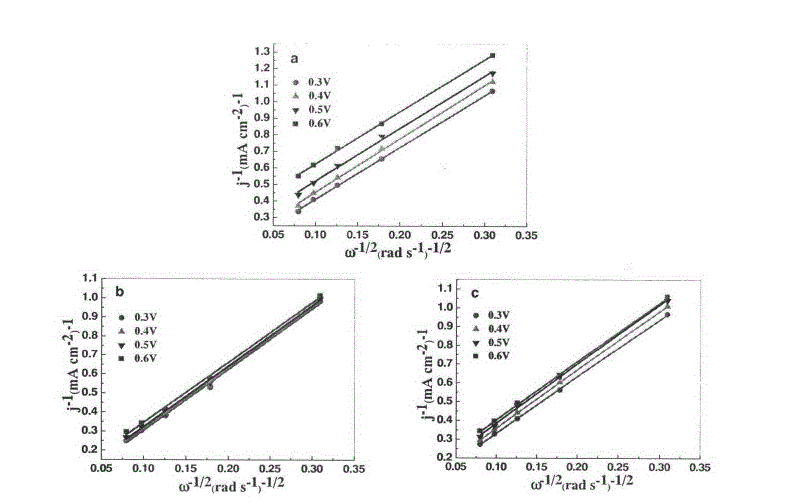

Preparation method for base metal oxygen reduction catalyst

InactiveCN102614915AImproving Oxygen Reduction Catalytic PerformanceLow costOrganic-compounds/hydrides/coordination-complexes catalystsCarbon dustOxygen

The invention discloses a preparation method for a base metal oxygen reduction catalyst. The preparation method includes following steps: weighing a defined amount of carbon dust treated by concentrated nitric acid; adding newly steamed pyrrole, oxidizing agent (ferric chloride) and doping agent (para-toluenesulfonic acid) in the carbon dust; decompressing and filtering mixed solution after uniformly stirring; then drying in a vacuum manner for a few of hours; weighing a defined amount of cobalt salt to be mixed with the mixed solution; decompressing and evaporating after uniformly stirring; and calcinating dried powder at a high temperature so as to obtain the base metal oxygen reduction catalyst with good electrochemical performances. The cheap and environment-friendly ferric chloride is used as the oxidizing agent, the base metal catalyst with the excellent oxygen reduction performance is prepared, the maximum peak potential of an oxygen reduction process catalyzed by the catalyst reaches 0.686V, and the maximum electron transfer number reaches 3.84.

Owner:EAST CHINA UNIV OF SCI & TECH +1

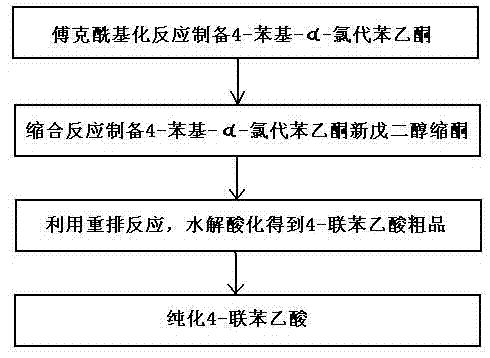

Method for preparing 4-felbinac through rearrangement reaction

InactiveCN102503805ALow toxicityToxicOxygen-containing compound preparationOrganic compound preparationChemical synthesisPtru catalyst

The invention relates to a medicinal chemistry synthesis technology, in particular to a method for preparing 4-felbinac through rearrangement reaction. The method comprises the following steps of: 1, performing Friedel-Crafts acylation on biphenyl and chloroacetyl chloride which serve as raw materials by using chloroform, dichloromethane or 1,2-dichloroethane as a solvent and alchlor as a catalyst to obtain 4-phenyl-alpha-chloroacetophenone; 2, performing condensation on the 4-phenyl-alpha-chloroacetophenon and neopentyl glycol under the catalysis of toluenesulfonic acid to prepare ketal; 3, performing hydrolysis and acidification through the rearrangement reaction to obtain coarse 4-felbinac; and 4, recrystallizing the coarse 4-felbinac by using ethanol, ethyl acetate or 40 to 70 percent acetic acid to obtain the 4-felbinac with the purity of 99.8 percent. The method has the advantages that: the raw materials are readily available and low in toxicity, and new compounds with high toxicity cannot be generated in production; and conventional equipment is used, the yield of the coarse product is 70 to 80 percent and the prepared 4-felbinac has the purity of 99.8 percent.

Owner:SHANGHAI TUPA MEDICAL TECH

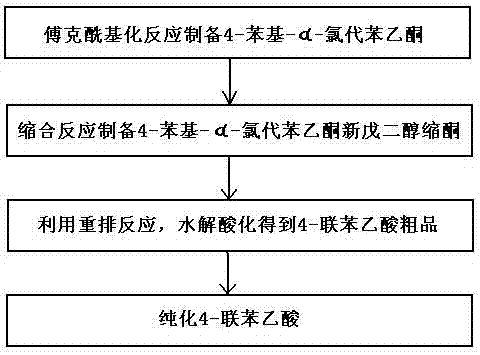

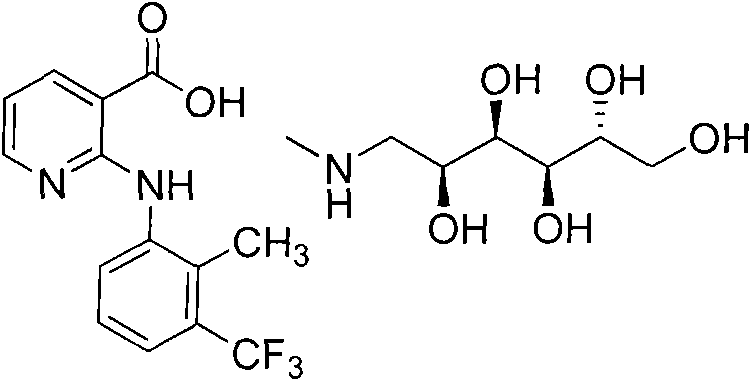

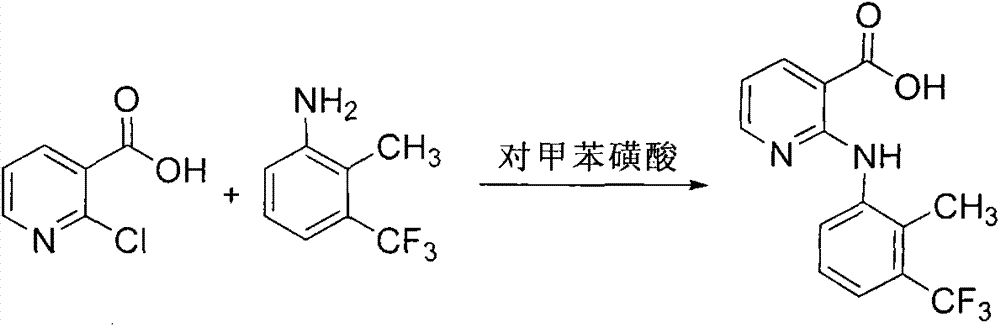

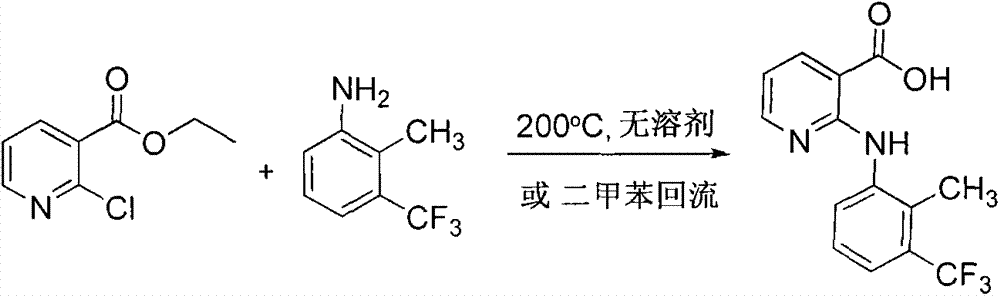

Method for synthesizing flunixin meglumine

InactiveCN103694167AHigh catalytic efficiencyEfficient responseOrganic compound preparationAmino-hyroxy compound preparationFLUNIXIN MEGLUMINEAcetonitrile

The invention provides a method for synthesizing flunixin meglumine. According to the method, reaction is carried out in a manner that 2-chloronicotinic acid and 2-methyl-3-trifluoromethylaniline serve as raw materials, water serves as a solvent and cupric oxide and para-toluenesulfonic acid serve as catalysts. According to the method, on the premise that the condition that para-toluenesulfonic acid serves as a catalyst is reported in the existing literature, cupric oxide is added, so that the catalysis efficiency is increased greatly, the reaction can be carried out efficiently, the reaction time is shortened, and the yield is increased; obtained flunixin and meglumine are salified in an acetonitrile solvent and are recrystallized, so as to obtain flunixin meglumine, and the total yield is about 90%; through synthesizing flunixin meglumine by the method, the operation is convenient and simple, and the requirements for equipment are low, so that the method is applicable to industrial large-scale production.

Owner:WEIHAI YARUI BIOLOGICAL SCI & TECH

Preparation method of peanut shell based foam carbon

Belonging to the field of foam carbon, the invention discloses a preparation method of peanut shell based foam carbon. The method consists of: firstly conducting peanut shell liquefaction, making liquefied peanut shell and formaldehyde into peanut shell based thermosetting resin, and then acquiring short bamboo charcoal fiber from bamboo splits, and putting the short bamboo charcoal fiber and peanut shell based thermosetting resin, p-toluenesulfonic acid, sodium bicarbonate and fatty glyceride as raw materials into a mould to conduct foaming to obtain short bamboo charcoal fiber modified foamed resin, and finally charring the short bamboo charcoal fiber modified foamed resin to obtain the peanut shell based foam carbon. The peanut shell based foam carbon prepared by the method provided by the invention has uniform foam carbon aperture, large specific surface area and strong adsorption capacity, utilizes the short bamboo charcoal fiber modified foamed resin to enhance the mechanical strength of foam carbon so as to avoid crack phenomenon, and by using peanut shell as the foam carbon base material, the preparation cost is low.

Owner:陈毅忠

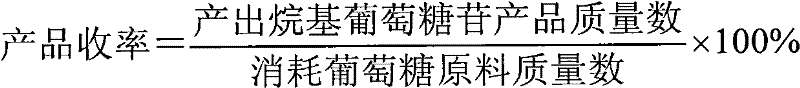

Method for preparing alkyl glucoside

ActiveCN102127126AEasy to operateGood colorSugar derivativesSugar derivatives preparationPhosphoric acidFatty alcohol

The invention provides a method for preparing alkyl glucoside. The method for preparing the alkyl glucoside comprises the following steps of: (1) performing vacuum reaction on glucose and C8-C12 fatty alcohol in the presence of a composite catalyst for 2 to 8 hours, wherein the composite catalyst consists of a main catalyst, a cocatalyst and an auxiliary catalyst, the main catalyst is para-toluenesulfonic acid or dodecylbenzene sulfonic acid, the cocatalyst is phosphoric acid or sulfurous acid, and the auxiliary catalyst is sulfamic acid; (2) cooling and adding an alkaline substance until the pH value of a system is neutralized to be 6 to 8 to obtain a mixture of the alkyl glucoside and the fatty alcohol; and (3) removing the fatty alcohol under high vacuum, adding water until the solid content of the system is 45 to 50 weight percent, and adding the alkaline substance to adjust the pH value of the system to be 12 to 14 to obtain the product. By the method, the final yield of the product is more than 155 percent and a small number of monosaccharide residues and other byproducts are obtained. The color and the luster of the product are not changed obviously in the dealcholization process; and the final product is colorless transparent liquid.

Owner:SHANGHAI CHLOR ALKALI CHEM

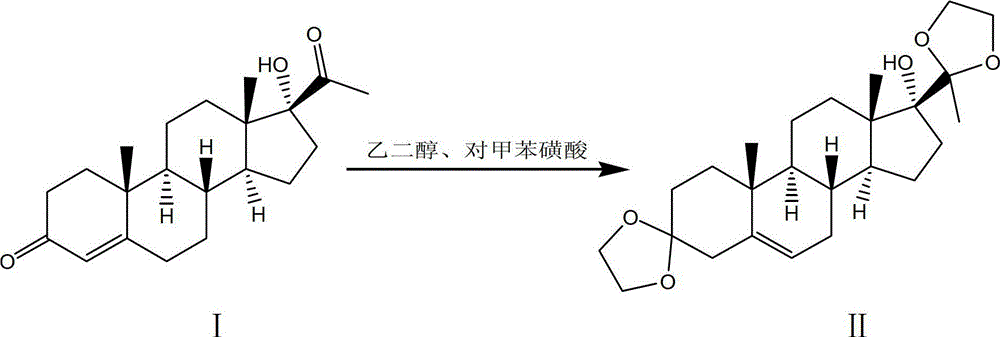

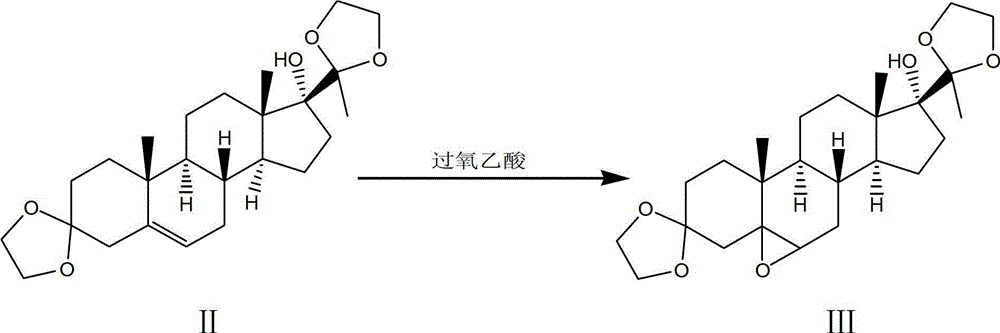

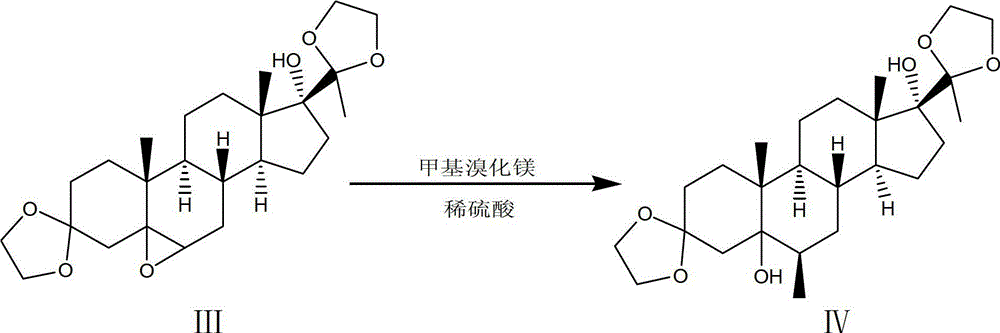

Synthesis method of medroxyprogesterone acetate

The invention discloses a synthesis method of medroxyprogesterone acetate. The method comprises the following steps of: 1) enabling 17 alpha-hydroxyprogesterone and ethylene glycol to perform ketalation under the catalysis of para-toluenesulfonic acid to obtain a ketal; 2) enabling the ketal to perform epoxidation reaction under the action of a peroxyacetic acid solution of anhydrous sodium acetate to obtain an epoxide; 3) enabling the epoxide and methylmagnesium bromide to perform Grignard reaction, and then performing hydrolysis reaction by dilute sulphuric acid to obtain a Grignard matter; 4) performing hydrolysis on the Grignard matter by glacial acetic acid to perform deprotection so as to obtain 5 alpha, 17 alpha-dihydroxy-6 beta-methyl progesterone; 5) performing hydrogenation translocation reaction under the action of hydrogen chloride to obtain 6 alpha-methyl-17 alpha-hydroxyprogesterone; and 6) enabling the 6 alpha-methyl-17 alpha-hydroxyprogesterone to perform acetylation reaction with acetic acid and acetic anhydride so as to obtain the medroxyprogesterone acetate. During the reaction process of the method disclosed by the invention, the use of a precious metal catalyst, namely palladium on carbon is avoided, the cost of auxiliary materials and the recovery cost are greatly reduced, the reaction conditions in each step are mild, the violent heat release and deflation phenomena are avoided, and the safety in production is good.

Owner:BAOJI KANGLE BIOTECH

Fluorine-carbon coil coating and method of producing the same

InactiveCN101402814AGood weather resistanceGood stain resistanceReflecting/signal paintsWaxIsophorone

The invention relates to a fluorocarbon coil coating and a preparation method thereof. The invention is characterized in that the method comprises steps as follows: teflon resin, acrylic block copolymer dispersants, aerosil, cobalt blue pigments, titanium pigments, ferrochrome black pigments, ceramic beads, 100 type aromatic solvents, cyclohexanone and dibasic ester are mixed uniformly according to certain proportion and sequence; after passing through a high-speed disperser, the mixtures are ground for 3 to 5 times by a grinding machine; and then methyl-etherified melamine resin, closed paratoluenesulfonic acid catalysts, micronized PE waxes, acrylic ester flatting agents, acrylic ester foam killers, silicon dioxide flatting silica, hindered amine stabilizers, butyl acetate and isophorone are added, stirred uniformly, filtered and packaged into a finished product. The coating has excellent weatherability and dirt-resistance performance; the solidifying temperature is relatively lower than that of polyvinylidene fluoride and the color is bright; the infrared emission rate is higher; the lustrousness can be freely adjusted; and the solid content is high and waste gas discharge can be reduced.

Owner:无锡银星涂层板有限公司

Method for preparing lubricant for wood-plastic composites with illegal cooking oil

The invention discloses a method for preparing lubricant for wood-plastic composites with illegal cooking oil, which includes the steps of dissolving acrylic acid into 12-hydroxystearic acid prior to adding into a reaction kettle with catalyst, and obtaining an esterification product by means of reaction for 2-6 hours at the temperature ranging from 100 DEG C to 150 DEG C under the protection of N2 (nitrogen); and adding the illegal cooking oil and polyethylene polyamine into the esterification product, heating up to the temperature ranging from 100 DEG C to 200 DEG C, adding addition polymerization initiator, carrying out hybrid reaction for 2-10 hours under the protection of N2 and cooling to the room temperature so that faint yellow oily liquid, namely the lubricant, is obtained. The catalyst is one of stannous chloride and para-toluenesulfonic acid, and the initiator is one of cyclohexanone peroxide and methyl ethyl ketone peroxide. The method is low in production cost and simple in reaction, and by the aid of the obtained lubricant, liquidity of blend can be improved, compatibility among inorganic filler, wood powder and plastics is improved, so that mechanical property of the manufactured wood-plastic composites is enhanced.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for manufacturing organic light emitting display device

ActiveCN104868062AImprove etching effectSimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePhosphoric acid

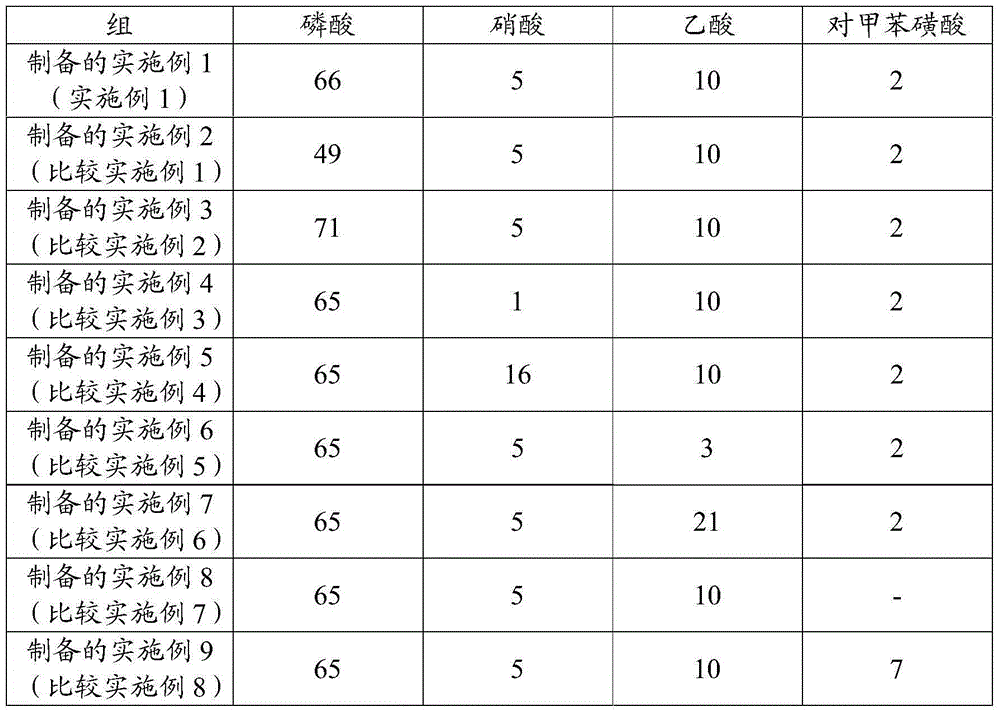

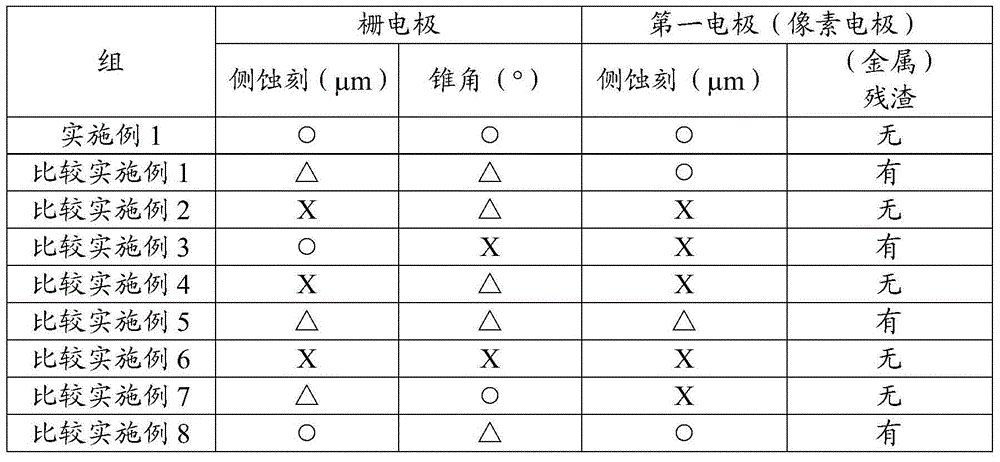

The present invention discloses a method for manufacturing an organic light emitting display device, comprising the steps of: a) forming a gate electrode on a substrate; b) forming a gate insulating layer on the substrate comprising the gate electrode; c) forming an active layer on the gate insulating layer; d) forming an insulating layer on the active layer; e) forming a source electrode and a drain electrode contacted with the active layer on the insulating layer; f) forming a passivation layer on the insulating layer for covering the source electrode and the drain electrode; and g) forming an organic light emitting element electrically connected with one of the source electrode and the drain electrode, wherein the step a) comprises forming a metal layer or a laminating layer of aluminum, molybdenum, or silver, and etching the metal layer to form the gate electrode through an etching agent composition, wherein the etching agent composition comprises 50%-70% by weight of phosphoric acid, 2%-15% by weight of nitric acid, 5%-20% by weight of acetic acid, 0.1%-5% by weight of para-toluenesulfonic acid, and the balance water, in this way, metal layers of the gate electrode and a pixel electrode can be etched at the same time, thus excellent etching effect can be achieved, and the organic light emitting display device can be manufactured with improved process efficiency.

Owner:DONGWOO FINE CHEM CO LTD

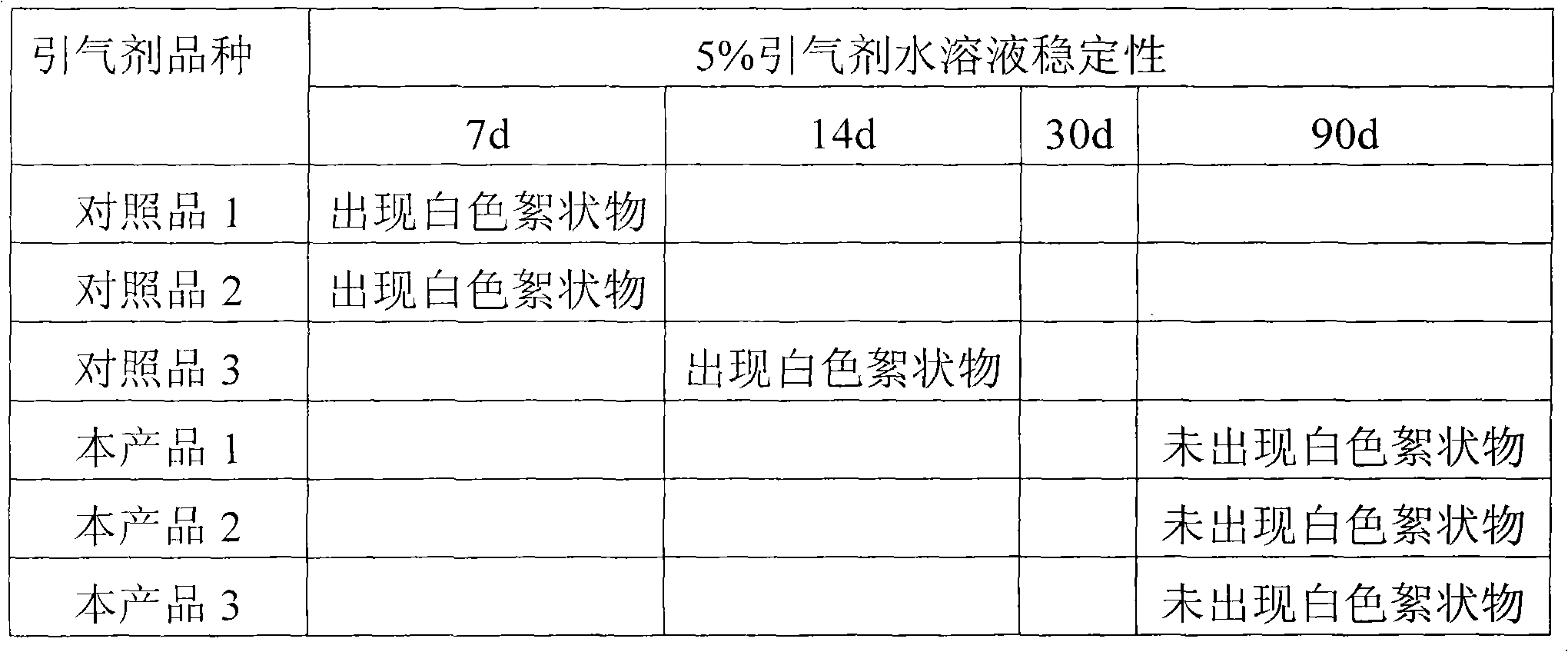

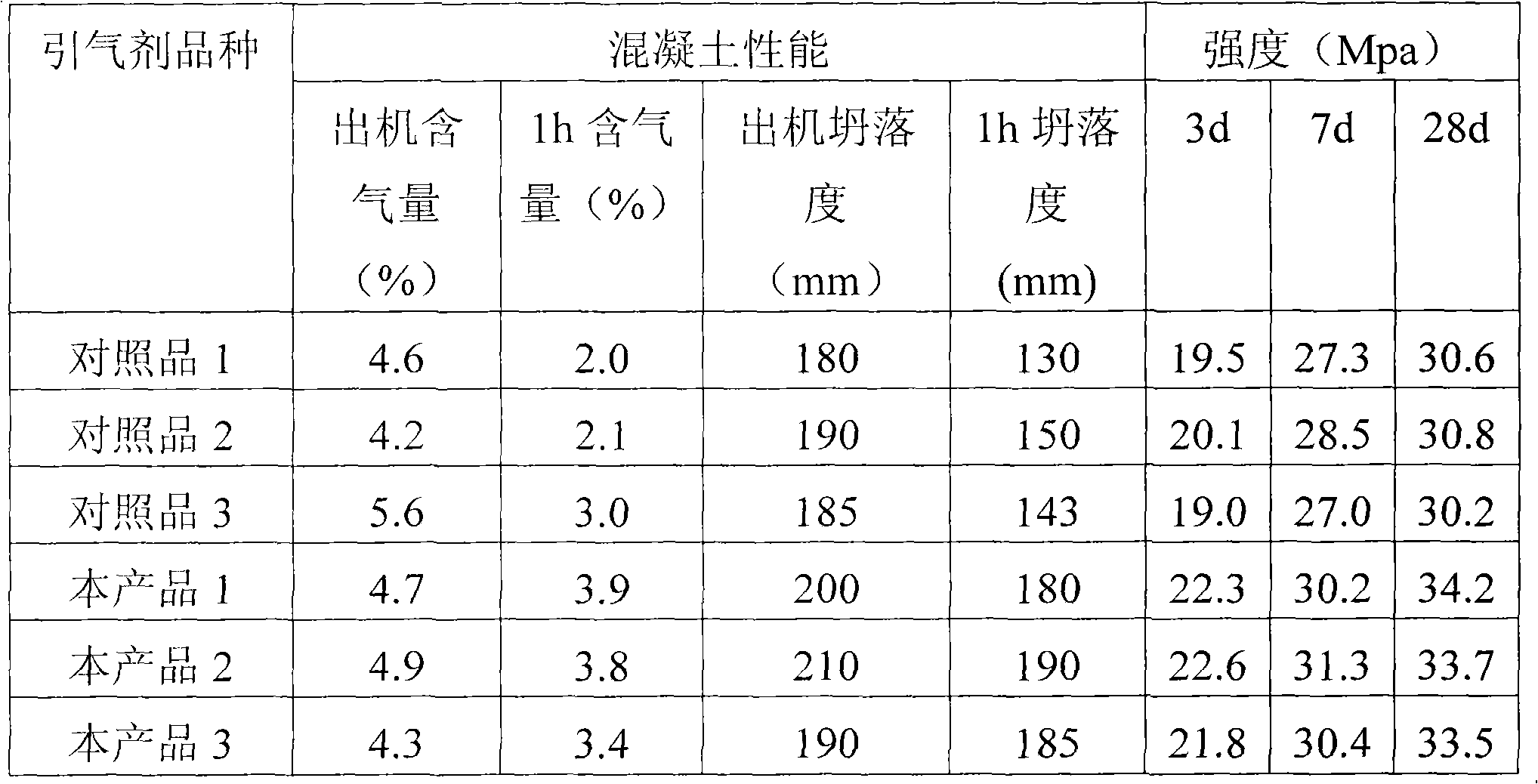

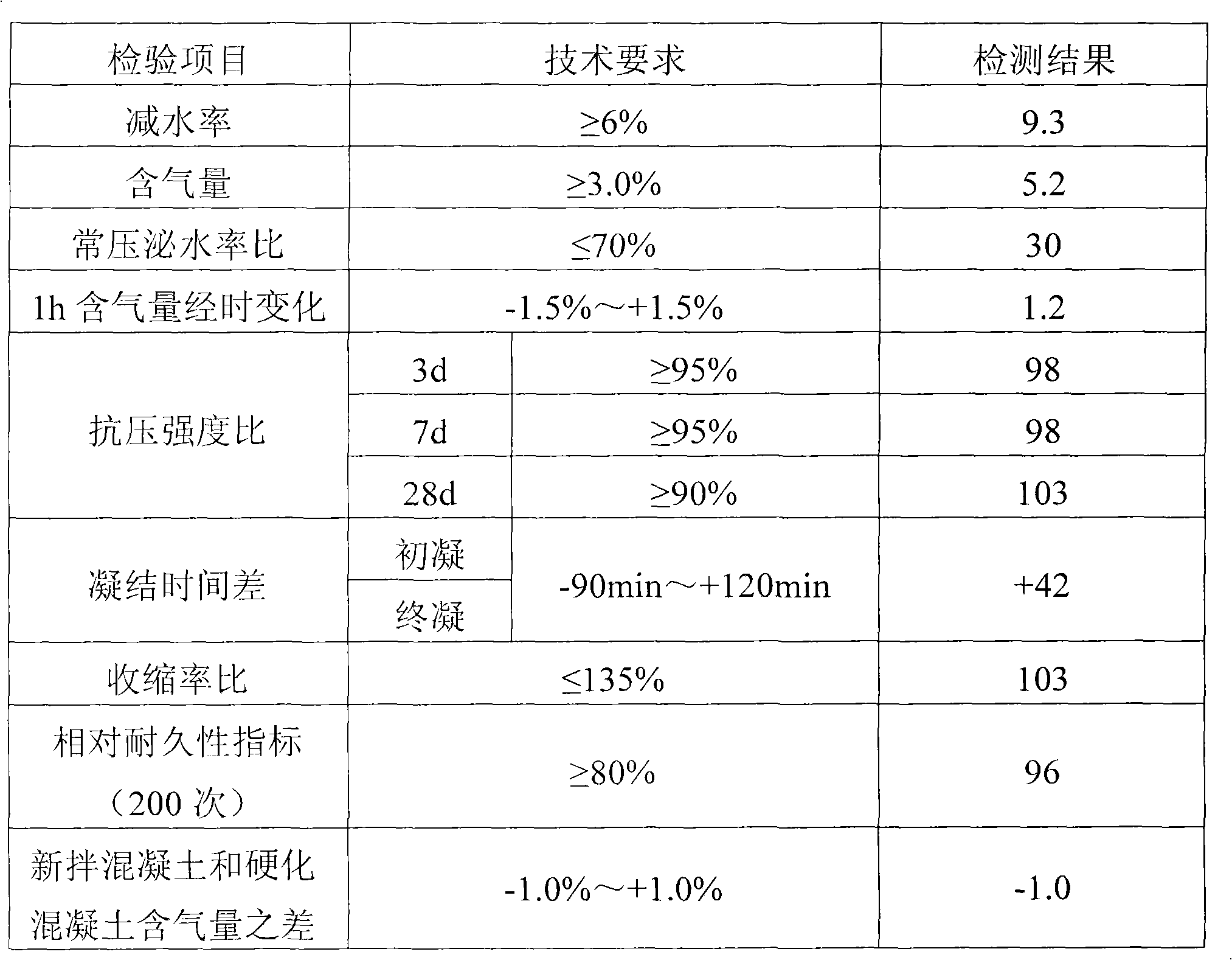

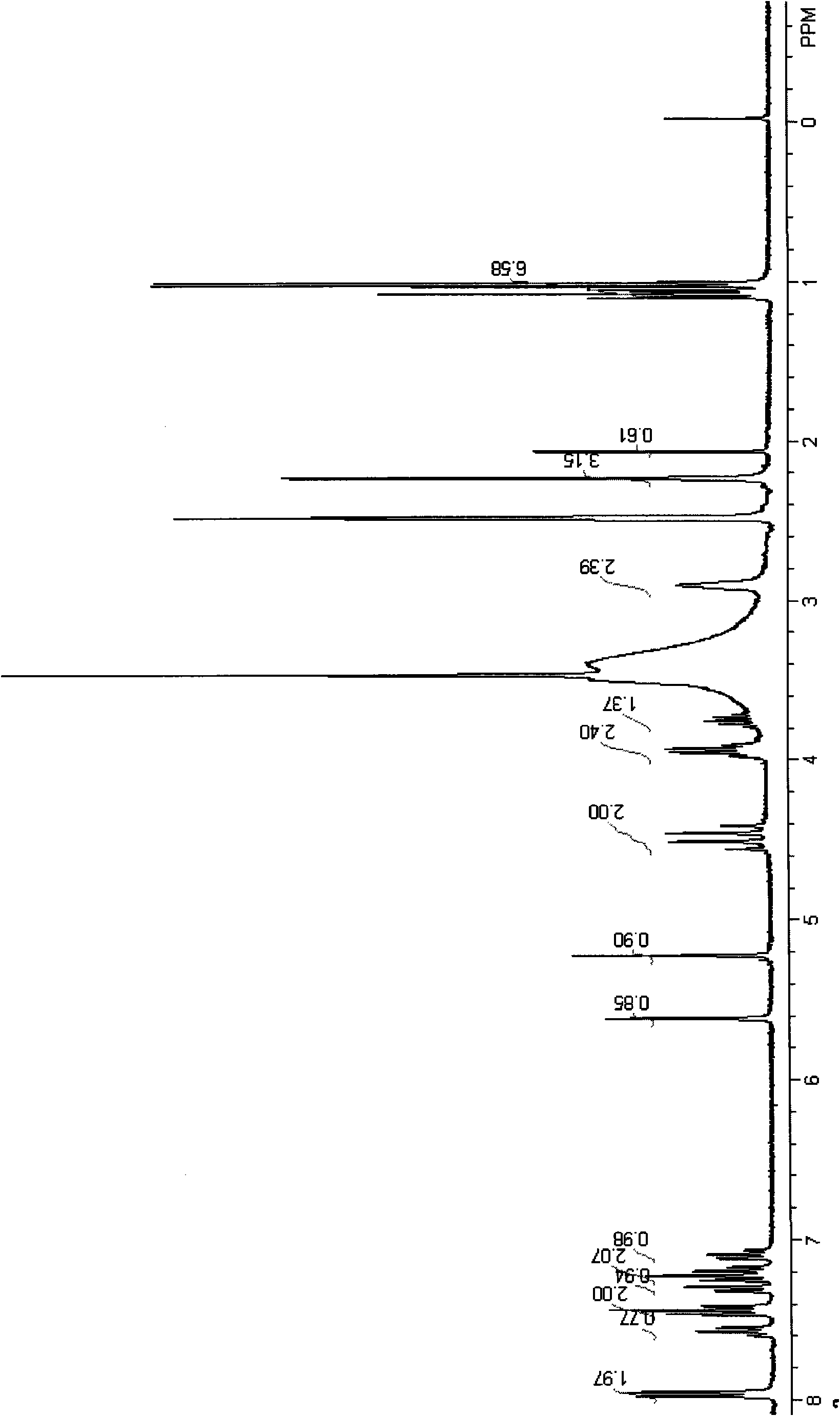

Method for preparing air entraining agent for concrete

ActiveCN101805148ASolve solubilityAddressing Adaptive IssuesPara-toluenesulfonic acidMaleic anhydride

The invention discloses a method for preparing an air entraining agent for concrete, which comprises the following steps: crushing colophony into powder, and oxidizing colophony powder in the air until the color becomes dark slightly; adding the oxidized colophony powder into a reaction kettle, and heating to melt the colophony powder; adding polyethylene glycol, and carrying out esterification reaction at 160-230 DEG C under the catalysis of para-toluenesulfonic acid; neutralizing with liquid caustic soda at 85-95 DEG C, and adding a modifier; and diluting with tap water to obtain the liquid air entraining agent, of which the solid content is 35+ / -1% and the pH value is 8.5-9.5. The invention has the advantages of simple synthesis technique and good product performance, and the product does not contain flammable and explosive hazardous article maleic anhydride. By using the air entraining agent, lots of fine, uniform and stable bubbles can be introduced into the concrete. After being compounded with the water reducer, the air entraining agent can obviously improve the concrete workability, enhance the concrete impermeability and frost resistance and reduce the concrete slump loss without reducing the concrete strength.

Owner:深圳市五山新材料股份有限公司

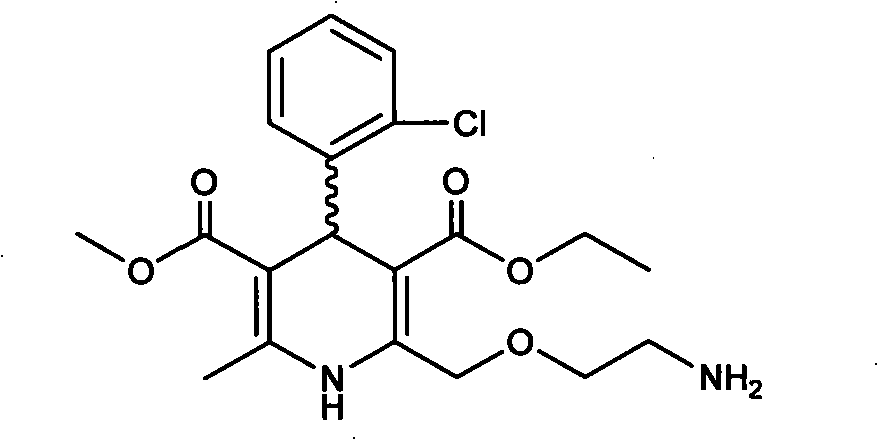

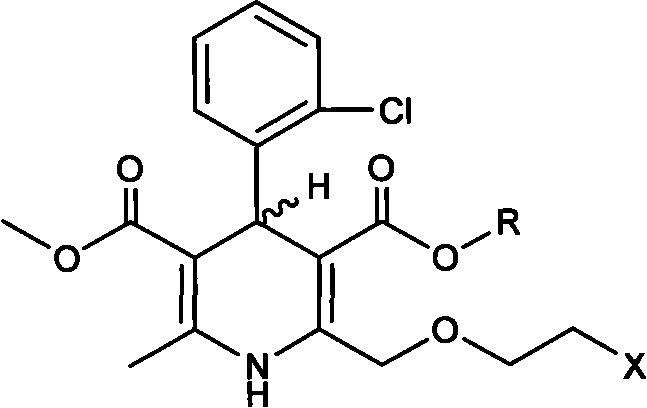

Method for preparing optically active amlodipine tosilate

The invention discloses a method for preparing optically active amlodipine tosilate. The method comprises the following steps: reacting (R, S)-amlodipine with 0,0'-dimethyl-p benzoyl-D-tartaric acid which is a resolving agent in an isopropanol solvent; crystallizing and filtering a reaction product to obtain optically active S-(-)-amlodipine-semi-dimethyl-p benzoyl-D-tartrate or a solvate thereofand collecting a mother liquor; then treating the obtained optically active S-(-)-amlodipine-semi-dimethyl-p benzoyl-D-tartrate or the solvate thereof with alkali; reacting the tartrate or the solvatethereof treated with alkali with para-toluenesulfonic acid to obtain optically active S-(-)-amlodipine tosilate; and finally, concentrating the mother liquor obtained after filtering to be dry and reacting the dry mother liquor with para-toluenesulfonic acid to obtain R-(+)-amlodipine tosilate. The invention is suitable for industrial production, has less environmental pollution and can reduce the production cost.

Owner:NANJING UNIV

Tanning method for tanning sheepskin clothing leather by hyperbranched polymer-aluminum salt tanning agent

InactiveCN103060490AIncrease shrinkage temperatureHas a tanning effectTanning treatmentPre-tanning chemical treatmentPolymer scienceMeth-

The invention relates to a tanning method for tanning sheepskin clothing leather by a hyperbranched polymer-aluminum salt tanning agent. Current chrome free tanning agents cannot completely replace chrome tanning agents for realizing better anti-hydrothermal stability of leather. The tanning method provided by the invention comprises the following steps of: pre-treating; pickling; tanning; degreasing; retanning; neutralizing; filling; oiling and drying acidic leather. The preparation method of the hyperbranched polymer-aluminum salt tanning agent used in the tanning process comprises the following steps of: mixing diethanol amine and methyl acrylate, and adding methanol to obtain an AB2 type monomer; carrying out reaction of the AB2 type monomer with trimethylolpropane, and adding para-toluenesulfonic acid for temperature rising reaction to prepare hydroxyl-terminated hyperbranched polymer; carrying out reaction of the hydroxyl-terminated hyperbranched polymer with maleic anhydride, adding para-toluenesulfonic acid to prepare an intermediate of an aqueous liquor of the hydroxyl-terminated hyperbranched polymer, and mixing and reacting the intermediate aqueous liquor with analytically pure analytically pure at normal temperature to obtain the hyperbranched polymer-aluminum salt tanning agent. The method provided by the invention is higher in shrinkage temperature and can replace the conventional chrome tanning method, so that chrome tanning pollution is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Novel oil soluble viscosity breaking agent for thickened oil recovery

ActiveCN102363726AAvoid regroupingEvenly distributedDrilling compositionPara-toluenesulfonic acidMaleic anhydride

The invention relates to a novel oil soluble viscosity breaking agent for thickened oil recovery. The novel oil soluble viscosity breaking agent for thickened oil recovery consists of the following raw materials in part by weight: 60 to 80 parts of maleic anhydride, 10 to 20 parts of para-hydroxyl anisole, 130 to 170 parts of methylbenzene, 2 to 4 parts of crylic acid, 3 to 5 parts of para-toluenesulfonic acid, 0.2 to 0.6 part of azodiisobutyronitrile and 260 to 300 parts of dichloroethane. The novel oil soluble viscosity breaking agent for thickened oil recovery is prepared by the following steps of: adding the maleic anhydride, the para-hydroxyl anisole and the methylbenzene into a reaction kettle; stirring and heating to 80 DEG C; after dissolution, adding the crylic acid and the para-toluenesulfonic acid; performing reflux reaction for 3 to 4 hours; cooling to room temperature; filtering to obtain a maleic anhydride solvent; placing the maleic anhydride solvent into the dichloroethane; heating to 60 DEG C; stirring for 2 to 3 hours; adding the azodiisobutyronitrile under the condition of introducing nitrogen; heating to 90 to 100 DEG C; after 4 hours, stopping heating; washing by using a 10 percent sodium hydroxide solution until the material is alkalescent; washing by using distilled water until the material is neutral; drying at the temperature of 40 DEG C for 6 hours, wherein the vacuum degree is -0.02 to -0.03 mpa; filtering; drying at the temperature of 60 DEG C for 4 to 6 hours, wherein the vacuum degree is -0.05 to -0.06 mpa; and cooling to room temperature to obtain the novel oil soluble viscosity breaking agent. The novel oil soluble viscosity breaking agent is needed to be used together with thin oil, wherein the ratio of the viscosity breaking agent to the thin oil is 1:4; and the adding amount of the pure agent is 1,300 to 5,000 ppm.

Owner:XINJIANG DELAND

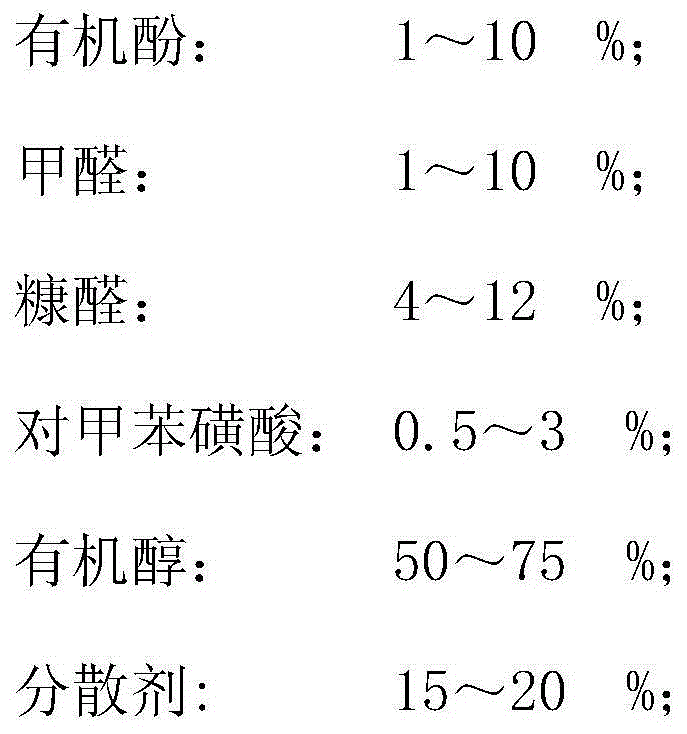

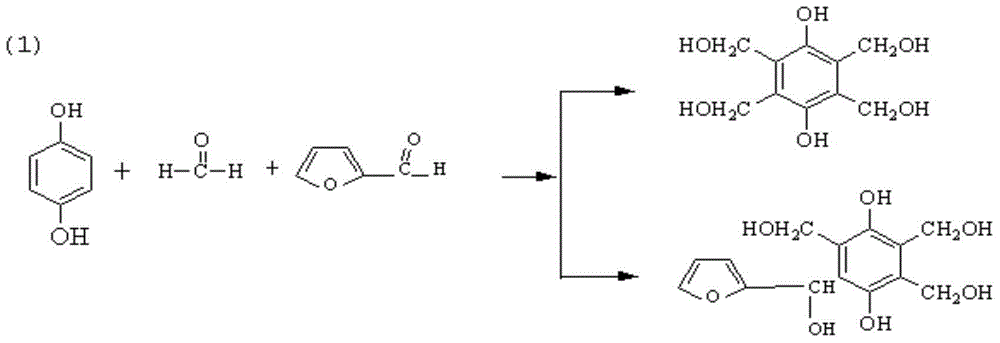

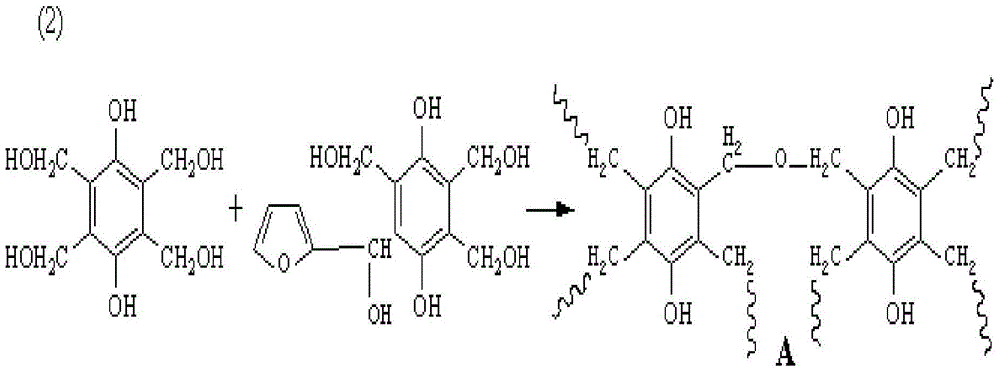

Organic granular plugging agent for CO2-driving high-temperature low-permeation water-sensitive oil deposit and preparation method thereof

InactiveCN104479664AReduce viscosityReduce injection pressureDrilling compositionBulk chemical productionSolubilityFuran

The invention relates to an organic granular plugging agent for a CO2-driving high-temperature low-permeation water-sensitive oil deposit and a preparation method thereof, and belongs to the technical field of chemical agent application in petroleum drilling engineering. The organic granular plugging agent is characterized by comprising organic phenol, formaldehyde, furfural, para-toluenesulfonic acid, organic alcohol and a dispersing agent; an adopted isolation section plug is a gas: N2 or CO2; the plugging agent is subjected to carbonyl addition and condensation reaction mainly through the raw materials under the action of a catalyst to form a polymer which takes fural as a bridge and furan hydroxymethyl as an end group, and an organic gel granule is synthesized at an atmosphere of acidity or supercritical CO2 through a solution-sol-gel method; and polymer molecules are enlarged to a certain degree with polymerization reaction, and when the polymer molecules are enlarged to exceed solubility, the polymer molecules are condensed with each other to form an organic granule. The organic granular plugging agent provided by the invention is low in viscosity, easy to pump into a stratum, controllable in gelling time and high in strength and controllable in reaction time after being gelled under the condition of normal temperature, and has the characteristics of high temperature resistance, scouring resistance, stability in property and high plugging rate.

Owner:YANGTZE UNIVERSITY

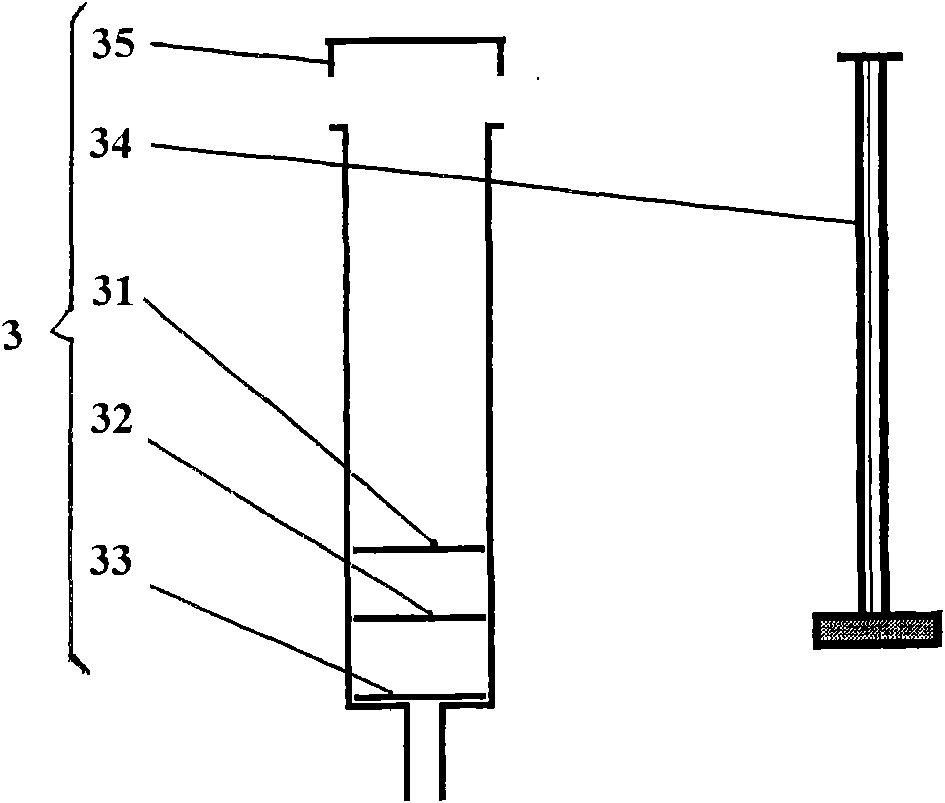

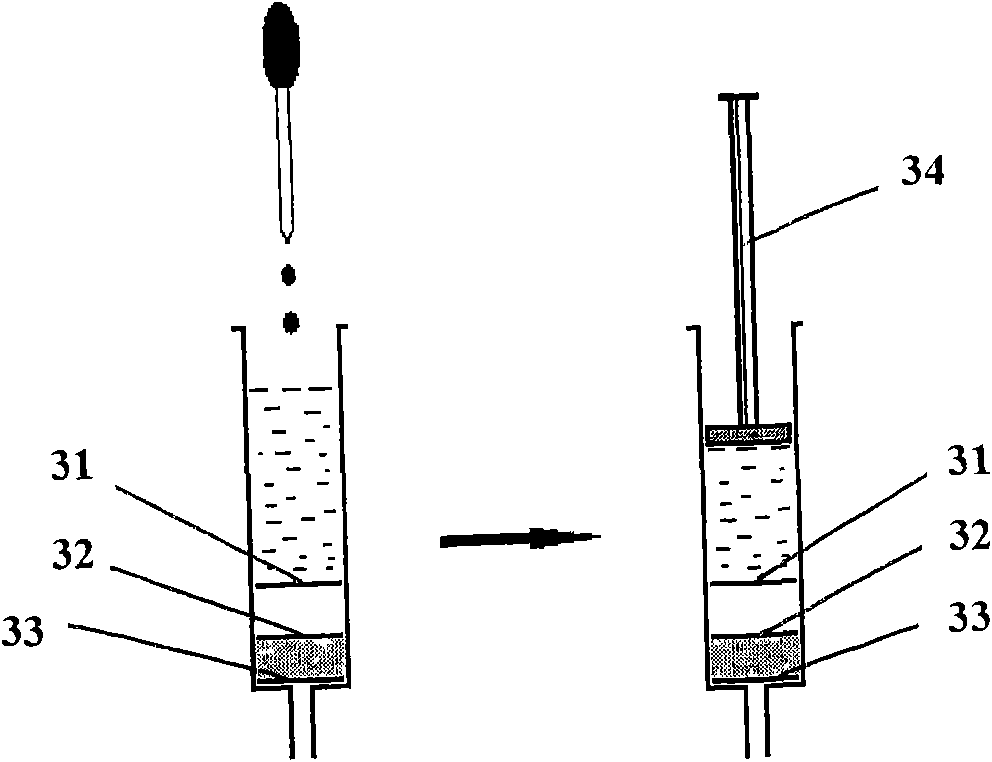

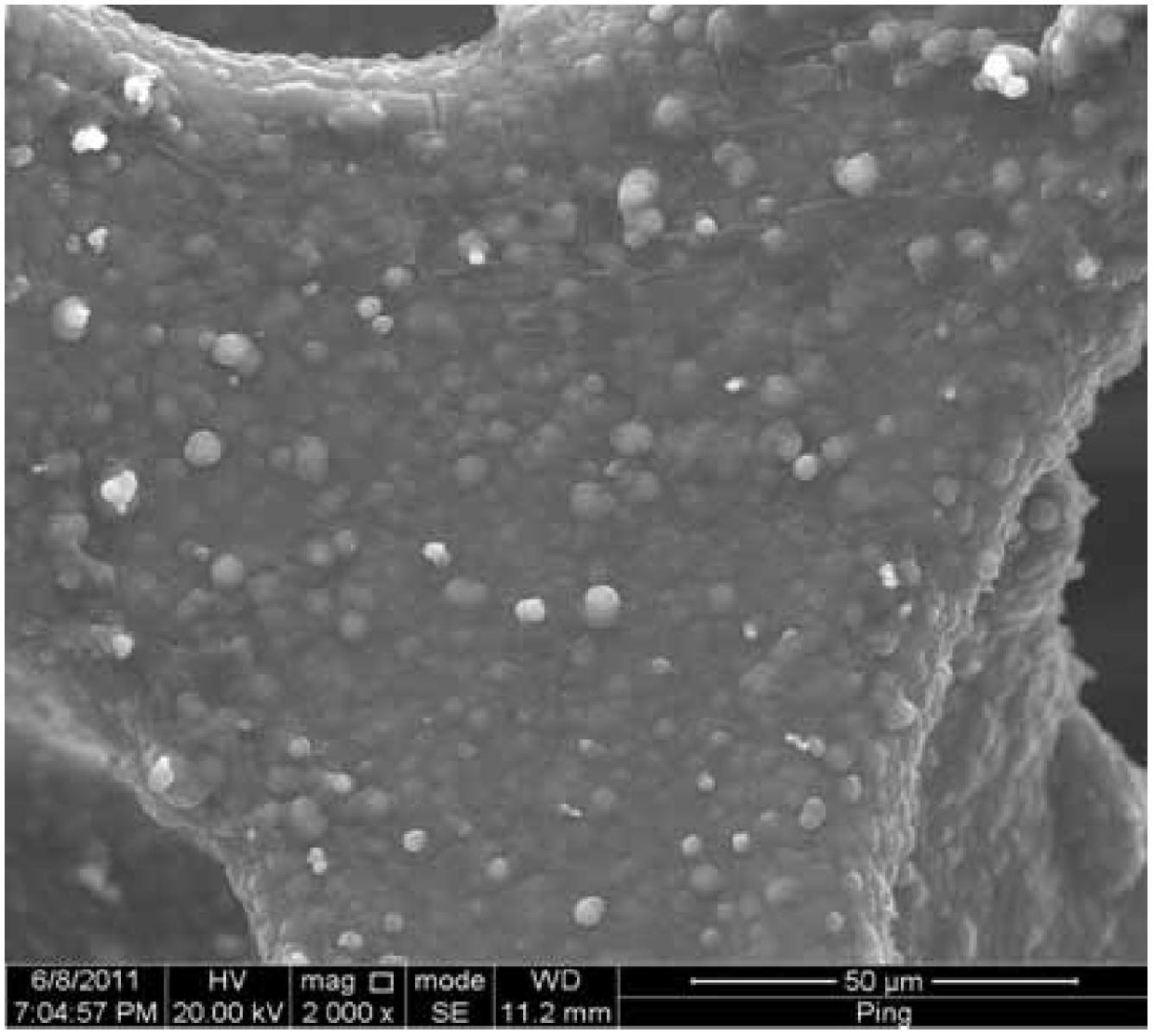

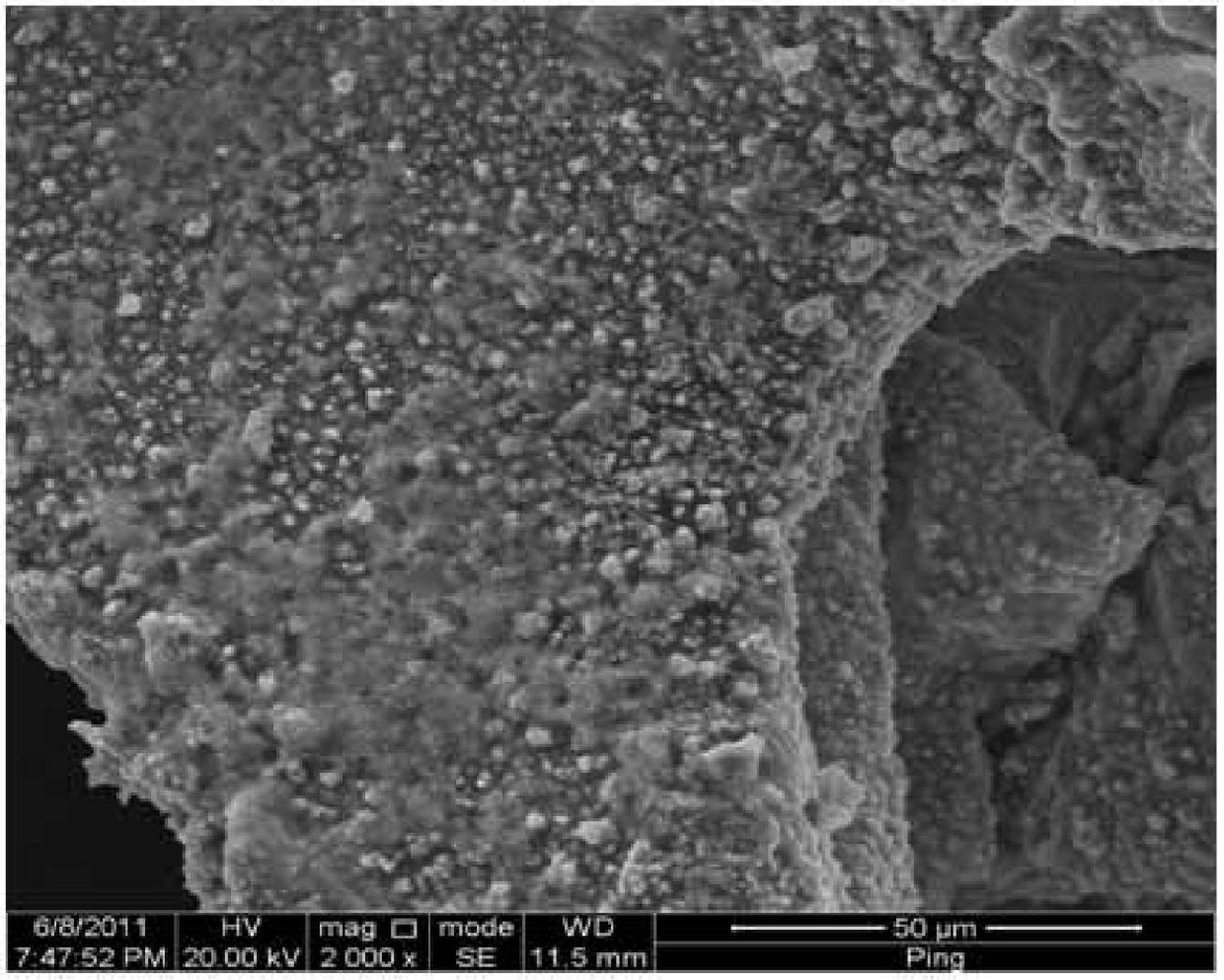

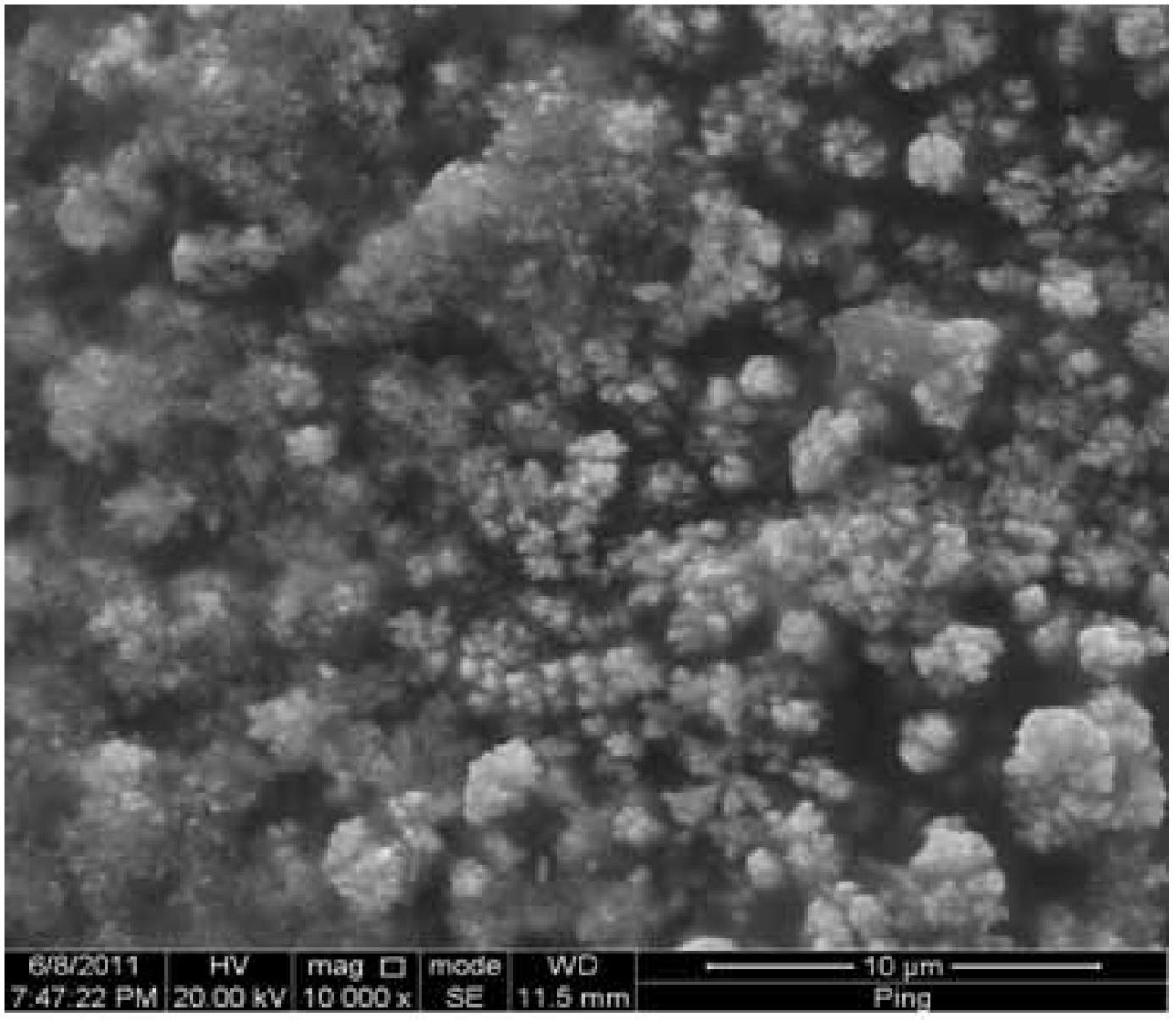

Preparation method for palladium modified electrode with base body formed by para-toluenesulfonic acid mixed with polypyrole

A preparation method for a palladium modified electrode with a base body formed by para-toluenesulfonic acid mixed with polypyrole relates to a preparation method of electrodes. The preparation method solves the technical problem of being uneven in palladium particle dispersion on the existing electrodes. The method includes the following steps: 1 preparing a pyrrole solution of para-toluenesulfonic acid; 2 preparing a PPy (PTS) / Ni electrode; 3 using the PPy (PTS) / Ni electrode as a cathode, using a platinum sheet as an anode and depositing so as to obtain a Pd / PPy (PTS) / Ni electrode. A layer of pyrrole is polymerized on a foam nickel base body, and polypyrrole is in an even micro-ball shape. Adding of the polypyrrole increases material specific surface area for bearing palladium, and dispersion of the palladium particles is even, so that the prepared electrode has good electro-catalysis reduction dechlorination efficiency, is good in stability, and has good application prospects.

Owner:HARBIN INST OF TECH

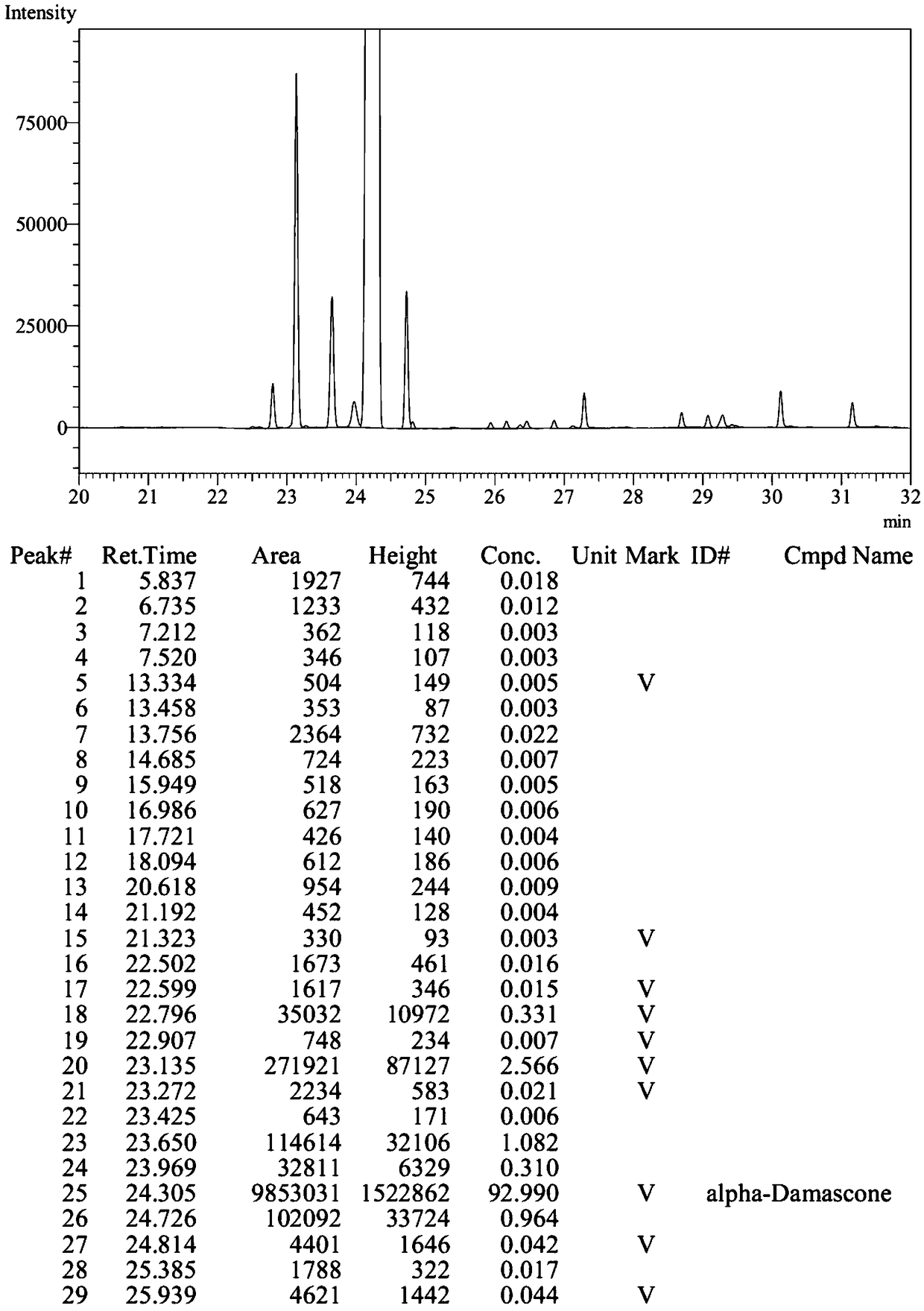

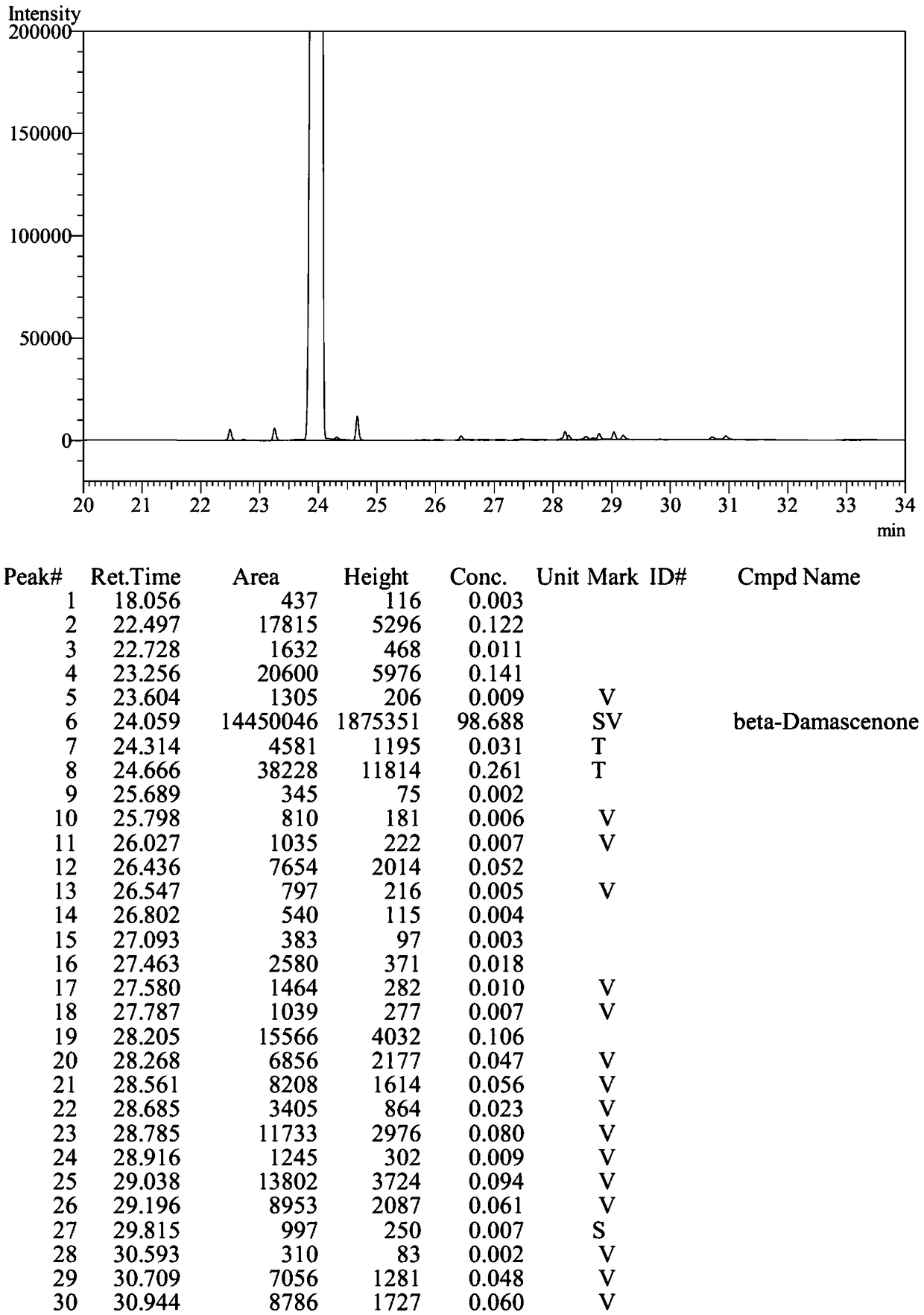

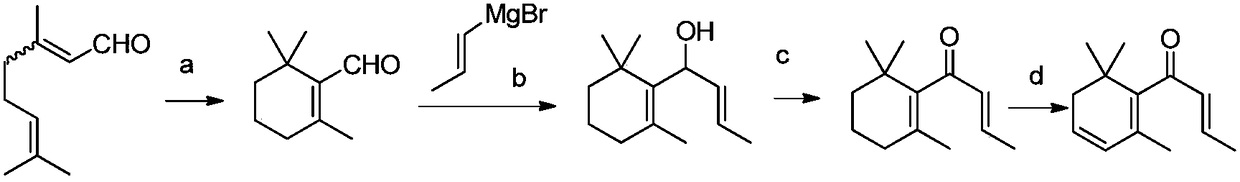

Method for synthesizing beta-damascenone

ActiveCN109053407AConvenient sourceThe source is convenient and easy to obtainOrganic compound preparationCarboxylic compound preparationIsomerizationPhosphoric acid

The invention discloses a method for synthesizing beta-damascenone. The method mainly comprises the following steps: oxidizing citral through sodium chlorite; carrying out catalytic cyclization through concentrated phosphoric acid to obtain alpha-cyclogeranic acid; eliminating the alkalinity of the alpha-cyclogeranic acid under the action of thionyl chloride to obtain cyclogeranenone; carrying outaddition on the cyclogeranenone and allylmagnesium chloride and carrying out acidic isomerization to obtain alpha-damascenone; carrying out epoxidation on the alpha-damascenon through peroxyacetic acid, and carrying out alkaline ring opening through potassium carbonate; catalytically heating and dehydrating through para-toluenesulfonic acid to obtain the beta-damascenone. The method disclosed bythe invention has the advantages that raw materials are cheap and easy to obtain, reaction conditions are moderate and the operation is simple and convenient; another useful spice alpha-damascenone can be synchronously synthesized and the method is a method which is suitable for industrial production of the beta-damascenone.

Owner:XIAMEN OMIC BIOTECH CO LTD

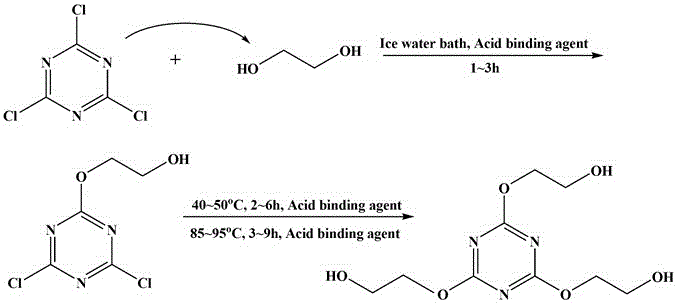

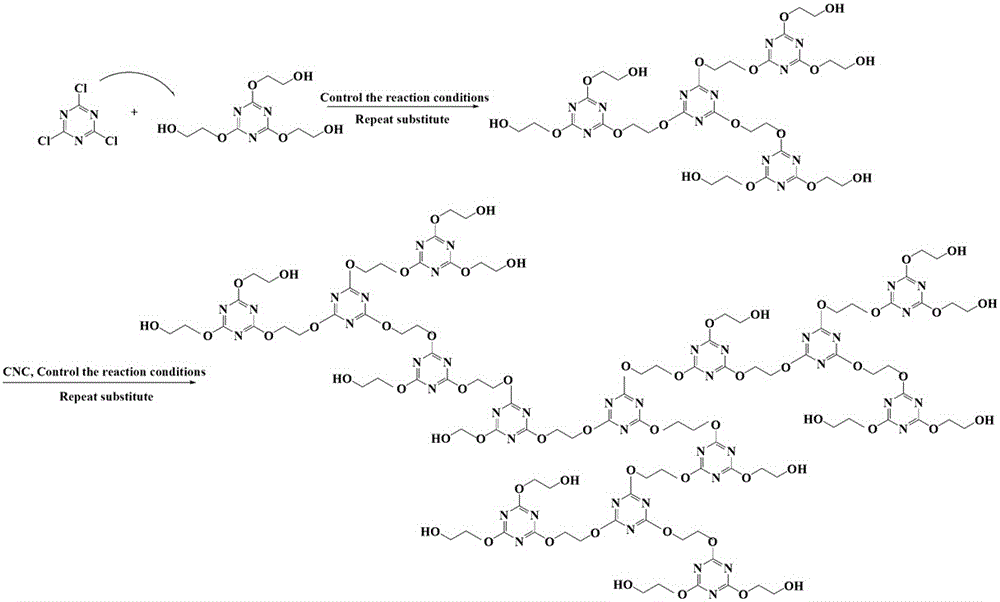

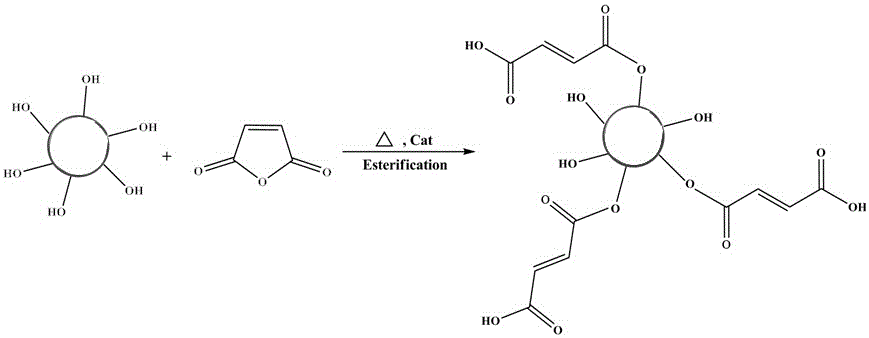

Carboxyl terminated dendritic polymer adsorption material and preparation method thereof

ActiveCN105013455AImprove adsorption capacityActive reaction site is goodOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceBenzenesulfonic acid

The invention relates to a carboxyl terminated dendritic polymer adsorption material and a preparation method thereof. The dendritic polymer has a network spherical three-dimensional structure, and can greatly improve the adsorption efficiency as an adsorption material. The preparation method includes: dissolving cyanuric chloride in acetone or tetrahydrofuran, adding the mixture into an acetone solution of diol to obtain a primary hydroxy terminated dendritic polymer crude product, conducting purification to obtain a primary hydroxy terminated dendritic polymer; taking cyanuric chloride as the core, adopting the primary hydroxy terminated dendritic polymer as the branching unit to prepare a secondary hydroxy terminated dendritic polymer crude product and a tertiary hydroxy terminated dendritic polymer crude product, and carrying out purification; and dispersing the hydroxy terminated dendritic polymer in water, adding maleic anhydride and p-toluenesulfonic acid to prepare a carboxyl terminated dendritic polymer crude product, and conducting purification to obtain the carboxyl terminated dendritic polymer adsorption material. The method provided by the invention has the characteristics of mild conditions, simple process and short production cycle. The product contains a lot of active carboxyl terminal groups, has strong adsorption performance, and is expected to be used in heavy metal ion and organic wastewater treatment and other fields.

Owner:上海球球云环保科技有限公司

Sand mixing technology for water jacket core in diesel engine cylinder cover casting blank

InactiveCN107695285AEasy to cleanSolve the sticky sand problemFoundry mouldsFoundry coresFuranEngineering

The invention is mainly applied to the technical field of diesel engine cylinder covers and particularly relates to a sand mixing technology for a water jacket core in a diesel engine cylinder cover casting blank. The sand mixing technology is characterized by comprising the following steps that firstly, 45 parts to 55 parts of ceramsite, 20 parts to 30 parts of chromite sand and 20 parts to 30 parts of quartz sand are weighed and mixed, and the above sand is evenly mixed; secondly, furan resin accounting for 1% to 3% of the mass of the above mixed sand is weighed, and para-toluenesulfonic acid accounting for 75% to 85% of the mass of the furan resin is weighed; thirdly, the weighed para-toluenesulfonic acid is poured into a molding sand mixing stirring machine to be stirred; and fourthly,the weighed furan resin is poured into the molding sand mixing stirring machine to be stirred, after the sand, the resin and the acid are evenly mixed, and the mixture is received through a sand hopper and is used for make preparation to forge the core. By means of the improvement on the sand mixing technology, the cleaning effect of a large water jacket cavity and a small water jacket cavity ofa cylinder cover is good, and the problem of sand sticking of the large water jacket cavity and the small water jacket cavity is solved. The problem that sand is wrapped in iron of the interior is completely solved.

Owner:ZICHAI POWER CO LTD

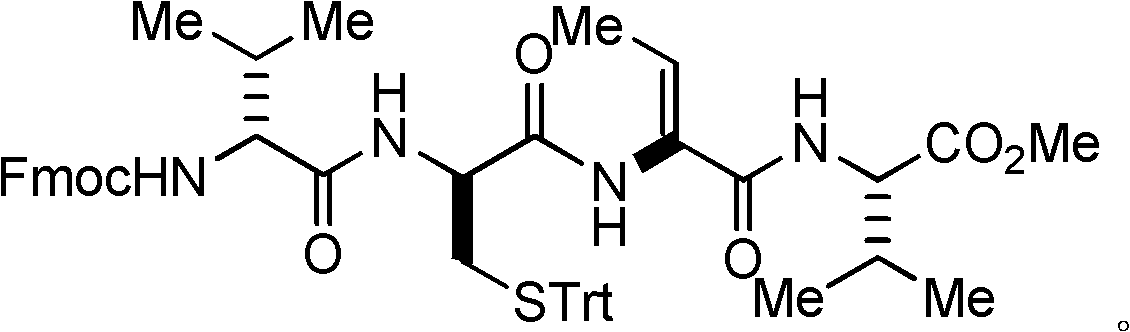

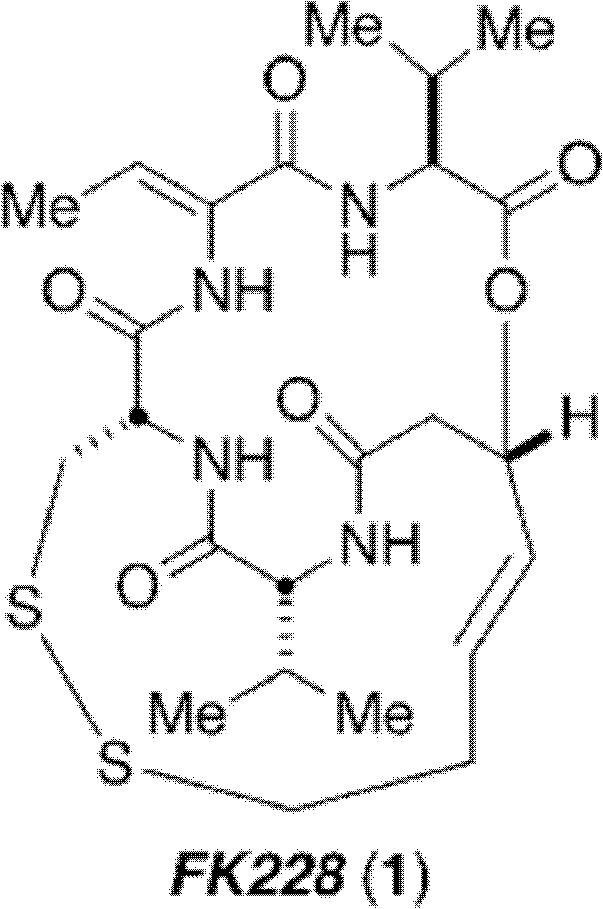

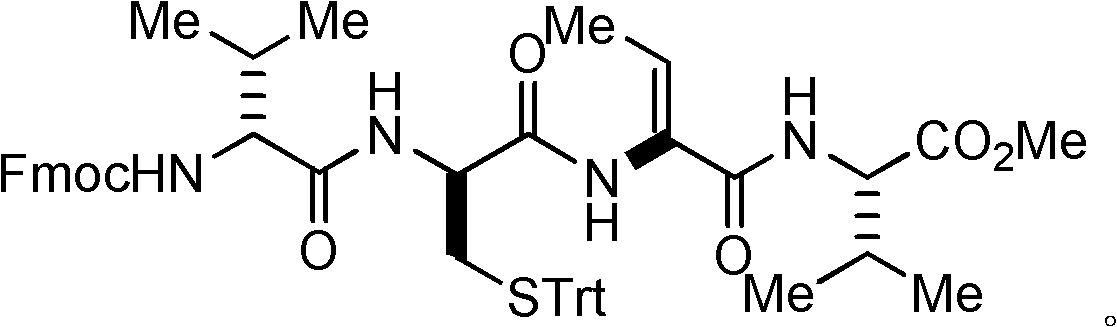

Method for synthesizing key intermediate of antitumour medicament Romidepsi

The invention discloses a method for synthesizing a key intermediate of an antitumour medicament Romidepsi, comprising the following steps of: with PyBop as a condenser, carrying out condensation on L-Val-OMe and Fmoc-L-Thr by dehydrating, removing a Fmoc protective group with diethylamine, carrying out condensation on the obtained dipeptide and N-Boc-D-Cys(Trt), reacting the obtained tripeptide with para-toluenesulfonic acid anhydride, then adding DABCO (1,4-Diazabicyclo[2.2.2]octane), and carrying out elimination reaction by virtue of E1 to form tripeptide containing double bonds; removing a Boc protective group with boron trifluoride etherate, and condensing Fmoc-D-Val with tripeptide the terminal of which is a free amino group to obtain the key intermediate of Romidepsi, wherein the structure of the key intermediate is shown by a formula (described in the specification). According to the method disclosed by the invention, two commercial L-type amino acids and two commercial D-typeamino acids are taken as raw materials, a classical peptide condensing agent is utilized, and the key intermediate is obtained at high total yield of 63.8% and can be directly applied to the next synthesis step of Romidepsi.

Owner:NANTONG SHIMEIKANG PHARMA CHEM

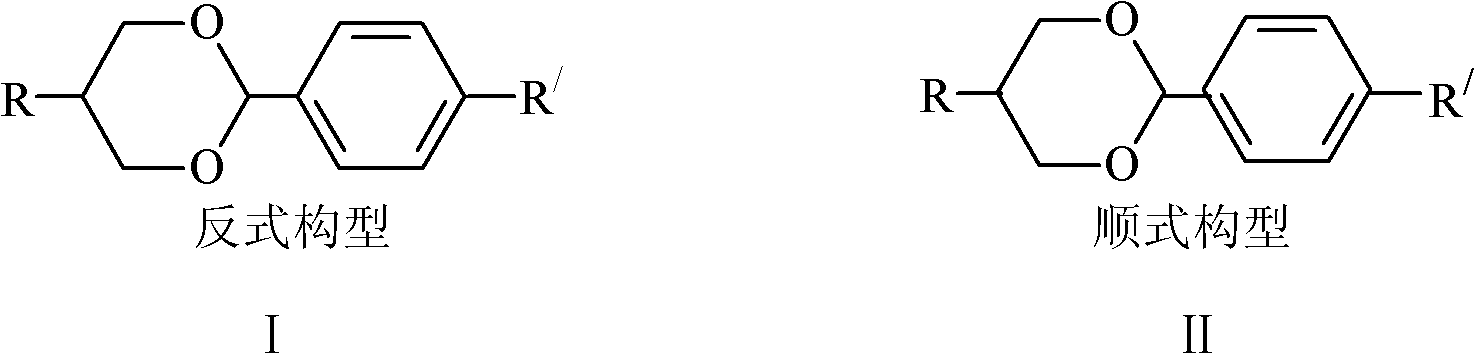

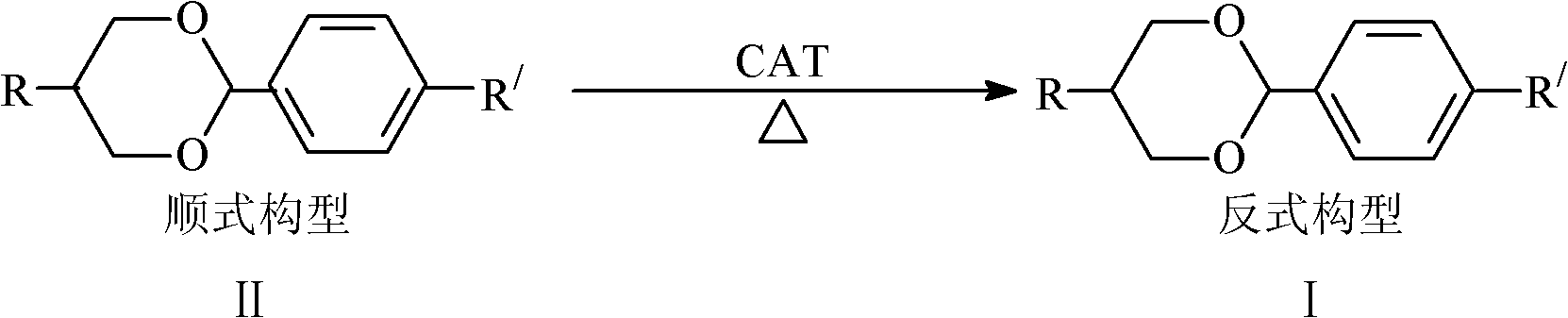

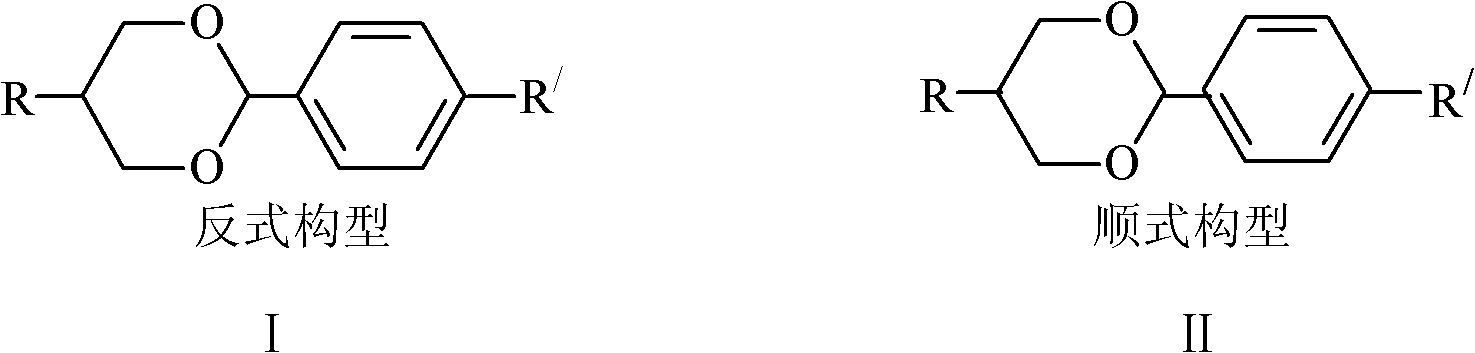

Method for transforming cisconfiguration of oxane compounds to transconfiguration

The invention relates to a synthetic method of important functional materials liquid crystal monomer oxane compounds, and particularly relates to a method for transforming cisconfiguration of oxane compounds to transconfiguration. The method comprises the following steps: reacting for 2-12 hours at the temperature of 35-200 DEG C by taking cis-oxane compounds as raw materials, para-toluenesulfonic acid as a catalyst and an organic solvent as a reaction medium, thereby transforming the cis-oxane compounds to obtain corresponding trans-oxane compounds; and purifying. After purifying, omega of the trans-oxane compounds is more than 99%, the total yield of reaction is more than 69%, the purpose of recovering useful products is realized, the emission of wastes during the production of oxane transconfiguration products is reduced, and the utilization rate of raw materials during the production of similar transconfiguration oxane compounds is improved. The method is simple to operate, the reaction conditions are easy to control, and the industrial production is easy to realize.

Owner:WEINAN HIGH NEW DISTRICT HAIQIN NEW ELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com