Lignin-based phenolic foam material and preparation method thereof

A lignin-based and lignin-based technology, which is applied in the field of preparation of lignin-based phenolic insulation materials, can solve the problems of foam cavity and slow curing speed, and achieve cost reduction, fast curing speed and adjustable foaming ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

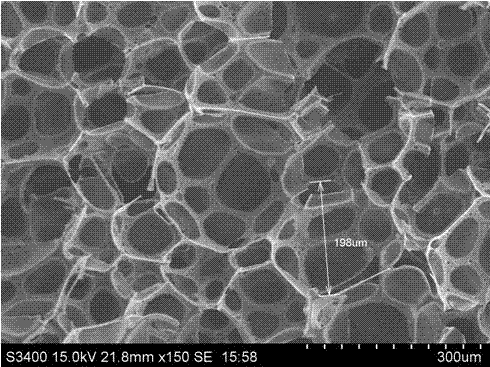

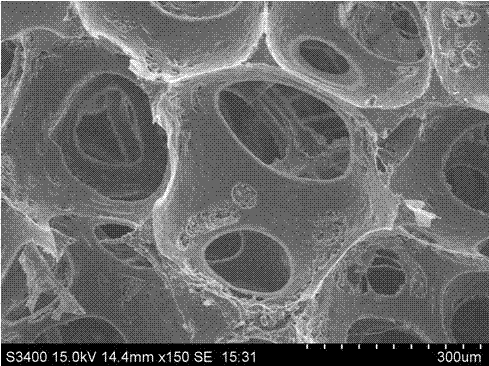

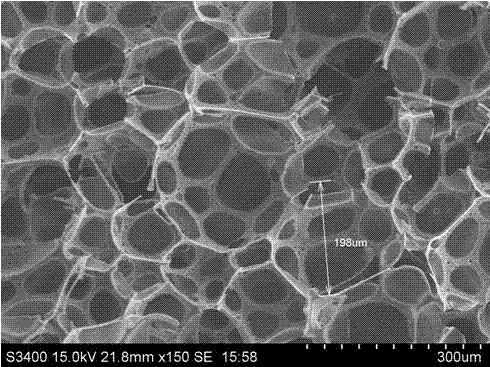

Image

Examples

Embodiment 1

[0033] a Preparation of expandable lignin-based phenolic resin (30% lignin replacement)

[0034] After melting 400 parts of phenol, 111 parts of paraformaldehyde and 22 parts of distilled water were added into a four-necked flask equipped with a condenser, an electric stirrer and a thermometer, and the temperature of the entire reaction process remained at 80°C. In the first step, add 8 parts of Ba(OH) in batches 2 , the addition was completed within 60 minutes; in the second step, 137.8 parts of paraformaldehyde, 22 parts of distilled water, 171.44 parts of lignin and 15 parts of Ba(OH) were added in batches 2 , the addition was completed within 50 minutes; in the third step, 138.2 parts of paraformaldehyde and 7 parts of Ba(OH) were added in batches 2 , The addition was completed within 40 minutes; the fourth step was to add 20 parts of urea, and the addition was completed within 30 minutes.

[0035] b Preparation of copolymerized foam

[0036] Add 6.8 parts of phosphor...

Embodiment 2

[0038] Embodiment 2--A / B=0.1 /

[0039] a Preparation of expandable lignin-based phenolic resin

[0040] 140 parts of phenol melting and 36.5 parts of 37% formaldehyde solution were added into a four-necked flask equipped with a condenser, an electric stirrer and a thermometer, and the temperature was maintained at 80°C throughout the reaction process. In the first step, add 5.9 parts of Ba(OH) in batches 2 , the addition was completed within 60 minutes; in the second step, 41.94 parts of paraformaldehyde and 5.9 parts of Ba(OH) were added in batches 2 and 60 parts of lignin were added within 50 minutes; in the third step, 41.94 parts of paraformaldehyde and 2.8 parts of Ba(OH) were added in batches 2 , Added within 40min.

[0041] In the fourth step, the temperature is still maintained at 80° C., 6.15 parts of urea is added, and the reaction is carried out for 30 minutes to obtain a PUF resin with a lignin equivalent of 0.1.

[0042] b Preparation of copolymerized foam ...

Embodiment 3

[0044] Embodiment 3--C / D / E=0.2 / /

[0045] a preparation of high activity lignin phenolic resin

[0046] Add 140 parts of phenol after melting and 38 parts of 37% formaldehyde solution into a four-necked flask equipped with a condenser, an electric stirrer and a thermometer, and the temperature of the entire reaction process remains at 80°C. In the first step, add 5.9 parts of Ba(OH) in batches 2, the addition was completed within 60 minutes; in the second step, 43.66 parts of paraformaldehyde, 60 parts of lignin and 5.9 parts of Ba(OH) were added in batches 2 , the addition was completed within 50 minutes; in the third step, 43.66 parts of paraformaldehyde and 2.8 parts of Ba(OH) were added in batches 2 , added within 40min;

[0047] In the fourth step, the temperature is still maintained at 80°C, 6.15 parts of urea is added, and the reaction is carried out for 30 minutes to obtain PUF resins with different lignin equivalents.

[0048] b Preparation of copolymerized foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com