Patents

Literature

85results about How to "Reduce formaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing HMMM resin

InactiveCN101333198AImprove performanceGood cross-linking effectOrganic chemistryHexa(methoxymethyl)melamineOrganic acid

The invention discloses a preparation method for hexakis (methoxymethyl) melamine resin, namely, in the first step; 92% polyformaldehyde, melamine and methanol are reacted in alkaline environment through hydroxymethylation to generate the intermediate product hexamethylolmelamine crystals; in the second step, the intermediate product and methanol are reacted with organic acid through etherification to prepare the hexakis (methoxymethyl) melamine resin. The method of the invention is non-polluting, odorless and easy to operate. The hexakis (methoxymethyl) melamine resin produced through the method of the invention is stable and non-crystalline, which is used in coiled materials and baking varnish, with very good cross-linking effect.

Owner:ZHANGJIAGANG SHUNCHANG CHEM

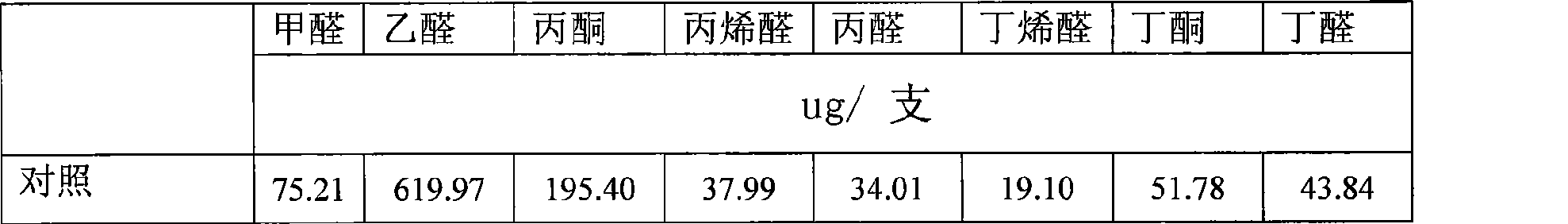

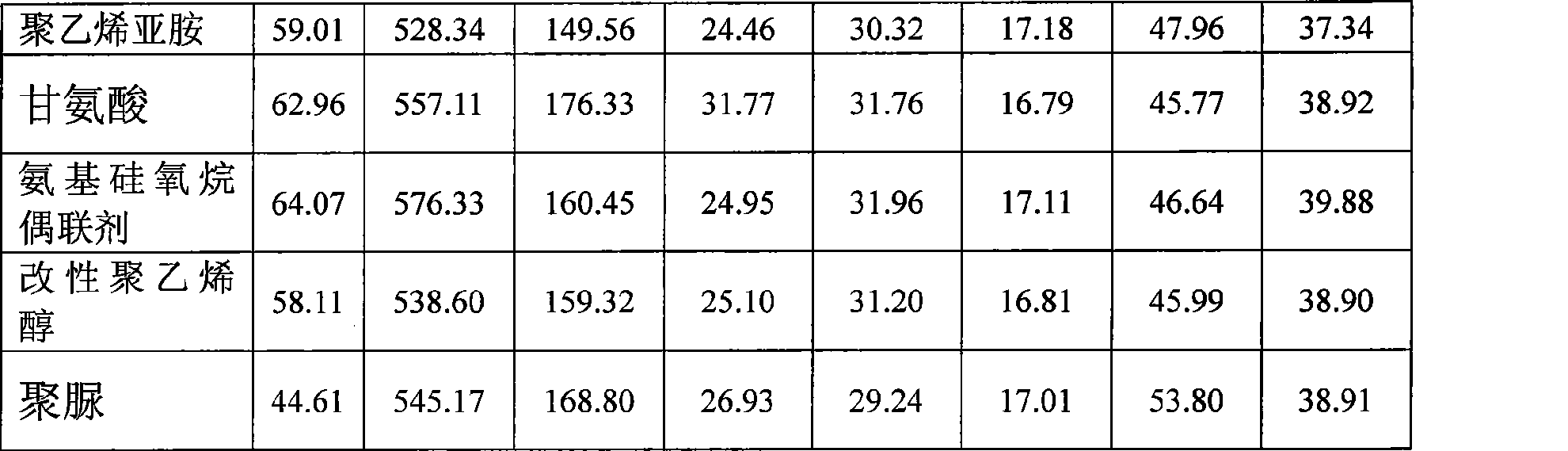

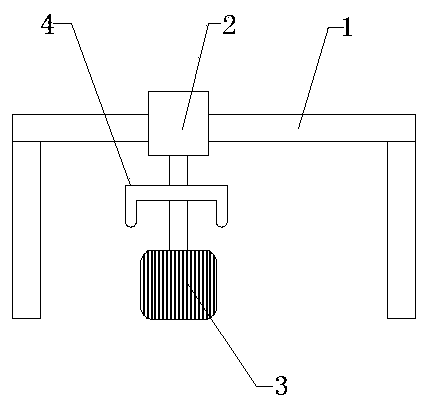

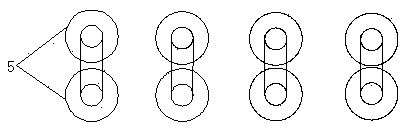

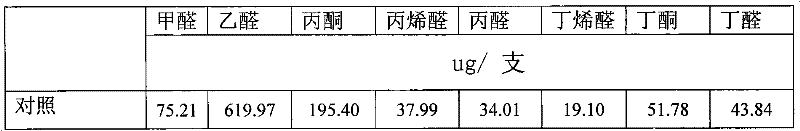

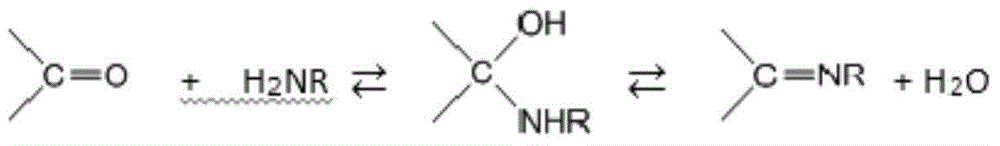

Papery filter tip for reducing aldehydes material in smoke of cigarette and preparation method thereof

The invention relates to a paper filter tip capable of reducing aldehydes in cigarette smoke gas and a preparation method thereof. The paper filter tip capable of reducing aldehydes in cigarette smoke gas adopts the paper containing one or a plurality of wood pulp fibers or jute pulp fibers. The paper undergoes a coating process. Through the high water absorption of the paper, compound solution containing amino groups are coated onto the paper; and after drying, cutting and embossing, the paper filter tip is prepared by the paper through a filter tip forming machine. The paper filter tip can effectively reduce formaldehyde by 15 to 40 percent, acetaldehyde by 10 to 25 percent, acrolein by 15 to 30 percent and crotonaldehyde by 10 to 20 percent in cigarette smoke gas.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Marine organism shell powder paint

ActiveCN102167936AImprove finenessHigh whitenessAlginic acid coatingsHyaluronic acid coatingsCitric Acid MonohydrateCitric acid

The invention provides a type of marine organism shell powder paint, mainly comprising biosynthesis adhesive, sodium hexametaphosphate, shell powder, emulsifier, and citric acid mono. The marine organism shell powder paint is purely natural, environment-friendly, of simple preparation and of low manufacturing cost, and has no toxic effects on human body.

Owner:青岛万源生物科技有限公司

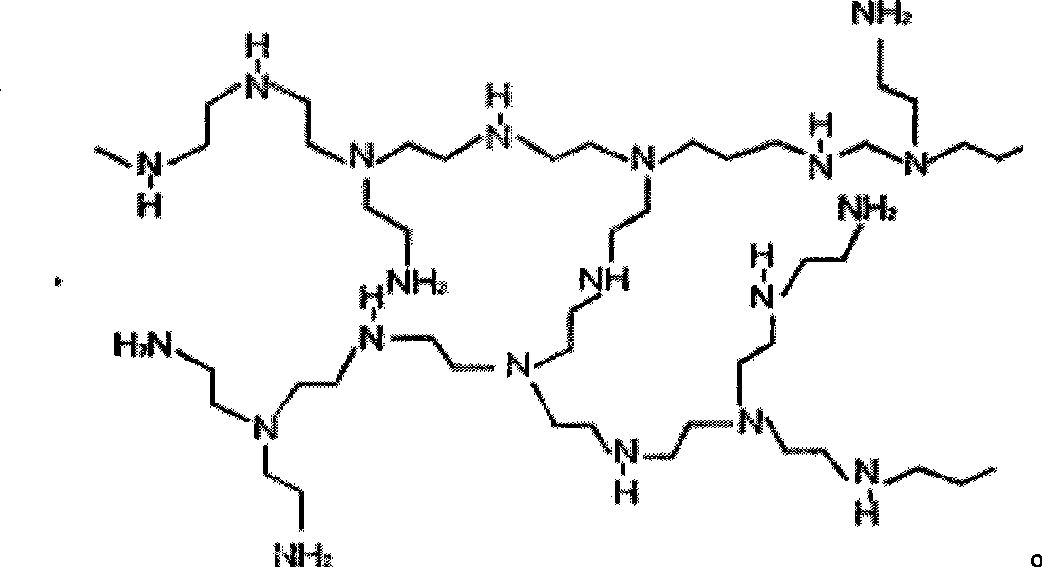

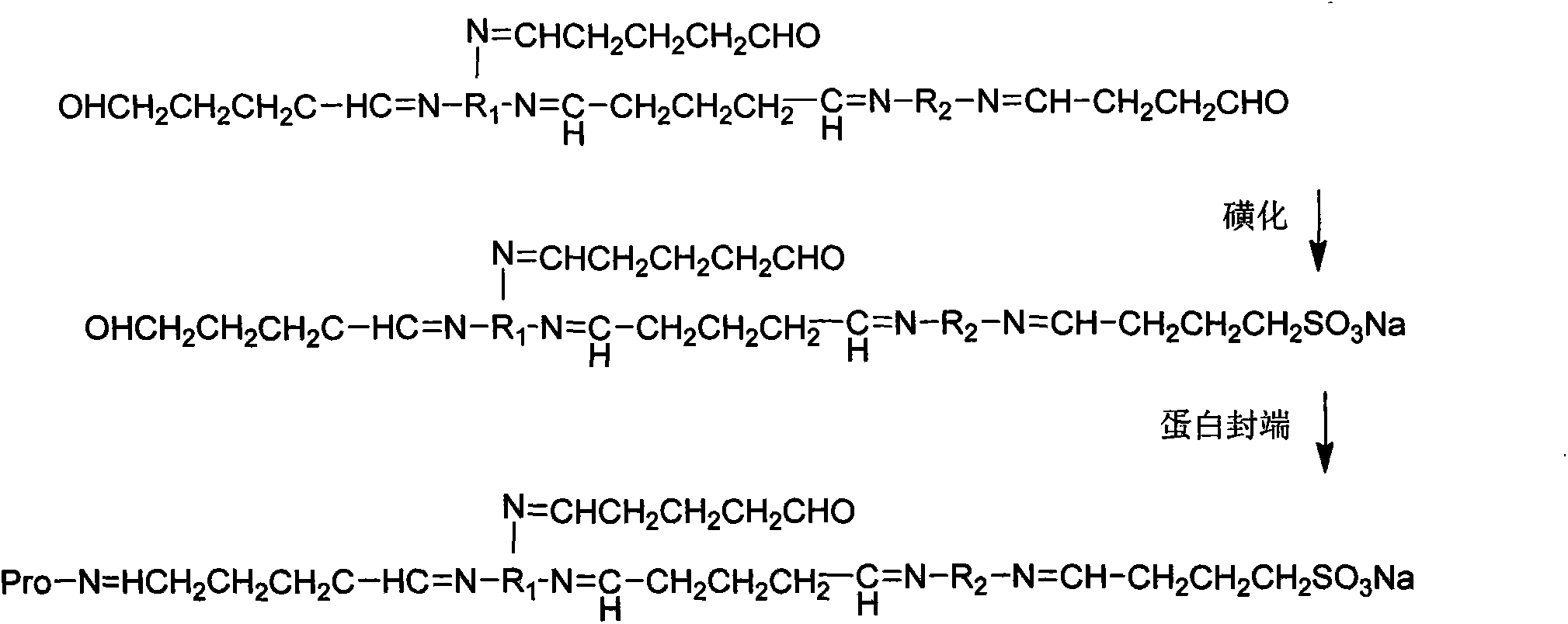

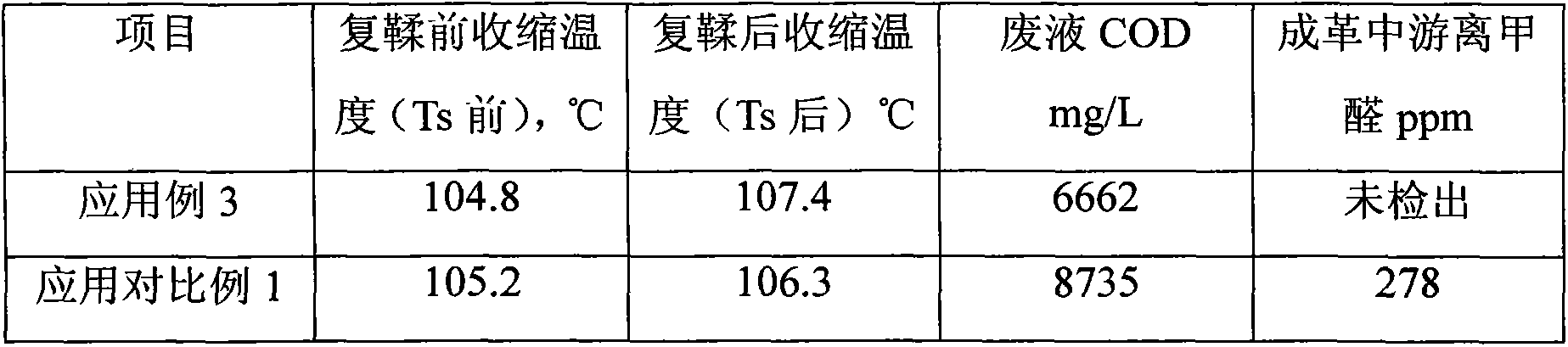

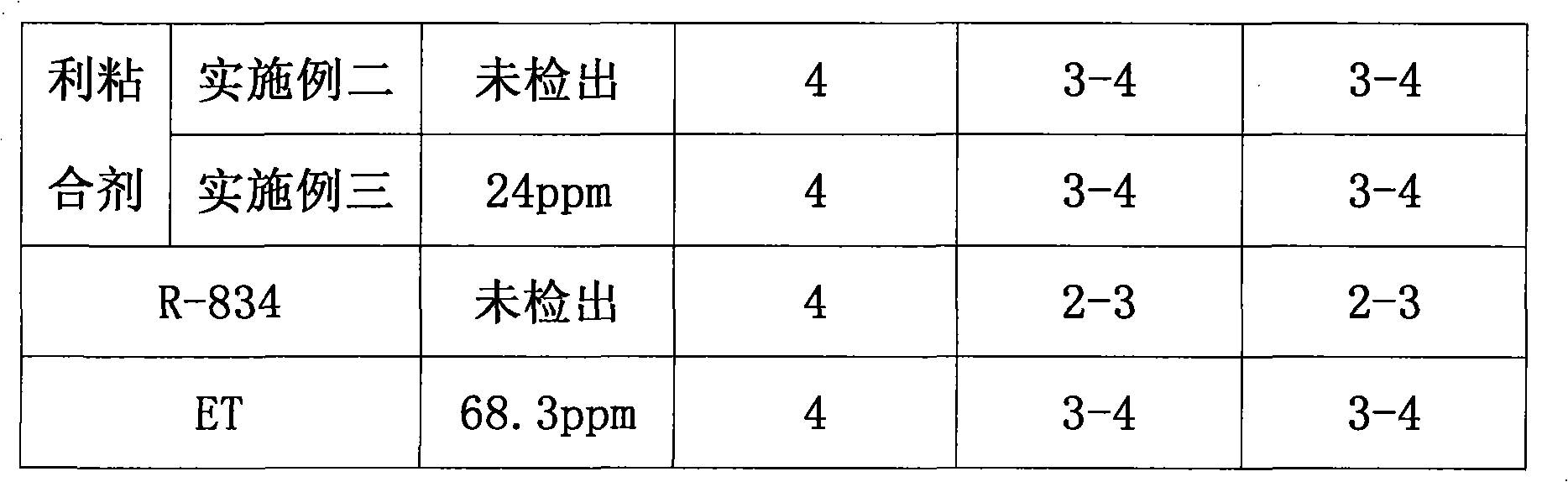

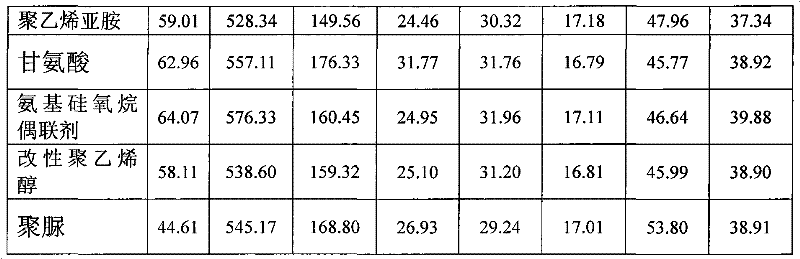

Formaldehyde-free amino resin retanning agent

The invention discloses a formaldehyde-free amino resin retanning agent. The formaldehyde-free amino resin retanning agent is characterized by being formed as follows: firstly, obtaining an intermediate containing hydroxyl and aldehyde group residue in molecule by using an amino monomer and glutaraldehyde through nucleophilic addition; then, obtaining the formaldehyde-free amino resin retanning agent by a series of reactions such as sulfonation, hydrolyzed collagen end-blocking, condensation and etherification. The formaldehyde-free amino resin retanning agent provided by the invention is an amino resin condensation product containing an aldehyde group, has retanning performance comparable with that of the conventional amino resin retanning agent, has an aldehyde group capable of performing covalent cross-linking reaction with the amino on collagenous fiber in molecule, and can be used for improving the humidity and heat-resistant stability of finished leather. Formaldehyde is not used in a preparation process of the formaldehyde-free amino resin retanning agent, so that harms of formaldehyde in the finished leather can be greatly lowered.

Owner:四川德赛尔新材料科技有限公司 +1

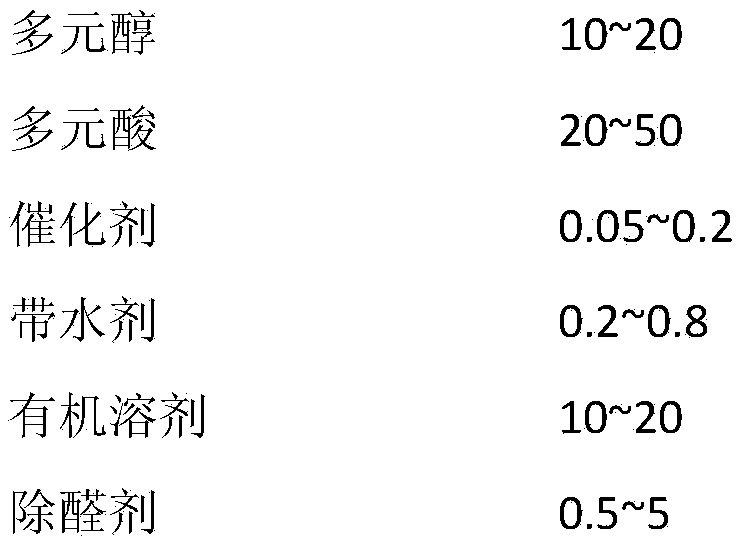

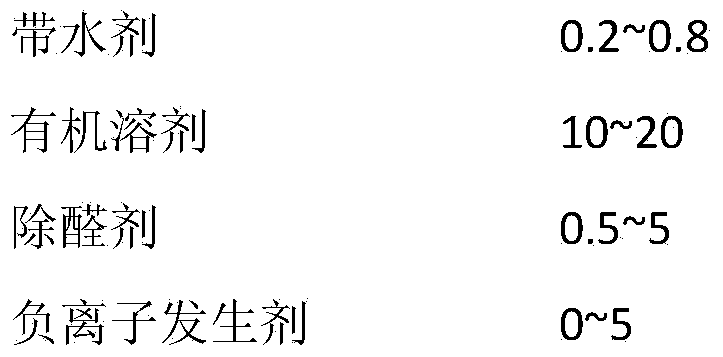

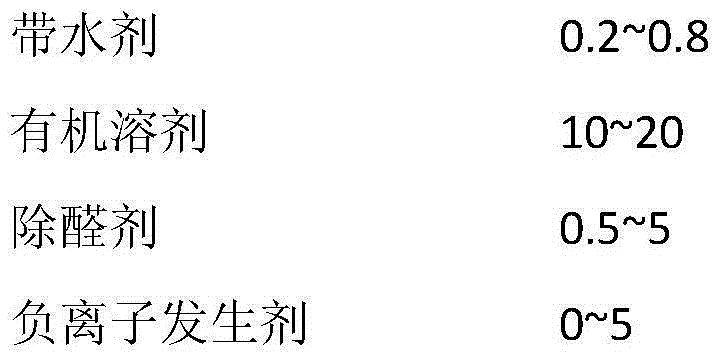

Formaldehyde-purifying alkyd resin and preparation method thereof

ActiveCN103421173ADoes not affect colorHas the effect of purifying formaldehydePolyester coatingsPolyolAlcohol

The invention discloses formaldehyde-purifying alkyd resin and a preparation method thereof. The formaldehyde-purifying alkyd resin is prepared through reaction of polyhydric alcohols, polyatomic acids, organic solvents, formaldehyde removing agents and anion generating agents. The method includes during preparation, by the protection of nitrogen, firstly adding the polyhydric alcohols and the polyatomic acids, and raising the temperature to 100 to 160 DEG C; adding catalyst, raising the temperature to 220 to 260 DEG C, and keeping the temperature for 1 to 3.5 hours; control the temperature from 200 to 220 DEG C, adding water-carrying agents, and raising the temperature to 250 to 280 DEG C to flow back until the acid value is lower than 7; adding the organic solvents and mixing evenly to obtaining the alkyd resin; adding the formaldehyde removing agents, and reacting at the temperature of 25 DEG C to 80 DEG C for 3 to 30 minutes to obtain modified alkyd resin, namely the formaldehyde-purifying alkyd resin. When the formaldehyde-purifying alkyd resin reacts with the formaldehyde, a resulting product is not volatile and non-toxic, and secondary contamination is eliminated; the preparation process in simple, requirement for equipment is low, and the formaldehyde-purifying alkyd resin is adaptable to mass production.

Owner:SOUTH CHINA UNIV OF TECH

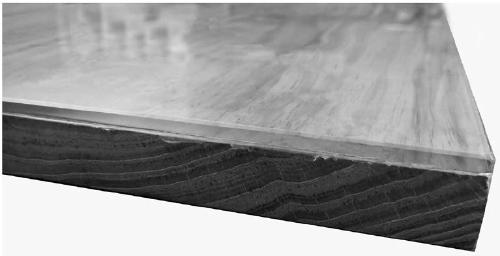

Novel solid ecological bamboo board and production process thereof

InactiveCN105415457AThe process is simple and reasonableShort production processOther plywood/veneer working apparatusWood veneer joiningEnvironmentally friendlySolid wood

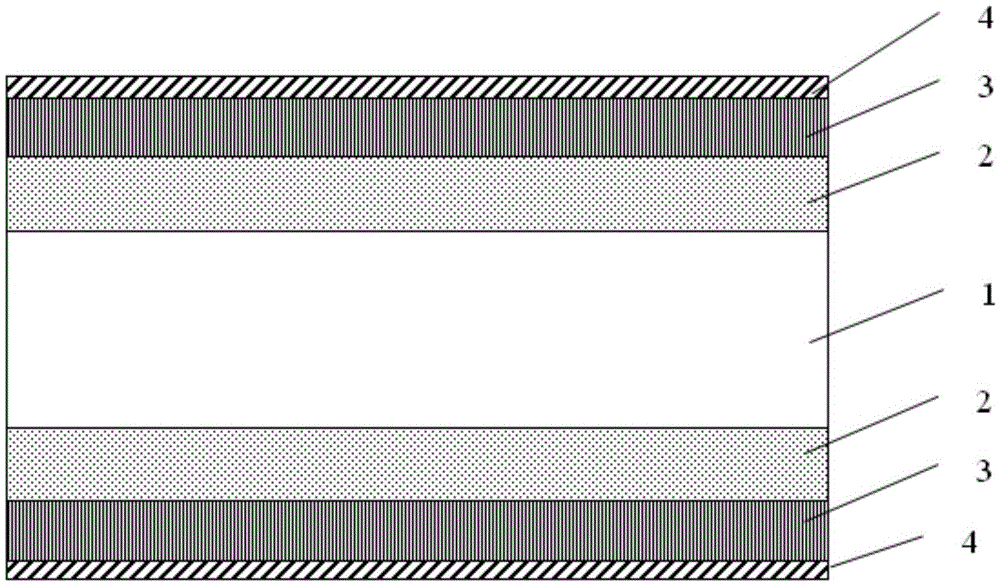

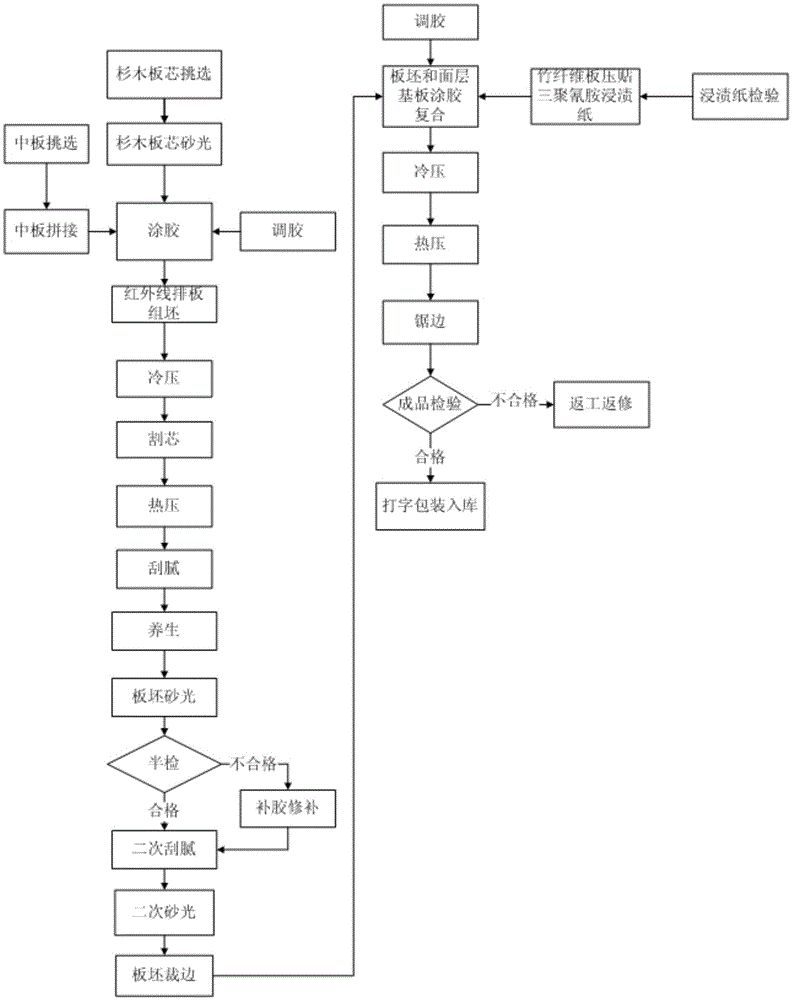

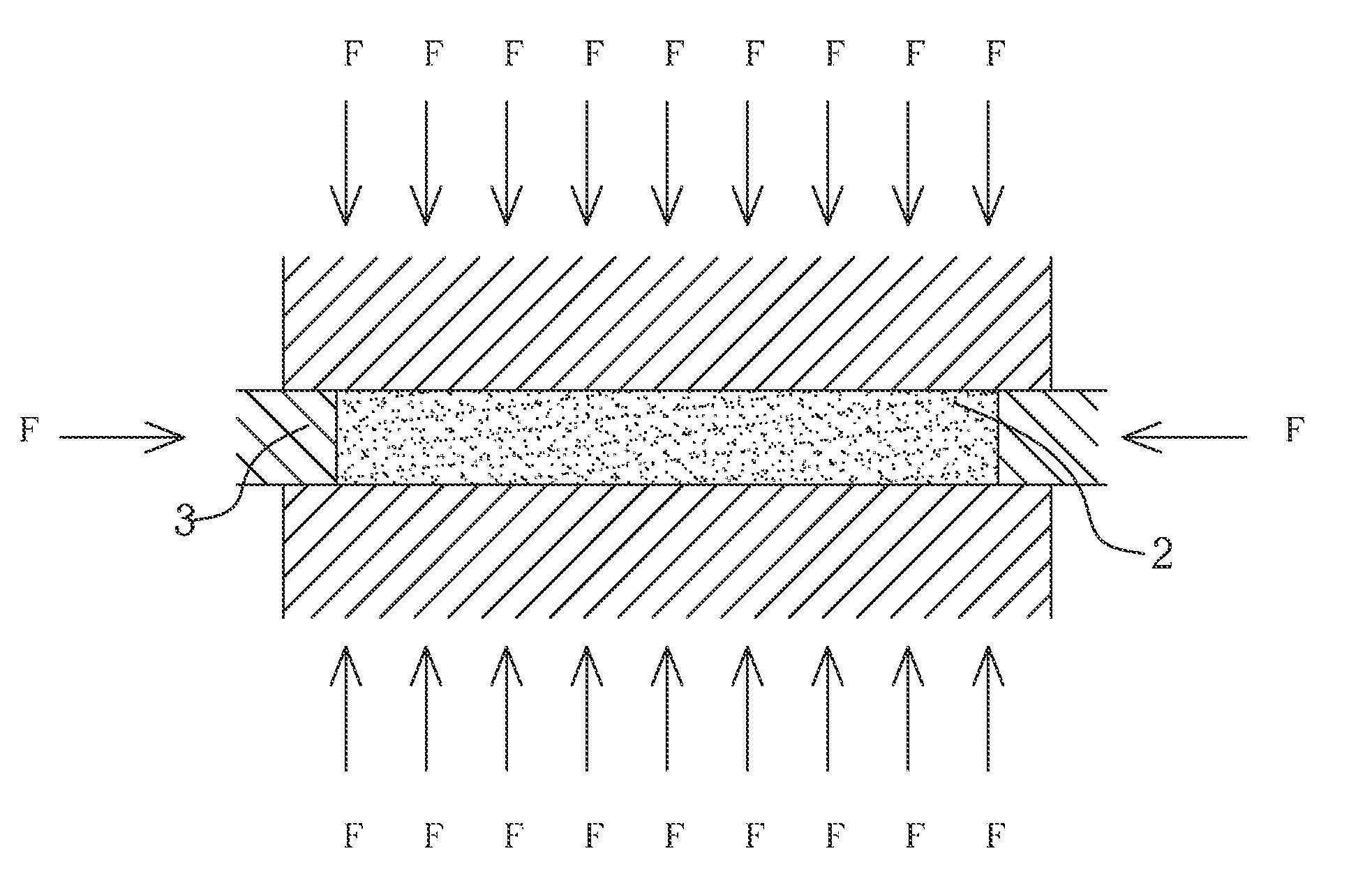

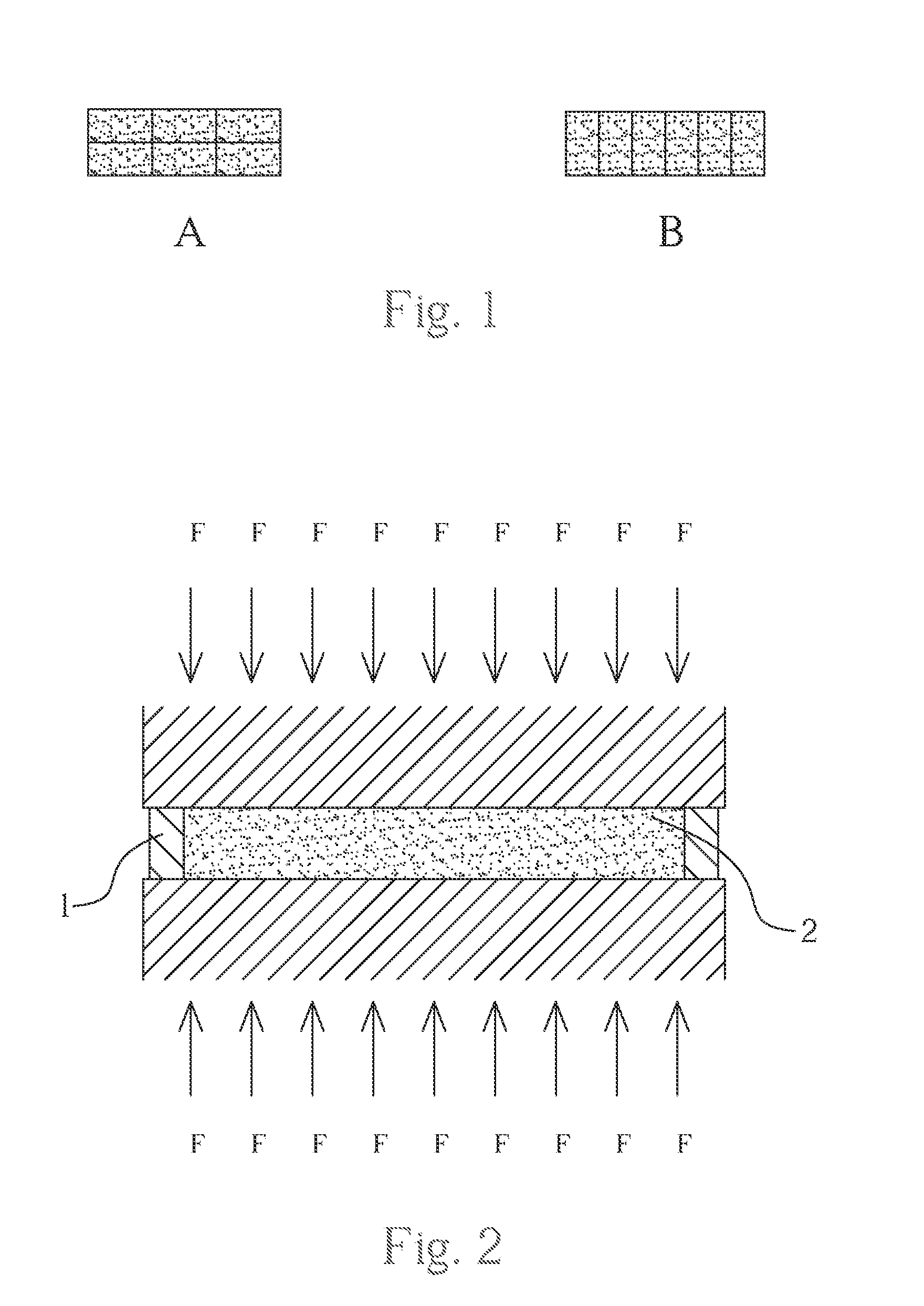

The invention belongs to the field of board machining and provides a novel solid ecological bamboo board and a production process thereof. The novel solid ecological bamboo board comprises a cedarwood board core, middle boards, bamboo fiber boards and melamine impregnated paper. The upper surface and the lower surface of the cedarwood board core are covered with the middle boards through gluing and integrally pressed to form a board blank; the melamine impregnated paper is stuck to the bamboo fiber boards in a pressed mode to integrally form surface-layer substrates; the upper surface and the lower surface of the board blank are gelatinized and coated with the surface-layer substrates and integrally formed through hot pressing to obtain a finished product. The novel solid ecological bamboo board and the production process thereof have the advantages that 1, a novel assembly structure is adopted, and the hardness, nail-holding ability, static bending strength and surface evenness of the board are greatly improved; and 2, the bamboo fiber boards are adopted for the surface-layer substrates, the fracturing resistance and the thermocycling resistance of melamine ecological boards are greatly improved, and thus the melamine ecological board can meet the all-weather all-region using requirement; besides, the finished product is low in formaldehyde content, economical, environmentally friendly, and the advantages of water resistance, mould resistance, inflaming retarding, moth resistance and the like are achieved at the same time.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

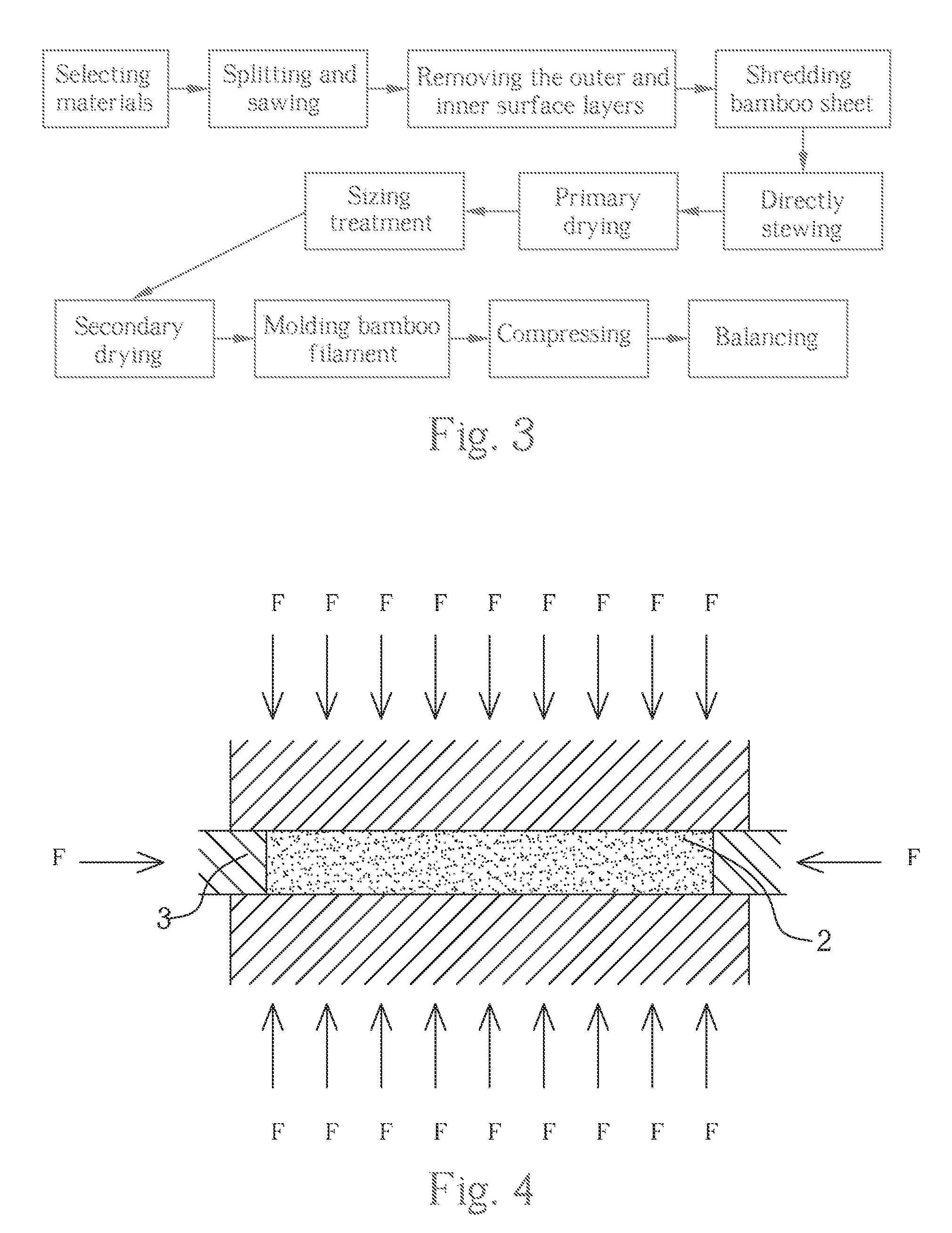

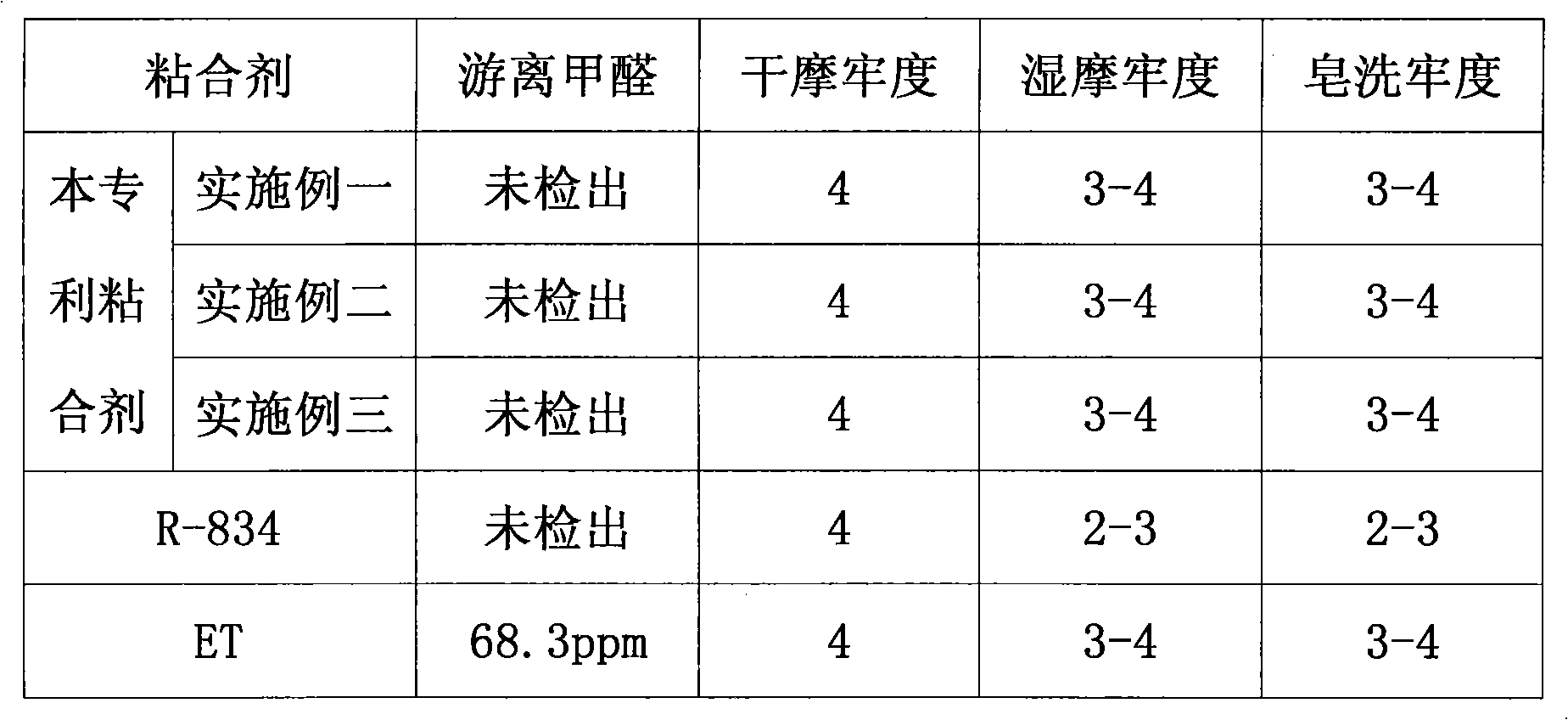

Process for Making a Bamboo Filament Slab Floor by Opposite Directional Hot Pressing

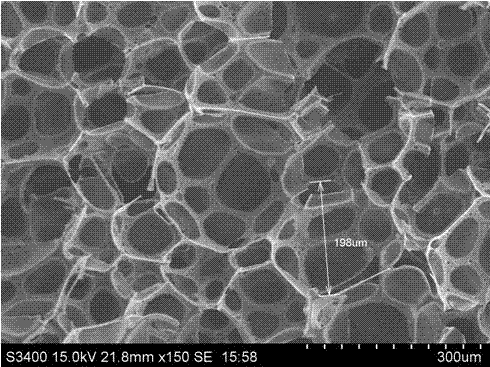

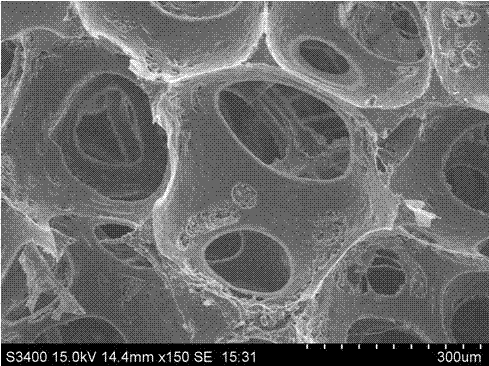

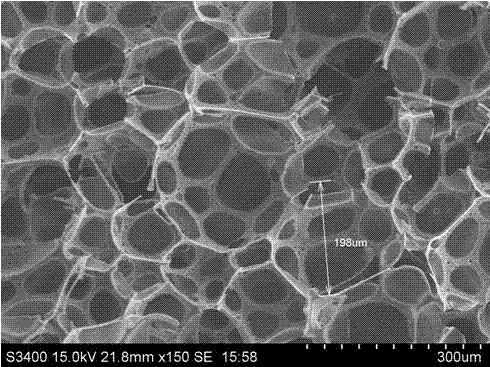

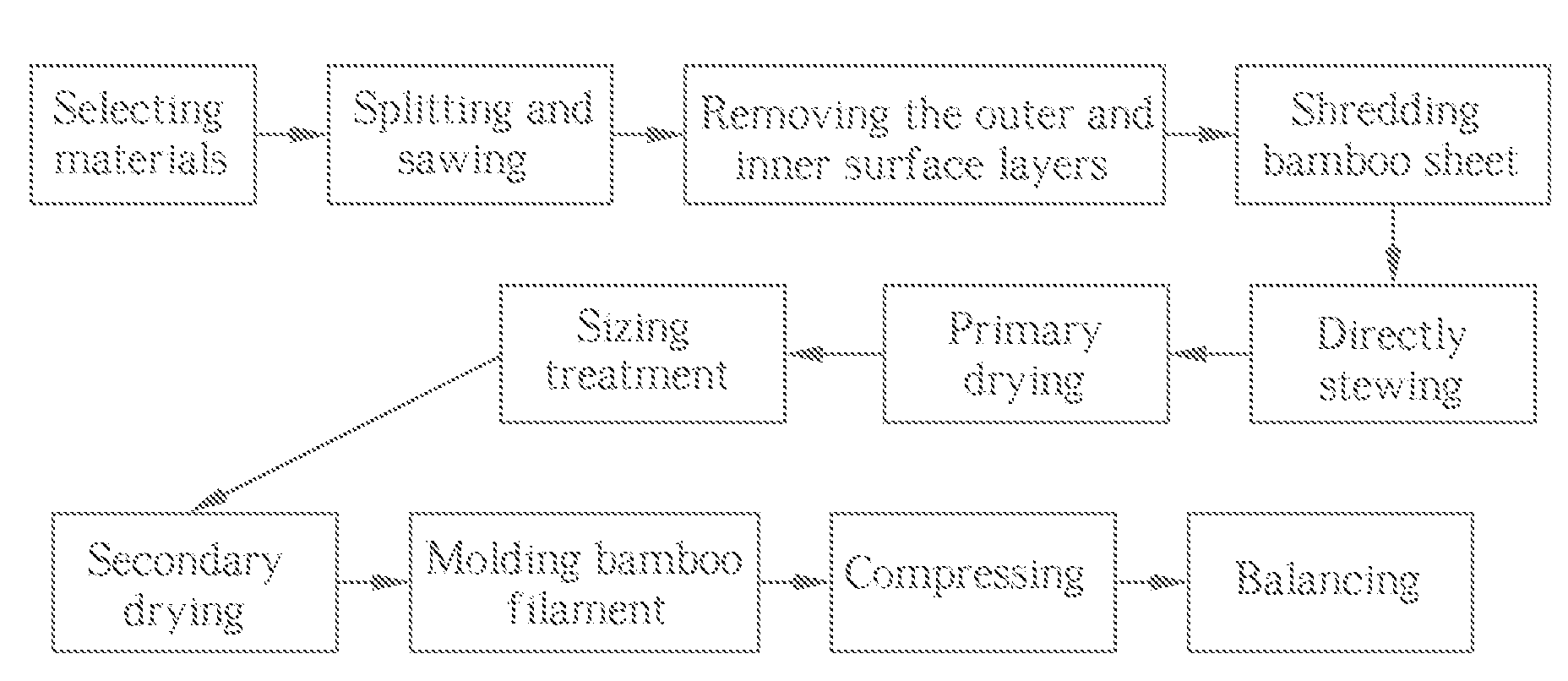

InactiveUS20080053570A1Stable qualityEasy to heat and coolStapling toolsWood compressionSizingHot press

The present invention relates to bamboo manufacturing field, in particular, to a process for making a bamboo filament slab floor by opposite directional hot pressing. Aiming to overcome the defects that, while compressing, the existing bamboo filament slab floor at normal temperature under cold pressing is easy to rebound and expand, has low strength and weak resistance to abrasion and is easy to mildew while using for a long time, the present invention adopts shredding bamboo sheet, sizing treatment, moulding bamboo filament and etc. procedures, characterized in that, a secondary drying procedure should be inserted between said sizing treatment and bamboo filament moulding procedure; said sizing treatment should be implemented by soak sizing bamboo filament; said compressing includes opposite directional hot pressing of positive pressing and side pressing. The present invention adopts specific manufacturing technology, thus the floor can avoid the occurrence of holes and gaps inside bamboo filament slab floor and discharge formaldehyde and has stable quality, and will be not prone to mildew and deform while using for a long time. It can be widely used and suitable for indoor and outdoor flooring and various boards used in decoration and furniture.

Owner:WANG ZHENGFENG

Lignin-based phenolic foam material and preparation method thereof

The invention discloses a lignin-based phenolic heat insulating material and a preparation method thereof. The preparation method comprises the following steps of: uniformly stirring expandable lignin basic phenolic resin with the conventional pH adjusting agent and a surfactant; adding a foaming agent and rapidly and uniformly stirring; adding a curing agent lastly; and uniformly stirring, and rapidly pouring into a specified enclosed container for foaming to the obtain lignin-based phenolic heat insulating material, wherein the used curing agent is a compound curing agent obtained by mixing toluenesulfonic acid and phosphoric acid in the mass ratio of 1.5:1. The foaming multiplying power of the lignin-based phenolic foam material is adjustable, the form hole fineness uniform density is 40-60 kg / m<3>, the compression strength is 0.07-0.45MPa, and the water absorbing rate is 7-15.5 percent.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Process for making a bamboo filament slab floor by opposite directional hot pressing

InactiveUS7661450B2Easy to reboundEasy to expandStapling toolsWood compressionManufacturing technologyEngineering

Owner:WANG ZHENGFENG

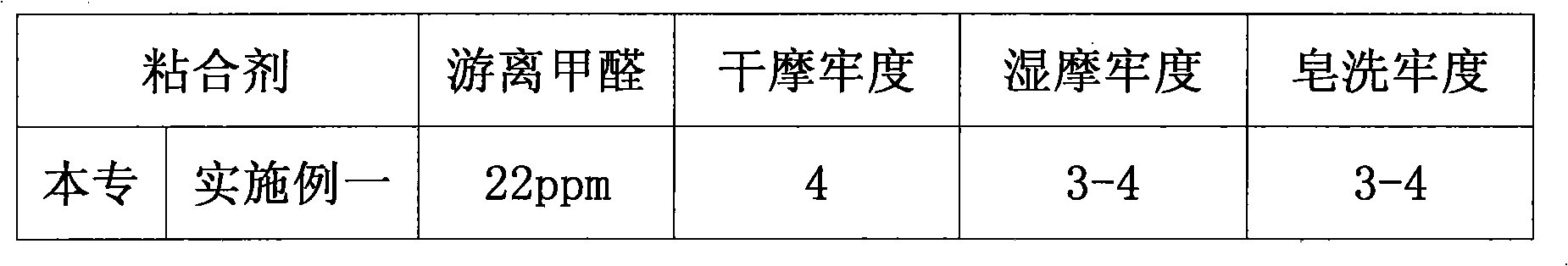

Low-formaldehyde soaping-resistant adhesive for textile pigment printing and preparation method thereof

InactiveCN101942772AReduce formaldehyde contentAvoid Soap FastnessDyeing processAmmonium sulfateMethacrylamide

The invention relates to a low-formaldehyde soaping-resistant adhesive for textile pigment printing and a preparation method thereof. The low-formaldehyde soaping-resistant adhesive is prepared from polyethylene glycol methacrylate, N-butoxy methacrylamide, acetoacetic acid ethyl methacrylate, sodium lauryl sulfate, acrylic acid, styrene, acrylate, ammonium persulfate and deionized water through emulsion polymerization. The content of free formaldehyde can be lower than 20 ppm; and the low-formaldehyde soaping-resistant adhesive has the advantages of soft feeling and high fastness soaping fastness.

Owner:YANCHENG SILU INFORMATION TECH SERVICE CO LTD

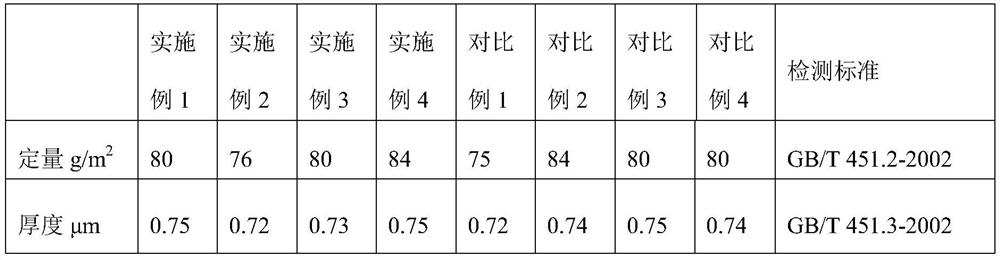

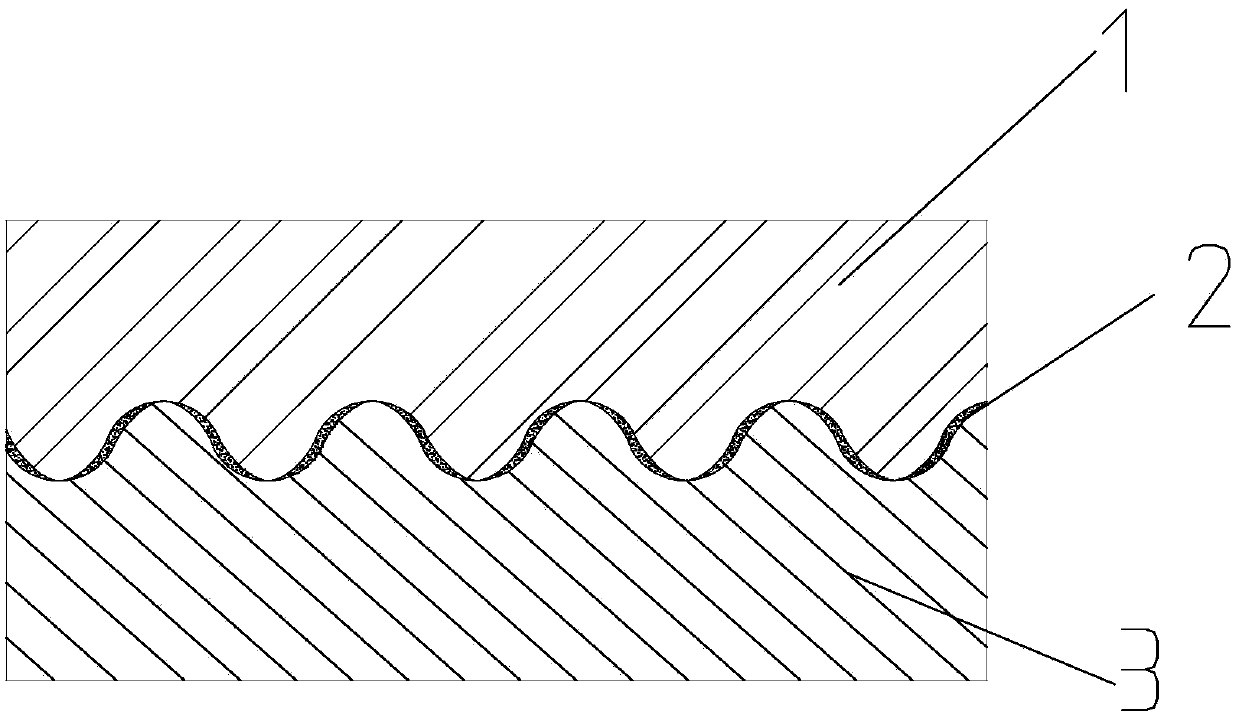

Manufacturing method of short cycle wear-resistant decorative paper

ActiveCN105369688AShort curing timeFast curingSpecial paperPaper/cardboardWear resistantPre treatment

The invention discloses a manufacturing method of short cycle wear-resistant decorative paper. The method comprises the steps of selection and pre-treatment of raw paper; uncoiling; pre-wetting; impregnation; first time drying press-sticking; preparation of coating glue; second time drying press-sticking; deviation adjustment traction, and cutting; the quality of the short cycle wear-resistant decorative paper manufactured with the method is high, the curing time is shortened, the production efficiency is improved, the uniformity of impregnation and gluing of the short cycle wear-resistant decorative paper is guaranteed in the manufacturing process, the flexibility of a glue layer and the sealing performance of the surface of the glue layer are guaranteed, and accordingly, the problems that the quality of the short cycle wear-resistant decorative paper is not high and the efficiency is low are fundamentally solved.

Owner:成都建丰新材料股份有限公司

Production method for polyacetal copolymer

A production method for a polyacetal copolymer that makes deactivation of a catalyst simple and efficient and that achieves a high polymerization yield and high quality using equipment that does not require a cleaning step and a process that involves a simple operation technique. The production method for a polyacetal copolymer uses trioxane as a main monomer and a cyclic ether and / or a cyclic formal having at least one carbon-carbon bond as a comonomer. In the production method, a predetermined heteropoly acid is used as a polymerization catalyst to perform copolymerization, a predetermined salt is added to the reaction product, melt kneading processing is performed, and the polymerization catalyst is deactivated.

Owner:POLYPLASTICS CO LTD

Papery filter tip for reducing aldehydes material in smoke of cigarette and preparation method thereof

The invention relates to a paper filter tip capable of reducing aldehydes in cigarette smoke gas and a preparation method thereof. The paper filter tip capable of reducing aldehydes in cigarette smoke gas adopts the paper containing one or a plurality of wood pulp fibers or jute pulp fibers. The paper undergoes a coating process. Through the high water absorption of the paper, compound solution containing amino groups are coated onto the paper; and after drying, cutting and embossing, the paper filter tip is prepared by the paper through a filter tip forming machine. The paper filter tip can effectively reduce formaldehyde by 15 to 40 percent, acetaldehyde by 10 to 25 percent, acrolein by 15 to 30 percent and crotonaldehyde by 10 to 20 percent in cigarette smoke gas.

Owner:CHINA TOBACCO HUNAN INDAL CORP

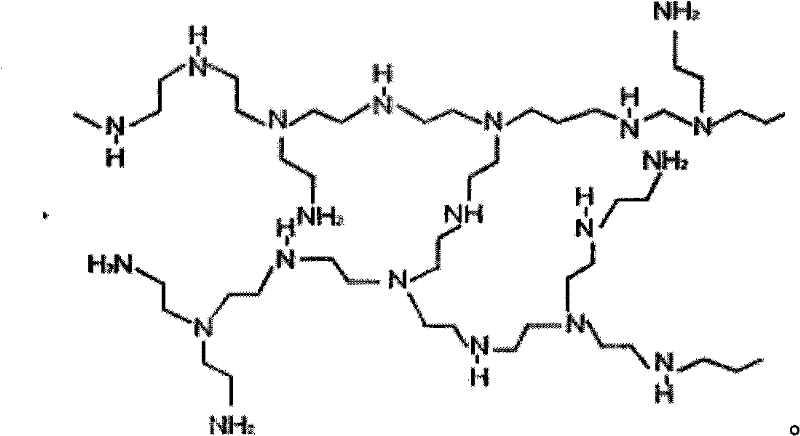

Adhesive for indoor plywood

InactiveCN104762039AIncrease productivityReduce formaldehydeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesSodium stearateAdhesive

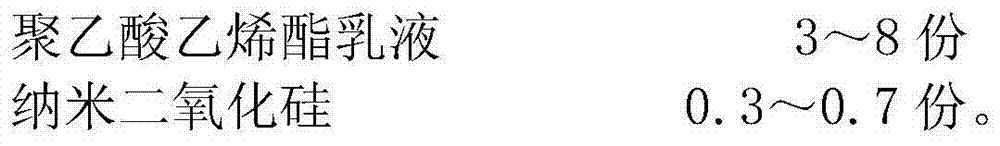

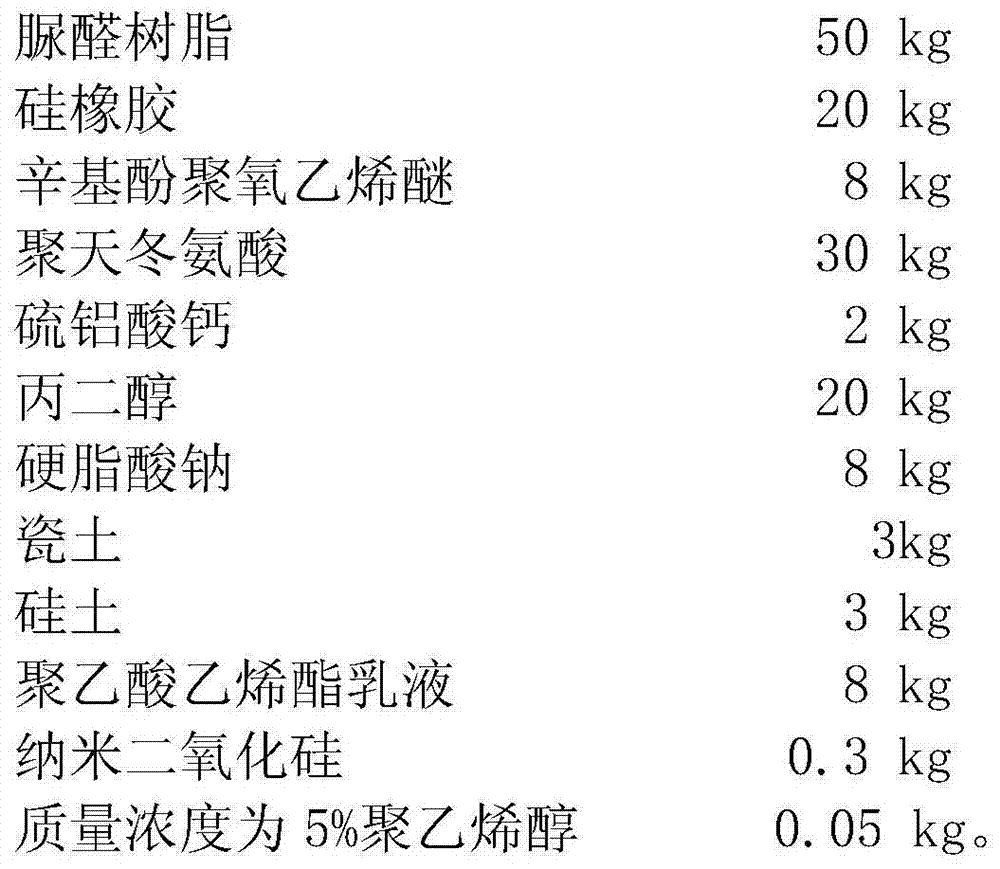

The invention relates to the technical field of adhesive, in particular to adhesive for indoor plywood. The adhesive comprises, by weight, 50-70 parts of urea resin, 10-20 parts of silicone rubber, 8-15 parts of octyl phenol polyoxyethylene ether, 20-30 parts of polyaspartic acid, 2-4 parts of calcium sulphoaluminate, 10-20 parts of propylene glycol, 8-13 parts of sodium stearate, 6-12 parts of porous inorganic filler, 3-8 parts of polyvinyl acetate emulsion, 1-5 parts of nano-silica and 5-10 parts of water. The adhesive for the indoor plywood is good in viscosity, has the antiseptic and anti-static functions and contains lower formaldehyde, the water resistance and aging resistance of the adhesive are improved greatly, and the service life of the adhesive is prolonged by half a year to one year. The adhesive is mainly applied to bonding of the inner plywood.

Owner:黄琳

Method for removing formaldehyde and methanol from carboxylic ester containing material and application

ActiveCN108129315AReduce formaldehydeReduce Methanol ContentOrganic compound preparationCarboxylic acid esters preparationDistillationAzeotrope

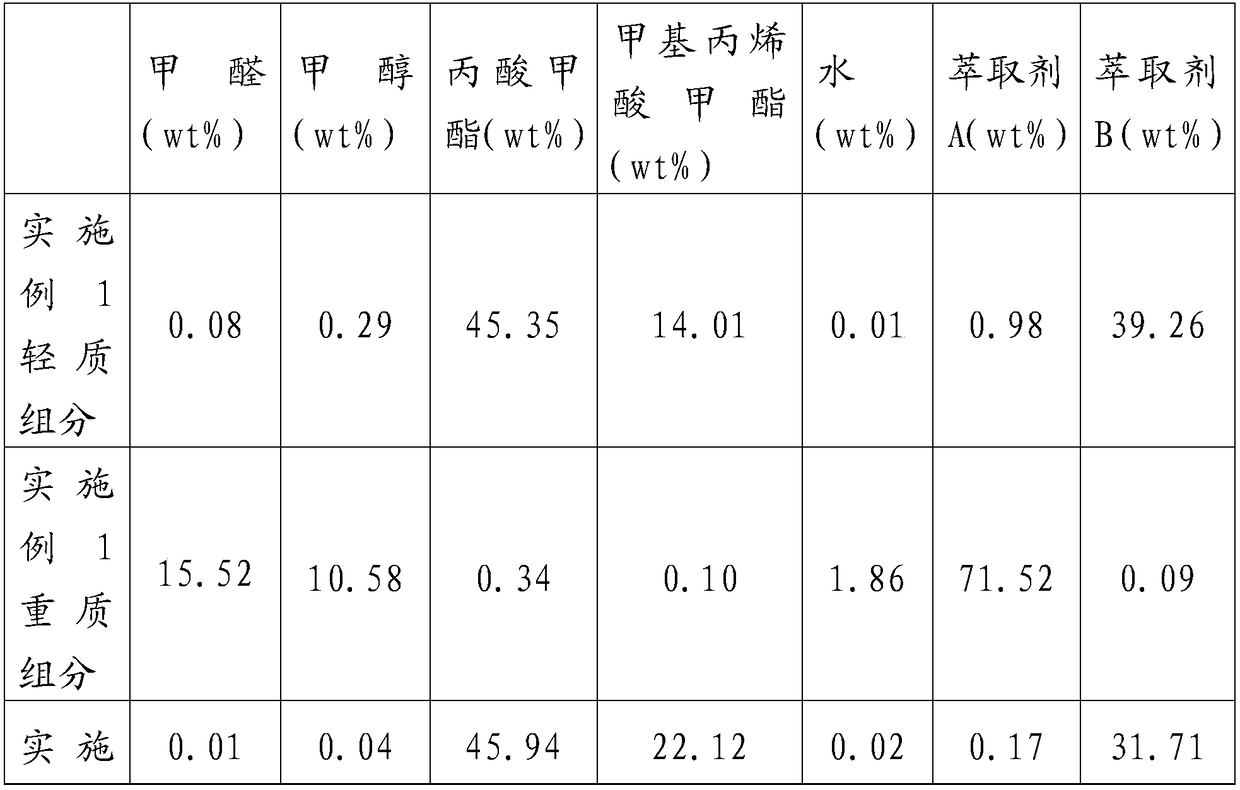

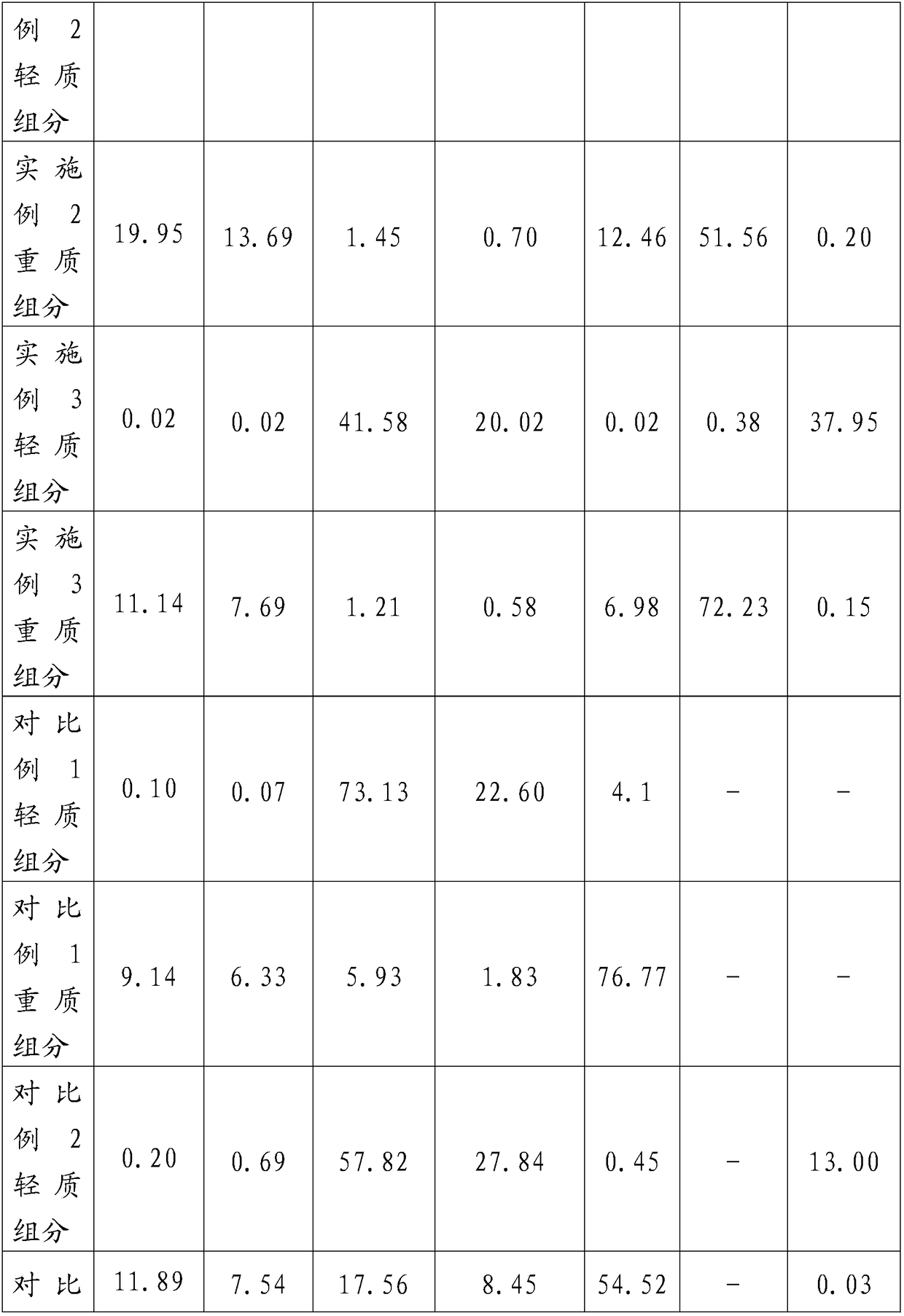

The invention provides a method for removing formaldehyde and methanol from a carboxylic ester containing material. The method comprises the following steps: a) subjecting the carboxylic ester containing material to pre-distillation treatment so as to remove a part of an azeotrope; and b) subjecting the pre-distilled carboxylic ester containing material, an extractant A and an extractant B to reverse contacting in an extraction device so as to obtain a light component through extraction of the extractant A and obtain a heavy component through extraction of the extractant B; wherein reverse contacting in the step a) is performed as follows: dissolving the carboxylic ester containing material in the extractant B and carrying out contacting with the extractant A during flowing in a reverse direction, or adding the carboxylic ester containing material in the contacting process of the extractant B and the extractant A during flowing in the reverse direction. The extraction separation process provided by the invention breaks an azeotropic system, and high-purity carboxylic ester can be obtained through simple distillation of an organic phase obtained by separation.

Owner:WANHUA CHEM GRP CO LTD

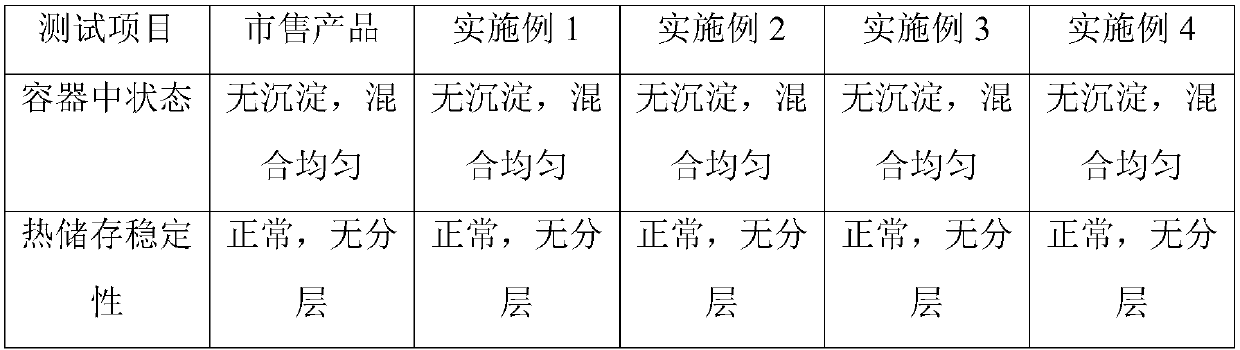

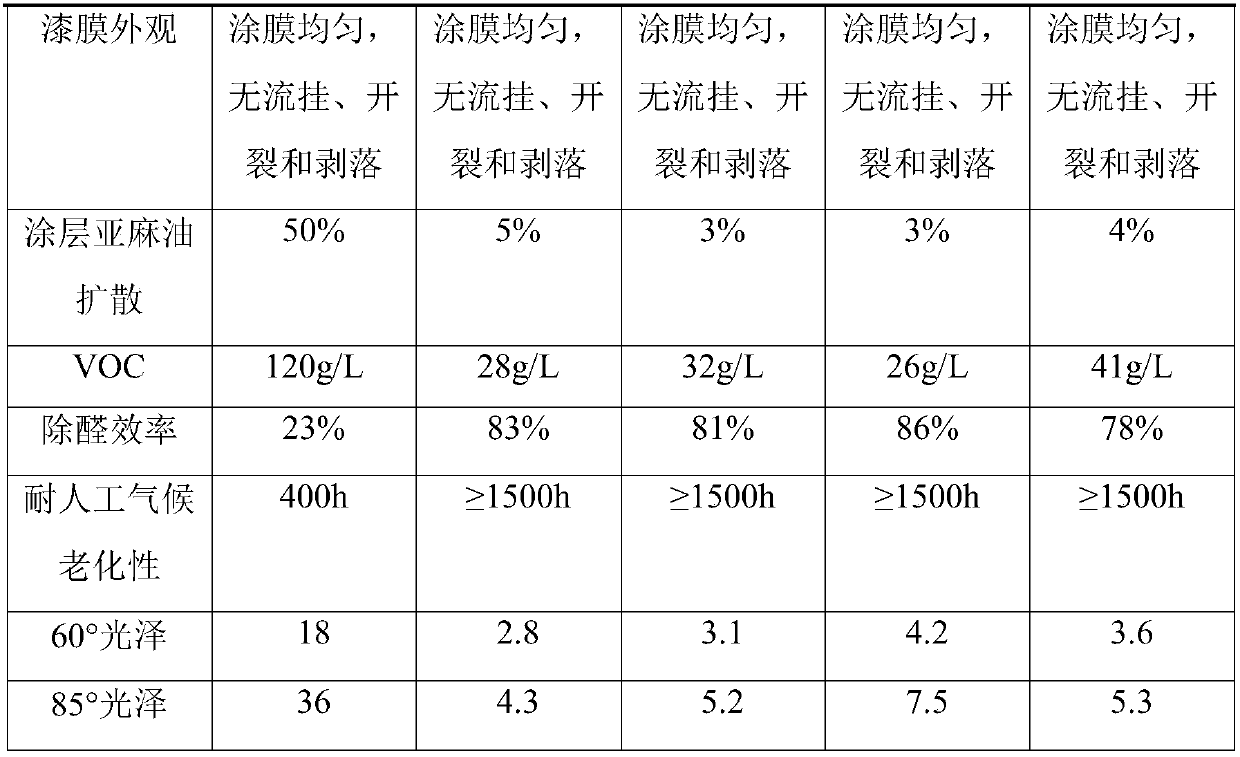

Waterborne matte environment-friendly canvas coating material with high weather resistance and preparation method thereof

The invention relates to a waterborne matte environment-friendly canvas coating material with high weather resistance. The waterborne matte environment-friendly canvas coating material is prepared from deionized water, cellulose, dispersant, a wetting agent, a defoaming agent, AMP-95, titanium dioxide, diatomite, heavy calcium, gaseous silicon dioxide, waterborne acrylate copolymer emulsion, film-forming additive, cosolvent, photocatalyst material, epoxy silane, ultraviolet absorber, bactericide, mildew inhibitor and thickening agent. The waterborne matte environment-friendly canvas coating material with high weather resistance overcomes the defects that the existing canvas coating material is not environment-friendly, is high in VOC and high in gloss, and does not have long-term weather resistance and mildew resistance and the like. The matte environment-friendly canvas coating material is low in gloss, photosensitive and soft; the matte environment-friendly canvas coating material has appropriate oleophobic effect, and the pigment diluent such as linseed oil is not easy to diffuse and permeate; the affinity with the a base material and pigments is high, and the adhesion is good;the waterborne matte environment-friendly canvas coating material is odorless, environment-friendly, low in -VOC, capable of removing formaldehyde, and capable of meeting the EN71-9 standard requirements; and a coating of the waterborne matte environment-friendly canvas coating material is resistant to yellowing, excellent in weather resistance and good in mildew resistant effect.

Owner:成都巴德富科技有限公司

Production process of environment-friendly antibacterial parquet

InactiveCN104772811AReduce harmReduce formaldehydeWood veneer joiningWood impregnation detailsSolid woodBiochemical engineering

The invention discloses a production process of environment-friendly antibacterial parquet, which relates to the production field of a floor slab. The environment-friendly antibacterial parquet is prepared in seven steps such as coating a single plate, pre-hot pressing, hot pressing, soaking, hot pressing, carrying out the antibacterial treatment and air drying. According to the production process of the environment-friendly antibacterial parquet, the produced wood floor slab is environment-friendly, less released formaldehyde, slightly harmful to the human body and capable of effectively resisting the bacteria.

Owner:安徽浩峯塑业有限公司

Manufacturing process of renewable cotton and linen plastic composite material

InactiveCN110170502ASolve processing problemsLow costWaste processingSolid waste disposalEnvironmental resistanceFiber

The invention discloses a manufacturing process of a renewable cotton and linen plastic composite material. The manufacturing process comprises the following steps of (a) collecting fiber materials: collecting old clothes, removing metal accessories including zippers, buttons and the like from the clothes, and then shredding into fine linen by using a shredding machine; (b) machining the fiber materials; (c) collecting plastic materials; (d) mixing and stirring; (e) forming; and (f) trimming and storing. The manufacturing process has the beneficial effects that the old clothes can be recycled,so that the problem of difficulty in processing the old clothes is solved; cotton and linen fiber and plastic particles are mixed so as to prepare a new material, so that the excellent performance ofthe two materials can be combined, the cost is reduced, and additionally, the use effect is good; formaldehyde is not generated, so that the effects of environmental friendliness and health are achieved during use; and the strength is high, the toughness is good, the aging is resistant, the wear resistance is good, the material can be processed into films, plates or sections as required, the userange is wide, and the effect is good.

Owner:刘云山

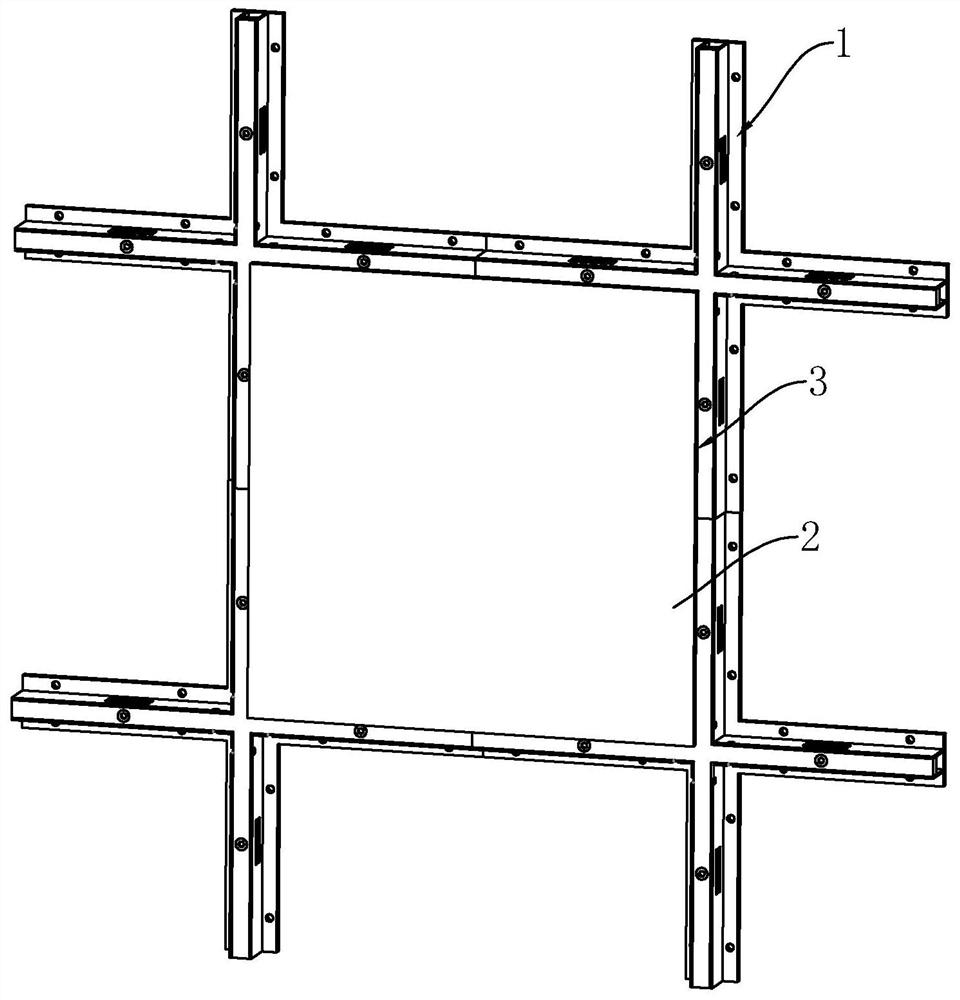

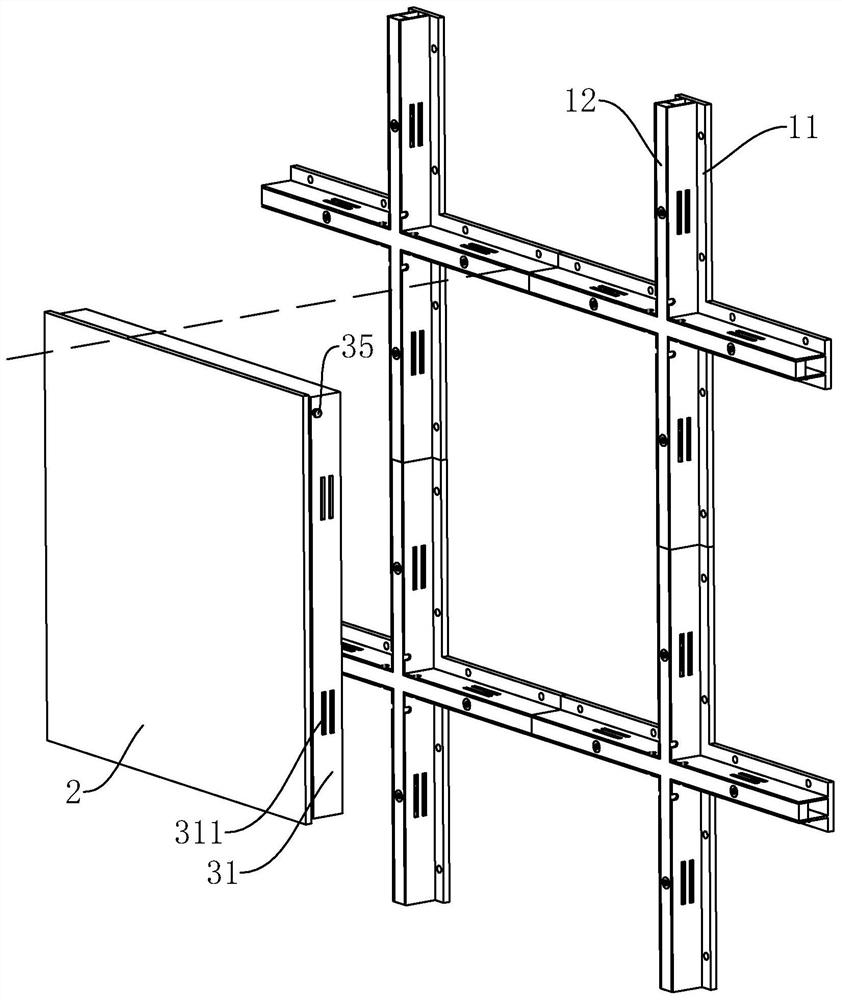

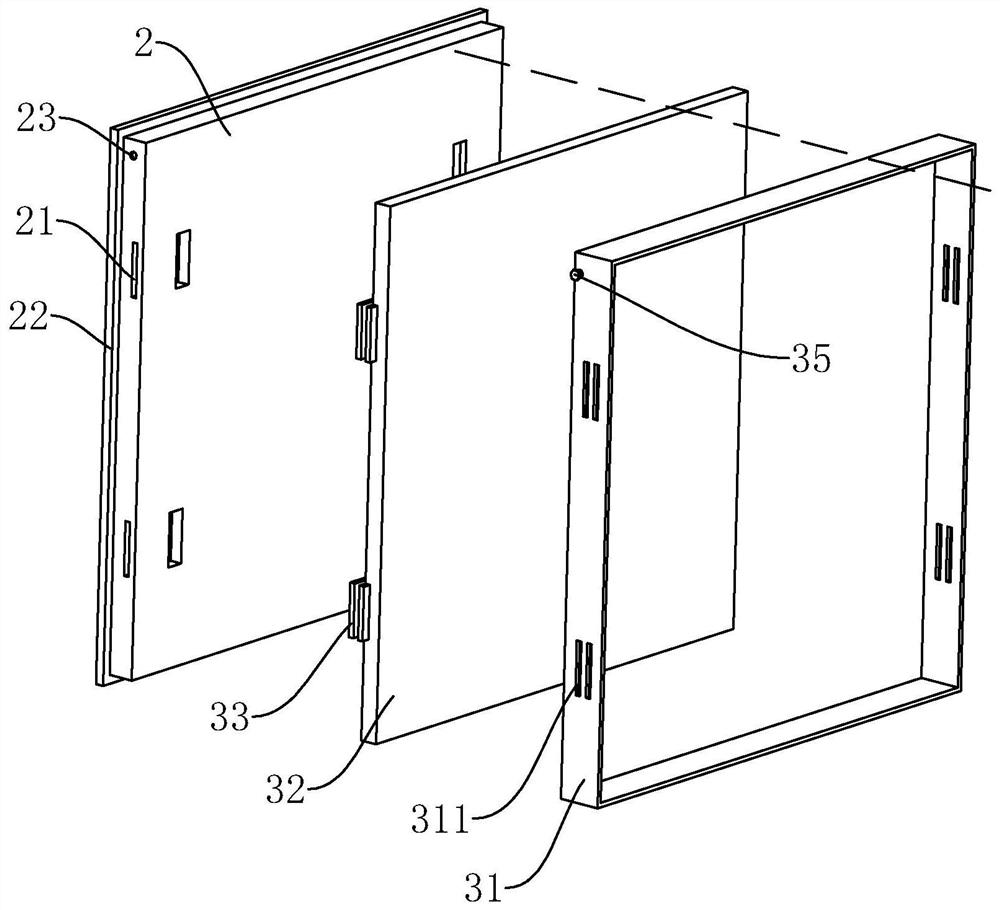

Wall surface assembly type ceramic tile structure and installation method

InactiveCN113293955AEasy to replaceReduce replacement costsCovering/liningsBuilding material handlingComposite materialCeramic tiles

The invention relates to a wall surface assembly type ceramic tile structure and an installation method, and relates to the field of ceramic tile installation. The wall surface assembly type ceramic tile structure comprises a keel assembly, a decorative ceramic tile and a connecting assembly used for connecting the decorative ceramic tile and the keel assembly, wherein the connecting assembly comprises a connecting frame, a back plate, an inserting part and a driving part; the connecting frame sleeves the outer side of the decorative ceramic tile and is clamped into the keel assembly; the back plate is connected to one side, facing a wall body, of the decorative ceramic tile; a guide groove for the inserting part to slide is formed in one side, facing the decorative ceramic tile, of the back plate; the driving part is used for driving the inserting part to slide outwards; the connecting frame is provided with a through hole for the inserting part to penetrate through; and the decorative ceramic tile is provided with a connecting hole for the inserting part to penetrate through. The ceramic tile structure is beneficial to rapid replacement of the damaged decorative ceramic tile, other intact decorative ceramic tiles cannot be influenced, and the replacement cost is low.

Owner:变形积木(北京)科技有限公司

Production process of antibacterial laminated wood floor

InactiveCN112025889AImprove stabilityNot easy to absorb waterWood treatment detailsCoating impregnationSolid woodMaterials preparation

The invention discloses a production process of an antibacterial laminated wood floor, and particularly relates to the technical field of wood floor production. The production process specifically comprises the steps of step 1, feeding raw materials into a processing factory for material preparation, and cutting a plate for preparation into plate blanks with the same size and the thickness of 1.2-3cm; and step 2, conveying the plate blanks obtained through cutting in the step 1 to a drying room to be dried, wherein the temperature controlled in the drying room is set to be 150 DEG C, and the drying time is 40-80 minutes. The wood floor manufactured through the production process is high in stability, not prone to water absorption, high in cracking resistance, capable of restraining and killing bacteria in the solid wood floor, capable of preventing the bacteria from damaging the solid wood floor, capable of effectively prolonging the service life of the floor, little in released formaldehyde, small in harm to the human body, simple in process, low in equipment requirement and high in operability, and has good social popularization and application.

Owner:浙江品阁新材料科技有限公司

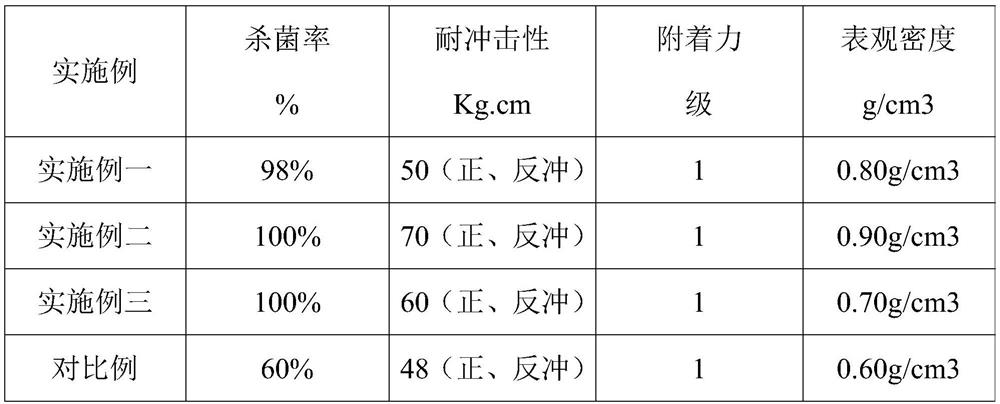

Water-based polymer antibacterial material with good water resistance and preparation method thereof

InactiveCN113372766AImprove water resistanceImprove salt water resistanceStarch dervative coatingsAntifouling/underwater paintsPhenolic antioxidantSalt water

The invention discloses a water-based polymer antibacterial material with good water resistance and a preparation method thereof. The water-based polymer antibacterial material is prepared from the following components in parts by weight: 50-70 parts of modified starch, 20-30 parts of modified water-based polyurethane, 40-50 parts of a reactive emulsifier, 10-15 parts of a nano-silver dispersant, 5-10 parts of negative ion crystals and 10-20 parts of a phenolic antioxidant. The problem that a coating film formed by waterborne polyurethane is low in initial viscosity and poor in water resistance is solved. The water resistance, salt water resistance, corrosion resistance and other physical and mechanical properties of the coating can be effectively improved by adding the reactive emulsifier, and the negative ion crystals are used, so that the waterborne polymer coating can release a large number of negative ions, the content of formaldehyde, voc and dust in indoor air is effectively reduced, and the effects of killing bacteria and removing peculiar smell are achieved.

Owner:SHENZHEN DECHENGDA PHOTOELECTRIC MATERIAL CO LTD

Negative oxygen ion modified PVC hard composite floor and preparation process thereof

InactiveCN109849473AImprove freshnessReduce formaldehydeSynthetic resin layered productsLaminationUV curingOxygen ions

The invention provides a negative oxygen ion modified PVC hard composite floor. The composite floor comprises a UV layer, a PVC wear-resistant layer, a PVC pattern fabric, a negative oxygen ion modified PVC middle material layer, and a negative oxygen ion modified PVC bottom material layer from the top to the bottom in sequence. A preparation process of the composite floor comprises the followingsteps: spreading the PVC wear-resistant layer, the PVC pattern fabric, the negative oxygen ion powder modified middle material layer, and the negative oxygen ion powder modified bottom material layer,sending the spread materials into a hot press, performing heating and pressurization, and performing cooling molding; coating the surface of a semi-finished product by a UV curing layer; sending thesemi-finished product into a tempering line for tempering, and performing natural curing; and performing trimming on the semi-finished product, performing cutting, performing slotting, and performingpacking. According to the process provided by the invention, the refractory floor prepared by the method has a higher release amount of negative oxygen ions and good scratch resistance.

Owner:龙岩市锐美家装饰材料有限公司

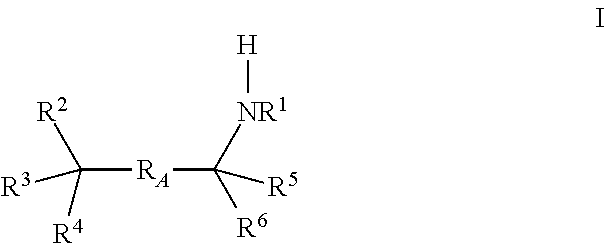

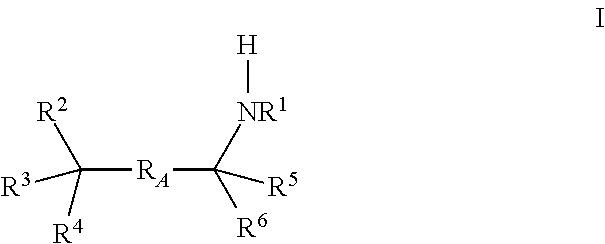

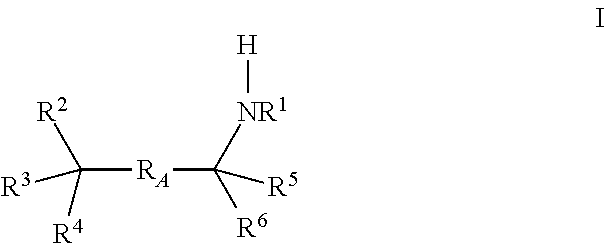

Polyurethane foams having reduced aldehyde emissions

Polyurethane foams are made by curing a reaction mixture that contains an aromatic polyisocyanate, at least one isocyanate-reactive material having an average functionality of at least 2 and an equivalent weight of at least 200 per isocyanate-reactive group, at least one blowing agent, at least one surfactant and at least one catalyst, at least one aminoalcohol compound and least one antioxidant. Foams so produced emit low levels of both formaldehyde and acetaldehyde.

Owner:DOW GLOBAL TECH LLC

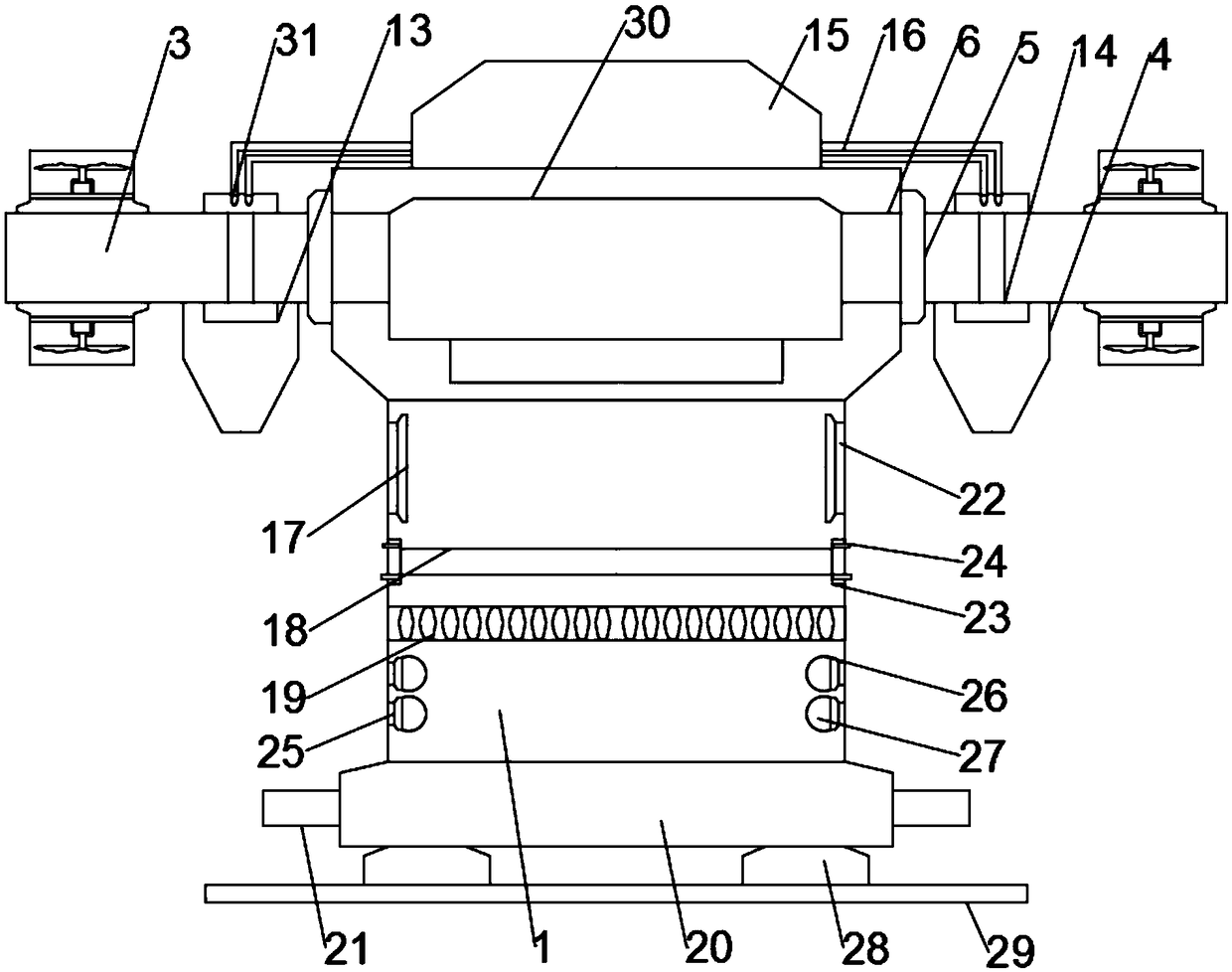

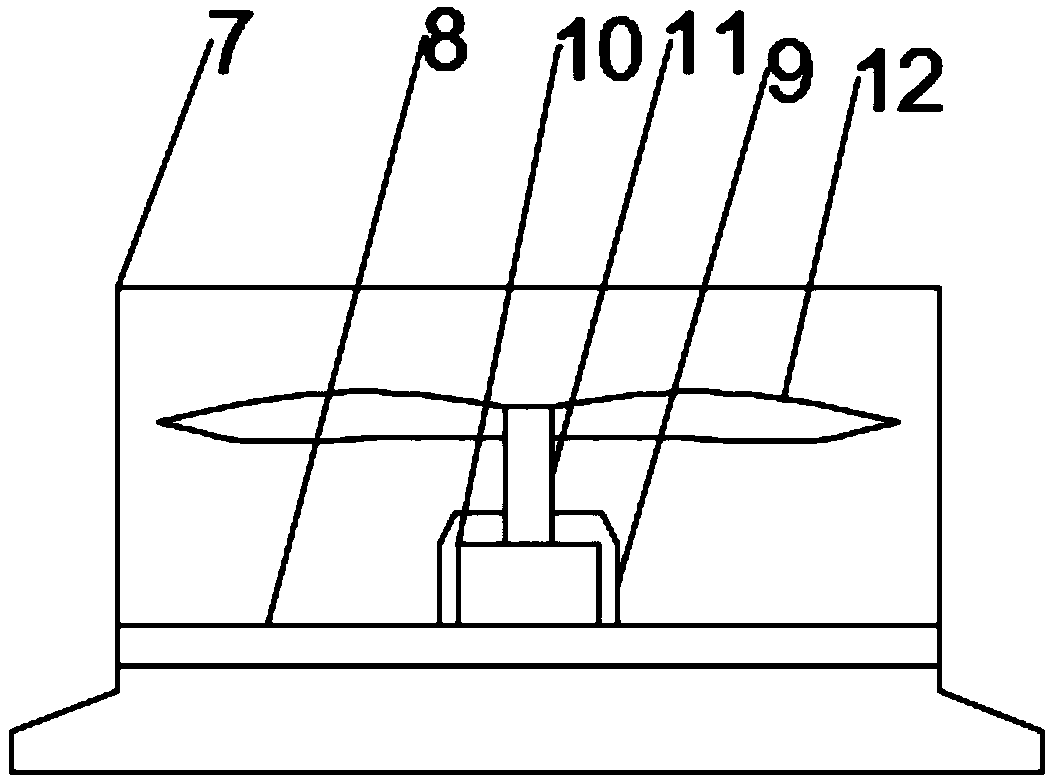

Environment-friendly air purifying system for household toilet

InactiveCN108800335AQuality improvementReduce odorMechanical apparatusLighting and heating apparatusActivated carbonMotor drive

The invention discloses an environment-friendly air purifying system for a household toilet. The environment-friendly air purifying system comprises an air inlet system, a purifying system body, an exhaust system and a purifying barrel. The air inlet system comprises an air inlet barrel, an air inlet pipe and a cleaning hopper. An exhaust fan is mounted in the air inlet barrel, and the surface ofthe outer end of the air inlet pipe is connected with a fixed ring. The inner wall of the fixed ring is connected with a connecting frame, and the center of the connecting frame is connected with a fixed seat. A motor is mounted in the fixed seat, and the motor drives fan blades to rotate through a rotary shaft. A filtering seat is arranged in the air inlet pipe, and the cleaning hopper is arranged at the bottom end of the filtering seat. A nozzle is arranged at the top end of the filtering seat, and the purifying system body comprises an electrode plate, an activated carbon filtering screen and a catalyzing grid. The exhaust system comprises an exhaust barrel and an exhaust pipe, and the exhaust pipe and the exhaust barrel are connected together. Air in the toilet is stirred, comprehensive purifying of the air in the toilet is achieved, and the air quality of the toilet is effectively improved. A multistage air purifying manner is adopted for purifying the air, and the purifying effect is good.

Owner:安徽悦达环保科技有限公司

Method for preparing base paper of facing paper from plant fibers

The invention relates to a method for preparing raw paper of facing paper from plant fibers. The method comprises the following steps: (1) preparing raw materials of plant fibers, inorganic fibers, sepiolite, EVA (Ethylene Vinyl Acetate) resin and a modifier; (2) adding water into plant fibers, stirring, then adding inorganic fibers, sepiolite, EVA resin and a modifier, and uniformly stirring to obtain a mixed material; (3) carrying out disc milling and pulping on the mixed material to obtain slurry; and (4) carrying out vacuum dehydration, squeezing dehydration and drying dehydration to prepare the raw paper of the facing paper. According to the invention, the environment-friendly, moisture-proof, antibacterial and formaldehyde-free process is prepared from the raw materials; the prepared facing paper is relatively good in flexibility and can be freely bent; the base paper is attached through the hot melt adhesive film, formaldehyde can be reduced, the film attaching process can be reduced, energy consumption is reduced, and the floor production period is shortened.

Owner:CHANGZHOU BEMATE HOME TECH CO LTD

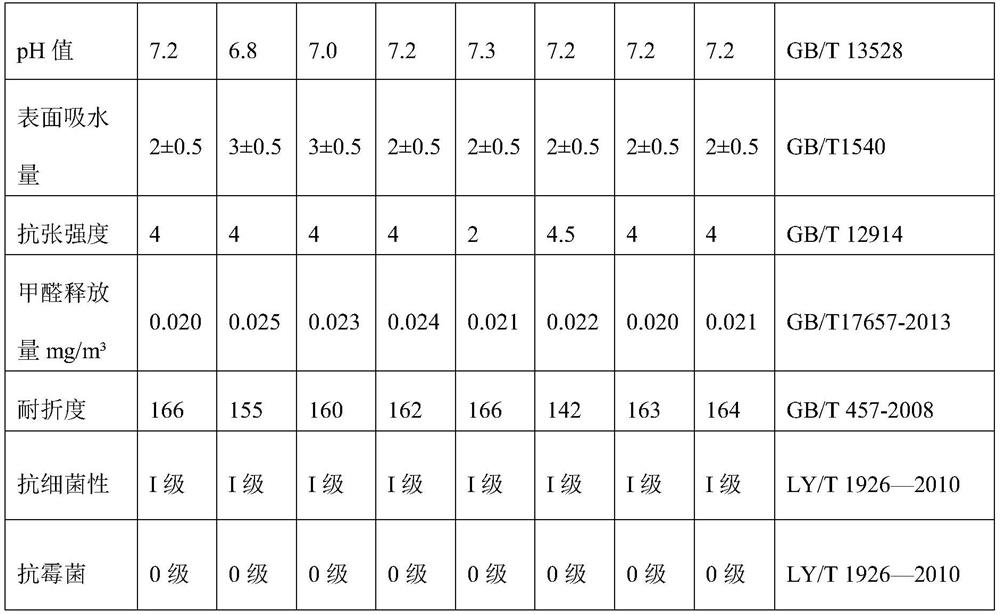

Aloe natural environmental-protection wall coating

InactiveCN105623424AUnique natural propertiesExcellent anti-corrosion and anti-bacterial functionAntifouling/underwater paintsPaints with biocidesEmulsionPlant Gums

The invention discloses an aloe natural environmental-protection wall coating, which is characterized by being mainly prepared from the following ingredients (by weight): 200-340 parts of water, 130-250 parts of titanium dioxide, 20-80 parts of talcum powder, 1-4 parts of alkaloid, 2-8 parts of a dispersant, 1-4 parts of a wetting agent, 1-8 parts of an antifoaming agent, 100-240 parts of aloe-gel, 150-320 parts of an acrylic emulsion and 20-80 parts of vegetable glue. The coating has full film, has excellent effects in aspects of smell, environmental protection and performance, has good decorative function and environmental protection function, and is an aloe natural environmental-protection wall coating with excellent comprehensive properties.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Environment-friendly inner wall paint

InactiveCN107652895APrevent intrusionReduce formaldehydeAntifouling/underwater paintsPaints with biocidesAcrylic resinPerilla oil

The invention relates to environment-friendly inner wall paint. The environment-friendly inner wall paint comprises fatty acid latex paint, alcohol-soluble acrylic resin, n-butyl alcohol, shell powder, ethanol, a dispersing agent, a defoaming agent, an anti-settling agent, ethylene glycol, a pH regulator, sterilizing anti-mildew agent, eucalyptus oil, tea tree oil, lemon eucalyptus oil, litsea cubeba oil, perilla oil, camphor oil, capsaicin and fructus cnidii. The environment-friendly inner wall paint has the advantages that the various components are reasonably combined to obtain the environment-friendly inner wall paint which is harmless to human bodies and can adsorb and reduce formaldehyde and volatile harmful gas in air; meanwhile, the environment-friendly inner wall paint is low in heat conductivity, capable of achieving energy saving and thermal insulation, good in construction performance, good in adhesive force, good in leveling property, resistant to aging, capable of preventing the invasion and harassment of mice and ants and suitable for being popularized and used.

Owner:周瑛

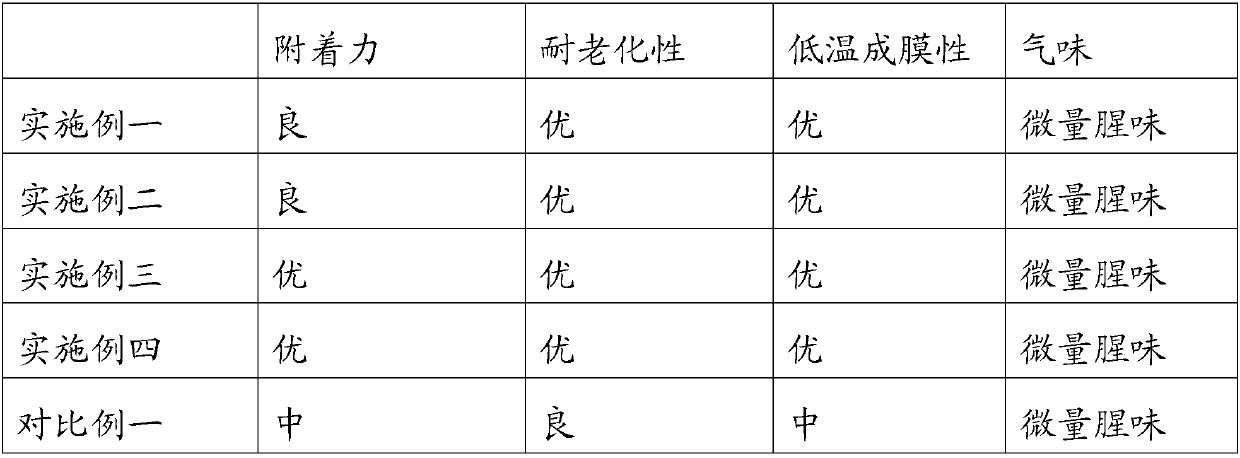

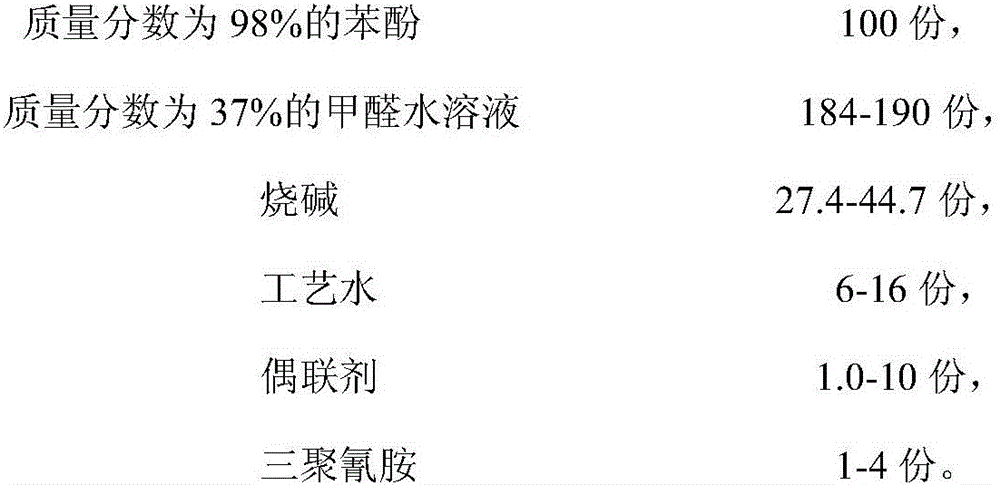

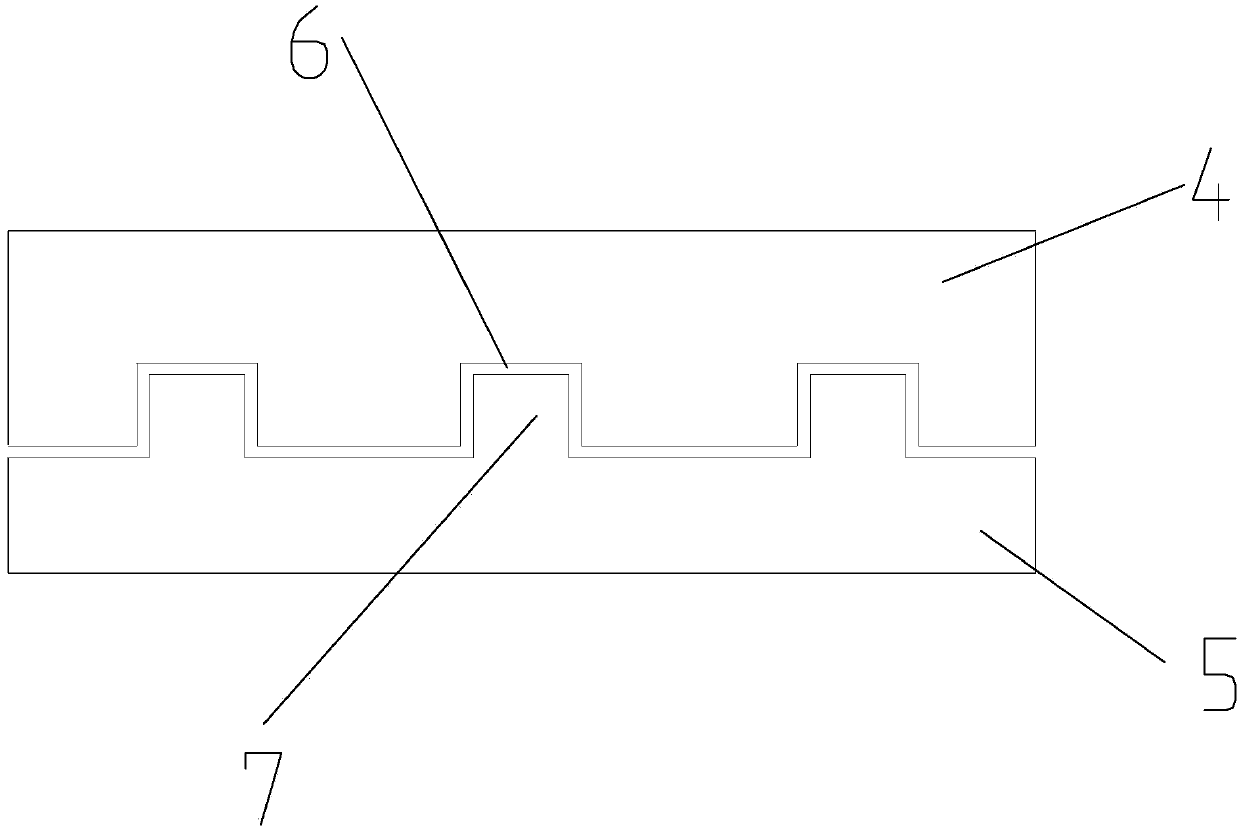

High-molar-ratio environment-friendly phenolic resin glue and preparation method and application thereof

InactiveCN106117480AIncrease the amount of participationReduce dosageAldehyde/ketone condensation polymer adhesivesChemical reactionAqueous solution

The invention discloses a high molar ratio environment-friendly phenolic resin glue and its preparation method and application. The phenolic resin glue is prepared from the following components: phenol with a mass fraction of 98%, formaldehyde aqueous solution with a mass fraction of 37%, caustic soda, Process water, coupling agent, melamine. P:F=1:(2.18-2.25) of the present invention, the amount of formaldehyde added is higher than that of ordinary phenolic resin glue formula, which saves the amount of phenol and reduces the production cost; the preparation process makes phenol and formaldehyde go through multiple polycondensation The reaction is divided into three feedings, the chemical reaction is more thorough, and the curing temperature is lower, the amount of free formaldehyde and phenol in the phenolic resin glue is small, and no toxic substances are released during the preparation process, which is harmless to the human body and beneficial to environmental protection; the present invention The phenolic resin glue has great industrial application value.

Owner:福建和其昌竹业股份有限公司

Preparation method of mixed-material glue-free composite material based on high-frequency waves

ActiveCN111347511AAvoid problems such as crackingAvoid the problem of gelatinization of the outer surfaceWood veneer joiningXylyleneFrequency wave

The invention relates to a preparation method of a mixed-material glue-free composite material based on high-frequency waves. The method is characterized in that at least two wood boards with densities not exceeding 0.7 kg / m3 are heated and pressed through the high-frequency waves, so that a degraded connection layer is formed between the two adjacent wood boards. The preparation method specifically comprises the following steps of pretreatment, laminating treatment, heating and pressurizing treatment, curing treatment, cooling treatment and health preservation treatment. The novel composite material prepared by the method has the characteristics of high strength, high toughness and low content of formaldehyde and xylene, and also has waterproof and anti-cracking performances.

Owner:广平凯王压密科技有限公司

A kind of purification formaldehyde alkyd resin and preparation method thereof

ActiveCN103421173BDoes not affect colorHas the effect of purifying formaldehydePolyester coatingsOrganic solventAlcohol

The invention discloses formaldehyde-purifying alkyd resin and a preparation method thereof. The formaldehyde-purifying alkyd resin is prepared through reaction of polyhydric alcohols, polyatomic acids, organic solvents, formaldehyde removing agents and anion generating agents. The method includes during preparation, by the protection of nitrogen, firstly adding the polyhydric alcohols and the polyatomic acids, and raising the temperature to 100 to 160 DEG C; adding catalyst, raising the temperature to 220 to 260 DEG C, and keeping the temperature for 1 to 3.5 hours; control the temperature from 200 to 220 DEG C, adding water-carrying agents, and raising the temperature to 250 to 280 DEG C to flow back until the acid value is lower than 7; adding the organic solvents and mixing evenly to obtaining the alkyd resin; adding the formaldehyde removing agents, and reacting at the temperature of 25 DEG C to 80 DEG C for 3 to 30 minutes to obtain modified alkyd resin, namely the formaldehyde-purifying alkyd resin. When the formaldehyde-purifying alkyd resin reacts with the formaldehyde, a resulting product is not volatile and non-toxic, and secondary contamination is eliminated; the preparation process in simple, requirement for equipment is low, and the formaldehyde-purifying alkyd resin is adaptable to mass production.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com