Fluorocarbon coating for anticorrosion of offshore environment concrete

A concrete and anti-corrosion technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of high-temperature viscosity loss, easy loss of light and pulverization, poor water resistance, etc., to achieve excellent corrosion resistance, enhance the protective effect, and prepare The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

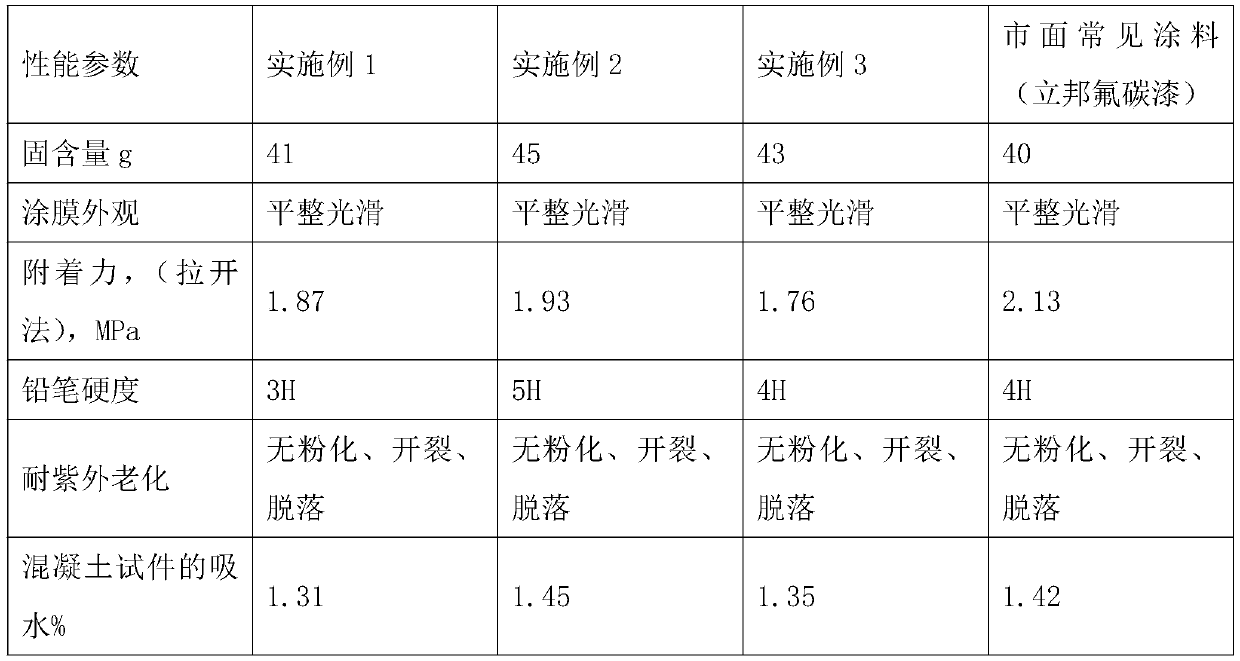

Embodiment 1

[0028] Add 22g of water to the container, gradually add 17g of titanium dioxide and 6g of talc, add 0.2g of dispersant 5040 and 0.2g of wetting agent CF-10, then add 0.2g of silicone defoamer 110, 0.3g of leveling Agent RM-2020, use a disperser to disperse until uniform; in the uniformly dispersed pigment and filler slurry, add 44g of water-based fluorine-containing acrylic emulsion, and finally add 3g of film-forming aid alcohol ester twelve, 0.4g of coupling agent KH-550 , 0.2g multi-functional additive 2-amino-2-methyl-1-propanol, 1g antifreeze ethylene glycol and 0.5g polyurethane alkali-swellable thickener, continue to disperse until the system is evenly mixed to obtain concrete anti-corrosion fluorocarbon Coating, described coating comprises following component, by weight (g), self-made fluorine-containing acrylic acid emulsion 44g, titanium dioxide 17g, talcum powder 6g, dispersant 0.2g, wetting agent 0.2g, defoamer 0.2g, forming Membrane aid 3g, antifreeze agent 1g, co...

Embodiment 2

[0030] Add 22g of water to the container, gradually add 21g of titanium dioxide and 9g of talc, add 0.2g of dispersant 5040 and 0.2g of wetting agent CF-10, then add 0.2g of silicone defoamer 110, 0.3g of leveling Agent RM-2020, use a disperser to disperse until uniform; in the uniformly dispersed pigment and filler slurry, add 48g of water-based fluorine-containing acrylic emulsion, and finally add 3g of film-forming aid alcohol ester twelve, 0.4g of coupling agent KH-550 , 0.2g multi-functional additive 2-amino-2-methyl-1-propanol, 1g antifreeze ethylene glycol and 0.5g polyurethane alkali-swellable thickener, continue to disperse until the system is evenly mixed to obtain concrete anti-corrosion fluorocarbon Coating, described coating comprises following component, by weight (g), self-made fluorine-containing acrylic acid emulsion 48g, titanium dioxide 21g, talcum powder 9g, dispersant 0.2g, wetting agent 0.2g, defoamer 0.2g, forming Membrane aid 3g, antifreeze agent 1g, co...

Embodiment 3

[0032] Add 22g of water into the container, gradually add 19g of titanium dioxide and 7g of talc, add 0.2g of dispersant 5040 and 0.2g of wetting agent CF-10, then add 0.2g of silicone defoamer 110, 0.3g of leveling Agent RM-2020, use a disperser to disperse until uniform; in the uniformly dispersed pigment and filler slurry, add 46g of water-based fluorine-containing acrylic emulsion, and finally add 3g of film-forming aid alcohol ester twelve, 0.4g of coupling agent KH-550 , 0.2g multi-functional additive 2-amino-2-methyl-1-propanol, 1g antifreeze ethylene glycol and 0.5g polyurethane alkali-swellable thickener, continue to disperse until the system is evenly mixed to obtain concrete anti-corrosion fluorocarbon Coating, described coating comprises following component, by weight (g), self-made fluorine-containing acrylic acid emulsion 46g, titanium dioxide 19g, talcum powder 7g, dispersant 0.2g, wetting agent 0.2g, defoamer 0.2g, forming Membrane aid 3g, antifreeze agent 1g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com