Low-formaldehyde soaping-resistant adhesive for textile pigment printing and preparation method thereof

A pigment printing and low-formaldehyde technology, which is applied in textiles, papermaking, dyeing, etc., can solve the problems of far-reaching differences, uncontrollable formaldehyde content, and excessive formaldehyde in products, achieving excellent fastness, avoiding soaping fastness, and hand feeling soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

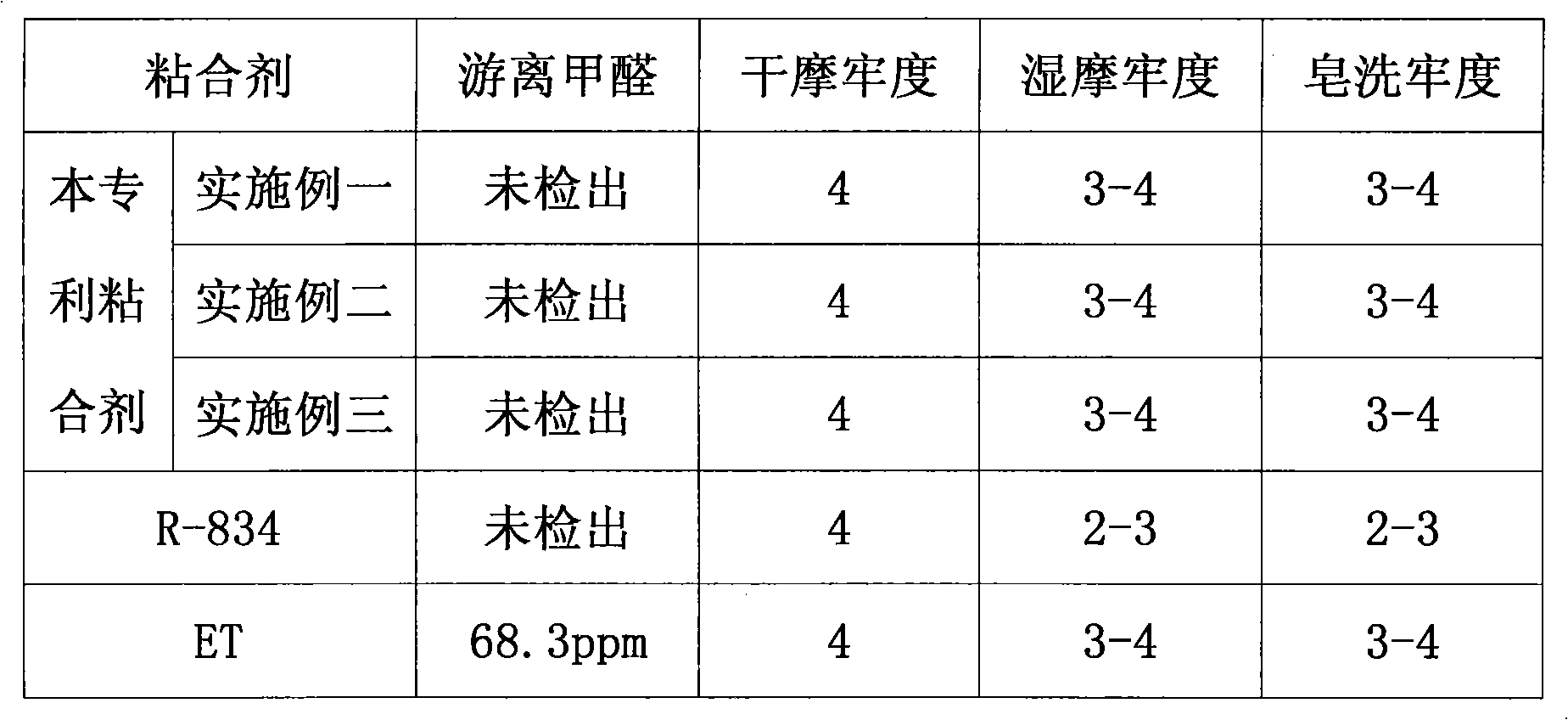

Examples

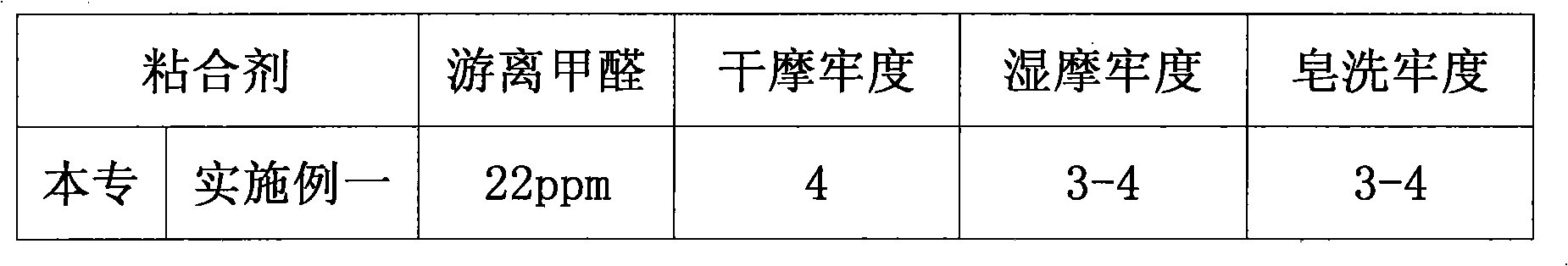

Embodiment 1

[0029] ① Dissolve 0.8 grams of sodium lauryl sulfate in 25 grams of deionized water, add to an emulsification kettle, and mix 2.5 grams of polyethylene glycol methacrylate (polyethylene glycol molecular weight 750), N-butoxymethyl propylene Add 1.4 g of amide, 1.2 g of acetoacetoxyethyl methacrylate, 0.6 g of acrylic acid, 2 g of styrene, 26.3 g of butyl acrylate, and 5.2 g of ethyl acrylate into an emulsification kettle, stir and emulsify to prepare a pre-emulsion.

[0030] ② Dissolve 0.6 g of ammonium persulfate in 6 g of deionized water to make an initiator solution for use.

[0031] ③Add 27 grams of deionized water to the reactor, heat up to 85-95°C, add 9.75 grams of 15% of the total mass of the pre-emulsion prepared in step ① to the reactor, and then add the initiator solution prepared in step ② 33% of the total mass was 2.2 grams, and the polymerization reaction was started.

[0032] ④ After 20 minutes, add the remaining emulsion prepared in step ① and the remaining in...

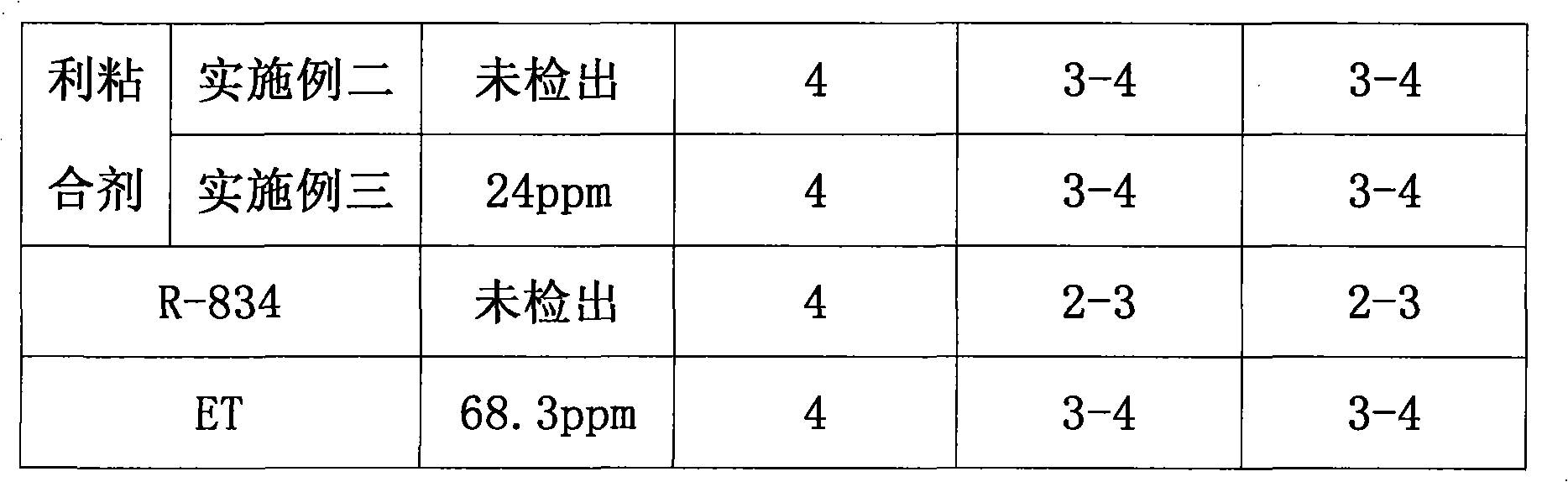

Embodiment 2

[0035] ① Dissolve 0.7 g of sodium lauryl sulfate in 25 g of deionized water, add to an emulsification kettle, and mix 2.8 g of polyethylene glycol methacrylate (polyethylene glycol molecular weight 750), N-butoxymethyl propylene Add 1.3 grams of amide, 1.3 grams of acetoacetoxyethyl methacrylate, 0.5 grams of acrylic acid, 5 grams of styrene, 24.4 grams of butyl acrylate, and 4 grams of 2-ethylhexyl acrylate into an emulsification kettle, stir and emulsify to prepare pre-emulsion.

[0036] ② Dissolve 0.7 g of ammonium persulfate in 7 g of deionized water to make an initiator solution for use.

[0037] ③Add 27 grams of deionized water to the reactor, heat up to 85-95°C, add 13 grams of 20% of the total mass of the pre-emulsion prepared in step ① to the reactor, and then add the initiator solution prepared in step ② 40% of the total mass was 3.08 grams, and the polymerization reaction was started.

[0038] ④ After 20 minutes, add the remaining emulsion prepared in step ① and t...

Embodiment 3

[0041] ① Dissolve 0.6 g of sodium lauryl sulfate in 27 g of deionized water, add to an emulsification kettle, and mix 3 g of polyethylene glycol methacrylate (polyethylene glycol molecular weight 750), N-butoxymethyl propylene Add 1.6 grams of amide, 1.2 grams of acetoacetoxyethyl methacrylate, 0.6 grams of acrylic acid, 4 grams of styrene, 23.2 grams of butyl acrylate, and 6 grams of 2-ethylhexyl acrylate into an emulsification kettle, stir and emulsify to prepare pre-emulsion.

[0042] ② Dissolve 0.8 g of ammonium persulfate in 8 g of deionized water to prepare an initiator solution for use.

[0043] ③Add 23 grams of deionized water to the reactor, heat up to 85-95°C, add 13.44 grams of 20% of the total mass of the pre-emulsion prepared in step ① to the reactor, and then add the initiator solution prepared in step ② 40% of the total mass was 3.52 grams, and the polymerization reaction was started.

[0044] ④ After 20 minutes, add the remaining emulsion prepared in step ① a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com