Wall surface assembly type ceramic tile structure and installation method

A prefabricated and ceramic tile technology, which is applied in building construction, covering/lining, construction, etc., can solve problems such as difficult replacement of tiles, achieve fast and convenient installation, speed up installation efficiency, and reduce gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

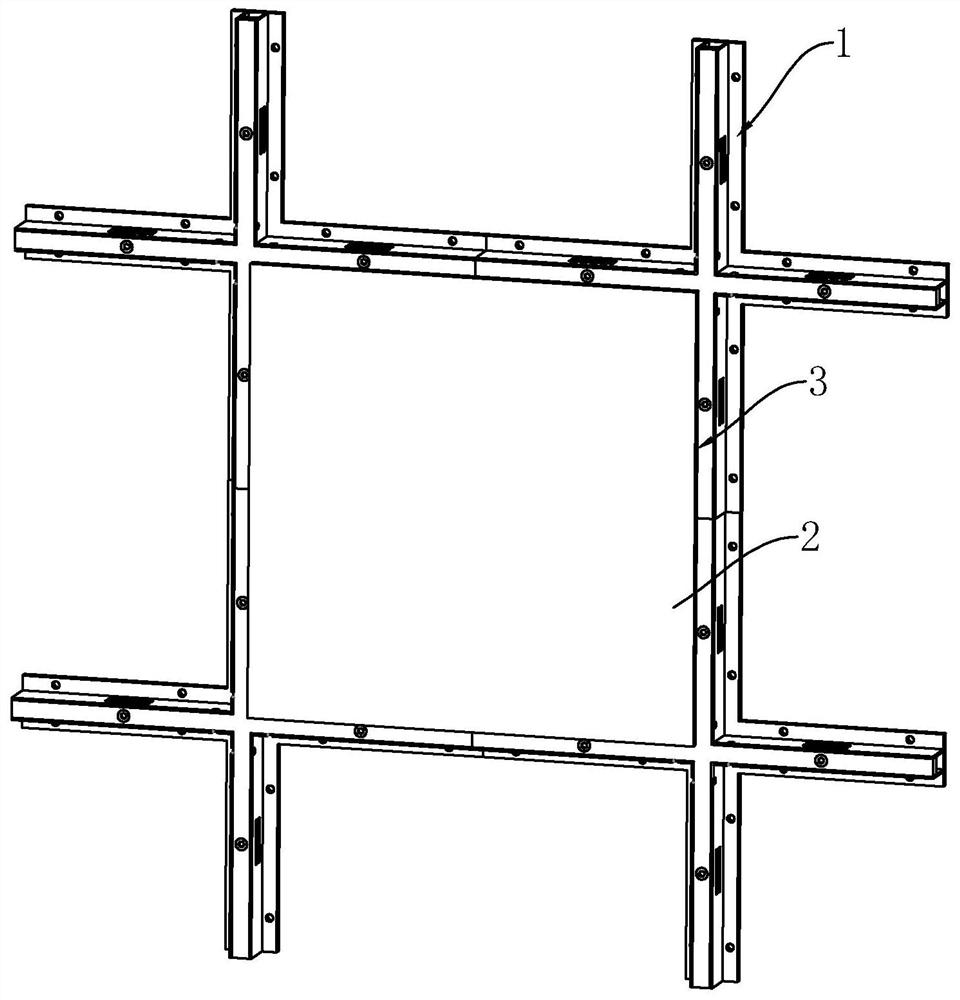

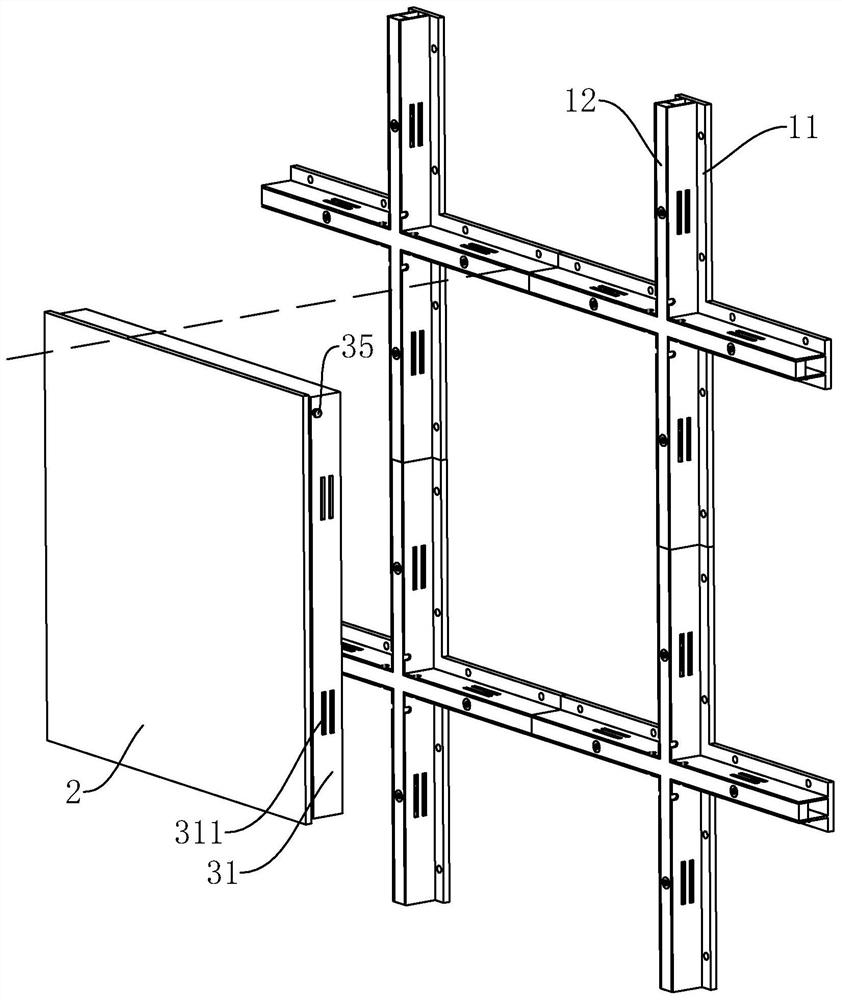

[0052] refer to figure 1 , figure 2 The wall prefabricated ceramic tile structure includes a keel assembly 1, a decorative tile 2, and a connecting assembly 3 for connecting the decorative tile 2 and the keel assembly 1. The keel assembly 1 is in the shape of a well, and the decorative tile 2 is square and installed on each keel assembly 1. In a well.

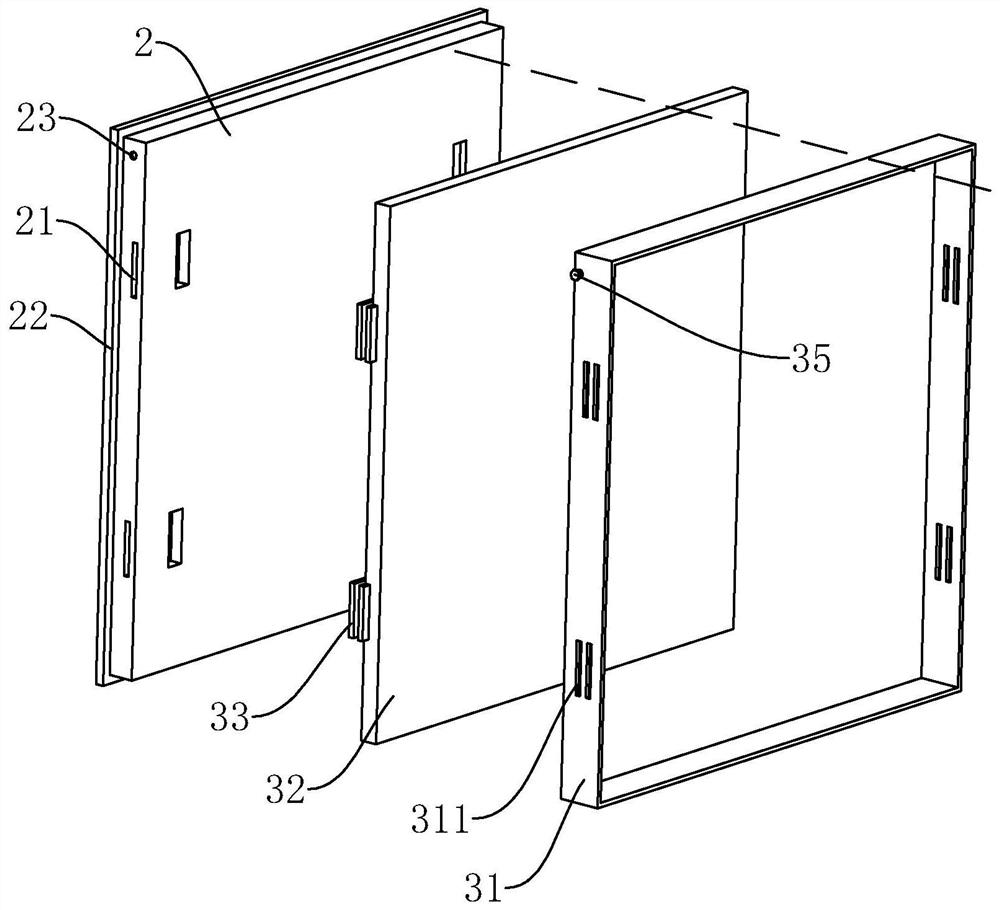

[0053] refer to figure 2 , image 3 , the connection assembly 3 includes a connection frame 31 , a backplane 32 , an insertion portion 33 and a driver 34 . The connecting frame 31 is square, and its inner side is attached to the outer edge of the decorative tile 2 , and the outer side is attached to the inner edge of the well of the keel assembly 1 . The backboard 32 is fixedly connected to the side of the decorative tile 2 facing the wall, and the connection method at this place can be fixed by screws, glued, etc. The backboard 32 is as large as the side of the decorative tile 2 facing the wall.

[0054] refer to imag...

Embodiment 2

[0068] refer to Figure 7 , Figure 8 , the only difference from the first embodiment is that the structure of the driving member 34 is different, and the connecting bolt 35 , the notch 1122 and the threaded hole 23 are not provided.

[0069] refer to Figure 8 , Figure 9 , the driving member 34 includes a driving gear 341, a driving rack 342, a connecting bar 343, a guide rod 344 and an operating handle. There are two driving racks 342 which are symmetrical to the center of the driving gear 341 , and the driving racks 342 mesh with the driving gear 341 . A rotating cavity 322 for the driving gear 341 is provided in the middle of the back plate 32 , and a square hole 3411 is formed in the middle of the driving gear 341 . The rotating cavity 322 communicates with a sliding cavity 323 for the driving rack 342 to snap into and slide. perpendicular to each other. A connection bar 343 is fixedly connected to two corresponding plug boards 332 . The sliding cavity 323 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com