Photocatalysis self-cleaned amphiphilic network ocean anti-flouring coating and preparation method thereof

A marine antifouling and self-cleaning technology, applied in antifouling/underwater coatings, coatings, biocide-containing paints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] A method for preparing a photocatalytic self-cleaning amphiphilic network marine antifouling coating, the specific steps are:

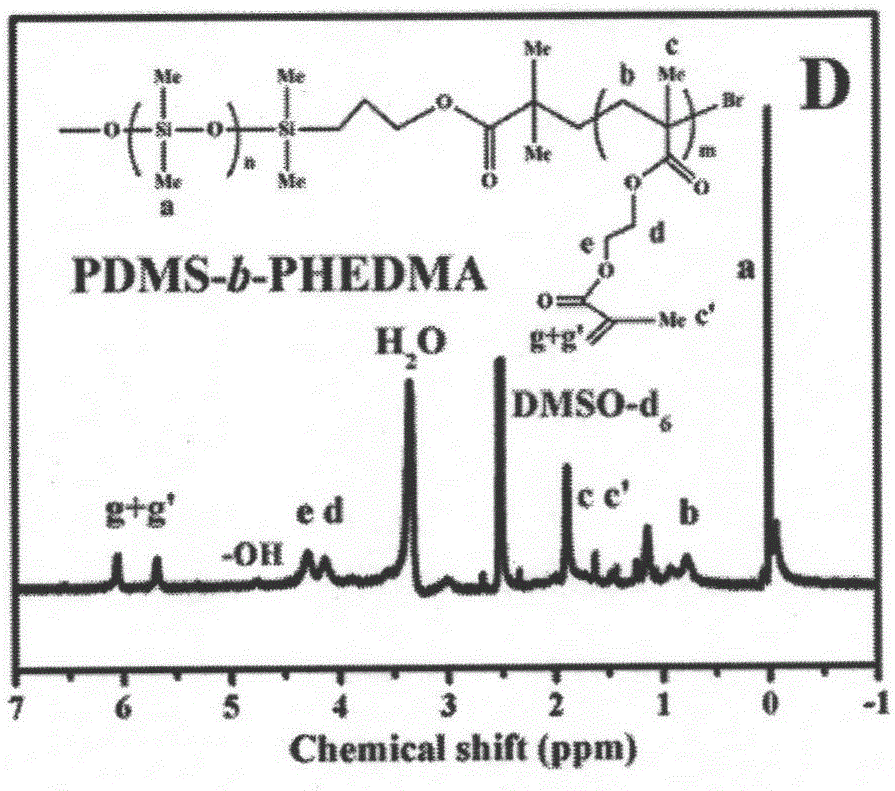

[0087] 1. Preparation of amphiphilic tri-block copolymers by ATRP (atom transfer radical polymerization) method:

[0088] (1) Preparation of PDMS-based macromolecular initiator:

[0089] Dissolve 10 parts of polydimethylsiloxane (here hydroxypolydimethylsiloxane) (company Gelest, type DMS-C21) (Mn=4000g / mol) in 80 parts of tetrahydrofuran to obtain functionalized Polydimethylsiloxane solution, add 0.5 parts of triethylamine, slowly drop 0.5 parts of 2-bromoisobutyryl bromide, react in an ice-water bath at -10°C for 3 hours, remove the precipitate by suction filtration after the reaction, The solvent was removed by rotary evaporation, then dissolved in n-hexane, washed and purified with deionized water three times, and dried in an oven for 24 hours to obtain a bromine-terminated PDMS-based macroinitiator.

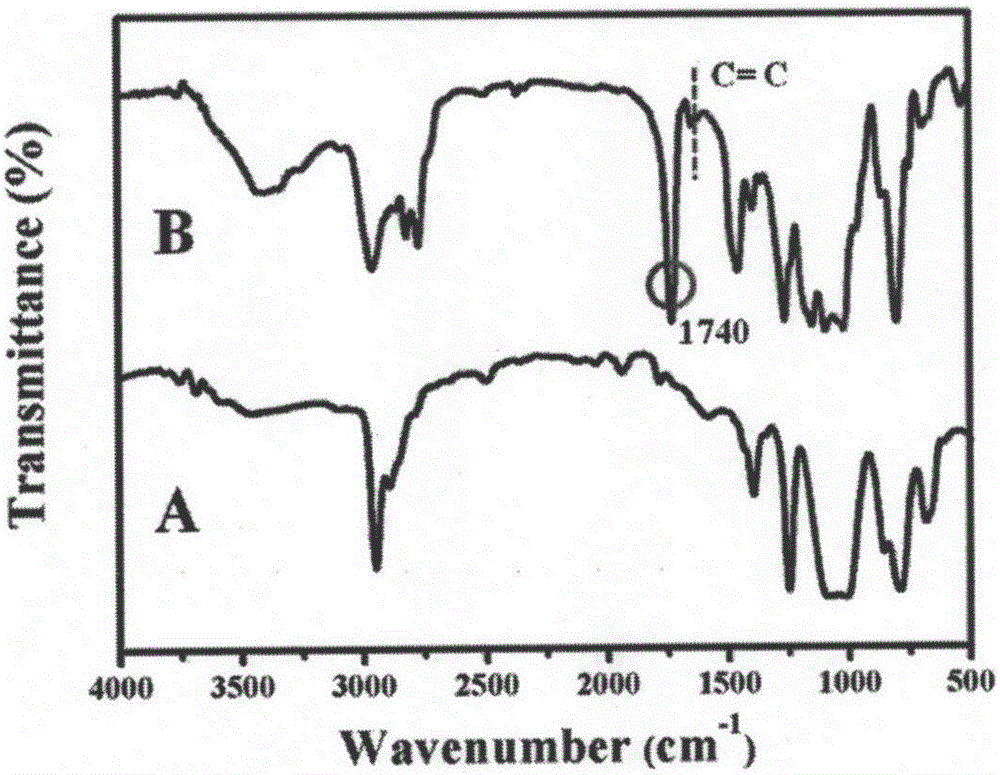

[0090] (2) Preparation of PDMS-based...

Embodiment 2

[0104] Similar to Example 1, the difference is:

[0105] The preparation of step 6, photocatalytic self-cleaning amphiphilic network marine antifouling coating is as follows:

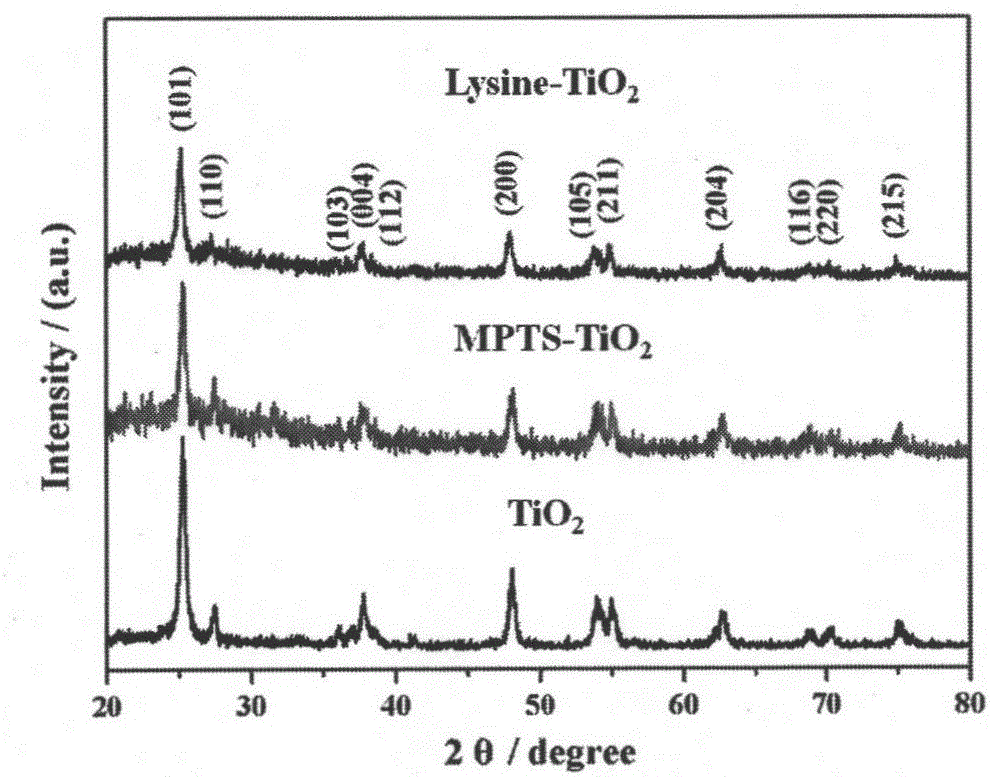

[0106] The obtained MPTS modified nano-titanium dioxide hybrid amphiphilic copolymer network coating is placed in a toluene solution of 0.1% trimesoyl chloride to react for 10 minutes, and after the reaction, the coating is taken out and placed in a concentration of 0.8%. Lysine-TiO 2 React in the dispersion liquid (the solvent is toluene) for 20 minutes, take it out, and obtain the photocatalytic self-cleaning amphiphilic network marine antifouling coating.

[0107] The original contact angle of the prepared marine antifouling coating is 100°, and the contact angle is reduced to 35° after 7 days of sunlight exposure, the breaking strength is 4.5MPa, the swelling rate in water is 2.5%, and the BSA adsorption capacity is 40ug / cm 2 , compared to glass sheets, can be reduced by 80%, and the adhesion of d...

Embodiment 3

[0109] Similar to Example 1, the difference is:

[0110] The preparation of step 6, photocatalytic self-cleaning amphiphilic network marine antifouling coating is as follows:

[0111] The obtained MPTS modified nano-titanium dioxide hybrid amphiphilic copolymer network coating is placed in a toluene solution of 0.3% trimesoyl chloride to react for 10 minutes, and after the reaction, the coating is taken out and placed in a concentration of 0.2%. Lysine-TiO 2 React in the dispersion liquid (the solvent is toluene) for 20 minutes, take it out, and obtain the photocatalytic self-cleaning amphiphilic network marine antifouling coating. The original contact angle of the prepared marine antifouling coating was 105°, and the contact angle decreased to 38° after 7 days of sunlight exposure, the breaking strength was 4.8MPa, the swelling rate in water was 2.3%, and the BSA adsorption capacity was 43ug / cm 2 , compared with the glass sheet, it can be reduced by 76%, and the adhesion am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com