Patents

Literature

316results about How to "Good cross-linking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application of magnetic silicon dioxide composite microsphere

ActiveCN103903827AEasy to separateSmall particle sizeMicrobiological testing/measurementInorganic material magnetismProtein targetMicrosphere

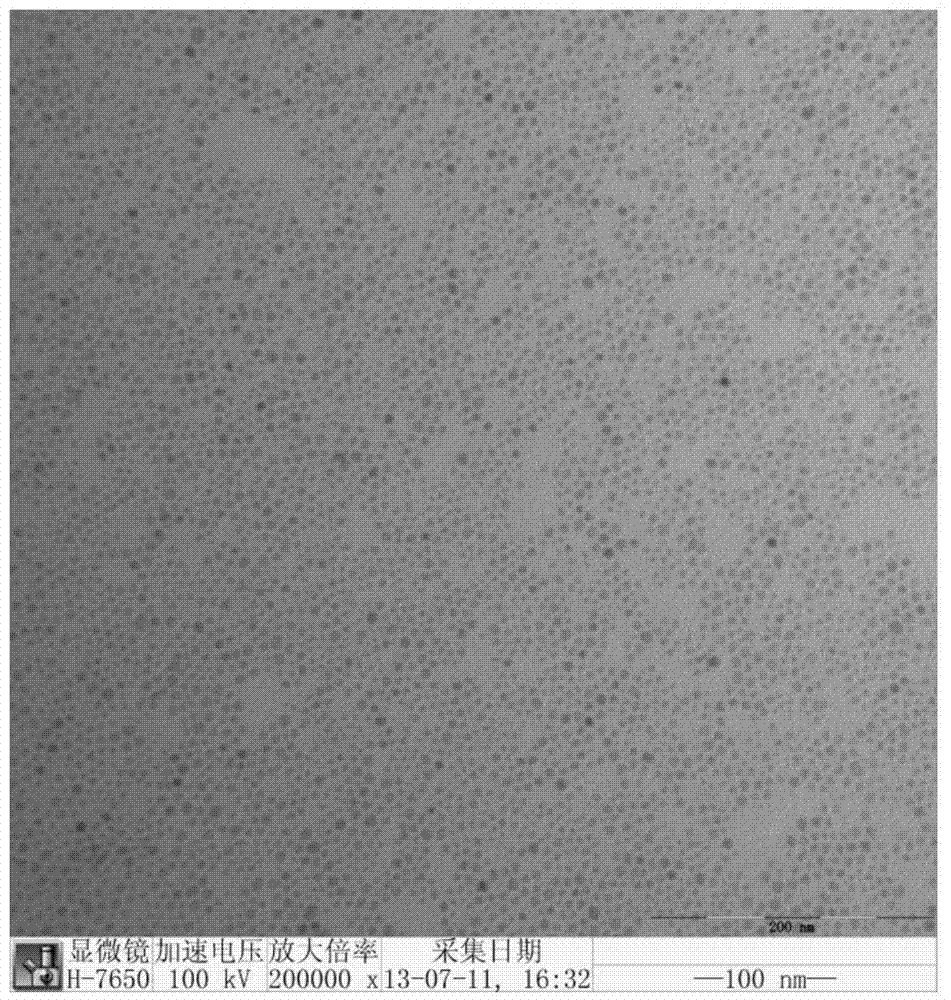

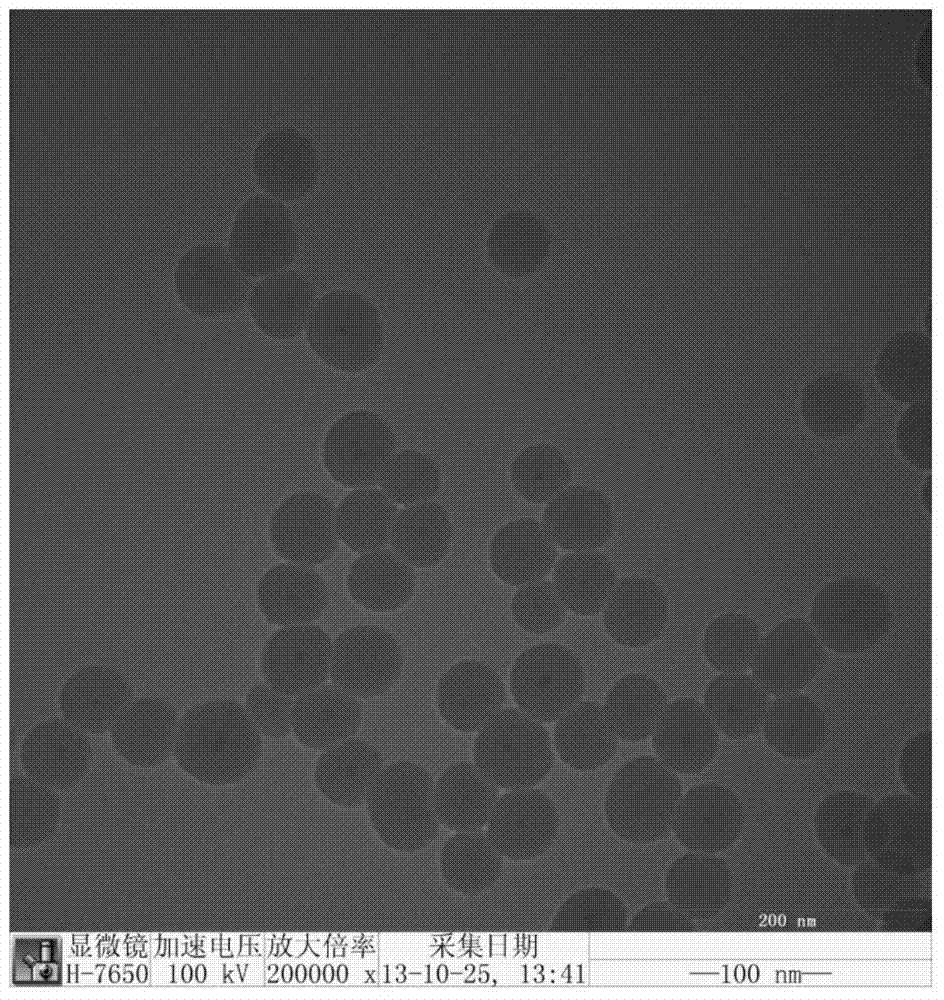

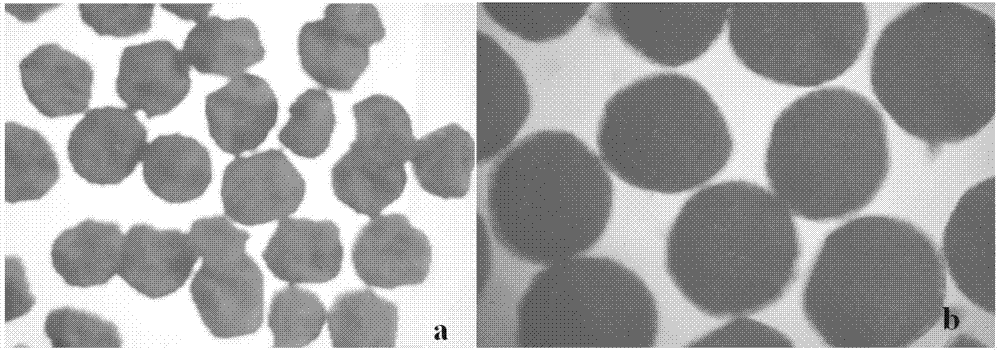

The invention relates to a preparation method and application of a magnetic silicon dioxide composite microsphere. Superparamagnetic ferroferric oxide nano particles of which the diameter ranges from 4 nm to 30 nm are prepared through a high-temperature pyrolysis method, a silicon dioxide shell of which the thickness ranges from 5 nm to 20nm covers the outer surfaces of the magnetic ferroferric oxide nano particles through a reverse microemulsion method, amination modification is conducted on the silicon dioxide surface, glutaraldehyde is used as a crosslinking arm, ligand protein is connected into, and protein separation is conducted through specific binding of ligand protein and target protein. The prepared magnetic microsphere is small in particle diameter and good in monodispersity, the composite microsphere with amine is large in specific surface area, nucleophilic addition is utilized, after the crosslinking arm glutaraldehyde is connected into, multiple kinds of ligand protein can be connected into, and then multiple kinds of target protein can be separated. The method is suitable for rapid separation and application of protein in biological samples, and has wide application prospect and great application value in the biomedical field and other fields.

Owner:HARBIN YICAI NEW MATERIAL

Method for preparing HMMM resin

InactiveCN101333198AImprove performanceGood cross-linking effectOrganic chemistryHexa(methoxymethyl)melamineOrganic acid

The invention discloses a preparation method for hexakis (methoxymethyl) melamine resin, namely, in the first step; 92% polyformaldehyde, melamine and methanol are reacted in alkaline environment through hydroxymethylation to generate the intermediate product hexamethylolmelamine crystals; in the second step, the intermediate product and methanol are reacted with organic acid through etherification to prepare the hexakis (methoxymethyl) melamine resin. The method of the invention is non-polluting, odorless and easy to operate. The hexakis (methoxymethyl) melamine resin produced through the method of the invention is stable and non-crystalline, which is used in coiled materials and baking varnish, with very good cross-linking effect.

Owner:ZHANGJIAGANG SHUNCHANG CHEM

Method for preparing natural cross-linking halogen-free flame-retardant polyolefin thermal conductive foam

InactiveCN102010538ASimple structureImprove heat resistanceFloor carpetsLow-density polyethyleneCross-link

The invention provides a method for preparing natural cross-linking halogen-free flame retardant polyolefin thermal conductive foam. The method comprises the following steps of: kneading low-density polyethylene resin, vinyl tri-methoxysilane, white carbon black and an auxiliary agent, and discharging to prepare a cross-linking master batch A; kneading the low-density polyethylene resin, the ethylene-vinyl acetate copolymer, ethylene propylene diene monomer, the cross-linking master batch A and the auxiliary agent, banburying, and extruding by using a single screw to prepare a basic raw material B; kneading the low-density polyethylene resin, dibutyltin dilaurate and the auxiliary agent, and extruding by using the single screw to prepare a catalyst master batch C; kneading the low-density polyethylene resin, a foaming agent, sodium phosphate dibasic dehydrate and the auxiliary agent, and extruding by using the single screw to prepare a foam master batch D; and kneading the basic raw material B, the catalyst master batch C and the foam master batch D, extruding by using the single screw and foaming by using a foaming furnace to prepared the product. By the method, natural cross-linking effect is good, process is simple and production cost is low; and the product has good thermal conductive performance, strong flame retardant performance and good environmental protection effect.

Owner:HUBEI LEYUAN NEW MATERIAL TECH

Preparation technique of sodium hyaluronate gel granule

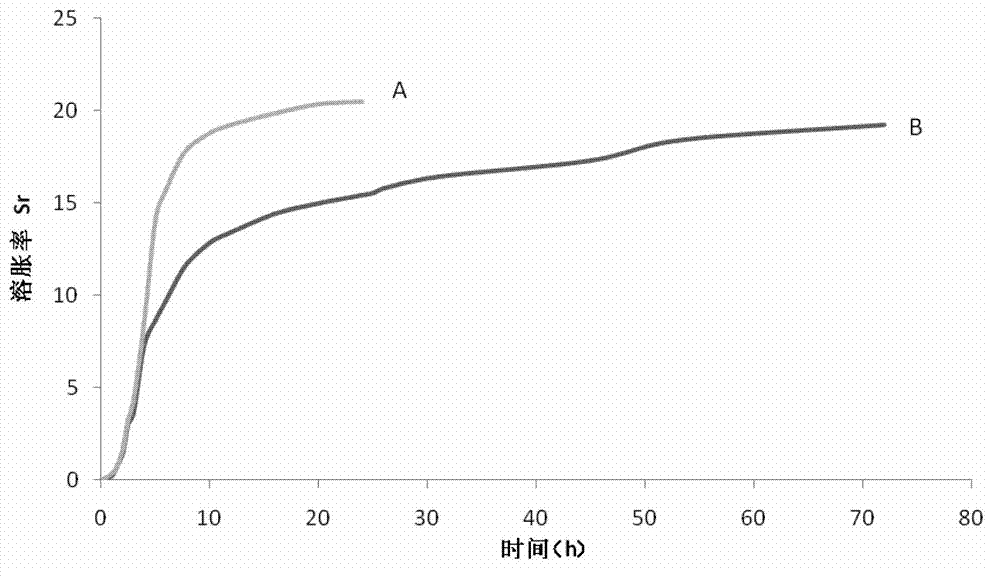

The invention provides a preparation method of sodium hyaluronate gel particle, which comprises (1) crosslinking reaction for preparation of crosslinking sodium hyaluronate gel, (2) dialysis for the process of hyaluronic acid gel, and (3) grading of gel particle. The preparation method of sodium hyaluronate gel particle has the advantages of excellent crosslinking performance and being suitable for medical cosmetology field, compared with the prior similar gel particle.

Owner:SHANDONG KAILEPU PHARMA

Injectable type collagen-based soft tissue filling material and preparation method thereof

The invention discloses an injectable type collagen-based soft tissue filling material and preparation method thereof, wherein the filling material mainly comprises collagen 0.5-20%, heparin 0.1%-10%, cell growth factor 0-1%, cushion liquid 70-99.4%, and its preparation comprises extracting soluble collagen from animal connective tissue, cutting off antigen deciding family from the collagen molecules through proteinase hydrolysis, purifying treatment, crosslinking by utilizing safety and nontoxic crosslinking agent, charging biologically active components, kneading the mixture repeatedly into grease form, sealing under asepsis condition and storing at low temperature.

Owner:JINAN UNIVERSITY

Preparation method of aqueous polyurethane for middle-high-density fiberboard

ActiveCN103320083AImprove stabilityLow costPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesPolyesterFiberboard

The invention relates to a preparation method of aqueous polyurethane for a middle-high-density fiberboard. The preparation method comprises the steps of synthesis of a hydrophilic polyurethane prepolymer and blending and modifying of low-molecular-weight amino resin, wherein the hydrophilic polyurethane prepolymer comprises the following components in percentage by weight: 8-15% of polyester polyol, 40-60% of isocyanate a, 1.5-6% of hydrophilic chain extender, 0.5-3% of catalyst, 10-25% of isocyanate b, 0.5-3% of amino silane coupling agent and 4-10% of neutralizer. According to the aqueous polyurethane prepared by utilizing the preparation method, a -NCO group in the resin is reasonably closed; and due to the introduction of MUF (melamine-modified urea formaldehyde) resin, a microstructure of the resin is improved, the molecular weight of the aqueous polyurethane is reduced and the stability of the resin is improved. The aqueous polyurethane is synthesized by utilizing manners of inner-crosslikining and blending dual-modifying, the cost is much lower than that of the commercially available PMDI (polydiphenylmethane diisocyanate) resin, and the pressed fiberboard can meet emission loads of formaldehyde and VOC (volatile organic compounds) in export requirements of automotive trims.

Owner:DONGYING ZHENGHE WOOD IND

Preparation method for silk fibroin composite gel

The invention discloses a preparation method for silk fibroin composite gel. The preparation method comprises the following steps: conducting a dissolution treatment on silk fibroin obtained by degumming in a LiBr solution; preparing a regenerated fibroin solution through dialysis; mixing the regenerated fibroin solution with Gamma- polyglutamic acid; finally, preparing the silk fibroin composite gel under the action of a cross linking agent. The preparation method is simple in technology and short in the gelation time; the efficiency is greatly improved; the required amount of the cross linking agent is small; the safety is strong; the prepared silk fibroin composite gel is degradable and has relatively high mechanical property and stronger water absorbability, so that the silk fibroin composite gel is superior to silk fibroin composite gel prepared from other methods. The silk fibroin composite gel can be used for the fields of medicine and health, tissue engineering, environmental protection and the like; the application of the silk fibroin composite gel is broadened and a novel thought and a novel method of preparing high-strength silk fibroin composite gel are provided.

Owner:ZHEJIANG UNIV

Ethylene/alpha-olefin/non-conjugated polyene copolymer, and production process and use thereof

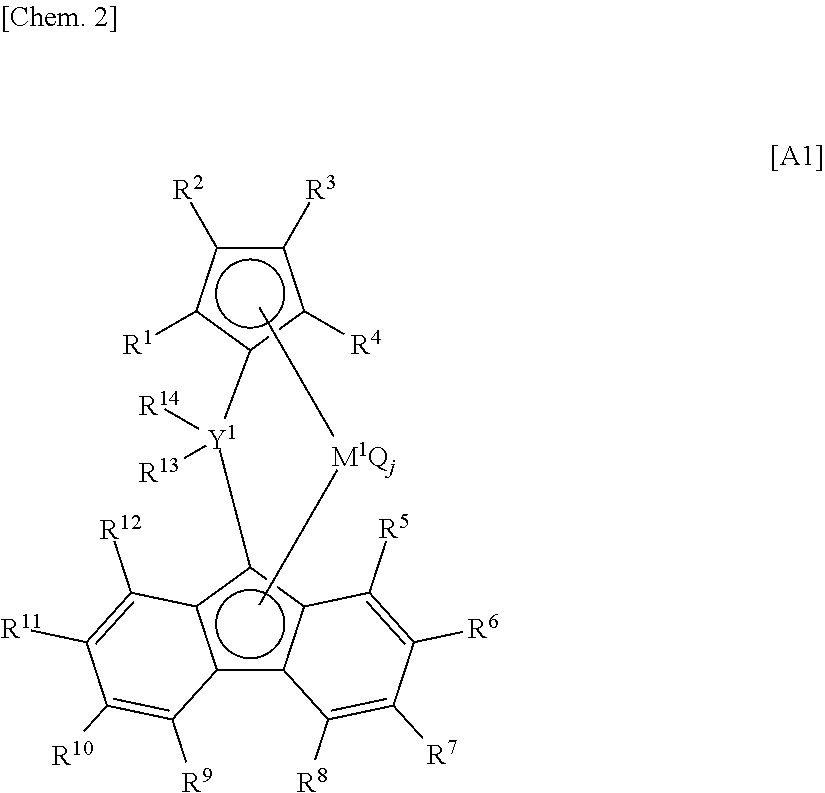

ActiveUS20160355622A1Small long-chain branch contentExcellent curing propertyPlastic/resin/waxes insulatorsSpecial tyresChemistryStructural unit

A novel ethylene / α-olefin / non-conjugated polyene copolymer comprising structural units derived from ethylene (A), an α-olefin (B) of 3 to 20 carbon atoms, and a non-conjugated polyene (C) containing intramolecularly two or more partial structures in total selected from the group consisting of structures of Formulae (I) and (II), and having a small number of long-chain branches,The novel ethylene / α-olefin / non-conjugated polyene copolymer contains a non-conjugated polyene such as VNB as a copolymerization component and a small long-chain branch content and is excellent in curing properties in the case of crosslinking using peroxide; and a process for producing the ethylene / α-olefin / non-conjugated polyene copolymer, and a use thereof are provided.

Owner:MITSUI CHEM INC

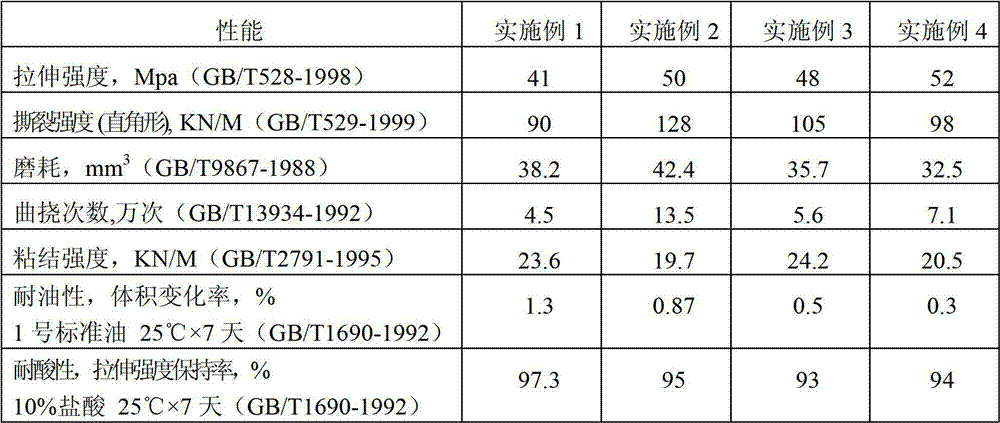

Metal composite delivery pipe with polyurethane elastomer lining and manufacturing method and application of metal composite delivery pipe

ActiveCN102814888AHigh bonding strengthImprove adhesionRigid pipesPolyurethane elastomerVulcanization

The invention discloses a metal composite delivery pipe with a polyurethane elastomer lining and a manufacturing method and application of the metal composite delivery pipe. Low-polymer polyhydric alcohol and isocyanate are used as raw materials, and the quantities of the raw materials and the reaction temperature are controlled, so that a prepared polyurethane elastomer is good in toughness and high in strength, and adhesion strength of the prepared polyurethane elastomer and metal is high; resin type adhesive is adopted, the polyurethane lining is tightly combined with the inner surface of a metal pipe by a centrifugal casting process and control of the rotational speed and the casting speed for centrifugal casting, and the adhesion strength is high; and adhesion between the polyurethane lining and the inner surface of the metal pipe is further strengthened by improving a crosslinking effect of the polyurethane lining via after-vulcanization. The manufacturing method of the metal composite delivery pipe with the polyurethane elastomer liner is simple, is low in cost and can be applied to industrial production. The manufactured metal composite delivery pipe with the polyurethane elastomer lining cannot be corroded or abraded by delivered media, and the service life of the delivery pipe is prolonged.

Owner:东莞华工佛塑新材料有限公司

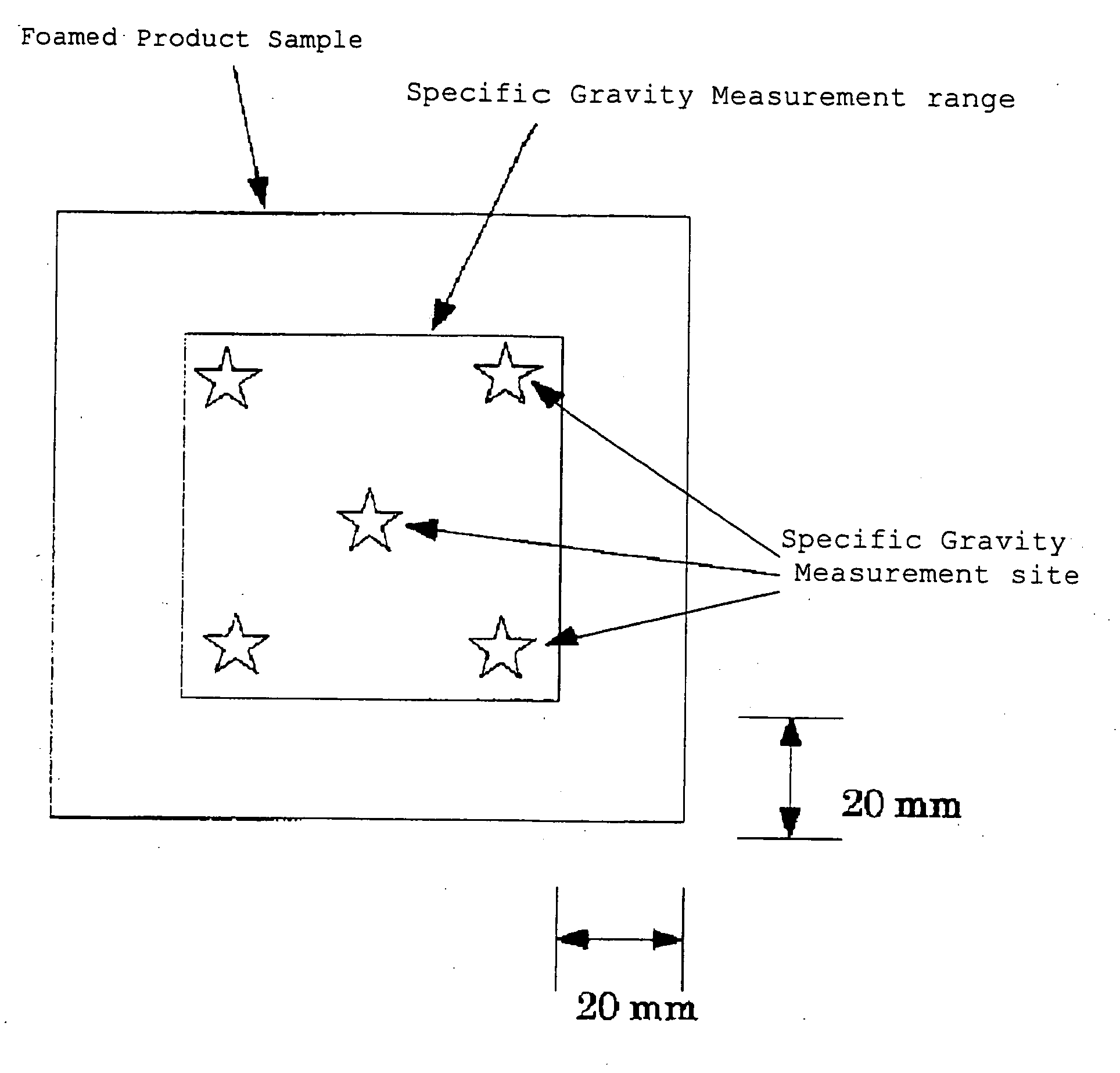

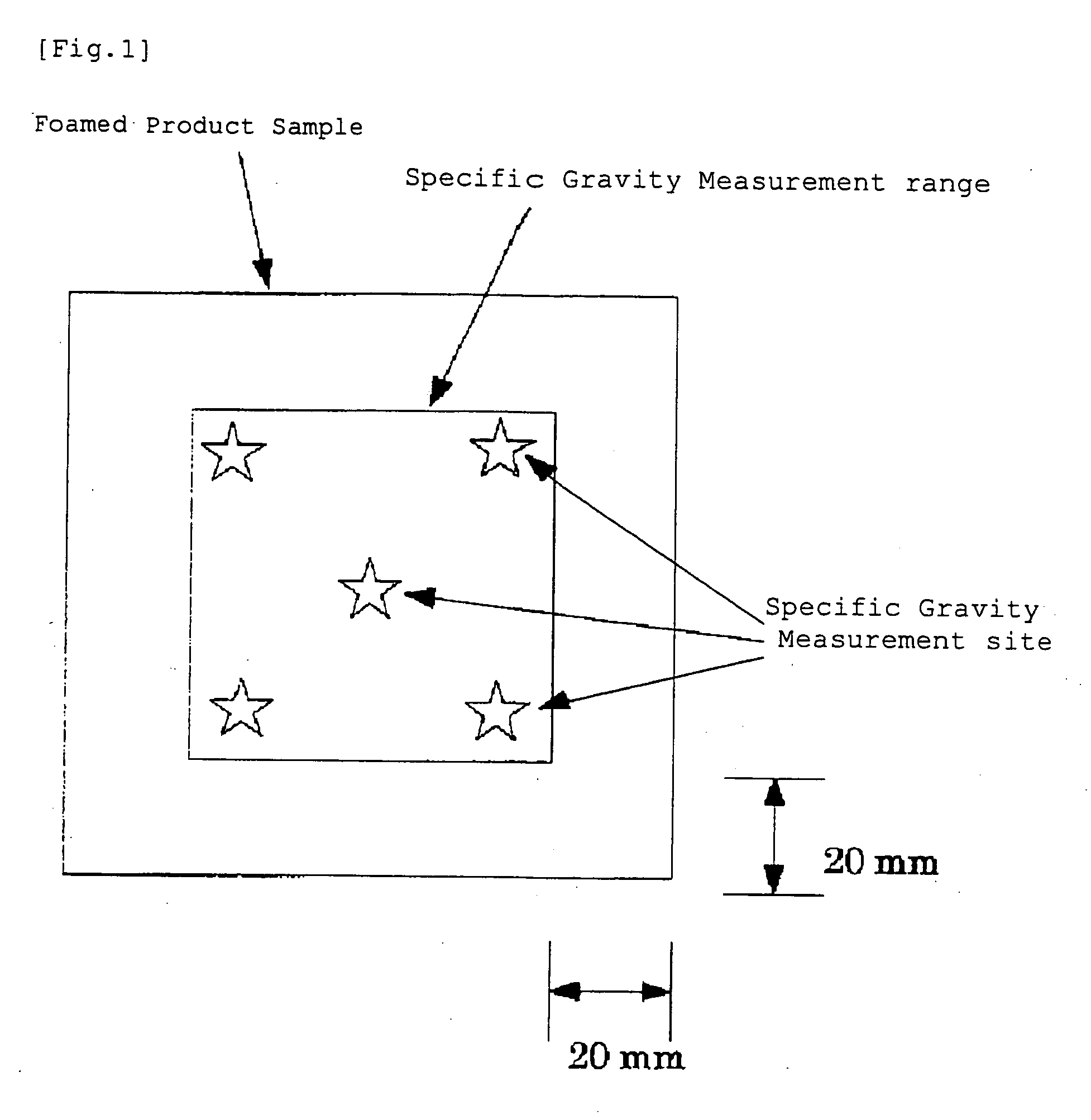

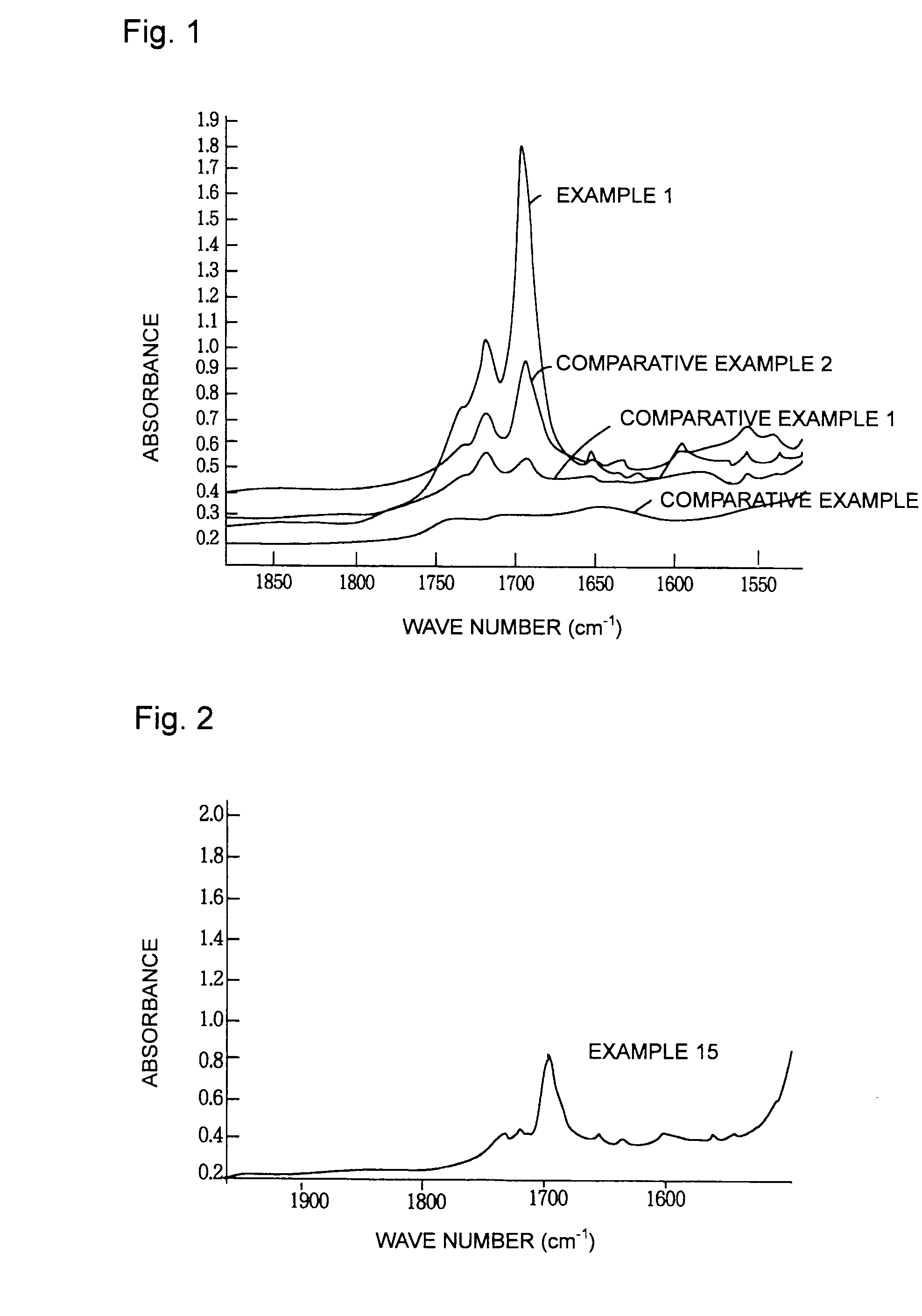

Ethylenic copolymer, composition containing the copolymer and use thereof

ActiveUS8329848B2High vinyl-group contentGood cross-linking effectDomestic footwearFootwearAlpha-olefinCompression set

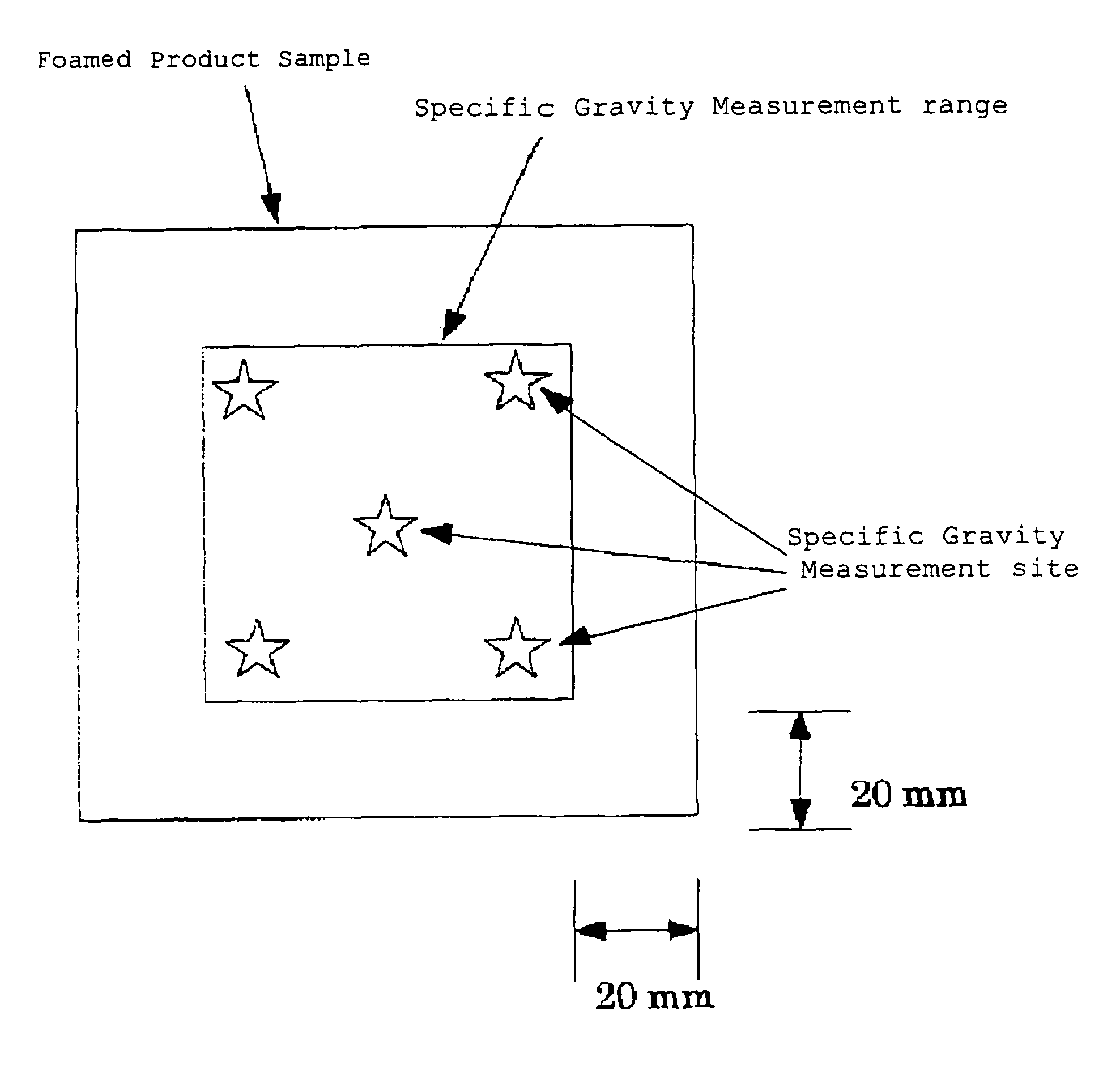

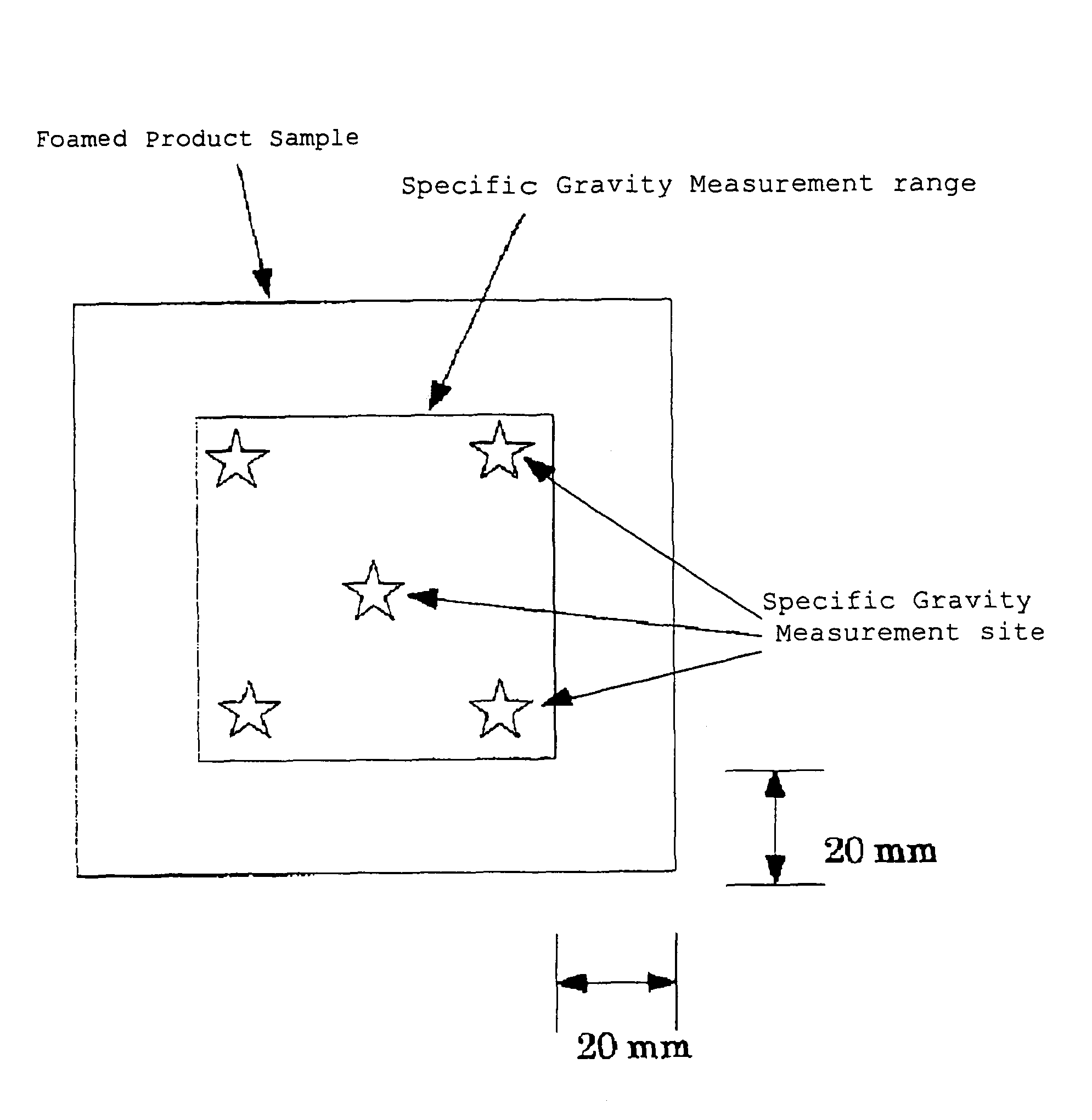

An object of the present invention is to provide a novel ethylene-α-olefin copolymer excellent in crosslinking properties; a foamed molded article having a low specific gravity and a low compression set (CS) and a composition capable of producing the foamed molded article, footwear parts composed of a foamed molded article; an ethylenic copolymer composition excellent in balance between weather resistance and mechanical strength, and an electric wire coating material and an electric wire sheath using the ethylenic copolymer composition; and a thermoplastic elastomer capable of producing a molded article excellent in balance between mechanical strength and toughness. The ethylenic copolymer (A) of the present invention is a copolymer composed of only ethylene and an α-olefin having 3 to 20 carbon atoms, and is characterized in that vinyl-group content (a) per 1000 carbon atoms as measured by infrared absorption spectroscopy, MFR10 / MFR2.16 (b), and the specific gravity (c) are within a specific range.

Owner:MITSUI CHEM INC

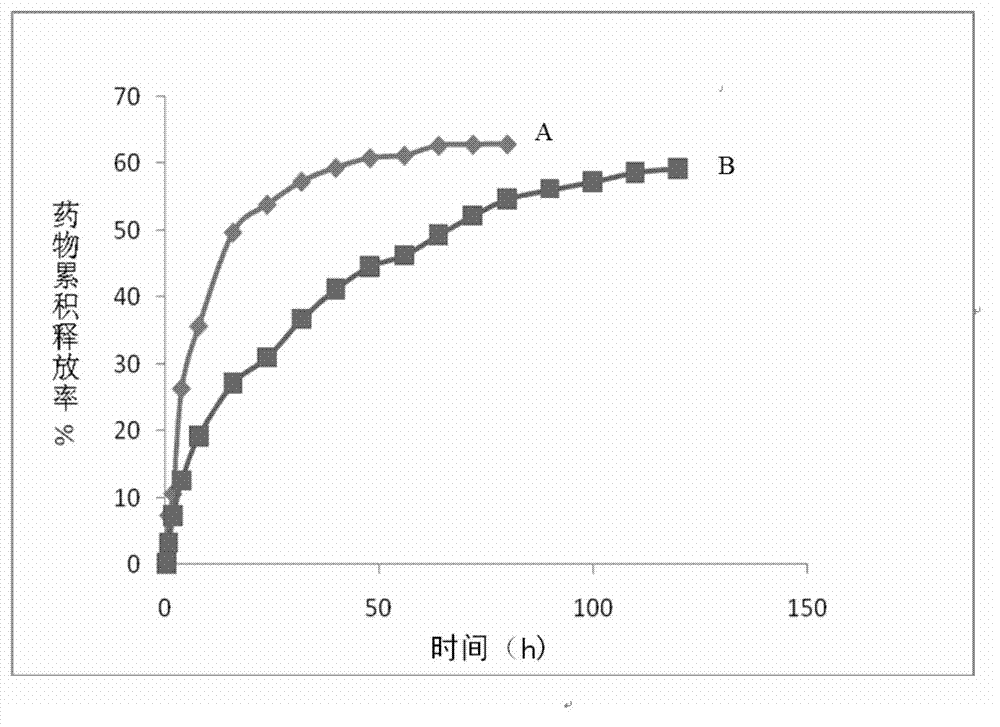

Medical sodium alginate gel microsphere and preparation method and application thereof

InactiveCN103239730AControl releaseReduce erosionAntibacterial agentsPharmaceutical non-active ingredientsWater insolubleMicrosphere

The invention provides a medical sodium alginate gel microsphere and a preparation method and application of the medical sodium alginate gel microsphere. The medical sodium alginate gel microsphere consists of a composite medicine carrier and a water-insoluble medicine; the medicine is coated with the composite medicine carrier; and the composite medicine carrier is an ion crosslinking agent-sodium alginate-divalent metal ion, wherein the ion crosslinking agent is 4-aminomethylbenzoic acid or tranexamic acid. The preparation method comprises the following steps of: (1) mixing ion crosslinking agent aqueous solution with divalent metal ion solution in the same volume to obtain composite solidifying liquid; (2) dispersing medicine powder or an agent into sodium alginate aqueous solution; uniformly mixing; dropwise adding the mixture into the composite solidifying liquid obtained in step (1) through a high-voltage static droplet generating device or a syringe needle, so that the mixture drops are solidified into spheres; and (3) dehydrating gel microspheres which are washed with the distilled water; and drying at normal temperature. The medical sodium alginate gel microsphere can be used for treating tuberculosis, endocrine disease and tumor, and also can be used for treating local acute hemorrhage and chronic errhysis.

Owner:THE 309TH HOSPITAL OF CHINESE PEOPLES LIBERATION ARMY

Ethylenic copolymer, compostion containing the copolymer and use thereof

ActiveUS20090249645A1High contentLow specific gravityPlastic/resin/waxes insulatorsDomestic footwearSpecific gravityWeather resistance

An object of the present invention is to provide a novel ethylene-α-olefin copolymer excellent in crosslinking properties; a foamed molded article having a low specific gravity and a low compression set (CS) and a composition capable of producing the foamed molded article, footwear parts composed of a foamed molded article; an ethylenic copolymer composition excellent in balance between weather resistance and mechanical strength, and an electric wire coating material and an electric wire sheath using the ethylenic copolymer composition; and a thermoplastic elastomer capable of producing a molded article excellent in balance between mechanical strength and toughness. The ethylenic copolymer (A) of the present invention is a copolymer composed of only ethylene and an α-olefin having 3 to 20 carbon atoms, and is characterized in that vinyl-group content (a) per 1000 carbon atoms as measured by infrared absorption spectroscopy, MFR10 / MFR2.16 (b), and the specific gravity (c) are within a specific range.

Owner:MITSUI CHEM INC

Lightweight aggregate concrete and preparation method thereof

The invention discloses a lightweight aggregate concrete and a preparation method thereof. The lightweight aggregate concrete comprises the following components in parts by weight: 360-400 parts of cement, 55-75 parts of ore powder, 730-760 parts of sand, 460-500 parts of lightweight aggregate, 180-195 parts of water, 75-80 parts of fly ash, 6.8-11.08 parts of an additive, the additive comprises carbon fiber, a water reducer and a dispersant, wherein the carbon fiber accounts for 0.8-2.88 parts, the water reducer accounts for 5-6 parts, and the dispersant accounts for 1-2.2 parts, and the intensity of the lightweight aggregate is increased.

Owner:天津金隅混凝土有限公司

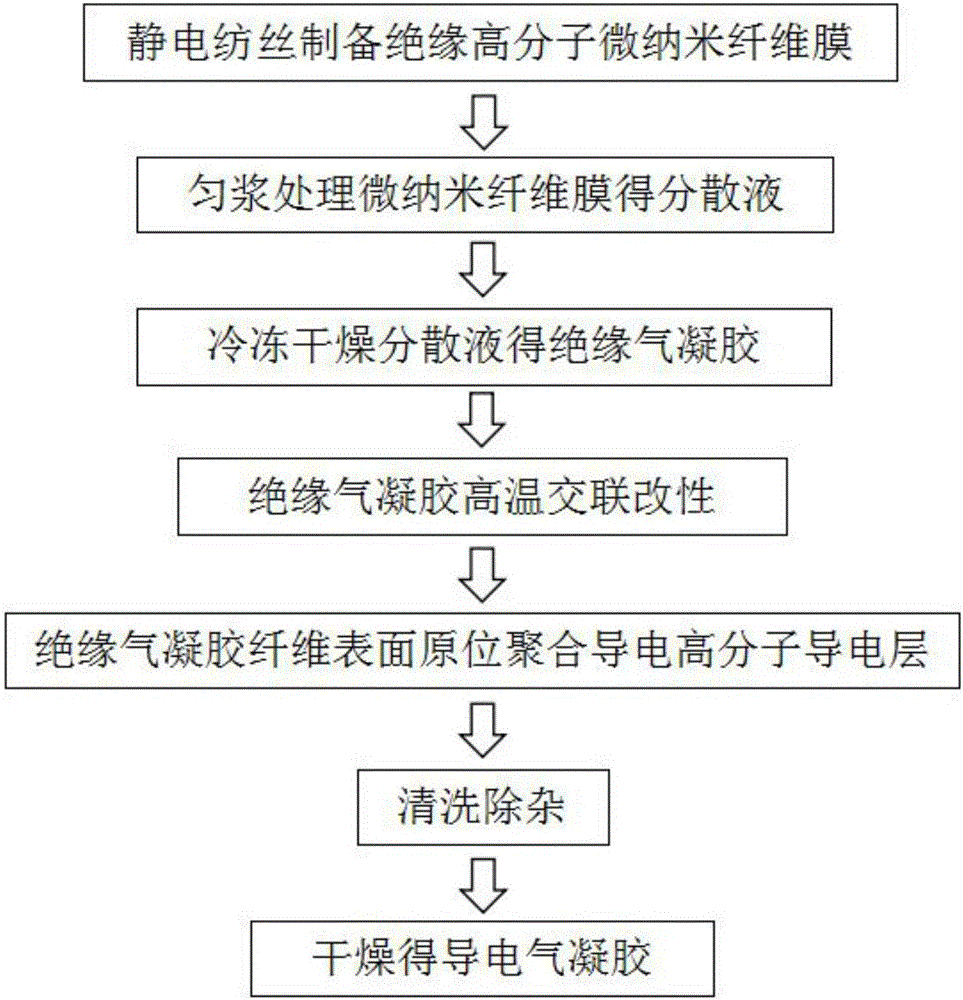

Conductive aerogel and preparation method thereof

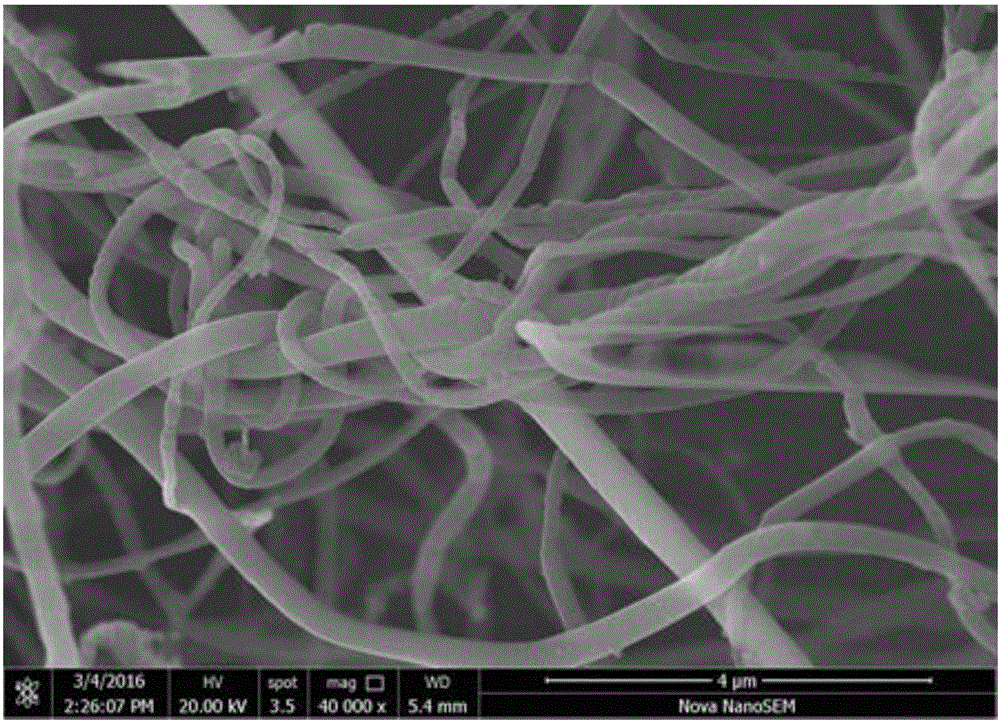

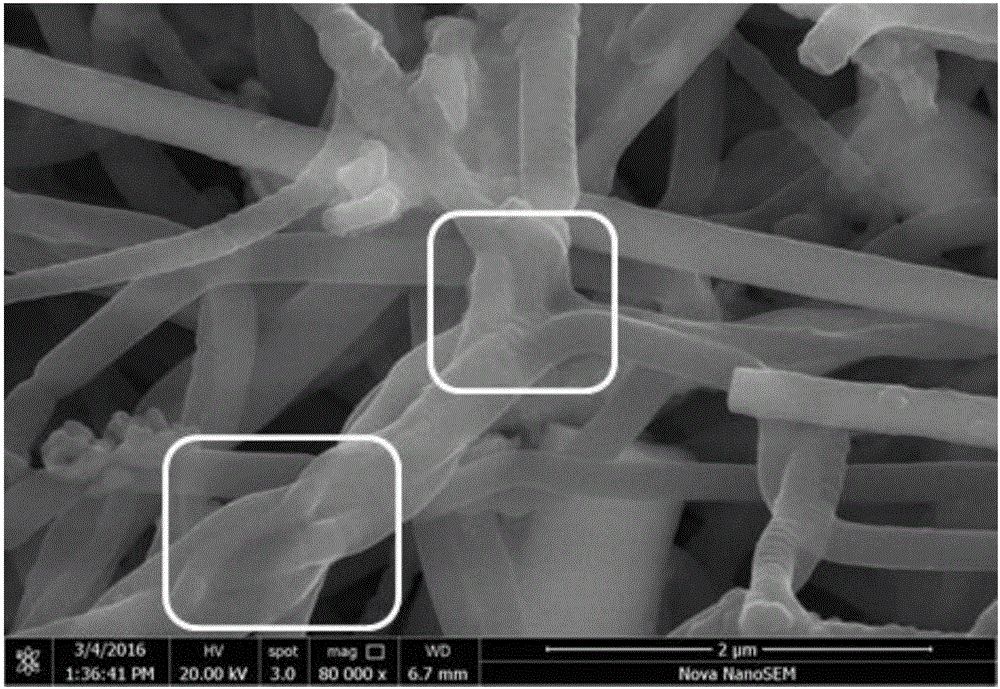

ActiveCN105820372AEasy to prepareImprove conductivityElectro-spinningNon-woven fabricsFiberElectrospinning

The invention discloses conductive aerogel and a preparation method thereof. Coaxial composite micro-nanofibers are adopted as fibers for preparing the aerogel, an insulated macromolecular micro-nanofiber prepared through electrostatic spinning serves as the axis of the coaxial composite micro-nanofibers, and the outer surface of the insulated macromolecular micro-nanofiber is coated with a conductive layer through an in-situ polymerization reaction of a conductive polymer material. The conductive aerogel has the good conductivity, the preparation method of the aerogel is simple, has the universality and is suitable for large-scale preparation, and the types of the conductive aerogel can be greatly increased through the preparation method.

Owner:QINGDAO UNIV

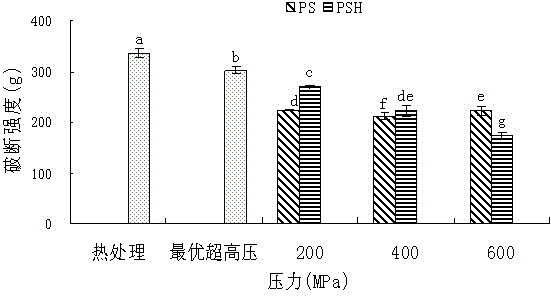

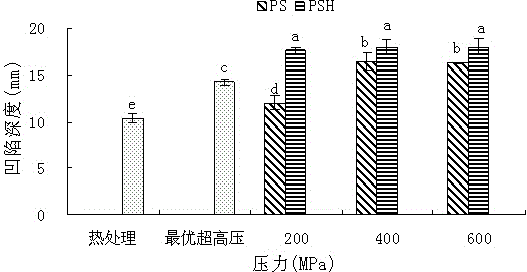

Low-protein noodles and preparation method thereof

InactiveCN104397593APromote absorptionImprove population ratioFood ingredient as thickening agentFood preparationPotato starchGuar gum

The invention provides low-protein noodles and a preparation method thereof. The noodles comprises the following components in parts by weight: 50-80 parts of edible starch, 10-40 parts of pregelatinized starch, 1-30 parts of wheat powder and 1-10 parts of viscosity-enhanced polysaccharide, wherein the edible starch is one or multiple of wheat starch, corn starch, potato starch, rice starch and cassava starch; the protein content of the edible starch is 0.3-0.6 percent; the wheat powder is low-gluten wheat powder, intermediate-gluten wheat powder and high-gluten wheat powder; the pregelatinized starch is potato pregelatinized starch or cassava pregelatinized starch; the viscosity-enhanced polysaccharide is formed by compounding guar gum and pectin according to the mass ratio of 1 to 1. The noodles are prepared by performing powder mixing, flouring, curing, forming, cold-air drying, hot-air drying and air cooling and can be used for inhibiting generation of necrotic substances in the intestinal tract and growth of harmful germs, promoting intestinal and stomach peristalsis and enhancing the intestines and stomach digestive function.

Owner:中恩(天津)营养科技有限公司

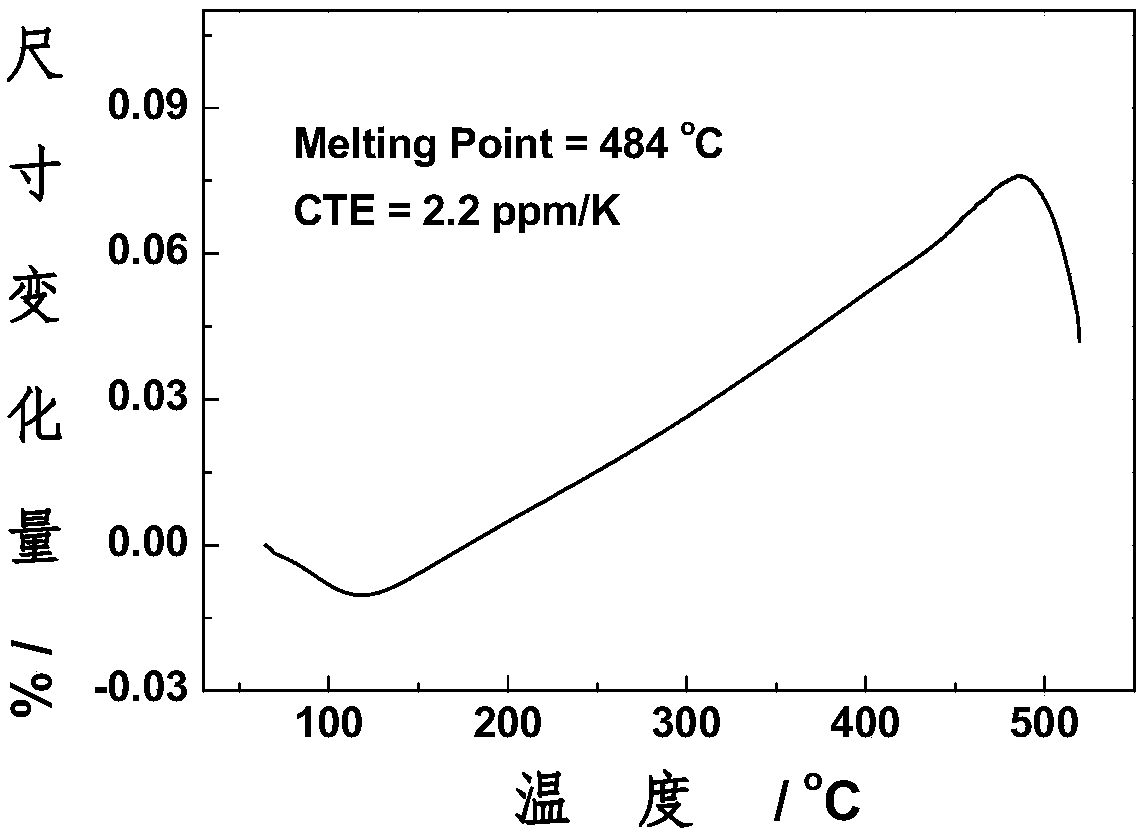

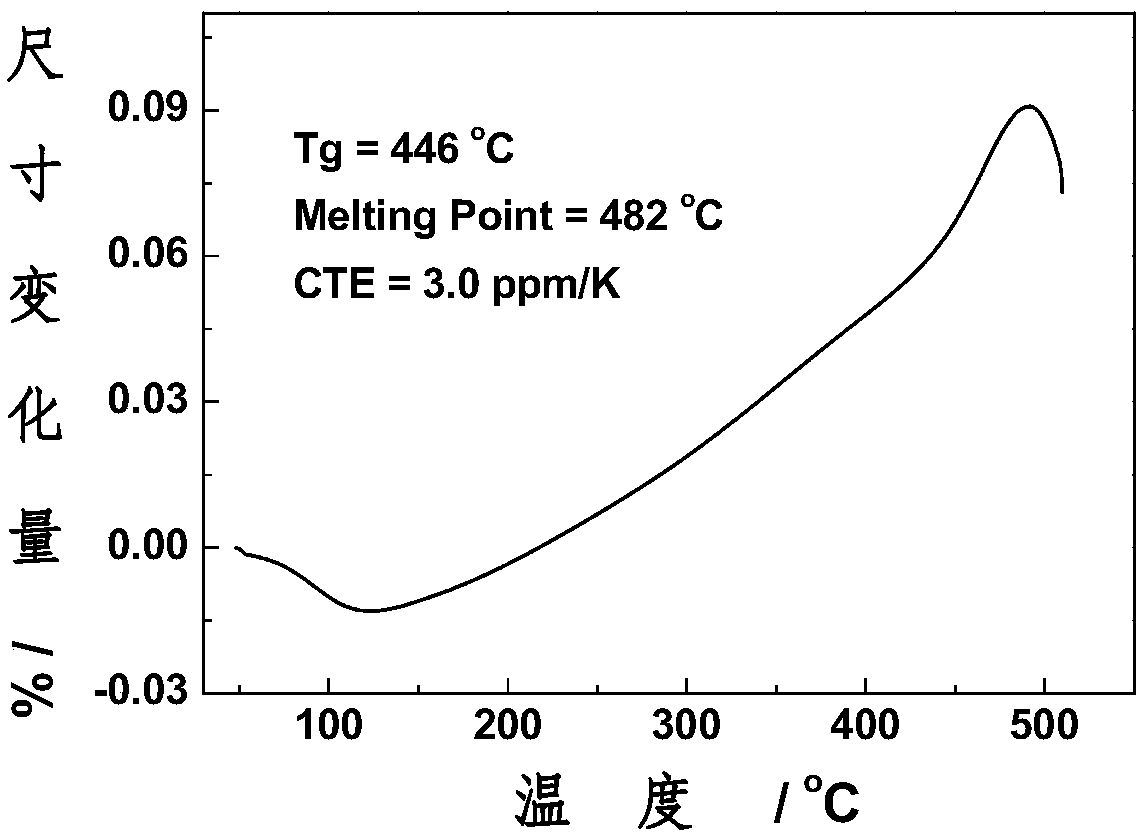

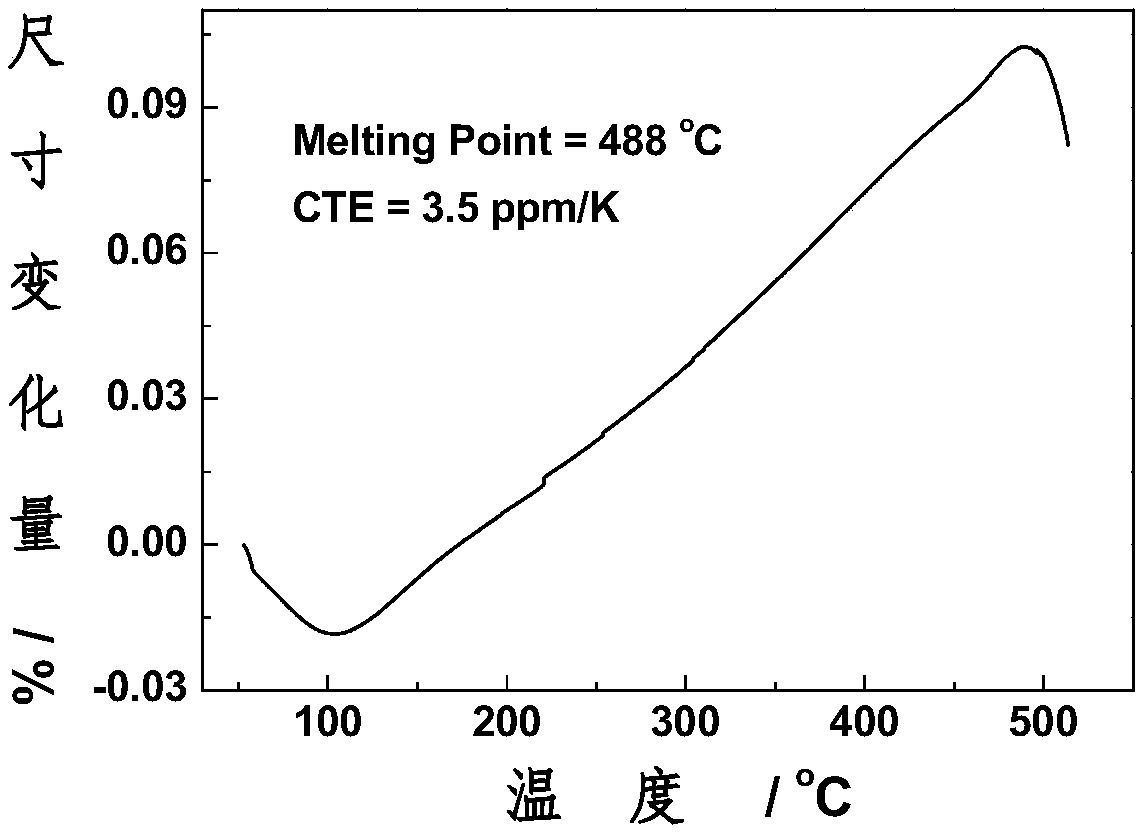

Thermosetting polyimide with high glass transition temperature and high heat resistance, and preparation method thereof

The invention discloses a thermosetting polyimide with a high glass transition temperature and a high heat resistance, and a preparation method thereof. An alkynyl anhydride compound is introduced into a PI molecular chain, and a crosslinking reaction of an alkynyl functional group is carried out to obtain the thermosetting polyimide having a network crosslinked structure. The polymerization process of a polyimide precursor and separation of an imidization process and a crosslinking process are controlled to make the network crosslinked structure of the polyimide tend to be complete. The thermosetting polyimide in the invention forms the network crosslinked structure, so the glass transition temperature is high, and even a significant glass transition process disappears; the heat resistance is improved; and the CTE is also kept close to that of the glass. The thermosetting polyimide with the high glass transition temperature and the high heat resistance in the invention keeps the performances of a film stable in the high-temperature processing process, meets the requirements of a flexible OLED panel product for a flexible substrate, and ensures the application in the OLED panel.

Owner:HANGZHOU FIRST ELECTRONIC MATERIAL CO LTD

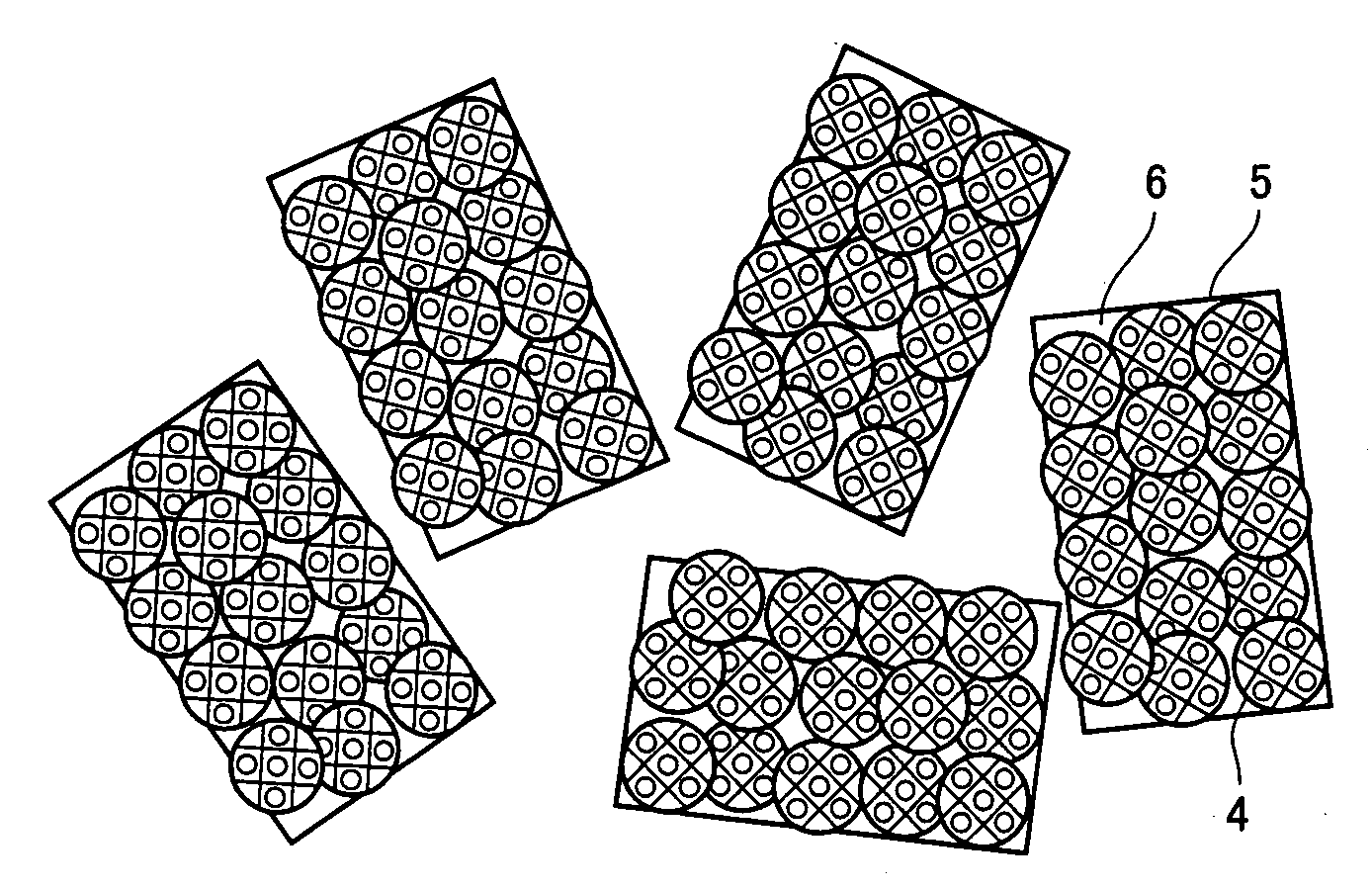

Molding material, molded part, and method for manufacturing them

InactiveUS20080036119A1High affinityGood mixing propertiesFilament/thread formingWood working apparatusCross-linkShell molding

A method for manufacturing a molded part with an improved convenience and a high degree of efficiency in molding is provided, the molded part containing a biodegradable resin composite, which has the heat resistance in a wide temperature range and which is provided with the flexibility and the elongation in accordance with the use. A kneaded product of a biodegradable resin component and a cross-linkable monomer is prepared. The biodegradable resin component is cross-linked and ground to prepare a biodegradable resin cross-linking product powder. An impregnant at a temperature of 60° C. or higher, and lower than or equal to the melting point or degradation temperature of the biodegradable resin component is impregnated to prepare a molding material composed of a biodegradable resin composite powder. The molding material is heated to a temperature higher than or equal to the melting point of the biodegradable resin component to mold into pellets.

Owner:SUMITOMO ELECTRIC FINE POLYMER INC

Fluorinated elastic copolymer, process for producing same, and crosslinked rubber

To provide a fluorinated elastic copolymer having a high crosslinkability and flowability and excellent in the compression set and the resistance to bases, and a process for its production, and a crosslinked rubber.A fluorinated elastic copolymer having repeating units (A) based on at least one monomer (a) selected from the group consisting of tetrafluoroethylene, hexafluoropropylene, vinylidene fluoride, chlorotrifluoroethylene and a perfluoro(alkyl vinyl ether), repeating units (B) based on at least one monomer (b) selected from the group consisting of vinyl crotonate, divinyl adipate and 1,4-butanediol divinyl ether and, as the case requires, repeating units (C) based on at least one monomer (c) selected from ethylene or propylene, and having iodine atoms, and a crosslinked rubber obtained by crosslinking the fluorinated elastic copolymer by an organic peroxide.

Owner:ASAHI GLASS CO LTD

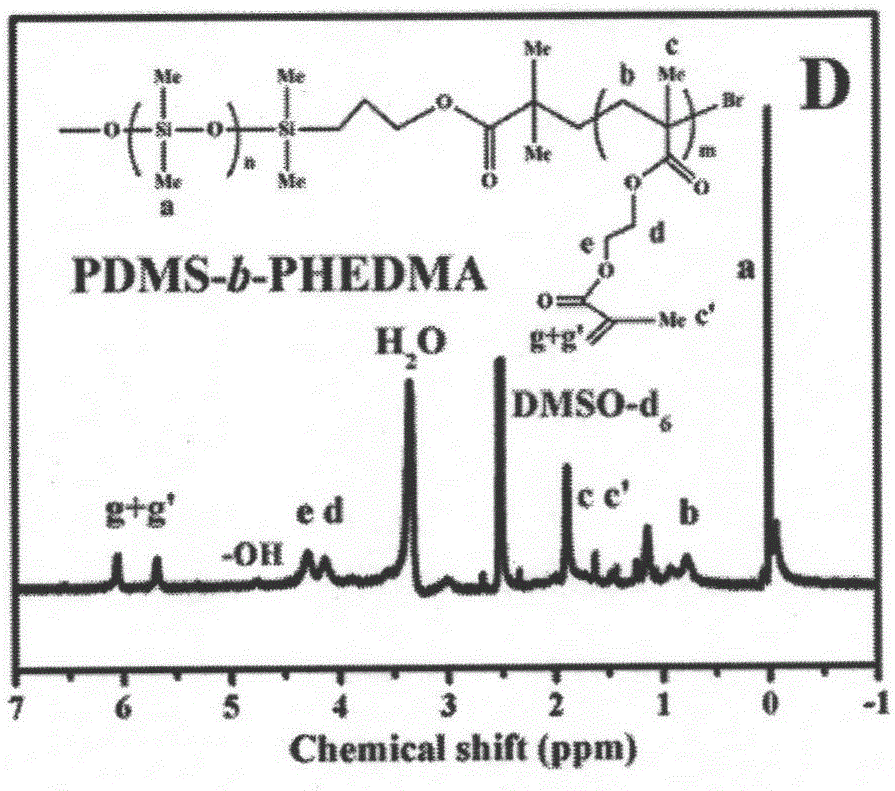

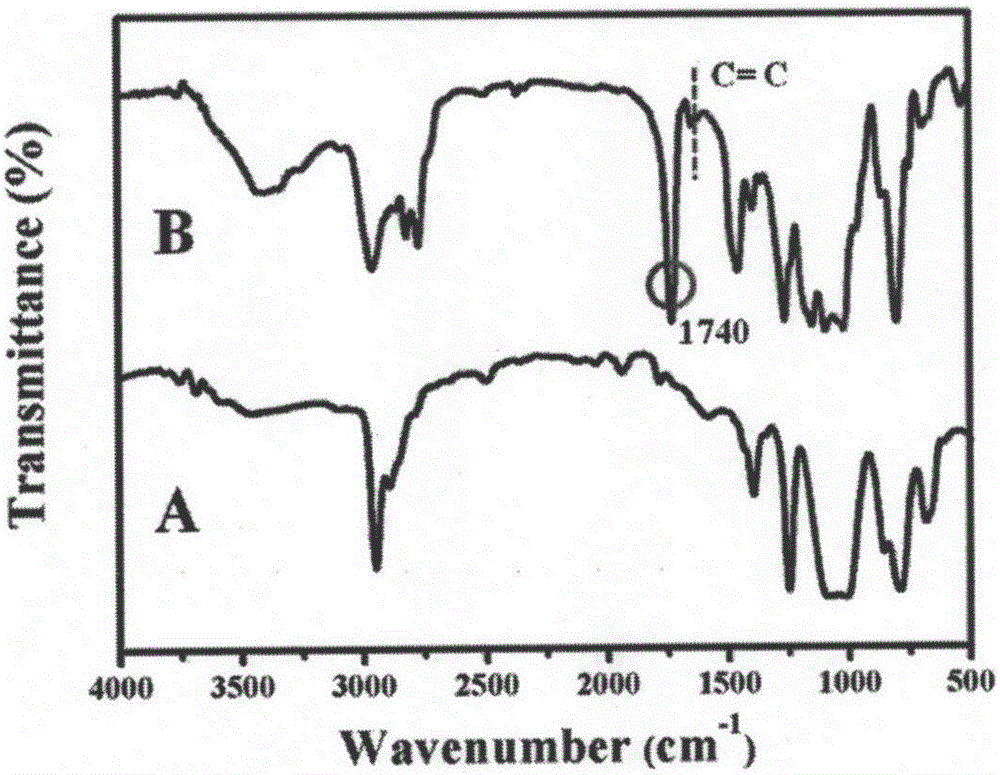

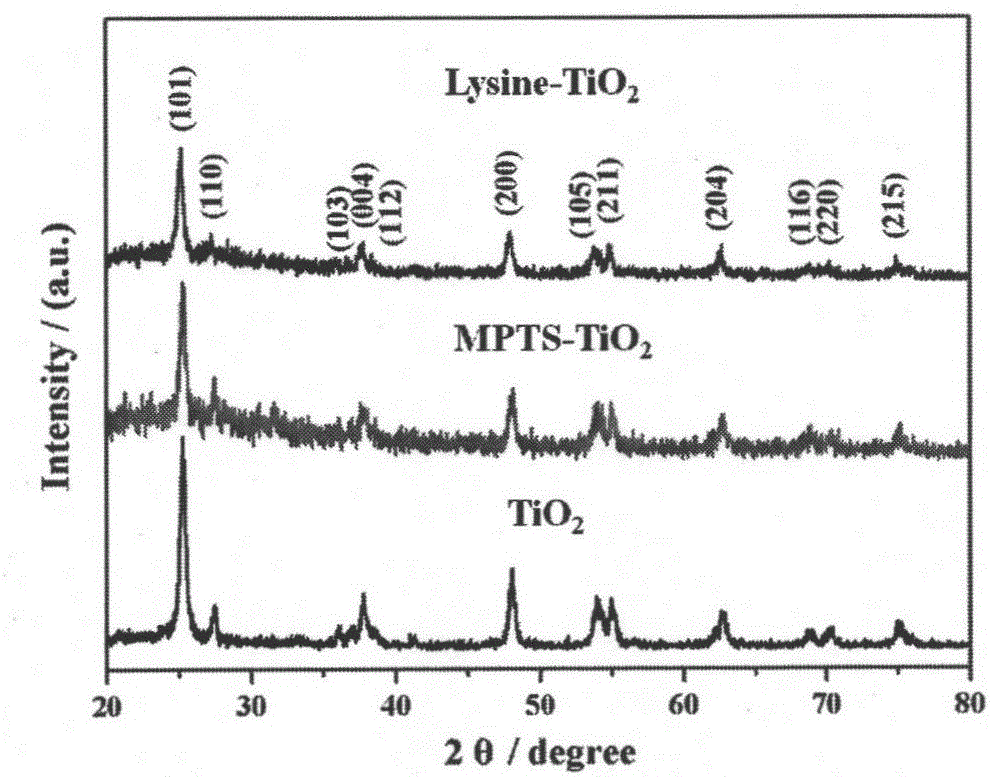

Photocatalysis self-cleaned amphiphilic network ocean anti-flouring coating and preparation method thereof

ActiveCN106497302AImprove surface energyIncrease elasticityAntifouling/underwater paintsPaints with biocidesCross-linkSilanes

The invention provides a preparation method of a photocatalysis self-cleaned amphiphilic network ocean anti-flouring coating. The preparation method is characterized by comprising the following steps: preparing an amphiphilic triblock copolymer according to an ATRP (atom-transfer radical-polymerization) method; modifying the obtained amphiphilic triblock copolymer by using an acyl halide monomer so as to obtain an amphiphilic block copolymer with unsaturated double bonds; performing ultraviolet irradiation on the amphiphilic block copolymer with unsaturated double bonds, a cross-linking agent and MPTS (methacryloxy propyl trimethoxy silane) modified nano titanium dioxide to implement a curing cross-linking reaction, so as to obtain an MPTS modified nano titanium dioxide hybridized amphiphilic copolymer network coating; sequentially putting the obtained MPTS modified nano titanium dioxide hybridized amphiphilic copolymer network coating into a trimesoyl chloride solution and a dispersing liquid of amino acid amphiphilic ion modified titanium dioxide nanoparticles, implementing reactions, and taking out, so as to obtain the photocatalysis self-cleaned amphiphilic network ocean anti-flouring coating. The photocatalysis self-cleaned amphiphilic network ocean anti-flouring coating can be applied to aspects such as ship coating and long-term anti-flouring of underwater equipment. The invention further discloses a method for preparing an amphiphilic copolymer network.

Owner:DONGHUA UNIV

Cross-linkable fluoroelastomer excellent in cross-linkability and method for its production

InactiveUS20100196709A1Excellent in cross-linkabilityExcellent productivityRubber insulatorsCellulosic plastic layered productsChemistryAliphatic alcohol

To provide a cross-linkable fluoroelastomer remarkably excellent in cross-linkability and a method for its production, a fluoroelastomer composition excellent in the cross-linked physical properties, and a cross-linked rubber.A cross-linkable fluoroelastomer having a Mooney viscosity of from 20 to 300, obtainable by heat-treating a mixture of a fluoroelastomer (A), an organic peroxide (B) and at least one additive (C) selected from the group consisting of a C12-28 higher fatty acid, a metal salt of a C12-28 higher fatty acid, an ester of a C12-28 higher fatty acid, an amide of a C12-28 higher fatty acid and a C12-28 higher aliphatic alcohol, at a temperature of from 110 to 380° C.

Owner:ASAHI GLASS CO LTD

High-performance composite cable jacket material for cables

InactiveCN104610666ALow costDelay agingInsulated cablesInsulated conductorsStearic acidChlorinated paraffins

The invention discloses a high-performance composite cable jacket material for cables. The high-performance composite cable jacket material is prepared from the following raw materials in parts by weight: 35-45 parts of ethylene propylene terpolymer, 30-50 parts of EVA resin, 30-45 parts of modified nanokaolin, 1-2 parts of dibenzothiazyl disulfide, 1.5-2.5 parts of zinc oxide, 1-3 parts of zinc dimethyldithiocarbamate, 1-2 parts of anti-aging agent ODA, 45-55 parts of high abrasion furnace black, 25-35 parts of calcined clay, 20-30 parts of nano calcium carbonate, 1-1.8 parts of dioctyl phthalate, 1-3 parts of stearic acid, 0.5-1.5 parts of chlorinated paraffin, 2-4 parts of solid calcium-zinc stabilizer and 1-2.5 parts of anti-aging agent RD. The high-performance composite cable jacket material for cables disclosed by the invention has good ageing resistance, good mechanical properties and low cost.

Owner:ANHUI HONGYI CABLE GROUP

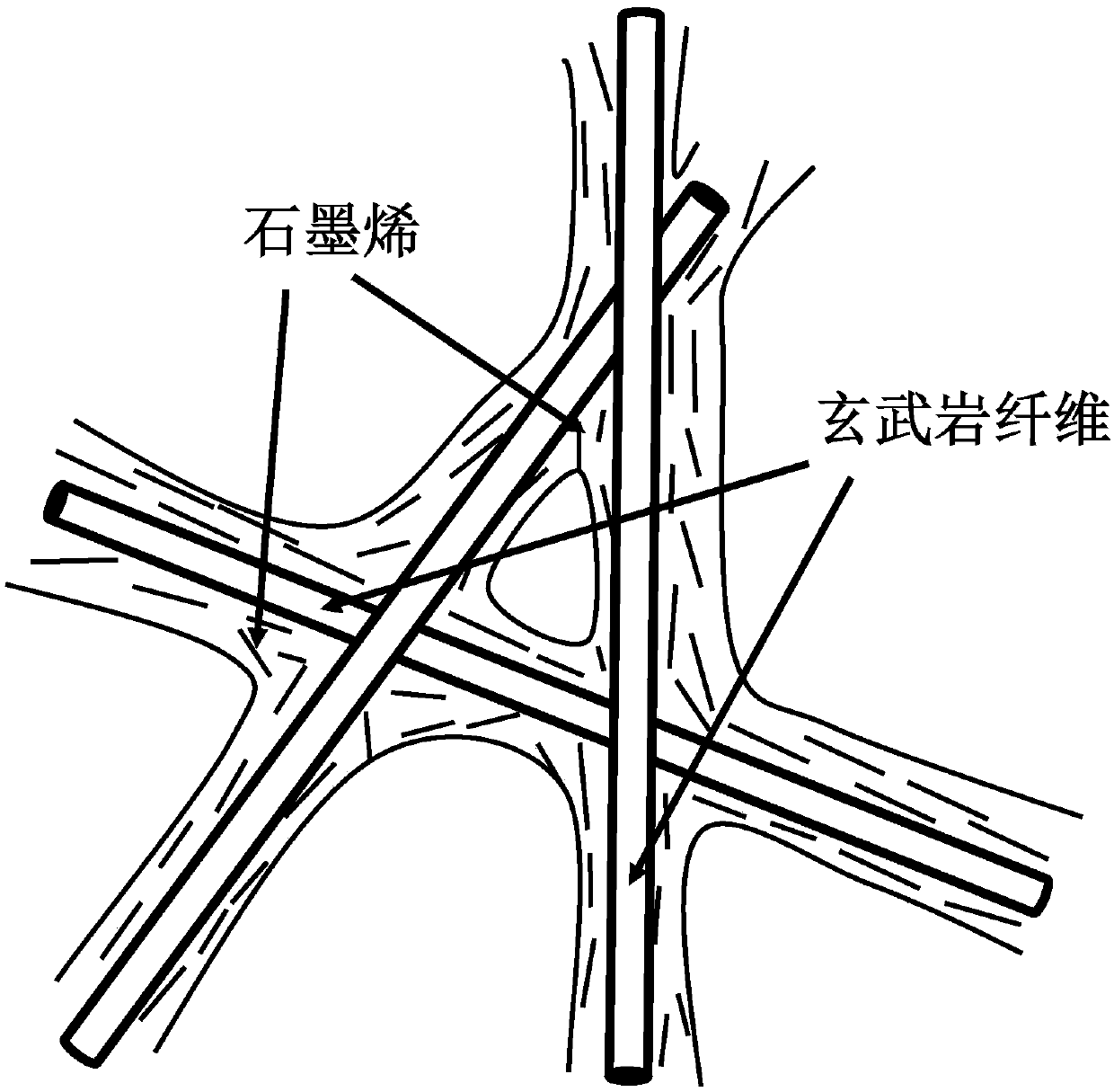

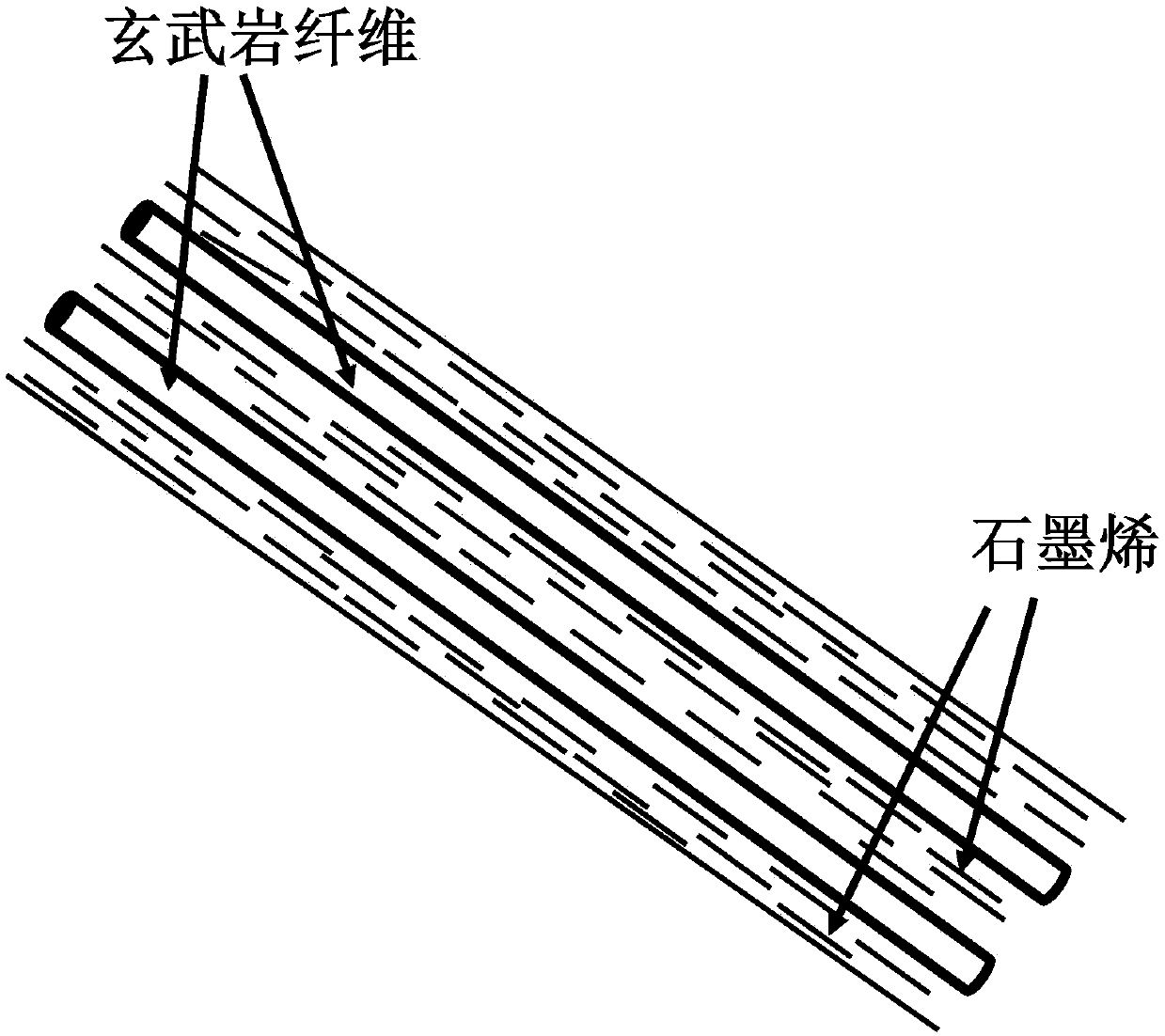

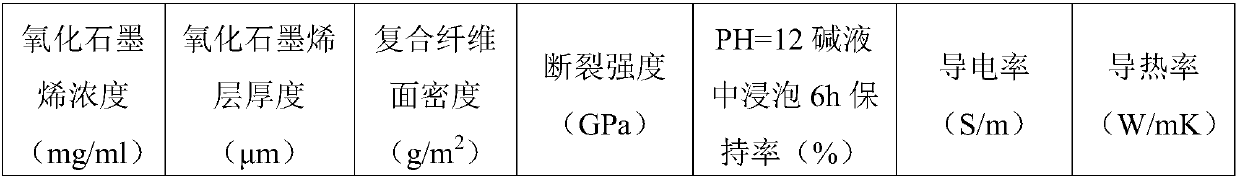

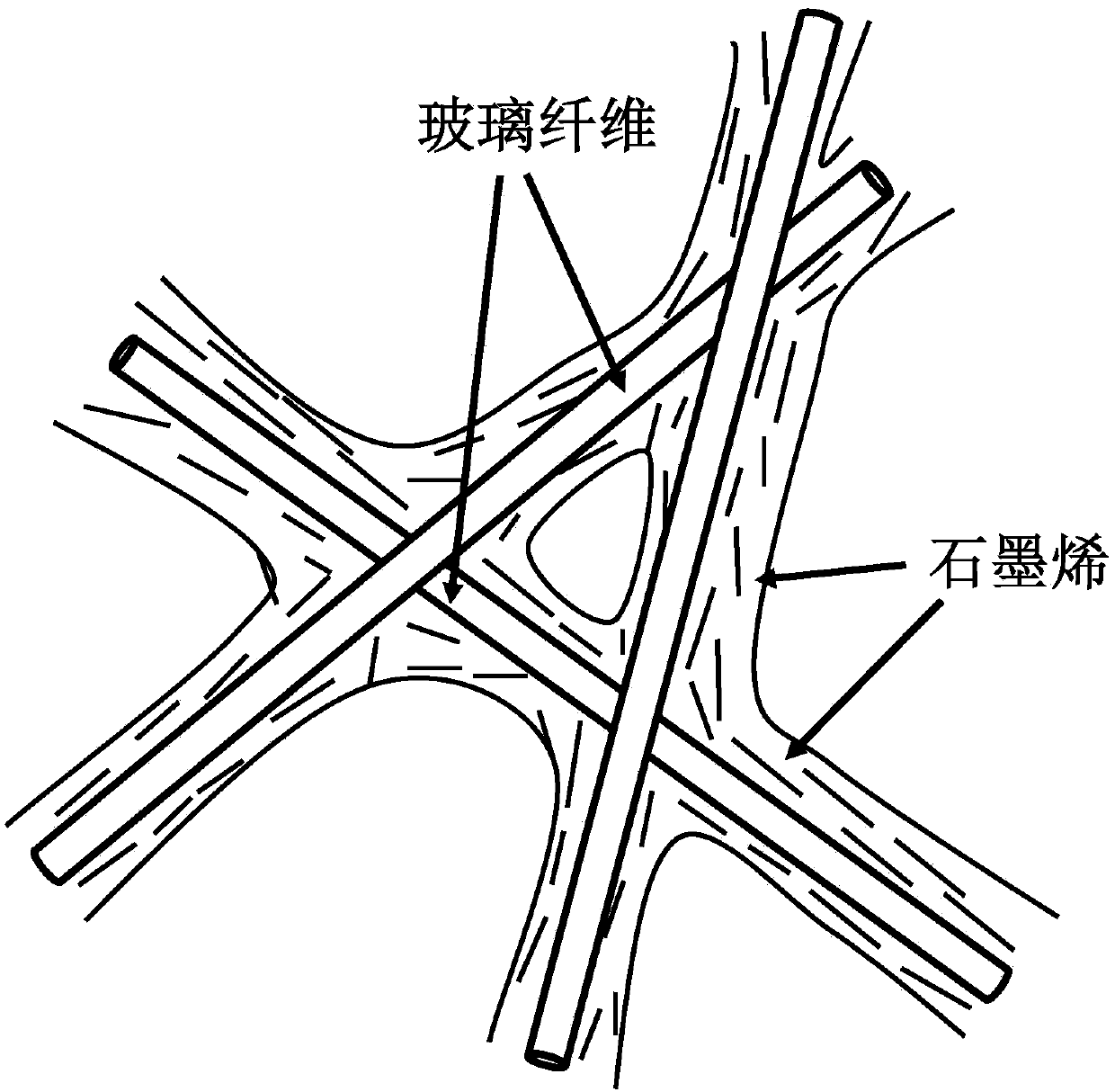

Graphene-basalt fiber composite material and preparation method thereof

InactiveCN107805886AEvenly distributedHigh interface adhesion strengthGlass making apparatusNon-woven fabricsCross-linkBasalt fiber

The invention discloses a graphene-basalt fiber composite material and a preparation method thereof. The cross-linking of the basalt fiber can be achieved by utilizing the swelling and fusion effectsof graphene oxide coating on the surface of the basalt fiber. The graphene oxide is taken as a sizing agent and a cross-linking agent, the basalt fiber can be evenly coated with the grapheme oxide, the cross-linking process is fast and easy, and the cross-linking intensity is high. After further deoxidization, a grapheme oxide cross-linking layer converts into a graphene cross-linking layer, the interaction between the basalt fibers is enhanced, the contact resistance between fibers is decreased, so that the basalt fiber demonstrates excellent mechanical property and electric and thermal conductivity, which can be used for reinforcement phase of the composite material and differentiated fiber application. The method of cross-linking the basalt fiber with the graphene is of great research value and extensive application prospect.

Owner:HANGZHOU GAOXI TECH CO LTD

Corrosion-resistant cable material and preparation method thereof

InactiveCN109233295AExcellent radiation resistance and aging resistanceGood weather resistanceRubber insulatorsCross-linkAntioxidant

The invention discloses a corrosion-resistant cable material and a preparation method thereof. The corrosion-resistant cable material is prepared from the following raw materials in parts by weight: 30-45 parts of fluorinated silicone rubber, 15-25 parts of ethylene propylene diene monomer rubber, 18-30 parts of an ethylene-vinyl acetate copolymer, 6-12 parts of glass fiber, 10-20 parts of flame retardant, 4-10 parts of an anti-aging agent, 12-25 parts of a softening agent, 1-3 parts of an antioxidant, 3-8 parts of a plasticizer and 2-6 parts of a cross-linking agent. The corrosion-resistant cable material is high in toughness and high in corrosion resistance.

Owner:国网河南省电力公司方城县供电公司

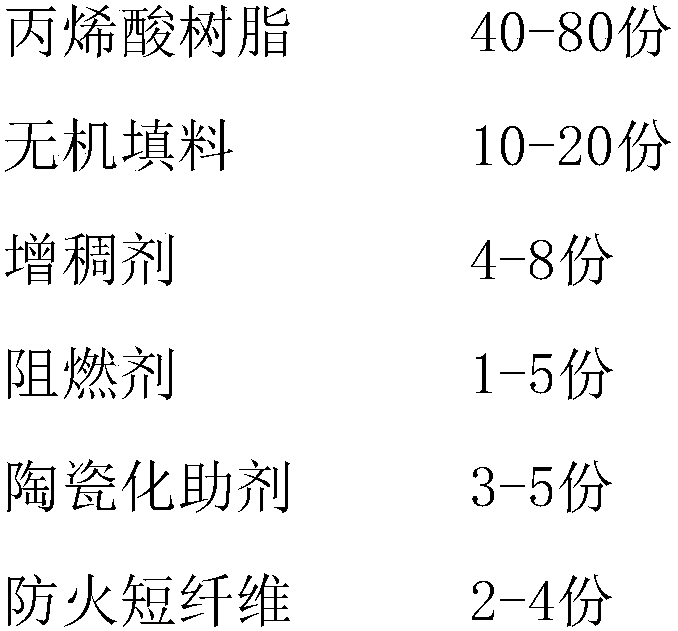

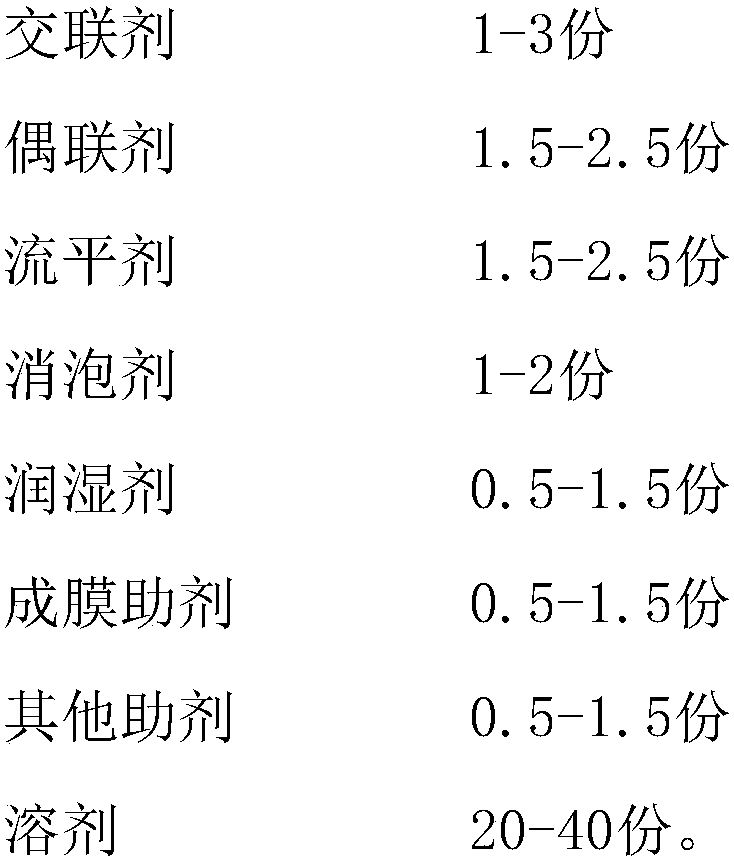

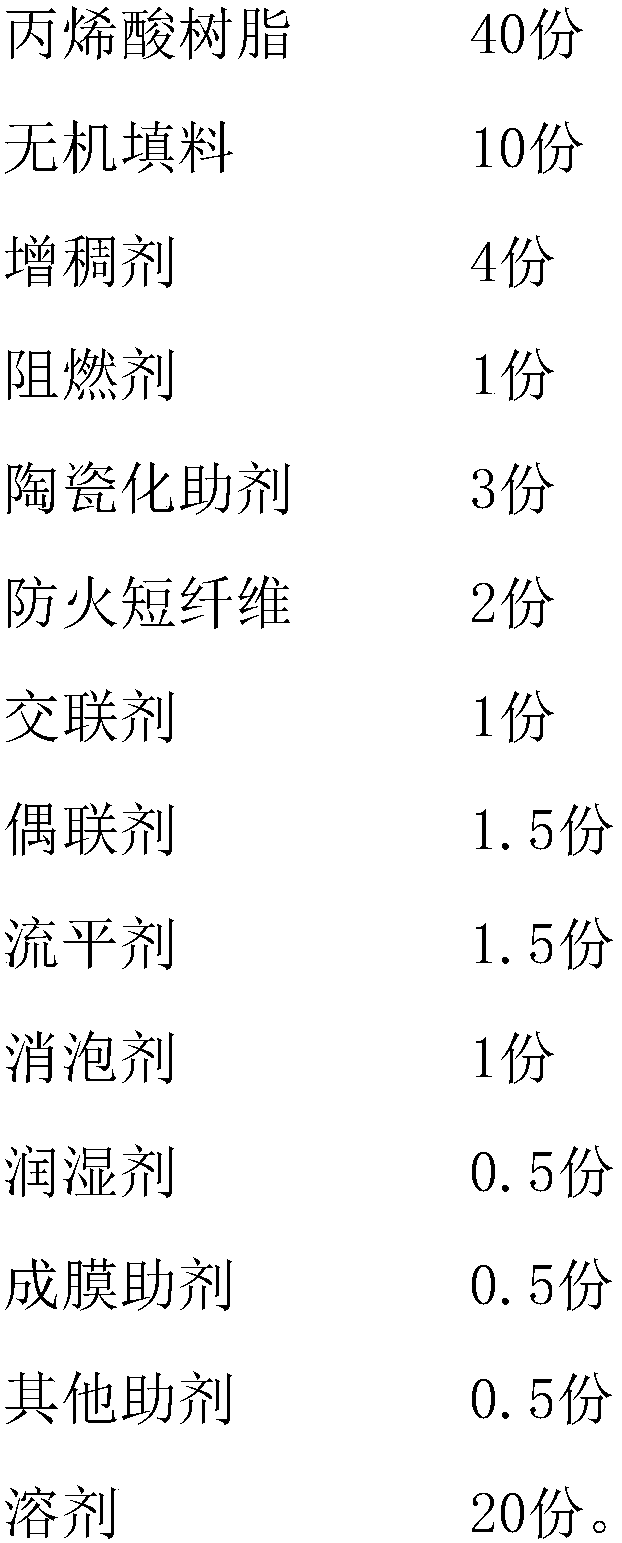

High temperature-resistant fireproof coating and preparation method thereof

ActiveCN108504257AGood weather resistanceImprove performance such as salt spray resistanceFireproof paintsEpoxy resin coatingsFiberAcrylic resin

The invention relates to the technical field of coatings, in particular to a high temperature-resistant fireproof coating and a preparation method thereof. The high temperature-resistant fireproof coating is prepared from the following raw materials in parts by weight: acrylic resin, inorganic filler, a thickener, a flame-retardant agent, a ceramic additive, fireproof short fibers, a crosslinkingagent, a coupling agent, a flatting agent, a defoaming agent, a wetting agent, a film forming additive, other additives and solvents. The high temperature-resistant fireproof coating has the advantages that high temperature can be endured, the flame-retardant property is good, the propagation of fire condition is well blocked, and the fireproof property is excellent; the effect of resisting long-time impact by 1100 DEG C hydrocarbon high-temperature fire hazard is realized; the weather-resistant property and waterproof property are realized, the shrinkage is avoided, the coating strength is high, and the surface is flat.

Owner:GUANGDONG ZHICHENG CHEM +1

High-flame retardation solar energy cell organosilicon pouring sealant and preparation method thereof

InactiveCN107384305AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkAcrylic resin

The invention relates to a high-flame retardation solar energy cell organosilicon pouring sealant and a preparation method thereof. The high-flame retardation solar energy cell organosilicon pouring sealant comprises the following raw materials in parts by weight: 40 parts of methyl phenyl vinyl silicone rubber, 20 parts of room-temperature sulfured phenylene silicone rubber, 20 parts of addition-type heat vulcanized nitrile silicone rubber, 20 parts of phosphate silicone oil, 20 parts of polyoxypropylene glycerol ether silicone oil, 10 parts of mercapto silicone oil, 5 parts of low-molecular hydroxy silicone oil, 5 parts of hydrogen-containing silicone oil with hydrogen containing amount accounting for 0.5% of mass content, 10 parts of an ethene-vinyl acetate copolymer, 10 parts of otcamethylcyclotetrasiloxane-modified acrylic resin, 7 parts of hydrogenated castor oil, 1-3 parts of an adhesion agent, 1-3 parts of a strengthening agent, 0.1-0.4 parts of a catalyst, 1-3 parts of a silicon nitrogen cross-linking agent, 0.5-2.5 parts of an inhibitor, and 1-2 parts of a flame-retardation filling material.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

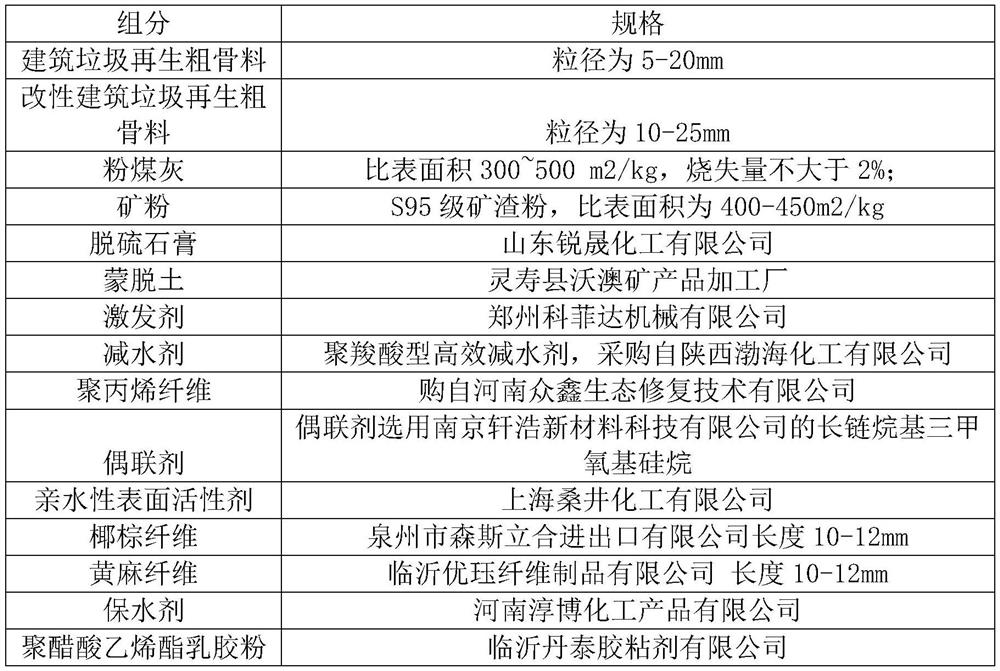

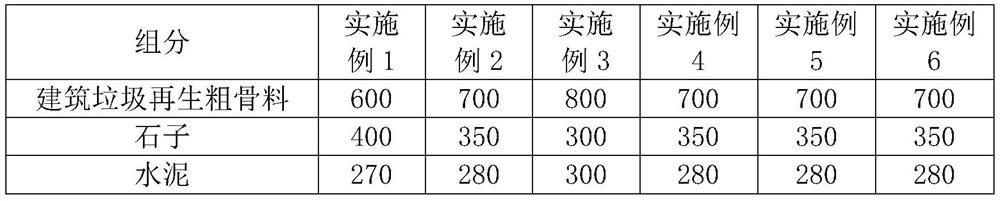

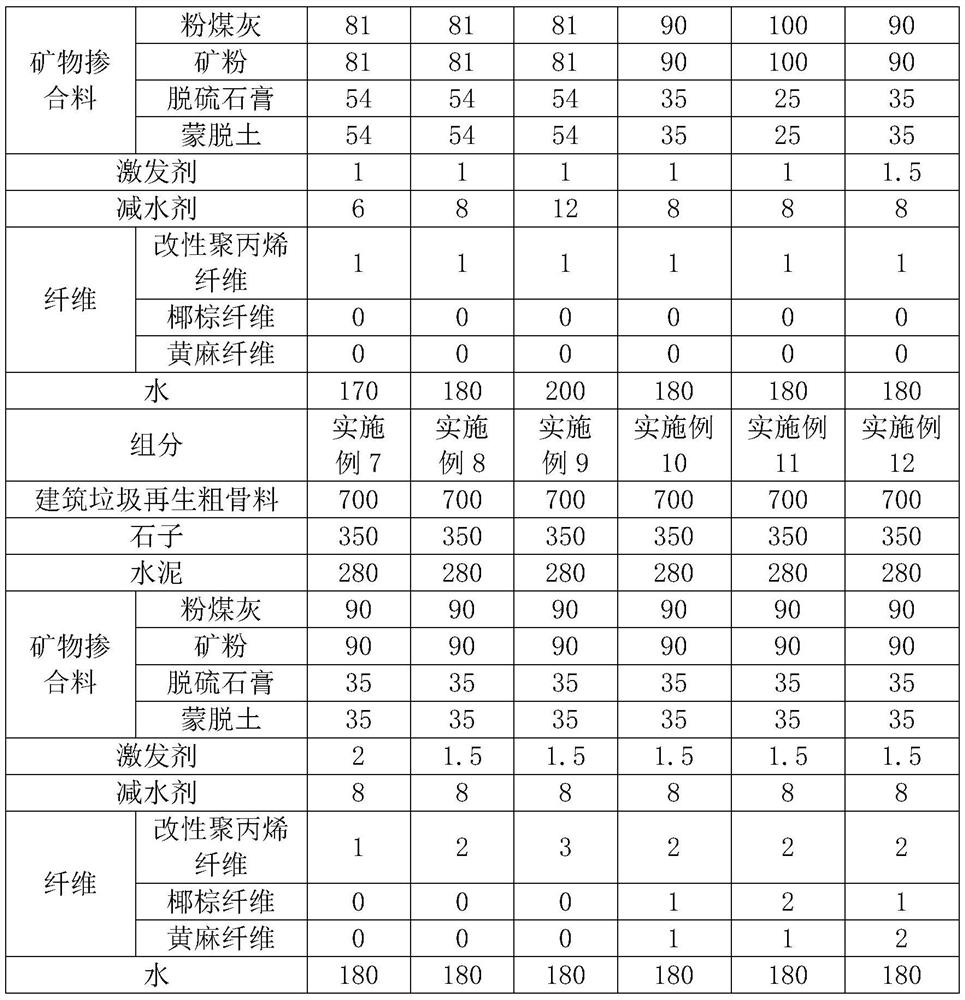

Recycled concrete and preparation method thereof

ActiveCN111943575AImprove crack resistanceGood cross-linking effectSolid waste managementWater reducerPolypropylene fiber

The invention discloses recycled concrete and a preparation method thereof. The recycled concrete comprises construction waste recycled coarse aggregate, stones, cement, a mineral admixture, an excitant, a water reducing agent, fibers and water, wherein the fibers comprise modified polypropylene fibers and plant fibers, and the modified polypropylene fiber modification process comprises the following steps: adding polypropylene fibers into an oxidant, mixing, soaking, washing to obtain a first intermediate product, adding the first intermediate product into a coating material, and uniformly mixing to obtain modified polypropylene fibers. The preparation method of the recycled concrete comprises: uniformly mixing a mineral admixture, cement and an excitant, adding water accounting for 1 / 3-1 / 2 of the total weight, and uniformly mixing to obtain a first intermediate product; uniformly mixing construction waste recycled coarse aggregate, the modified polypropylene fiber and plant fiber toobtain a second intermediate product; and uniformly mixing a water reducing agent, the first intermediate product, the second intermediate product, stones and the balance of water to obtain the recycled concrete. The anti-cracking performance of the recycled concrete is good.

Owner:陕西新意达建材产业发展有限公司

High temperature resistant coating

InactiveCN105001765AHigh temperature ablation performanceHigh hardnessFireproof paintsCarboxyl rubber coatingsPolyvinyl alcoholTemperature resistance

The invention discloses a high temperature resistant coating, which comprises the following raw materials by weight: 25-50 parts of silicone modified acrylate, 20-45 parts of epoxy acrylate resin, 2-8 parts of methyl phenyl organic siliconresin, 5-15 parts of carboxy nitrile rubber, 5-10 parts of nanographite, 3-10 parts of nano-silica, 3-10 parts of aluminum powder, 2-8 parts of zinc phosphate, 1-5 parts of magnesium hydroxide, 3-10 parts of hollow glass microspheres, 2-10 parts of expanded vermiculite, 1-5 parts of polyvinyl alcohol, 5-10 parts of polyamide resin, 1-5 parts of PESA, 5-10 parts of xylene, 1-5 parts of dilauryl thiodipropionate, 2-6 parts of aramid fiber, 2-4 parts of m-phenylenediamine, 3-8 parts of trimethylene tetramine, 1-3 parts of a coupling, 20-40 parts of water and 1-2 parts of an additive. The high temperature resistant coating provided by the invention has excellent high temperature resistance, good flame resistance and good adhesive force.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Preparation method of friction-resistant drainage pipeline

InactiveCN110790964AUniform coatingImprove drying process efficiencyPretreated surfacesAnti-corrosive paintsSilicon dioxideAntibacterial agent

The invention discloses a preparation method of a friction-resistant drainage pipeline. A formula comprises the following raw materials in parts by weight, 80-90 parts of chlorinated polyethylene, 15-20 parts of fluororubber, 8-12 parts of nano silicon dioxide, 4-9 parts of nano silicon carbide, 6-8 parts of nano calcium carbonate, 3-5 parts of nano bamboo charcoal powder, 6-10 parts of glass fiber, 1-2 parts of titanate coupling agent, 2-3 parts of an antibacterial agent, 3-5 parts of a plasticizer, 1-3 parts of an antioxidant and 1-3 parts of a light stabilizer. Nano silicon dioxide, nano silicon carbide and nano calcium carbonate are used as mixed auxiliary materials for preparing the drainage pipeline, so that polymer material strength can be increased; the nano bamboo charcoal powderis added in drainage pipeline material preparation process, the nano bamboo charcoal powder and the antibacterial agent are combined to improve the antibacterial property of the pipeline material, thedrainage pipeline corrosion resistance is improved further, and drainage pipeline service life is prolonged.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

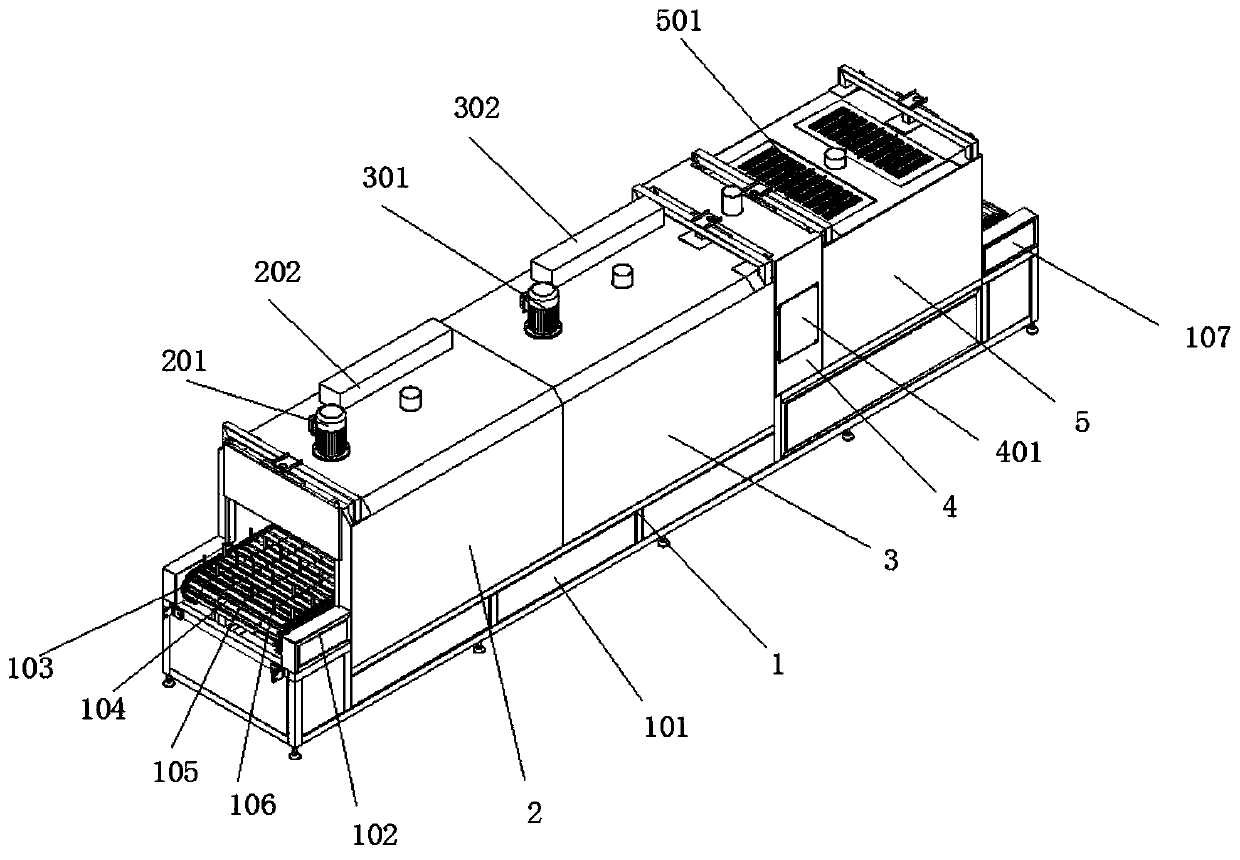

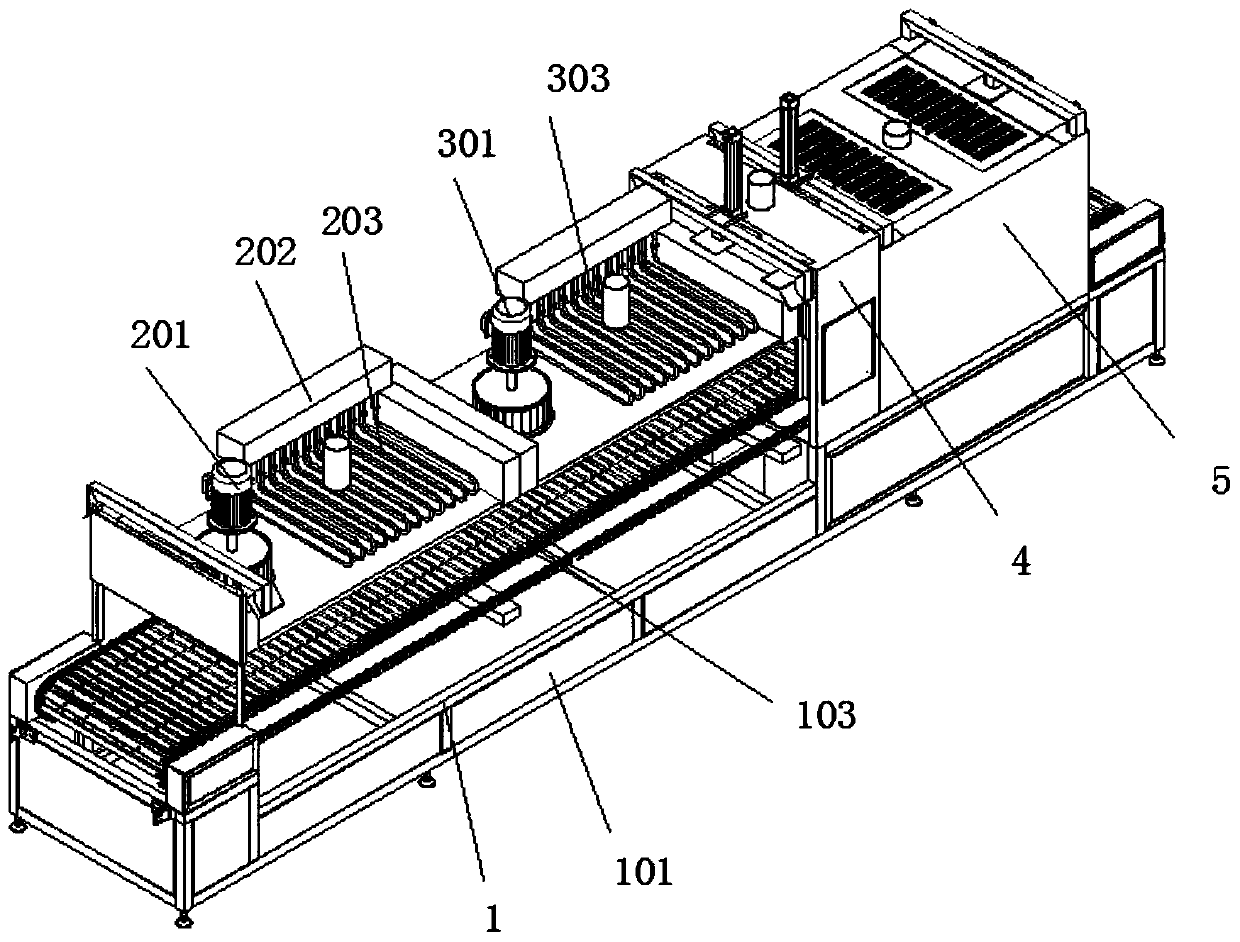

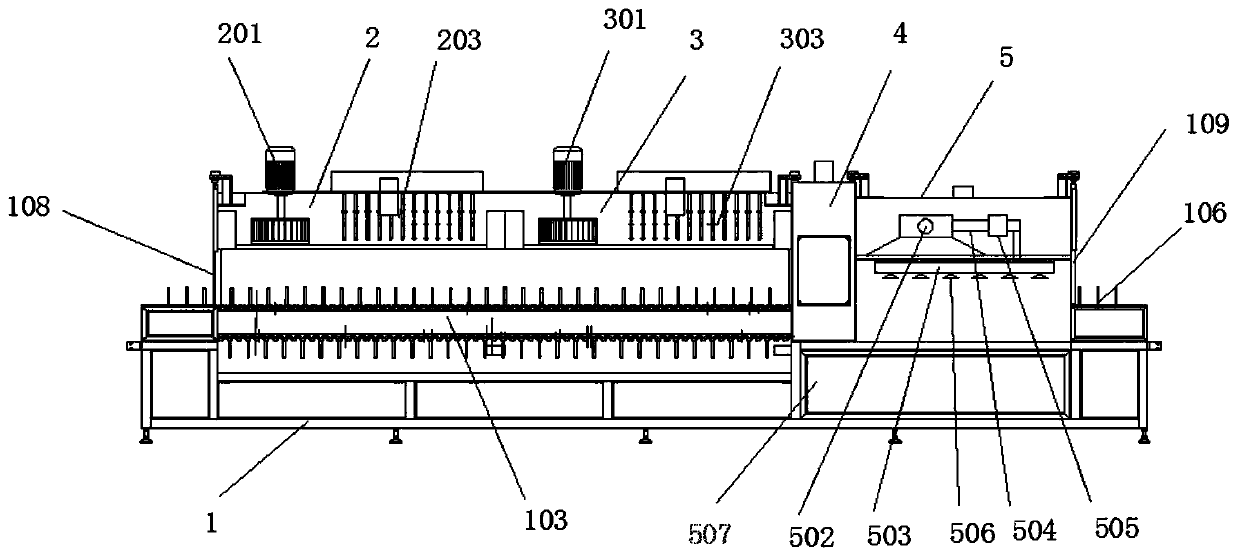

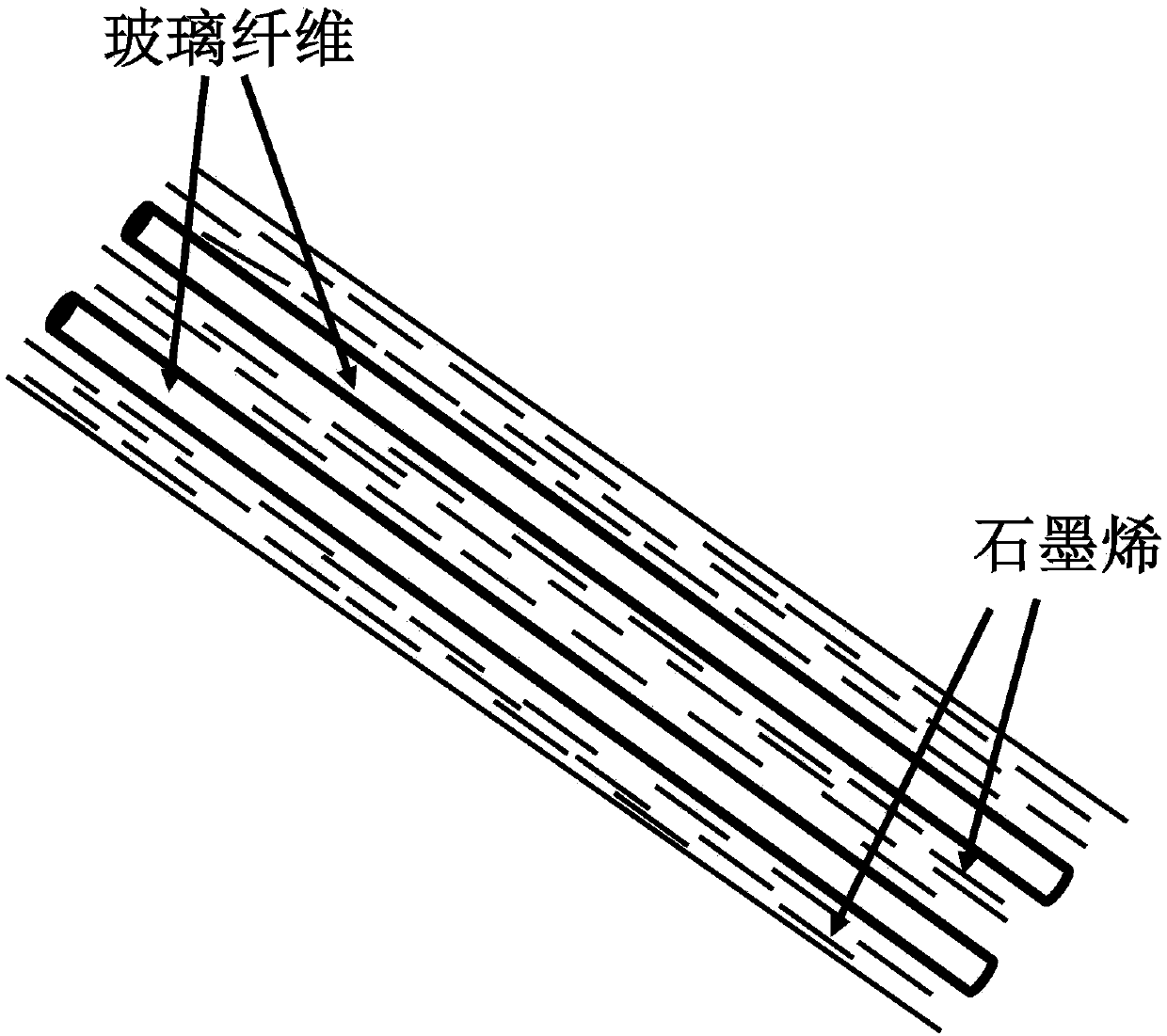

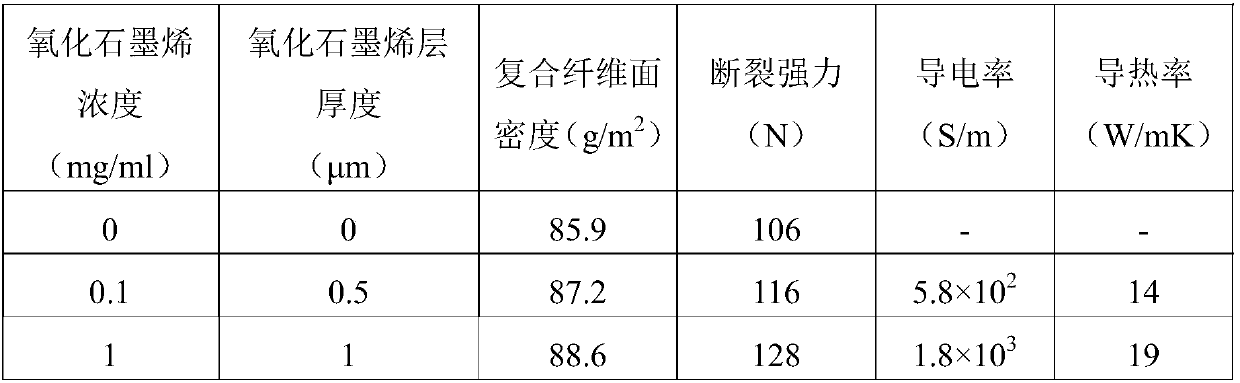

Graphene-glass fiber composite material and preparation method thereof

InactiveCN107761249AEvenly distributedHigh interface adhesion strengthGlass making apparatusNon-woven fabricsFiberGlass fiber

The invention discloses a graphene-glass fiber composite material and a preparation method thereof. Crosslinking of glass fibers can be realized by means of the swelling and fusing actions of grapheneoxide coatings on the surfaces of the glass fibers. Graphene oxide is taken as a sizing agent as well as a crosslinking agent with which the glass fibers can be coated uniformly, the crosslinking process is rapid and easy, and high crosslinking strength is achieved. Through further reduction, a graphene oxide crosslinking layer is turned into a graphene crosslinking layer, so that mutual action among the glass fibers is enhanced, contact resistance among the fibers is lowered, and the glass fibers show excellent mechanical performance, electric conductivity and heat conductivity and can be applied to a wild phase of the composite material. The method for crosslinking the glass fibers with the graphene has a great researching value and a wide application prospect.

Owner:HANGZHOU GAOXI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com