Carbon/carbon composite material densification method, stock column tool and assembling method

A technology of carbon composite material and material column, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of long production cycle, small number of products, long production cycle, etc., and improve single column production Efficiency, avoiding uneven deposition, and reducing the effect of occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

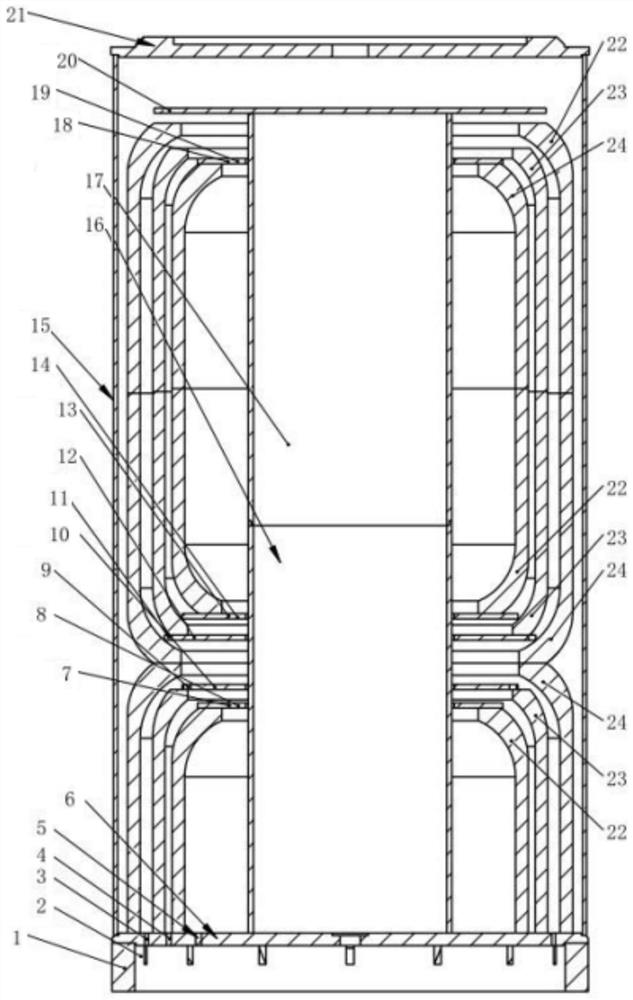

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the technical solutions of the present invention will be described clearly and completely below with reference to the accompanying drawings. Other similar embodiments obtained without creative work shall fall within the scope of protection of the present application. In addition, the directional terms mentioned in the following embodiments, such as "up", "down", "left", "right", etc., are only the directions of the drawings with reference to the drawings. Therefore, the directional terms used are used to illustrate rather than limit the present invention. invent.

[0033] like figure 1 As shown, a C / C composite material densification method, the specific embodiments are as follows:

[0034] (1) Place the base 1 on a flat tray, then fit the intake manifold 6 with the base 1, and then place the crucible help prefab A22 upside down on the intake manifold 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com