Bending insensitive multimode fiber and manufacturing method thereof

A bend-insensitive, multi-mode optical fiber technology, applied in the field of optical communication, can solve problems such as easy deterioration of optical fiber geometric parameters, partial corrosion of liner glass, low viscosity of quartz glass, etc., to improve the controllability of parameter distribution and excellent bending resistance and bandwidth performance, improving productivity and equipment usage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Provide several detailed embodiments below, the present invention is described further.

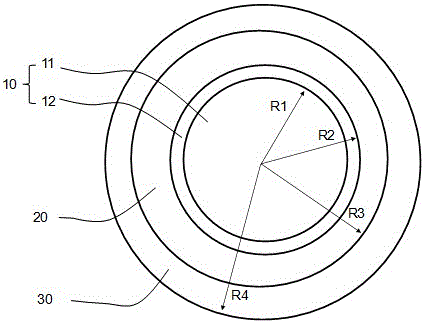

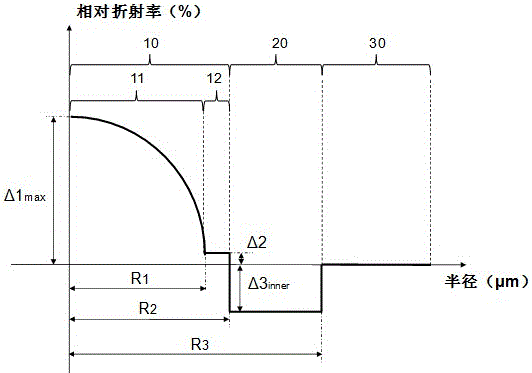

[0055] The optical fiber includes a core layer 11 and a cladding layer covering the core layer. The refractive index profile of the core layer is distributed as an α power exponential function. Layer 30, the outer cladding layer is a pure silica glass layer, and the radius R4 of the outer cladding layer is 62.5 μm.

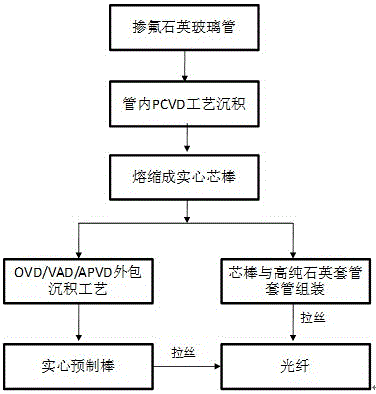

[0056] During preparation, a fluorine-containing quartz glass tube 20 with an outer diameter of 45 to 50 mm and a single side wall thickness of 5 to 8 mm is used as the core rod substrate tube, and the dopant deposition is performed using a plasma-enhanced chemical vapor deposition (PCVD) process; during the deposition process , when depositing the inner cladding layer, the furnace temperature is controlled at 1000-1100°C, when depositing the core layer, the furnace temperature is controlled at 1080-1120°C; during doping deposition, the reaction gas silicon tetrachlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical bandwidth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com