Metal composite delivery pipe with polyurethane elastomer lining and manufacturing method and application of metal composite delivery pipe

A polyurethane elastomer and metal composite technology, which is applied in the direction of rigid pipes, pipes, mechanical equipment, etc., can solve the problems of the thickness of the protective layer that is not resistant to impact, the protective layer is not wear-resistant, and the wear of the pipe, so as to achieve low cost and enhanced bonding , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

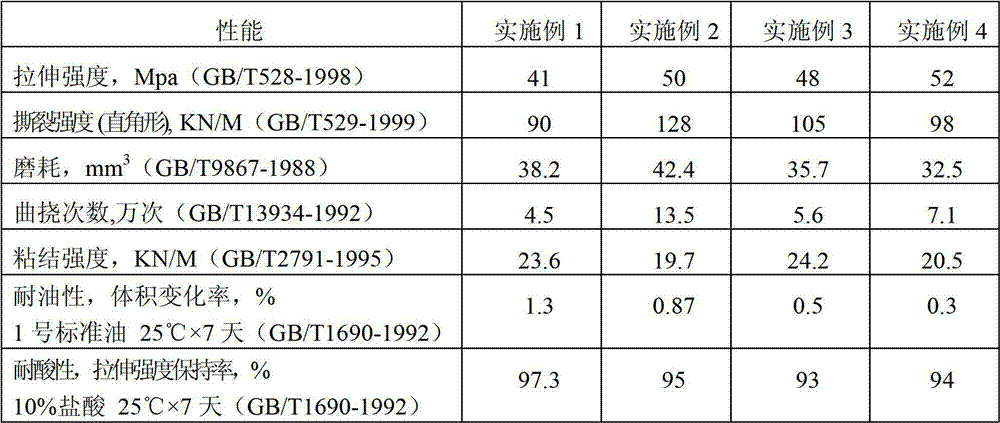

Examples

Embodiment 1

[0040] Preparation of adhesive solution Take 40 parts by weight of Chemlock 213 (Lord Corporation of the United States), add 60 parts by weight of mixed solvent, and stir evenly to obtain an adhesive solution; Percentage 30%, 35% and 35% mixed composition;

[0041] Inner surface treatment of metal pipe Sand blast the inner surface of the metal iron pipe, then degrease and degrease the inner surface with ethyl acetate, then evenly dip-coat the adhesive solution prepared above (dipping thickness is 20 μm), and park at room temperature for 30 minutes. Put it in an oven at 130°C and bake for 30 minutes, then it can be used for pouring;

[0042] The preparation of polyurethane prepolymer is that 15 weight parts of polytetrahydrofuran ether glycols with an average molecular weight of 650, 25 weight parts of polytetrahydrofuran ether glycols with an average molecular weight of 1000, 60 weight parts of polytetrahydrofuran ether glycols with an average molecular weight of 2000 and nano...

Embodiment 2

[0049]Preparation of adhesive solvent Take 20 parts by weight of Thixon406 (Dow Chemical), add 80 parts by weight of mixed solvent, and stir evenly to obtain adhesive solvent; Composition of 30% and 30%;

[0050] Inner surface treatment of metal pipe Sandblast the inner surface of the metal iron pipe, then degrease and degrease the inner surface with trichlorethylene, and then evenly dip-coat the adhesive solvent prepared above (the dipping thickness is 30 μm), and park it at room temperature for 60 minutes. Put it in an oven at 115°C and bake for 45 minutes, then it can be used for pouring;

[0051] Preparation of Polyurethane Prepolymer Put 35 parts by weight of polycaprolactone diol with an average molecular weight of 1000, 65 parts by weight of polycaprolactone diol with an average molecular weight of 2000, and 1.5 parts by weight of montmorillonite into a 300L stainless steel liner reactor , heated to 110°C, evacuated to an absolute pressure of less than 500Pa, dehydrate...

Embodiment 3

[0058] Preparation of adhesive solvent: Take 30 parts by weight of CILBOND48C (British Xibang Chemical Industry Co., Ltd.), add 70 parts by weight of mixed solvent, stir evenly, and obtain adhesive solvent; mixed solvent is composed of tetrahydrofuran, butyl acetate, and methyl pyrrolidone by volume percentage , 30% and 25%;

[0059] Inner surface treatment of metal pipe Sandblast the inner surface of metal iron pipe, degrease and degrease the inner surface with ethyl acetate, then evenly dip-coat the adhesive solvent prepared above (dipping thickness is 25μm), and park at room temperature for 45 minutes. Put it in a 100°C oven and bake for 60 minutes, then it can be used for pouring;

[0060] The preparation of polyurethane prepolymer is that the average molecular weight is 75 parts by weight of polyester diol of 2000, the average molecular weight is 25 parts by weight of polycarbonate diol of 1000, 1.5 parts by weight of nano-montmorillonite and 1.5 parts by weight of nano-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com