Patents

Literature

126results about How to "Short deposition time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

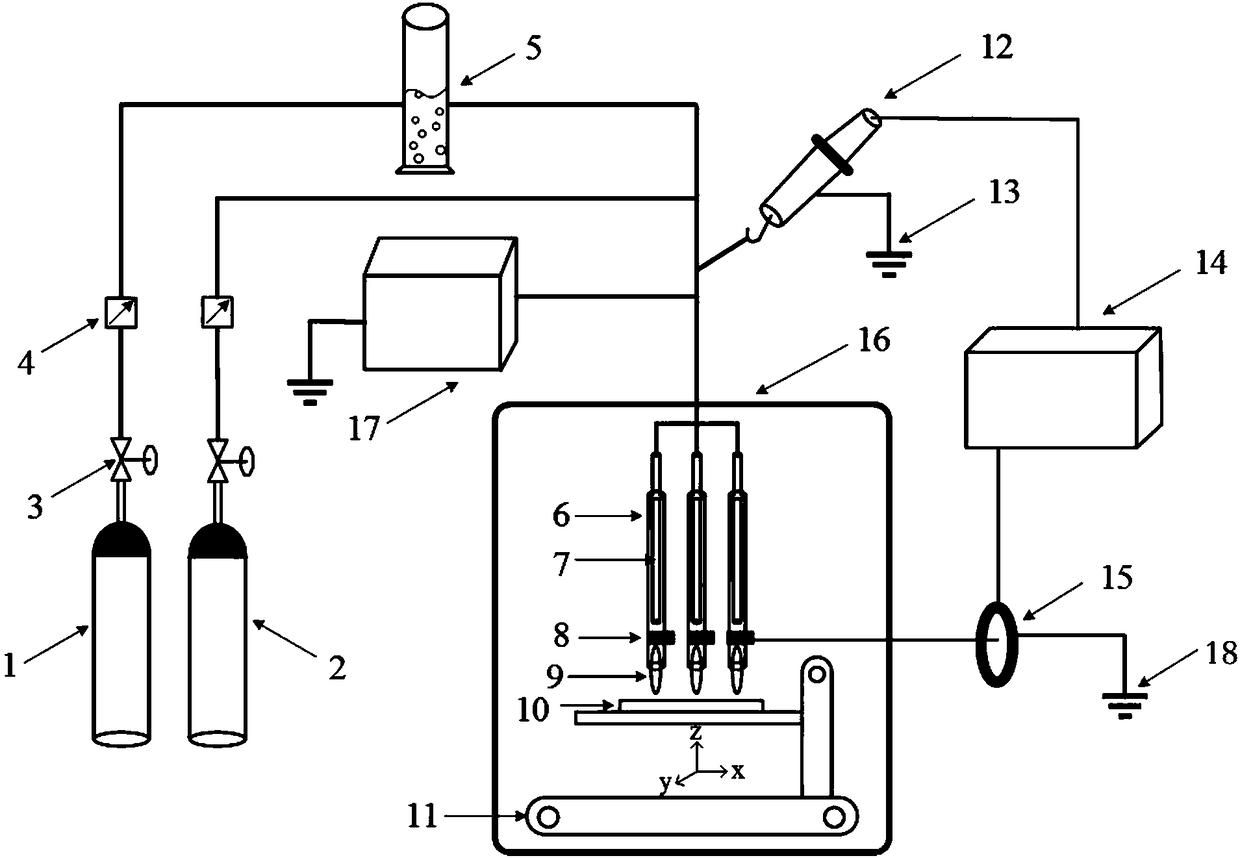

Preparation technology of carbon/carbon composite material crucible for monocrystalline silicon furnace

InactiveCN102660768AExtended temperature rangeHigh densityBy pulling from meltCarbon compositesDifferential pressure

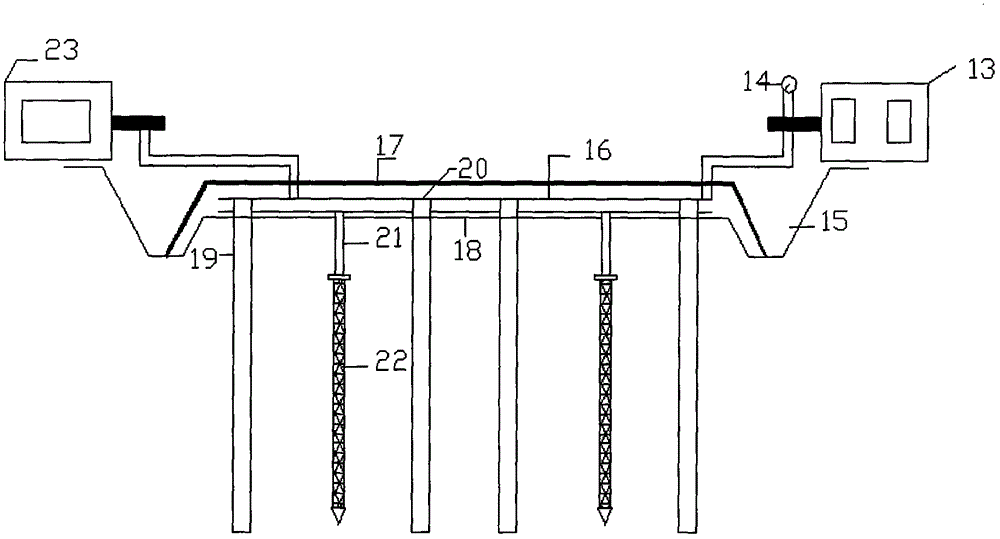

The invention discloses a preparation technology of a carbon / carbon composite material crucible for a monocrystalline silicon furnace, and the preparation technology comprises the following steps of: adopting a polyacrylonitrile nitrile base carbon fiber-woven performing body, taking mixed gas of natural gas, propylene, liquefied petroleum as a carbon source and nitrogen or argon as carrier gas, in a uniform temperature thermal field formed by a vertical pot type deposition furnace, timely switching the upper gas charging and lower gas charging of a pipeline, due to the pressure difference of the gas inside and outside the crucible, and in combination with a uniform temperature method, a differential-pressure method and a compulsive gas current method, realizing the quick densifying of the whole crucible blank body, wherein after 300-350 hours, the intensity of the crucible can reach to more than 1.6g / cm<3>, compared with the conventional free deposition technology, the preparation technology can be used for greatly shortening the deposition time, and reduces the production cost. After being mechanically machined, the crucible is used for a thermal field of the monocrystalline silicon furnace, compared with the hot isostatic pressure graphite crucible, the carbon / carbon composite material crucible has the advantages that the service life is prolonged by 3-5 times, the cost performance is obviously better than that of the graphite crucible, and the production cost and labor intensity of the monocrystalline silicon are greatly reduced.

Owner:保定顺天新材料股份有限公司

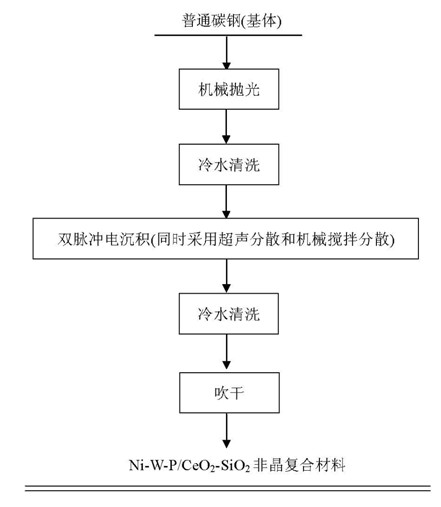

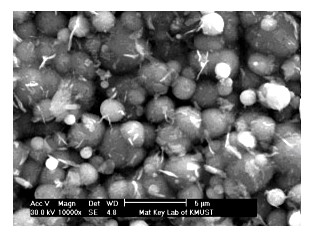

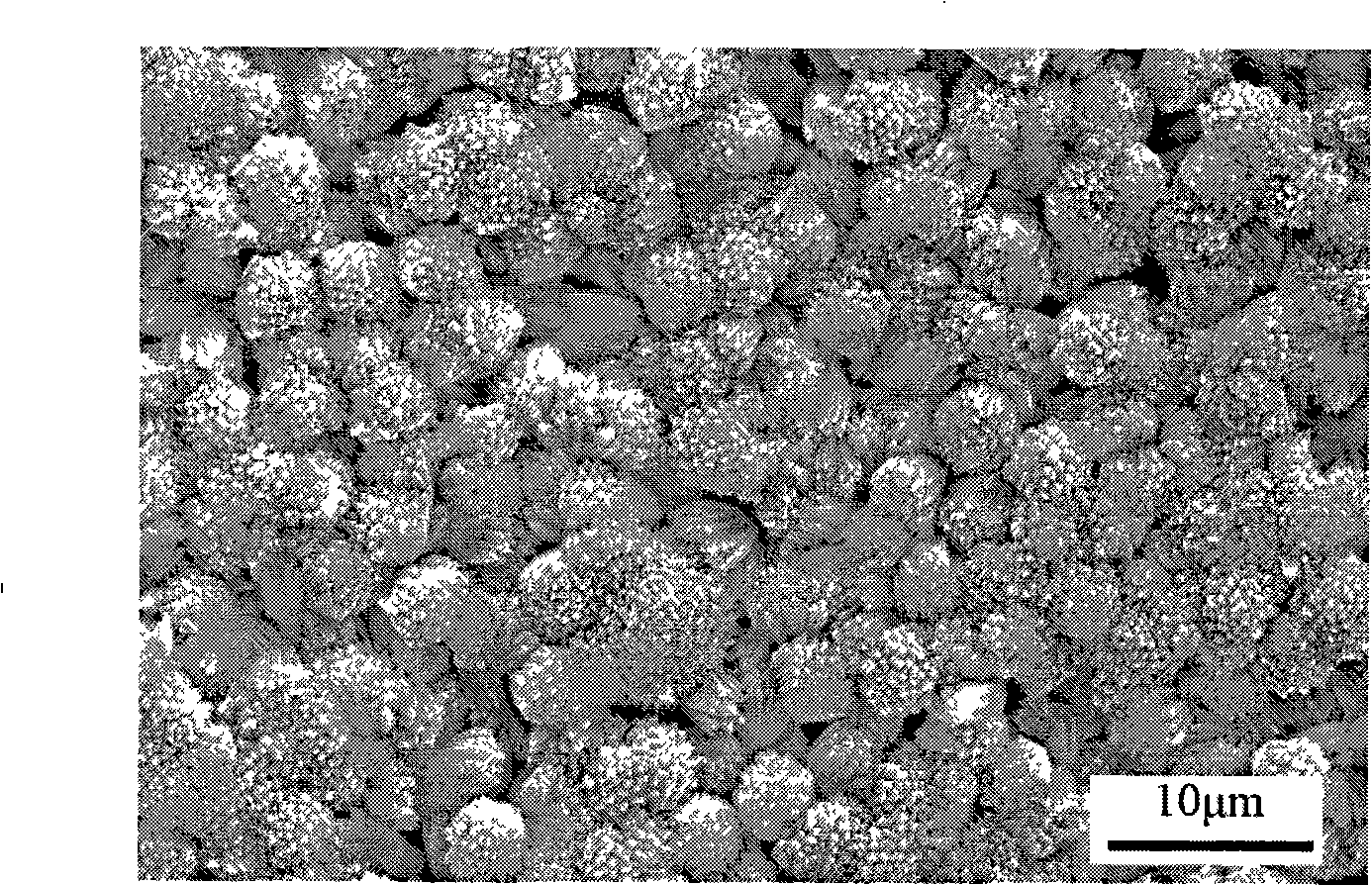

Nanometer granule reinforced metal-based amorphous composite material and preparation method thereof

InactiveCN102400066APrevent precipitationImprove stabilityElectrolytic coatingsElectrolytic agentChemical industry

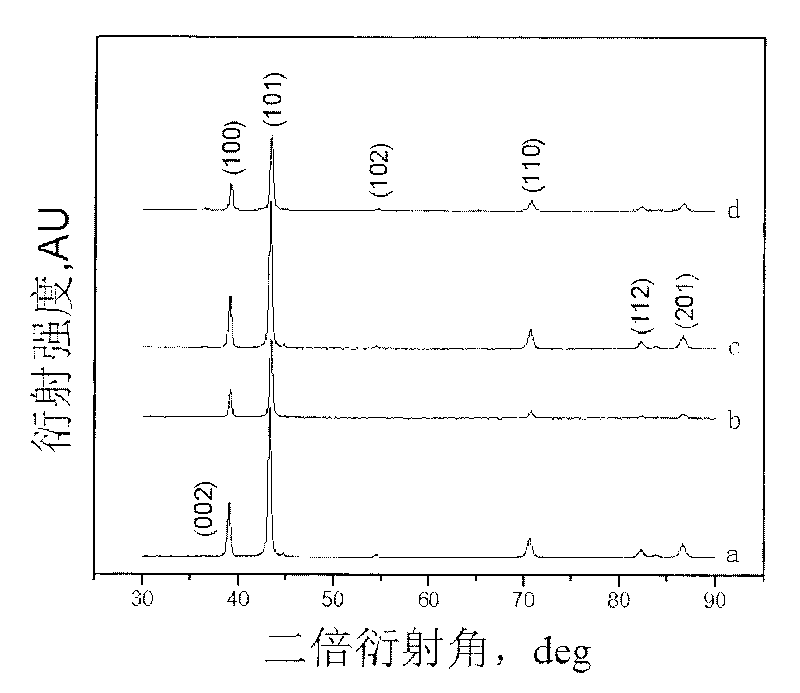

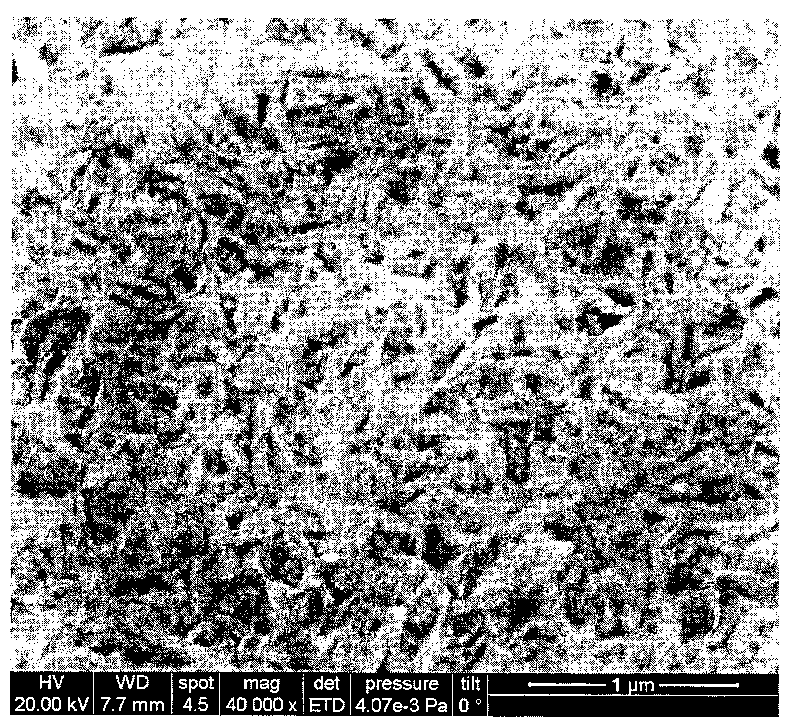

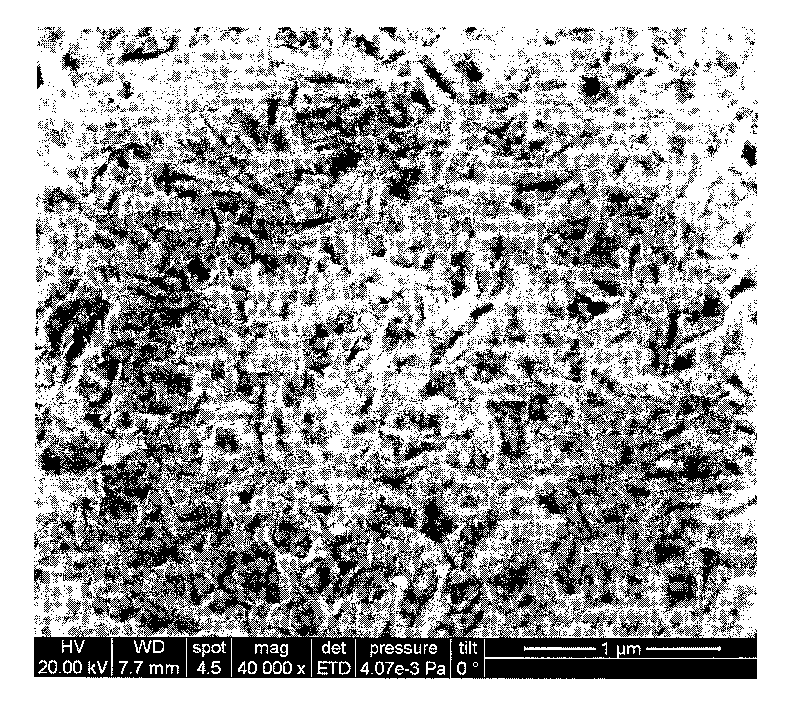

The invention provides a nanometer granule reinforced metal-based amorphous composite material and a preparation method thereof. In the method, the Ni-W-P / CeO2-SiO2 amorphous composite material of which the thickness is between 54 and 251 micrometers is prepared on the surface of ordinary carbon steel in electrolyte by utilizing dipulse electrolytic deposition for 1.5 to 6 hours under the action of ultrasound, mechanical stirring and the common dispersion of two surfactants. In the nanometer granule enhanced metal-based amorphous composite material, the electrolyte is high in stability, homogeneous plating capacity, current efficiency and deposition rates. CeO2 and SiO2 nanometer granule reinforced phases in the amorphous composite material are dispersed, the sizes of matrix metal granules ranges from 1 to 2 micrometers, and the composite material has a compact tissue structure, a thick deposition layer and high plating microhardness, is combined with a matrix firmly and can be used as surface functional plating layers of equipment parts of metallurgy, chemical industries, tobaccos, machines and the like.

Owner:KUNMING UNIV OF SCI & TECH

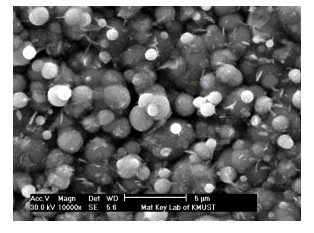

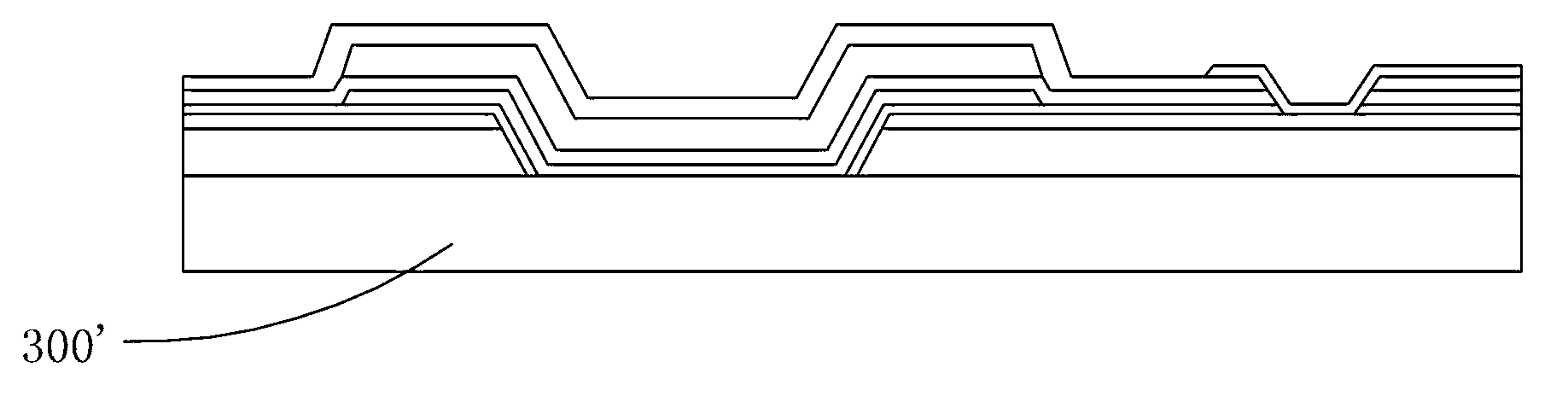

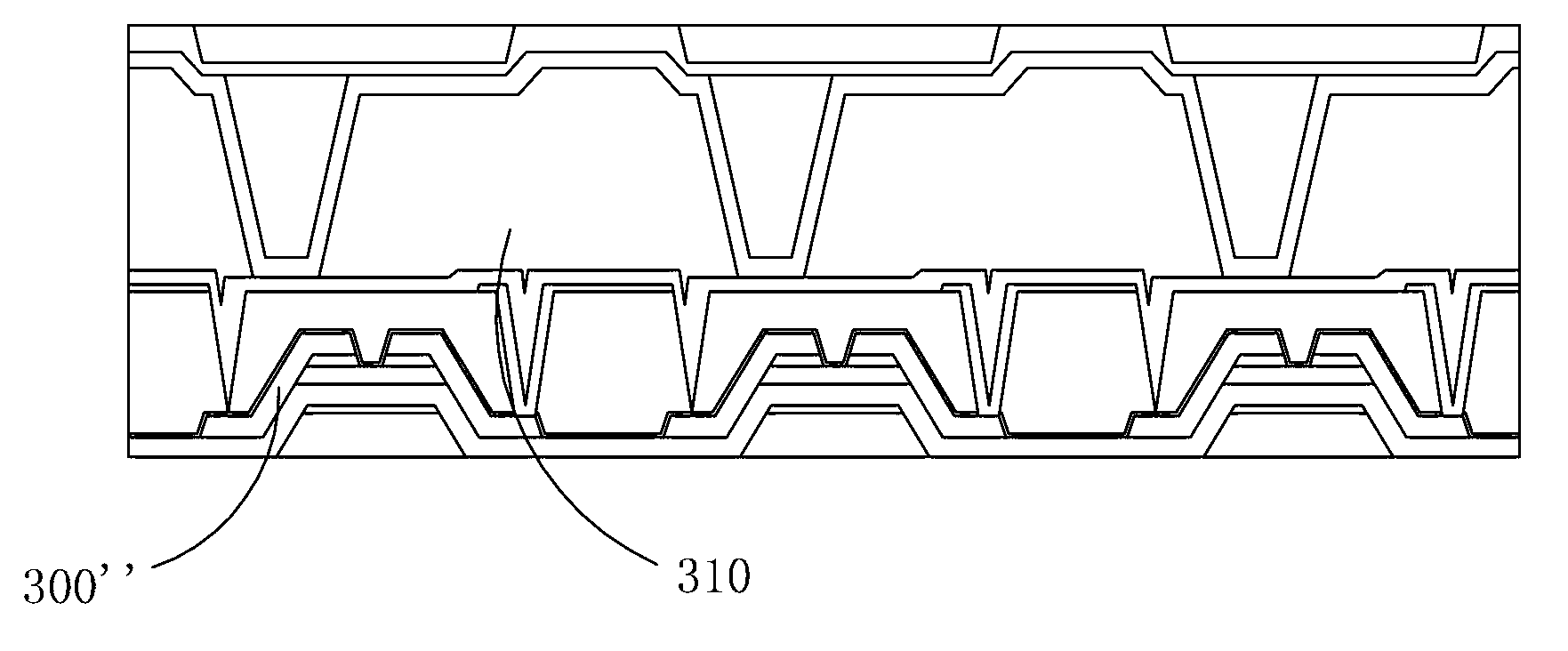

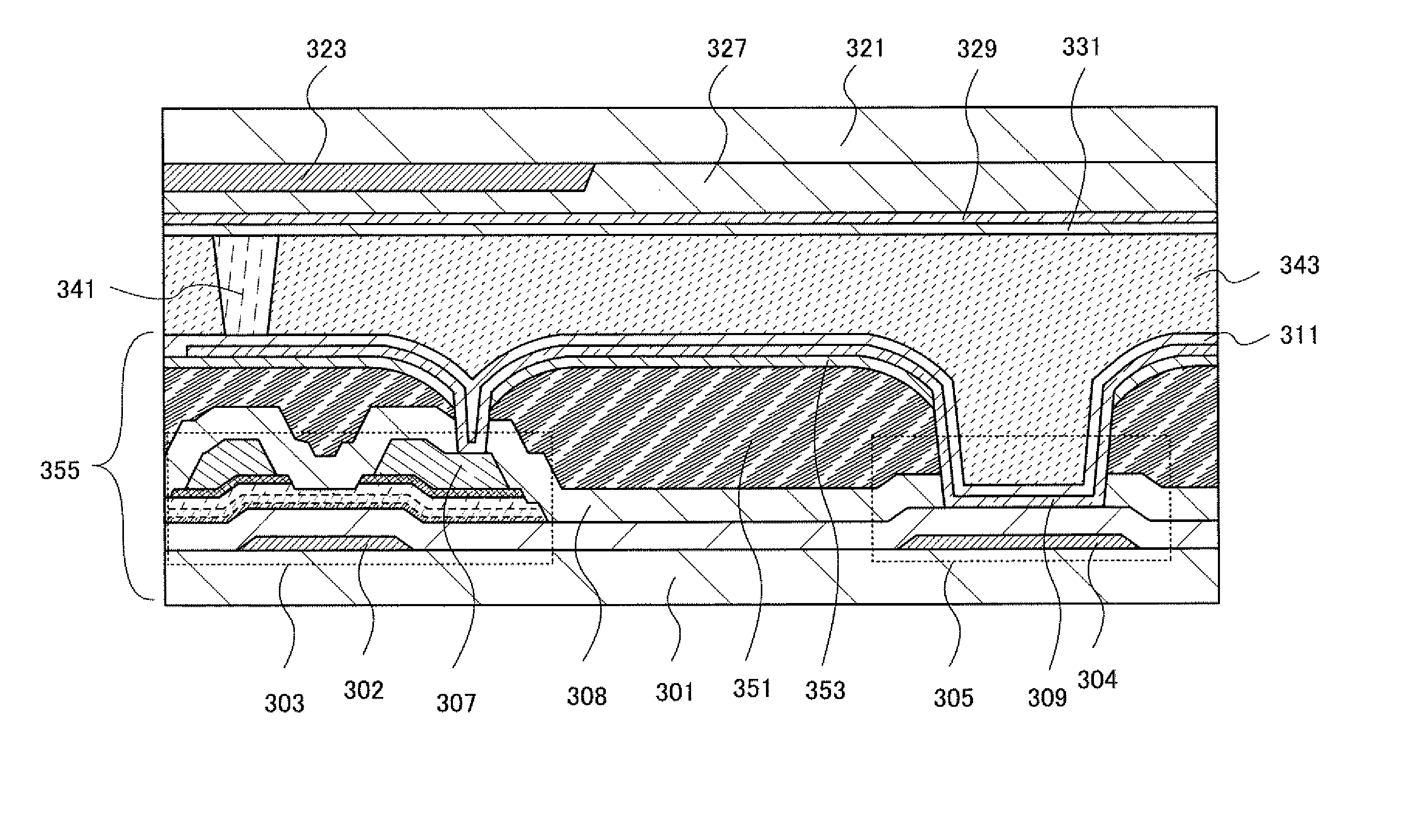

Method for producing liquid crystal display panel

ActiveCN102799014AEasy to controlSimple processSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceInsulation layer

The invention provides a method for producing a liquid crystal display panel, which comprises the following steps: 1, providing a substrate; 2, forming a black photoresist layer on the substrate, forming a preset pattern through a photomask process, and further producing a black matrix; 3, forming an isolating layer on the black photoresist layer; 4, producing a first metal layer on the isolating layer, forming a second metal layer on the first metal layer, forming the preset pattern through the photomask process, and furthermore, forming a source / drain electrode and a storage capacitor Com electrode; 5, forming an ohmic contact layer on the second metal layer, forming the preset pattern through the photomask process, and furthermore, forming a doped phosphorus film on a metal electrode; 6, arranging a channel layer on the ohmic contact layer, forming the preset pattern through the photomask process, and thus forming an island; 7, forming a gate insulation layer on the channel layer, arranging a third metal layer on the gate insulation layer, forming the preset pattern through the photomask process, furthermore, forming a grid and a storage capacitor counter electrode, and arranging a storage capacitor at the edge position of the black matrix; 8, forming a protective layer on the third metal layer; 9, forming right (R), green (G) and blue (B) pixels on the protective layer; 10, forming via holes in the positions of the R, G and B pixels, which correspond to the source electrode and the storage capacitor; 11, arranging a transparent electric conduction layer on the R, G and B pixels, forming the preset pattern through the photomask process, furthermore, forming a pixel electrode, and thus forming a color filter on array (COA) substrate; and 12, bonding the COA substrate with an upper substrate, filling liquid crystal into the COA substrate and the upper substrate, and thus forming the liquid crystal display panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

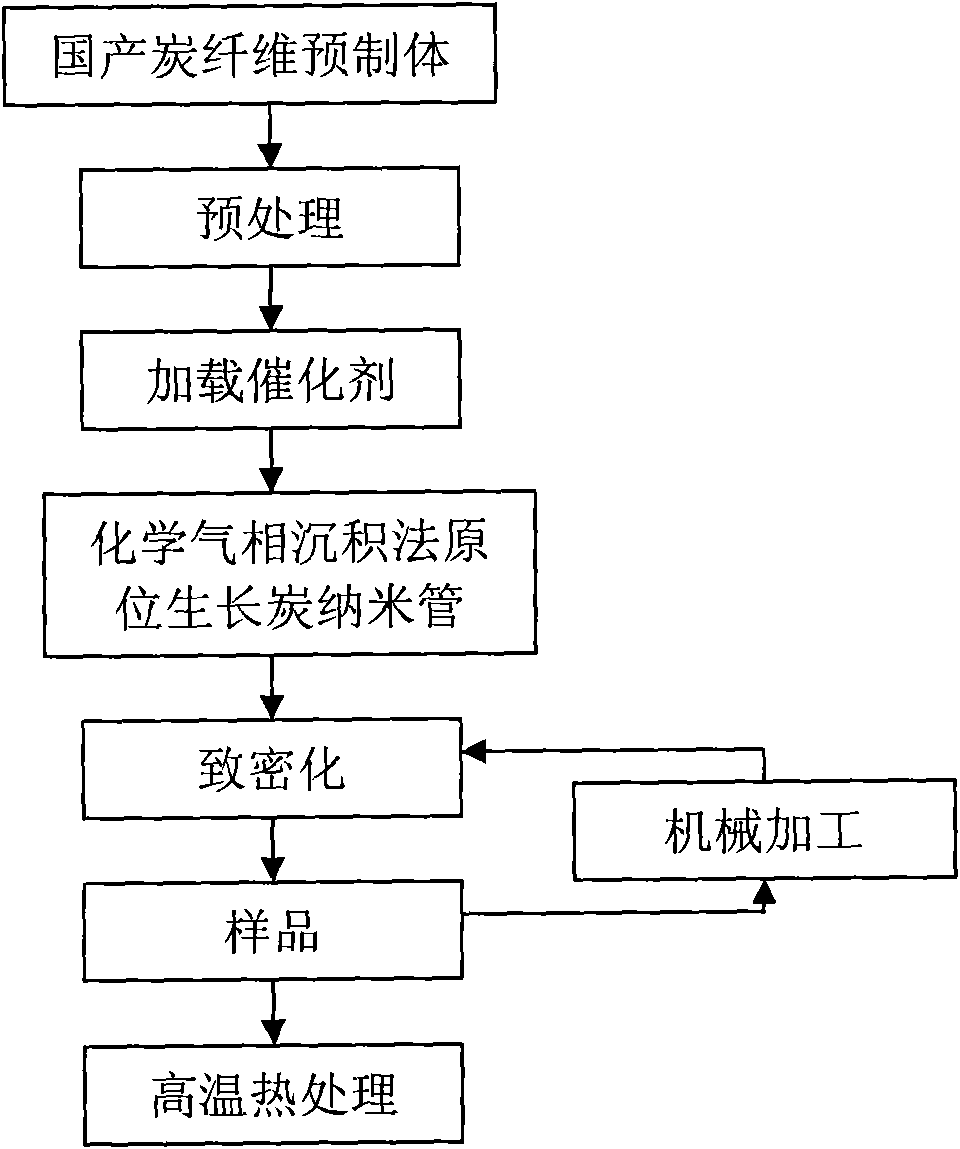

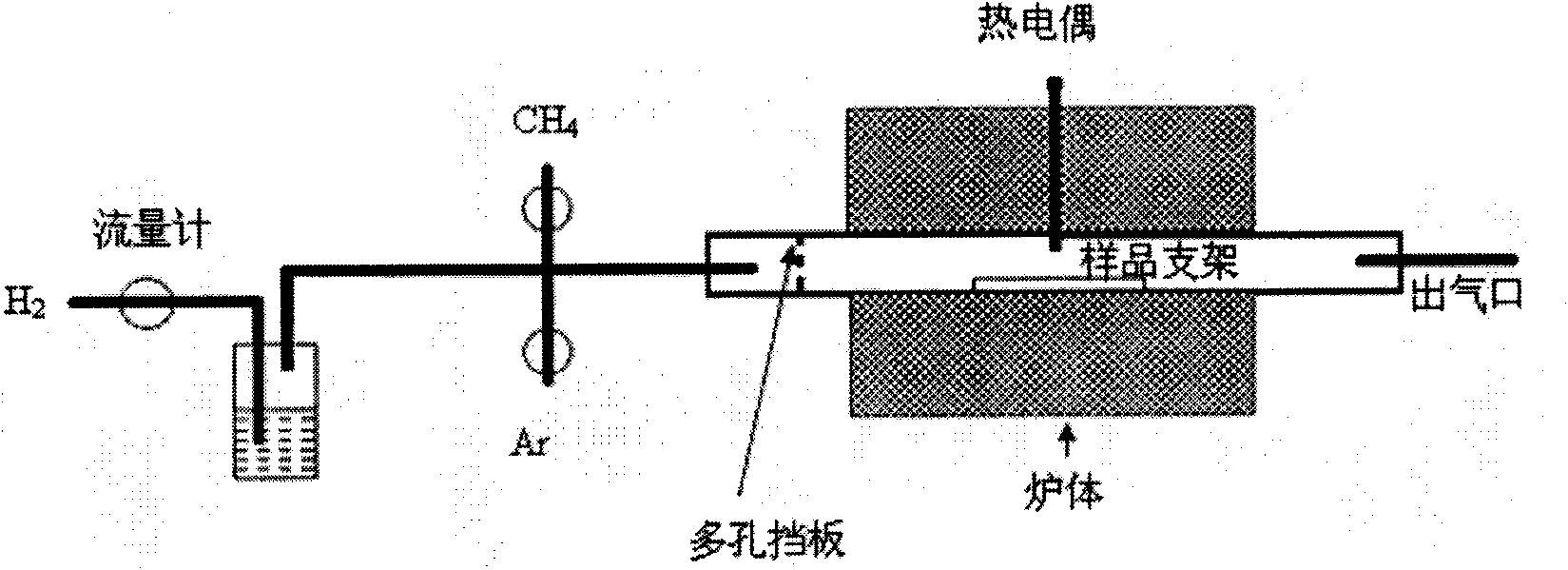

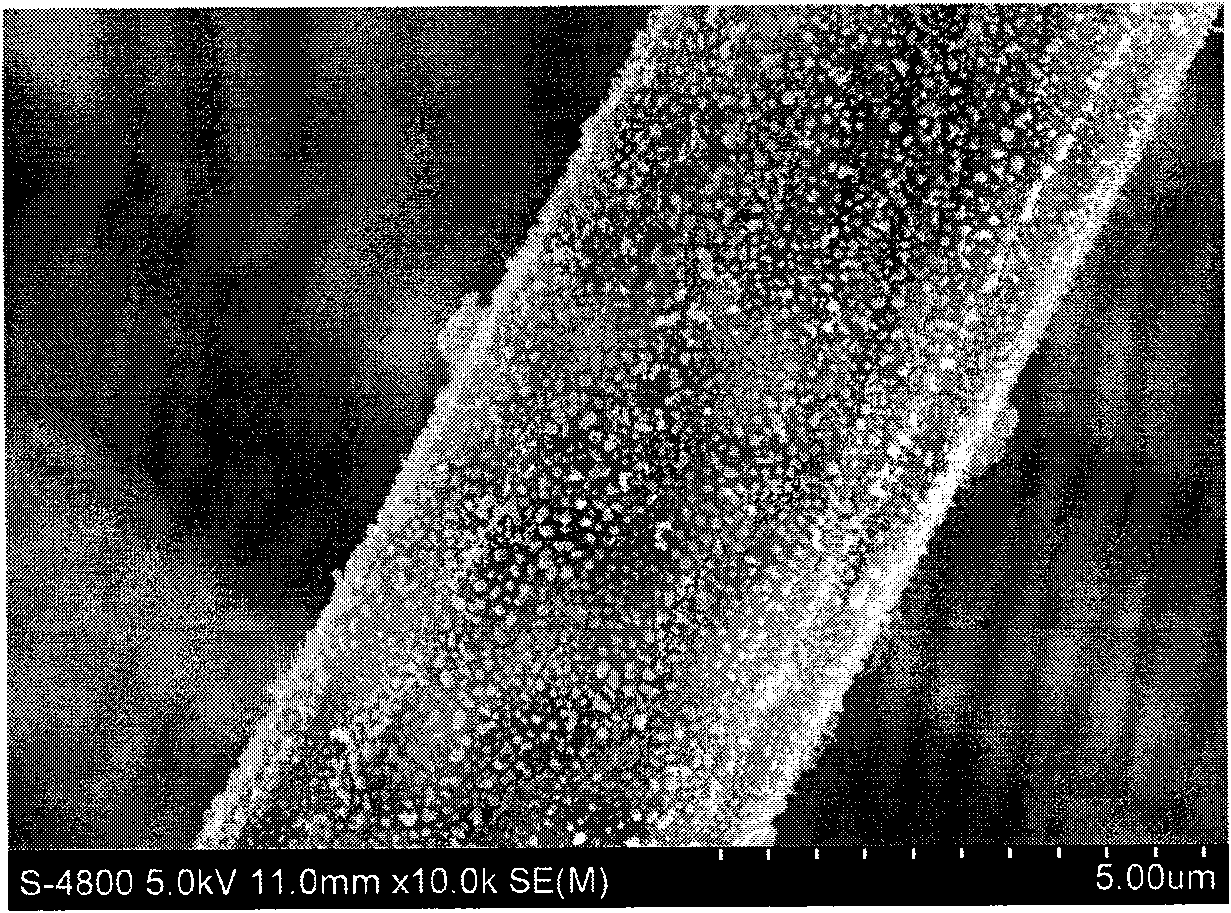

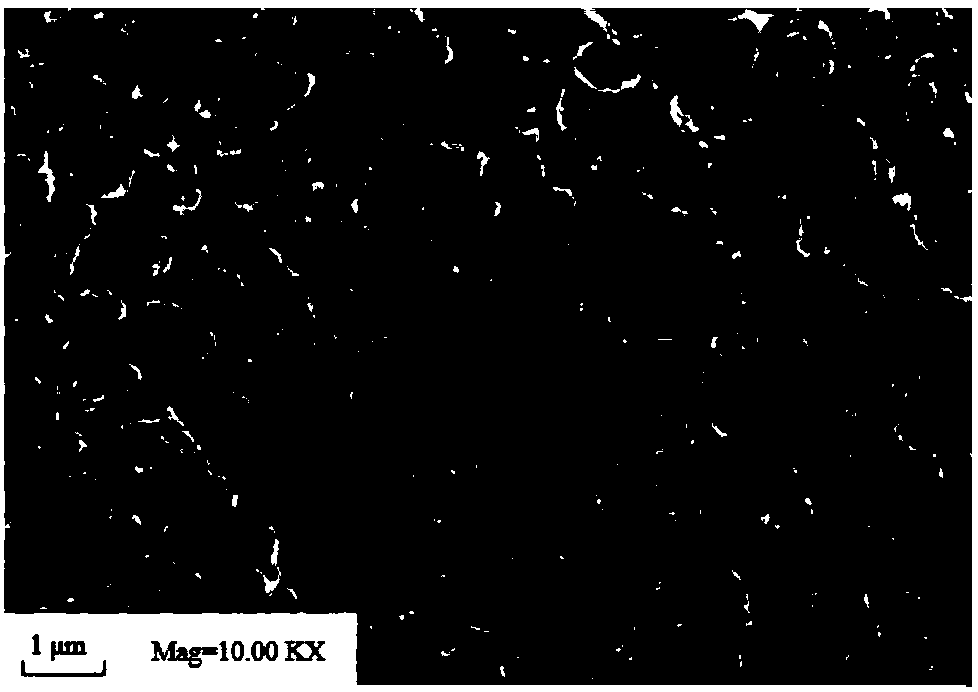

Method of carbon nanotube for modifying polyacrylonitrile-based carbon fiber interface produced in China

The invention provides a method of a carbon nanotube for modifying a polyacrylonitrile-based carbon fiber interface produced in China. The technology includes four parts: (1) surface treatment of thedomestic polyacrylonitrile-based carbon fiber: firstly treating and removing colloid on the surface of carbon fiber at the temperature of 600-800 DEG C and then using the mixed acid of nitric acid andsulfuric acid to remove the impurities on the surface of fiber; (2) preparation of domestic carbon fiber preform where the carbon nanotube grows in situ: firstly putting treated carbon fiber needle preform in the organic solution of catalyst precursor and then growing the carbon nanotube in situ in a chemical vapor deposition furnace; (3) densification of preform: adopting chemical vapor infiltration process to densify the preform and depositing the preform for 200-350h so that the density of the preform reaches 1.70-1.75g / cm<3>; and (4) high-temperature heat treatment: putting the material in a vacuum carbonization furnace, heating to the temperature of 2, 000-2, 300 DEG C at the heating rate of 30-50 DEG C / h under the protection of nitrogen, argon and other gases and preserving the heatfor 3-5h, and finally, the finished product is obtained.

Owner:BEIHANG UNIV

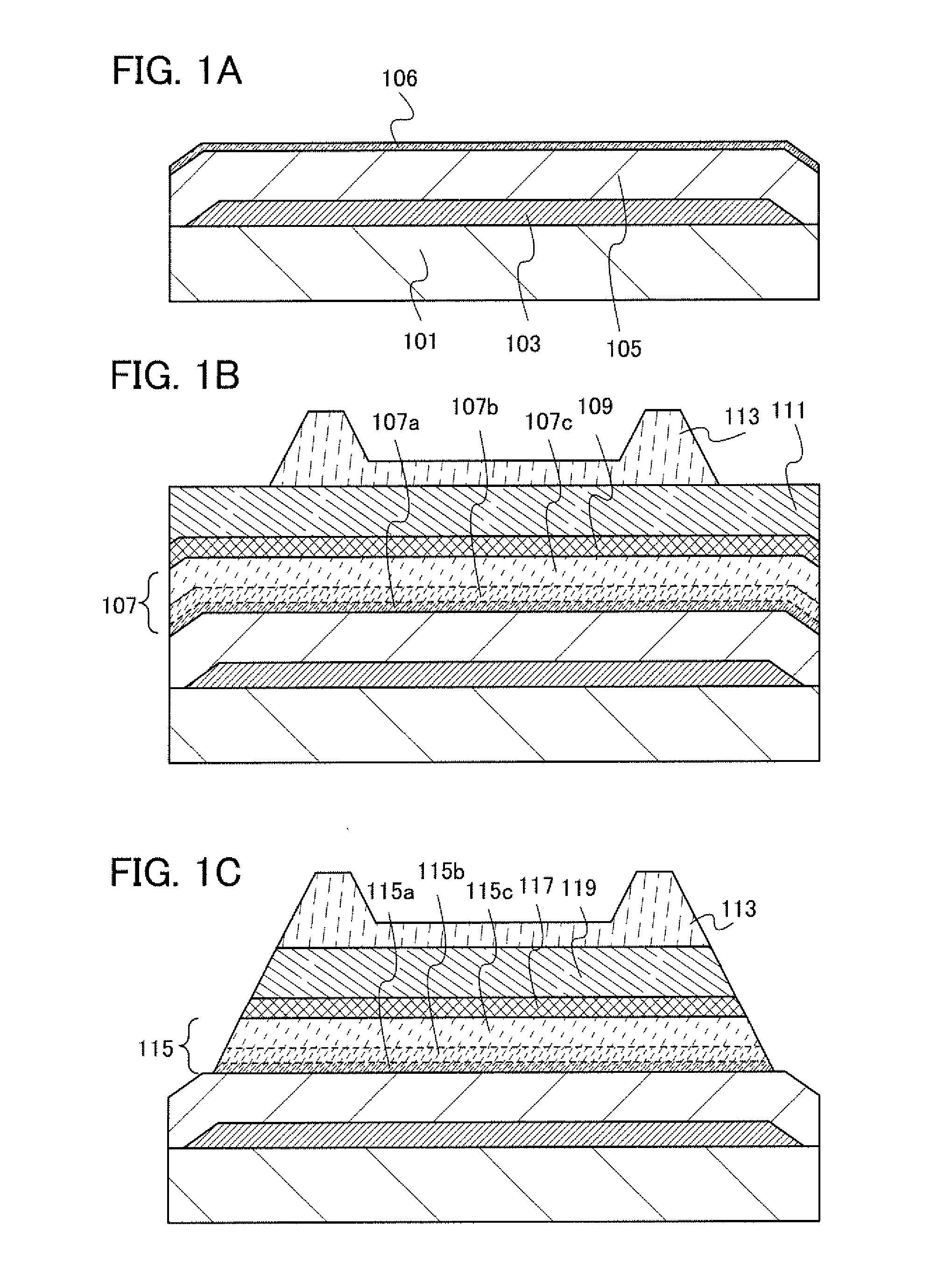

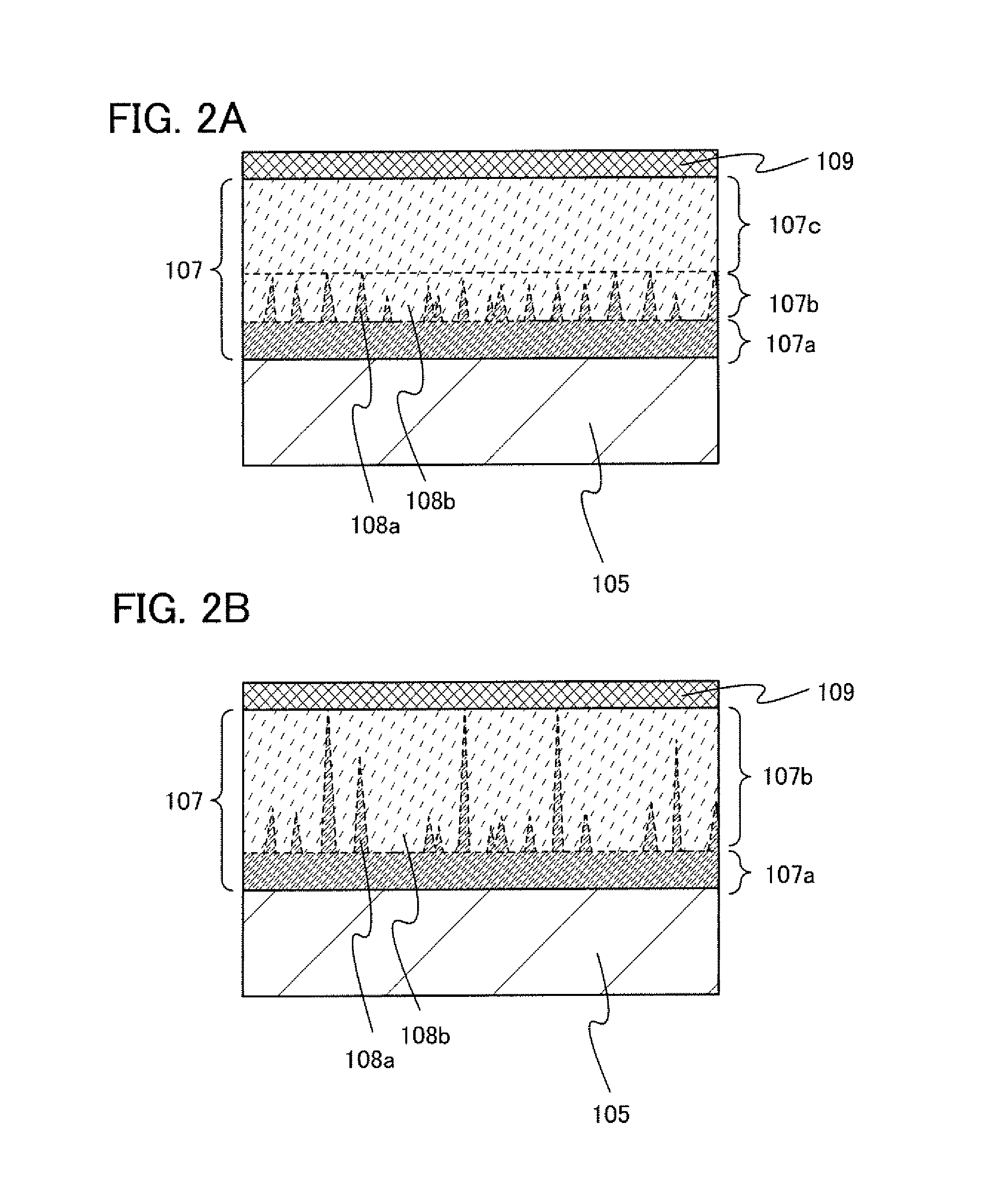

Method for manufacturing thin film transistor

InactiveUS20100124804A1Increase volumeReactionSolid-state devicesSemiconductor/solid-state device manufacturingNoble gasSeed crystal

An object is to provide a method for manufacturing a thin film transistor having favorable electric characteristics, with high productivity. A gate electrode is formed over a substrate and a gate insulating layer is formed over the gate electrode. A first semiconductor layer is formed over the gate insulating layer by generating plasma using a deposition gas containing silicon or germanium, hydrogen, and a rare gas. Next, a second semiconductor layer including an amorphous semiconductor and a microcrystal semiconductor is formed in such a manner that the first semiconductor layer is partially grown as a seed crystal by generating plasma using a deposition gas containing silicon or germanium, hydrogen, and a gas containing nitrogen. Then, a semiconductor layer to which an impurity imparting one conductivity is added is formed and a conductive film is formed. Thus, a thin film transistor is manufactured.

Owner:SEMICON ENERGY LAB CO LTD

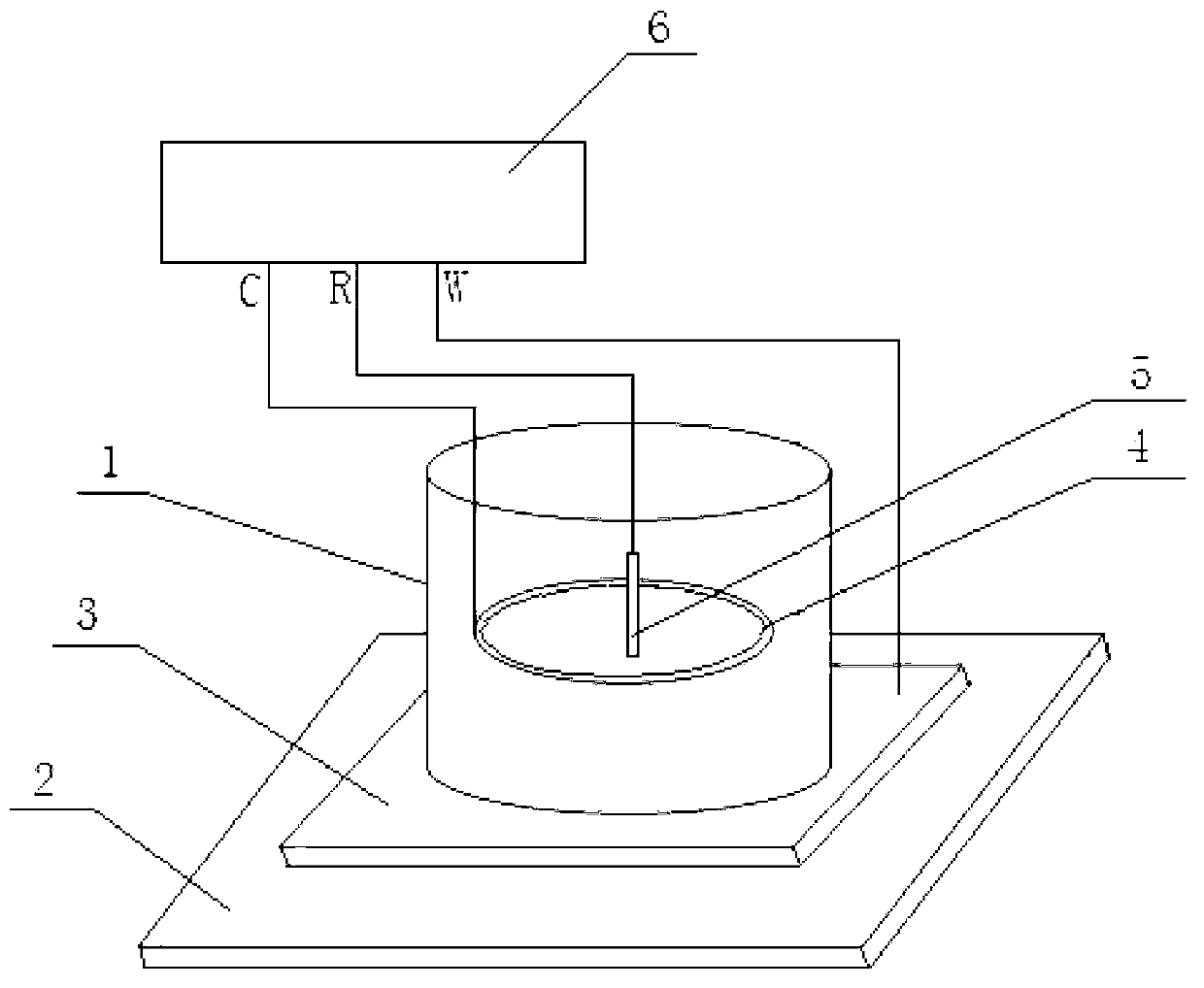

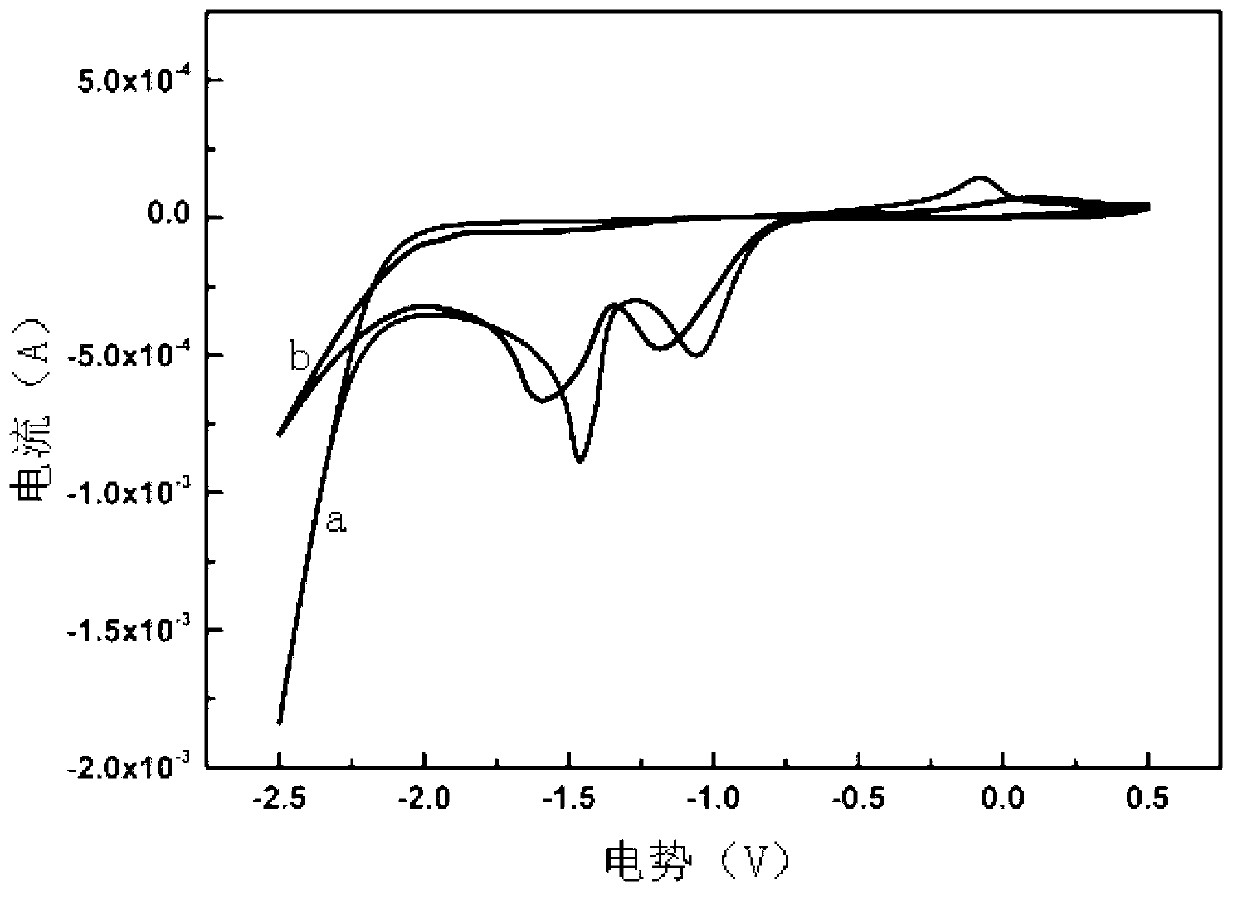

Method for preparing germanium nano cubic crystals through ionic liquid electro-deposition

The invention provides a method for preparing germanium nano cubic crystals through ionic liquid electro-deposition and relates to a preparation method of nano cubic crystal germanium. The method is used for solving the technical problem of difficulty in control and repetition in synthesis of nano cubic particles of germanium by the existing solvent synthetic method. The method comprises the following steps of: building an electrolytic tank for ultraviolet assisted electro-deposition in a glove box, wherein the electrolytic tank contains ionic liquid EmimTF2N electrolyte containing high-purity GeCl4; and then carrying out irradiation by using an ultraviolet lamp with the wavelength of 365nm; firstly, performing cyclic voltammetry curve scanning and then keeping ultraviolet irradiation, and then carrying out potentiostatic method based electro-deposition, and finally, cleaning the sample by using anhydrous isopropyl alcohol, thus obtaining the germanium nano cubic crystals. The method provided by the invention is simple in process and convenient to operate. Besides, the obtained germanium thin film deposited with germanium nano cubic crystals can be applied to a photoluminescent device and the like.

Owner:HARBIN INST OF TECH

Long-acting antibacterial multifunctional coating based on bionic dopamine as well as preparation method and application thereof

PendingCN112717207AImprove stabilityImprove the bactericidal effectSurgeryPharmaceutical containersAnti bacteriaDopamine

The invention provides a long-acting antibacterial multifunctional coating based on bionic dopamine as well as a preparation method and an application thereof. The preparation method comprises the following steps: carrying out ultrasonic cleaning on a base material by using acetone, absolute ethyl alcohol and ultrapure water in sequence; immersing the obtained base material into dopamine rapid deposition liquid for reaction to obtain a base material coated with a polydopamine coating; washing the obtained base material with deionized water, and drying; soaking the obtained base material in a multifunctional coating aqueous solution for reaction, and obtaining a functional coating on the surface of the base material; washing the obtained base material with ultrapure water and then drying; wherein Cu<2+> and H2O2 are dissolved in the dopamine rapid deposition liquid, and the multifunctional coating aqueous solution contains a hydrophilic polymer or a zwitterionic polymer. The preparation process is simple, conditions are mild, deposition preparation time is greatly shortened, and the method is suitable for large-scale industrial production.

Owner:SHANDONG UNIV

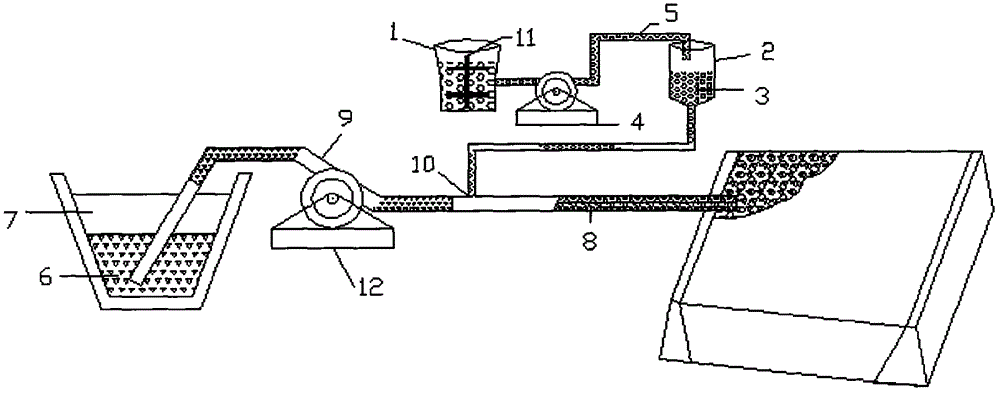

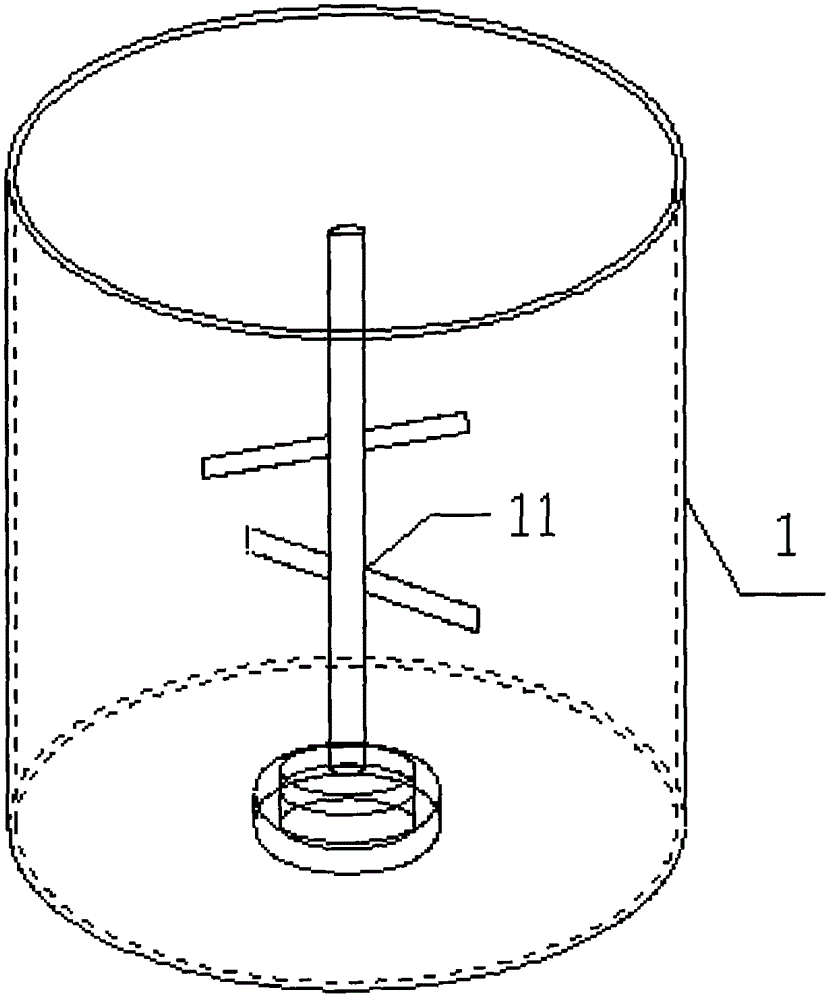

Microalgae collecting device and microalgae collecting method

ActiveCN102453669AShort deposition timeSimple structureBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorEngineering

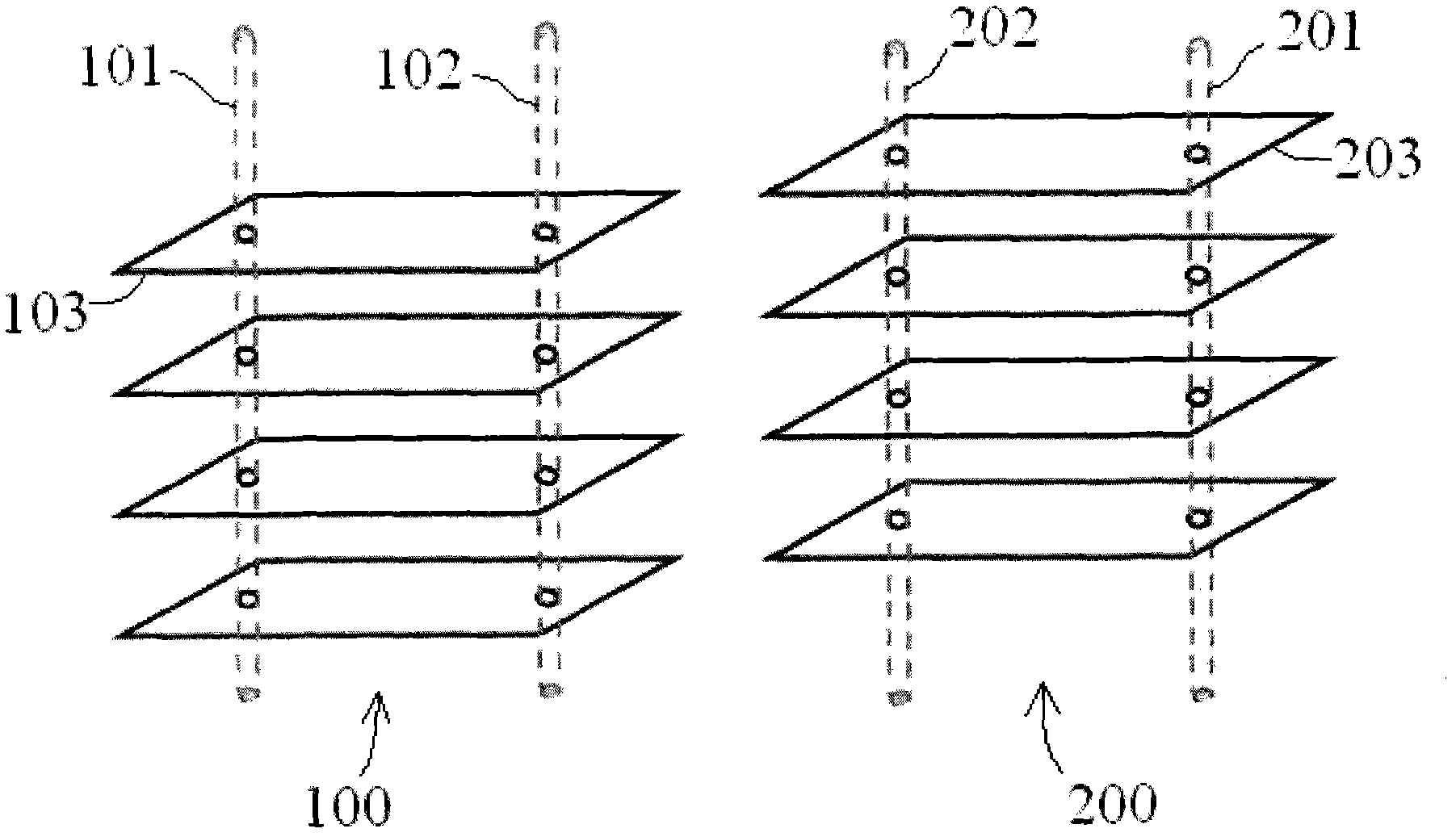

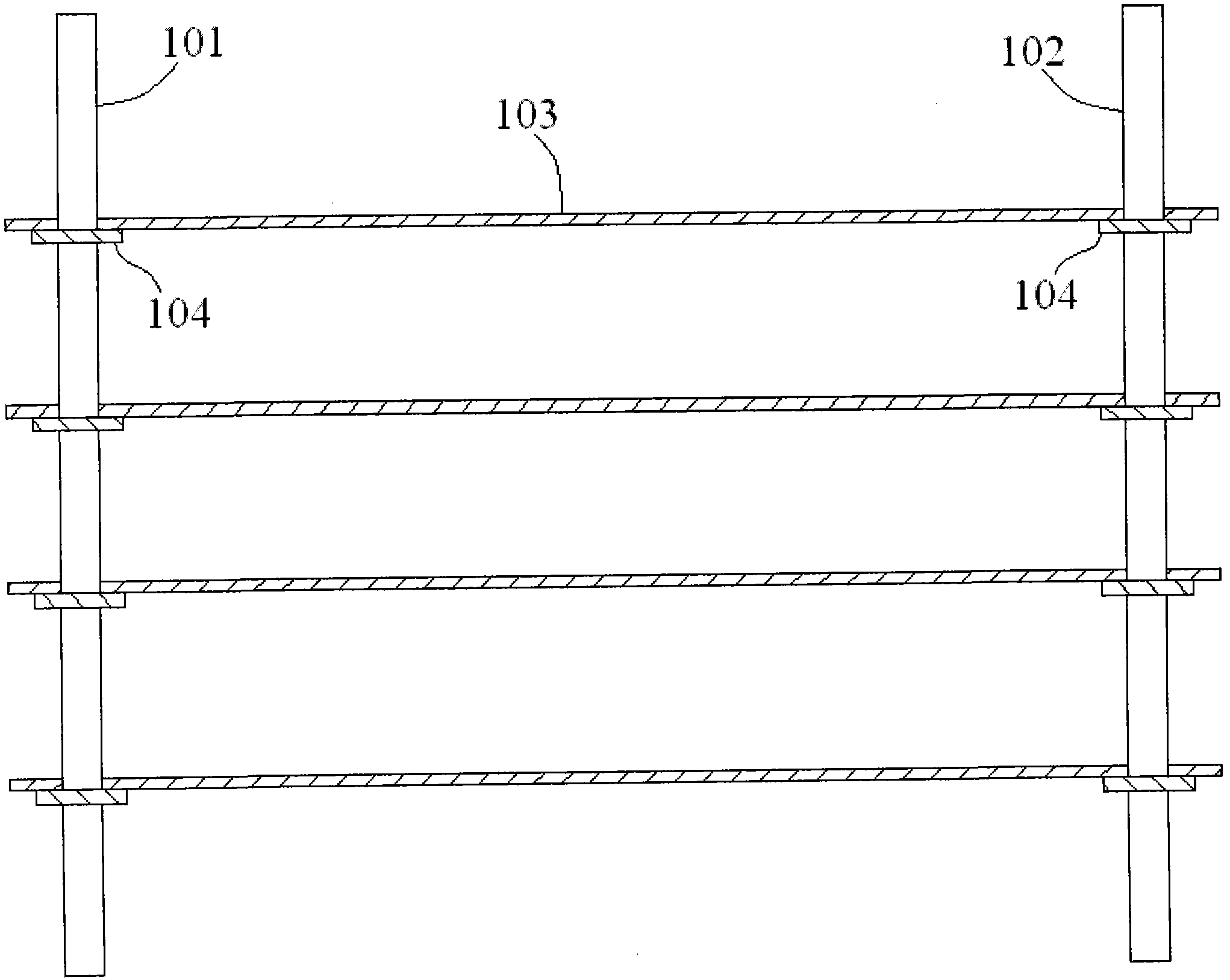

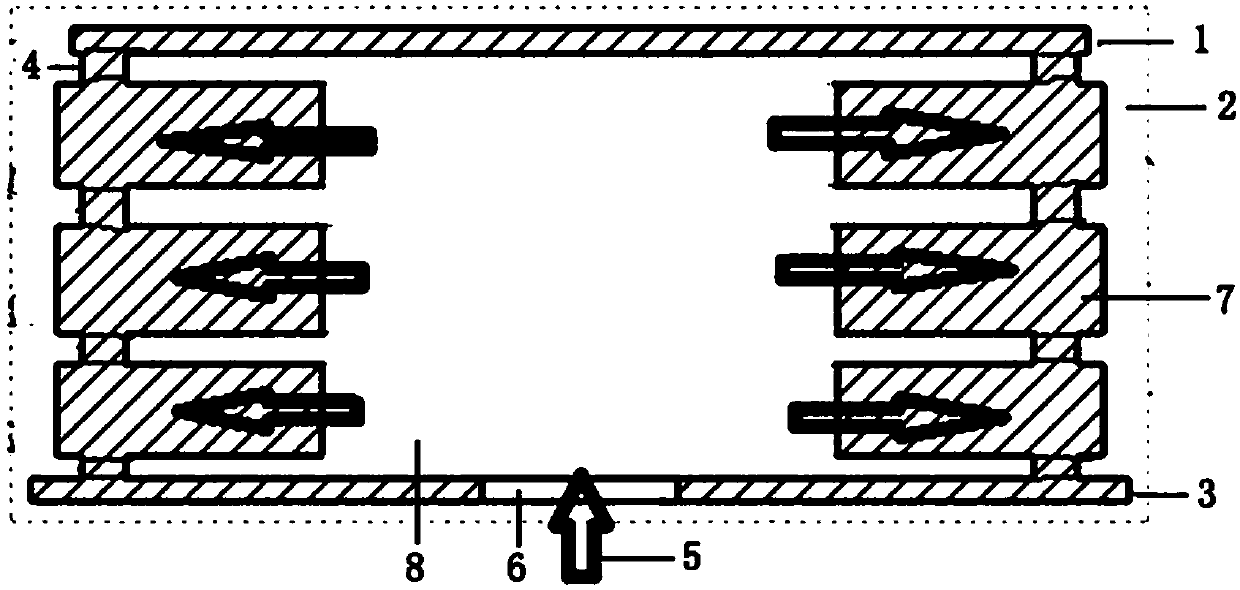

The invention discloses a microalgae collecting device, comprising at least two layers of collecting plates which are separated from each other in a vertical direction, wherein a first end of each of the at least two layers of collecting plates is supported on a first rod, while a second end thereof is supported on a second rod respectively; the first end of each layer of the collecting plate is equipped with a convex corner for preventing deposited microalgae from flowing out; and the second end of each layer of the collecting plate is an opened end good for the microalgae to flow out. When microalgae is deposited, the second rods are pulled upwards so that each layer of the collecting plate is inclined at a first inclination angle with respect to the horizontal direction, in this way, microalgae is deposited at the convex corner at the first end of each layer of the collecting plate; and when microalgae is collected, the first rods are pulled upwards so that each layer of the collecting plate is inclined at a second inclination angle with respect to the horizontal direction, in this way, deposited microalgae flows into a photo-biologic reactor from the opened second end of each layer of the collecting plate. The microalgae collecting device and the microalgae collecting method disclosed by the invention shorten the deposition time of microalgae, and make enrichment and collection of the microalgae easy; in addition, the microalgae collecting device is simple in structure, and suitable for large-scale application.

Owner:ENN SCI & TECH DEV

Process of preparing graphene

InactiveCN105585011AGood optical transmissionImprove electronic conductivityOptical transparencyCoating system

The invention provides a process of preparing graphene. According to the technical scheme, a radio frequency-plasma enhanced chemical vapor deposition (RF-PECVD) method is employed, wherein a polycrystal cobalt thin film prepared from a magnetron sputtering sputter coating system is employed as a substrate. At a low substrate temperature (800 DEG C) and low gas total flow quantity (78 sccm) and for a short deposition time (40 s), graphene having 1-5 carbon atom layers and being high quality is prepared successfully. The RF-PECVD allows the graphene to be prepared at low reaction temperature, for short deposition time and with less carbon resource, thereby greatly reducing the production cost of graphene and laying a foundation of promoting industrial application of the graphene. The graphene has high specific surface area, high optical transparency, high electric conductivity and high flexibility, so that the graphene has wide application value in the fields of electronic devices and optical devices.

Owner:PINGDU HUADONG GRAPHITE PROCESSING FACTORY

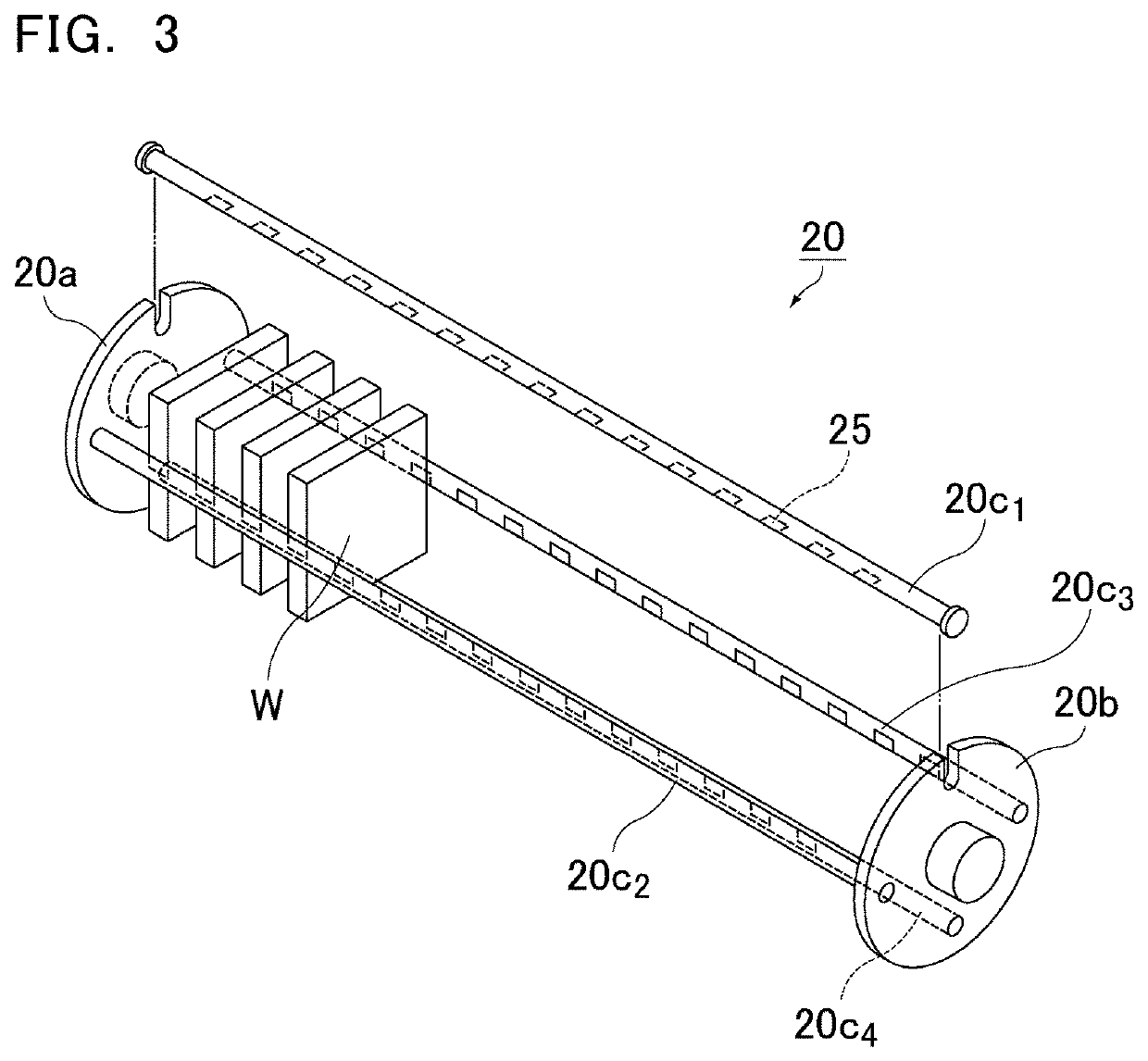

Film-forming device

ActiveUS11377731B2Materials is relatively shortShort timeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingMaterial supplyGas supply

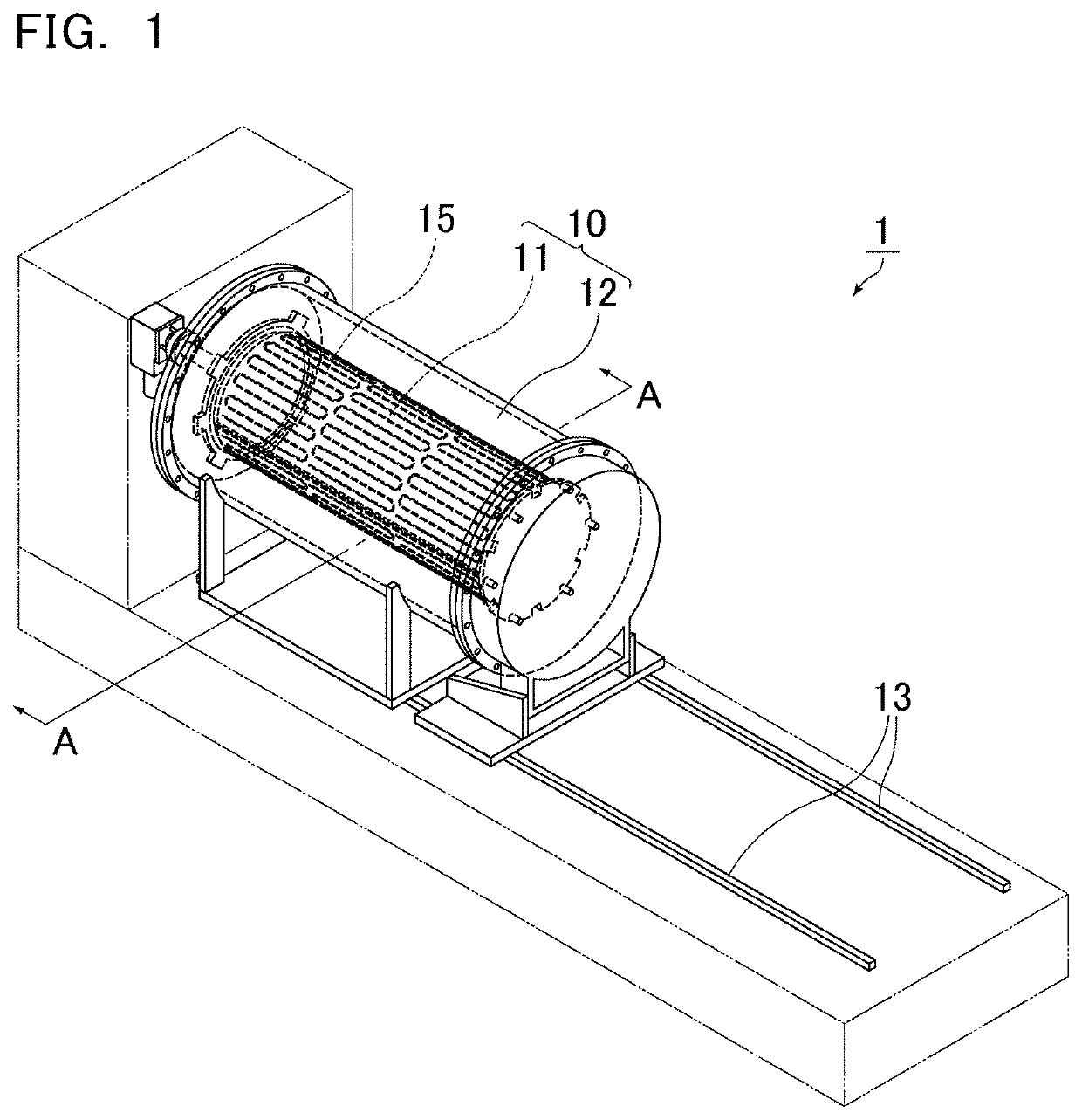

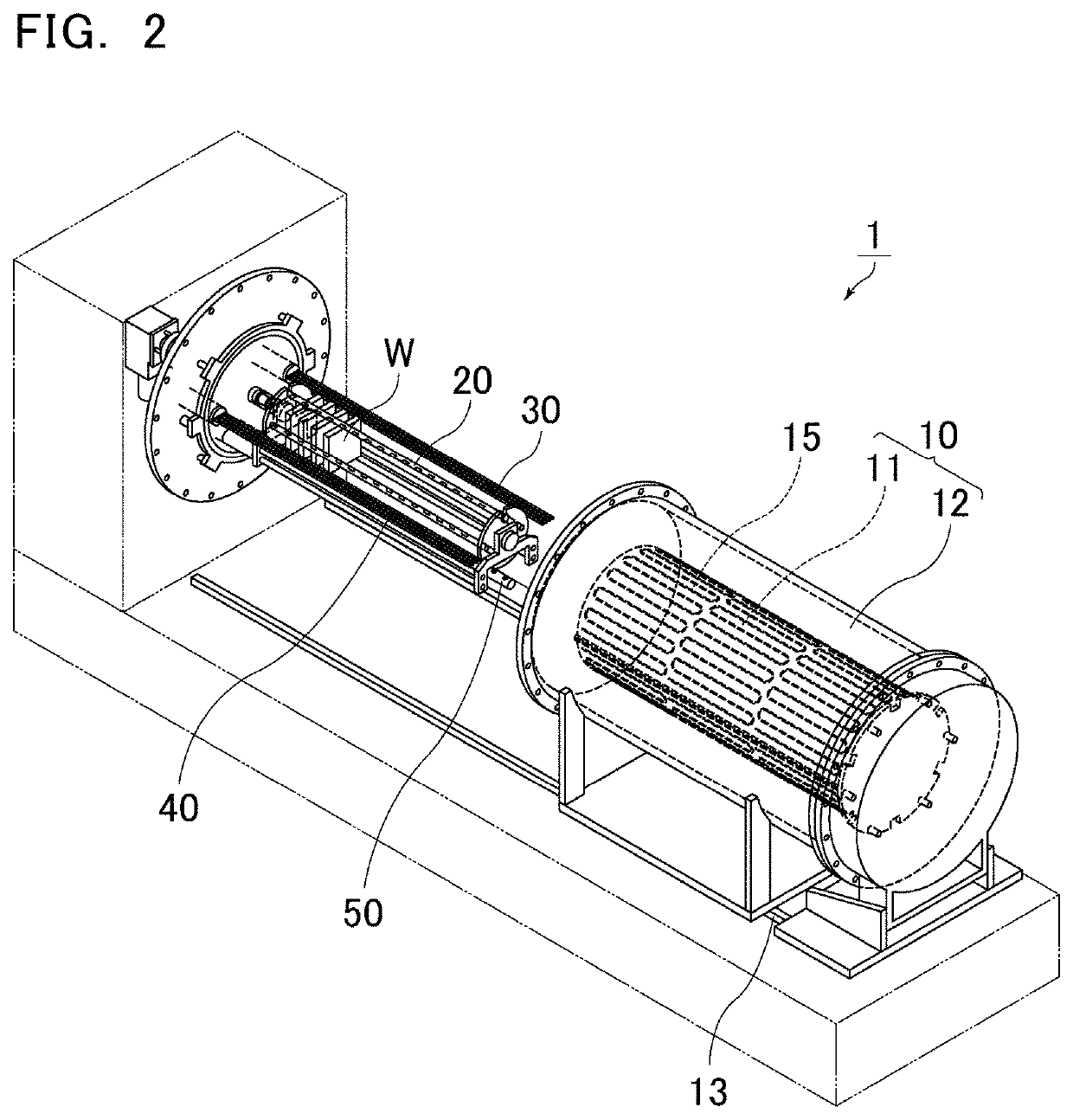

A film-forming device that includes a cylindrical chamber capable of maintaining vacuum therein, a workpiece holder that is constructed to align and hold workpieces to be processed in multiple stages such that main surfaces of the workpieces are oriented in a vertical direction relative to a central axis of the chamber, a deposition material supply pipe, a modifier supply pipe, a carrier gas supply pipe, and an exhaust mechanism, wherein in a cross section of the chamber in a direction parallel to the main surfaces of the workpieces, the exhaust mechanism is located on a side opposite to an opening direction of gas outlets of the deposition, modifier, and carrier gas supply pipes, and a total gas flow from the deposition, modifier, and carrier gas supply pipes is symmetric about a centerline of the chamber.

Owner:MURATA MFG CO LTD

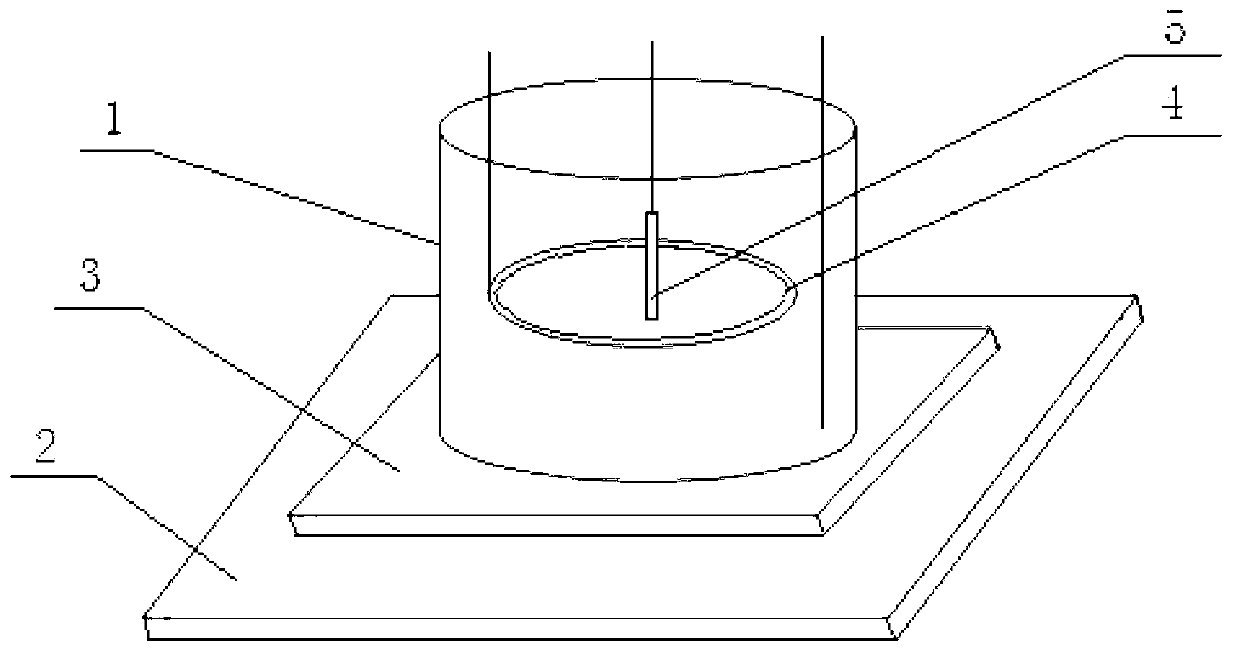

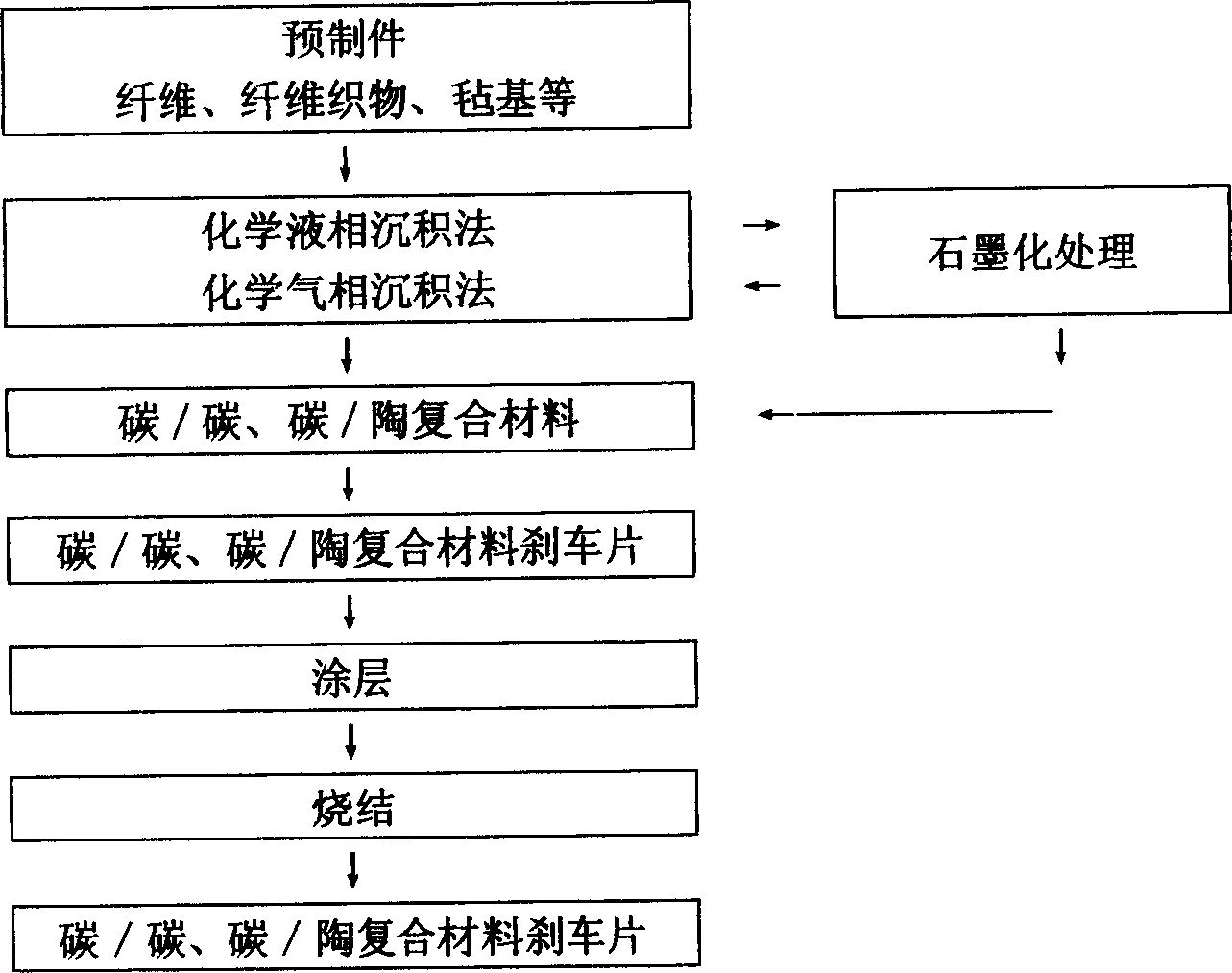

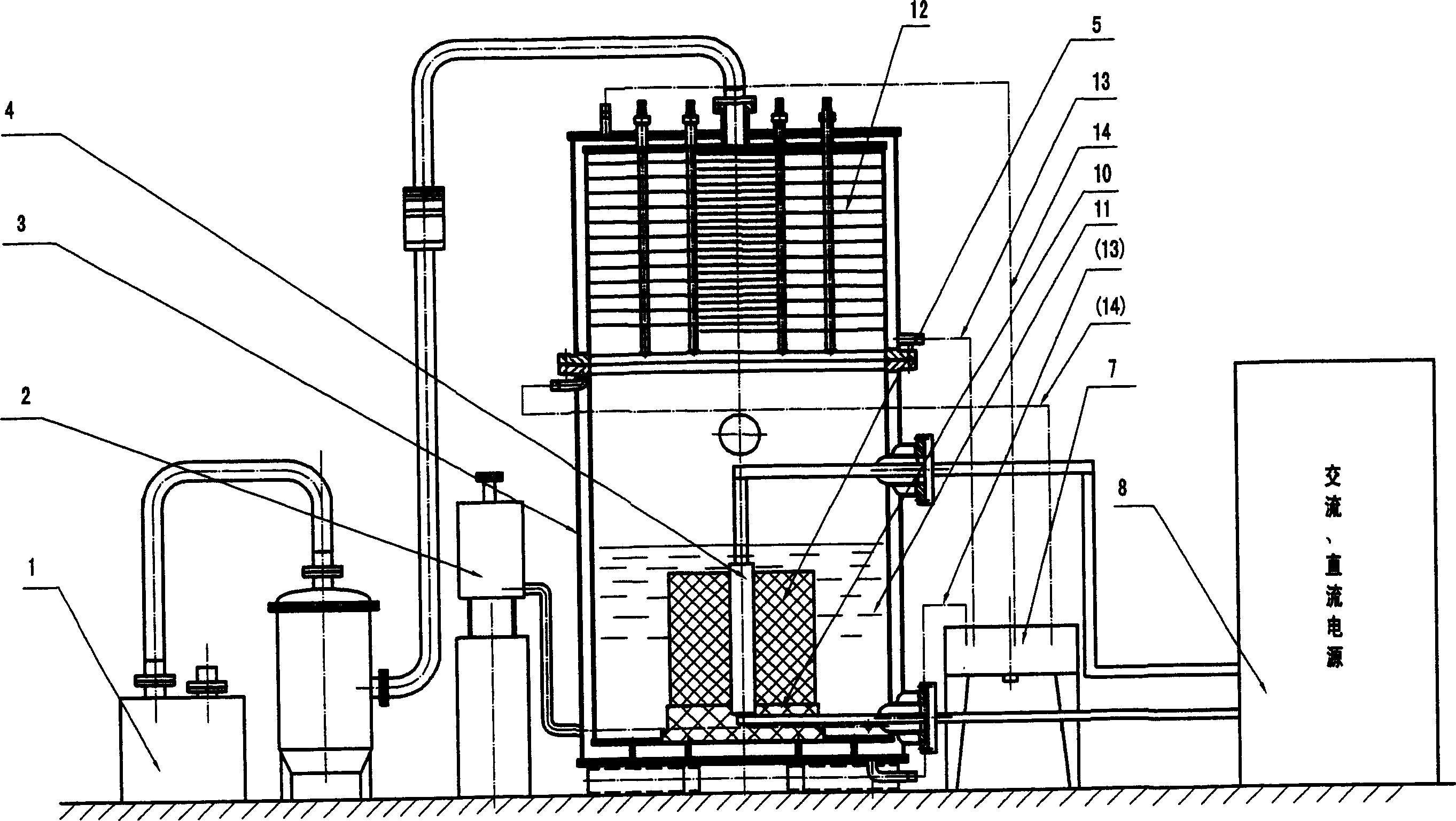

Use of carbon/carbon, carbon/ceramic composite material as brake lining, method and apparatus for making same

InactiveCN1544828AShort deposition timeIncrease productivityBraking element arrangementsBraking membersElectricityCeramic composite

The invention relates to the application of C / C and C / ceramic composite brake plate in motor vehicles, its preparing method: making the prefabricated piece, placing chemical liquid depositing device for chemical liquid deposition, graphitizing to form primary products; for size, processing into semifinished brake plate; coating the surface; sintering; finely processing to form finished composite brake plates. The device includes furnace body, vacuum system, condenser, water circulating system, liquid feeding system at the bottom of the furnace, the heated product placed on the base of the furnace body and a heating body in the center, where there are the inductor and the electric system connected of the doctor and variable-frequency power supply, both set on the periphery of the heated produce. It shortens the depositing time by several ten times or 101 times above, heightens the productivity, saves raw material and reduces product cost.

Owner:西安诚瑞科技发展有限公司

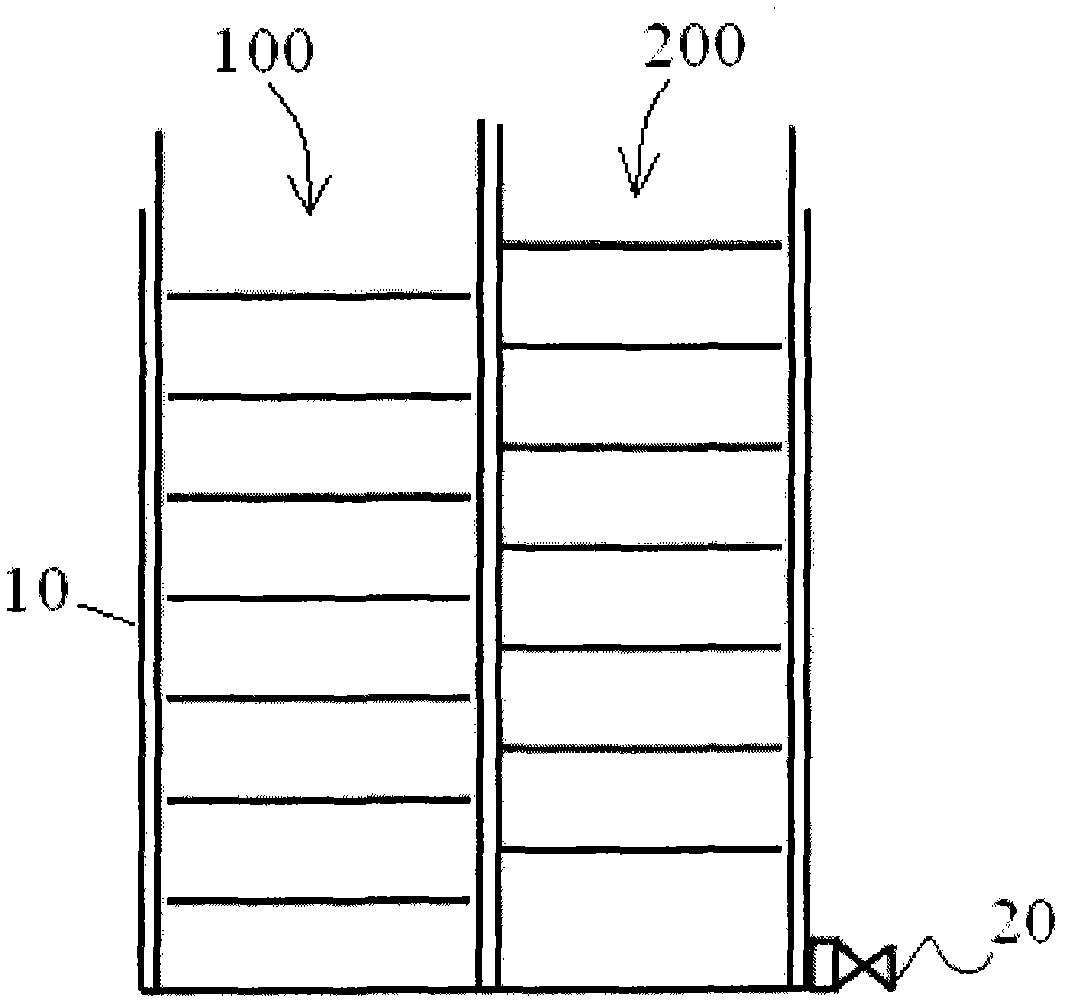

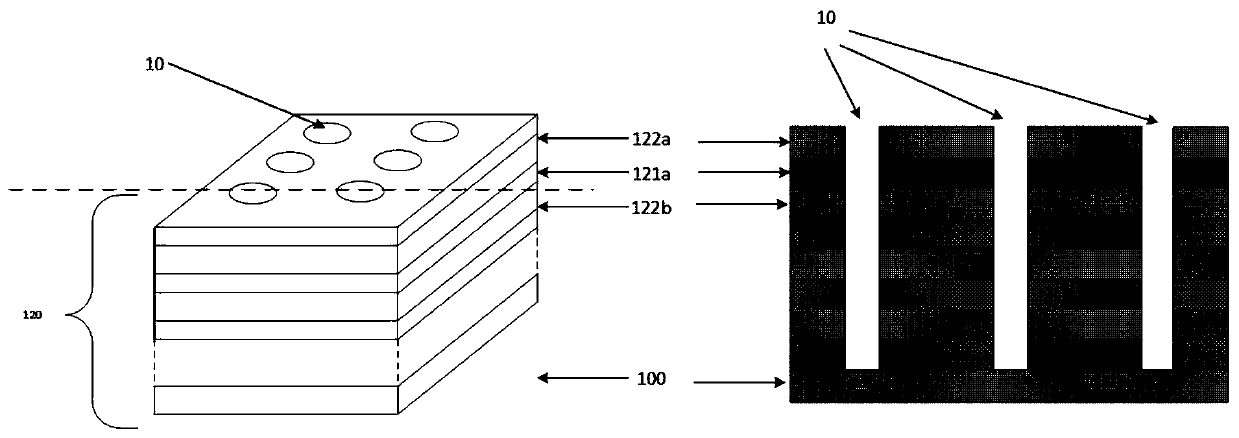

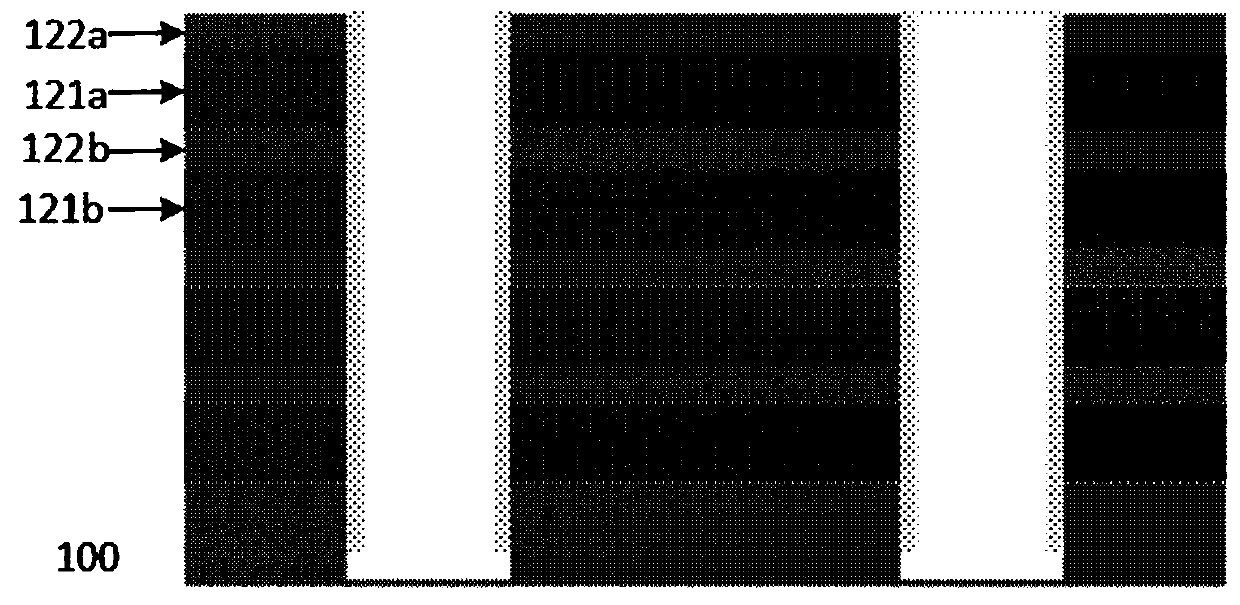

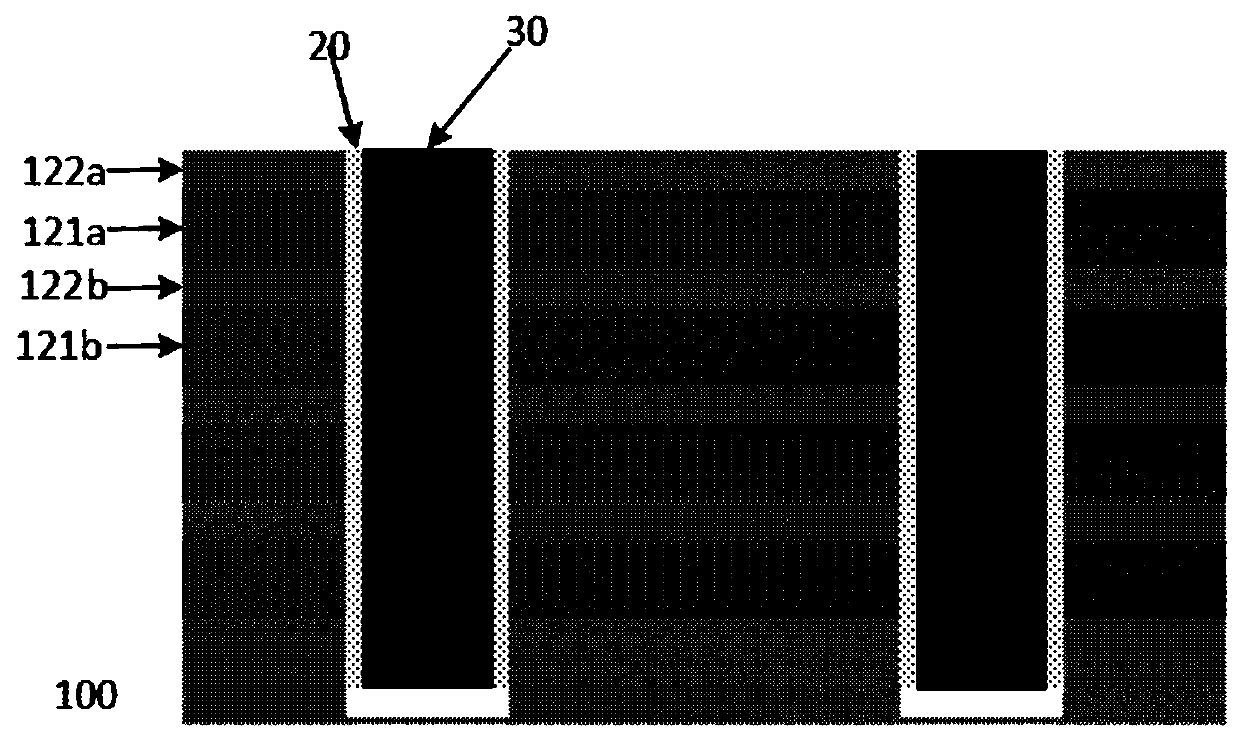

Three-dimensional flash memory based on vertical channels of two-dimensional semiconductor materials and preparation thereof

InactiveCN110148598AIncrease the on-state currentReduce operating voltage for reading and writingMaterial nanotechnologySolid-state devicesSemiconductor materialsCharge carrier mobility

The invention belongs to the field of semiconductor memory manufacturing and particularly relates to a three-dimensional semiconductor memory based on vertical channels of two-dimensional semiconductor materials and a preparation method thereof. The three-dimensional semiconductor memory comprises a plurality of three-dimensional storage strings in a vertical direction, and each three-dimensionalmemory string includes a semiconductor vertical channel whose length is determined by the number of layers of memory three-dimensional stack. The vertical channel materials comprise one or more two-dimensional semiconductor materials and protection layers on the surfaces of the two-dimensional semiconductor materials. The protection layers are used for supporting and protecting the two-dimensionalsemiconductor materials, and the carrier mobility of the two-dimensional semiconductor materials is higher than that of amorphous silicon. According to the invention, the two-dimensional materials are used as memory channels, higher memory cell on-state current can be provided, and therefore, the operational power consumption of the memory is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of long-fiber carbon ceramic fastener

The invention provides a preparation method of a long-fiber carbon ceramic fastener. The method comprises the following steps: alternately laying long-fiber non-weave cloth and short-fiber mesh tire,wherein the included angle between every two adjacent layers of long-fiber non-weave cloth is 90 degrees along the fiber direction, needling for once when each layer of short-fiber mesh tire is laid,and weaving a three-dimensional needled preform; densifying the obtained preform to 1.4-1.5g / cm<3> in precursor gas by means of pressure differential chemical vapor permeation to obtain a C / C complex;then, carrying out high-temperature heat treatment in protective gas; finally, putting the product into silicon powder, and carrying out high-temperature melting silicon infiltration, and machining and molding to obtain the long-fiber carbon ceramic fastener with the density of 2.2-2.4g / cm<3>. The preparation method provided by the invention is short in preparation period, low in residual porosity, rapid in densifying amplitude, low in cost and environmentally-friendly; the prepared carbon ceramic fastener is high in strength and volume density and better in high temperature resistance and corrosion resistance.

Owner:山东道普安制动材料有限公司

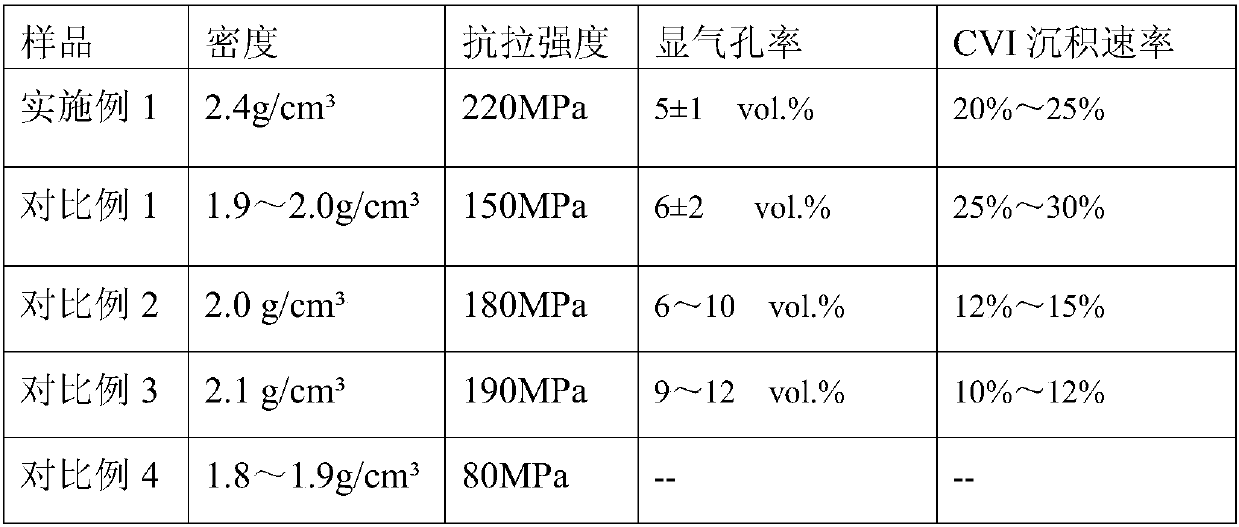

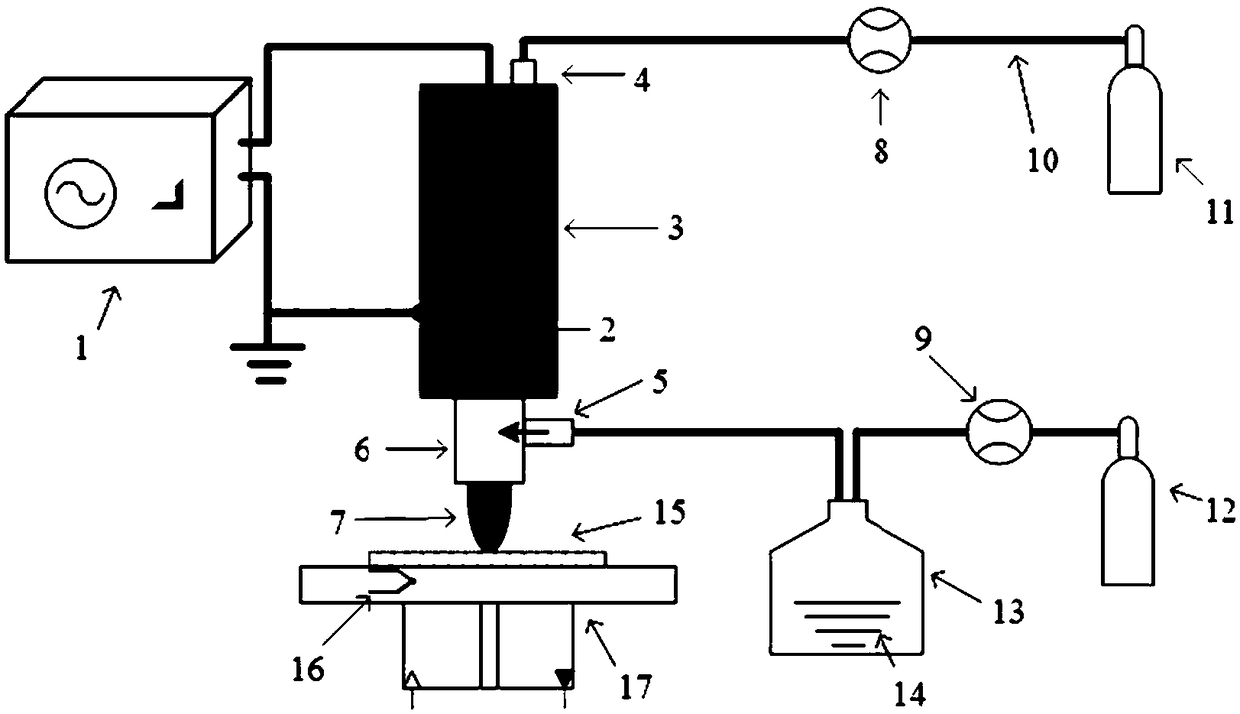

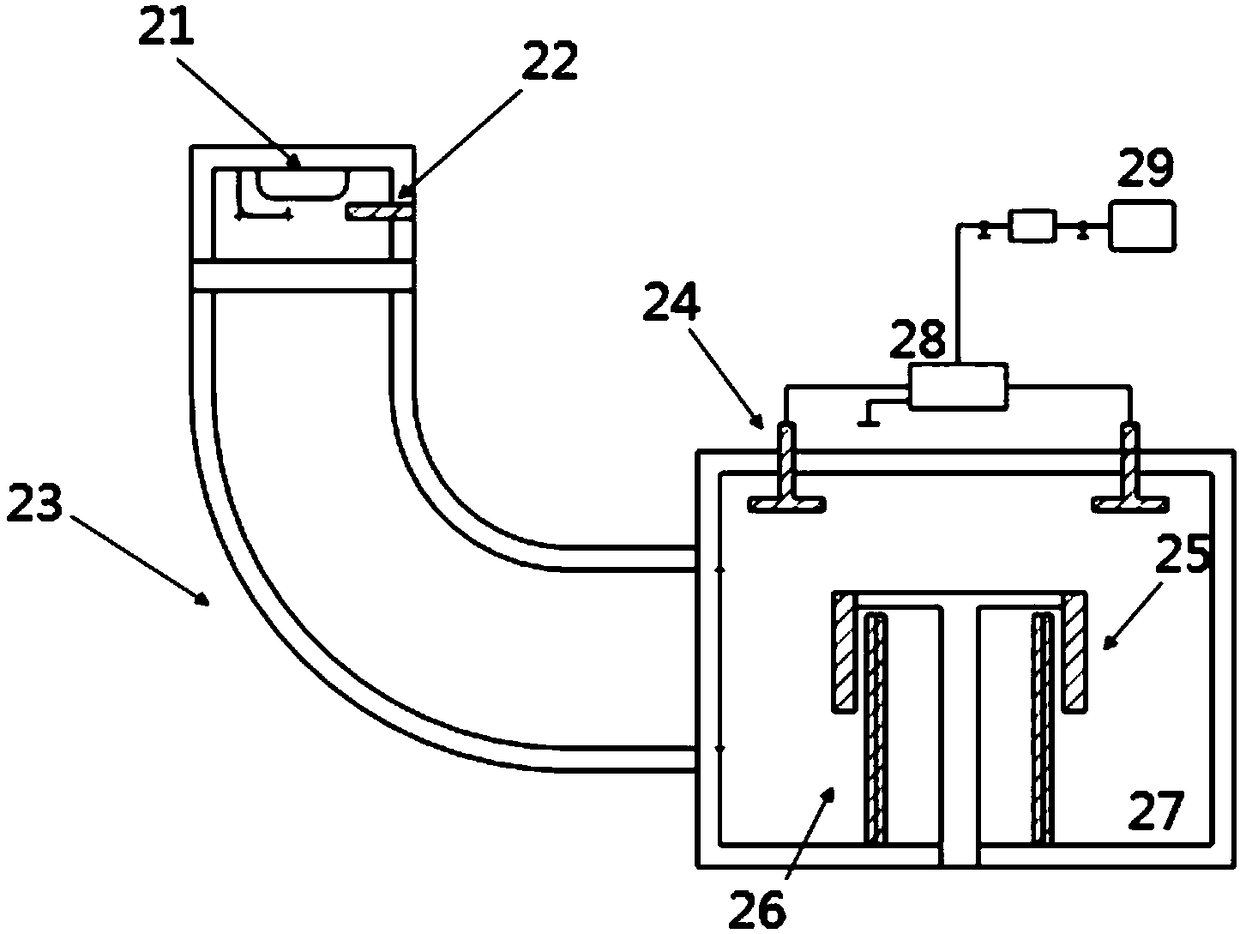

Plasma jet deposition film device and method of shallowing surface trap level

InactiveCN108130524AAvoid errorsLarge discharge areaChemical vapor deposition coatingPlasma jetGas cylinder

The invention discloses a plasma jet deposition film device and a method of shallowing a surface trap level. The device comprises a plasma jet array, a bubbling bottle, a second air cylinder and a power supply. The plasma jet array is arranged in a tempered glass cavity and comprises a quartz tube, a hollow metal capillary tube, a copper foil and a three-dimensional mobile platform, wherein the hollow metal capillary tube is interspersed into the quartz tube, and the outer wall of the hollow metal capillary tube is not in contact with the inner wall of the quartz tube; the copper foil is arranged in the bottom of the quartz tube for grounding; the three-dimensional mobile platform is arranged right below the quartz tube to regulate movement of a sample; one end of the bubbling bottle is connected to a first air cylinder while the other end is connected to the upper orifice of the hollow metal capillary tube; the second air cylinder is connected to the upper orifice of the hollow metalcapillary tube; and the power supply is connected to the hollow metal capillary tube.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

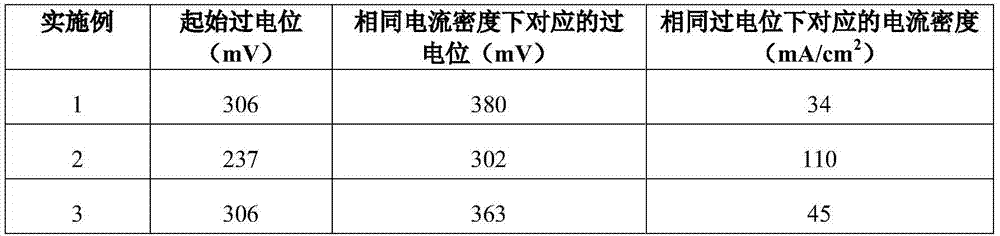

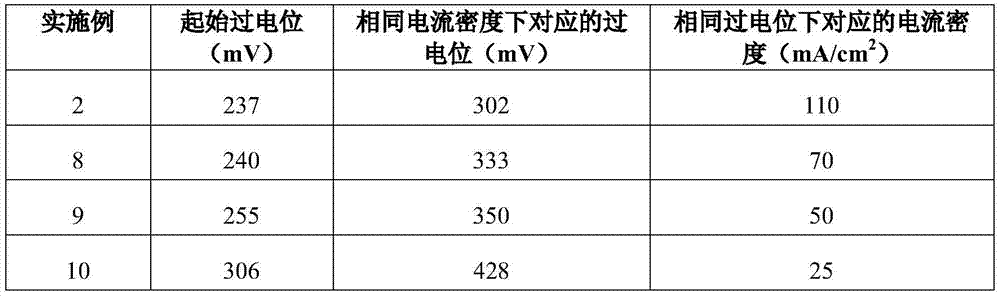

Preparation method for selenide thin film modifying foamed nickel electrode and application thereof

ActiveCN106868563ASimple methodEasy to operateElectrolytic inorganic material coatingSupporting electrolytePtru catalyst

The invention relates to a preparation method for a selenide thin film modifying a foamed nickel electrode and an application thereof. The preparation method comprises the following steps that the foamed nickel electrode is subjected to surface treatment through hydrochloric acid and ethanol, a nickel oxide layer on the surface of the foamed nickel electrode is removed, and the clean and fresh metal surface is obtained; and after pretreating, the foamed nickel electrode is immersed into a mixed solution of a transition metal chloride, a sulfur group oxide and a supporting electrolyte, and the selenide thin film is deposited on the surface of the foamed nickel electrode through a electrochemical method. The selenide thin film obtained through the electrochemical deposition method is stable, catalytic precipitation of hydrolyzed oxygen can be realized; the foamed nickel electrode is of a multi-layer structure, the special three-dimensional porous structure, compared with another one-dimensional or two-dimensional substrate electrodes, has a richer surface area, the price is low, so that the industrial large-scale application is facilitated; and a thin film catalyst is promising in being used in the research field of water-electrolytic hydrogen making.

Owner:OCEAN UNIV OF CHINA

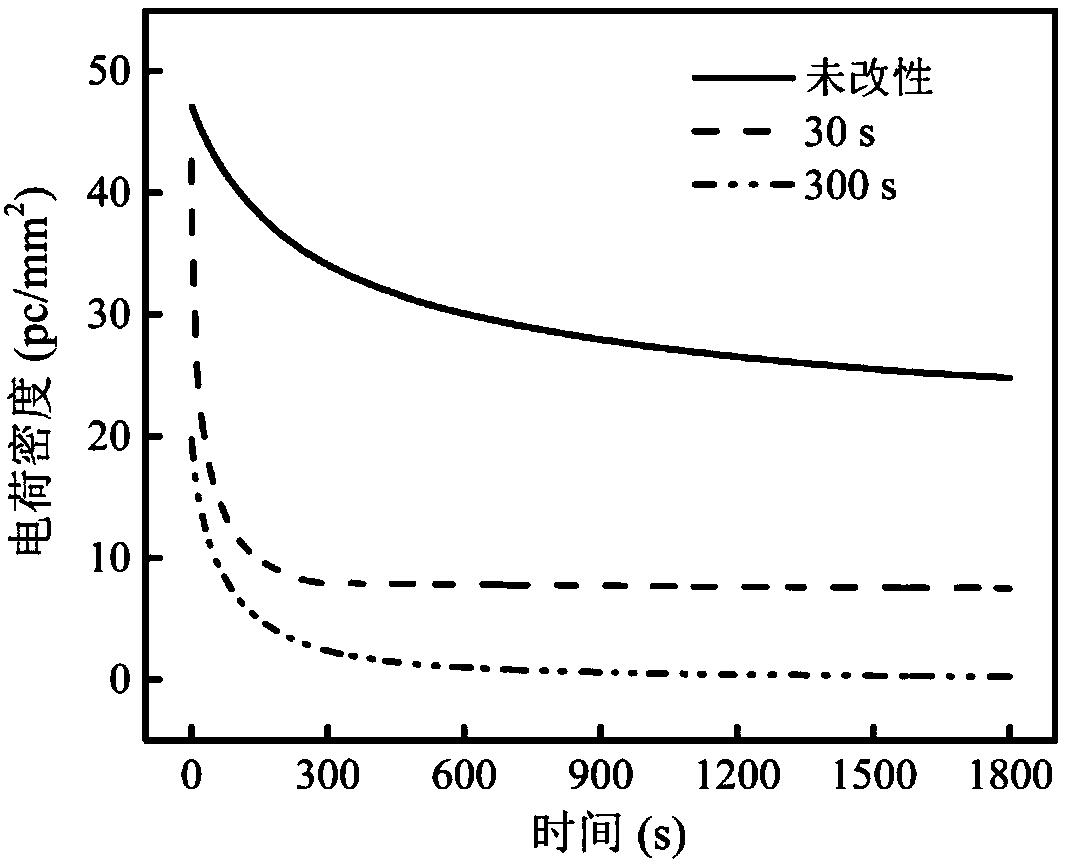

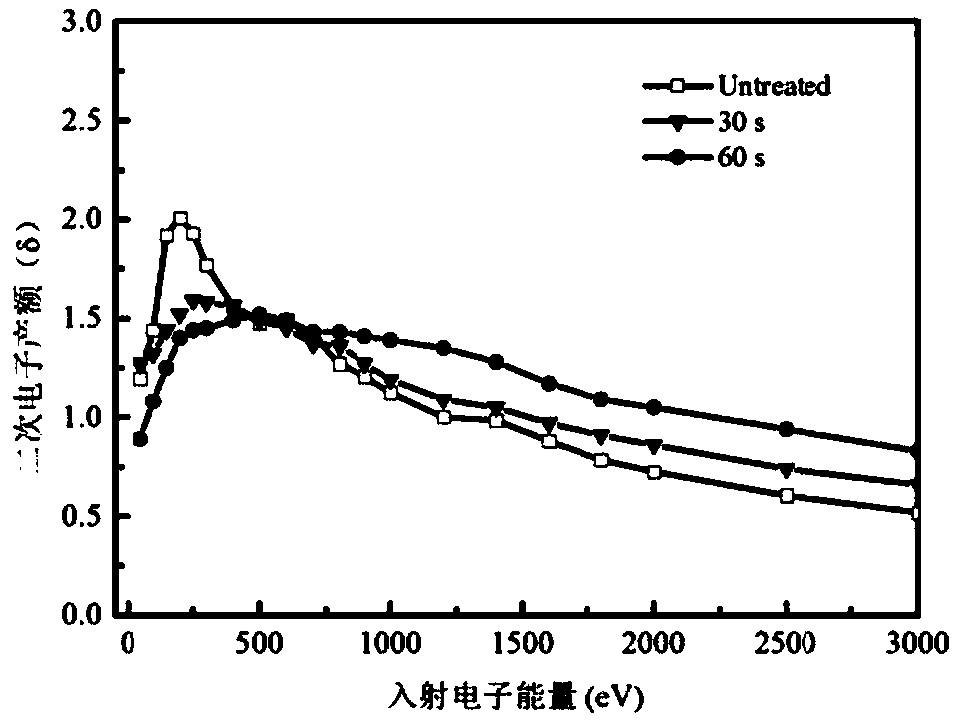

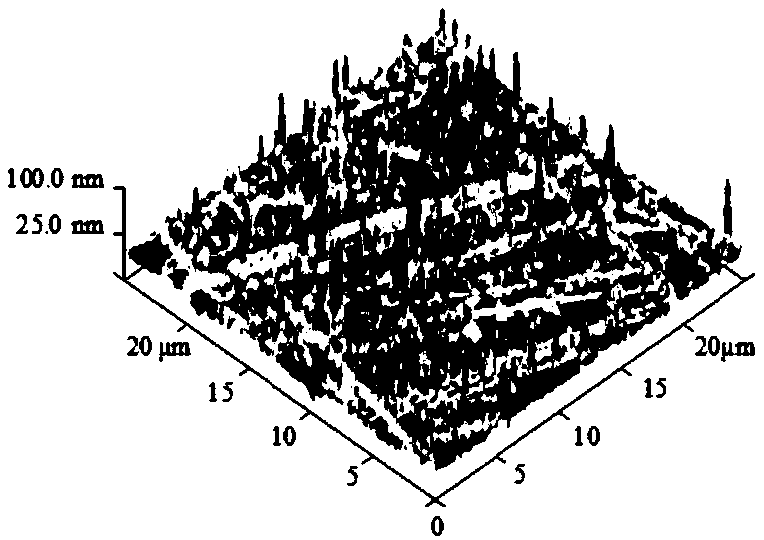

Spray-coating device and method for restraining secondary electron yield of solid dielectric material

ActiveCN108611623AAchieve modificationSimple structureChemical vapor deposition coatingDielectricDecomposition

The invention relates to a spray-coating device and a spray-coating method for restraining secondary electron yield of a solid dielectric material and belongs to the technical field of plasma. The spray-coating method comprises the following steps of: washing and drying a to-be-treated sample; building the spray-coating device for restraining the secondary electron yield of the solid dielectric material; carrying out an atmospheric plasma torch spray-coating experience; and carrying out a secondary electron yield test and material surface physical shape observation. According to the spray-coating device and the spray-coating method provided by the invention, by utilizing plasma torches generated by an atmospheric plasma spray gun, a reaction precursor reacts to generate a Ti-containing group and an N-containing group; a compact and uniform TiN film is deposited on the surface of a dielectric; specifically, a gas-carrying precursor has decomposition and polymerization reaction; polymerization, grafting and crosslinking effects are realized on the surface of the dielectric so that the deposited film forms a 'micro-trap' structure, the surface roughness is reduced, the secondary electron yield of the solid dielectric is restrained, and the surface insulation property of the dielectric is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Method of thin film electrospray deposition

ActiveUS7906182B1Short deposition timeImprove film qualityLiquid surface applicatorsCoatingsAmount of substanceSolubility

A method of forming a smooth thin film on a substrate within a short deposition time, the method comprising introducing ionic substances (salts, acids, bases) to a polymeric solution to be sprayed. These ions attach to the polymer strands in solution, increasing their charge to mass ratio. This results in mutual repulsion of the strands during the spray process and produces a smooth film, even at relatively high polymeric solution concentrations. A side effect of this process is the introduction of impurities (the added ions) to the polymer thin film. The proper choice of ionic compound allows a dissolution step to be used to “clean” the polymer film after deposition, using the solubility characteristics of the thin film versus the ionic compound.

Owner:UNIV OF SOUTH FLORIDA

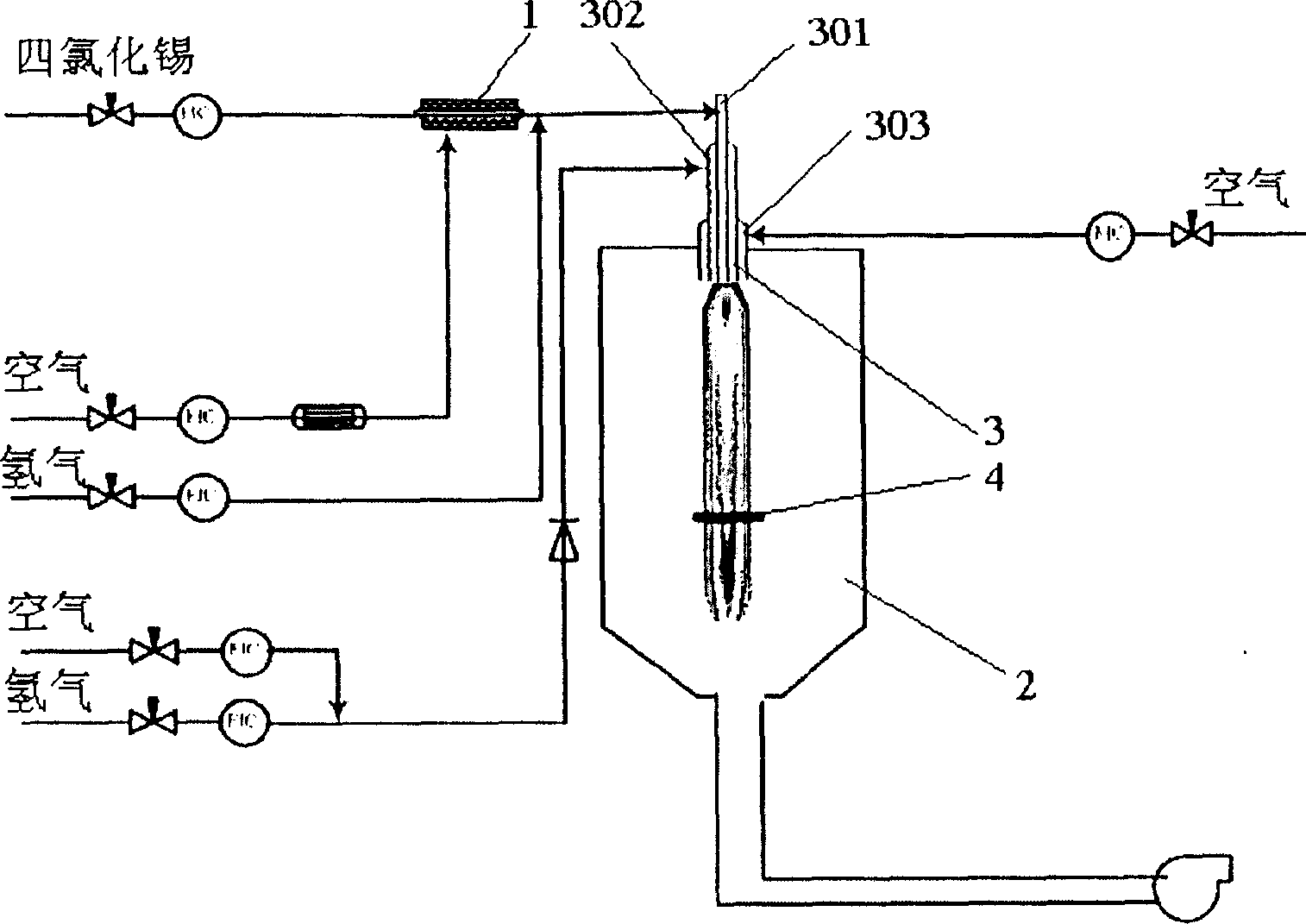

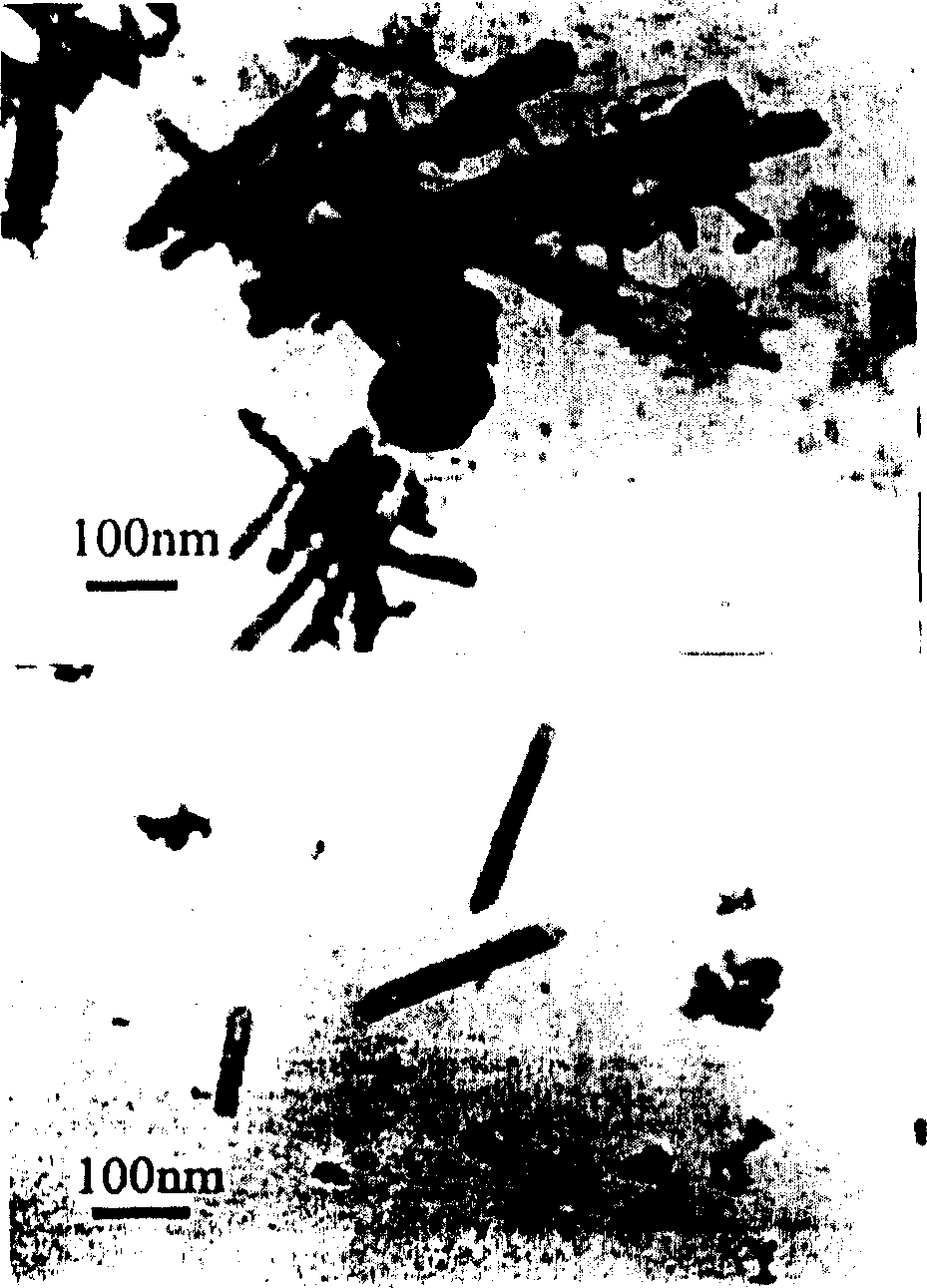

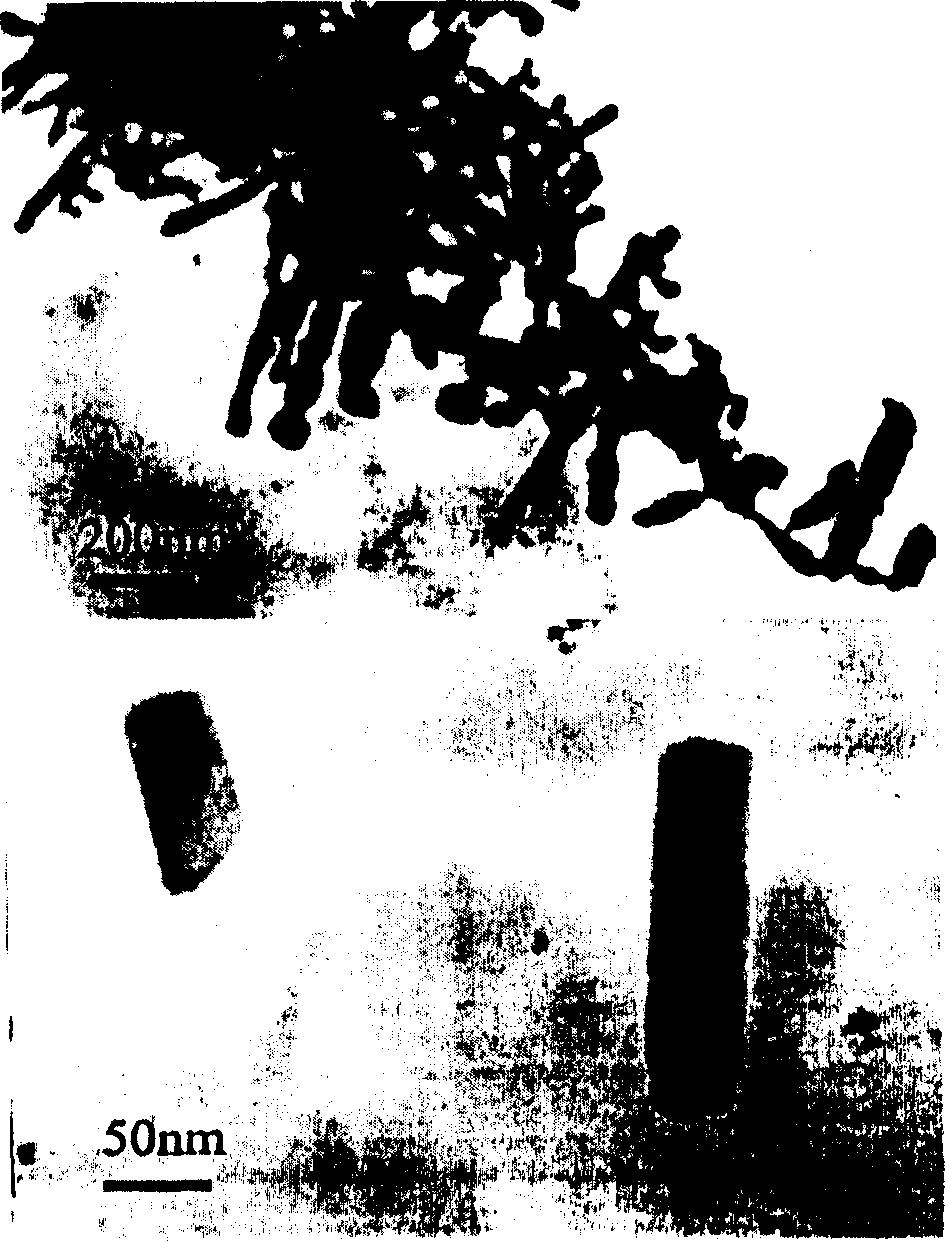

Prepn process of nanometer tin dioxide rod

InactiveCN1887723AAdjustable temperatureAdjust densityNanostructure manufactureTin oxidesTin dioxideTetrachloride

The preparation process of nanometer tin dioxide rod includes the following steps: mixing tin tetrachloride gas with hydrogen and air, introducing the mixture through the central tube of the three-channel jet in the top of the combusting reactor into the combusting reactor, feeding gas mixture of hydrogen and air through the middle ring tube of the three-channel jet into the combusting reactor, feeding air through the out ring tube of the three-channel jet into the combusting reactor, setting inert base board in the outlet of the burning jet, and depositing the produced nanometer tin dioxide rod on the inert base board. The said preparation process is one simple and effective process for preparing nanometer tin dioxide rod.

Owner:EAST CHINA UNIV OF SCI & TECH

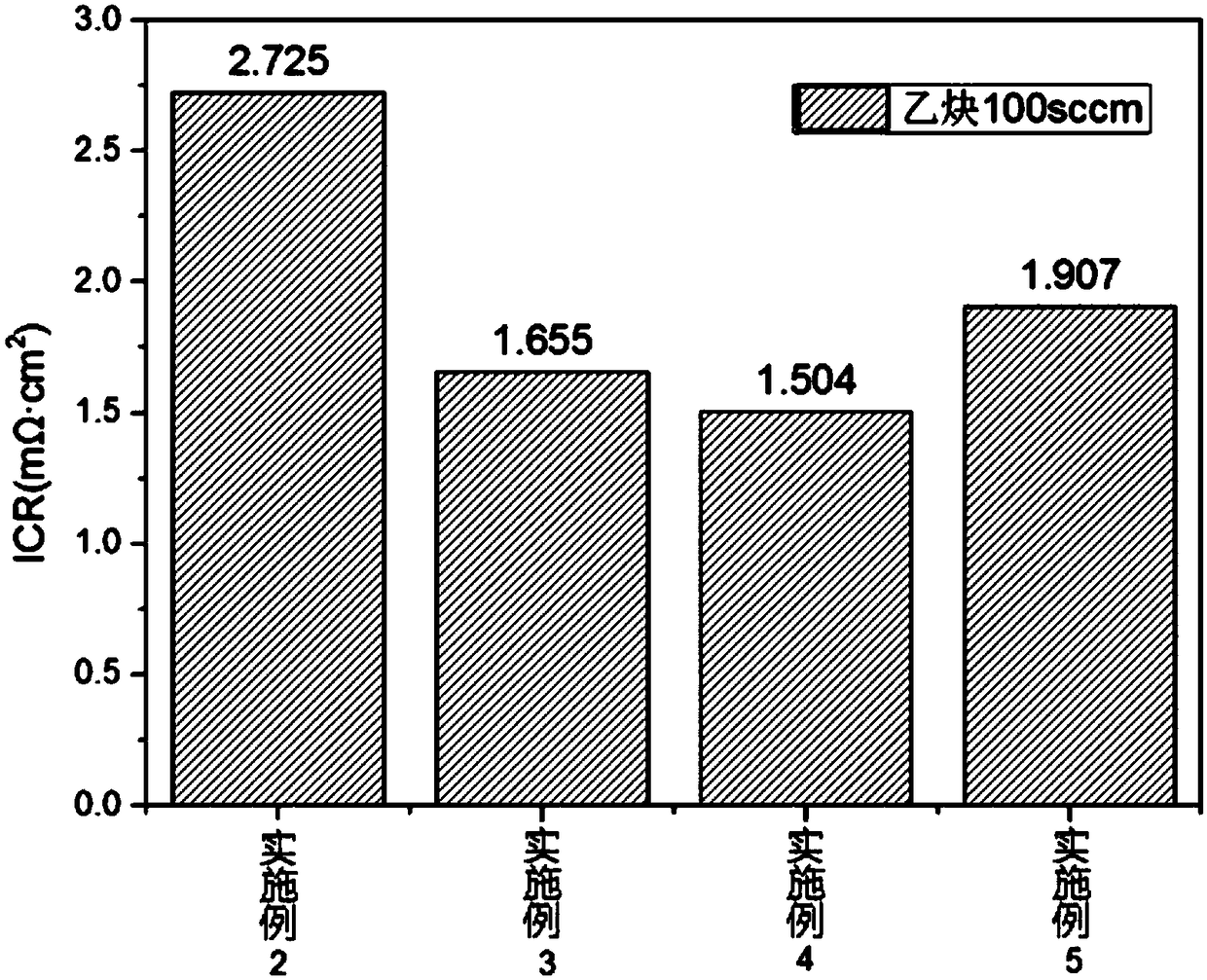

Fuel cell composite nano-coating and coating method thereof

InactiveCN108060398AMeet the use requirementsImprove compactnessVacuum evaporation coatingSputtering coatingFuel cellsCarbide

The invention relates to a fuel cell composite nano-coating and a coating method thereof. The composite nano-coating is an amorphous carbon coating inlaid with metal carbide, and is produced through fuel cell metal electrode plate surface pretreatment, composite nano-coating deposition and other steps. Compared with coatings in the prior art, the fuel cell composite nano-coating can improve the ionization rate in order to increase the carbide formation probability, improve the bombardment of particles to a matrix material, enhance the bonding force and the compactness of a film substrate and avoid cracks, through holes and other defects, still has good electric conductivity, and can meet use requirements of a fuel cell metal electrode plate.

Owner:SHANGHAI JIAO TONG UNIV

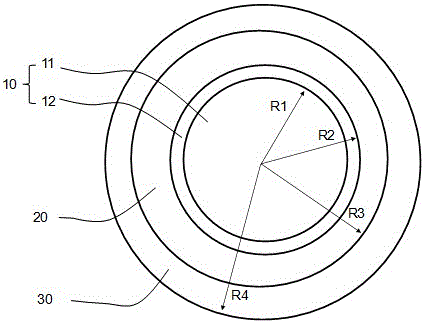

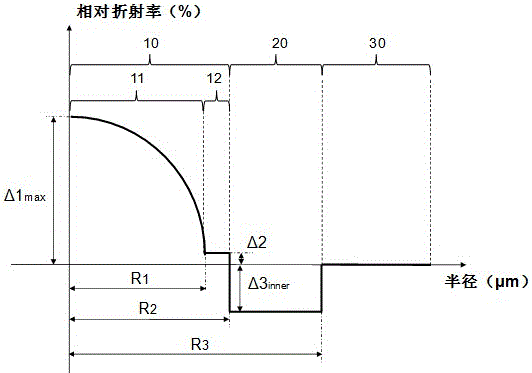

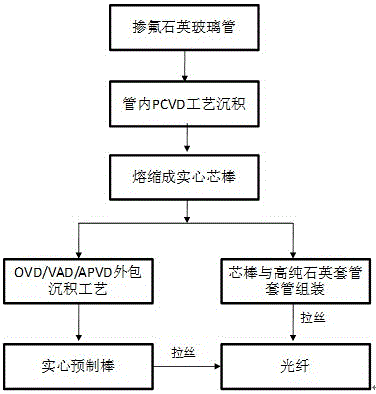

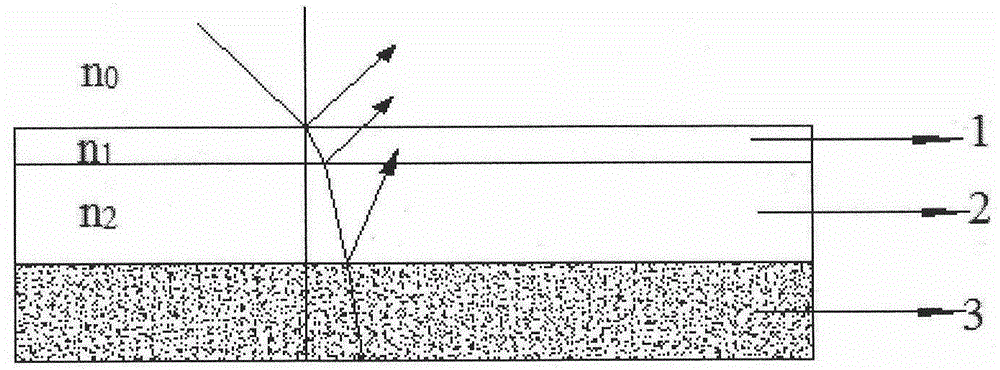

Bending insensitive multimode fiber and manufacturing method thereof

ActiveCN106094104AReasonable structural designImprove bending resistanceOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingDistributed indexRelative refractive index

The invention relates to a bending insensitive multimode fiber and a manufacturing method thereof. The bending insensitive multimode fiber comprises a core layer and a cladding coating the core layer, wherein the refractivity profile of the core layer presents alpha power exponent function distribution. The bending insensitive multimode fiber is characterized in that the cladding comprises an inner cladding layer, a depressed cladding layer and an outer cladding layer sequentially from inside to outside; the core layer distribution exponent alpha is 1.9 to 2.2, the radius R1 is 23 to 27 mum, and the maximum relative refractive index difference delta1max is 0.9 to 1.2%; the radius of the inner cladding layer is R2, the unilateral radial thickness is 1 to 3 mum, and the refractive index difference delta2 is 0 to 0.05%; the radius of the depressed cladding layer is R3, the unilateral radial width is 10 to 20 mum, and the relative refractive index difference delta3inner at the place close to the inner cladding layer along a diameter direction is -0.29 to -0.42%; and the outer cladding layer is a pure silica glass layer. Thus, the structure is reasonably designed, the anti-bending and the bandwidth performance are excellent, the process is convenient to control, and the manufacturing and the production are easy.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Process for preparing graphene through RF-PECVD

InactiveCN104709897AGood optical transmissionImprove electronic conductivityReaction temperatureOptical transmittance

The present invention discloses a process for preparing graphene through RF-PECVD. The technical scheme comprises that: a radio frequency plasma enhanced chemical vapor deposition (RF-PECVD) method is adopted and a polycrystal cobalt film prepared by adopting a magnetron sputtering film plating system is adopted as a substrate to successfully prepare high-quality graphene having 1-5 carbon atom layers at a low substrate temperature (800 DEG C) under less total gas flow rate (78 sccm) within a short deposition time (40 s). The process of the present invention has the following characteristics that: the graphene can be prepared under the conditions of the relatively low reaction temperature, the short deposition time and the less requirement of the carbon source through the RF-PECVD method so as to substantially reduce the graphene preparation cost and establish the foundation for the promotion of the industrial application of the graphene; and the graphene has excellent physical properties of high specific surface area, high optical transmittance, high electrical conductivity, high flexibility and the like, such that the graphene has wide application values in the fields of electronic devices, optical devices and the like.

Owner:QINGDAO SHENGLI BOILER

Preparation method of transparent tin antimony oxide electric heating film

InactiveCN102925880AReduce pollutionReduce close contactSolid/suspension decomposition chemical coatingElectric arc furnaceSolvent

The invention provides a preparation method of a transparent tin antimony oxide electric heating film, which belongs to the field of thin-film materials. The preparation method comprises the steps that tin and antimony raw materials and an additive are dissolved in a solvent to form a solution; a pH value of a system is adjusted to be neutral or slightly alkaline; the solution is put in an ultrasonic atomizer; a nozzle of the ultrasonic atomizer is positioned at the top of an electric box furnace; glass tubes or ceramic tubes to be coated are placed on a rack orderly and vertically; the rack on which the glass tubes or the ceramic tubes are placed is placed in the electric box furnace; a door of the electric box furnace is closed; the electric box furnace is switched on; the ultrasonic atomizer is switched on; and drops of the solution containing tin and antimony are deposited on the external surfaces of the glass tubes or the ceramic tubes uniformly to form transparent tin antimony oxide conductive films. The glass tubes or the ceramic tubes coated with the transparent tin-antimony oxide conductive films can be used as heating elements for heating liquid, gas, solid and the like.

Owner:NINGBO CIXI ELECTRICAL APPLIANCE

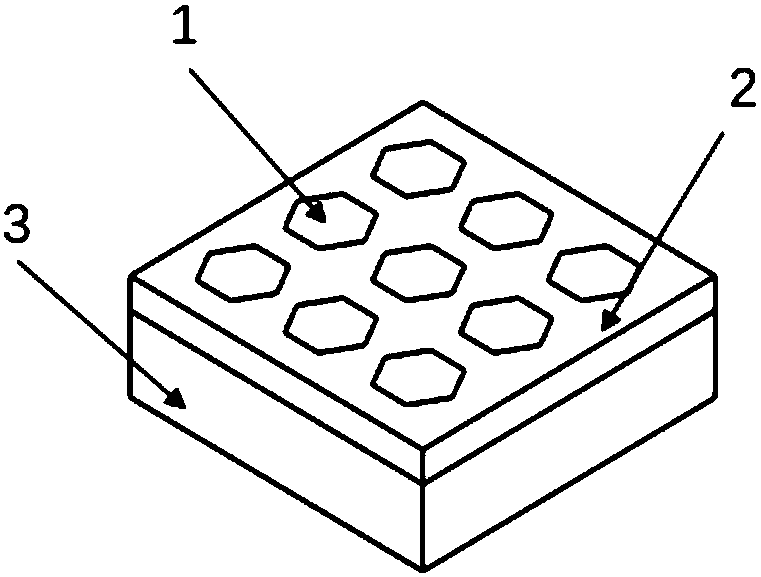

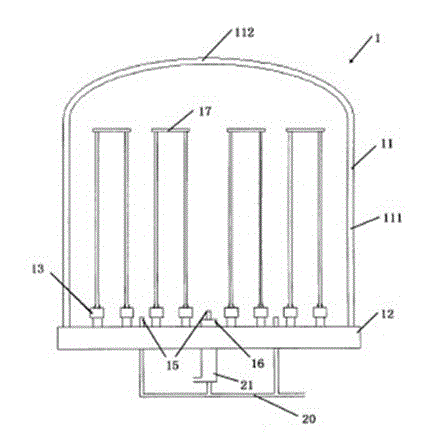

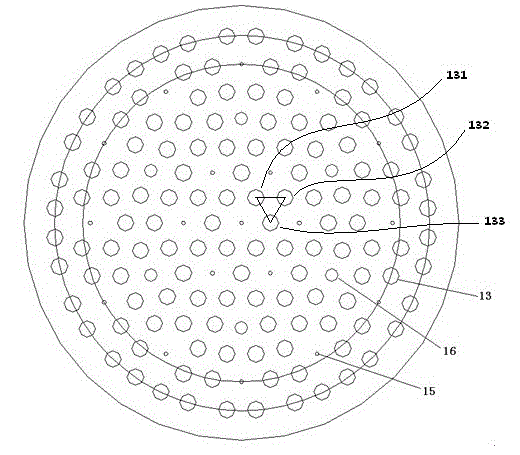

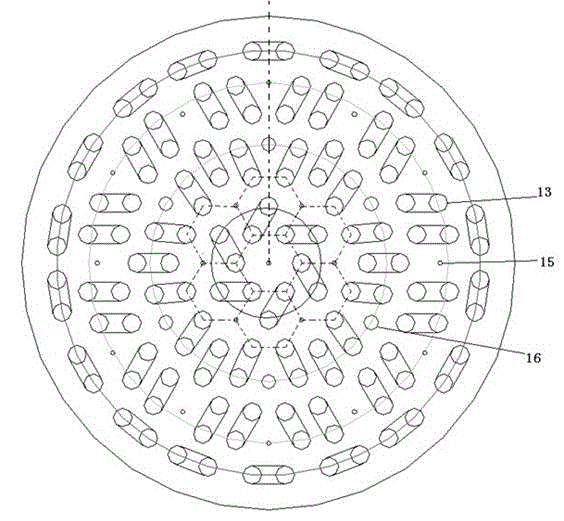

Reactor used for producing polycrystalline silicon

The invention discloses a reactor used for producing polycrystalline silicon. The reactor comprises a furnace tube with a cooling device, a chassis, and electrodes, raw material gas inlets and gas outlets positioned on the chassis. The reactor is characterized in that except the outermost electrodes close to the furnace tube, each electrode has 4 or 5 other adjacent electrodes and one or two adjacent gas inlets and / or outlets at distances of 150mm-300mm. A matrix formed by the electrodes, gas inlets and gas outlets is arranged as equilateral triangle and / or approximate equilateral triangle matrix. With the reactor, denser silicon core arrangement can be realized, thermal energy utilization rate in a reduction furnace can be improved, and more uniform flow field distribution is realized, such that polycrystalline silicon yield in each bath is improved, product surface quality is improved, and energy consumption is reduced.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

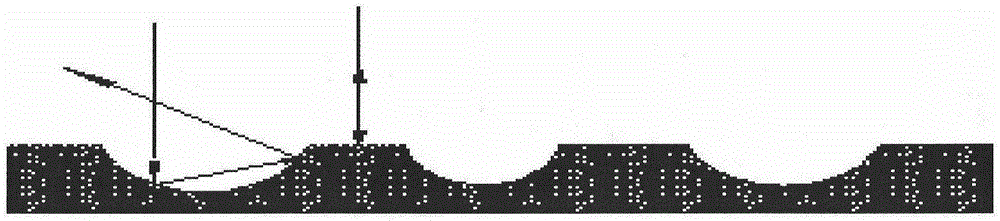

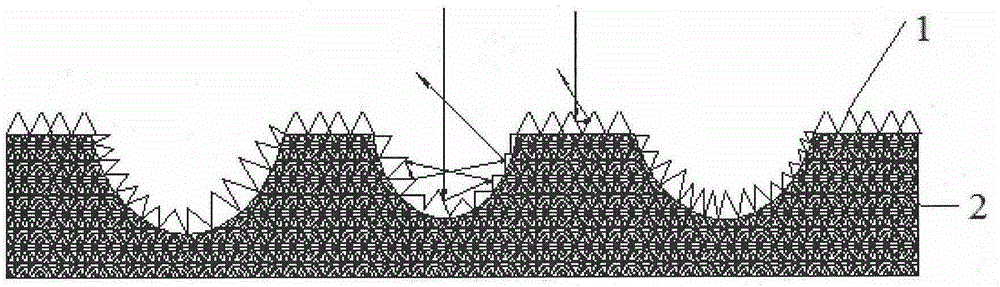

Double antireflection layer structure of solar cell reflection film and preparation method thereof

InactiveCN104966756AReduce energy consumptionHigh refractive indexFinal product manufacturePhotovoltaic energy generationTransmittanceRefractive index

The invention relates to a double antireflection layer structure of a solar cell reflection film and a preparation method thereof. The double antireflection layer structure is formed by an upper antireflection layer, a crater antireflection layer and a base layer in sequence. The crater antireflection layer in the middle is provided with arc-slope concave craters. The upper antireflection layer is composited on the upper surface of the crater antireflection layer and is formed by a bottom layer film and particles densely arranged thereon, wherein the surface of each particle has a suede shape. The bottom layer film and the upper surface of the crater antireflection layer are integrated and jointly form the concave craters. The crater layer is prepared through deposition by adopting the PECVD technology; the PECVD technology can be used to prepare the uniform and performance-stable crater layer structure; the controllability is high; and the thickness of the antireflection layer can be controlled accurately. A solar cell has more than 90 % high transmissivity. The antireflection layer is simple in specific processes, quick in deposition time and low in energy consumption; the double antireflection layers has sequentially-increasing refractive rate; and the structure can provide possibility for large-area industrial production.

Owner:常德东腾新能源有限公司

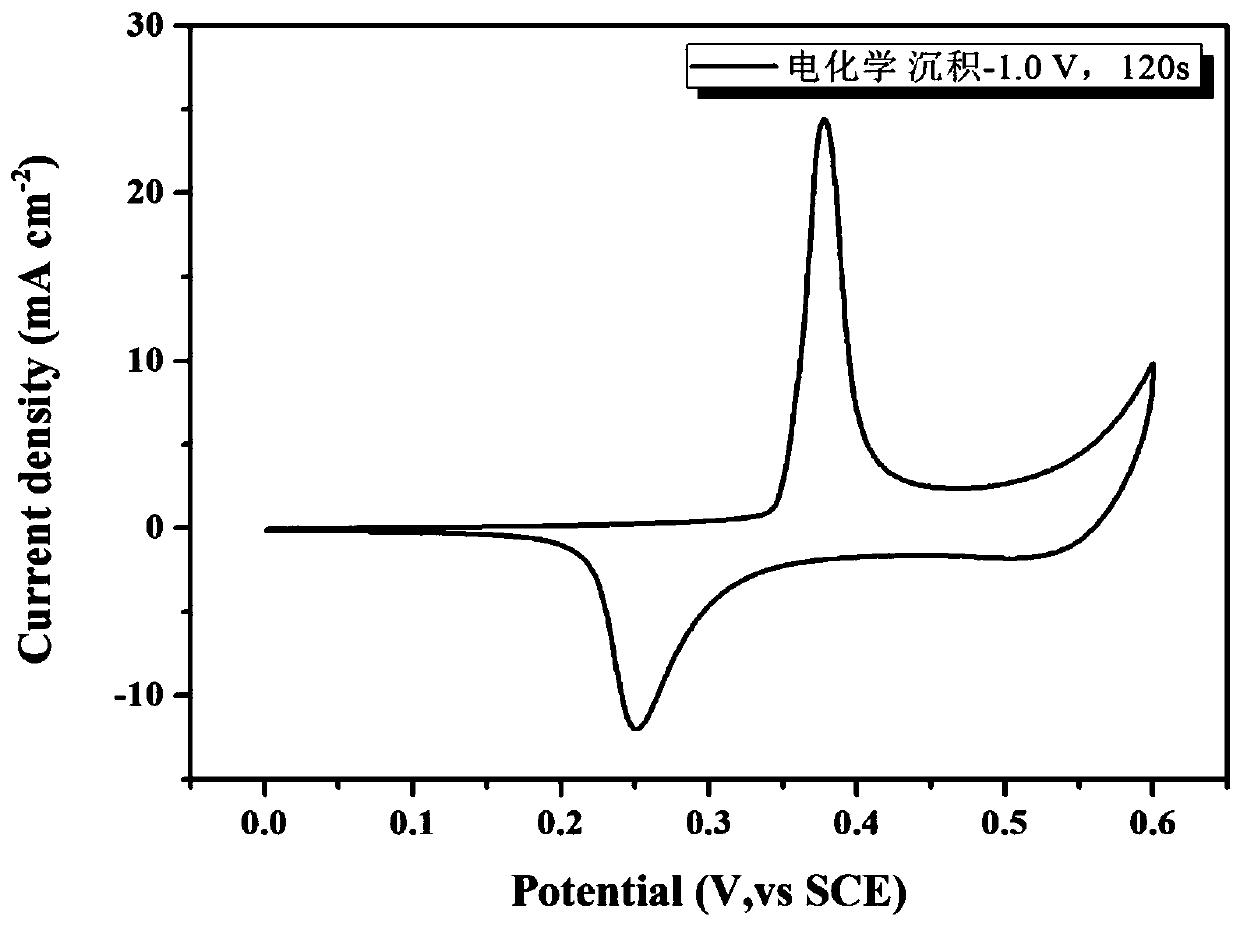

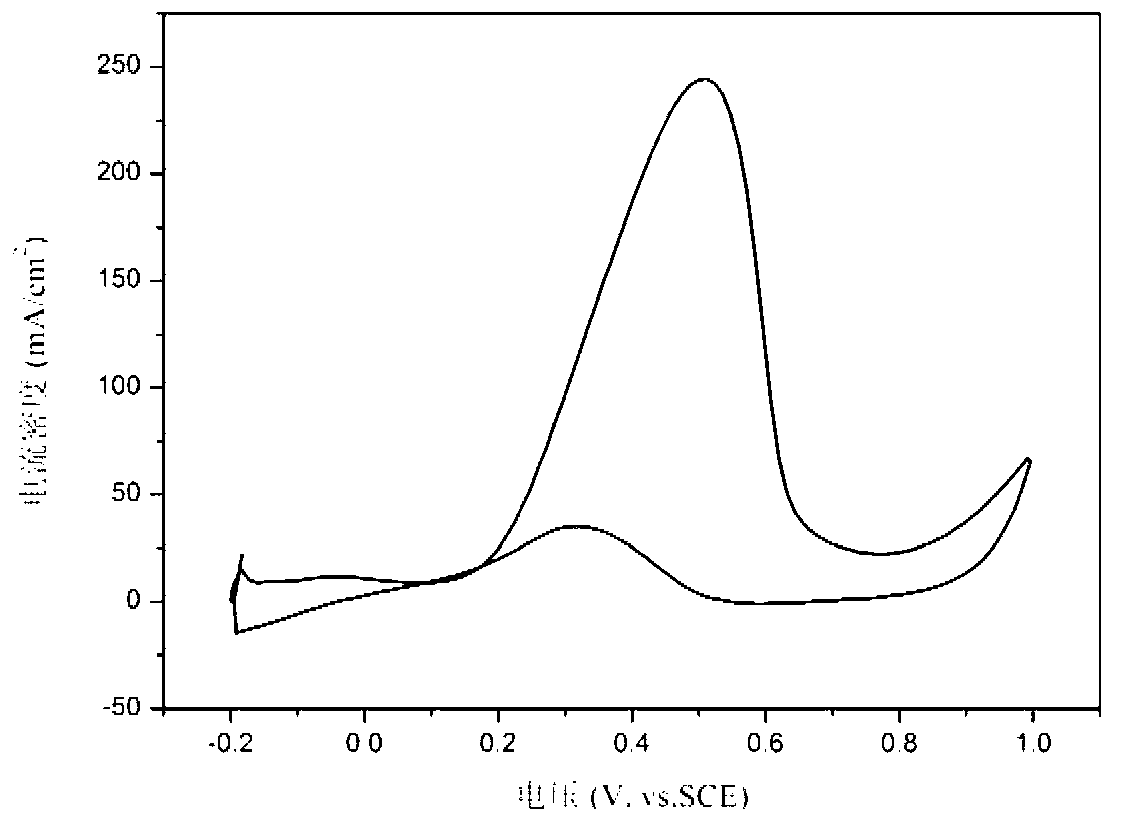

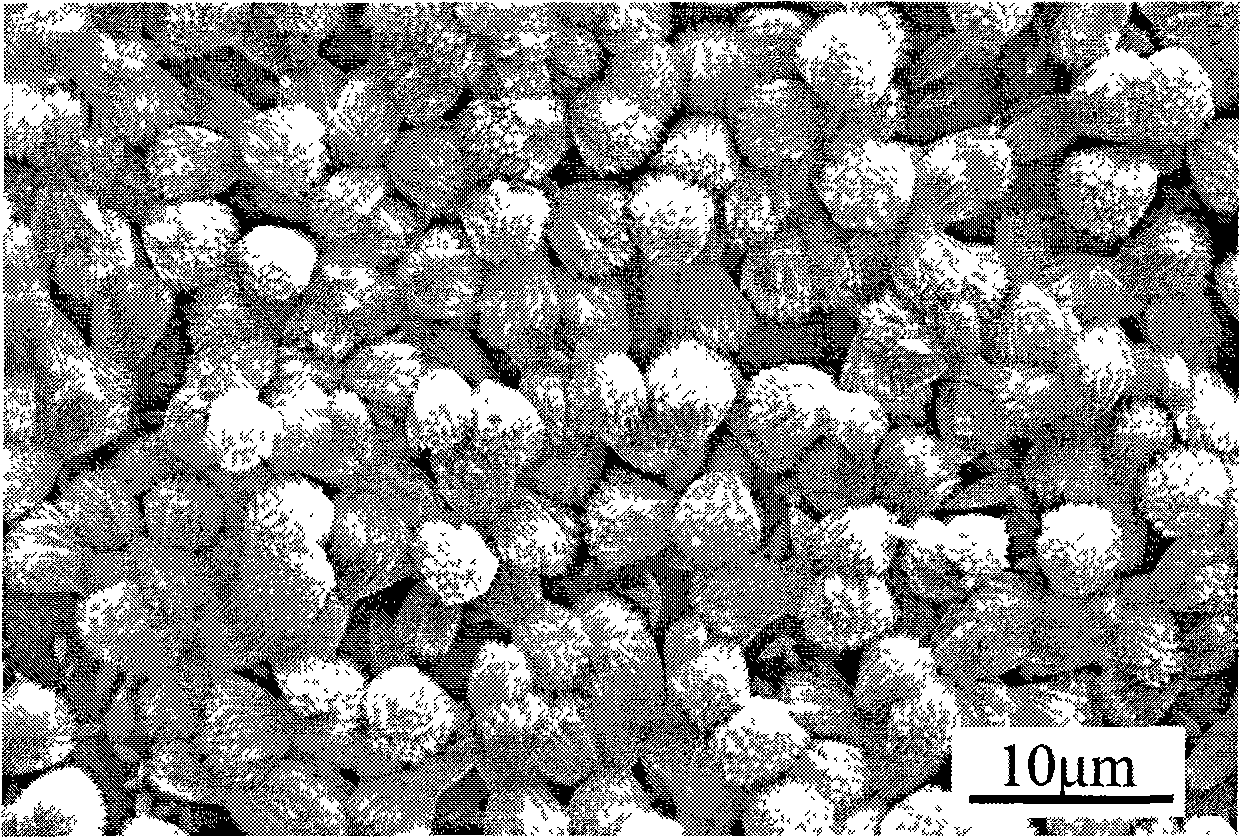

Zr-Cu-based amorphous alloy compound electrode material and preparation method thereof

InactiveCN110323077AEvenly distributedElectrochemical deposition is convenientHybrid capacitor electrodesHybrid/EDL manufactureNickel oxide hydroxideSupercapacitor

The invention discloses a Zr-Cu-based amorphous alloy compound electrode material and a preparation method thereof. The material comprises an amorphous core at the middle, nano-porous copper layers ontwo sides of the core and nickel hydroxide particles on the copper layers. The amorphous core is made from copper-zirconium alloy; the widths of the tough belts and hole diameters of the nano-porouscopper layers are 50-100nm, and the thicknesses of the nano-porous copper layers are about 2-3 microns; the sizes of the deposited nickel hydroxide particles are about 200-400nm, and the loading capacities of the same are 0.3-1.0mg / cm<2>. The copper-zirconium alloy comprises 30-70% of Zr and 70-30% of Cu. According to the Zr-Cu-based amorphous alloy compound electrode material and preparation method thereof provided by the invention, the electrochemical deposition condition can be adjusted through adjusting the voltage, time, electrolyte concentration and the like of electrochemical deposition, the deposition time is relatively short, heating is not needed, and the process is visible; and the prepared compound material can be directly applied to the electrode material of the supercapacitor.

Owner:HEBEI UNIV OF TECH

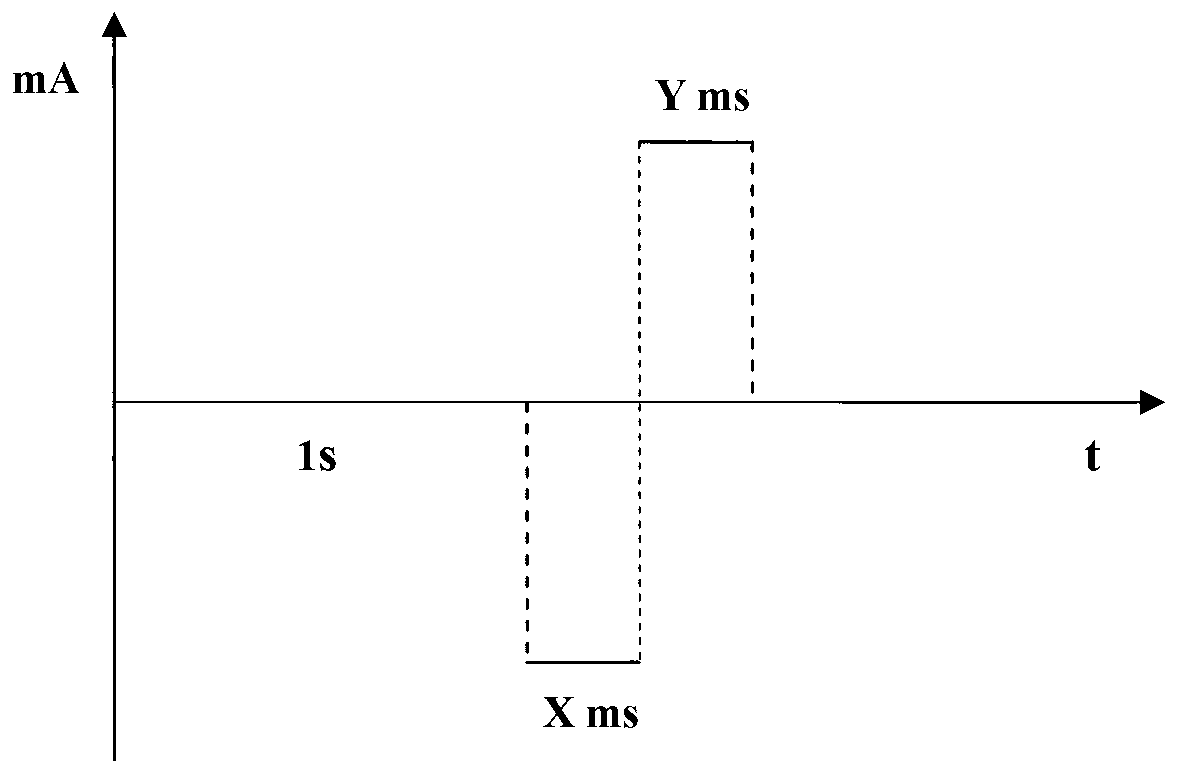

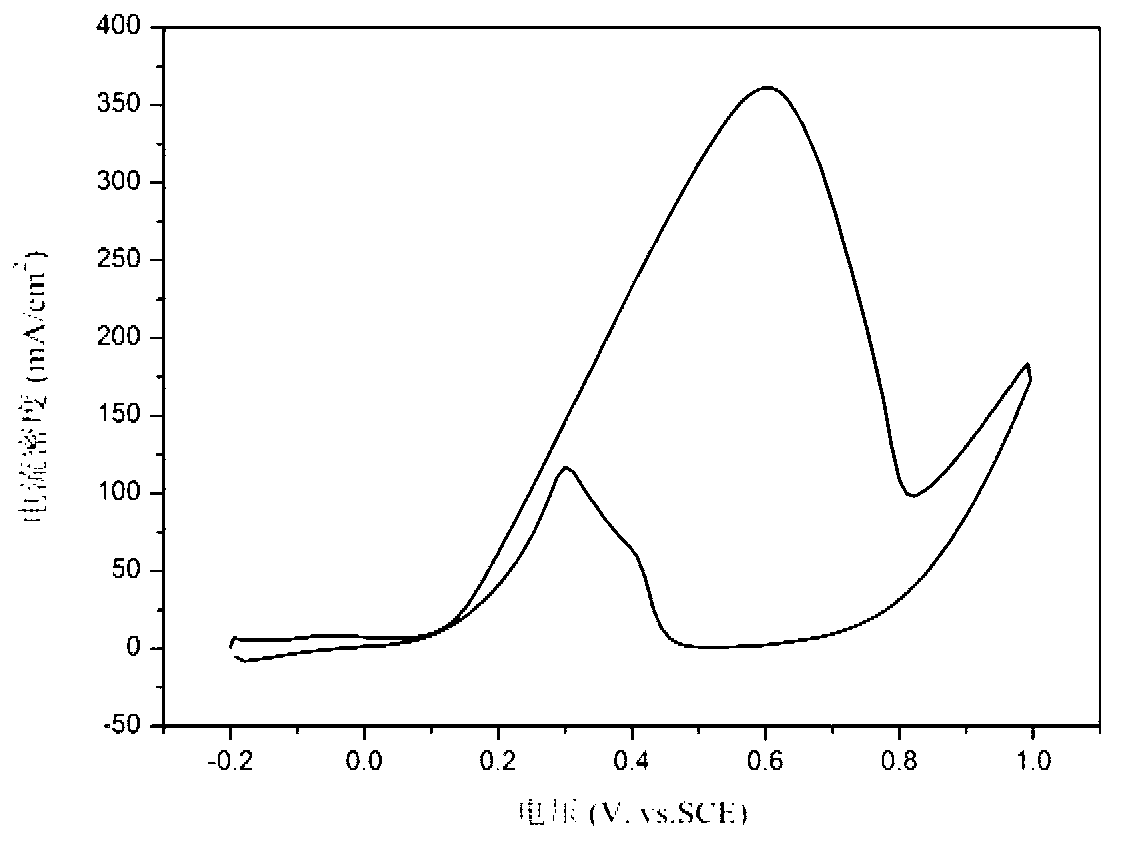

Method for preparing nano platinum/ruthenium modified titanium dioxide nanotube electrode by utilizing pulse electrodeposition

The invention discloses a method for preparing a nano platinum / ruthenium modified titanium dioxide nanotube electrode by utilizing pulse electrodeposition, and is applied to the technical field of photoelectrocatalysis. At present, most of the defects of a precious metal platinum modified titanium dioxide nanotube electrode include low current density, severe poisoning and low catalytic performance. The method for preparing the nano platinum / ruthenium modified titanium dioxide nanotube electrode provided by the invention comprises the following steps of: firstly preparing titanium dioxide nanotube arrays which are ranked in order and are oriented vertically on a titanium sheet by adopting an anodic oxidation method, and then preparing the nano platinum / ruthenium modified titanium dioxide nanotube electrode by adopting a pulse electrodeposition method. CO adsorbed on the surface of precious metal can be eliminated by the synergistic effect of platinum and ruthenium; catalyst damage is lowered; meanwhile, the catalytic initial potential moves negatively obviously, and the electro-catalytic property of the electrode is improved; and the method for preparing the nano platinum / ruthenium modified titanium dioxide nanotube electrode by utilizing pulse electrodeposition has an important research value and wide application prospects.

Owner:BEIJING UNIV OF TECH

Method for treating dredger fill foundation through flocculation combined with vacuum preloading

InactiveCN104674785AIncrease the mixing ratioAchieve separationSoil preservationFlocculationCut and fill

The invention relates to a method for treating a dredger fill foundation through flocculation combined with vacuum preloading. The method includes the processes of flocculation and vacuum preloading. Property of dredger fill is changed by early-stage flocculant, so that dewatering efficiency of late-stage vacuum preloading is improved. In addition, integral strength of the dredger fill foundation can be improved effectively by combining the flocculant with the dredger fill, so that integral reinforcing effect of the dredger fill foundation can be improved effectively through flocculation combined with vacuum preloading.

Owner:WENZHOU UNIVERSITY

Preparation method of nano-crystalline zinc plating layer by using direct current electrodeposition

The invention belongs to the technical field of surface engineering and surface treatment, in particular providing a preparation method of a nano-crystalline zinc plating layer by using direct current electrodeposition. The preparation method is characterized by taking acidic zinc sulfate solution as a base plating solution, adopting three organics of cetyl trimethyl ammonium bromide (CTAB), benzylidene acetone (BA) and polyethylene glycol (PEG) as mixed additives for remarkably increasing the cathodic polarization of zinc deposition; and applying direct current for deposition by taking carbon plated steel as a cathode and insoluble electrode as an anode with the application of the direct current electrodeposition method, wherein current density is 0.5-4 A / cm2, and electroplating time is 1-6 minutes. By adopting the invention, the zinc plating layer with a luminant and smooth surface and the size of a crystalline grain less than 50 nm.

Owner:SHANGHAI UNIV

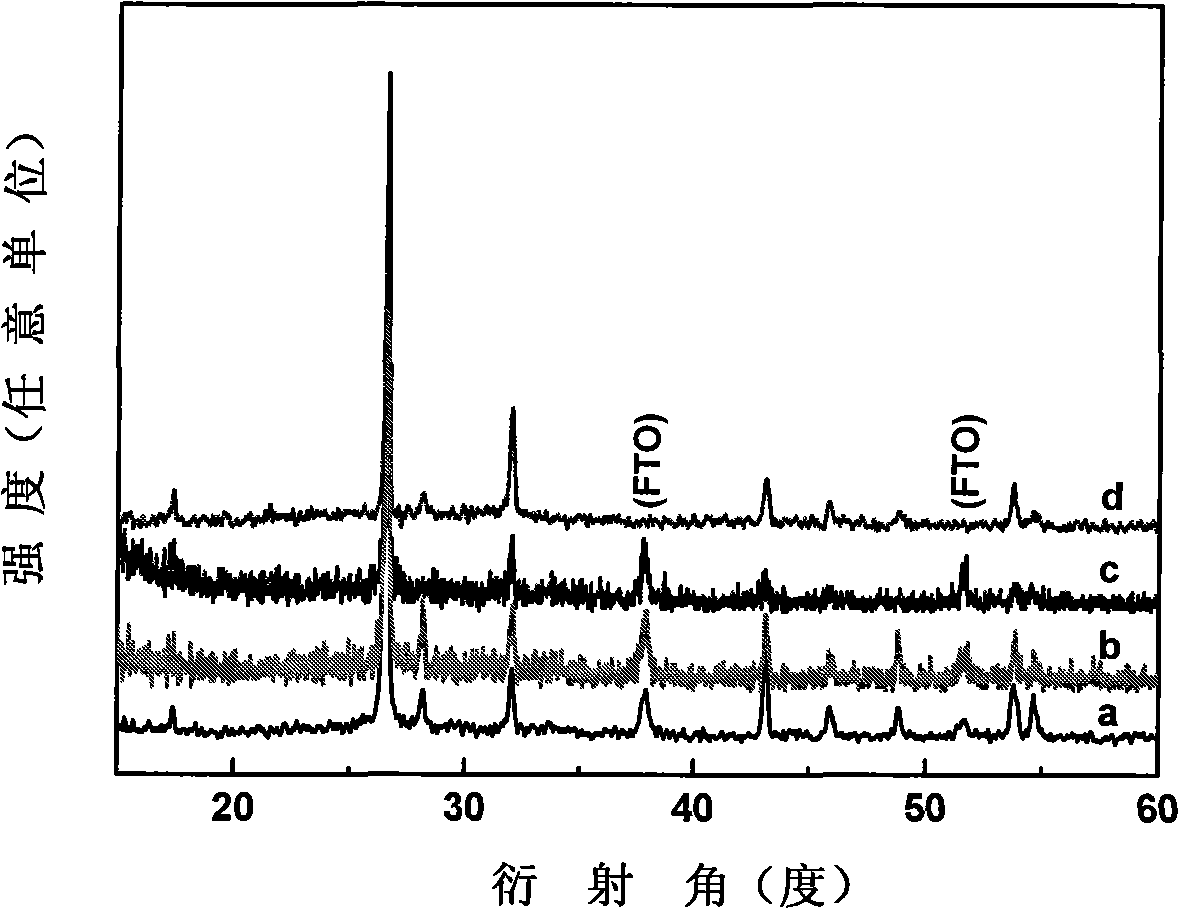

Method for electrophoretic deposition of rare-earth lanthanum oxide film on aluminium alloy surface

InactiveCN101451263ASimple processShort deposition timeElectrophoretic coatingsElectrophoresisRare earth ions

The invention belongs to the technical field of aluminum alloy surface modification and in particular relates to a method for depositing a rare-earth lanthanum oxide film on the surface of aluminum alloy through electrophoresis. The method is characterized in that a rare-earth ion organism complexing electrophoresis method is utilized to deposit the rare-earth film on the surface of the aluminum alloy; and an even rare-earth oxide film is obtained on the surface of the aluminum alloy through roasting. The method has the advantages of simple process, short deposition time, high stability, economy and no pollution; and the even lanthanum oxide film obtained from the surface of the aluminum alloy treated through the technology can effectively improve the anticorrosive performance of the aluminum alloy and has important application and research value.

Owner:FUDAN UNIV

Method for rapid depositing barium tungstate micron film at low-temperature

InactiveCN101358378AAvoid adsorptionEvenly heatedPolycrystalline material growthFrom normal temperature solutionsEthylenediamineWater baths

The invention relates to a method for quickly depositing barium tungstate micro film at low temperature, which belongs to the technical field of functional film material preparation. The prior barium tungstate film preparation methods have quite high requirement for the deposition condition, need vacuum, high temperature and other conditions, and restrict the substrates to be conductive. The method takes EDTA-2Na as the complexing agent and prepares the micro barium tungstate film which has pure white tungsten ore structure, small, even and compact grains and is highly crystallized in microwave water bath which is lower than 100 DEG C within 30min. The method has no special requirement for the substrates, i.e. conductive or non-conductive substrates are applicable; adopts a microwave heating method, has simple process, and does not need vacuum, high temperature and other conditions; in addition, the solution is evenly heated, which greatly shortens the deposition time of the film; that EDTA-2Na is adopted as the complexing agent effectively prevents barium ions and wolframate radical ions from being largely nucleated and deposited in the solution.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com