Patents

Literature

40results about How to "Increase product quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

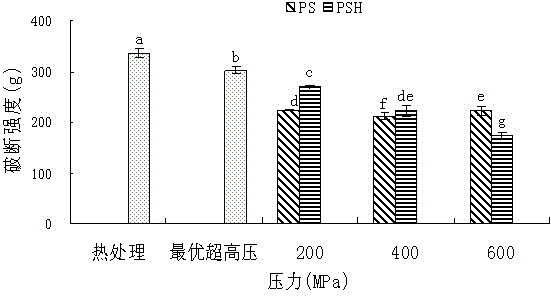

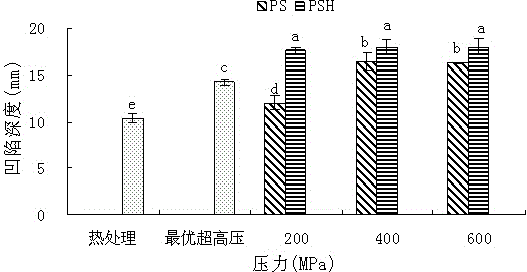

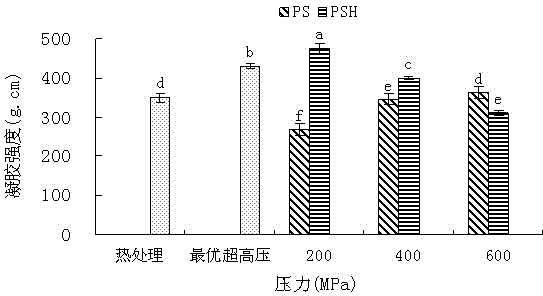

High-quality minced nemipterus hexodon product and preparation method thereof

ActiveCN103815435AIncrease product quantityIncrease valueFood preparationFish processingProcess engineering

Owner:广州尚好菜食品有限公司

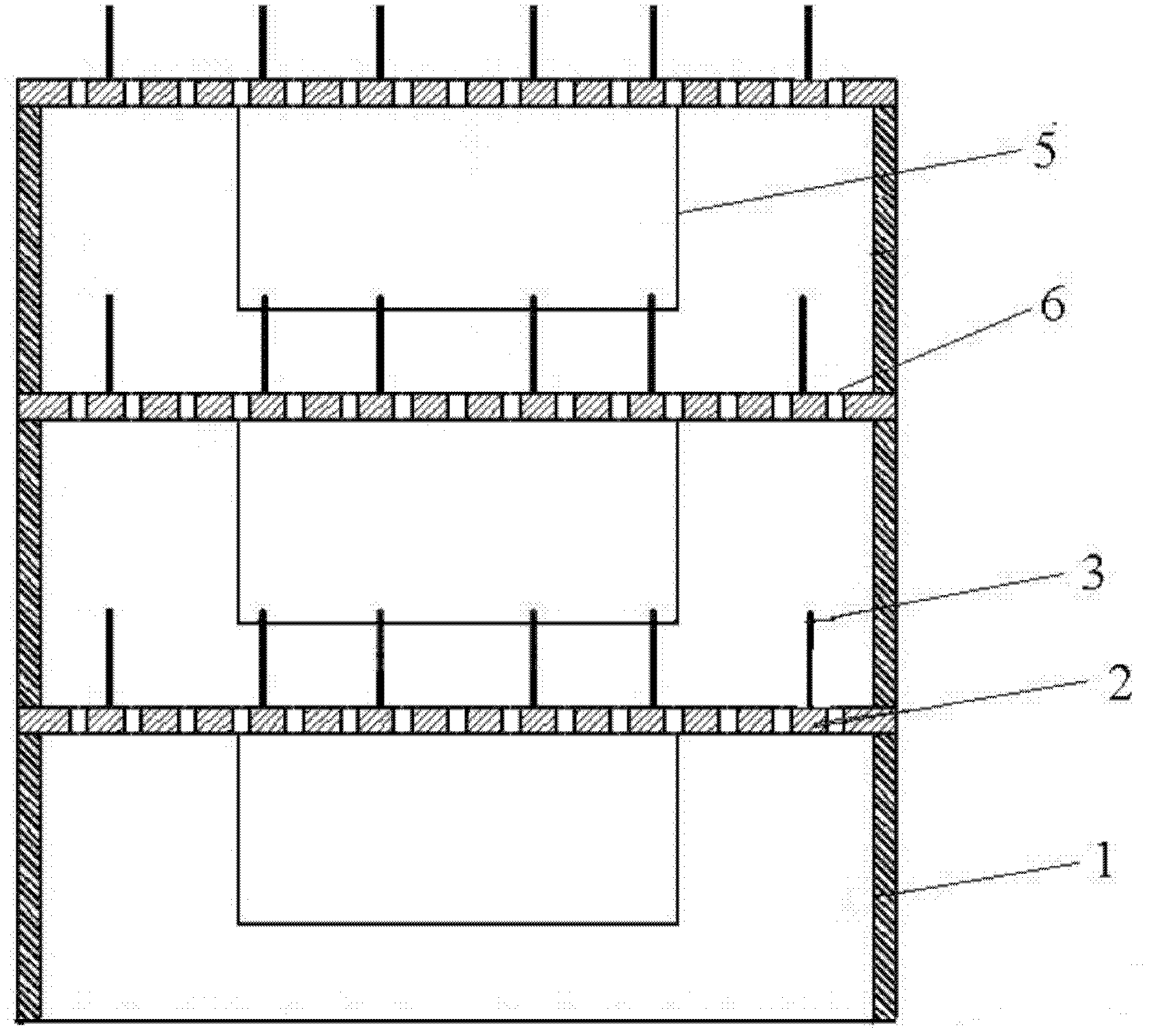

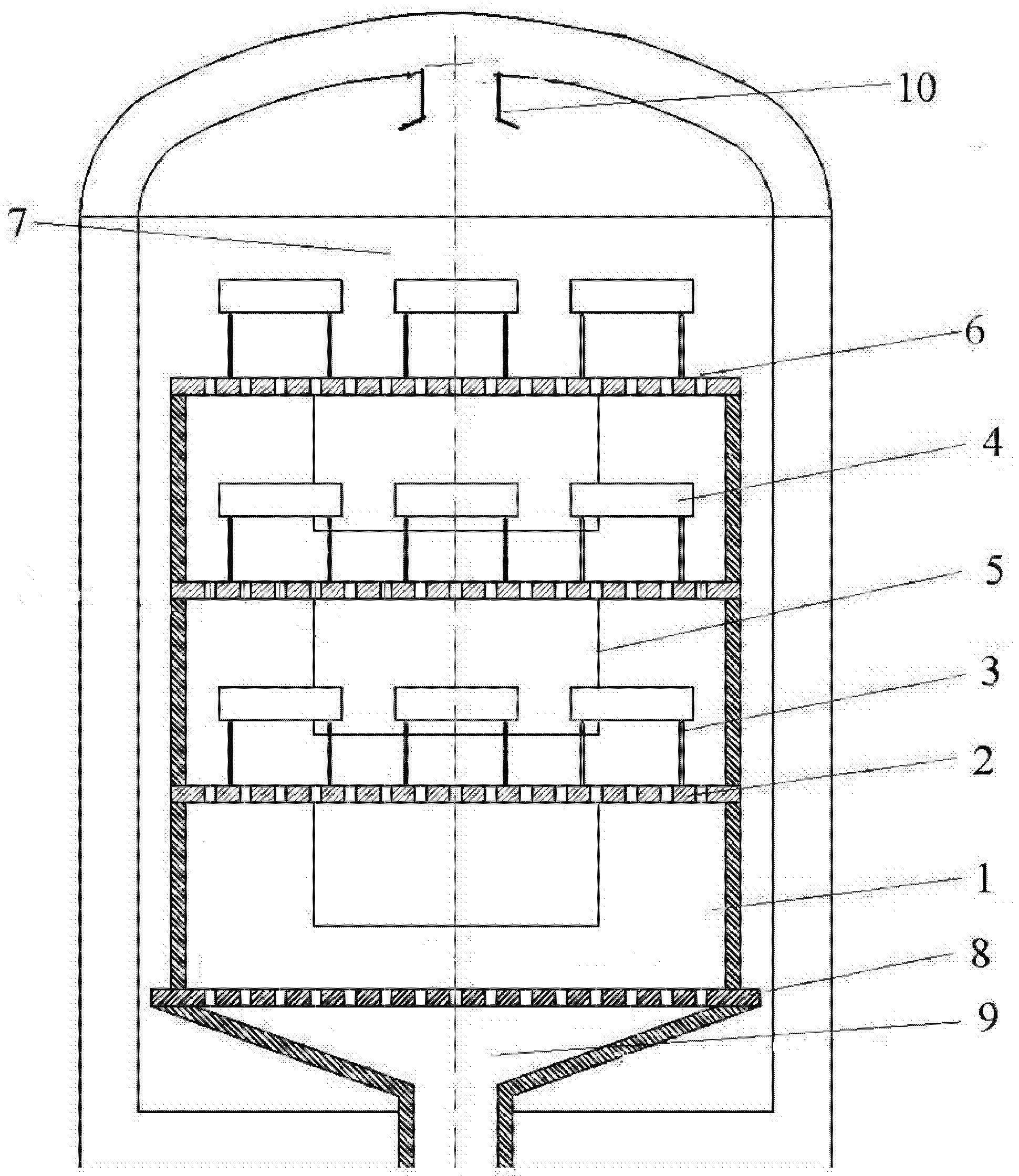

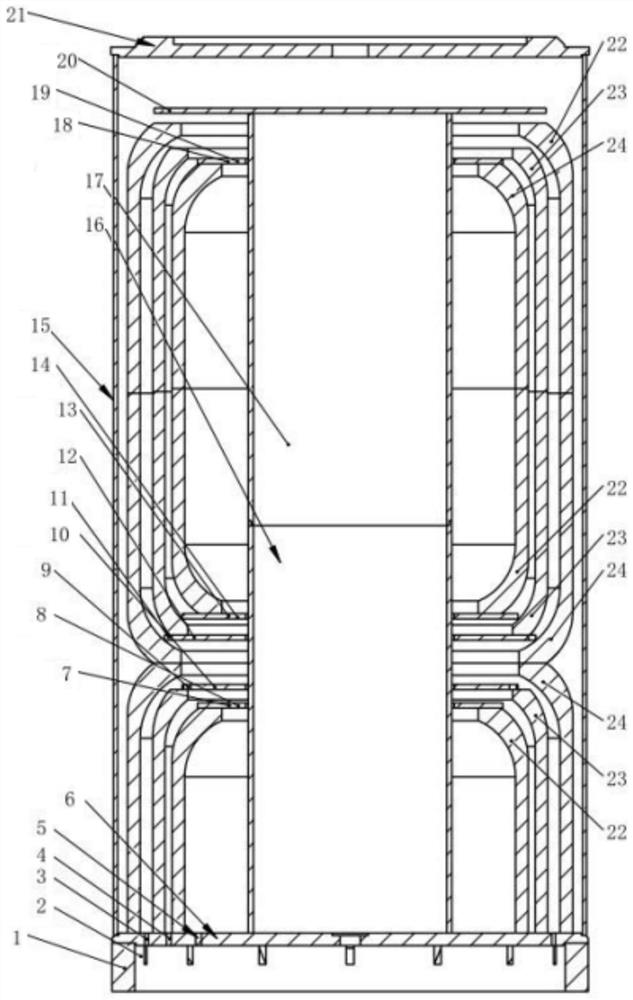

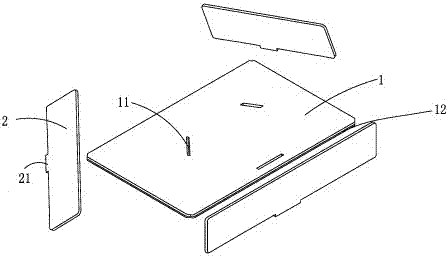

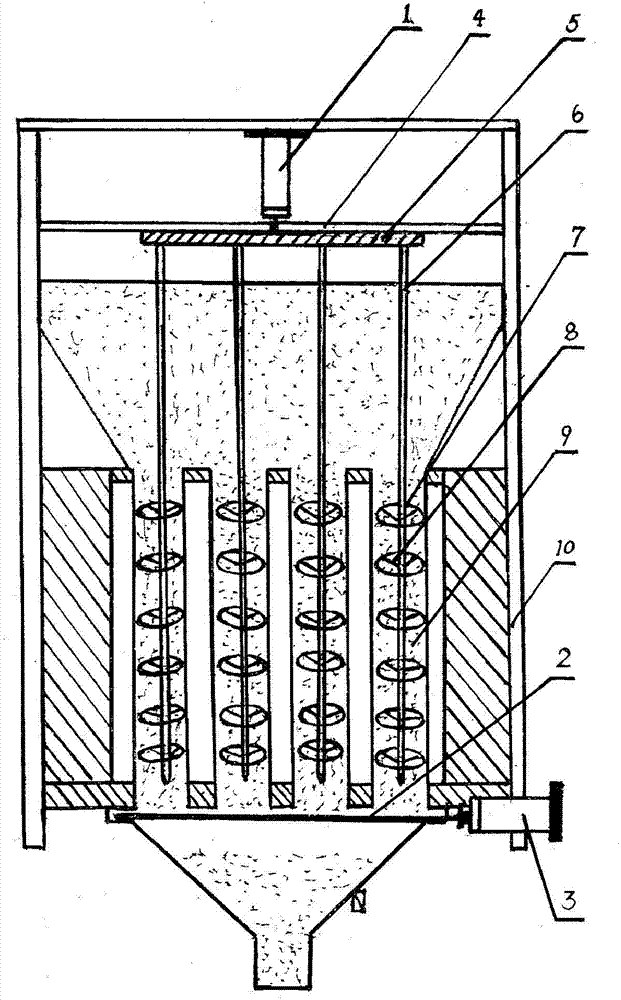

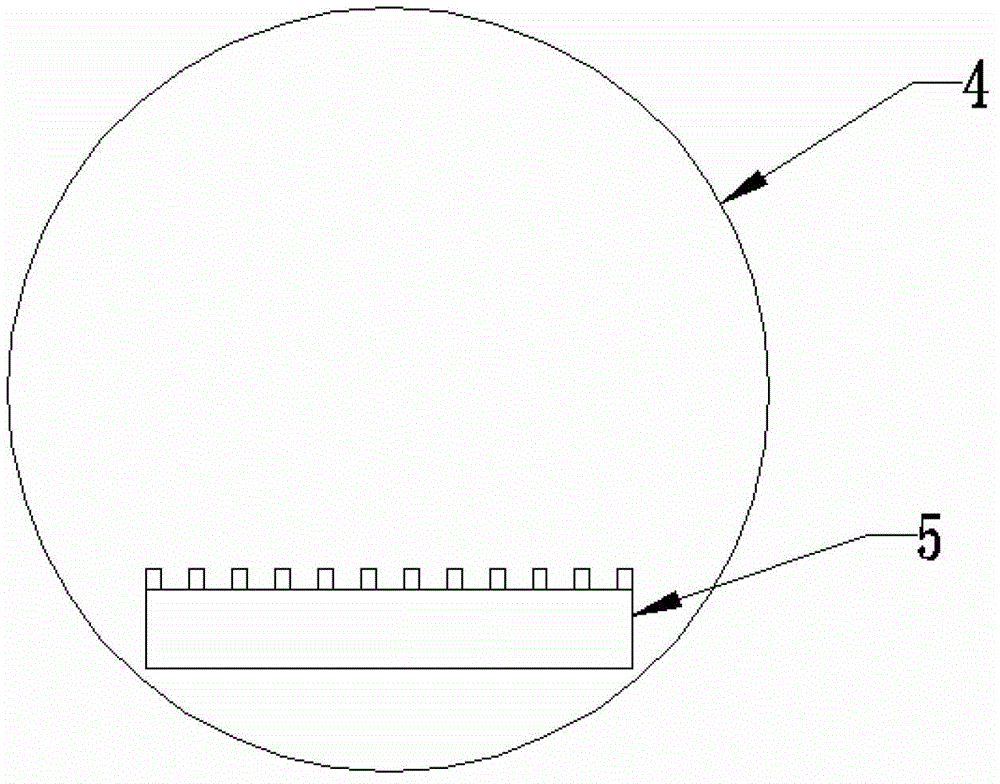

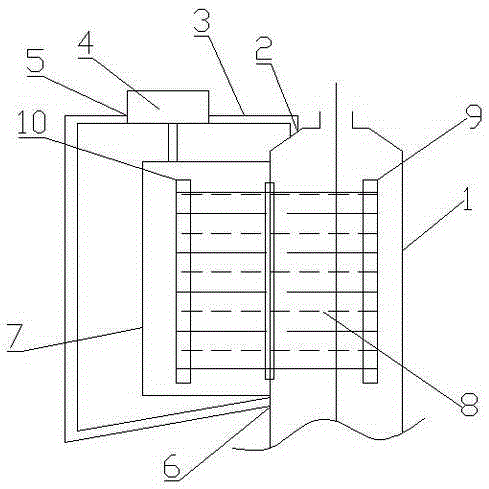

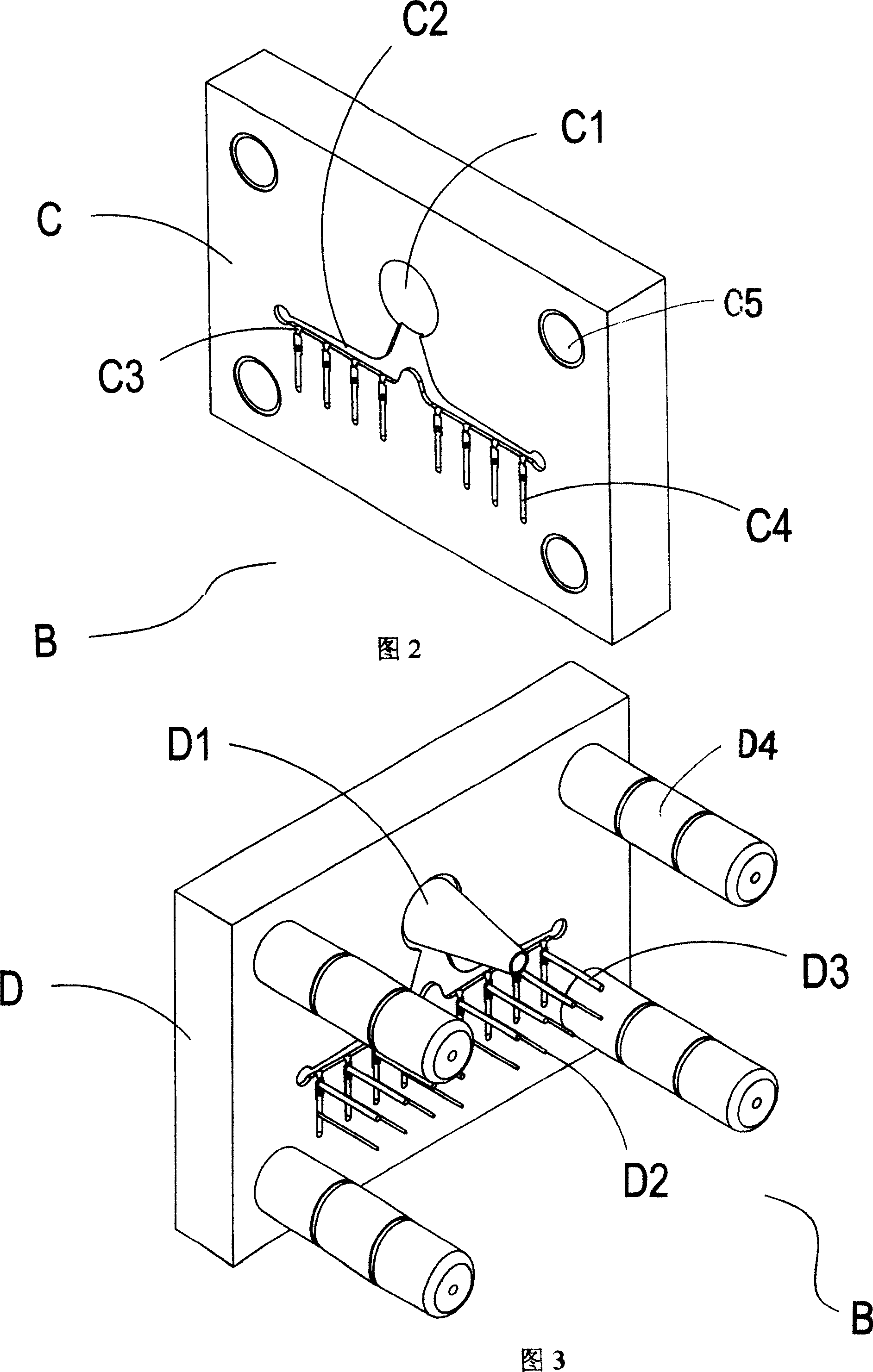

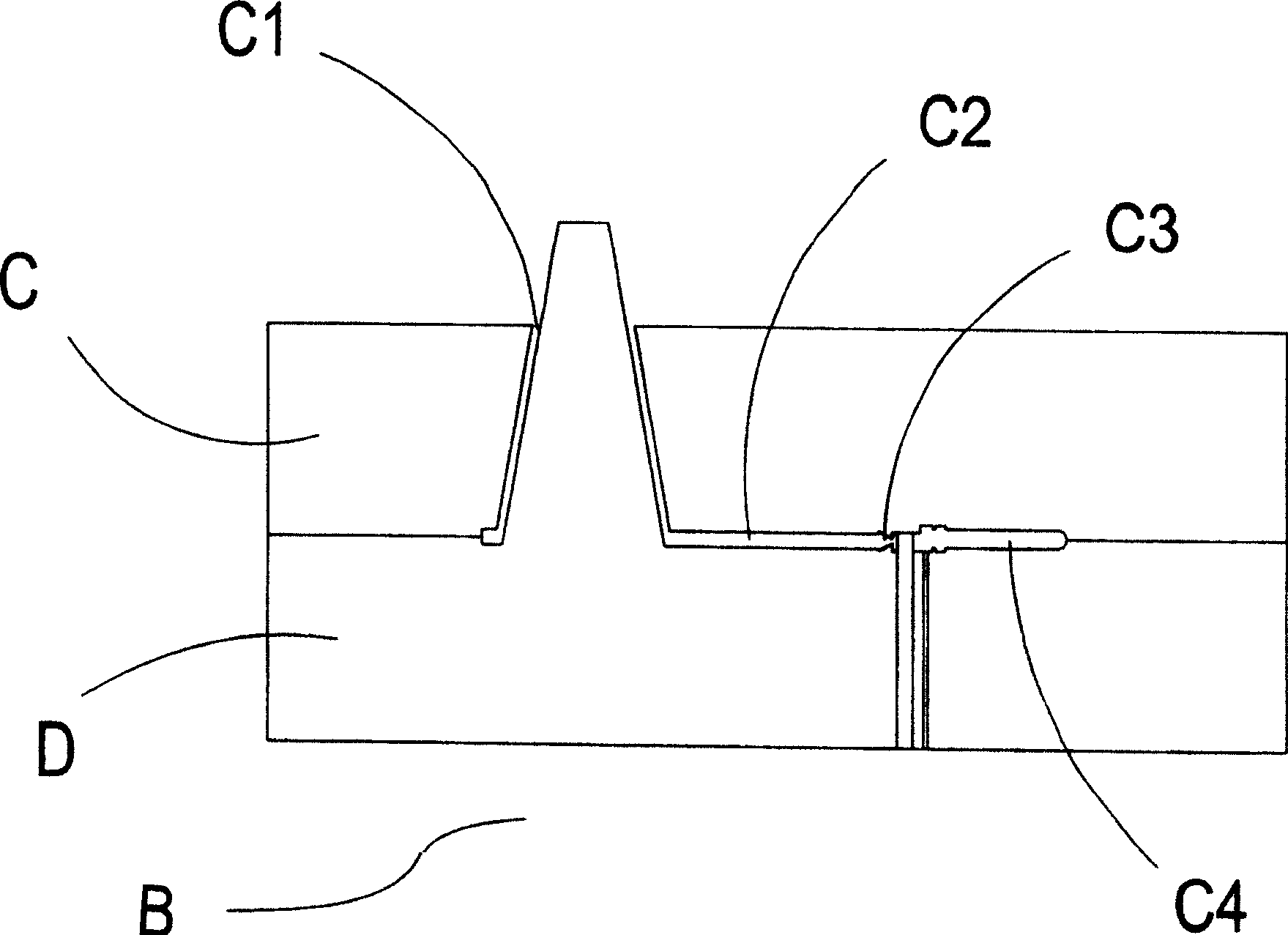

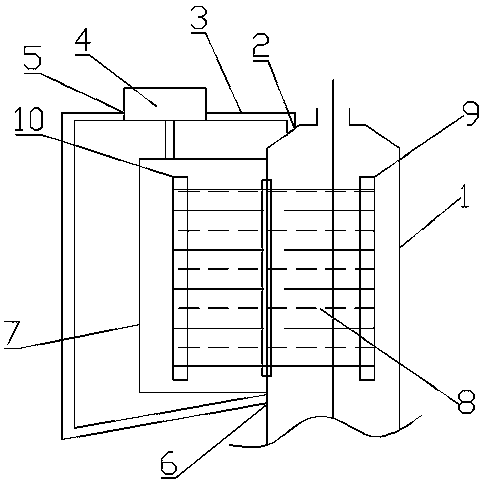

Multi-layer product support for vapor deposition, and chemical vapor deposition reaction chamber

ActiveCN102424957AIncrease productivitySimple structureChemical vapor deposition coatingGas phaseChemical vapor deposition

The present invention relates to a multi-layer product support for vapor deposition, and a chemical vapor deposition reaction chamber. The multi-layer product support comprises unit layers, wherein the unit layer comprises a round sleeve, a gas distribution disk and a support rod. The structure of the unit layer is characterized in that: the gas distribution disk is arranged on the round sleeve; the support rod is vertically fixed on the gas distribution disk, and is provided for supporting a substrate requiring coating; the round sleeve of the one unit layer is placed on the gas distributiondisk of the other unit layer; the upper part of the round sleeve wall is symmetrically provided with two notches, wherein the gas can conveniently flow by the notches. According to the chemical vapordeposition reaction chamber, the multi-layer product support is placed on an incoming gas distribution plate on the gas inlet inside the cavity; the gas inlet is positioned on the bottom of the reaction chamber; the position of the gas outlet is relative to the position of the gas inlet, and the gas outlet is positioned on the top of the reaction chamber. The quality of the coating product produced by the multi-layer product support of the present invention is uniform, the number of the coating product is increased by several times, and the production efficiency is improved.

Owner:山东国晶新材料有限公司

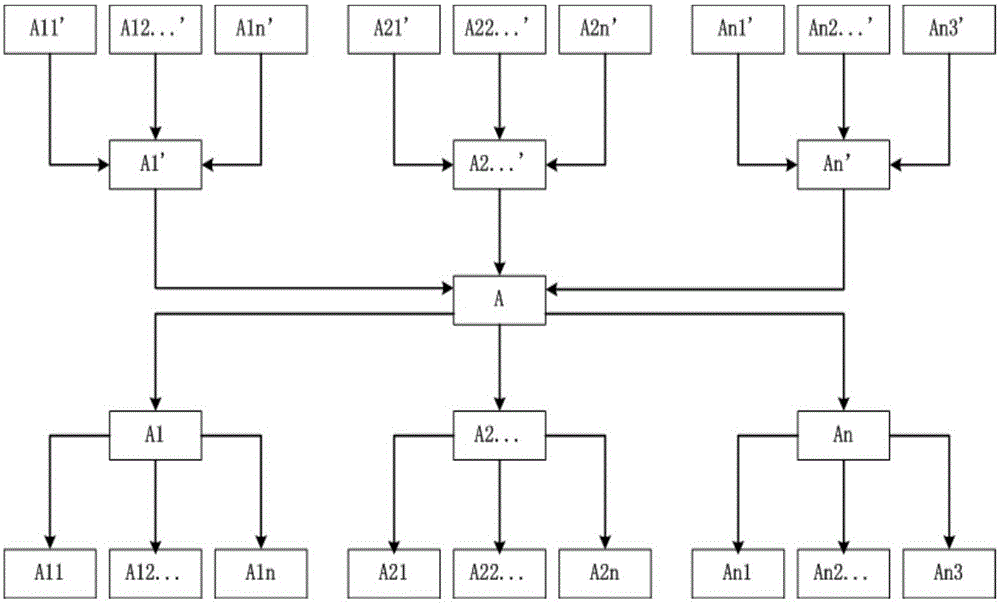

Trusted product transaction system realizing method and realizing system

InactiveCN105844484ASave the cost of counterfeitingResolve trust issuesCustomer relationshipRelational systemE-commerce

The present invention relates to the field of electronic commerce, and provides a reliable product transaction system realization method and realization system, and establishes a user-based user relationship system based on trusted acquaintances in the real society to control product transactions or product promotion levels, without restrictions Products with trustworthy qualifications continue to trade, restrict products that do not have trustworthy qualifications from continuing to recommend, prevent products from being traded or advertised at the level of untrustworthy users, and check products at all levels through trusted acquaintances in the real society, and trade products Or product promotion is always controlled within the trustworthy range, effectively solving the trust problem, so that users can shop online with confidence; and because users in the trusted user level are acquaintances in the real world, it is easy to form a community of interests, and the system can explore the community of interests. Allow users within the trusted hierarchy to benefit.

Owner:郭英

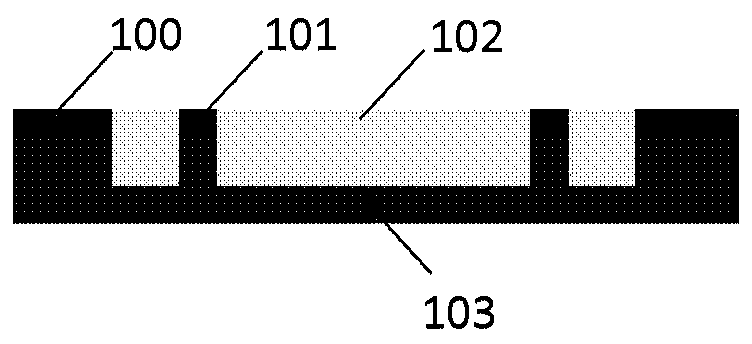

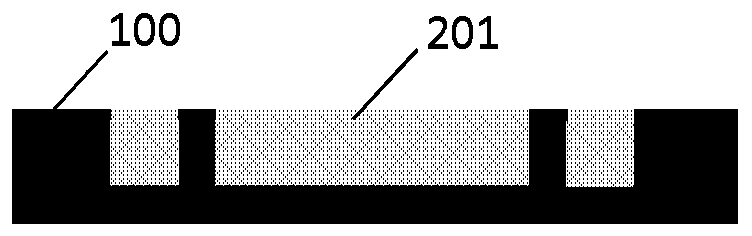

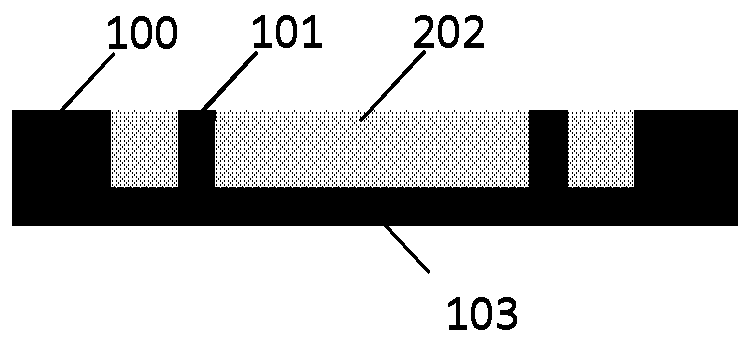

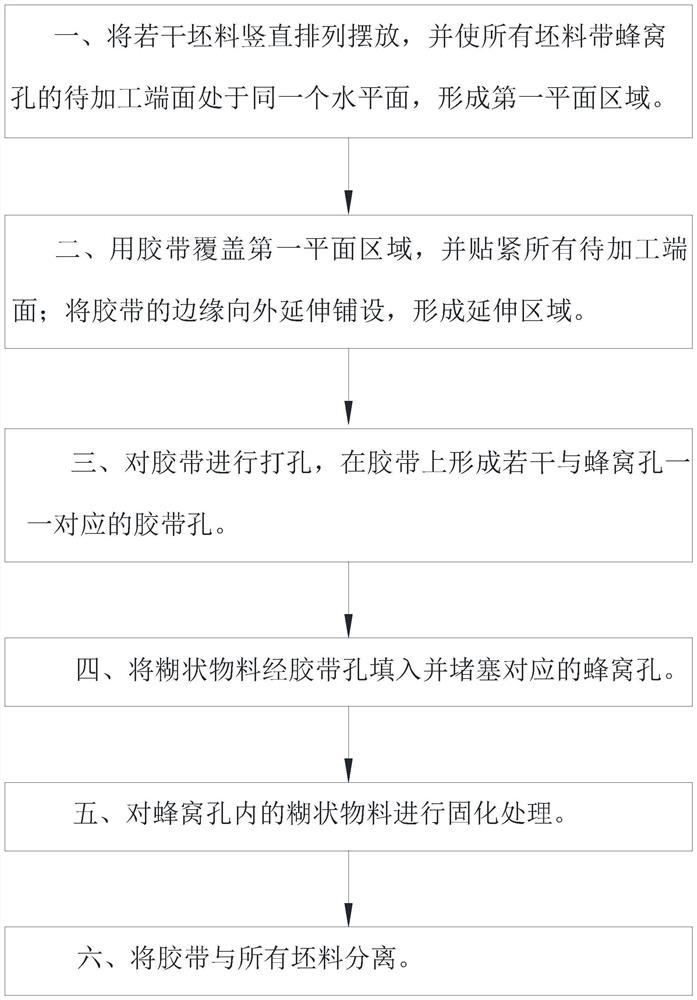

A microstructure packaging method and a packaging device

ActiveCN109928359AReduce the difficulty of fillingImprove yieldDecorative surface effectsSolid-state devicesBonding processElectrical connection

The invention provides a microstructure packaging method, which comprises the following steps that: a conductive silicon column and a silicon groove are etched on the upper surface of a monocrystalline silicon wafer, and a monocrystalline silicon material left between the bottom of the silicon groove and the back surface of the monocrystalline silicon wafer is a microstructure functional layer; asilicon groove is filled with the glass powder; the glass powder is sintered at a high temperature above the softening point of the glass powder to form a glass body; a microstructure containing a functional structure and an electrical connection structure and a frame are etched on the back surface of the monocrystalline silicon wafer; the cap and the frame are bonded through a bonding process, and the microstructure is sealed and packaged; And depositing a metal electrode on the conductive silicon column to realize ohmic contact with an external circuit.

Owner:INSTR TECH & ECONOMY INST P R CHINA

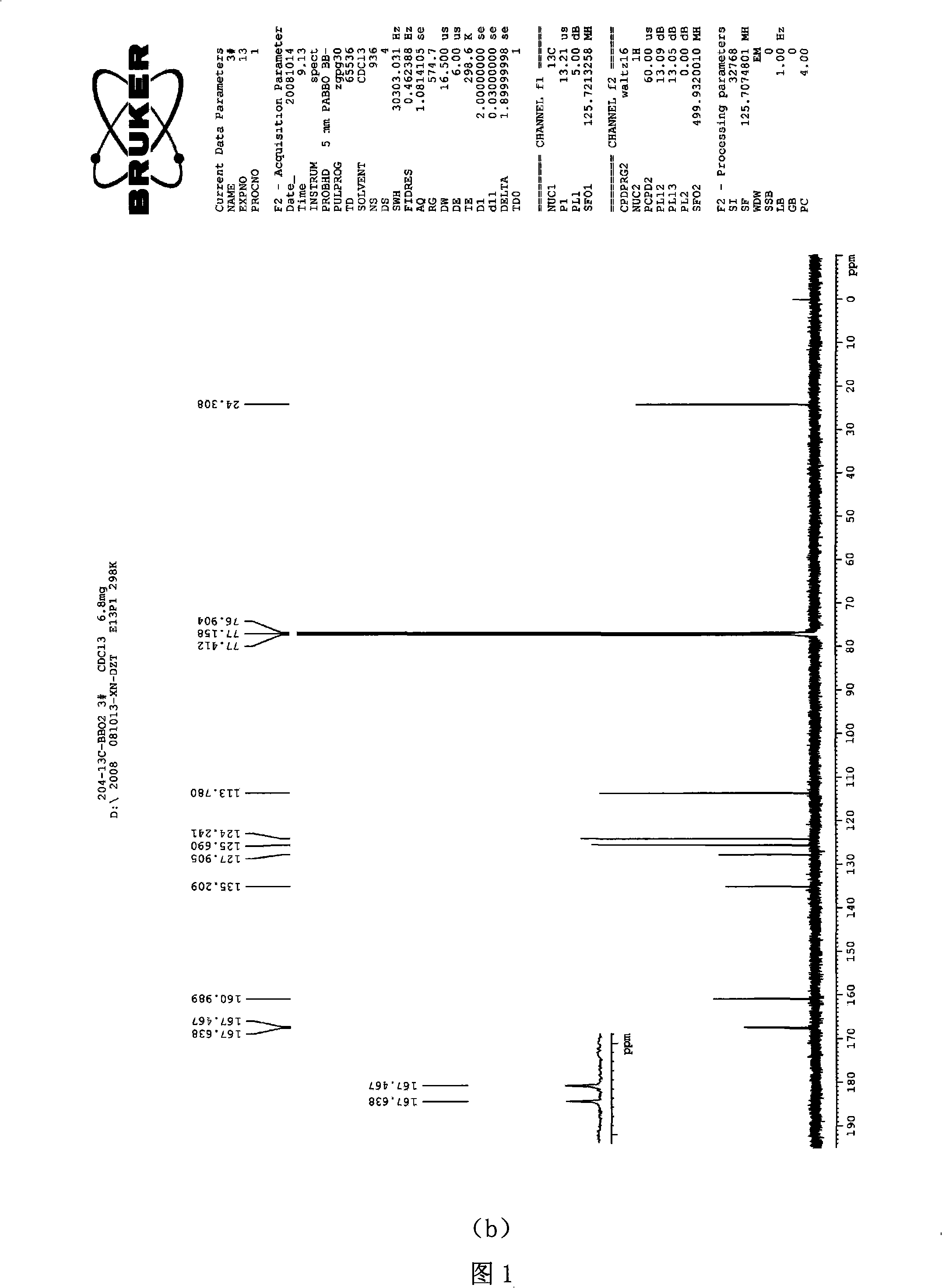

Bi(N-methylphthalic imidine) ester preparation method

InactiveCN101007782AReduce manufacturing costHigh yieldOrganic chemistrySodium carbonatePhase-transfer catalyst

The invention discloses a making method of di (N-methyl phthaloyl imine) ether, which comprises the following steps: proceeding self-condensing reaction for N-4-nitro phthaloyl imine in the polar non-proton solvent under composite catalyst and normal pressure; heating to reflux 6-8h; filtering; cooling; evolving product; washing; drying to recycle solvent; obtaining the composite catalyst with gas-phased silica, sodium carbonate and phase-transmitting catalyst.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

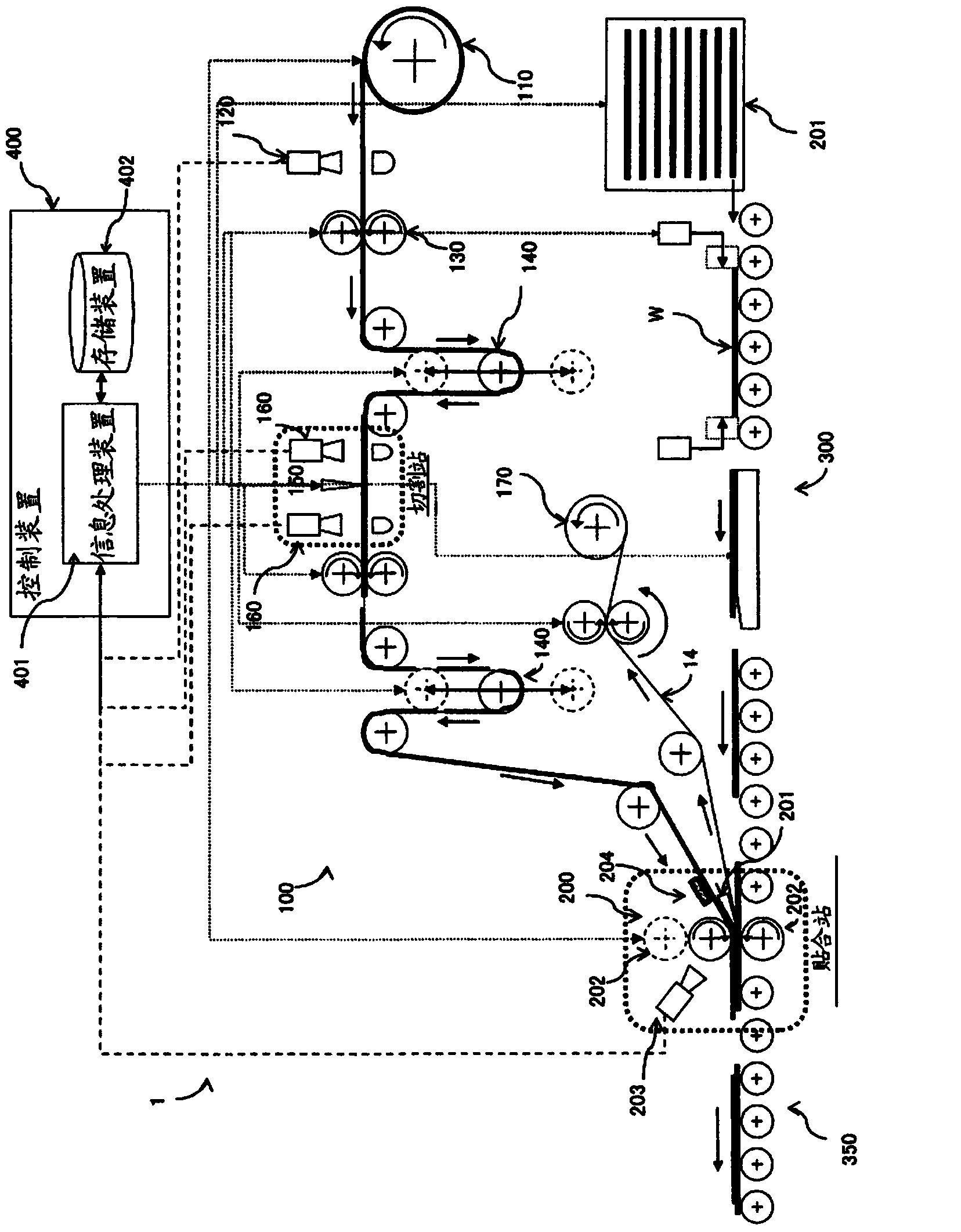

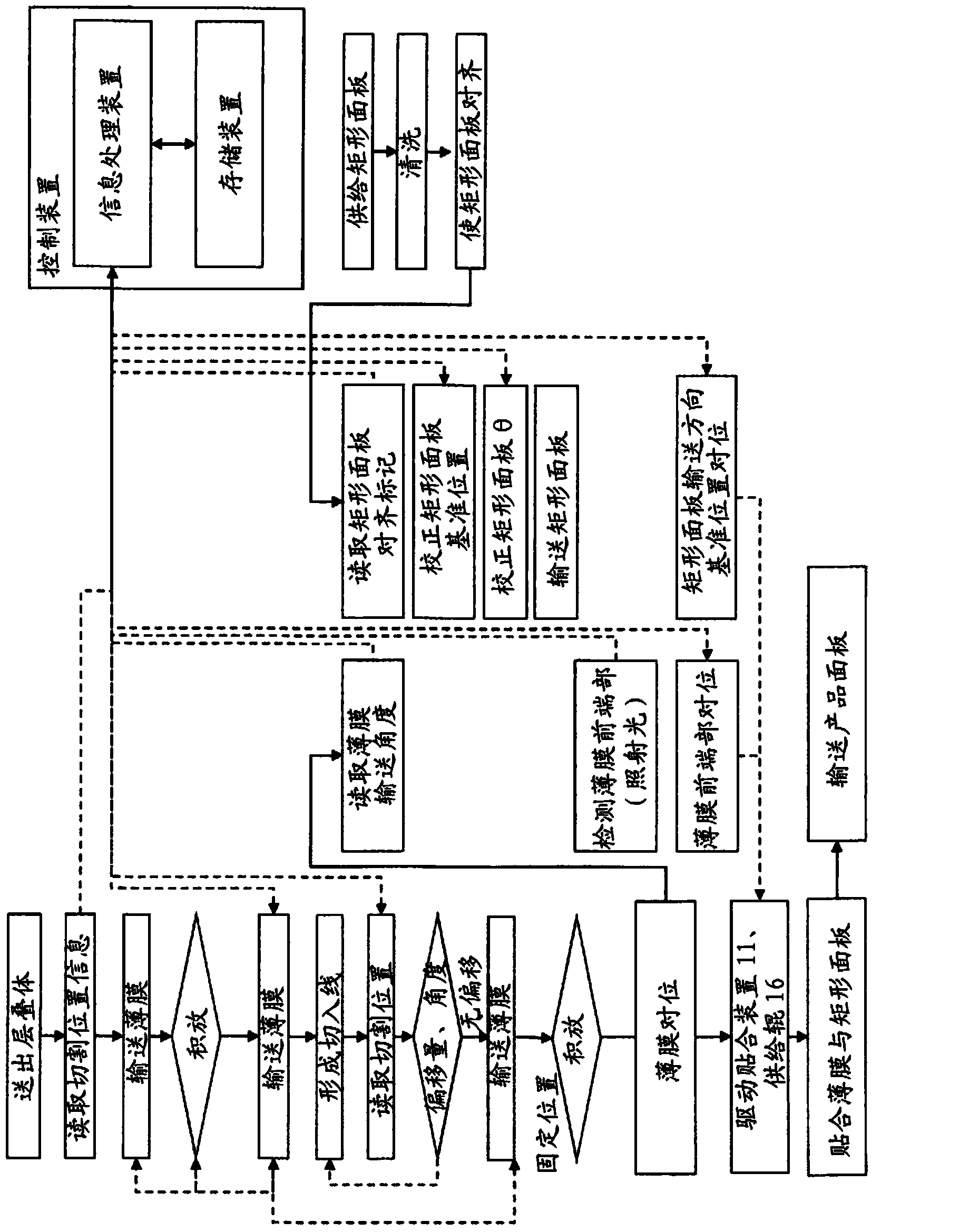

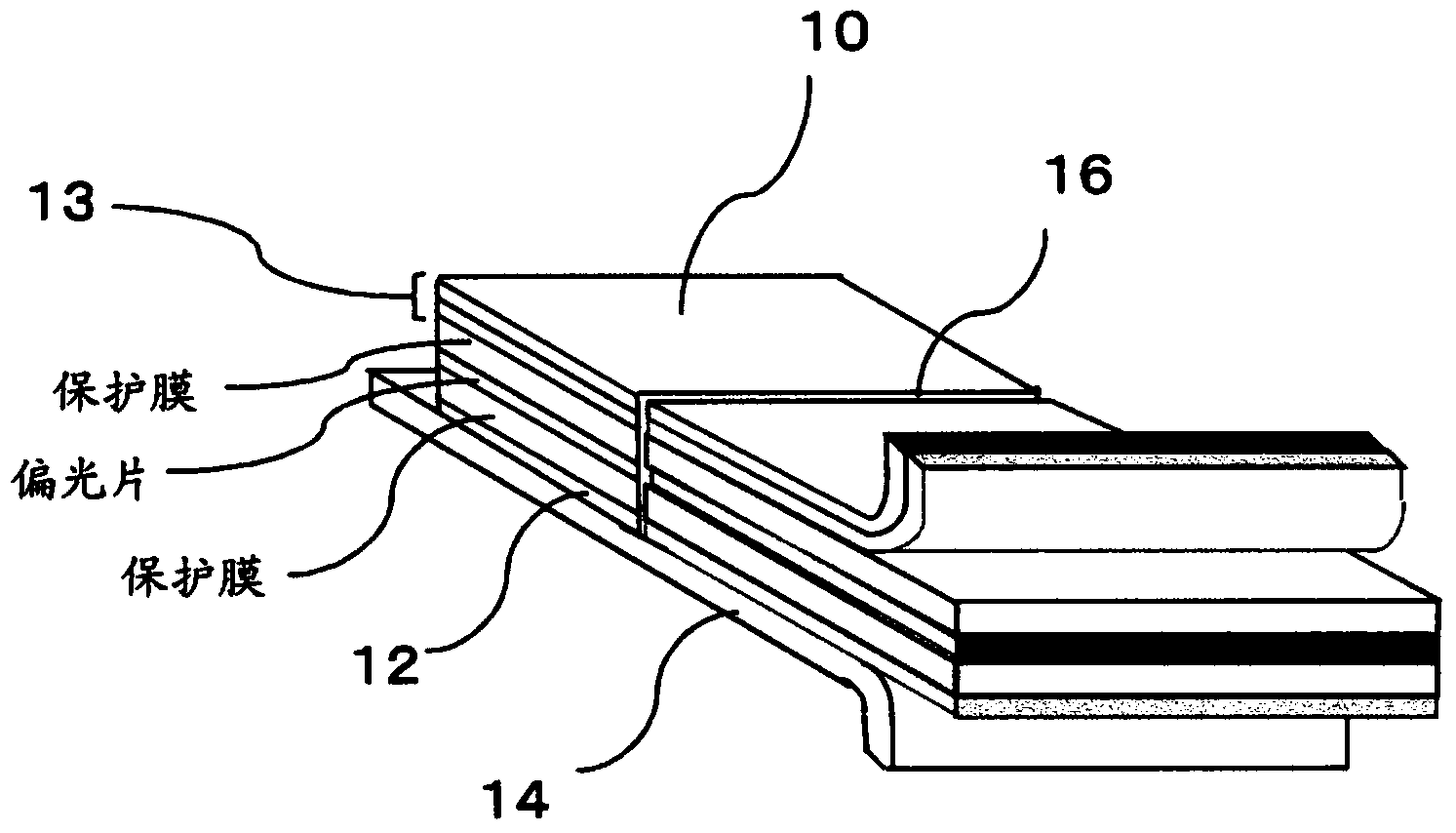

Method of continuously manufacturing a product panel and system and method of detecting the front edge of a film

ActiveCN103765298AShorten the timeIncrease manufacturing quantityLamination ancillary operationsLaminationAcute angleEngineering

[Problem] To provide a method of continuously manufacturing a product panel, whereby it is possible to continuously manufacture a product panel with high adhesion precision. [Solution] The method includes detecting the front edge of a film as the front edge of a polarising film in the form of a sheet approaches the position for sticking together with a rectangular panel, positional alignment of the polarising film in the form of a sheet with the rectangular panel based on information as to the position of the film front edge which is thus detected, and sticking together the polarising film in the form of a sheet and the rectangular panel. In order to detect the film front edge, light having an optical axis that makes an acute angle with respect to the direction of film feed is directed towards the film front edge from the upstream side of the direction of film feed of the polarising film in the form of a sheet, an image is acquired by image pickup of the region which is thus illuminated by the light, and the front edge of the film is identified, based on the difference in brightness of the image of the film front edge with respect to the image of portions other than the film front edge.

Owner:NITTO DENKO CORP

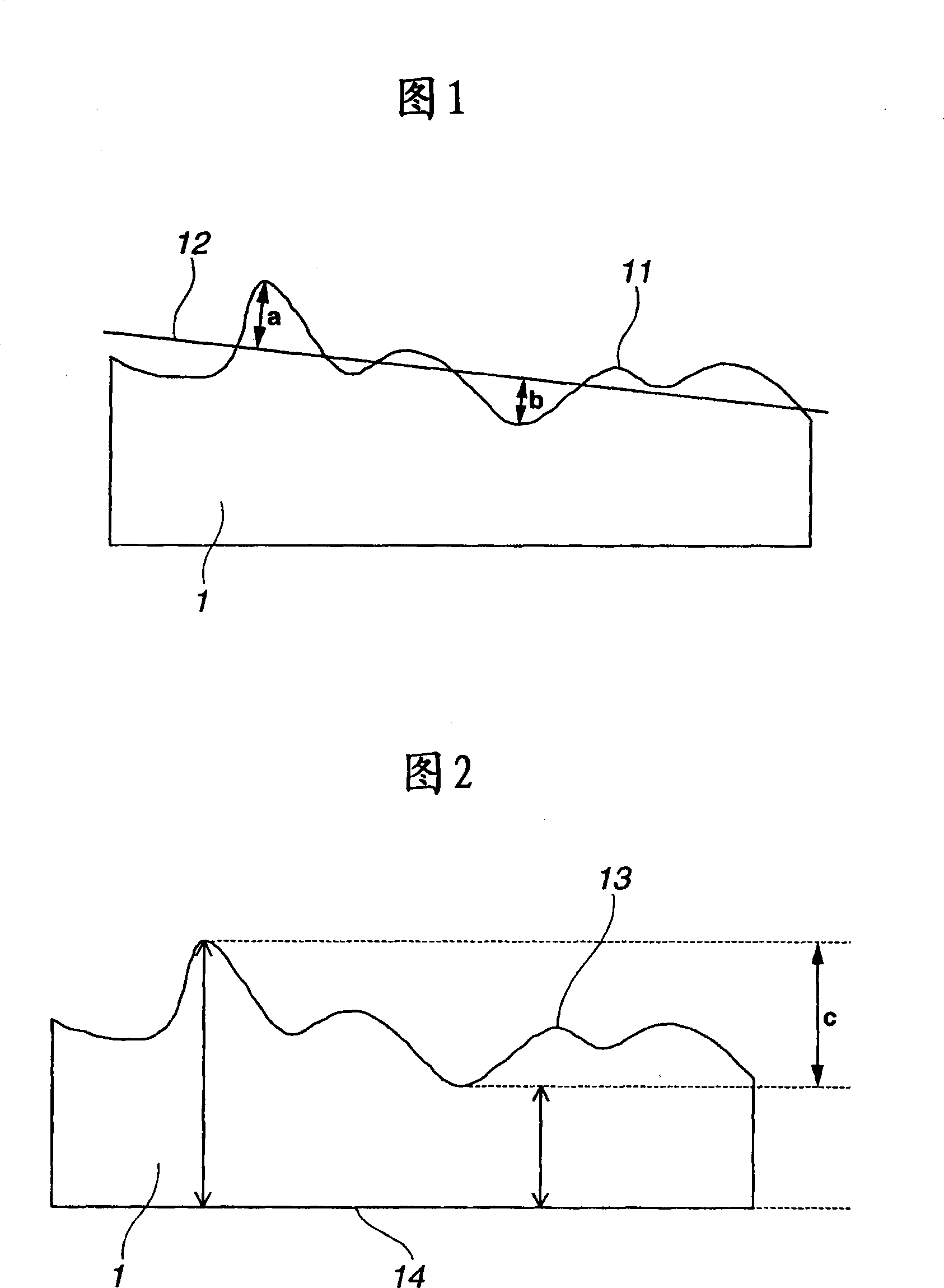

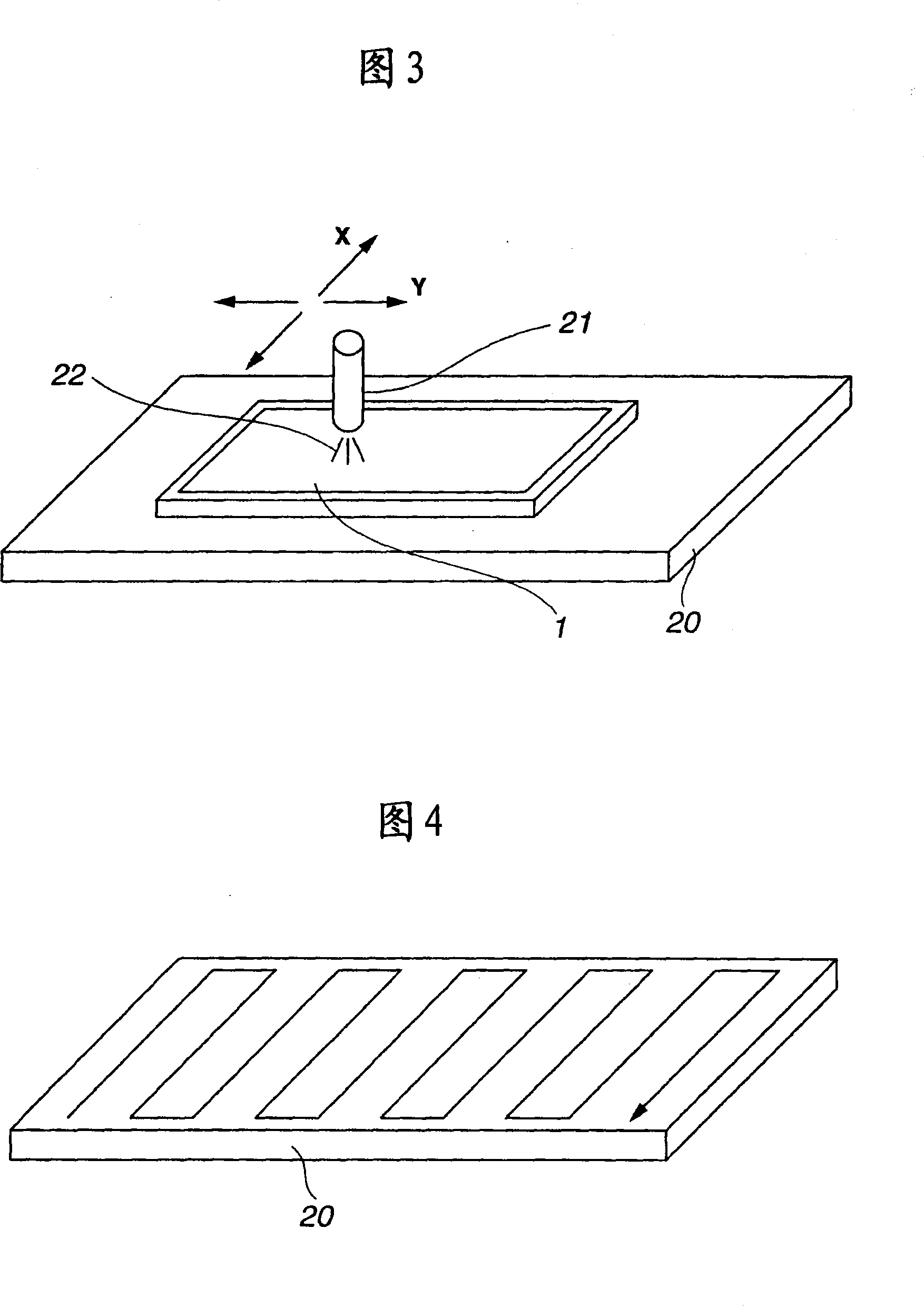

Large-size glass substrate for photomask and making method, computer-readable recording medium, and mother glass exposure method

ActiveCN101006021AIncrease productivityImprove Exposure AccuracyGroup 4/14 element organic compoundsPhotomechanical apparatusOptoelectronicsLarge size

A large-size glass substrate, from which a photomask substrate is formed, is prepared by processing a large-size glass substrate stock by (1) a flattening removal quantity based on height data of the substrate stock in the vertical attitude plus a deformation-corrective removal quantity. The deformation-corrective removal quantity is calculated from (2) a deflection of the substrate stock by its own weight in the horizontal attitude, (3) a deformation of the photomask substrate caused by chucking in an exposure apparatus, and (4) an accuracy distortion of a platen for supporting a mother glass.

Owner:SHIN ETSU CHEM IND CO LTD

Carbon/carbon composite material densification method, stock column tool and assembling method

ActiveCN114874021AImprove compactnessImprove product qualityChemical vapor deposition coatingCarbon compositesMaterials preparation

The invention belongs to the technical field of carbon material preparation, and particularly discloses a carbon / carbon composite material densification method, a stock column tool and an assembling method.The method comprises the steps that a base, a tray, an air inlet splitter plate and a plurality of crucible side preforms are subjected to stock column assembling according to a preset sequence; after the assembled stock column is lifted into a deposition furnace through a lifting appliance to be sealed, a first deposition process is executed according to a preset first gradient heating and pressurizing process, after the first deposition process is executed to reach a first time threshold value, the stock column is cooled and taken out, and surface impurities are removed; and carrying out stock column assembly on the base, the tray, the air inlet splitter plate and the plurality of crucible upper preforms subjected to impurity cleaning according to a preset sequence, carrying out a second-time deposition process according to a second gradient heating and pressurizing flow, cooling the stock column and taking out the stock column after the second-time deposition process is carried out to reach a second time threshold, and thus obtaining the crucible upper. And cleaning surface impurities to obtain the carbon / carbon composite material. And through two times of deposition, the compactness of the composite material is improved, and the product quality is improved.

Owner:青岛晶易新材料科技股份有限公司

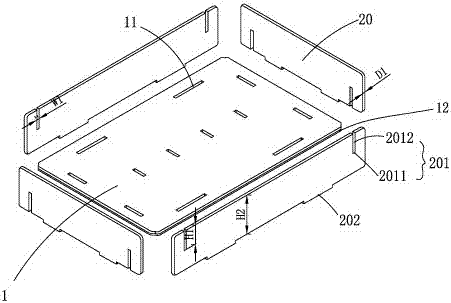

Packaging container convenient to rapidly manufacture, transport and store and manufacturing method

InactiveCN107010298AEasy to assemble by yourselfGuaranteed machining accuracyRigid containersInternal fittingsStructural engineeringLaser cutting

The invention discloses a packaging container convenient to rapidly manufacture, transport and store. The packaging container comprises a fixing base plate and at least three side plates. The side plates are mutually encircled to enable all the horizontal projections of the inner walls of the side plates to be mutually connected so as to form a closed face, and the side, facing the fixing base plate, of each side plate is at least provided with a downward extending convex block. The fixing base plate is at least provided with square through grooves with the number being the same as that of the convex blocks. Since the packaging container is formed by mutually embedding and splicing all single assemblies, and all the assemblies can be rapidly manufactured through laser cutting equipment, rapid production is facilitated, and meanwhile, storage cost and transportation and distribution cost are greatly reduced.

Owner:福建家友竹竹木有限公司

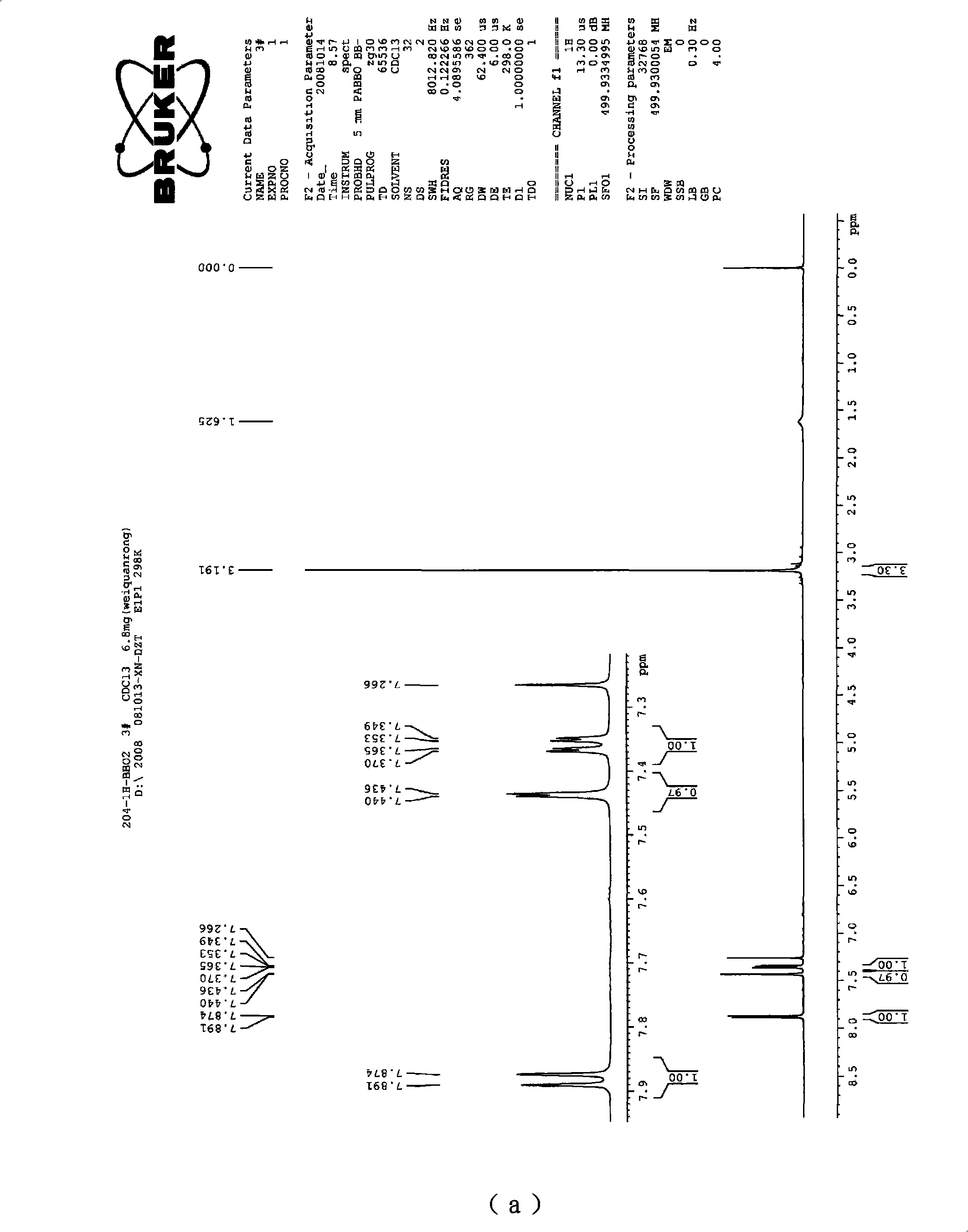

Method for preparing di-(N-methyl phthalimide) ether

InactiveCN101550102BReduce pollutionEasy to recycleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAlkaline earth metalSolvent

The invention discloses a method for preparing di-(N-methyl phthalimide) ether. The method comprises the following steps: firstly, one or two types of non-polar solvents and one kind of polar non-protonic solvent are mixed, the non-polar solvents are steamed out, then the mixed solvent reaches a certain proportion, N-methyl-4-nitryl phthalimide carries out self condensation reaction under the catalysis of one or two catalysts and normal pressure in the mixed solvent, heating and reflowing are conducted for 2 to 8 hours, and then the solvent is recovered, water is added, product is precipitatedafter cooling, and finally, tawny di-(N-methyl phthalimide) ether is obtained after filtering, washing and drying, the yield rate is 68 to 85 percent, and the melting point is 272.6 to 273 DEG C. Thecatalyst is organic acid salt and carbonate of organic acid salt of alkali metals and alkali-earth metals.

Owner:NORTHWEST A & F UNIV

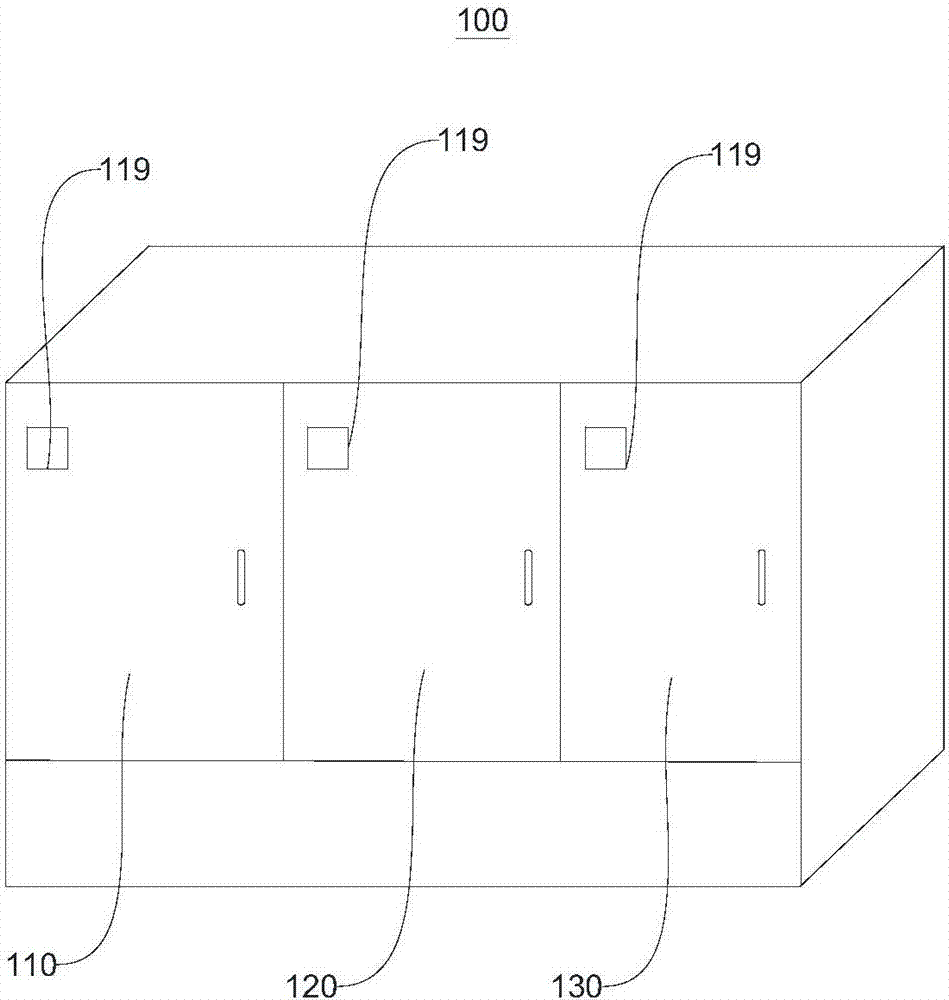

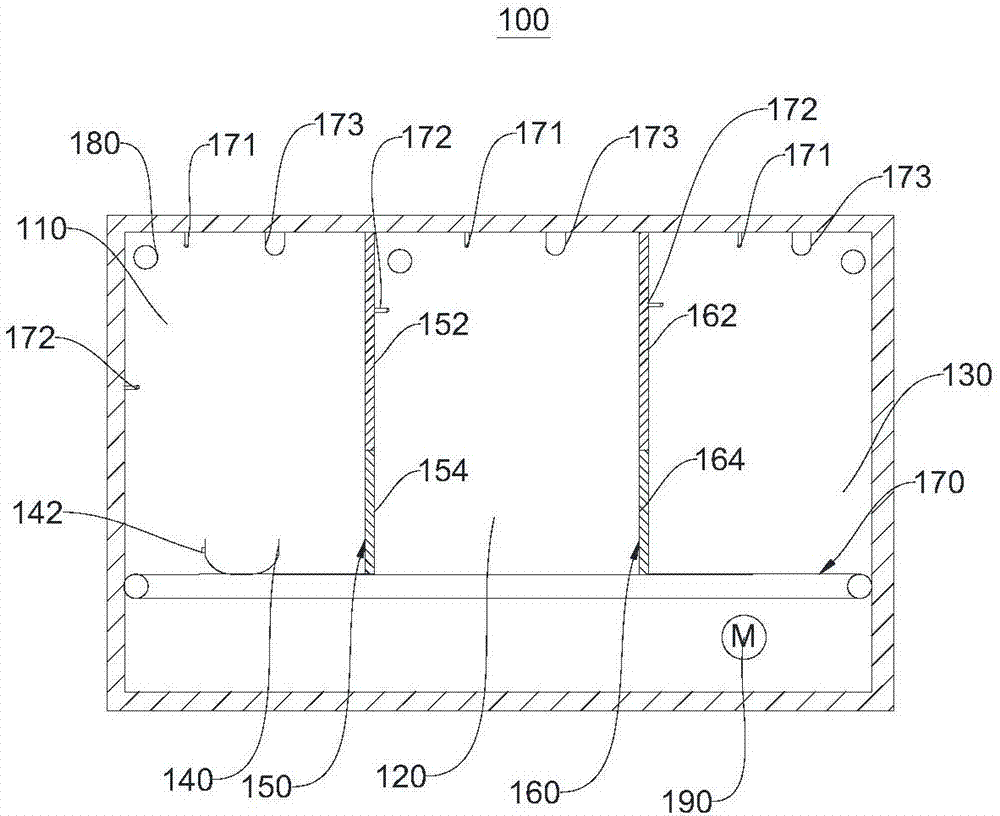

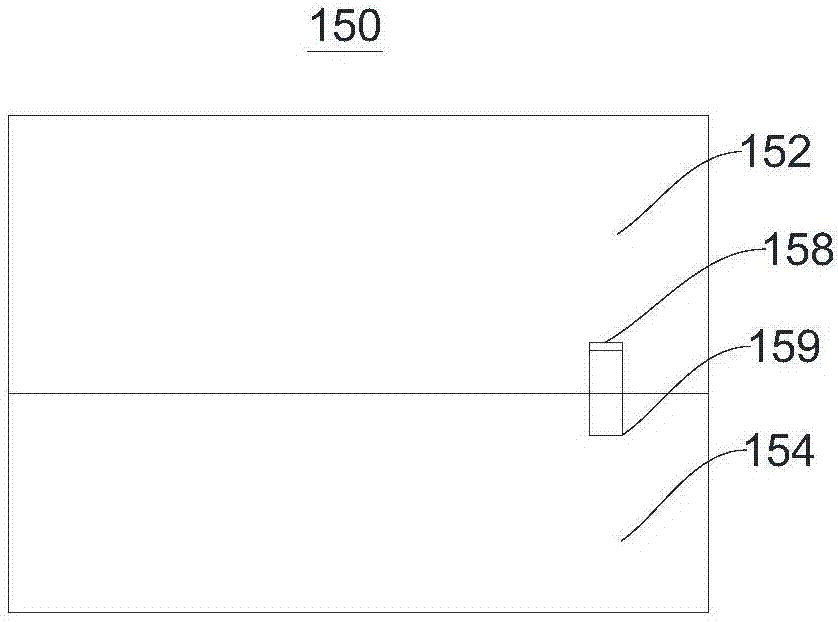

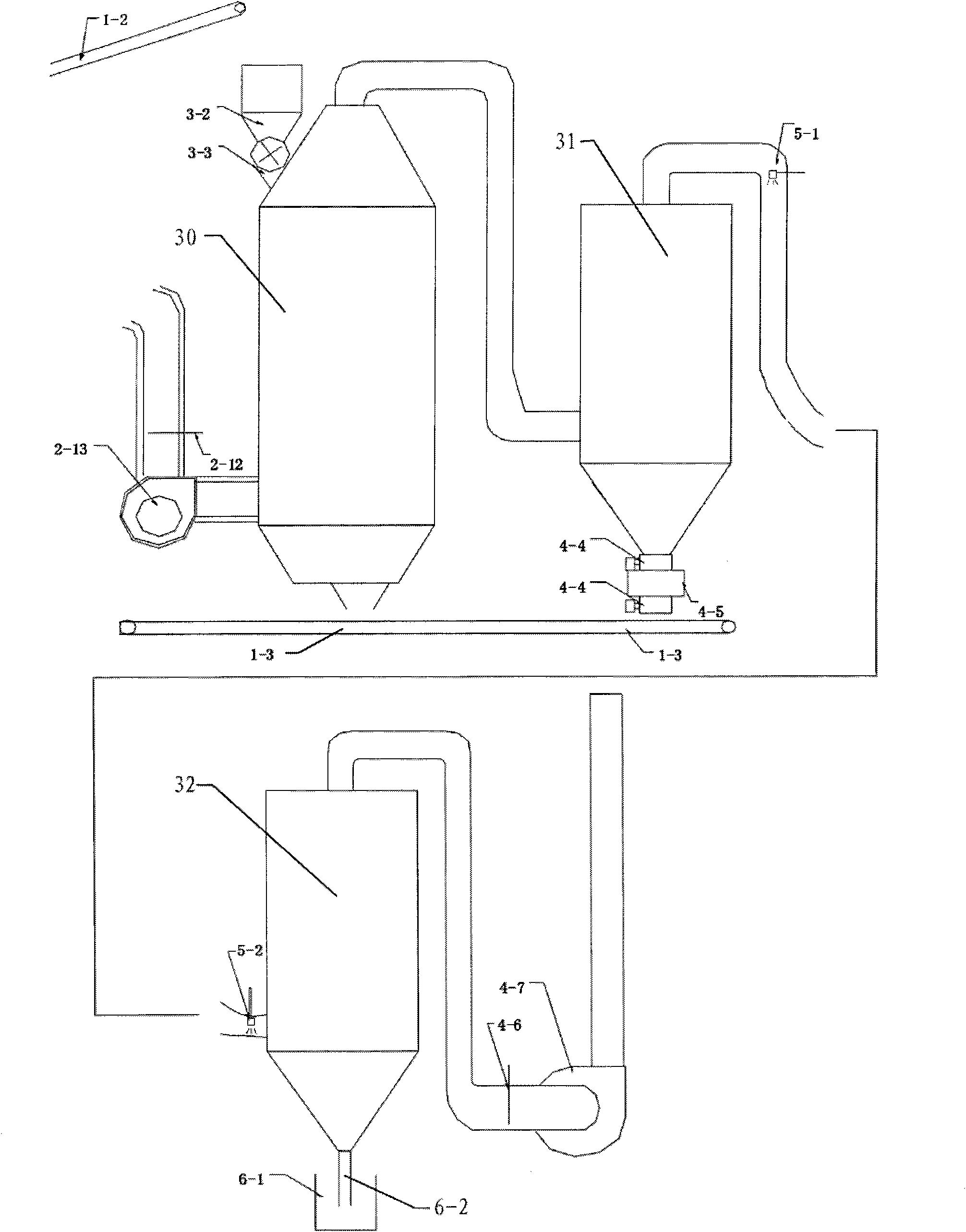

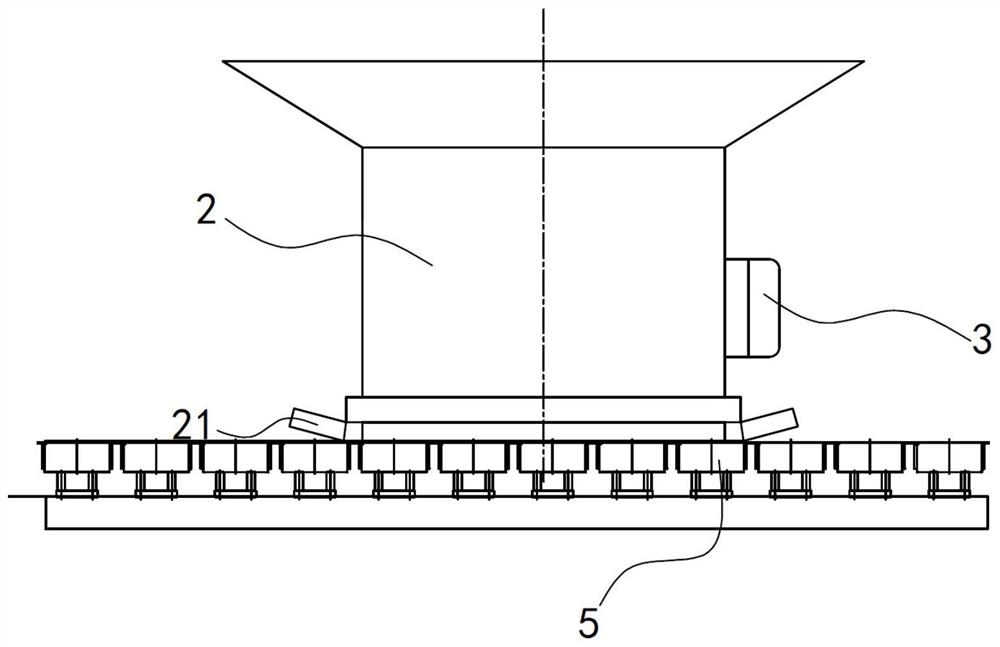

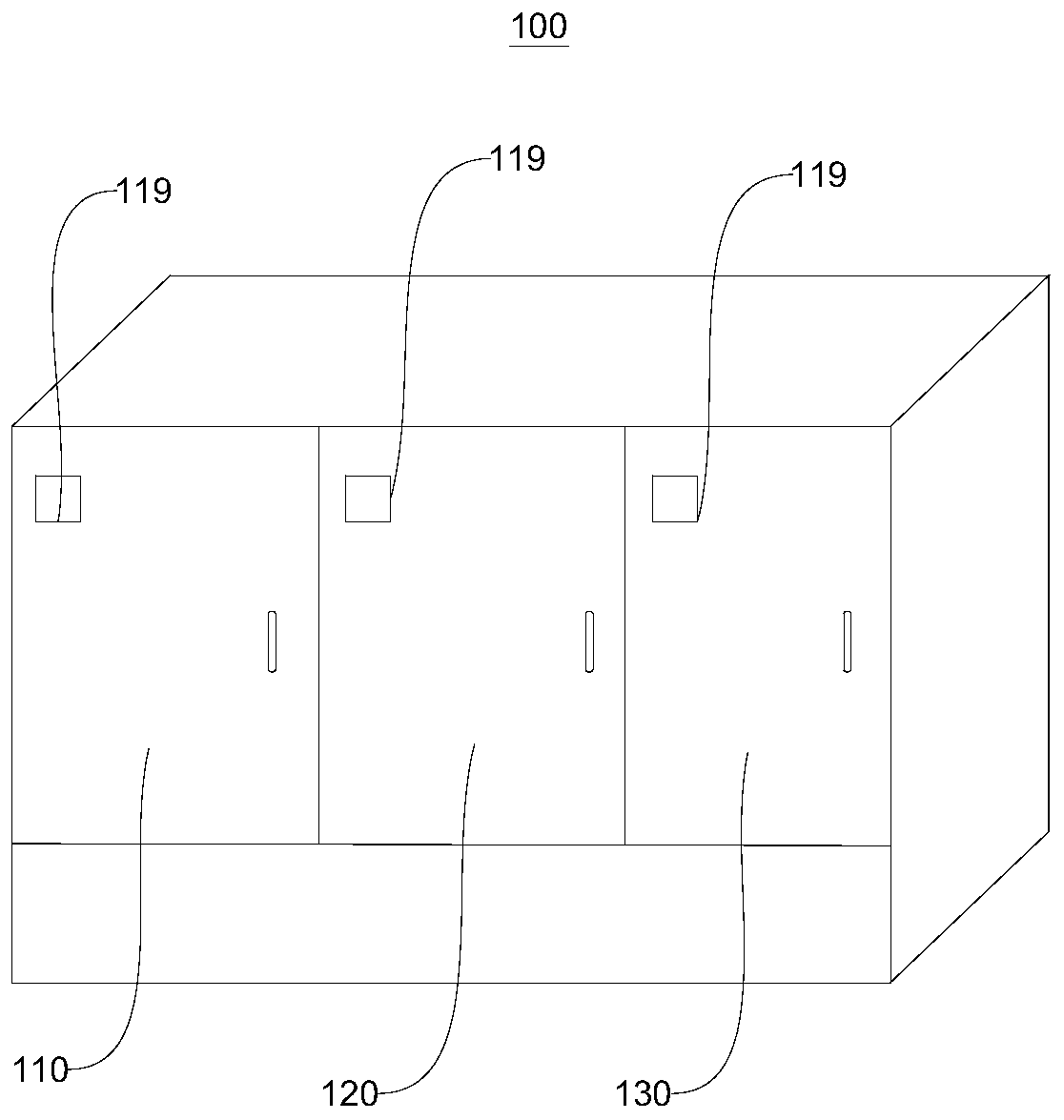

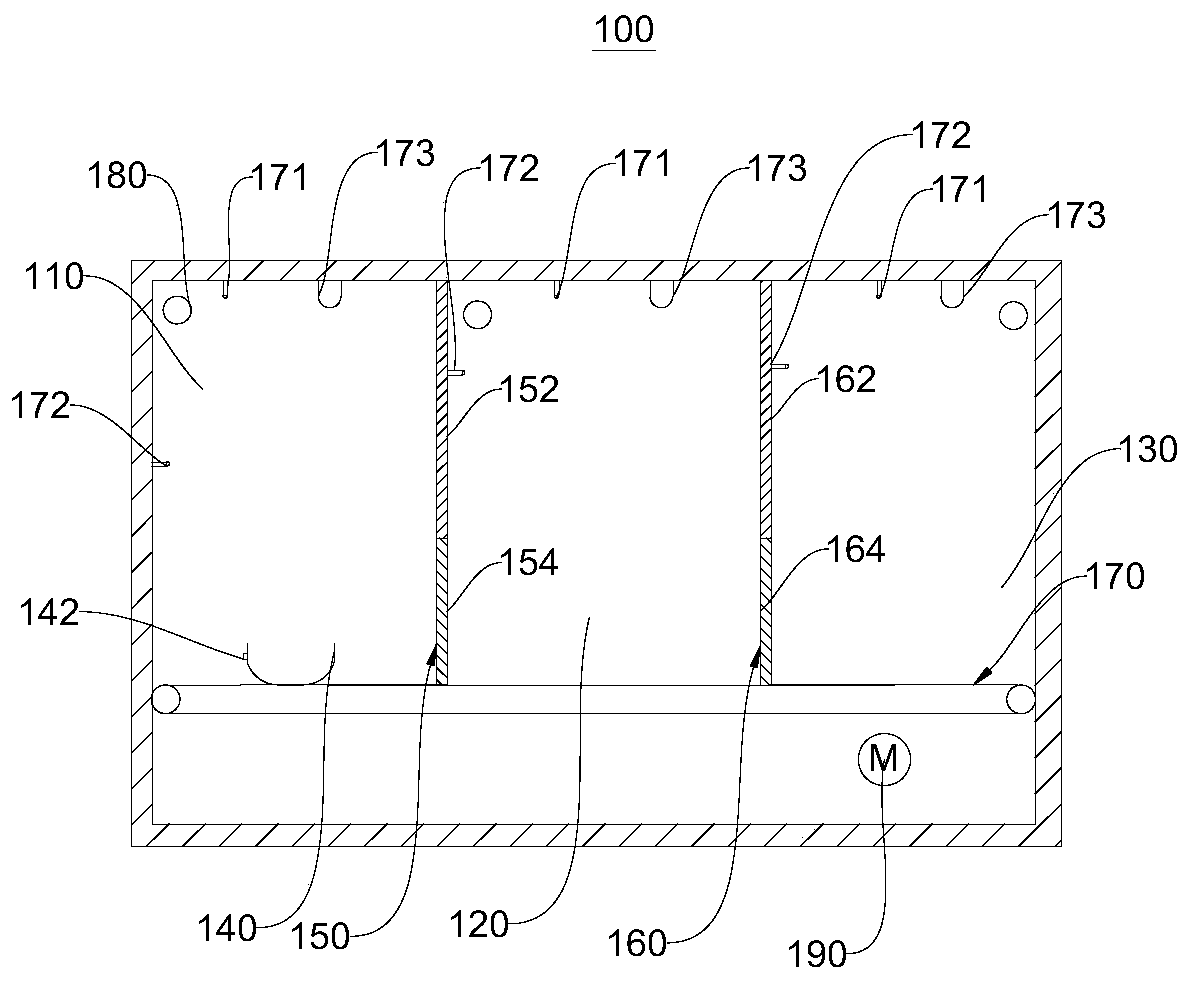

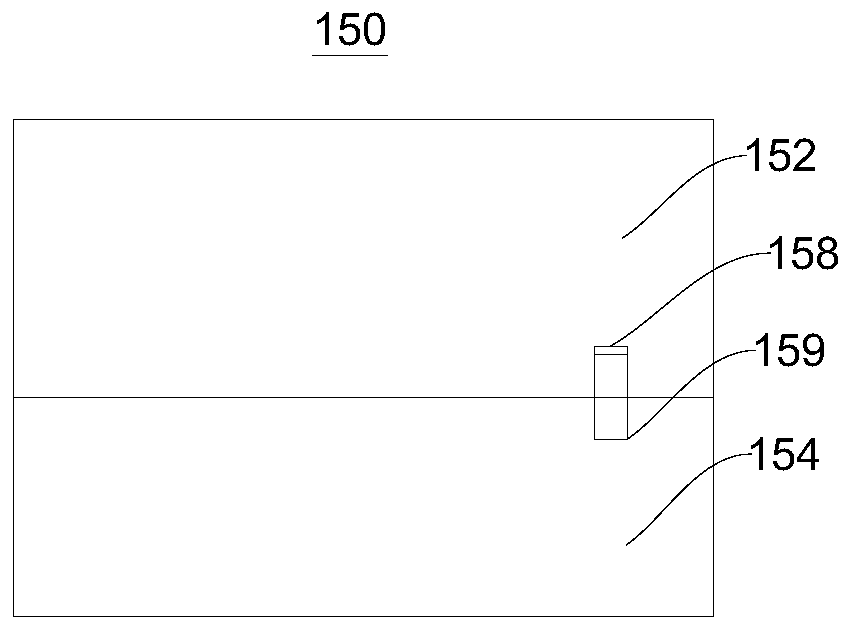

Sterilization device and sterilization system

ActiveCN106860881AIncrease product quantityImprove sterilization efficiencyLavatory sanitoryHeatEngineeringMechanical engineering

The invention provides a sterilization device and a sterilization system, and relates to the field of sterilization equipment. The sterilization device comprises a first sterilization chamber, a second sterilization chamber, a third sterilization chamber, a pipeline system, a conveying device used for conveying a material among the sterilization chambers, and a control system used for controlling the pipeline system and the conveying device, wherein the pipeline system comprises a preheating steam pipeline, a high-temperature steam pipeline, a cooling steam pipeline and a vacuum pipeline; the first sterilization chamber is communicated with the preheating steam pipeline; the second sterilization chamber is communicated with the high-temperature steam pipeline; the third sterilization chamber is communicated with the cooling steam pipeline. The sterilization device avoids the phenomenon that the performance of the material is influenced by the deterioration caused by contact between the material and the air in a cooling process after high temperature sterilization, and can enable a sterilization process and a cooling process to be carried out at the same time so as to increase the number of products processed within unit time. The sterilization system comprises the sterilization device, can avoid the deterioration caused by contact between the material and the air in the cooling process after sterilization, and increases the sterilization efficiency.

Owner:SHAANXI BICON PHARMA GRP HLDG COMPANY

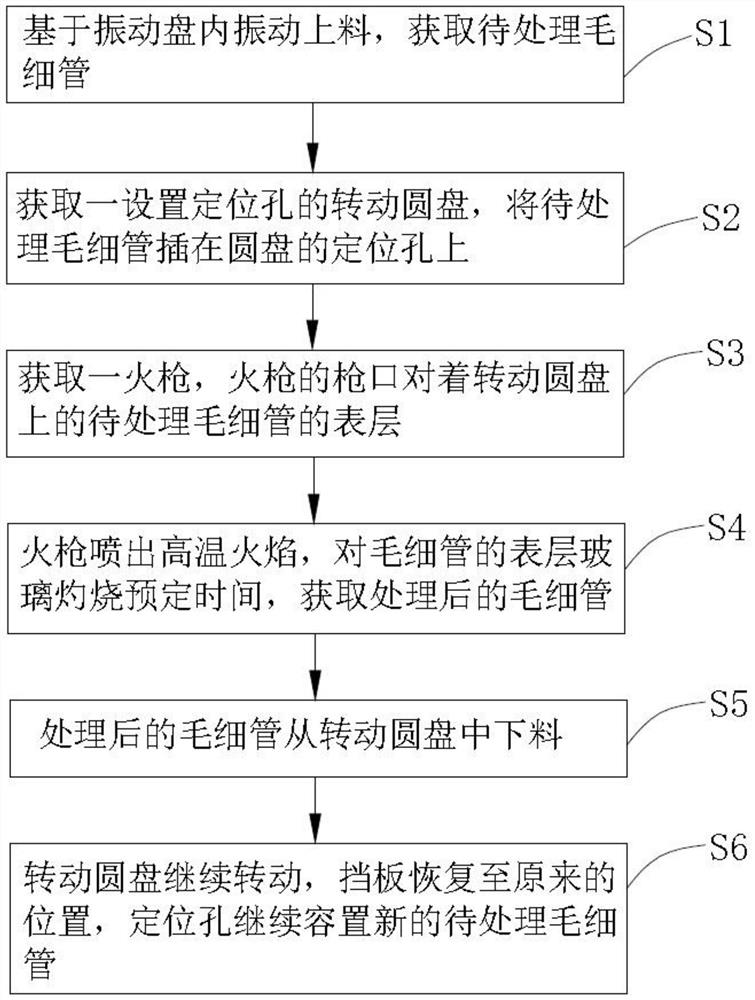

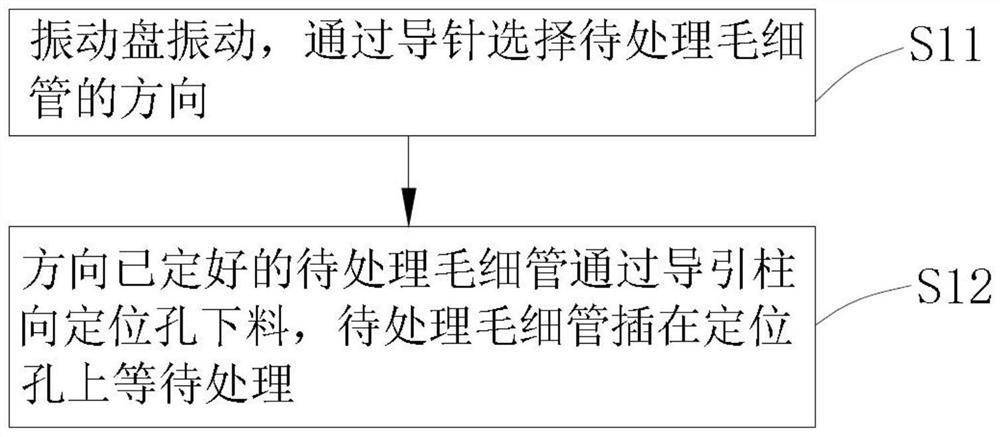

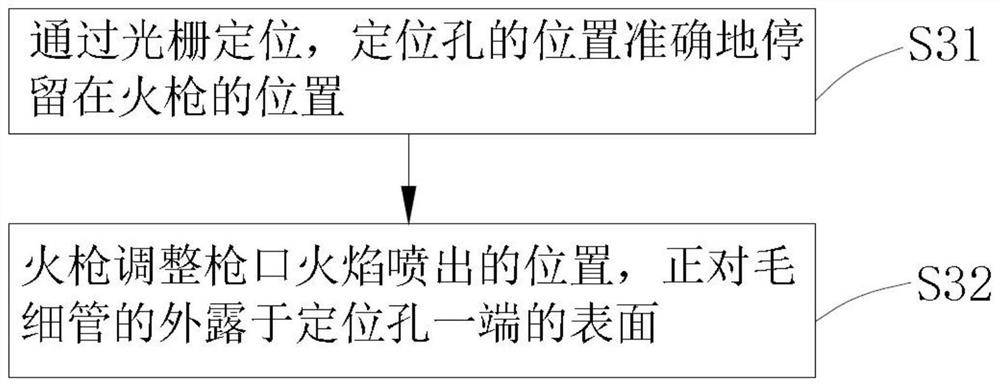

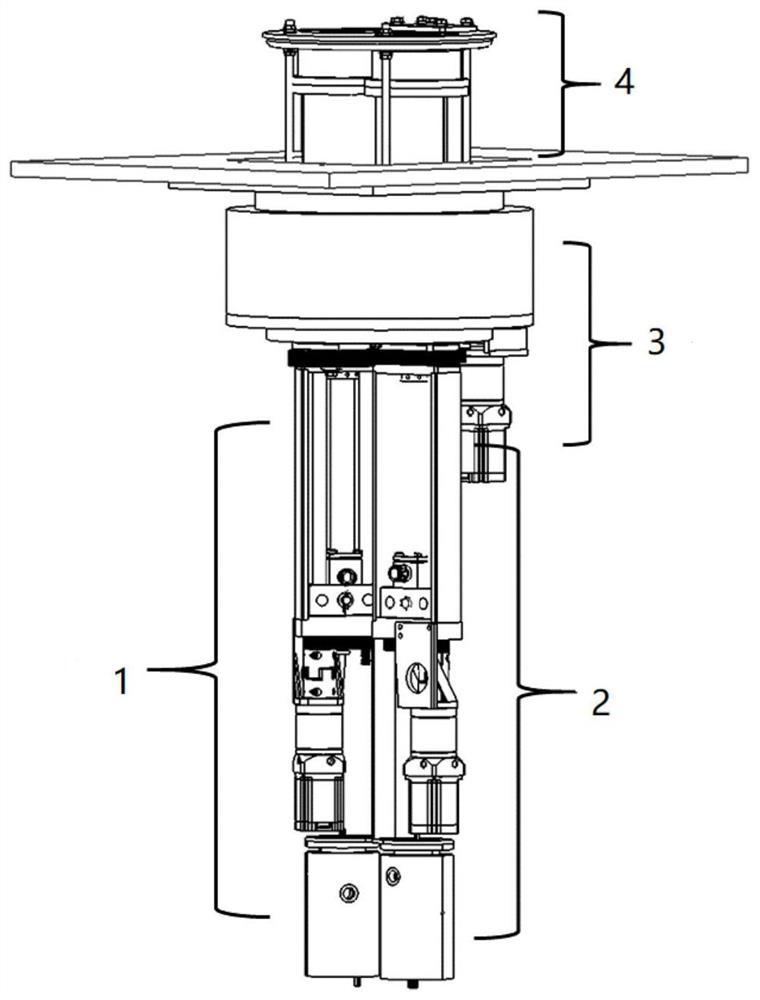

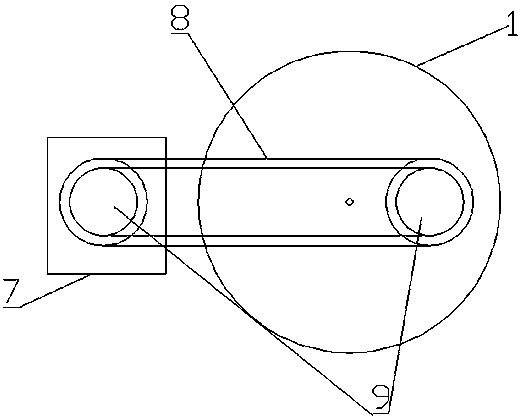

Glass capillary high-temperature treatment process and equipment

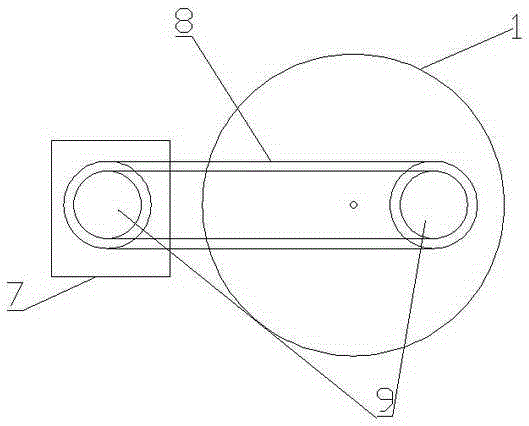

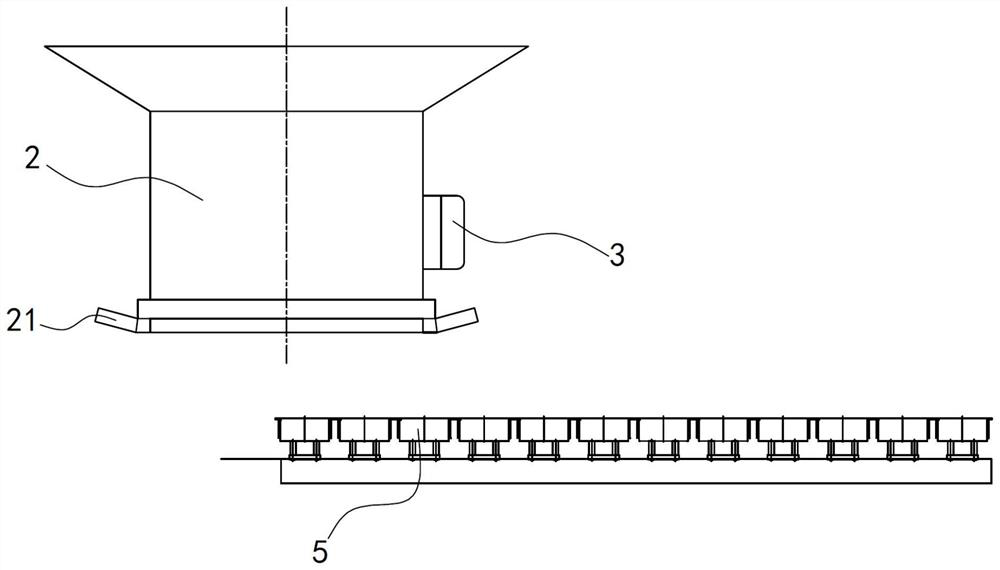

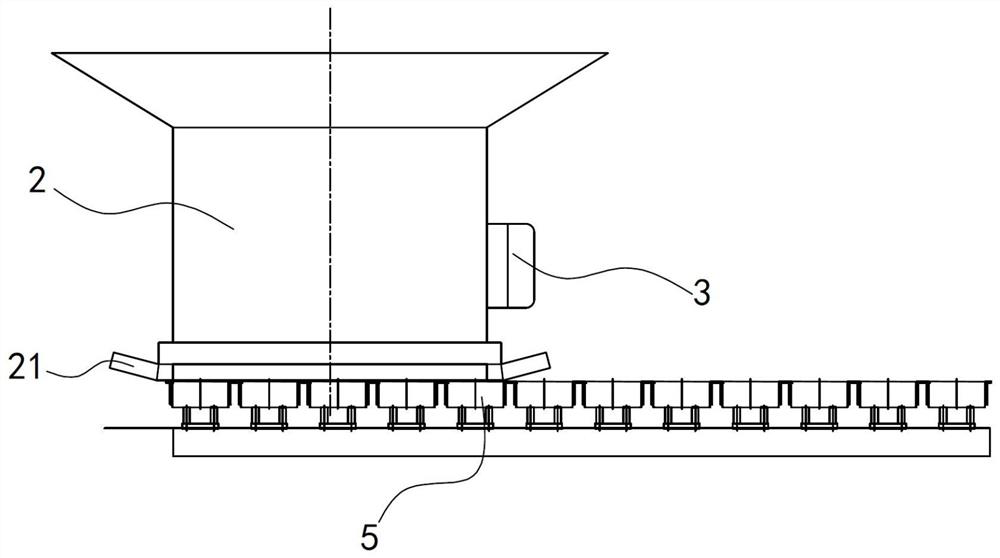

InactiveCN113754265AIncrease contactFacilitate optical signal transmissionCircular discCapillary Tubing

The invention provides a glass capillary high-temperature treatment process which comprises the following steps: obtaining a to-be-treated capillary based on vibration feeding in a vibration disc; obtaining a rotating disc provided with a positioning hole, and inserting the capillary tube to be treated into the positioning hole of the disc; obtaining a fire gun, wherein a muzzle of the fire gun faces the surface layer of the capillary tube to be treated on the rotating disc; allowing the fire gun to spray out high-temperature flames, and burning surface glass of the capillary tube for preset time to obtain the treated capillary tube; and discharging the treated capillary tube from the rotating disc. According to the glass capillary high-temperature processing technology, the surface of the port position of the glass capillary is burnt at high temperature, burrs and the like on the port of the glass capillary are burnt away, the port of the glass capillary becomes smooth, and optical signal transmission between optical fibers is facilitated. The invention also provides high-temperature treatment equipment for the glass capillary, which is suitable for the high-temperature treatment process for the glass capillary.

Owner:深圳市比洋互联科技有限公司

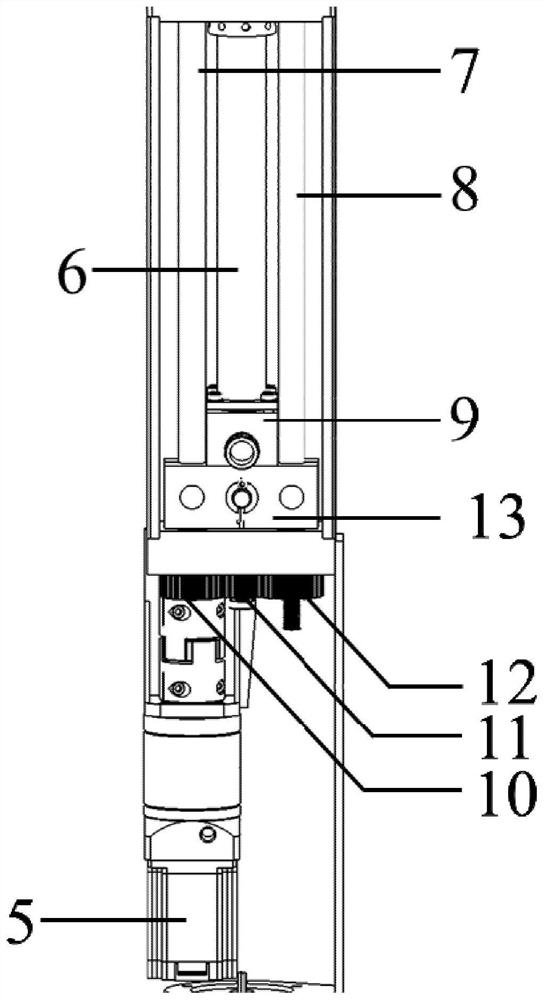

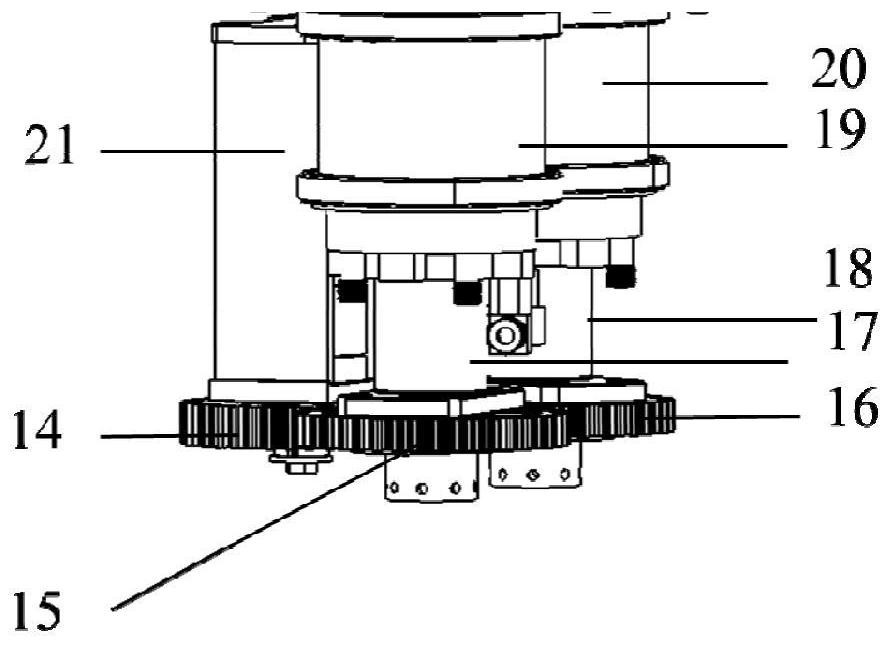

Device for preparing double-ceramic-layer coating by automatically evaporating ceramic target material

ActiveCN113564536AAutomatic uniformAutomatic stabilizationVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionBi layer

The invention provides a device for preparing a thermal barrier coating by automatically evaporating a ceramic target material and a preparation method. The device comprises a first material ejecting assembly (1), a second material ejecting assembly (2), a rotating assembly (3) and a crucible assembly (4). In the process of preparing the coating through electron beam physical vapor deposition, the rotating assembly (3) can drive the target material in the crucible assembly (4) to rotate at a certain speed, so that the surface of the target material is uniformly evaporated; the first material ejecting assembly (1) can drive the target material in a first crucible (26) to move up and down, and the second material ejecting assembly (2) can drive a target material in a second crucible (27) to move up and down, so that automatic replacement of the target material in the electron beam physical vapor deposition process is achieved, the working efficiency of preparing the thermal barrier coating through the electron beam physical vapor deposition coating is improved, the structural stability of the double-ceramic-layer coating is improved, and the process stability of the preparation process is improved.

Owner:BEIHANG UNIV +1

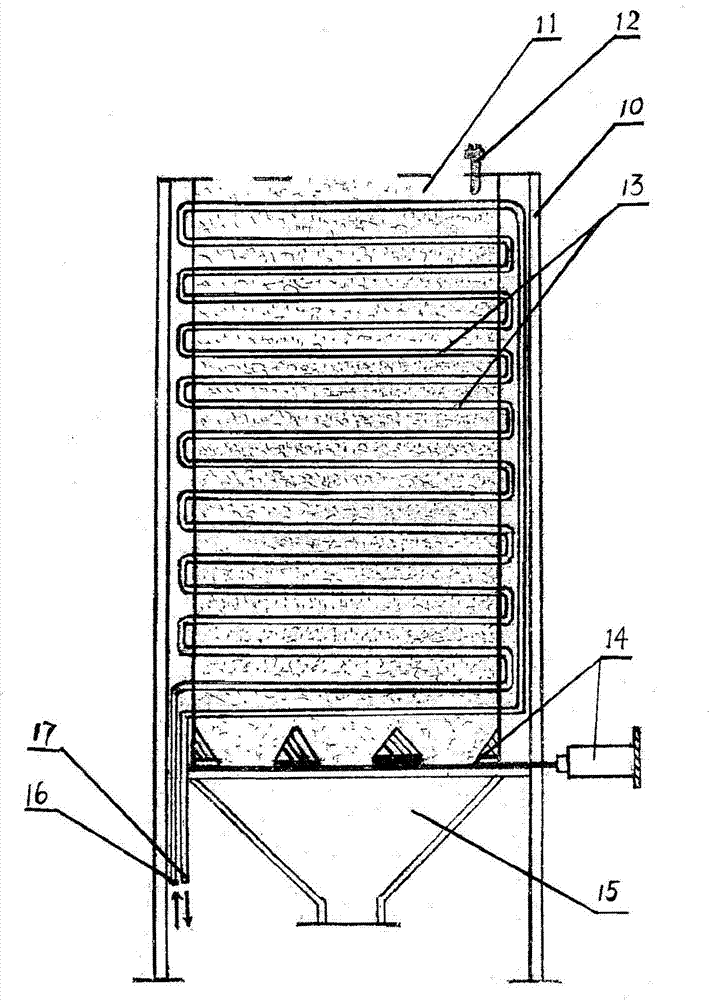

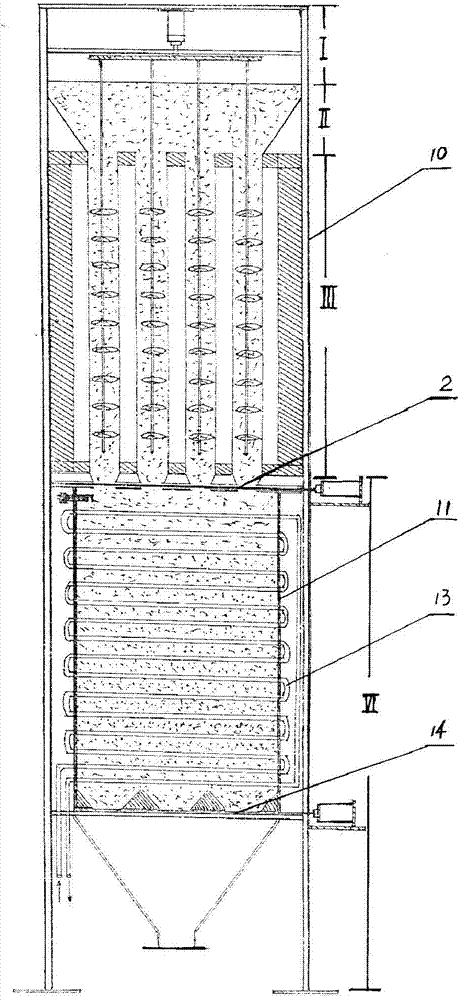

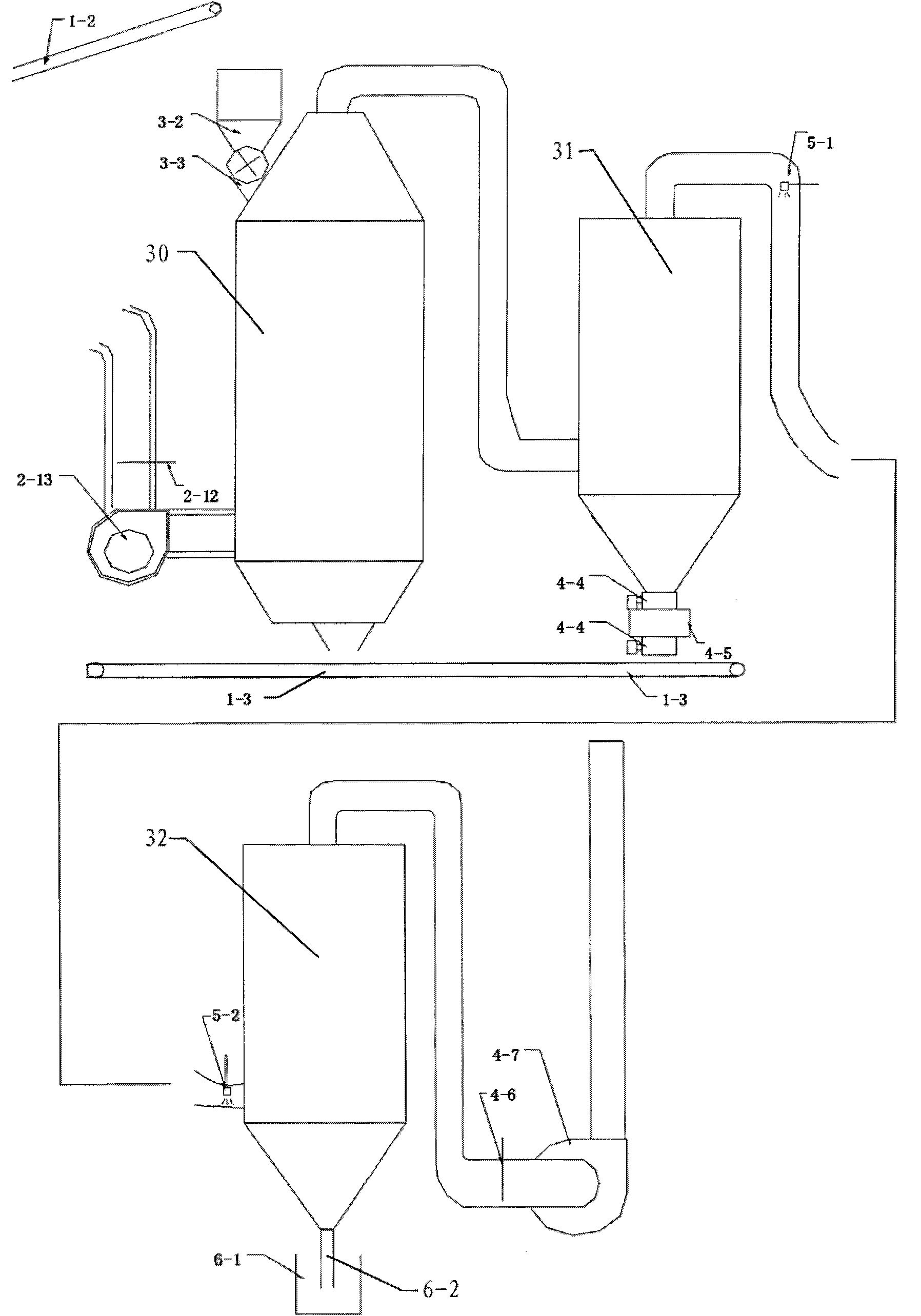

Vertical, multi-pipe and external heating type manganese dioxide reduction roaster

InactiveCN104748544AIncrease product quantityQuality improvementProcess efficiency improvementVertical furnacesControl systemHydraulic pump

The invention discloses a vertical, multi-pipe and external heating type manganese dioxide reduction roaster. The vertical, multi-pipe and external heating type manganese dioxide reduction roaster comprises a vertical roaster body, and a plurality of roasting pipes mounted in the roaster body, wherein pushing rods are mounted in the roasting pipes; a plurality of scrapping rings are fixedly mounted on the pushing rods; the pushing rods can discontinuously move up and down by reciprocating within a fixed stroke in the roasting pipes. According to the vertical, multi-pipe and external heating type manganese dioxide reduction roaster, a set of hydraulic multi-ring pushing rod roasting pipe sintering blocking cleaners is mounted on the vertical roaster body and controlled by a control system through a hydraulic pump to discontinuously work; an oil cylinder plunge piston drives a plurality of multi-ring pushing rods to discontinuously move up and down by reciprocating within the fixed stroke in the roasting pipes through a movable bracket; when in moving, a plurality of scraping rings fixed on the pushing rods can be used for scraping powder sintering blocks which are possibly produced on the inner walls of the roasting pipes, so that all powder in the pipes can be kept in a normal roasting state, and the problems of blasting and raw powder movement in roasting of the roaster can be completely removed; meanwhile, an external exciting type large-capacity roasting material cooler is added to the roaster body, so that the cooling capacity and the cooling contact area can be increased; a hydraulic system can be used for continuously automatically working, and thus the problem of the manganese dioxide reduction roaster body can be solved well.

Owner:张辞军 +1

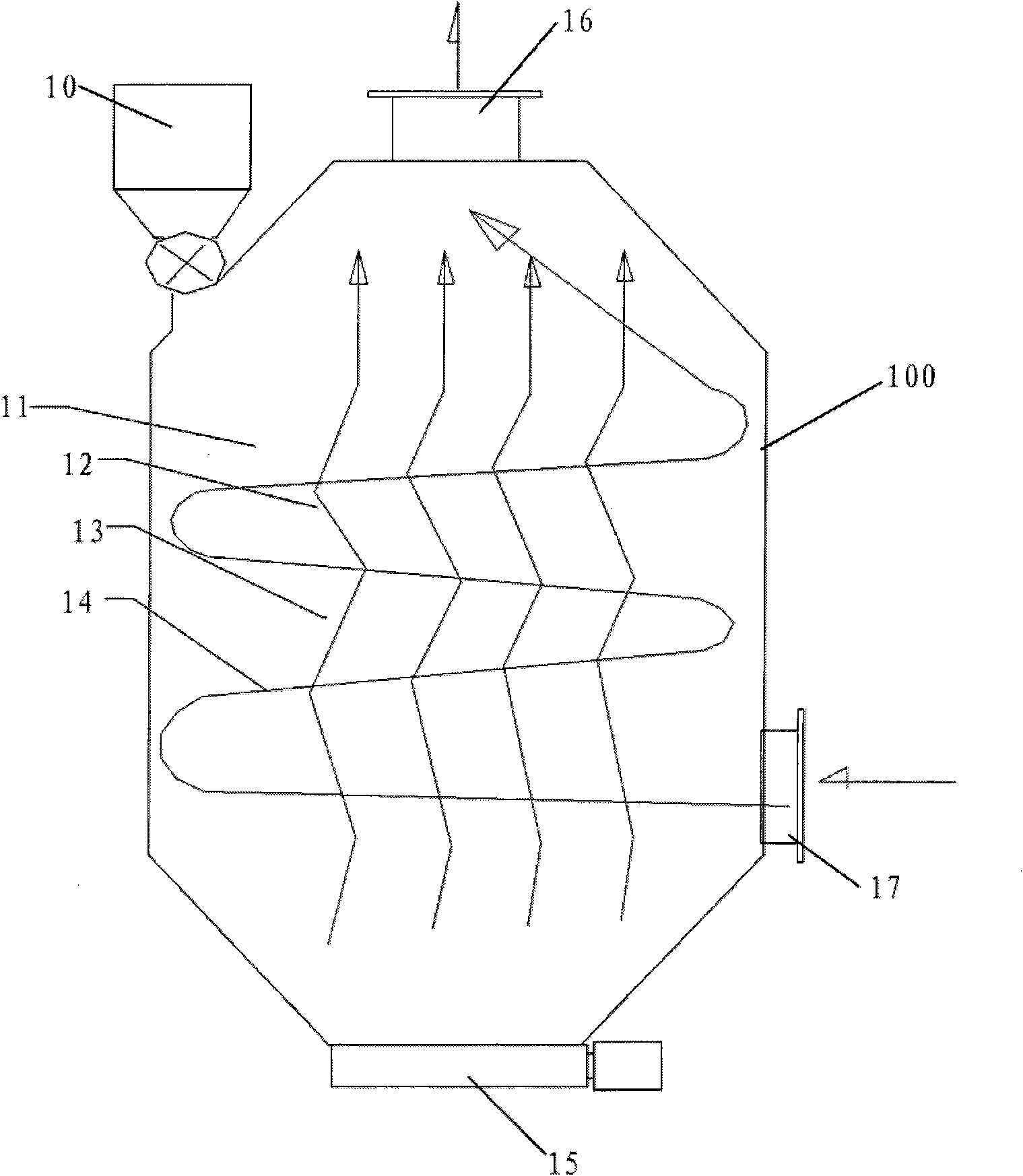

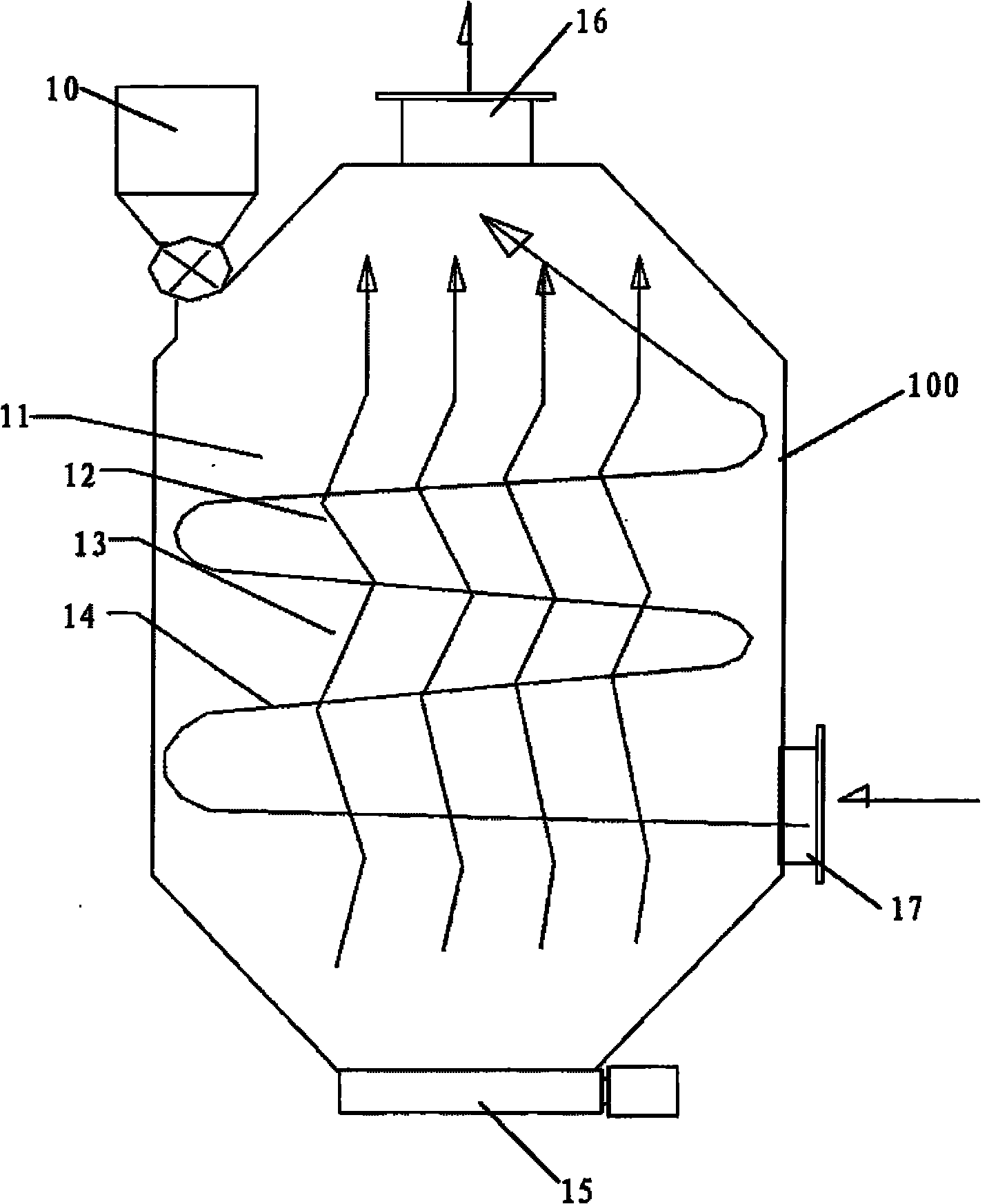

Dust collection device for vibration bed mixed flow dryer

ActiveCN102213543AAchieve emission standardsIncrease product quantityDrying solid materialsCycloneEmission standard

The invention relates to a dust collection device for a vibration bed mixed flow dryer. The device comprises a dryer, and at least one primary cyclone dust chamber and at least one secondary cyclone dust chamber which are connected with the dryer through a pipeline in turn; a steam humidifier is arranged in an outlet pipeline on the top of the primary cyclone dust chamber; a sprayer is arranged at an inlet of the secondary cyclone dust chamber; and the dryer is positioned in a micro negative pressure state and has an inner negative pressure value of -90 to -110Pa. A secondary cyclone dedusting and demisting integral structure is adopted, namely different equipment operating parameters and different dedusting processes are adopted for a secondary cyclone dust collection device respectively so as to achieve a two-stage complementary dedusting effect, namely large-particle coal dust is recovered through primary dry cyclone dedusting, and small-particle coal dust is removed through secondary humidifying, spraying and demisting so as to meet an emission standard.

Owner:CHINA SHENHUA ENERGY CO LTD

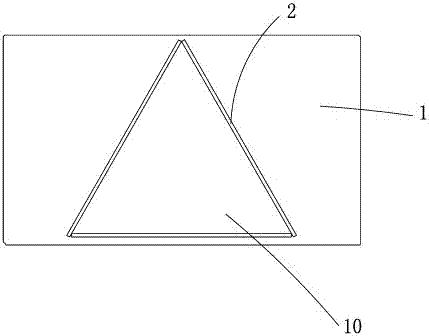

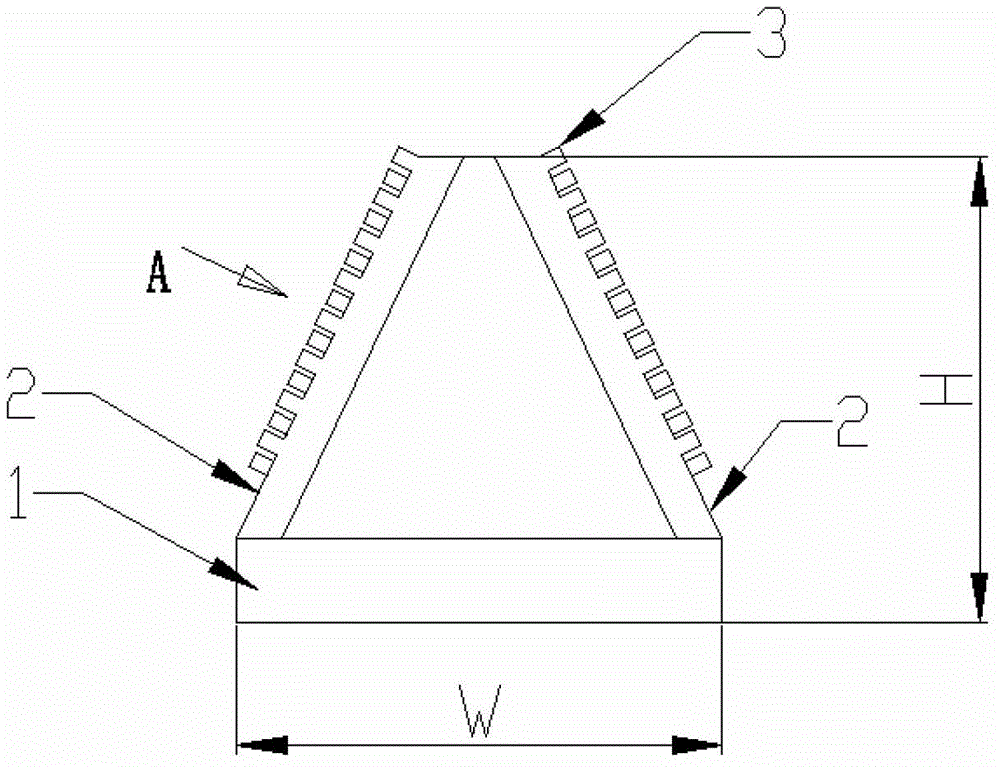

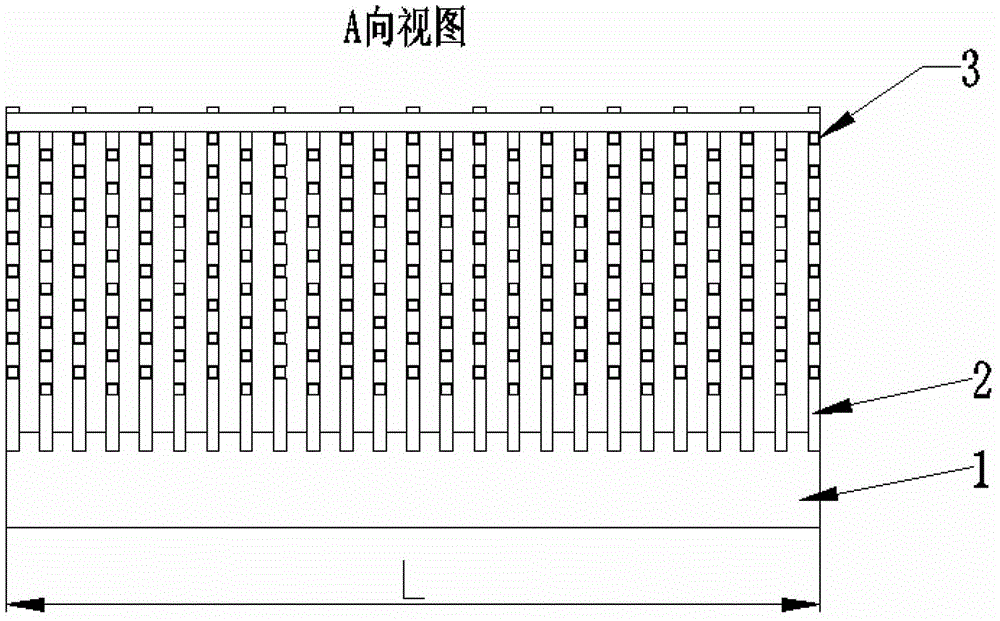

Triangular tray for vulcanized rubber tube

The invention relates to a triangular tray for a vulcanized rubber tube. The triangular tray comprises a base, support beams and square tubes, the entire section of the tray is triangular, two bevel edges of the triangle are the support beams, a plurality of square tubes are arranged on the support beams, and the calibers of the square tubes are larger than those of vulcanized core rod square tubes. A plurality of triangular support beams are welded on the base, the distance of each two support beams is larger than or equal to two times the width of the support beams, and the square tubes between each two adjacent support beams are staggered. The square tube ports on the support beams are upward obliquely, and the depths of the square tubes are the heights of the square tubes below core rods so as to prevent instability of the installed core rods. The distance between the square tubes on each support beam is larger than or equal to two times the side length of the square tube. By virtue of the triangular tray, a certain space is left for die sleeving operation, contact between the core rods can be prevented simultaneously, the internal space of a vulcanized tank is fully utilized, and products produced by the vulcanized tank increases by more than 30%.

Owner:TIANJIN PENGYI GRP CO LTD

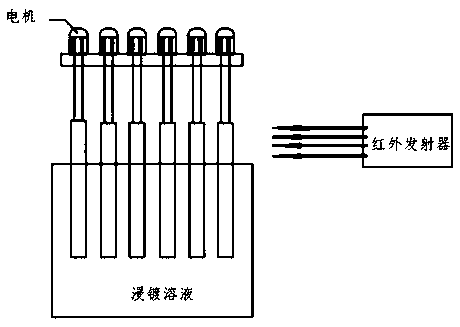

OPC drum batch-processing method capable of improving dropoff problem

ActiveCN110496765AImprove uniformitySpeed up evaporationPretreated surfacesCoatingsBatch processingEngineering

The invention discloses an OPC drum batch-processing method capable of improving the dropoff problem. The OPC drum batch-processing method comprises the following steps of: (S1) additionally installing a plurality of groups of driving devices on a workpiece gripper; (S2) grabbing base aluminum tubes by using the workpiece gripper; (S3) arranging an infrared transmitter at the side surface of a dipplating cylinder; (S4) pouring a dip plating solution into a plating bucket, and driving the base aluminum tubes to be dipped into the dip plating solution by using the workpiece gripper in order toimplement soaking of the base aluminum tubes; (S5) starting the infrared transmitter, subsequently lifting up the base aluminum tubes at a constant speed by using the workpiece gripper and making eachbase aluminum tube to rotate about the central axis of the workpiece gripper, shutting down the infrared transmitter when the lift distance of the base aluminum tubes reaches a preset lift distance,making the workpiece gripper lift up the base aluminum tubes continuously until the base aluminum tubes are completely separated from the dip plating solution; and (S6) discharging the dip-plated basealuminum tubes. The OPC drum batch-processing method disclosed by the invention guarantees the uniformity of volatilization of the film plating liquid at the outer side of each base aluminum tube andeffectively improves the uniformity of a surface film layer of a final OPC drum finished product.

Owner:苏州恒久光电科技股份有限公司

Dust collection device for vibration bed mixed flow dryer

ActiveCN102213543BAchieve emission standardsIncrease product quantityDrying solid materialsCycloneEmission standard

Owner:CHINA SHENHUA ENERGY CO LTD

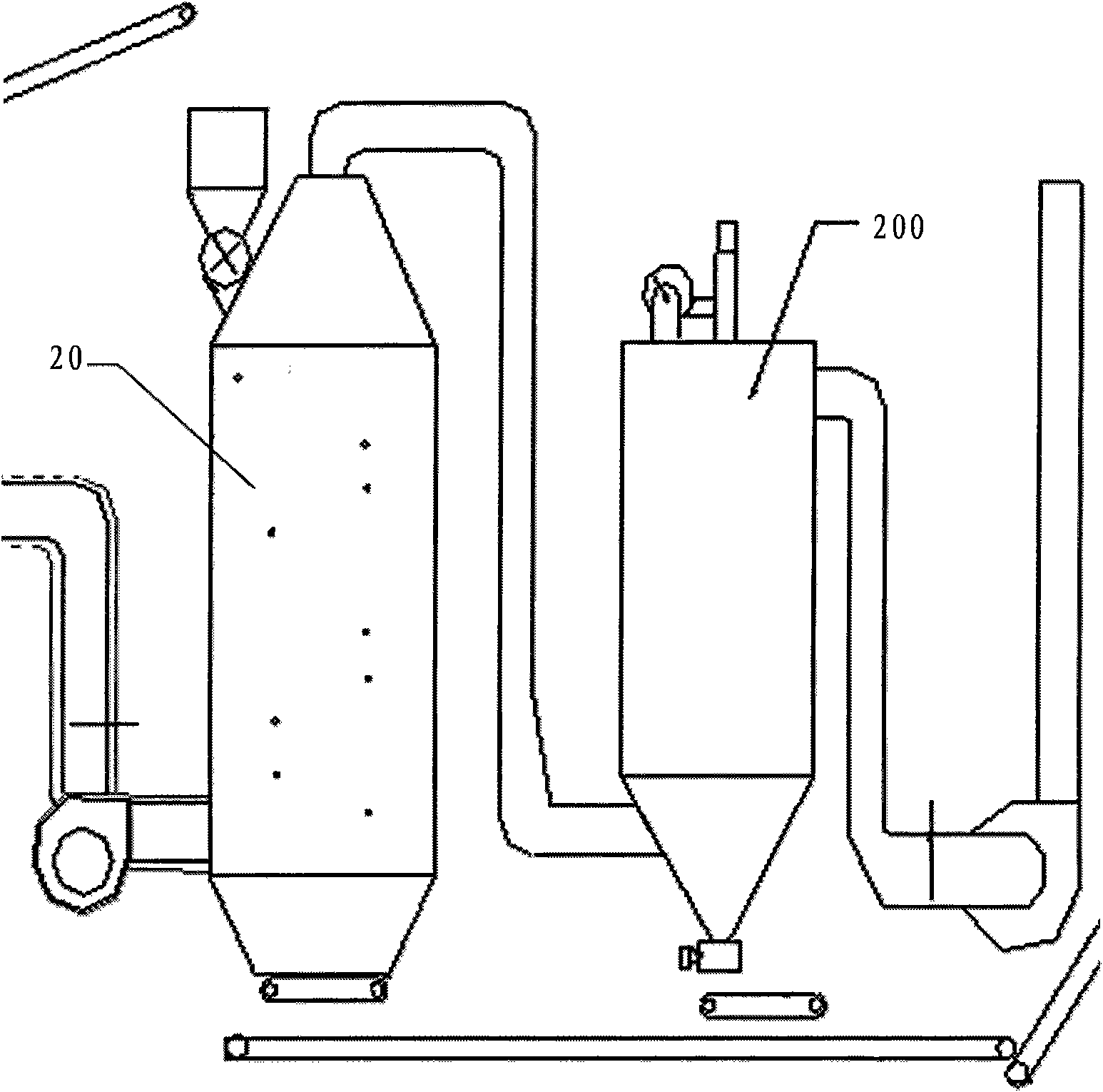

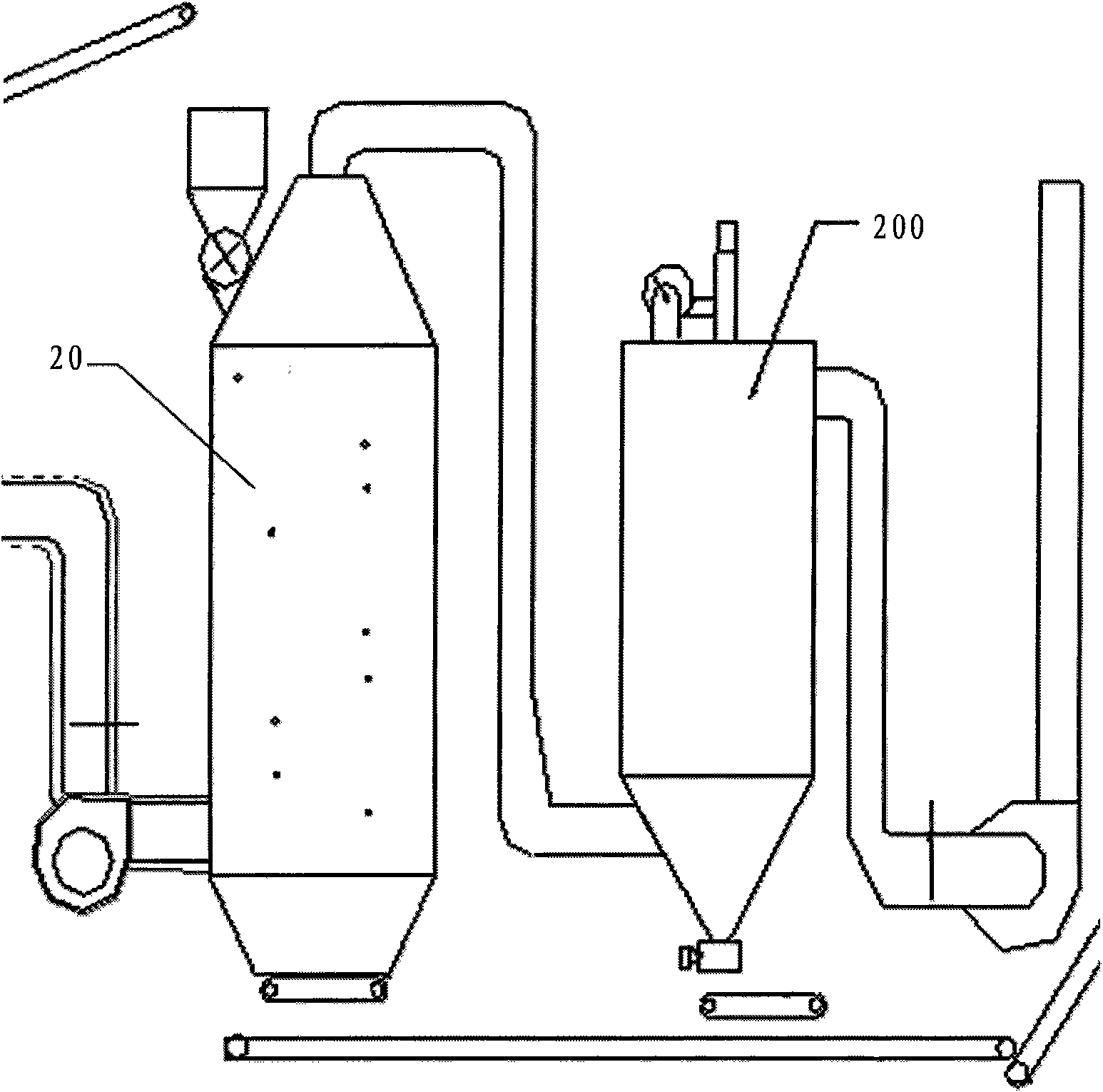

Vertical carbonization device for automatic tar removal for carbon fiber production

InactiveCN103498213BGood energy saving effectIncrease product quantityFibre chemical featuresFiberCarbon fibers

A vertical type carbonization device capable of automatically cleaning tar for carbon fiber production belongs to the field of carbon fiber production equipment. One side of a heating inner chamber is provided with a heating chamber, a driving roll is arranged in the heating inner chamber, a driven roll is arranged in the heating chamber, an absorption band takes the driving roll and the driven roll as the two ends to form a crawler structure, the absorption band goes through the joint position between the heating inner chamber and the heating chamber, and is in a cyclic motion; the gas outlet of the heating chamber is in a through connection with ultrasonic gas tar purification equipment through a gas recycling pipe line. The heating inner chambers of vertical type or inclined vertical type carbonization equipment both have circulation space which is beneficial for exhaustion of gas tar and occupation of tar-free gas, thus the gas tar generated during the production process will not be trapped in the heating area of the chamber to affect the product quality, and the protective gas and heat for production will not lose basically.

Owner:齐齐哈尔瑞兴碳纤维科技有限公司

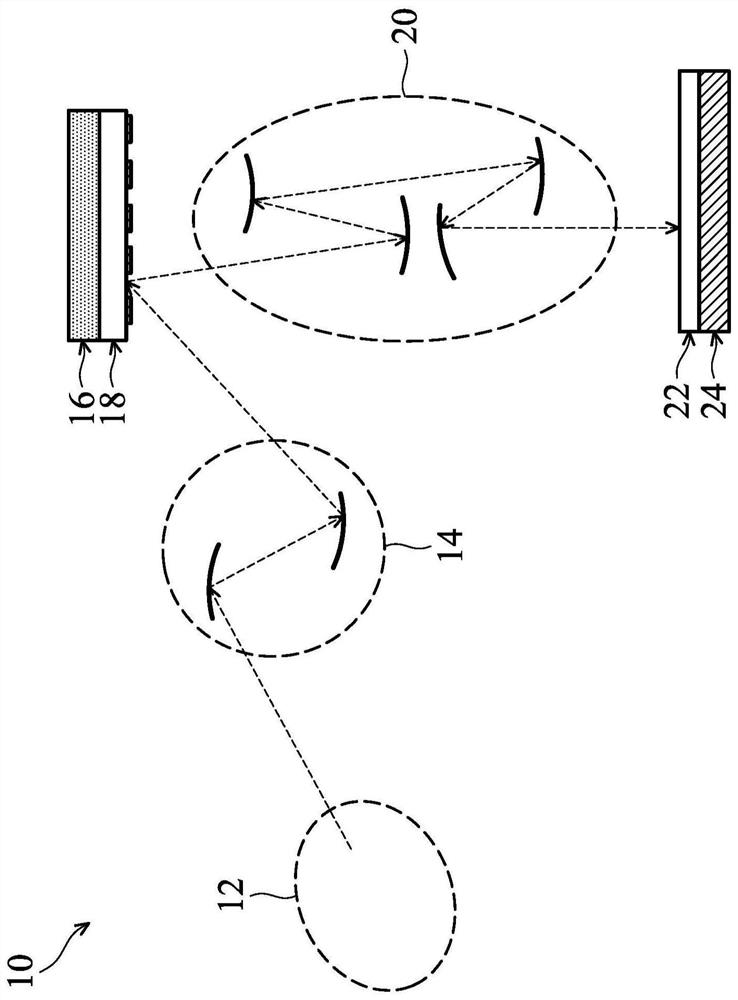

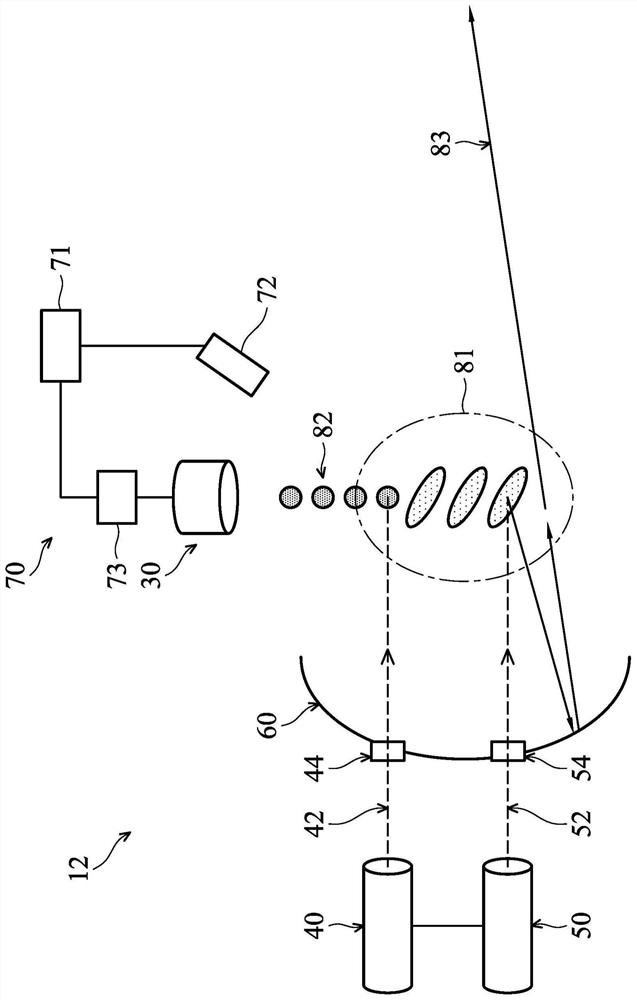

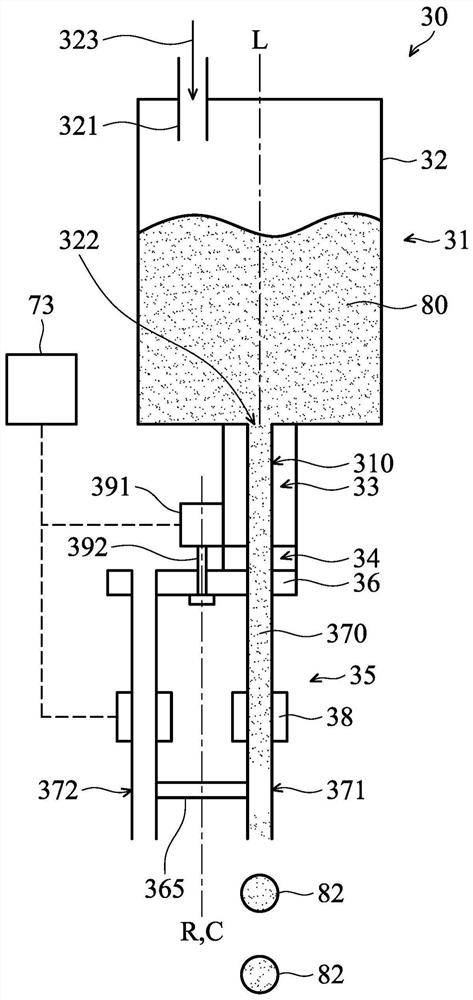

Target fuel generator and method of supplying target fuel

ActiveCN109461671BImprove yieldIncrease product quantitySemiconductor/solid-state device manufacturingElectrical and Electronics engineeringAutomotive engineering

Part embodiments of the invention provide a target fuel generator and a method for supplying a target fuel. The target fuel generator includes a storage assembly and a nozzle assembly. The storage assembly has a flow channel. The target fuel generator also includes a nozzle assembly. The nozzle assembly is connected to the storage assembly in a manner that the nozzle assembly can be rotated to a first rotation angle and a second rotation angle; and the nozzle assembly includes a first nozzle head and a second nozzle head. In a first rotational position, the first nozzle head is connected to the flow channel and the second nozzle head is separated from the flow channel; and in a second rotational position, the second nozzle head is connected to the flow channel and the first nozzle head isseparated from the flow channel.

Owner:TAIWAN SEMICON MFG CO LTD

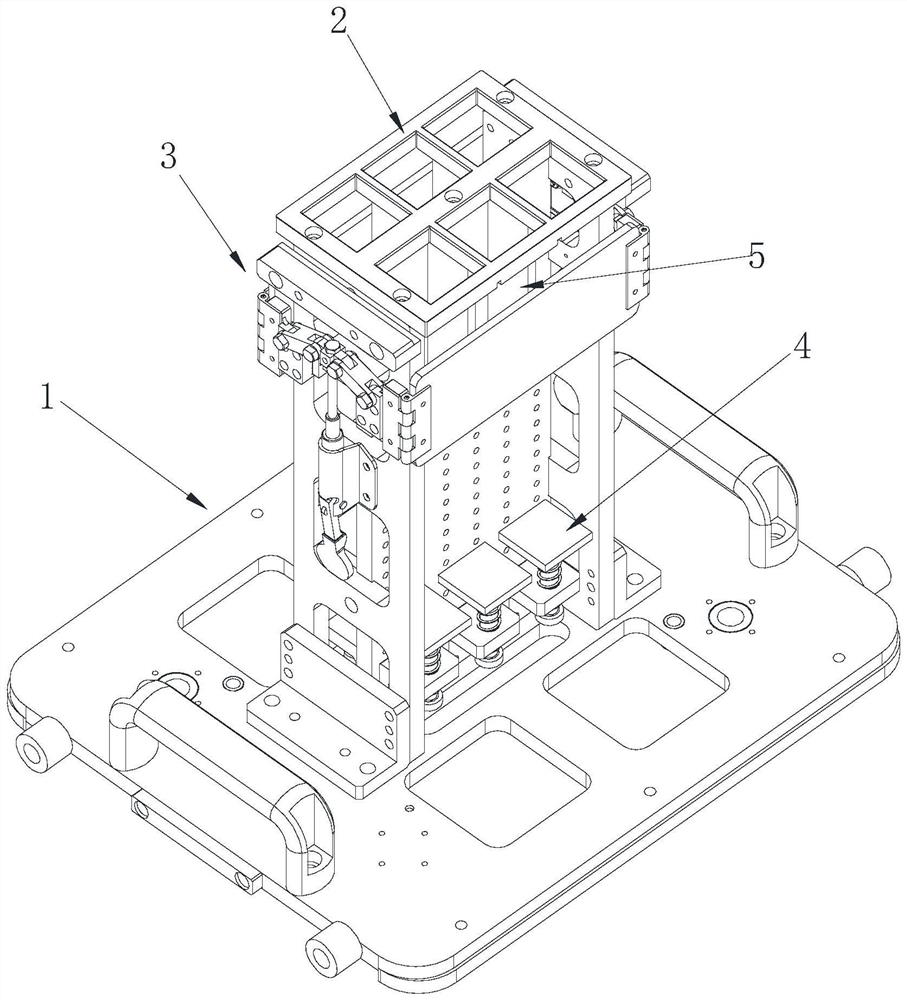

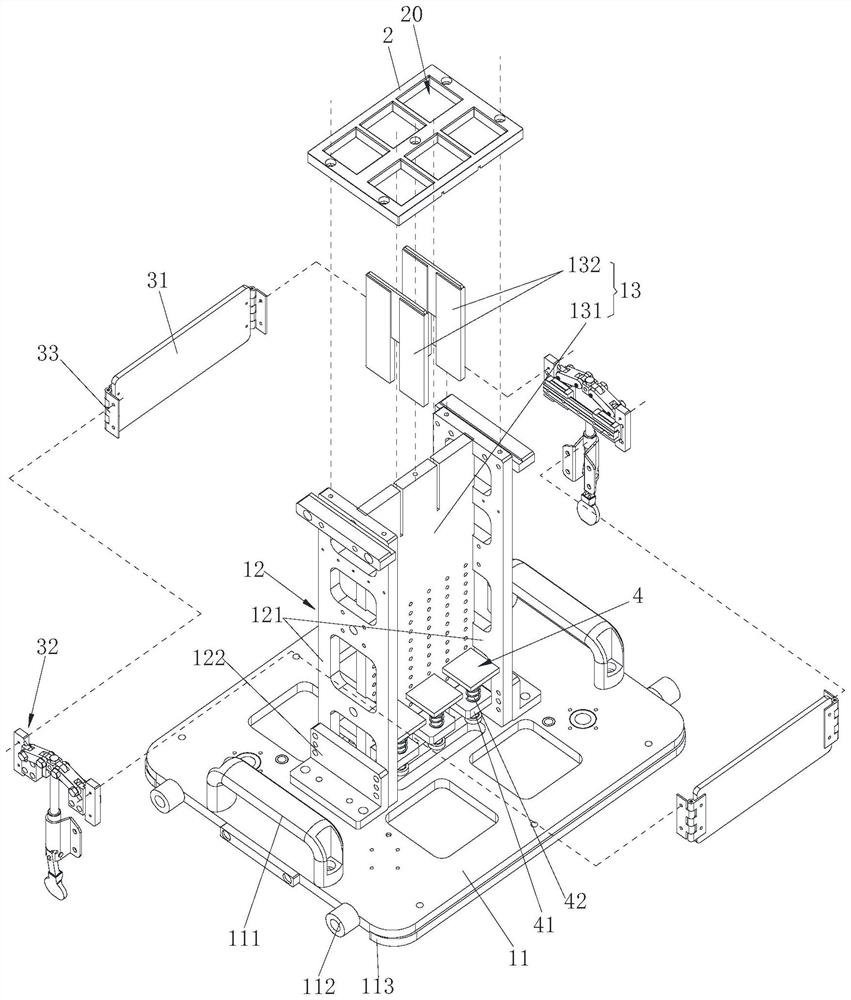

Processing method and equipment for silicon carbide DPF (diesel particulate filter)

ActiveCN114352380AAvoid enteringAvoid breakingInternal combustion piston enginesDispersed particle filtrationCarbide siliconSilicone tape

The invention discloses a silicon carbide DPF machining method and equipment, and belongs to the technical field of DPF machining. The method comprises the steps that S1, a plurality of silicon carbide DPF blanks are vertically arranged, and the to-be-machined end faces of all the blanks are located in a first plane area; s2, the first plane area is covered with an adhesive tape, and the edge of the adhesive tape extends outwards and is laid into an extension area; and S3, the adhesive tape above the blank is punched, blocked and cured, and then the adhesive tape is removed. Specifically, a tool clamp mainly comprising a supporting base, a mold frame, a locking device and a supporting block is adopted to achieve the step S1 and the step S2. It can be seen that multiple silicon carbide DPF blanks can be machined at the same time, efficiency is high, pasty materials for hole blocking can be prevented from entering partition honeycomb holes, the pasty materials for hole blocking are difficult to pollute the outer side walls of the blanks, the outer side walls do not need to be protected through adhesive pasting, and the problem that the outer side wall skins of the blanks are damaged due to adhesive tearing can be avoided.

Owner:岚士智能科技(上海)有限公司

Bi(N-methylphthalic imidine) ester preparation method

The invention discloses a making method of di (N-methyl phthaloyl imine) ether, which comprises the following steps: proceeding self-condensing reaction for N-4-nitro phthaloyl imine in the polar non-proton solvent under composite catalyst and normal pressure; heating to reflux 6-8h; filtering; cooling; evolving product; washing; drying to recycle solvent; obtaining the composite catalyst with gas-phased silica, sodium carbonate and phase-transmitting catalyst.

Owner:SHANGHAI INST OF TECH

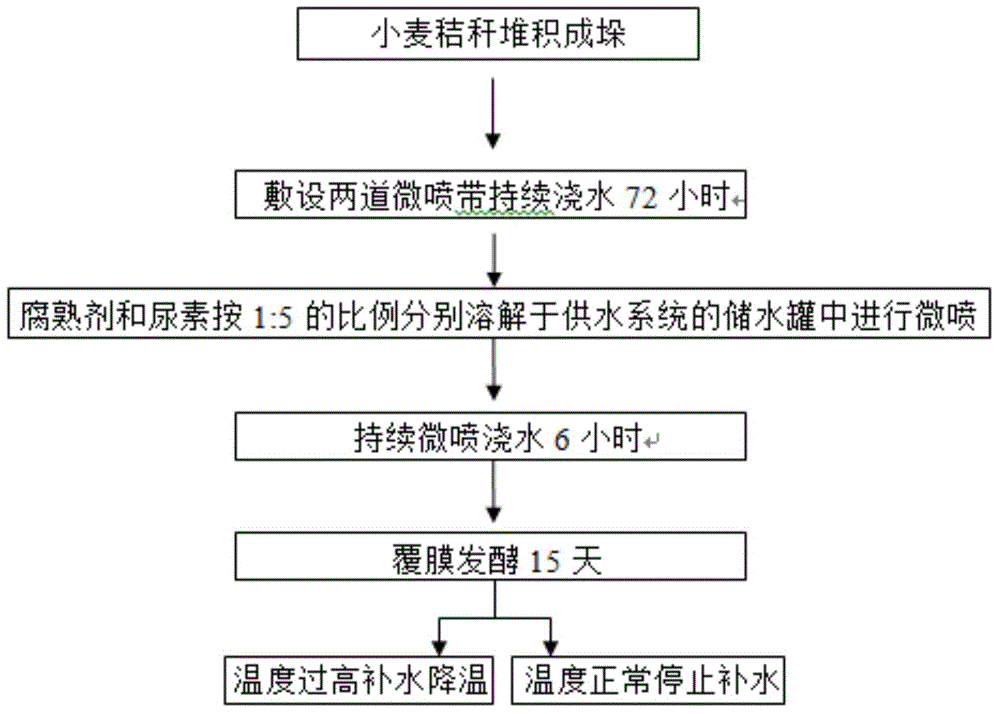

High-temperature composting process of wheat straw

InactiveCN105198516AFully soakedSpread evenlyBio-organic fraction processingOrganic fertiliser preparationMonitoring temperatureWater storage tank

The invention discloses a high-temperature composting process of wheat straw. The high-temperature composting process includes the following steps: (1), using a grass grasping machine to stack the wheat straw to form a long pile; (2), laying two micro-spraying hoses on the wheat straw pile, utilizing a full-automatic water supply system for micro spraying through the micro-spraying hoses, and continuously spraying water for 72 hours; (3), dissolving composting agent and urea in a water storage tank of the full-automatic water supply system according to a mass ratio of 1:5, and uniformly spraying a material solution through the micro-spraying hoses; (4), after spraying of the material solution is completed, continuously watering for 6 hours through micro spraying; (5), covering thin films on the wheat straw pile and the micro-spraying hoses laid above the same, sealing for fermentation for 15 days, and regularly measuring and monitoring temperature and humidity. The full-automatic water supply system is utilized to spray water and material to the straw pile through the micro-spraying hoses, so that the objectives of sufficient water soaking and uniform material scattering of the straw pile can be achieved, the straw can be composted quickly, automation level is high, and time and labor are saved.

Owner:安徽莱姆佳生物科技股份有限公司

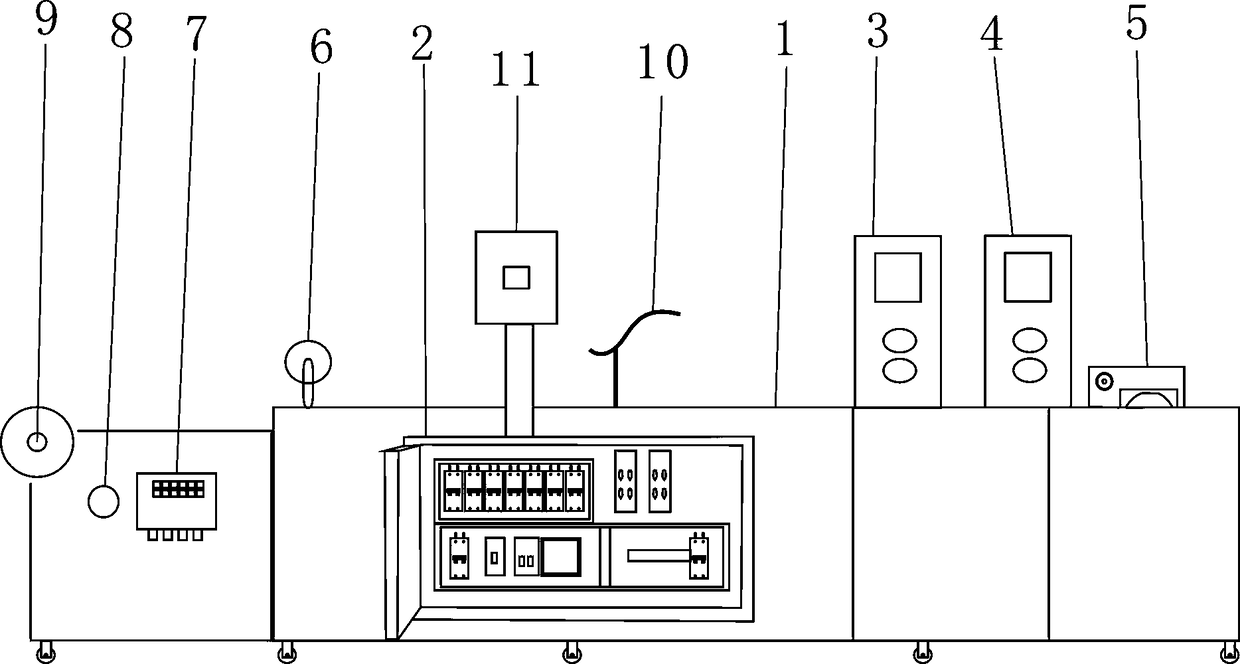

Preparation process of N-carbamylglutamic acid

InactiveCN112062694AIncrease product quantityImprove production efficiencyUrea derivatives preparationOrganic compound preparationCarbamylglutamic acidPtru catalyst

The invention discloses a preparation process of N-carbamylglutamic acid. The invention relates to the technical field of biochemical materials. The preparation process comprises glutamic acid, urea,a catalyst, concentrated hydrochloric acid, distilled water and a plurality of reaction tools. Meanwhile, the preparation efficiency of the N-carbamylglutamic acid is gradually improved by arranging areaction box with a heating device, an electric heating sleeve, a vacuum drying box, a circulating water vacuum pump, an ultralow-temperature refrigerator, a pulverizer, an electronic balance, a PH meter, a centrifugal machine, a high-power electric stirrer, an ultrapure water system and the like, so that the preparation efficiency of the N-carbamylglutamic acid is greatly improved; and in addition, the preparation process can be further suitable for factory-like large-scale processing, and the cost for preparing the N-carbamylglutamic acid is reduced.

Owner:TIANJIN QUANHECHENG TECH

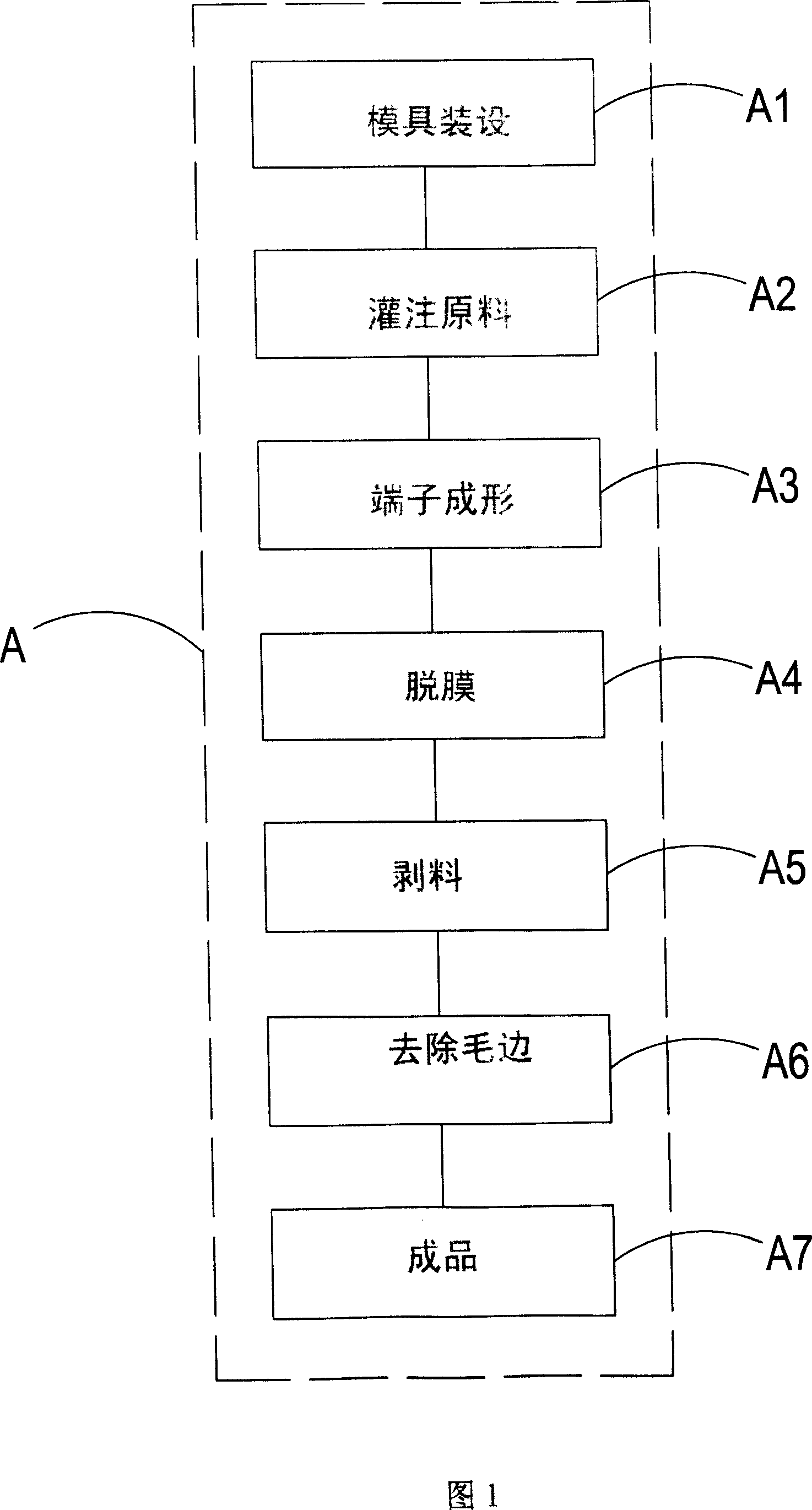

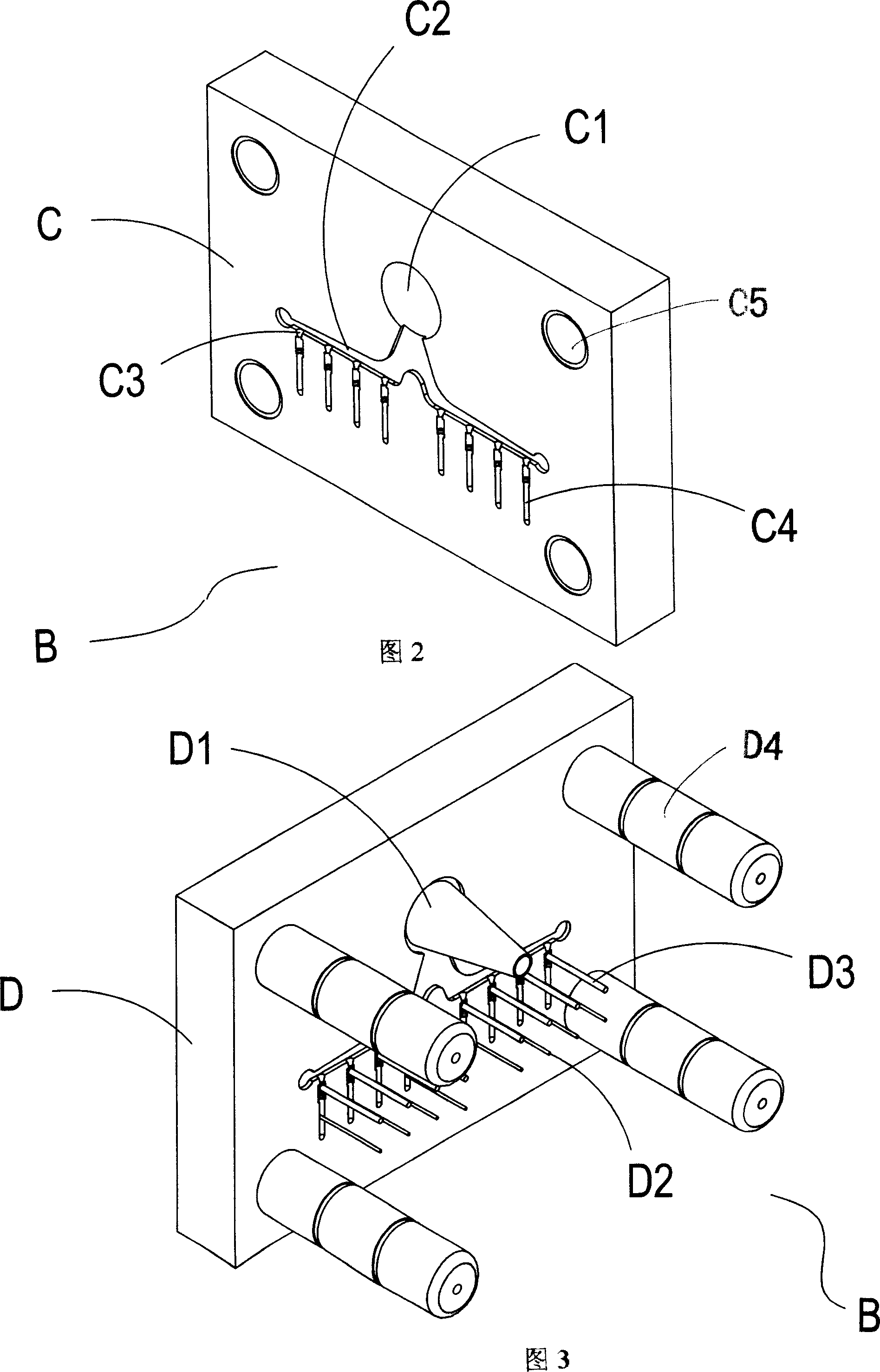

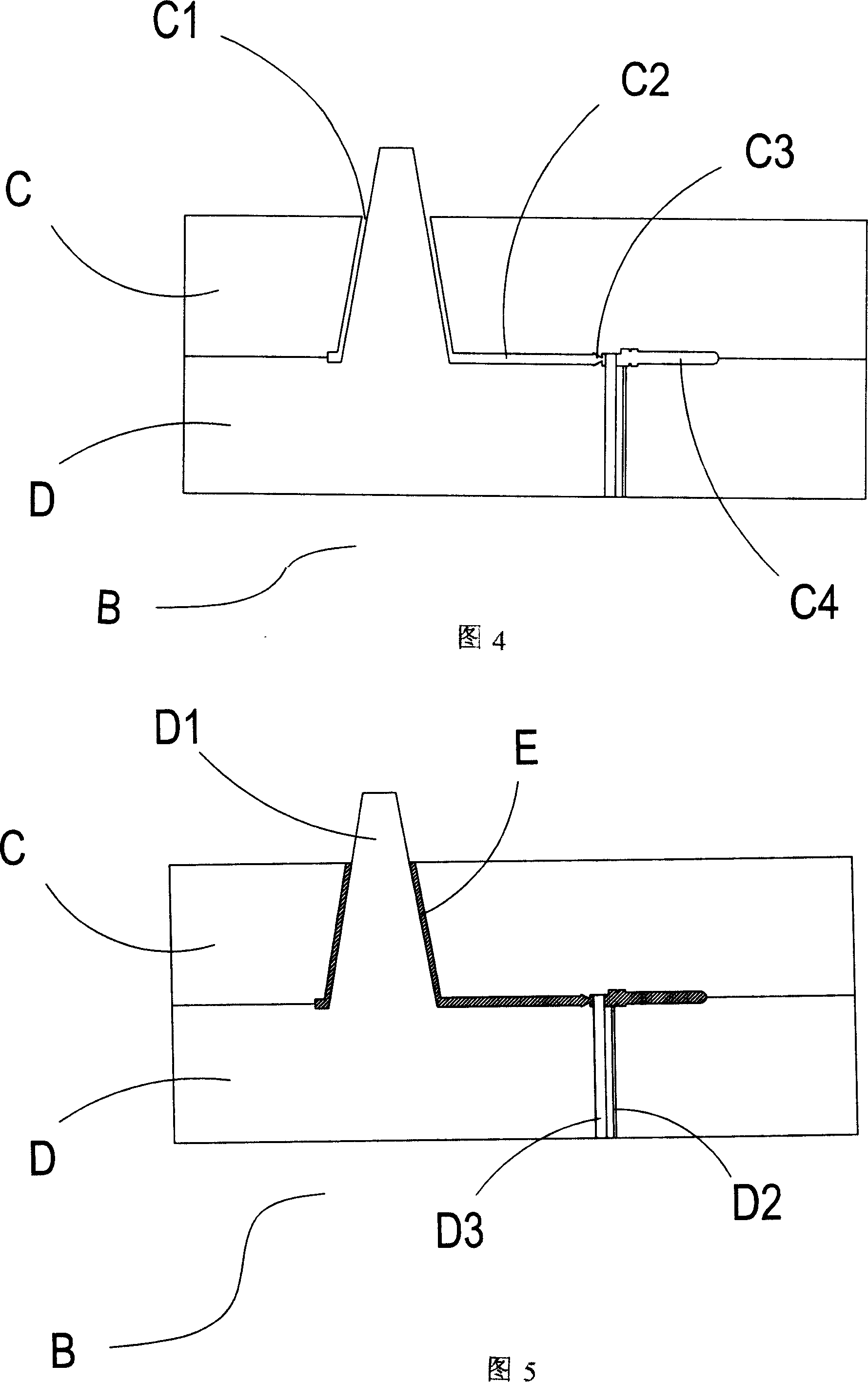

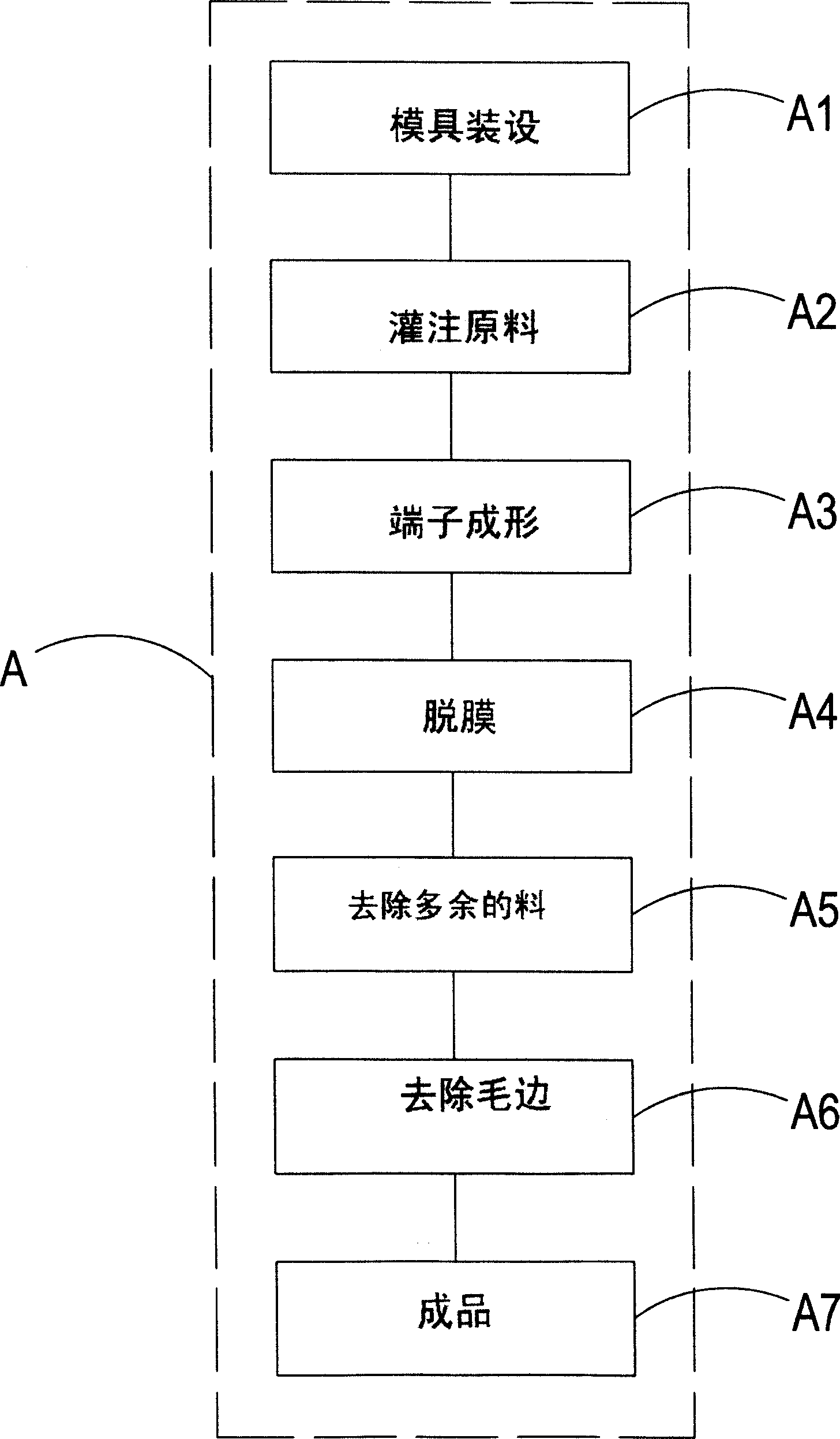

Method of manufacturing connector with ejection forming technique

The invention relates to the making of connectors using injection molding technique. It designs the mold for the terminal, then fills it will material, stripping the mold after the terminal formed into semi product, removing the flash with grinder with improved output and the filled material being zinc alloy. Using this casting method, it can save time, increase output, low in cost, high in hardness, high practicality.

Owner:SINGATRON ELECTRONICS CHINA

Method of manufacturing terminals

Owner:SINGATRON ELECTRONICS CHINA

Flexible cloth forming method

PendingCN114524287AImprove uniformitySmall weight differenceFood shapingLoading/unloadingPhysicsInternal rotation

The invention relates to the technical field of food cloth forming, in particular to a flexible cloth forming method which comprises the steps that raw materials are distributed into a forming mold through a cloth internal rotation mechanism, and meanwhile the raw materials in the forming mold are flattened through an external rotation material smearing mechanism; wherein the material distribution internal rotation mechanism is arranged in the cylinder body, the cylinder body is provided with a material inlet and a material outlet, the material outlet is located above the forming die, the material distribution internal rotation mechanism is provided with at least two material distribution claws, the material distribution claws and the transmission rod form the material distribution internal rotation mechanism, and the material distribution claws are located at the end of the material outlet. And the transmission rod is driven by the internal rotation driving mechanism to drive the material distribution claw to rotate in the circumferential direction in the cylinder body. During material distribution, the material distribution internal rotation mechanism distributes raw materials into a forming mold in a rotating mode through the rotating material distribution claw, the effect of artificial bionic material distribution is achieved, and the material distribution uniformity of a product is improved; the raw materials in the forming dies are trowelled through the external rotation material smearing mechanism, and when material distribution is conducted on the multiple forming dies, the weight difference between single products is reduced.

Owner:四川米老头食品工业集团股份有限公司

Vertical type carbonization device capable of automatically cleaning tar for carbon fiber production

InactiveCN103498213AGood energy saving effectIncrease product quantityFibre chemical featuresFiberCarbon fibers

A vertical type carbonization device capable of automatically cleaning tar for carbon fiber production belongs to the field of carbon fiber production equipment. One side of a heating inner chamber is provided with a heating chamber, a driving roll is arranged in the heating inner chamber, a driven roll is arranged in the heating chamber, an absorption band takes the driving roll and the driven roll as the two ends to form a crawler structure, the absorption band goes through the joint position between the heating inner chamber and the heating chamber, and is in a cyclic motion; the gas outlet of the heating chamber is in a through connection with ultrasonic gas tar purification equipment through a gas recycling pipe line. The heating inner chambers of vertical type or inclined vertical type carbonization equipment both have circulation space which is beneficial for exhaustion of gas tar and occupation of tar-free gas, thus the gas tar generated during the production process will not be trapped in the heating area of the chamber to affect the product quality, and the protective gas and heat for production will not lose basically.

Owner:齐齐哈尔瑞兴碳纤维科技有限公司

A kind of sterilization device and sterilization system

ActiveCN106860881BAffect performanceIncrease product quantityLavatory sanitoryHeatControl systemEngineering

The invention provides a sterilization device and a sterilization system, and relates to the field of sterilization equipment. The sterilization device comprises a first sterilization chamber, a second sterilization chamber, a third sterilization chamber, a pipeline system, a conveying device used for conveying a material among the sterilization chambers, and a control system used for controlling the pipeline system and the conveying device, wherein the pipeline system comprises a preheating steam pipeline, a high-temperature steam pipeline, a cooling steam pipeline and a vacuum pipeline; the first sterilization chamber is communicated with the preheating steam pipeline; the second sterilization chamber is communicated with the high-temperature steam pipeline; the third sterilization chamber is communicated with the cooling steam pipeline. The sterilization device avoids the phenomenon that the performance of the material is influenced by the deterioration caused by contact between the material and the air in a cooling process after high temperature sterilization, and can enable a sterilization process and a cooling process to be carried out at the same time so as to increase the number of products processed within unit time. The sterilization system comprises the sterilization device, can avoid the deterioration caused by contact between the material and the air in the cooling process after sterilization, and increases the sterilization efficiency.

Owner:SHAANXI BICON PHARMA GRP HLDG COMPANY

Servo constant speed paper folding control device

InactiveCN109110555AGuarantee product qualityIncrease product quantityFolding thin materialsWebs handlingConstant speedControl system

The invention discloses a servo constant speed paper folding control device. A controller is disposed in the middle of a wallboard; the controller is connected to a touch display screen; the upper right end of the wallboard is connected with a paper folding device, a feeding device, a slicing device, and a lamination device; and a rectification device, a tension controller, an unreeling pneumaticswitch, and an unreeling device are disposed on the left portion of the wallboard. A paper roll is placed into the unreeling device and is fixed by the unreeling pneumatic switch; a head of the paperroll passes through the rectification device, the paper folding device, the feeding device and the slicing device; power is turned on; a feeding servo parameter and a slicing servo parameter are adjusted on the touch display screen, and are transmitted to a programmable control system in the controller; the running tension of paper is adjusted by the tension controller; the feeding device drives the unreeling device to feed the paper; and the slicing device cuts the paper according to prescribed length, and the cut paper is sent to the lamination device to form a stack. Beneficial effects of the technology are that: the product quality is ensured, and the number of products is increased by double.

Owner:湖北厚友知识产权服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com