Patents

Literature

34results about How to "Improve equipment usage efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

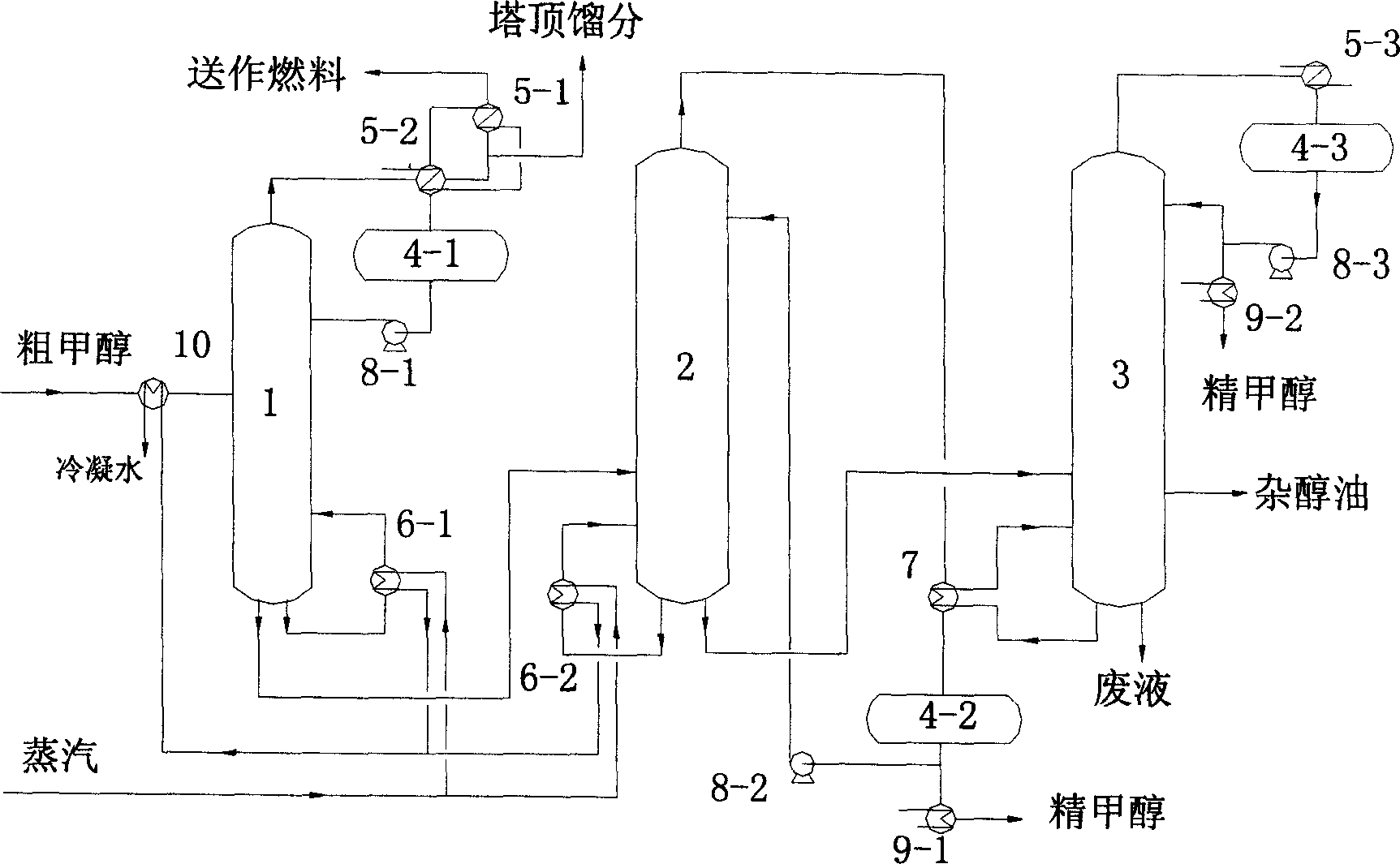

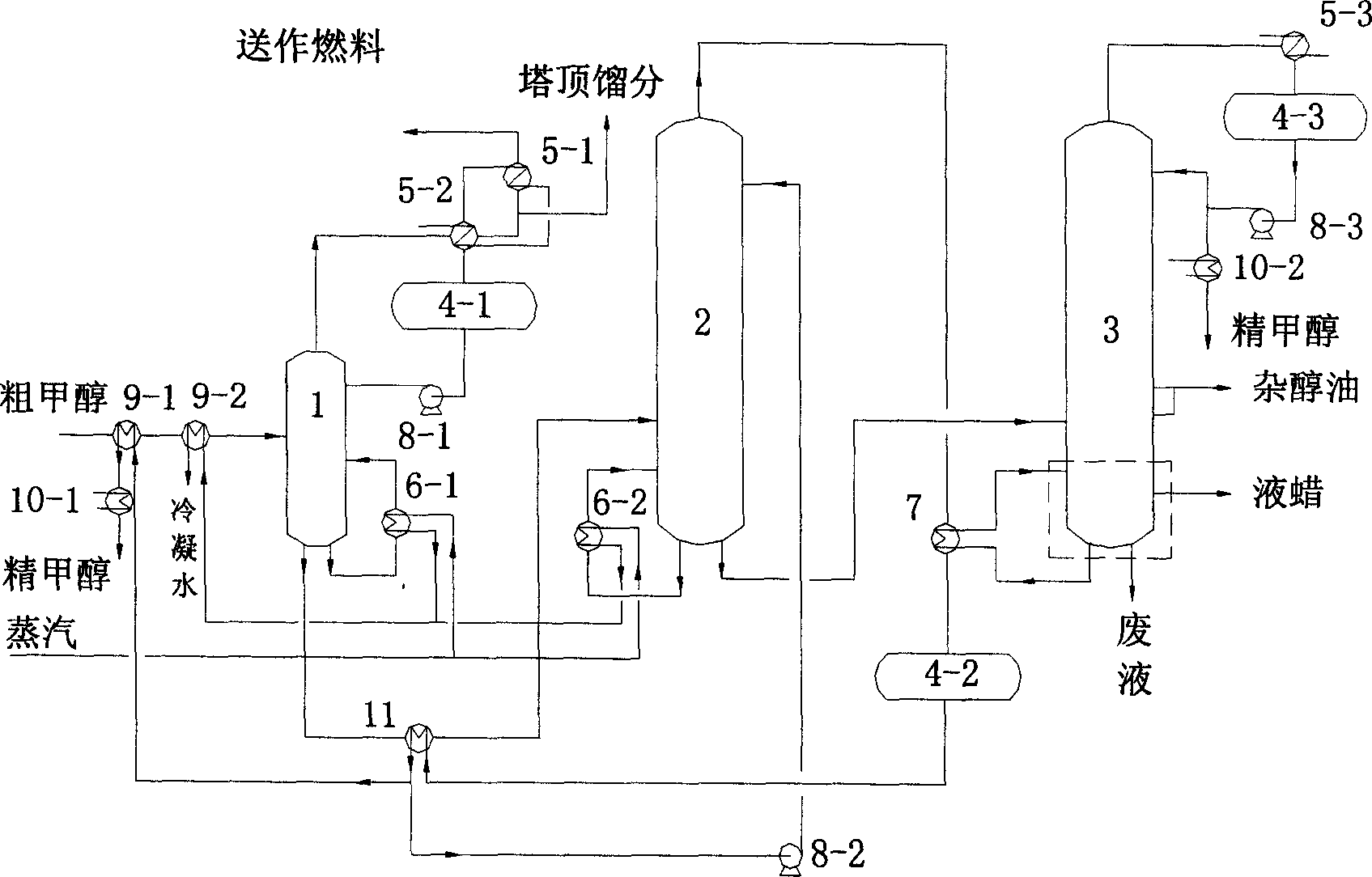

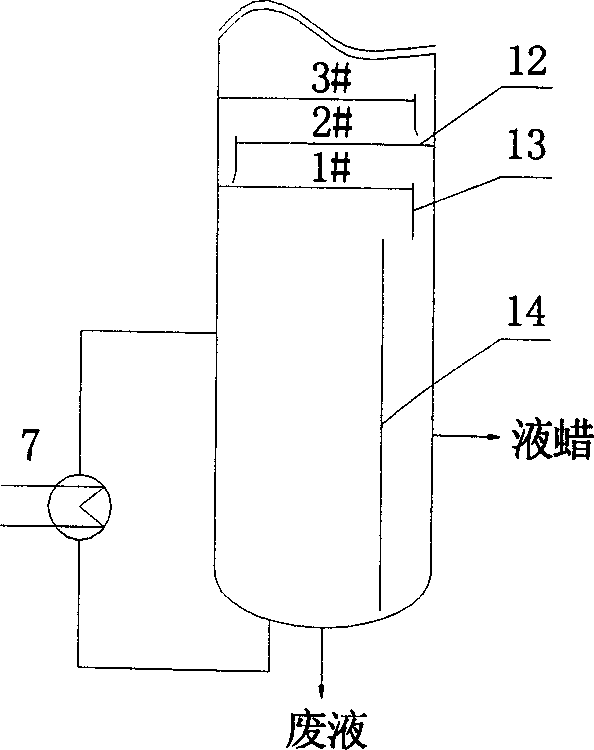

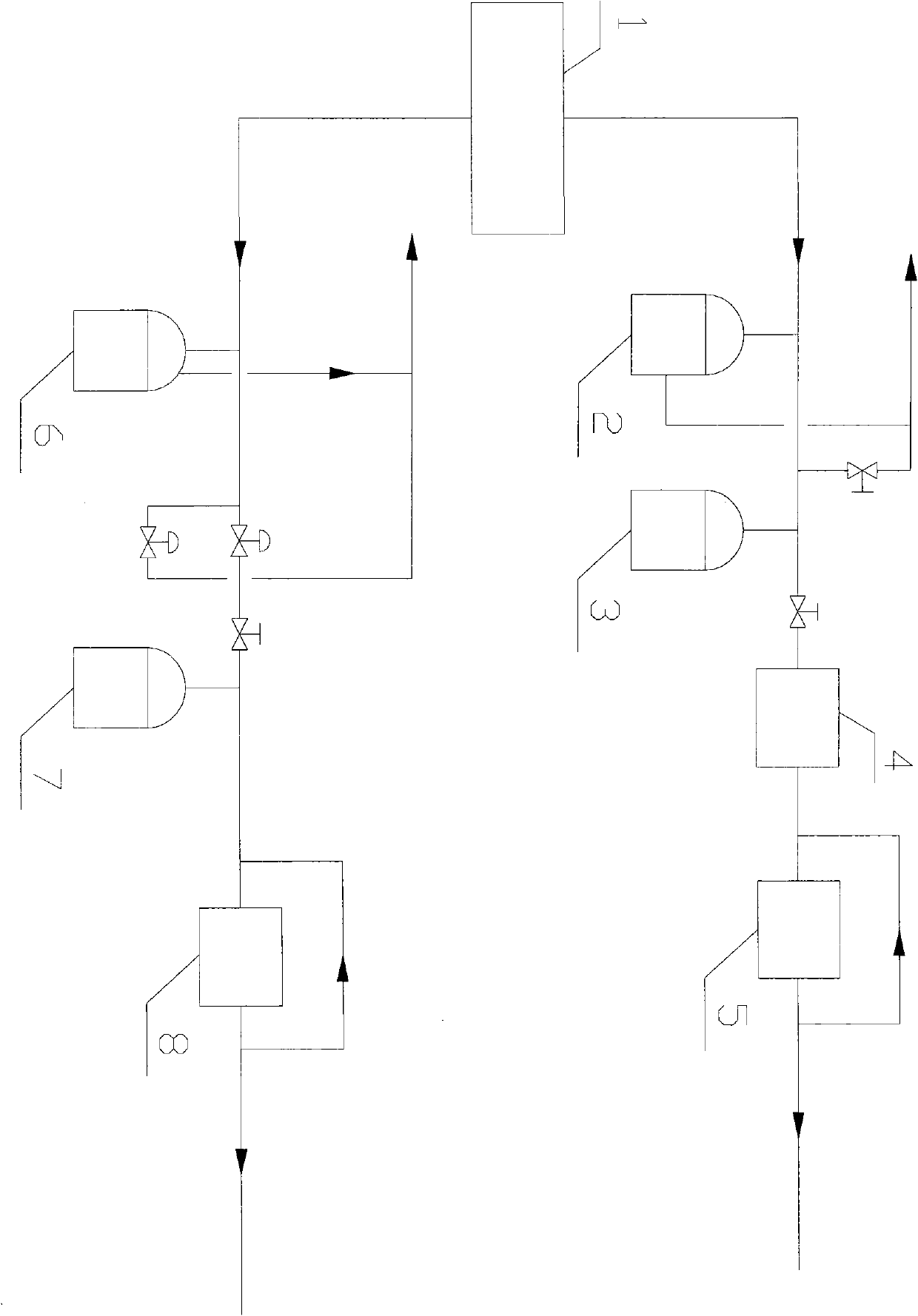

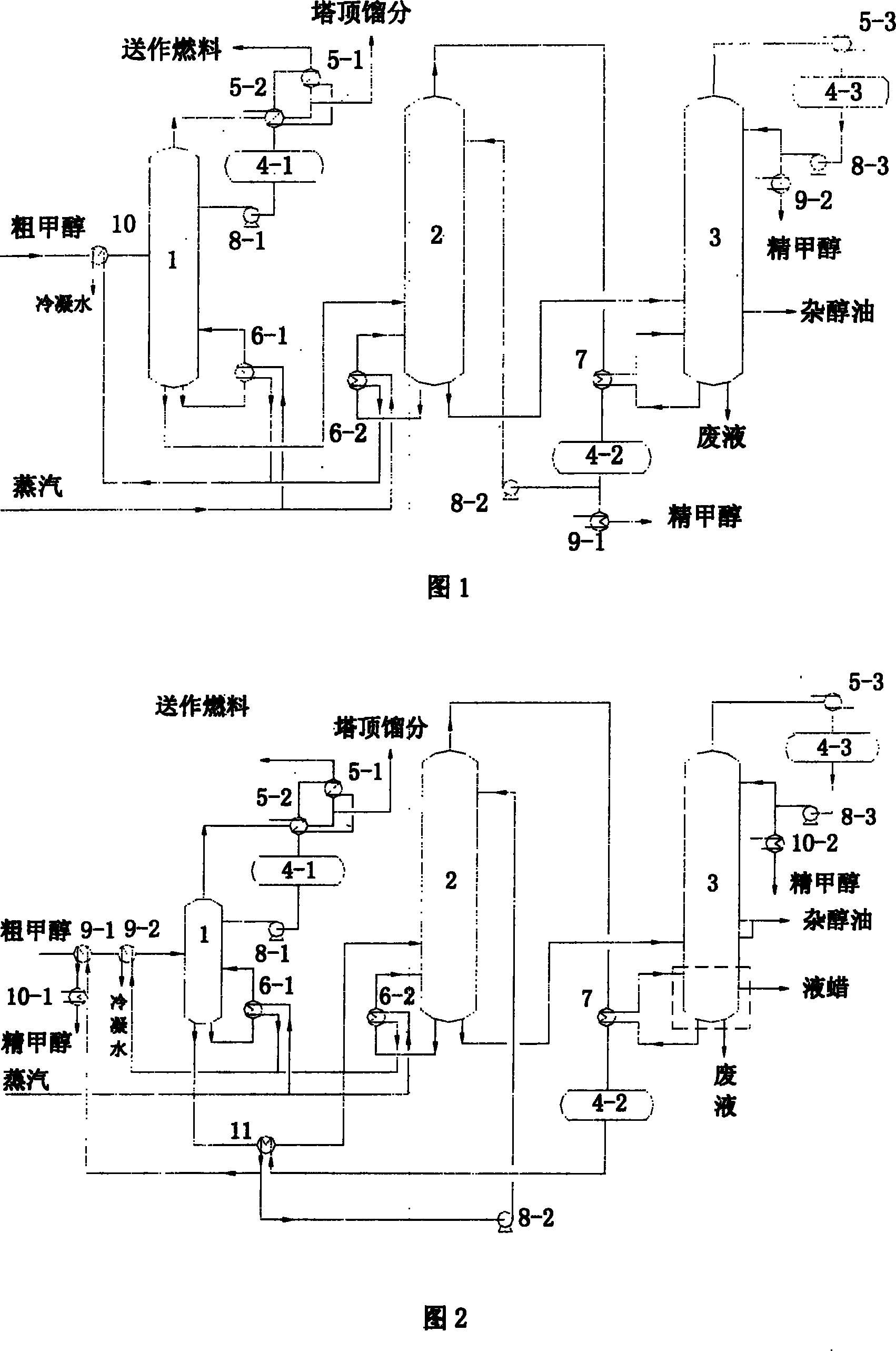

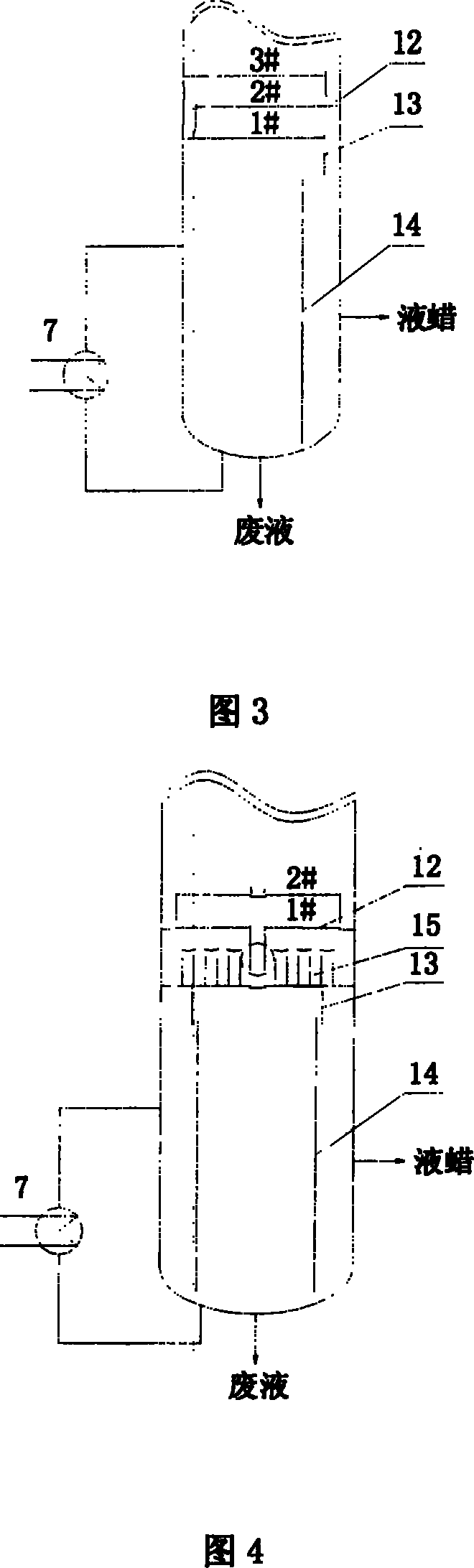

Rectifying tech. and equipment of high purity methanol

ActiveCN1861553ATo achieve the purpose of energy savingImprove product qualityOrganic chemistryReboilerProcess engineering

A rectifying apparatus for preparing high-purity (99.85%) methanol is composed of pre-rectifying tower, pressurizing tower, ordinary-pressure tower, condenser of reflux tank, re-boiler, reflux pump, pre-heater, and cooler. Its process is also disclosed. It features less consumption of energy and cooling water.

Owner:徐州友田生物科技有限公司

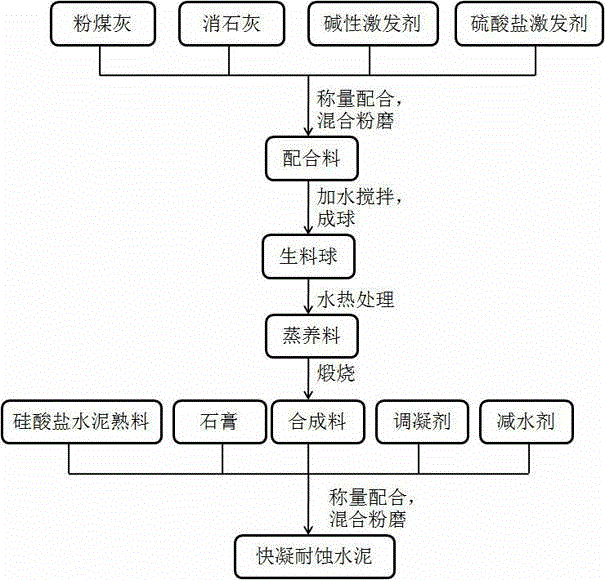

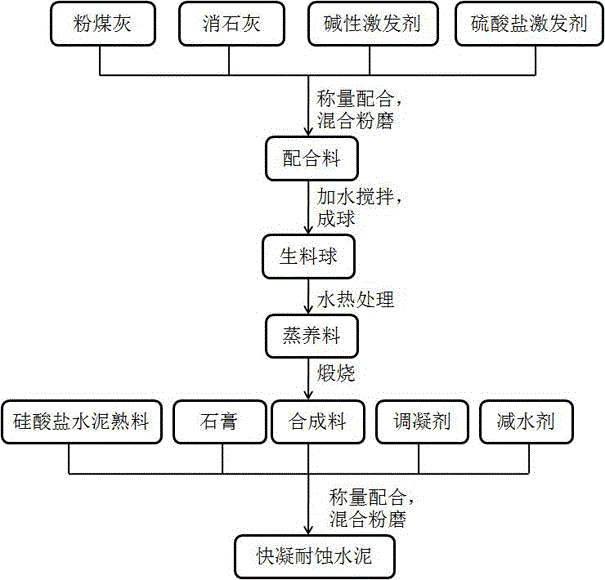

Fast-setting anti-corrosion cement using coal ash as raw material and preparation method thereof

The invention discloses a fast-setting anti-corrosion cement using coal ash as a raw material and a preparation method thereof. The fast-setting anti-corrosion cement is prepared from the following components in parts by mass: 60-75 parts of coal ash, 25-40 parts of slaked lime, 0.5-1.5 parts of alkaline excitant, and 1-2 parts of sulfate excitant; the preparation method comprises the following steps: ball-milling the raw materials to obtain a batch mixture with 80-micron screen residue content less than 5%, adding 20-25 parts of water, uniformly stirring to prepare a raw material ball, hydro-thermally treating the raw material ball at 95-98 DEG.C for 10-16 hours to obtain a steamed material, calcining the steamed material at 750-900 DEG.C for 15-90 minutes, and cooling to obtain a synthetic material; and commonly ball-milling 75-85 parts of the synthetic material and 10-20 parts of Portland cement together with 5-8 parts of gypsum, 0.2-1.0 part of thickening time control agent and 0.3-0.7 part of water reducing agent until the 80-micron screen residue content is less than 4%. The cement is low in calcining temperature and thermal loss, high in coal ash utilization rate, fast-setting and fast-hardening, high in strength, and goon in sulfate attack resistance.

Owner:吴忠赛马新型建材有限公司

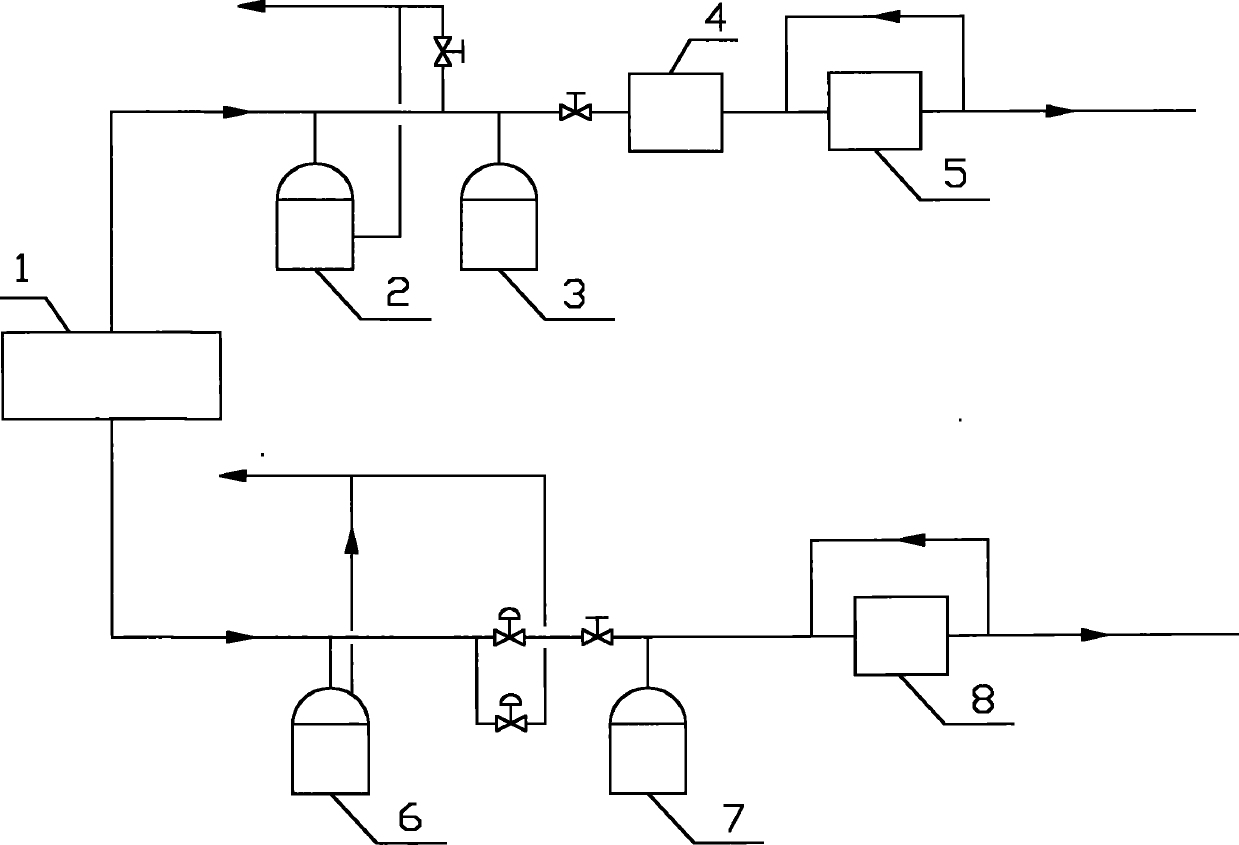

Chlorine zero-pressure control method applied to process for preparing alkali by utilizing zero-pole ionic membrane electrolytic cell

InactiveCN102021603AReduce equipment operating costsImprove equipment usage efficiencyElectrolysis componentsFluid pressure control using electric meansIonChemistry

The invention discloses a chlorine zero-pressure control method applied to a process for preparing alkali by utilizing a zero-pole ionic membrane electrolytic cell. In the method, zero-pole ionic membrane electrolytic cell, a chlorine safety water seal, a hydrogen safety water seal, a chlorine drying device, a 3K chlorine compressor and a hydrogen compressor which are sequentially connected are utilized; the difficulty that accidental injuries occur on elastomers and iconic membranes caused by the abnormal chlorine header pipe pressure difference and negative pressure difference occurrence when the iconic membrane device is in a normal production state and in an emergent condition is solved by setting the pressure of the chlorine generated by refining salt water though electrolysis of the zero-pole iconic membrane electrolytic cell into (0+ / -12) kPa, and the hydrogen pressure into (4+ / -2) kPa, thus lowering the equipment operation cost, improving the equipment use ratio and increasing the economic benefits. The method provided by the invention can be widely applied into the iconic membrane alkali production process, especially the method for producing the alkali by utilizing the high-current density zero-pole iconic membrane electrolytic cell.

Owner:TIANCHEN CHEM

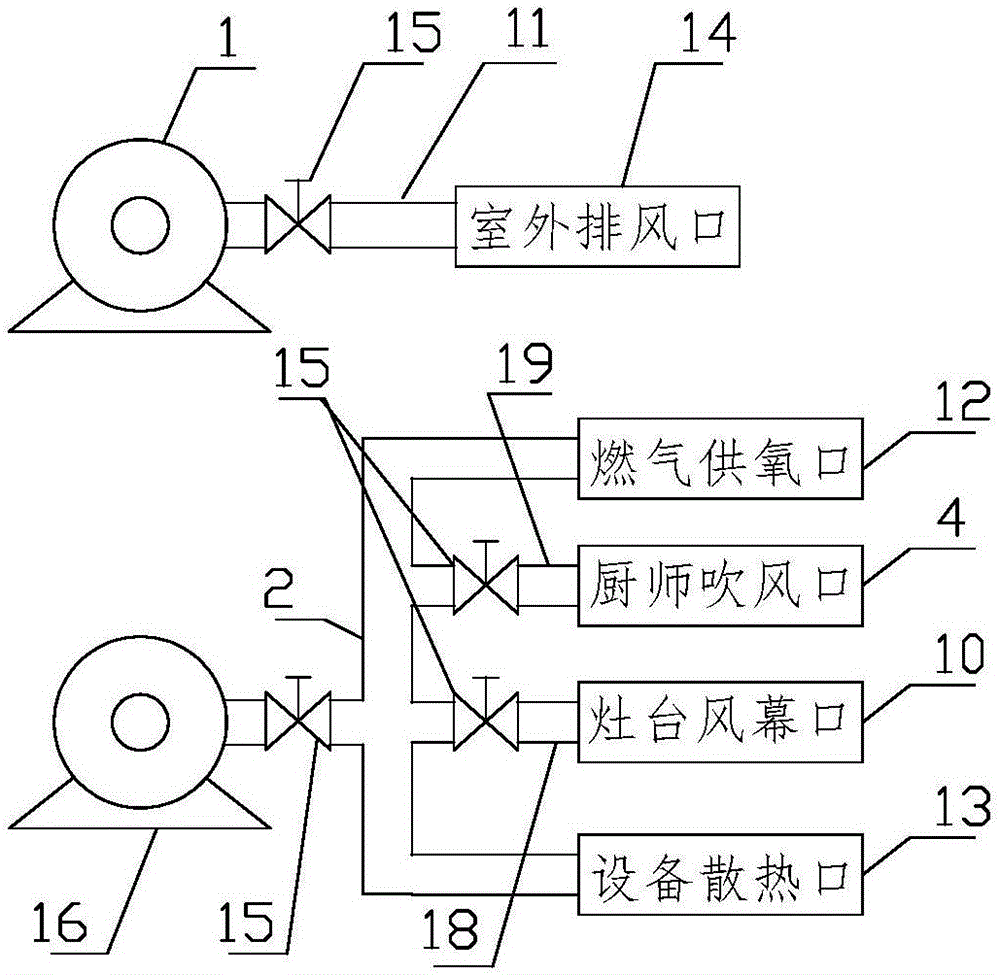

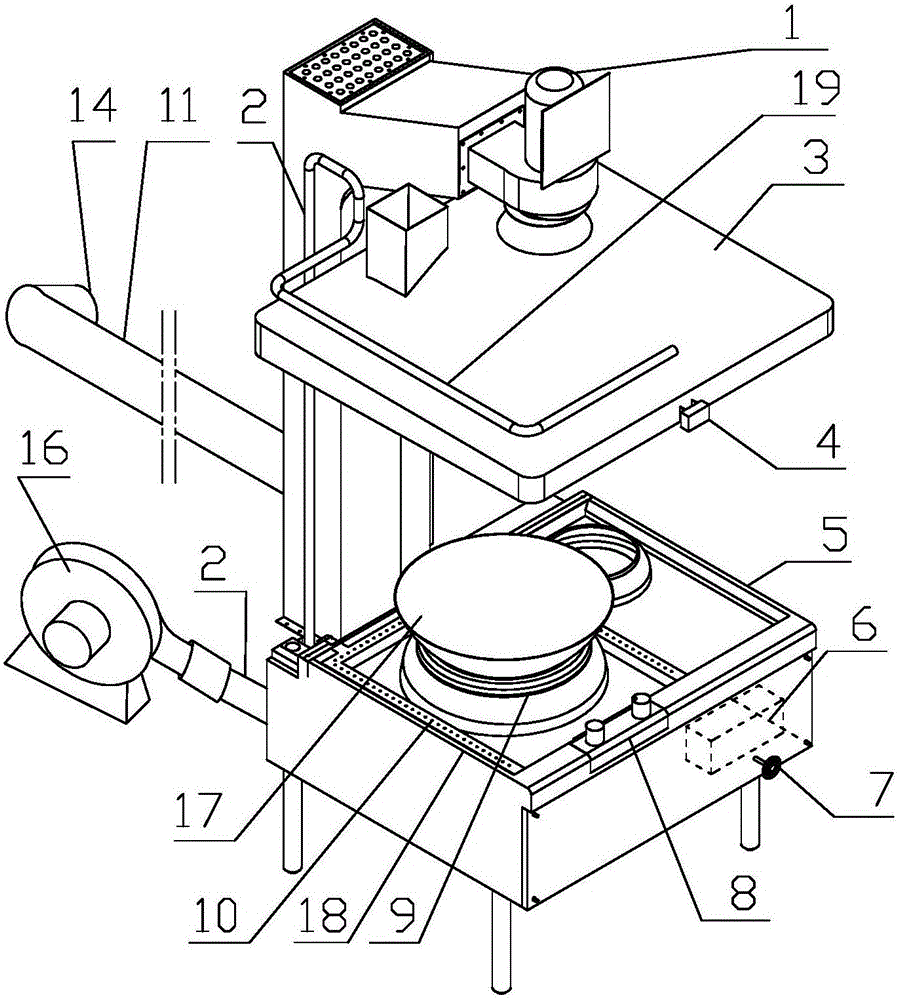

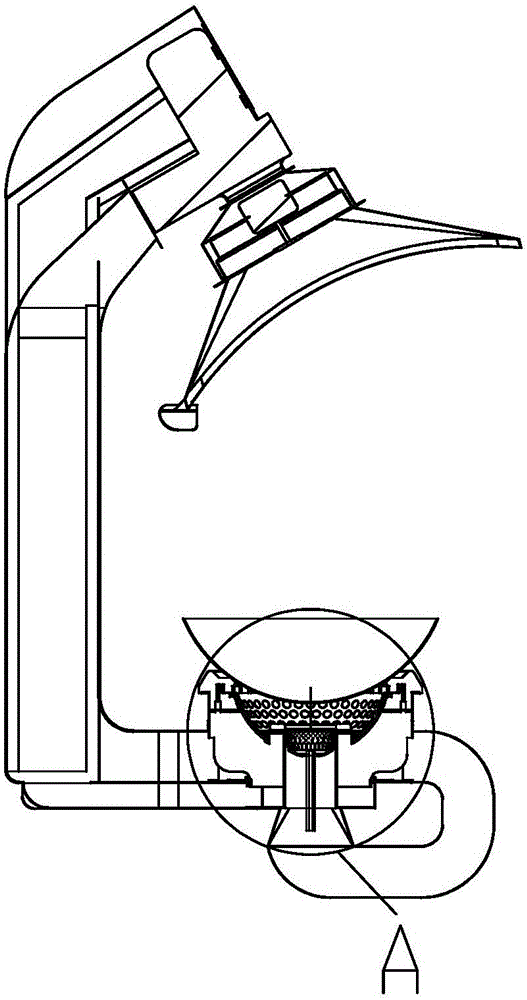

Environment-friendly combined fresh air system of stove

PendingCN106839039APrevent combustion exhaust gas and oil fume from overflowingImprove indoor air purification rateDomestic stoves or rangesLighting and heating apparatusIntegrated systemsIndoor air

The invention provides an environment-friendly combined fresh air system of a stove. A fume extraction hood is arranged above a furnace mouth; a stove body is provided with a cooking bench air curtain structure surrounding a furnace on a cooking bench; the cooking bench air curtain structure is used for isolating oil fume generated by cooking and the outside, so that the oil fume can arrive at an inlet of the fume extraction hood successfully; the cooking bench air curtain structure is arranged on a pipe for conveying fresh air; a fresh air inlet pipe is provided with branch pipes; the branch pipes are respectively communicated to the cooking bench air curtain structure, a cook cooling movable air blowing mouth, all electronic equipment and relevant pipeline air cooling mouth. According to the environment-friendly combined fresh air system, cook cooling, oil fume isolation and purification, the equipment and a pipeline cooling protection and fresh air oxygen supply system that are necessary in a kitchen are organically integrated into one at the first time, so that a complete indoor and outdoor air circulation of the kitchen is formed, so that the indoor air purification rate is greatly improved; meanwhile, the mechanical damage protection and the temperature rise protection for the equipment and the pipelines of the stove are enhanced, the service life of the equipment of the stove is prolonged, the equipment failure rate is greatly reduced, and the operation cost of an integrated system of the kitchen is obviously lowered.

Owner:HUBEI ZHONGRUITIANHENG ENERGY SAVING TECH DEV

Storage device of parking charging equipment

InactiveCN111145372AReduce lossImprove equipment usage efficiencyTicket-issuing apparatusAutomotive engineeringEngineering

The invention discloses a storage device of parking charging equipment. The device comprises a shell; a time delay cavity is formed in the shell; a time delay mechanism is arranged in the time delay cavity; a driving cavity is formed in the lower end wall of the time delay cavity; a driving mechanism is arranged in the driving cavity; a switching mechanism is arranged in the lower end wall of thedriving cavity; a transmission cavity is formed in the left side of the switching mechanism; a transmission mechanism is arranged in the transmission cavity; a working cavity is formed in the upper end wall of the transmission cavity; a charging device and a control mechanism are arranged in the working cavity; when an vehicle runs and enters a parking place, by gravity of the vehicle, the drivingmechanism raises the parking charging device to the ground, parking charging timing is provided, and when the vehicle drives away, the time delay mechanism triggers starting, if no vehicle drives toenter for a time, the driving mechanism can store the parking charging device underground, so that the parking charging device stops working, the loss of the parking charging device and the maintenance frequency of the parking charging device caused by external factors such as weather are effectively reduced, and the use efficiency of the parking charging device is improved.

Owner:温州市唐豪网络科技有限公司

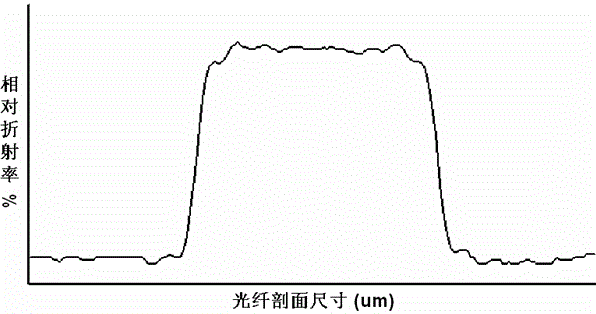

Bending insensitive multimode fiber and manufacturing method thereof

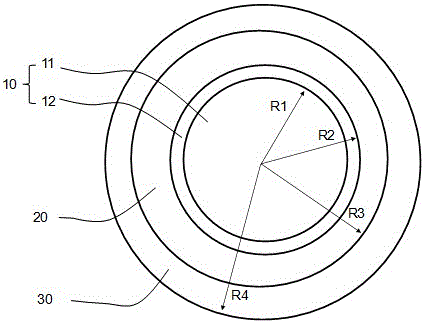

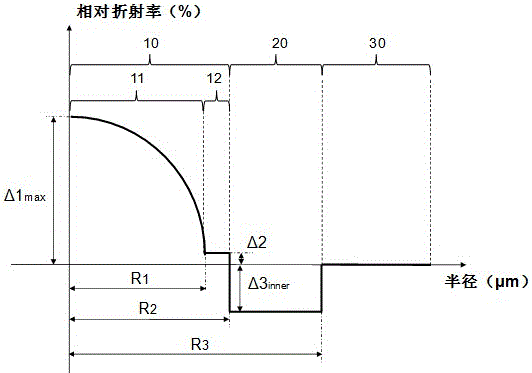

ActiveCN106094104AReasonable structural designImprove bending resistanceOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingDistributed indexRelative refractive index

The invention relates to a bending insensitive multimode fiber and a manufacturing method thereof. The bending insensitive multimode fiber comprises a core layer and a cladding coating the core layer, wherein the refractivity profile of the core layer presents alpha power exponent function distribution. The bending insensitive multimode fiber is characterized in that the cladding comprises an inner cladding layer, a depressed cladding layer and an outer cladding layer sequentially from inside to outside; the core layer distribution exponent alpha is 1.9 to 2.2, the radius R1 is 23 to 27 mum, and the maximum relative refractive index difference delta1max is 0.9 to 1.2%; the radius of the inner cladding layer is R2, the unilateral radial thickness is 1 to 3 mum, and the refractive index difference delta2 is 0 to 0.05%; the radius of the depressed cladding layer is R3, the unilateral radial width is 10 to 20 mum, and the relative refractive index difference delta3inner at the place close to the inner cladding layer along a diameter direction is -0.29 to -0.42%; and the outer cladding layer is a pure silica glass layer. Thus, the structure is reasonably designed, the anti-bending and the bandwidth performance are excellent, the process is convenient to control, and the manufacturing and the production are easy.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Ramee degumming process

InactiveCN101012575AEasy to separateLoose separationFibre treatment to obtain bast fibreOxalateBoiling process

The invention relates to a degumming technology for ramie, comprising unpacking and untying braches, loading cage, boiling, softening, bleaching and washing by acid, supplying oil, deoiling and drying. The boiling process is that the original fiber is put into the mixed solution, of which the weight is nine to twelve times of the weight of original fiber; the pressure is maintained in 0.1-0.2MPa and the maintaining time is for 1-1.5 hours. The mixed solution comprises sodium hydroxide, oxidant, oxalate and scouring agent. Thereinto, the content of sodium hydroxide is 5-8g / l, the content of oxidant is 5-10g / l, the content of oxalate is 3-8g / l and the content of scouring agent is 3-5g / l. By adopting the degumming technology for ramie, the scouring time for ramie is decreased, the manufacturing efficiency is improved, the circumstance pollution is decreased and the quality of ramie after degumming is improved.

Owner:CHONGQING FULING KINGLONG

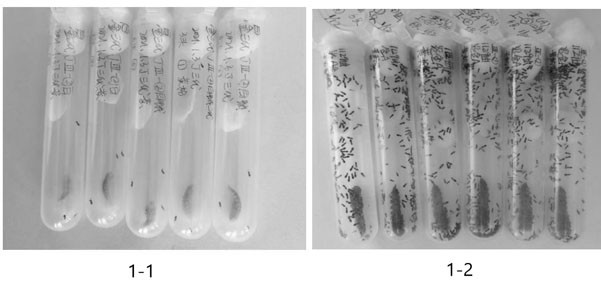

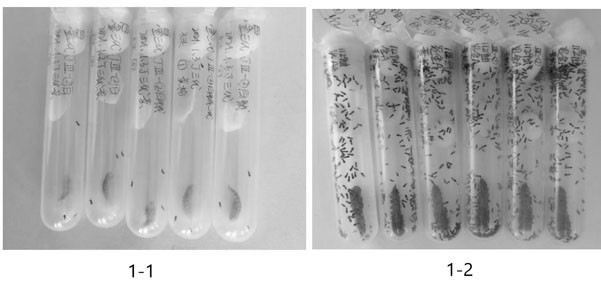

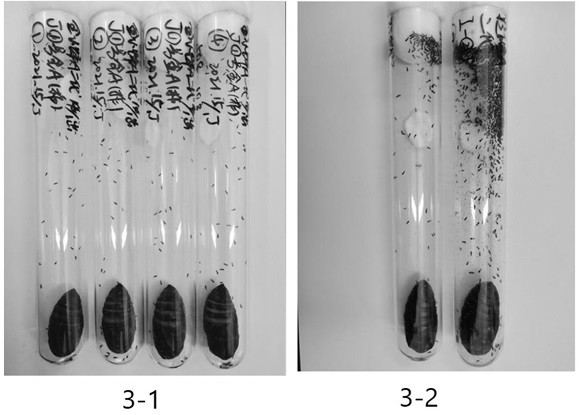

Artificial propagation method of meteorussp serving as natural enemy to camptoloma interiorata

InactiveCN107581159AImprove labor productivity and equipment efficiencyLow costAnimal husbandryAdult femaleNatural enemies

Provided is an artificial propagation method of meteorussp serving as a natural enemy to camptoloma interiorata. The method includes the steps of placing collected overwintering pest bags of camptoloma interiorata into feeding boxes for eclosion of meteorussp; collecting and bringing camptoloma interiorata egg blocks or primarily hatched larvae into a lab for culture, or using camptoloma interiorata subcultured in the lab as hosts; after larvae are hatched from the camptoloma interiorata eggs, putting the larvae into the feeding boxes for feeding to obtain low-age larvae of camptoloma interiorata; matching adult male meteorussp with adult female meteorussp, enticing the adult male meteorussp and the adult female meteorussp into the feeding boxes for natural mating, and letting the adult female meteorussp lay eggs parasitising in the hosts; continuing to put meteorussp into new feeding boxes without parasites in the hosts until female meteorussp dies. After the parasitic meteorussp is fed with natural feed or artificial feed, the eclosion of next generation of meteorussp can be achieved. By using the artificial propagation method, large-scale propagation of meteorussp can be achieved indoors, a practical technological biological prevention and control approach can be provided for prevention and control of camptoloma interiorata or other lepidoptera defoliators.

Owner:SHENYANG AGRI UNIV

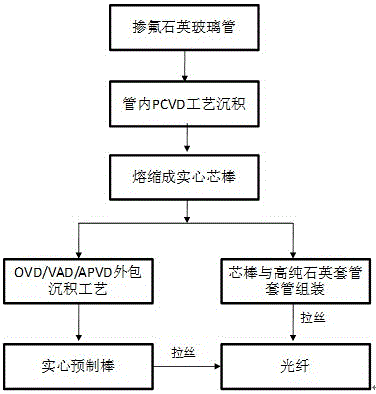

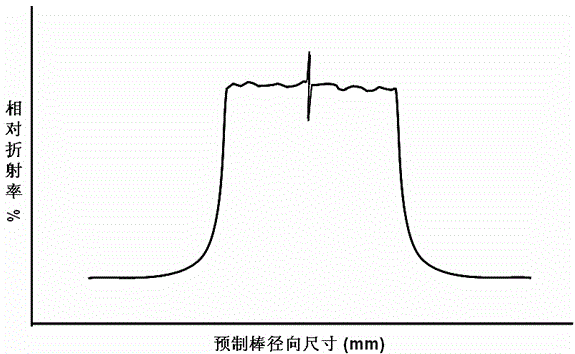

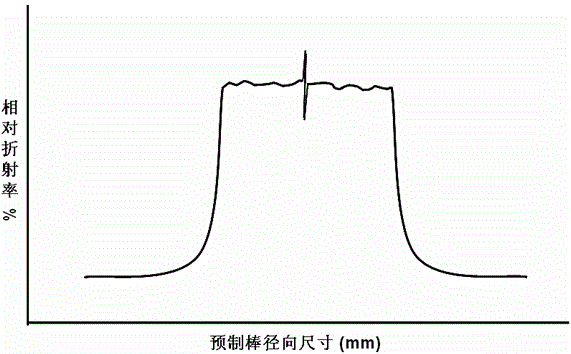

Fusion shrinkage preparation method of core rod of optical fiber preform rod

InactiveCN104086079ARefractive index dip avoidanceHighly corrosiveGlass making apparatusRefractive indexHeating furnace

The invention relates to a fusion shrinkage preparation method for preparing a core rod of an optical fiber preform rod through fusion shrinkage of a doped quartz liner tube. According to the fusion shrinkage preparation method of the core rod of the optical fiber preform rod, the deposited doped quartz liner tube is mounted on a fusion shrinkage lathe. The fusion shrinkage preparation method of the core rod of the optical fiber preform rod is characterized by comprising the following steps: enabling the doped quartz liner tube to rotate at a rotation speed being 15-30rad / min, supplying a heat source for fusion shrinkage by taking a heating furnace sleeve as a heating device, heating at the temperature of 1900 to 2250 DEG C, enabling the heating furnace sleeve to move forth and back from one end to the other end of an axial liner tube of the doped quartz liner tube, carrying out gradual fusion shrinkage on the doped quartz liner tube and finally firing; and sealing two ends of the doped quartz liner tube and introducing mixed gas for corroding the inner wall of the liner tube in the fusion shrinkage process. By virtue of the fusion shrinkage preparation method of the core rod of the optical fiber preform rod, an F-containing compound high in reactivity is taken as the lining corrosion gas; the fusion shrinkage and corrosion are carried out synchronously, so that the reduction of a refractive index of a core layer can be effectively avoided, the time for producing the core rod of the preform rod can be greatly reduced, the processing efficiency and the efficiency of using the device can be improved, the production cost of the optical fiber preform rod can be reduced, and the stability of the optical fiber water peak can be guaranteed, therefore the quality of the optical fiber processing is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

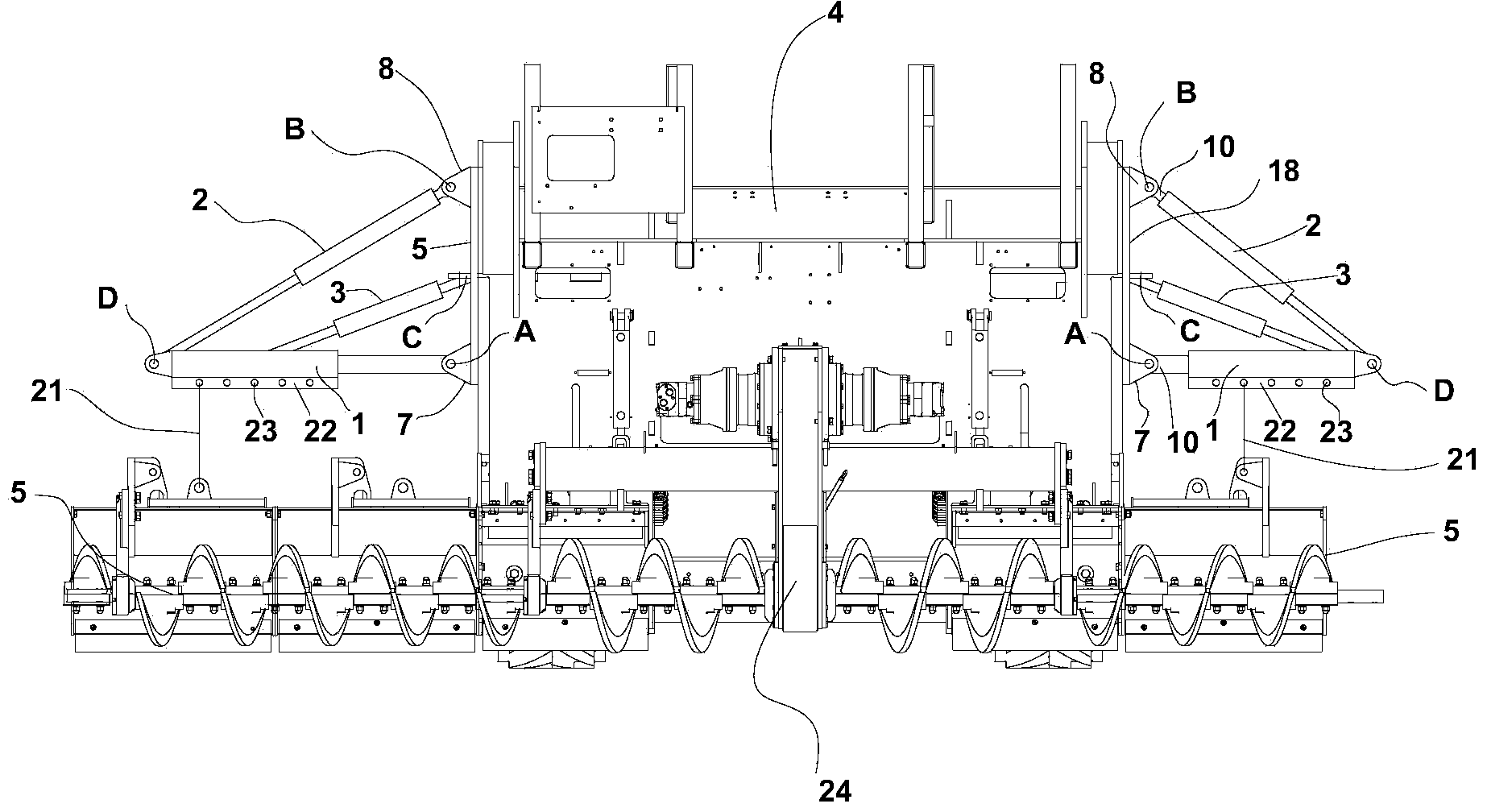

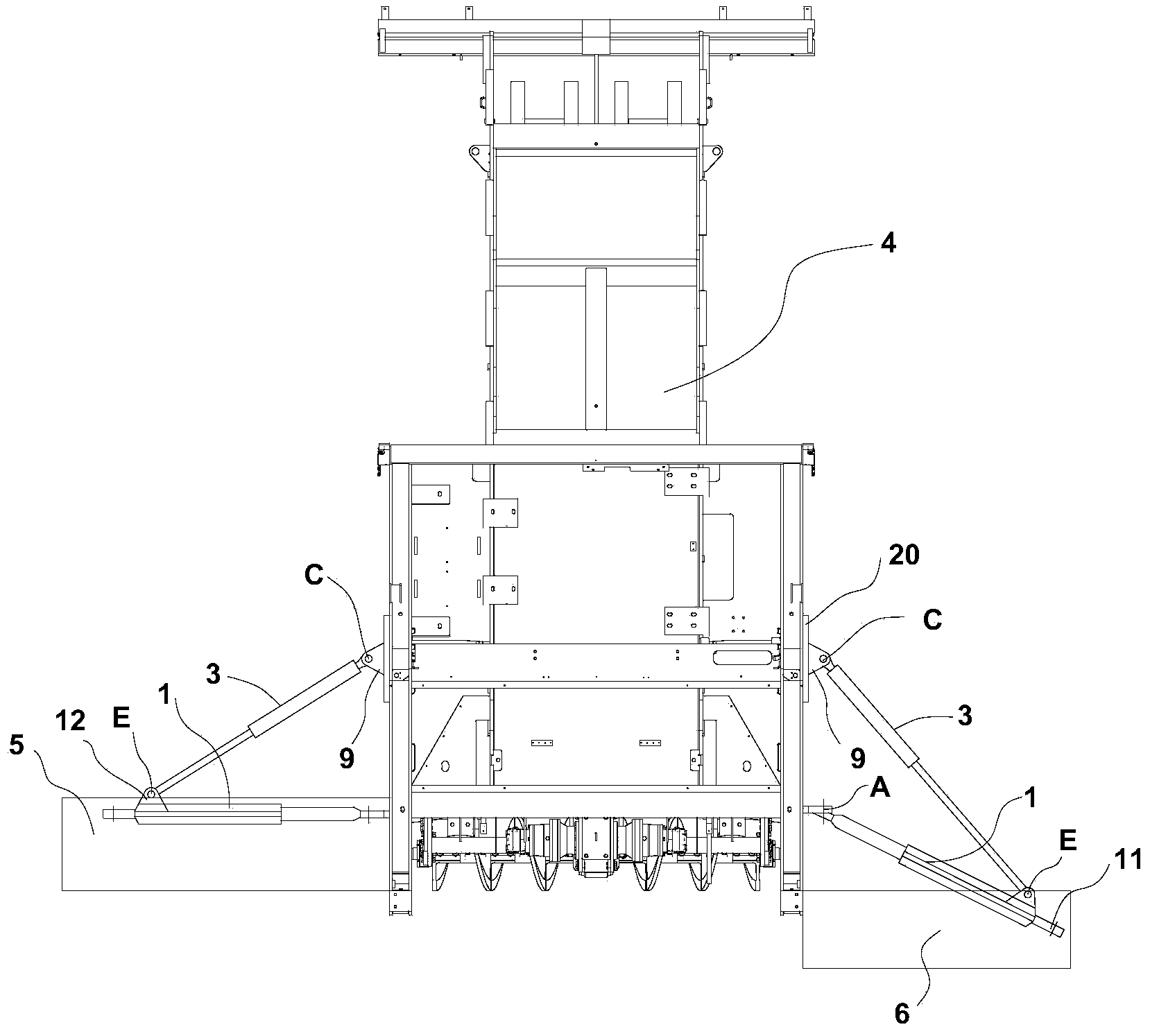

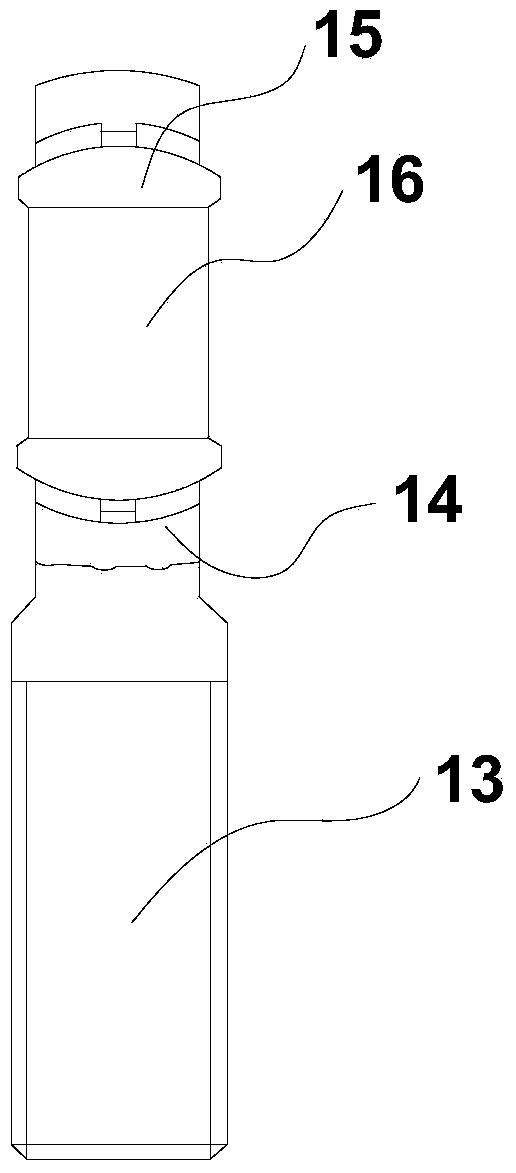

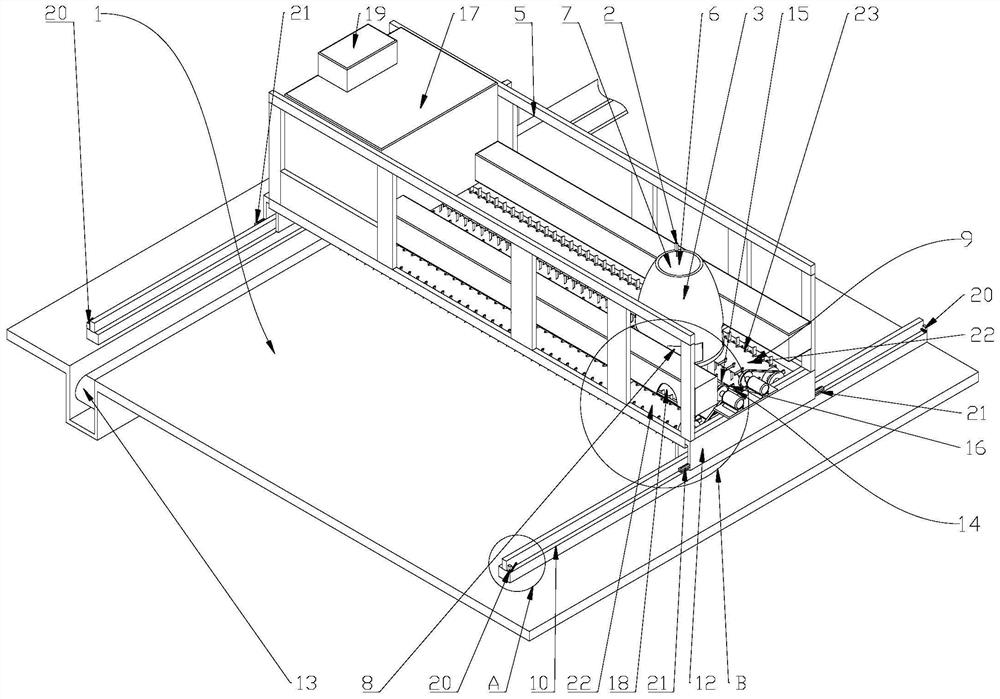

Lifting device and paver with same

InactiveCN103708389AEasy to liftImprove equipment usage efficiencyLifting devicesRoads maintainenceScreedHinge point

The invention discloses a lifting device and a paver with the lifting device. The lifting device comprises a first telescoping mechanism, a second telescoping mechanism and a third telescoping mechanism, wherein one end of the first telescoping mechanism is hinged to a rack to form a first hinge point, and a lifting connecting piece is arranged on the first telescoping mechanism; one end of the second telescoping mechanism is hinged to the rack to form a second hinge point, and the other end of the second telescoping mechanism is hinged to the other end of the first telescoping mechanism; one end of the third telescoping mechanism is hinged to the rack to form a third hinge point, and the other end of the third telescoping mechanism is hinged to the position, close to the other end of the third telescoping mechanism, of the first telescoping mechanism; the first hinge point, the second hinge point and the third hinge point are not in the same line, and the second hinge point is located above the first hinge point. The lifting device can be used for quickly lifting a spiral extending section and a screed plate extending section within the full paving width of the paver, lifting is convenient and fast, and saves time and labor are saved. The paver with the lifting device can be used for quickly lifting the spiral extending section and the screed plate extending section independently on a construction site without a forklift and other auxiliary lifting equipment.

Owner:DYNAPAC CHINA COMPACTION & PAVING EQUIP

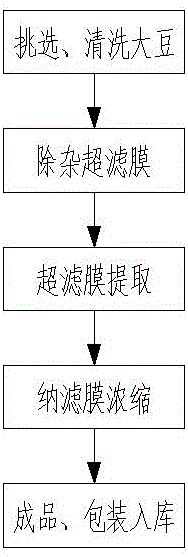

Membrane-method extraction process for soybean lecithin

InactiveCN106518906AGuaranteed continuityImprove equipment usage efficiencyGroup 5/15 element organic compoundsPhosphatide foodstuff compositionsUltrafiltrationChemistry

The invention discloses a membrane-method extraction process for soybean lecithin. The process comprises five steps, i.e., (1) picking full-grained raw material soybeans, and cleanly washing the soybeans; (2) carrying out ultrafiltration-membrane impurity removal; (3) carrying out ultrafiltration-membrane extraction; (4) carrying out nanofiltration-membrane concentration; and (5) thereby obtaining a finished product. According to the process, the separation and purification of macromolecular and micromolecular substances at a normal temperature are achieved through membrane-method production, and the traditional processes such as extraction and decolorization are replaced, so that on one hand, the efficiency of use of membrane equipment is increased, on the other hand, an ultrafiltration system can achieve continuous charging and continuous concentrated discharging, and thus, the quality and yield of the product are improved.

Owner:HEFEI XINDA MEMBRANE TECH

Rectifying technology and equipment of high purity methanol

ActiveCN100378051CReduce enrichment concentrationQuality improvementOrganic chemistryReboilerProcess engineering

A rectifying apparatus for preparing high-purity (99.85%) methanol is composed of pre-rectifying tower, pressurizing tower, ordinary-pressure tower, condenser of reflux tank, re-boiler, reflux pump, pre-heater, and cooler. Its process is also disclosed. It features less consumption of energy and cooling water.

Owner:徐州友田生物科技有限公司

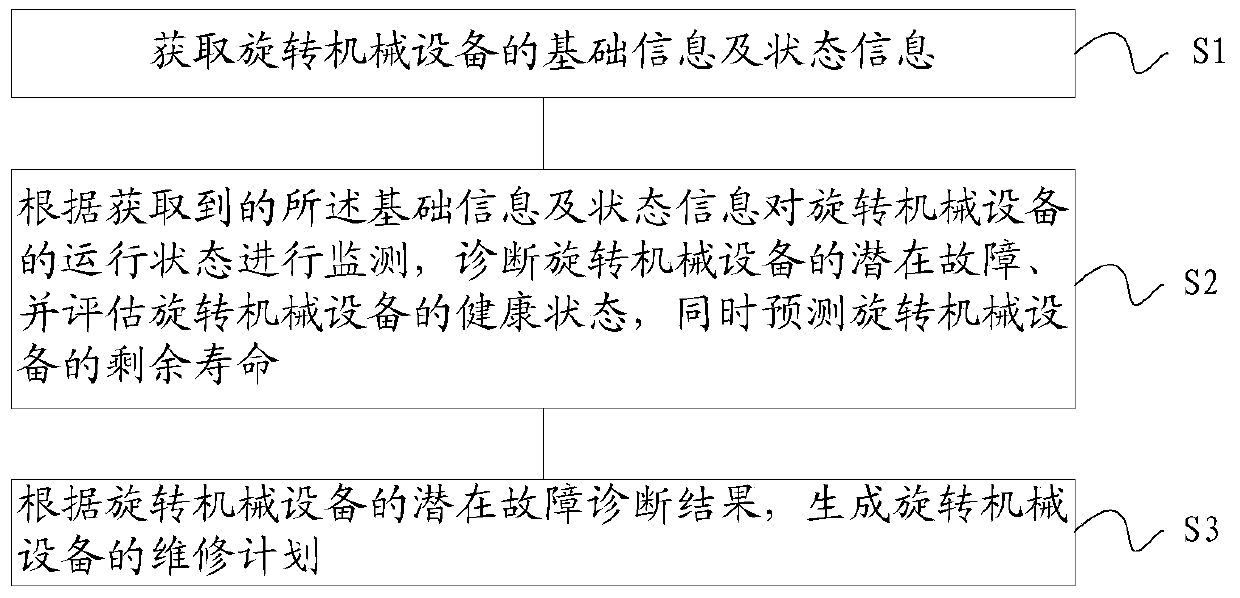

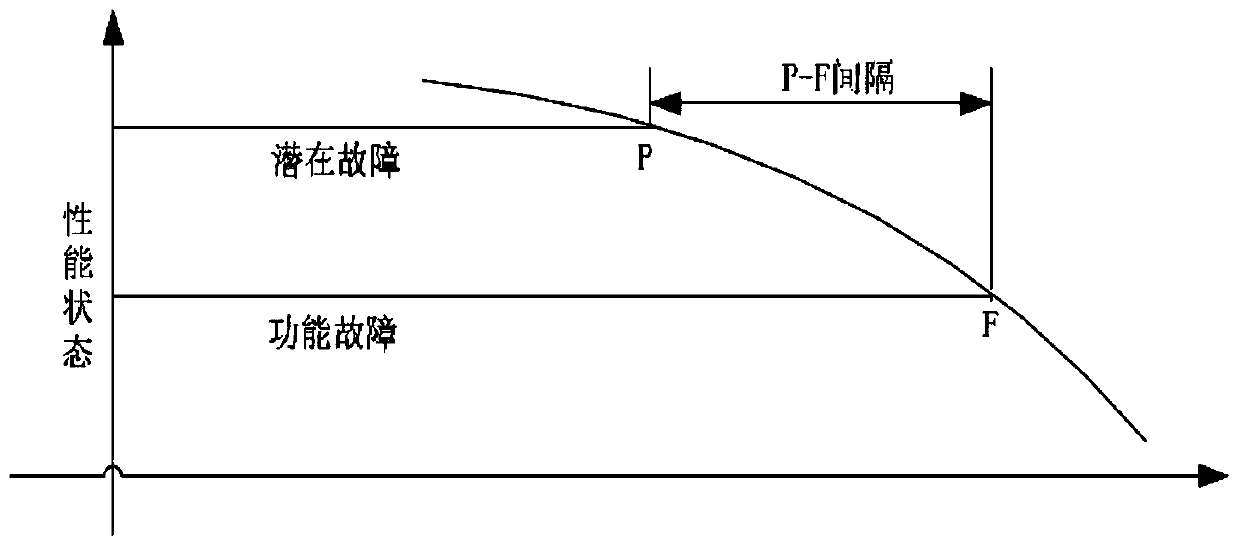

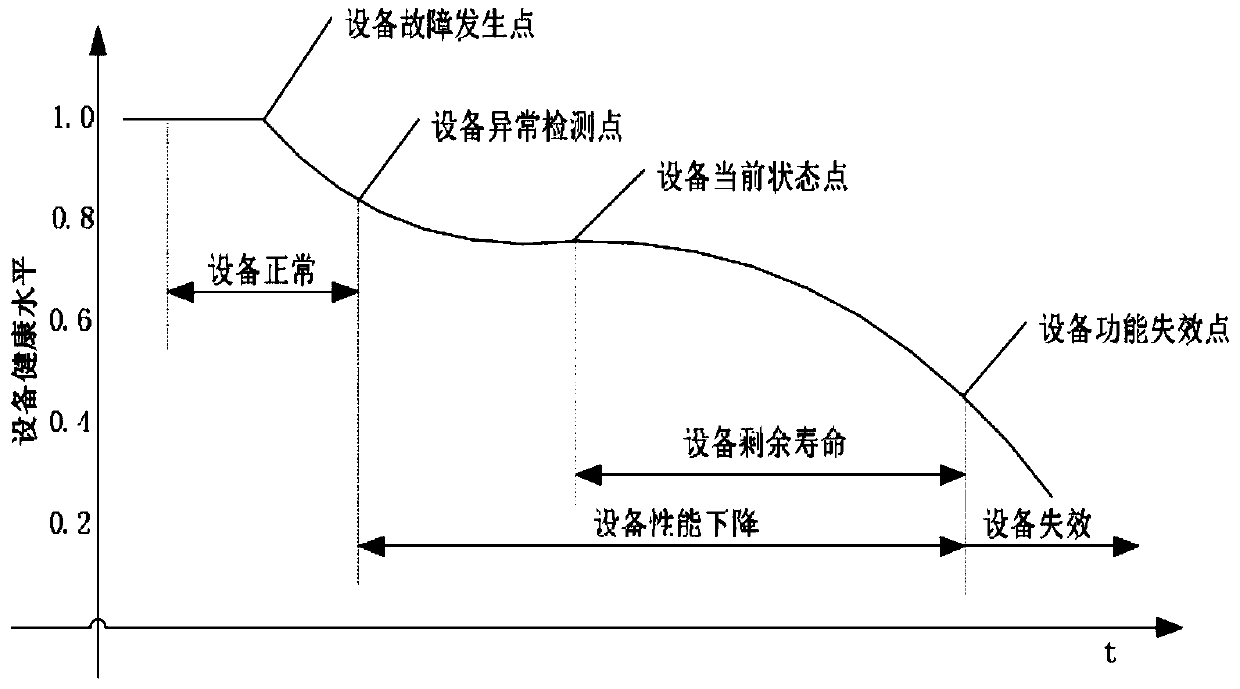

A method and system for health management of rotating machinery in thermal power plants based on the Internet of Things

ActiveCN105809255BGuaranteed reliabilityReduce maintenance costsData processing applicationsEngineeringInternet of Things

The invention provides an IoT-based heat-engine plantrotary machine health management method and system and is beneficial to the reduction of rotary machine maintenance cost and the improvement of rotary machine utilization efficiency. The method includes obtaining the basic information and the state information of rotary machines; monitoring the operation states of the rotary machines according to the obtained basic information and the state information, diagnosing potential faults of the rotary machines and evaluating the health state of the rotary machines, and predicating the rest service lifetime of the rotary machines; generating a rotary machine maintenance plan according to the potential fault diagnosis result of the rotary machines. The method and system provided by the invention are suitable for a field of heat-engine plant monitoring.

Owner:DATANG HUAINAN LUOHE POWER PLANT +1

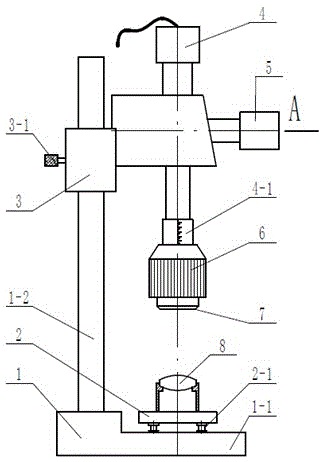

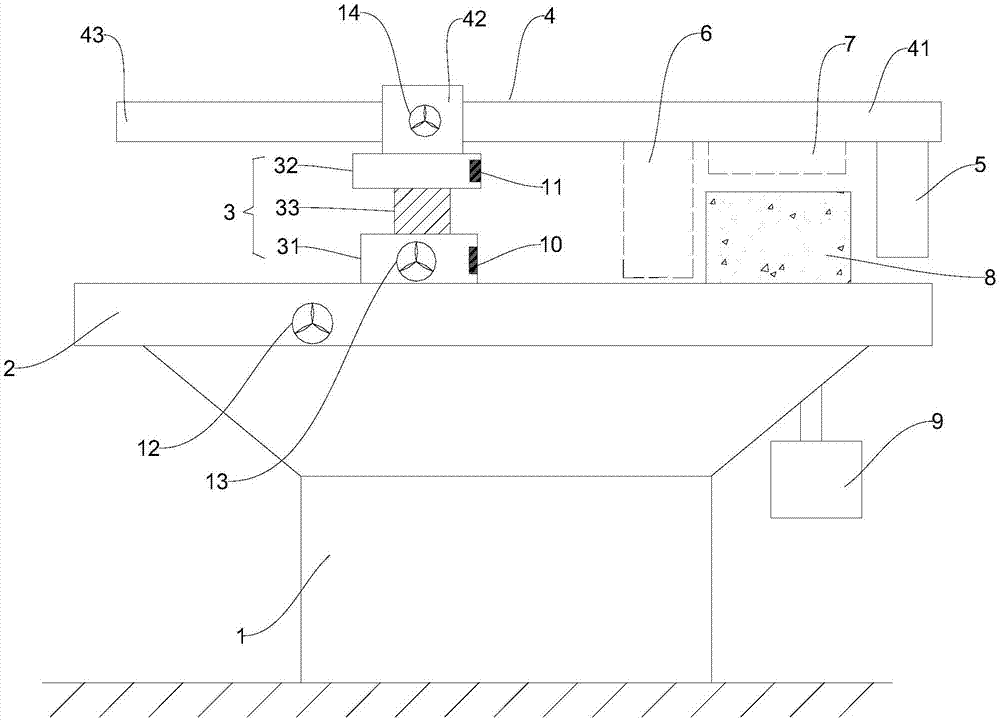

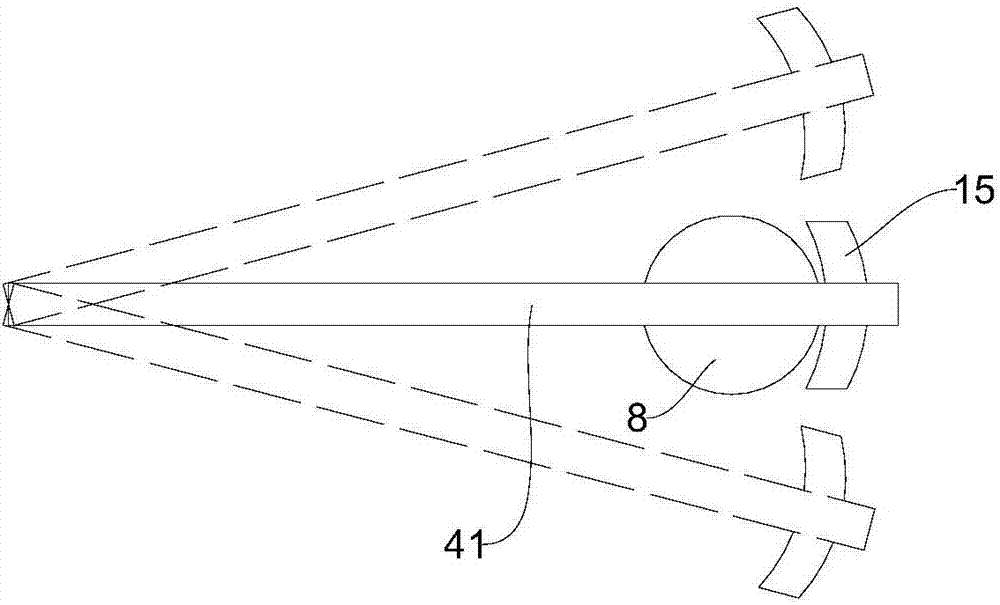

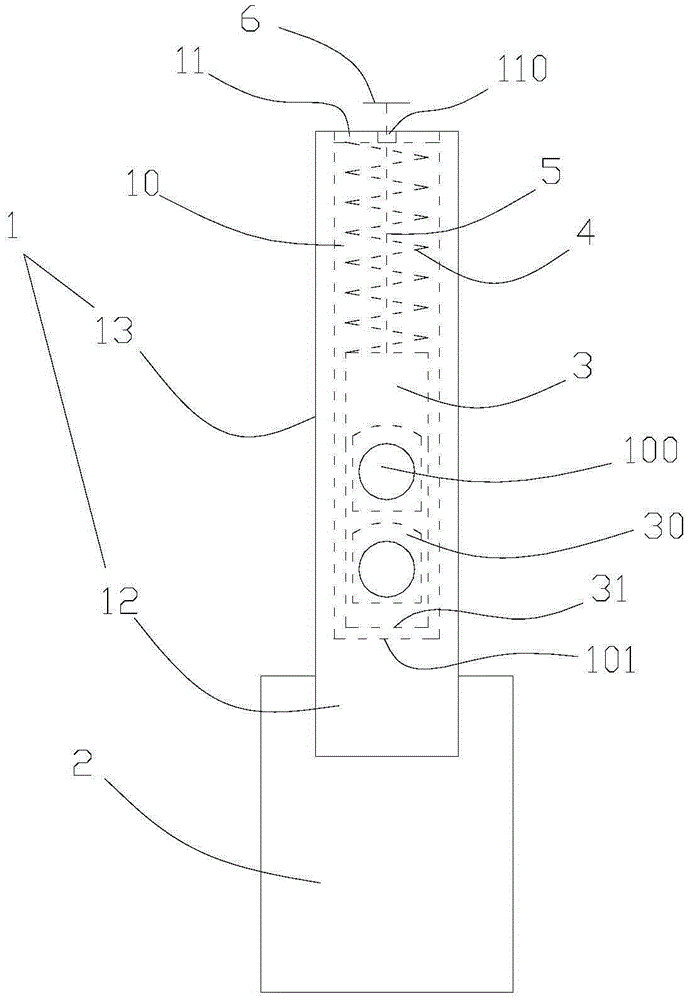

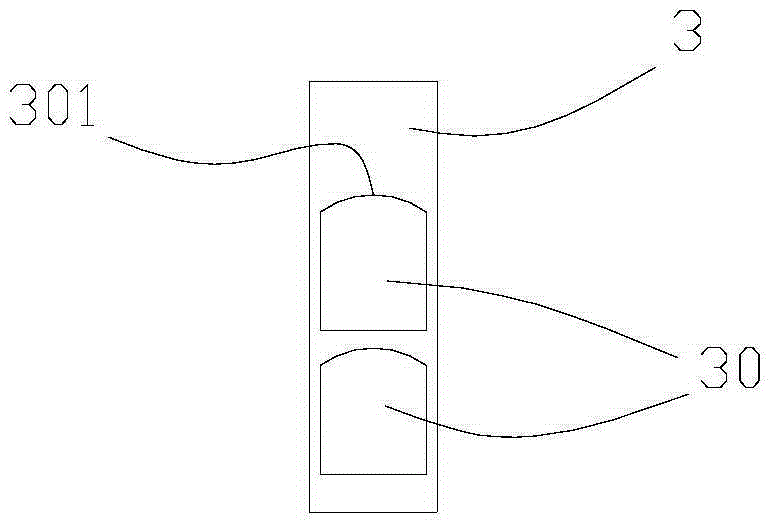

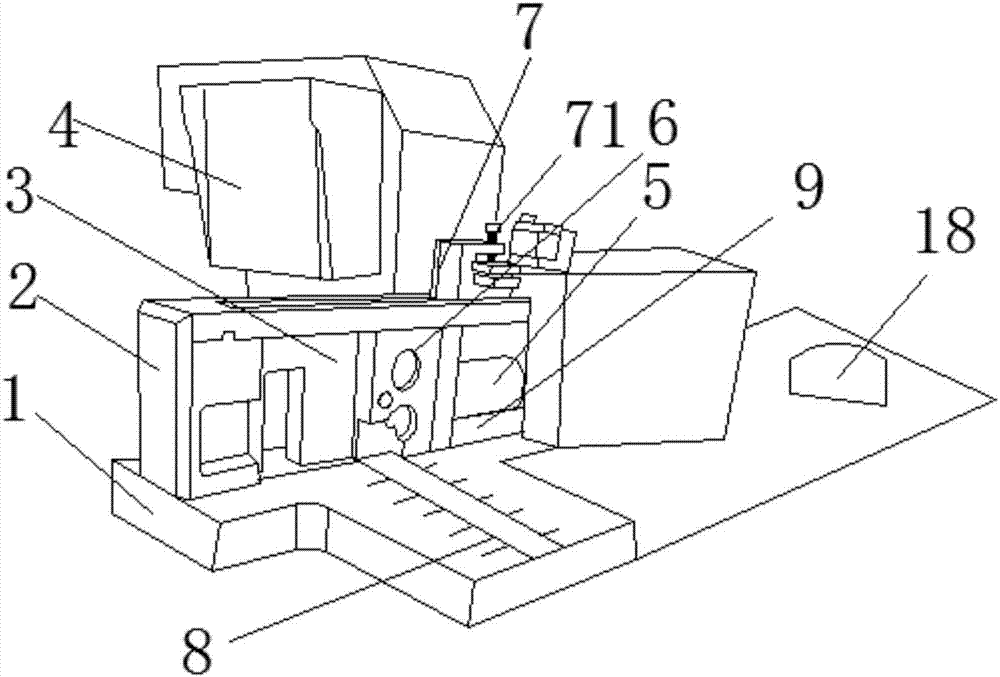

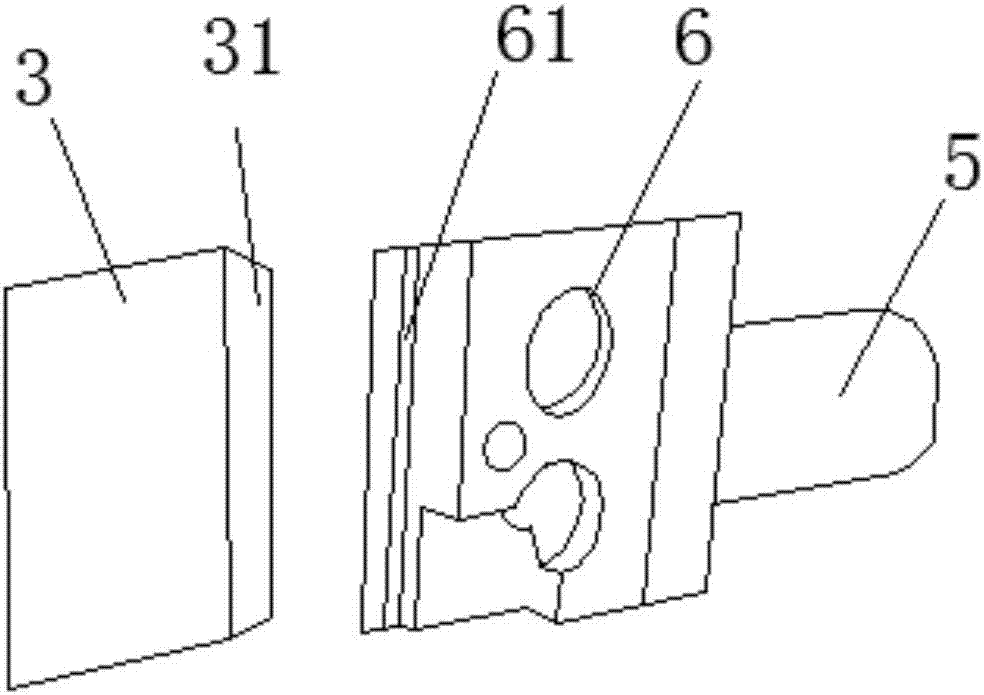

Collimation instrument for lens detection

InactiveCN105044921ASimple structureImprove equipment usage efficiencyOptical elementsLight sourceEngineering

A collimation instrument for lens detection is composed of a main bracket (1), an object placing platform (2), an auxiliary bracket (3), a light source (4), an observation opening (5), a focusing instrument (6), an eyepiece (7), and a lens component (8). The light source (4) is mounted above the auxiliary bracket (3), and penetrates through the auxiliary bracket (3). The observation opening (5) is arranged at the right end of the auxiliary bracket (3), and intersects with the light source (4). The eyepiece (7) and the focusing instrument (6) are connected together. The collimation instrument for lens detection is characterized in that the main bracket (1) is composed of a main bracket platform (1-1) and a main bracket column (1-2), and the center line of the main bracket column (1-2) and the upper surface of the main bracket platform (1-1) form an included angle of 90 degrees. By using an adjusting knob and the focusing instrument to adjust the distance between the eyepiece and a detected product and the focal length, products of different focal lengths and sizes can be detected, and therefore, the utilization efficiency of the equipment is improved.

Owner:江苏艺佳精密仪器制造有限公司

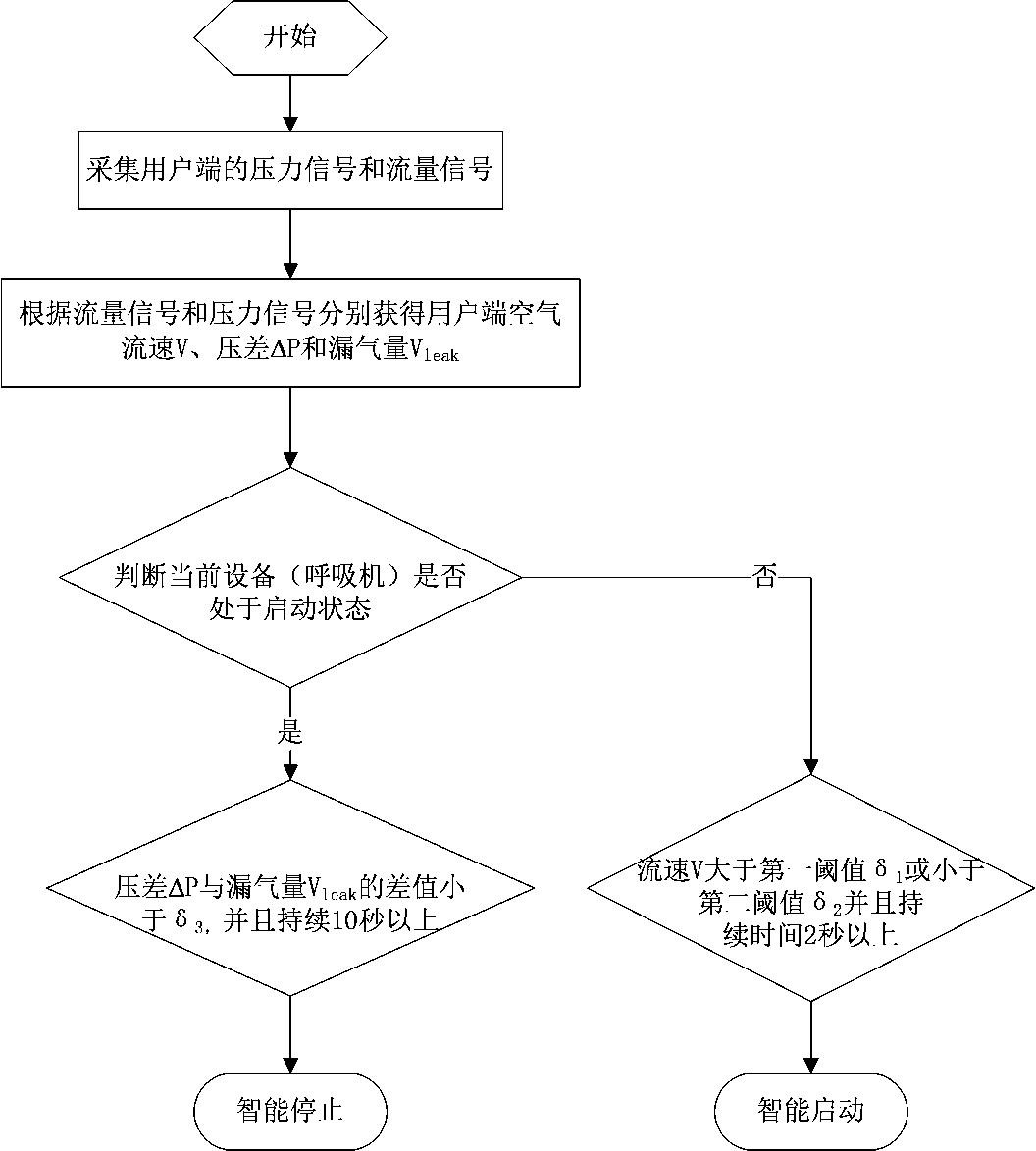

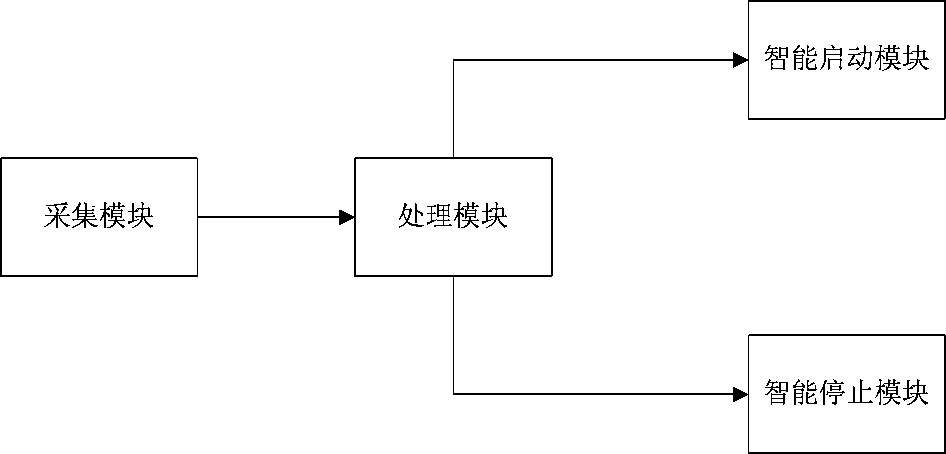

Intelligent start-stop method and device and breathing machine

PendingCN110496282AThe operation process is simpleImprove equipment usage efficiencyRespiratorsMedical devicesTraffic volumeAirflow

The invention discloses an intelligent start-stop method and device and a breathing machine. The intelligent start-stop method comprises the steps that step one, a pressure signal and a flow signal ofa user side are collected; step two, air velocity V, differential pressure Delta P and air leakage V<leak> of the user side are separately obtained according to the flow signal and the pressure signal; and step three, if a halted state is located at present and the flow velocity is greater than a first threshold value delta<1> or less than a second threshold value delta<2>, intelligent starting is started. According to the intelligent start-stop method and device and the breathing machine, intelligent start-stop is realized by identifying breathing airflow of a user, the operational process of the user is simplified, the using efficiency of the equipment is improved, the operating life of the equipment is prolonged, and energy conservation and environment protection are achieved.

Owner:广州和普乐健康科技有限公司

Plane, inner arc and outer arc grinding machine and grinding method thereof

PendingCN107363687AReduce investment and production costsImprove equipment usage efficiencyGrinding carriagesGrinding feed controlGrindingEngineering

The invention provides a plane, inner arc and outer arc grinding machine and a grinding method thereof, which relate to the technical field of machining and solve the technical problem that a plane, an inner arc and an outer arc cannot be finished on the same grinding machine. The plane, inner arc and outer arc grinding machine comprises a base, a swing arm support, a swing arm, work fixtures, and a grinding mechanism, a working platform is arranged on the base; the swing arm is articulated with the swing arm support, and can swing within a horizontal plane; the work fixtures are detachably arranged on the head of the swing arm, and the work fixtures include an inner arc-grinding fixture, an outer arc-grinding fixture, and a plane-grinding fixture. Since the inner arc-grinding fixture, the outer arc-grinding fixture and the plane-grinding fixture are detachably arranged on the head of the swing arm, an inner arc, an outer arc and a plane can be ground on the same grinding machine, moreover, choice is flexible according to the requirements of production, not only are investments and production costs of manufacturing enterprises reduced, but also the service efficiency of the equipment is increased, and enterprise incomes are increased.

Owner:TALFRI BRAKES

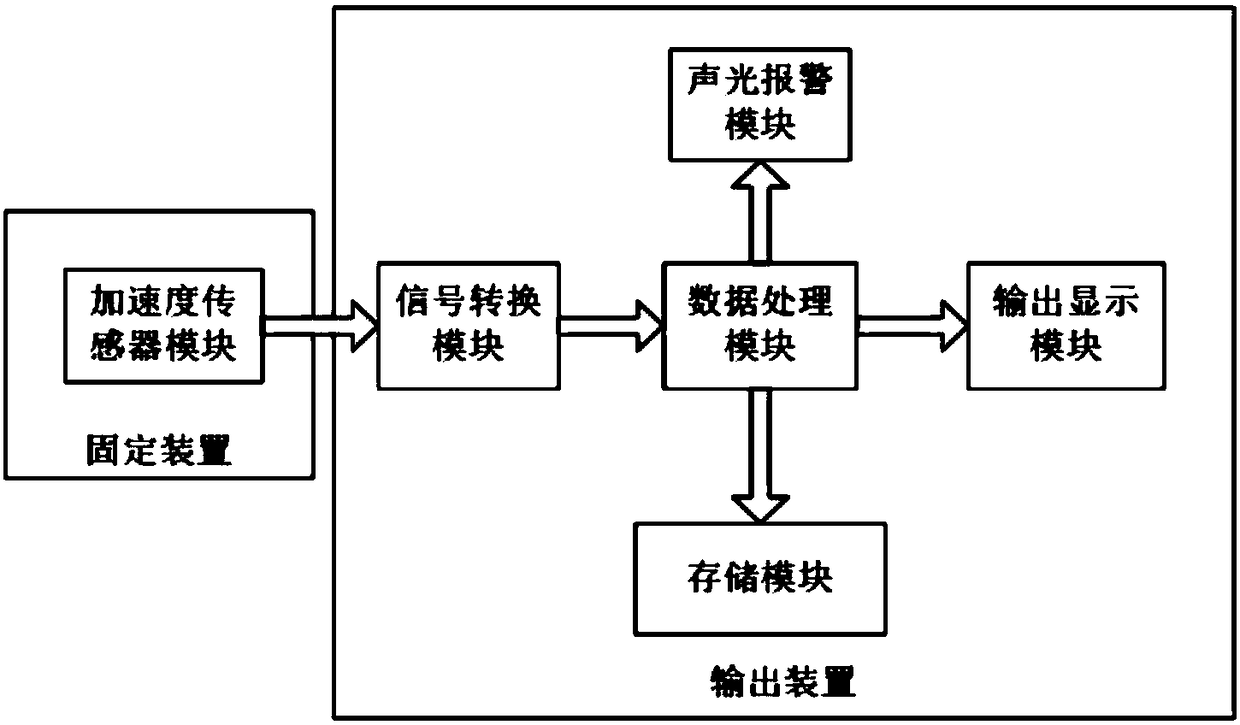

Sieving machine operation amplitude monitoring system and monitoring method

InactiveCN108267219AImprove equipment usage efficiencyImproved sieving stability and product qualitySubsonic/sonic/ultrasonic wave measurementUsing electrical meansStandard techniqueEngineering

The invention relates to a sieving machine operation amplitude monitoring system and monitoring method. The sieving machine operation amplitude monitoring system is formed by an acceleration sensor module, a signal conversion module, a data processing module, an output display module, a storage module, and a sound-light alarm module and the like, wherein when a sieving machine device is used to grade particles, the sieving machine operation amplitude monitoring system utilizes the acceleration sensor module to acquire the vibration offset of the sieving machine, and converts the vibration offset into the operating amplitude data of the sieving machine through the signal conversion module and the data processing module, can realize real-time display of the data and dynamic curve through theoutput module, can perform recording and storage through the storage module, and can realize alarming prompt through the sound-light alarm module when the standard technique is deviated. The sievingmachine operation amplitude monitoring system and monitoring method can be widely applied to sieving machine technology control of sieving of particles, can effectively improve the production efficiency, can reduce unnecessary loss and waste, and can guarantee the particle grading precision and stability.

Owner:BEIJING COMPO ADVANCED TECH

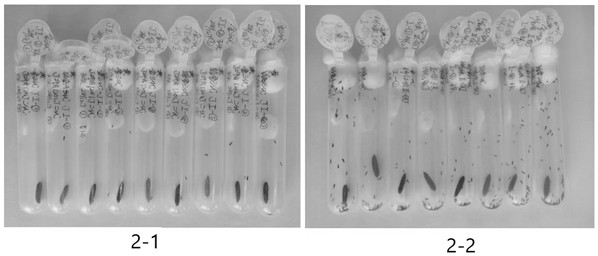

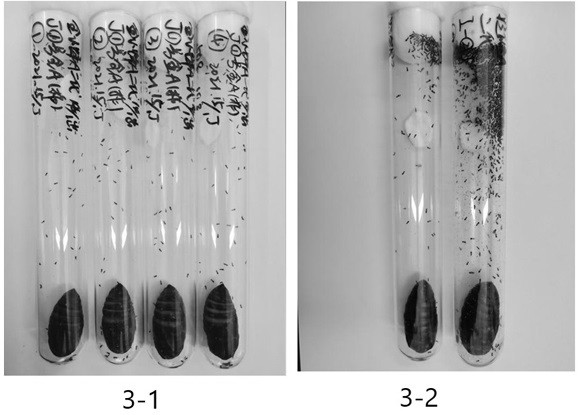

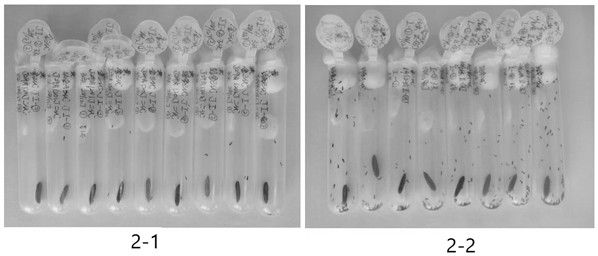

Method for preventing and controlling hyphantria cunea by using trichomalopsis genalis

ActiveCN113317282AGuaranteed source of supplyImprove labor productivityInvasive species monitoringAnimal husbandryAnimal scienceZoology

The invention relates to a method for preventing and controlling hyphantria cunea by using trichomalopsis genalis. The method comprises the following steps: (1) feeding trichomalopsis genalis adults; (2) cultivating tenebrio molitor pupae: transferring tenebrio molitor larvae into an insect breeding box with vent holes, carrying out gradient cooling treatment, and storing the treated tenebrio molitor pupae in a constant temperature box at 4 DEG C in a dark place to obtain the tenebrio molitor pupae for bee inoculation; (3) bee inoculation: heating the tenebrio molitor pupae obtained in step (2) in a reverse manner for bee inoculation, wherein a ratio of the tenebrio molitor pupae to the trichomalopsis genalis female adult is 1:3; (4) managing development of parasitic wasps; and (5) releasing parasitic wasps. In the method, the replacement host tenebrio molitor pupae are adopted to breed the trichomalopsis genalis indoors on a large scale, problems that a success rate of noculation of the replacement host bee is low and the number of bred bees is unstable are solved, meanwhile, a variety of dominant parasitic wasps for preventing and controlling hyphantria cunea is enriched, and a new means and a new method are added for biological prevention and control of the hyphantria cunea.

Owner:SHENYANG AGRI UNIV

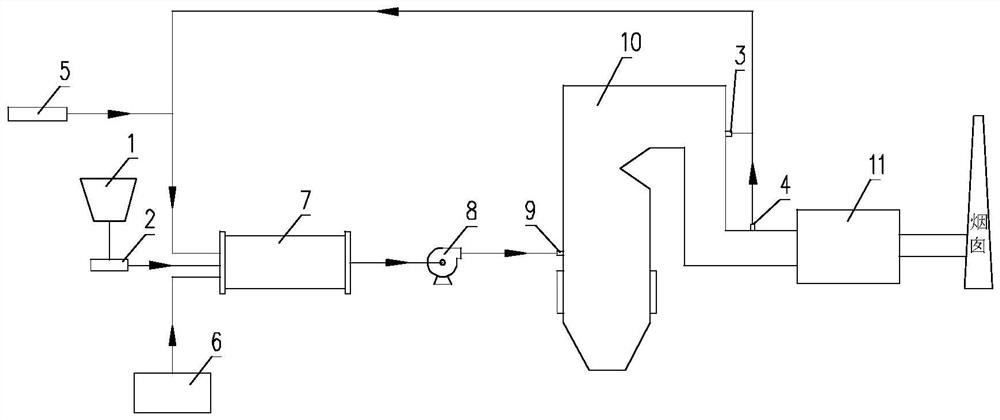

Multi-source waste disposal system and method based on pulverized coal boiler

ActiveCN113883528AEffective removalImprove equipment usage efficiencyIncinerator apparatusHot blastFlue

The invention discloses a multi-source waste disposal system and method based on a pulverized coal boiler. The multi-source waste disposal system comprises a material storage system, a hot air system, an alkaline removal agent system, an integrated disposal system, a burner, the pulverized coal boiler and a pollutant removal system; an outlet of the material storage system is connected with a material inlet of the integrated disposal system; a high-temperature flue gas connector is arranged on a flue between a hearth outlet of the pulverized coal boiler and a coal economizer, a medium-temperature flue gas connector is arranged on a flue at an outlet of the coal economizer of the pulverized coal boiler, and the high-temperature flue gas connector and the medium-temperature flue gas connector are connected with a flue gas inlet of the integrated disposal system; an outlet of the hot air system is connected with an air inlet of the integrated disposal system; an outlet of the alkaline removal agent system is connected with a solution inlet of the integrated disposal system; and an outlet of the integrated disposal system is connected with an inlet of the burner, and an outlet of the burner is connected with a hearth of the pulverized coal boiler. The system and the method can achieve disposal of multi-source waste.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

Ramie Degumming Process by Air Explosion at High Temperature

InactiveCN106637430BShort high temperature gas explosion timeIncrease productivityVegetable materialFibre treatment to obtain bast fibreProcess engineeringHigh pressure

Owner:WUHAN TEXTILE UNIV

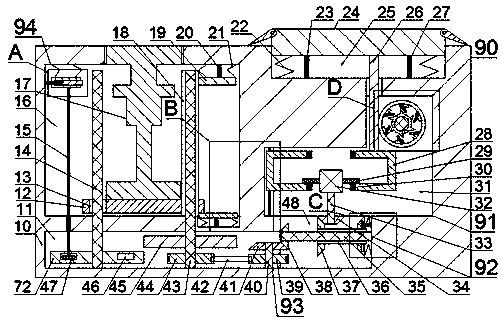

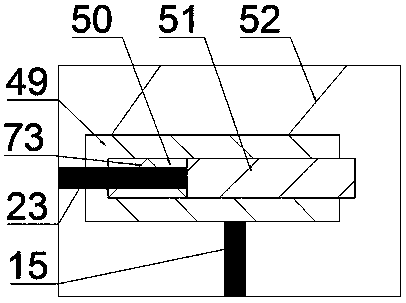

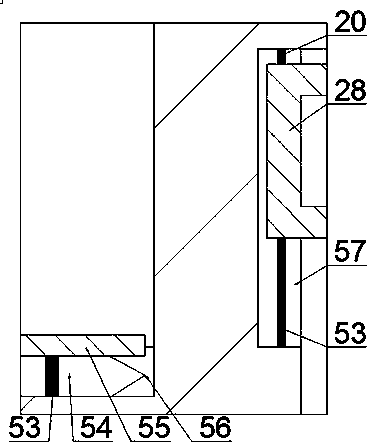

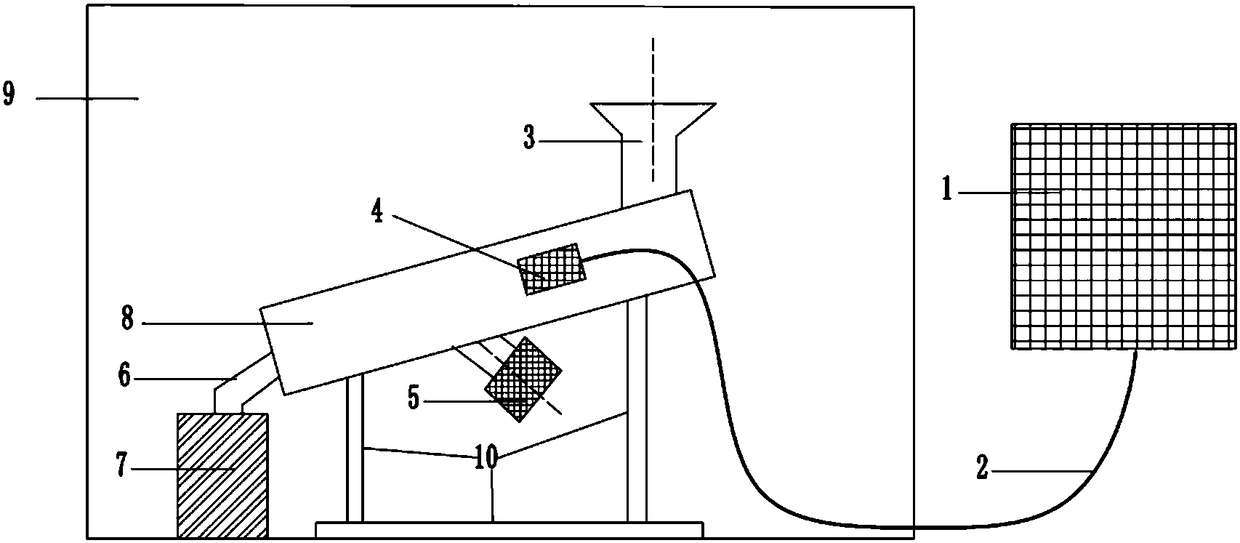

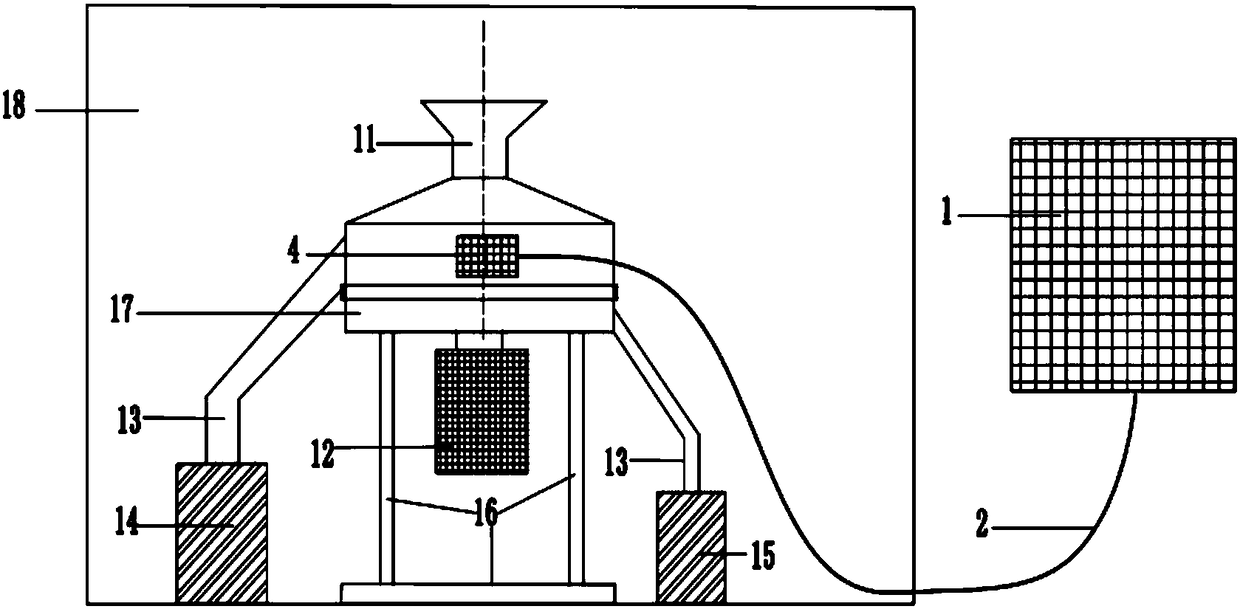

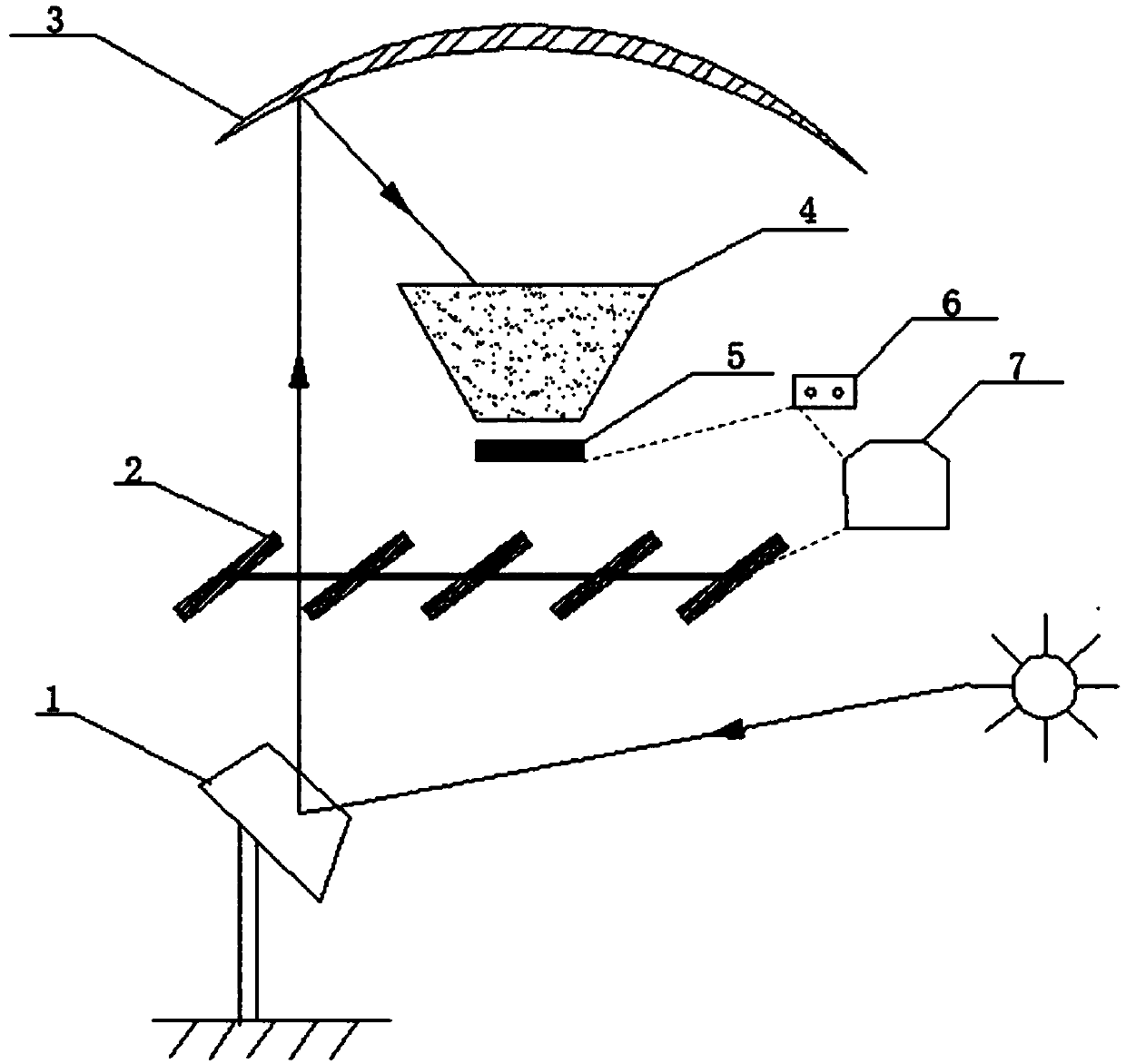

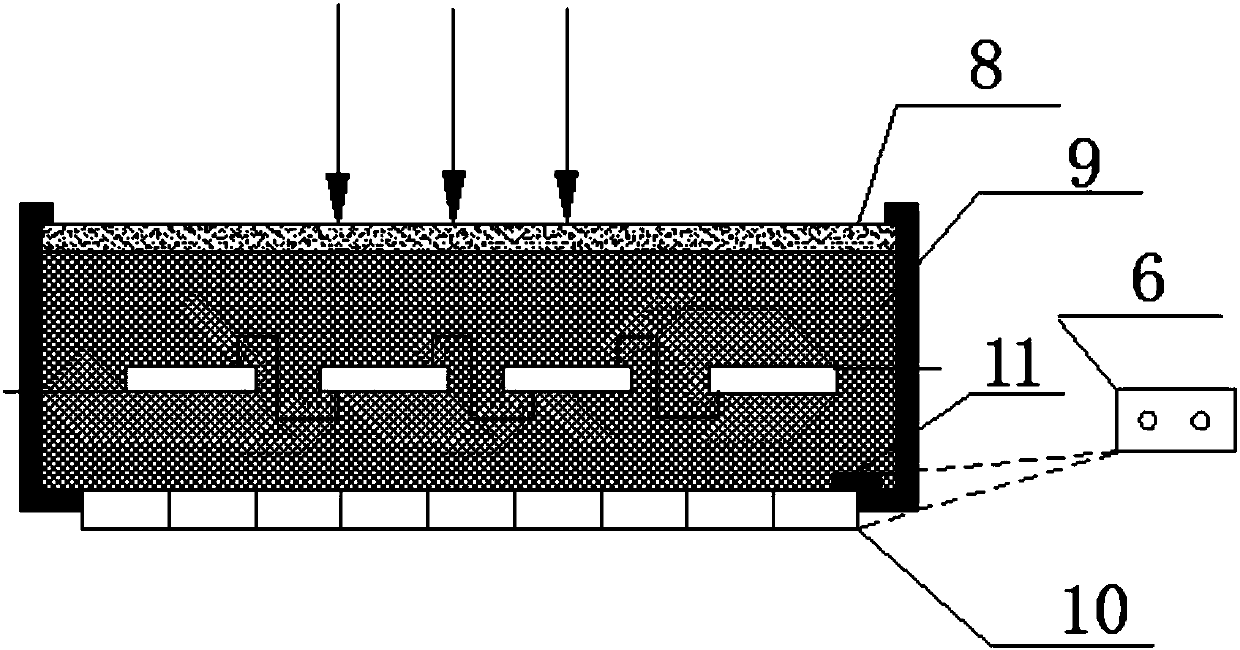

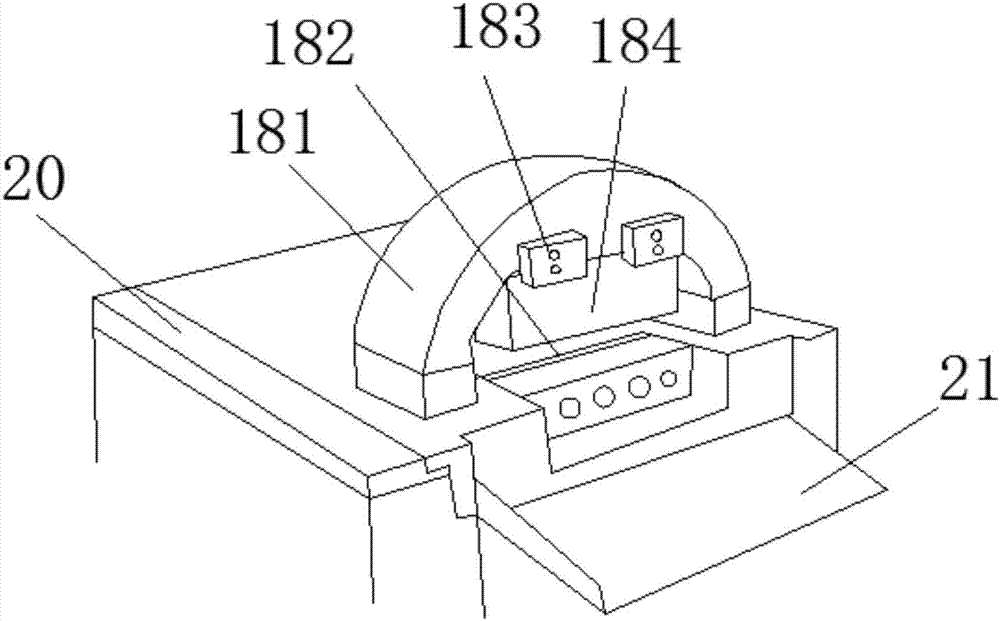

A photovoltaic module ultra-accelerated thermal cycle aging test device

ActiveCN106130482BImprove test efficiencyImprove equipment usage efficiencyPhotovoltaic monitoringPhotovoltaic energy generationDrive motorEngineering

The invention provides a super-accelerating thermal cycle aging test apparatus for a photovoltaic module. The super-accelerating thermal cycle aging test apparatus comprises an outdoor part and an indoor part, wherein the outdoor part comprises a heliostat; the indoor part comprises optical shutters, a parabolic reflecting mirror, a secondary condenser, a photovoltaic module receiver, a control unit and a driving motor, wherein the concave surface of the parabolic reflecting mirror is downward; the secondary condenser is arranged below the parabolic reflecting mirror; the photovoltaic module receiver is arranged below the secondary condenser; the optical shutters are arranged below the photovoltaic module receiver; the control unit and the photovoltaic module receiver are both electrically connected with the driving motor; a gear B is arranged on the output shaft end part of the driving motor; and the gear B is meshed with a gear A. The super-accelerating thermal cycle aging test apparatus is applicable to a common panel photovoltaic module, and also can be used for test and research for the condensation type photovoltaic module; and in addition, through a simple operation, the super-accelerating thermal cycle aging test apparatus also can be changed to be used for a high-condensation photovoltaic power generation system, so that the utilization efficiency of test equipment is improved.

Owner:泰州市海创新能源研究院有限公司

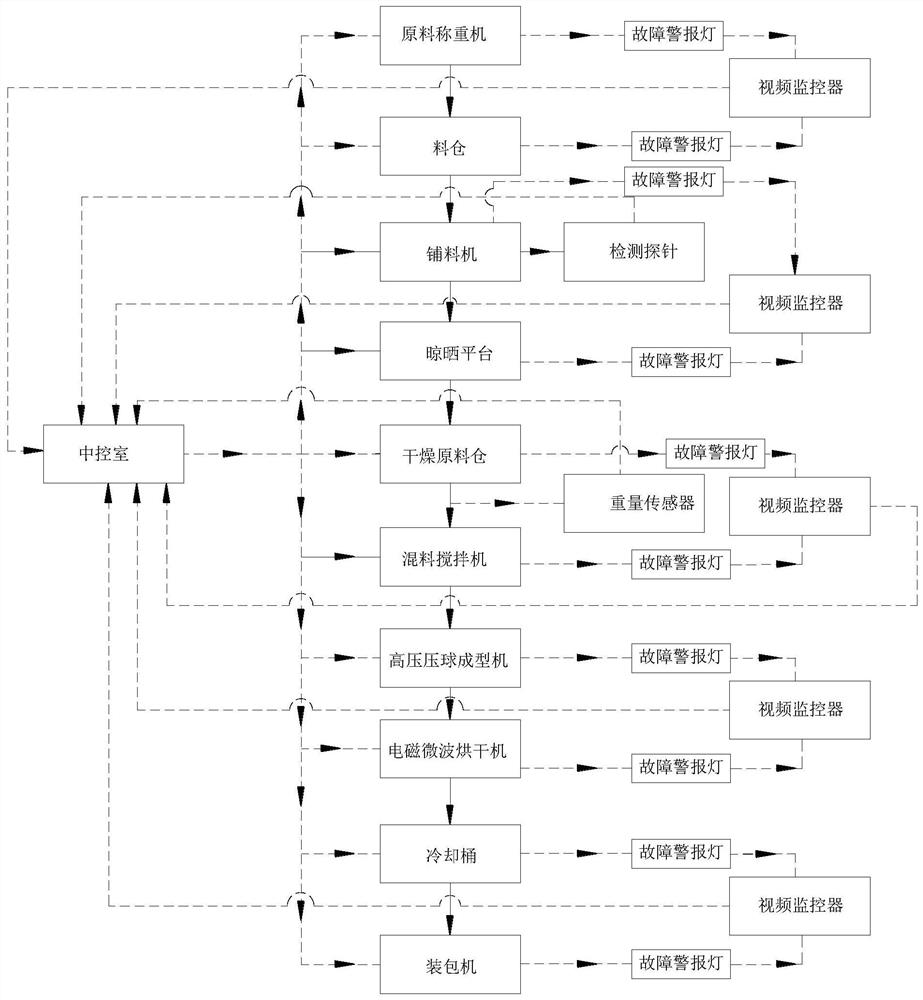

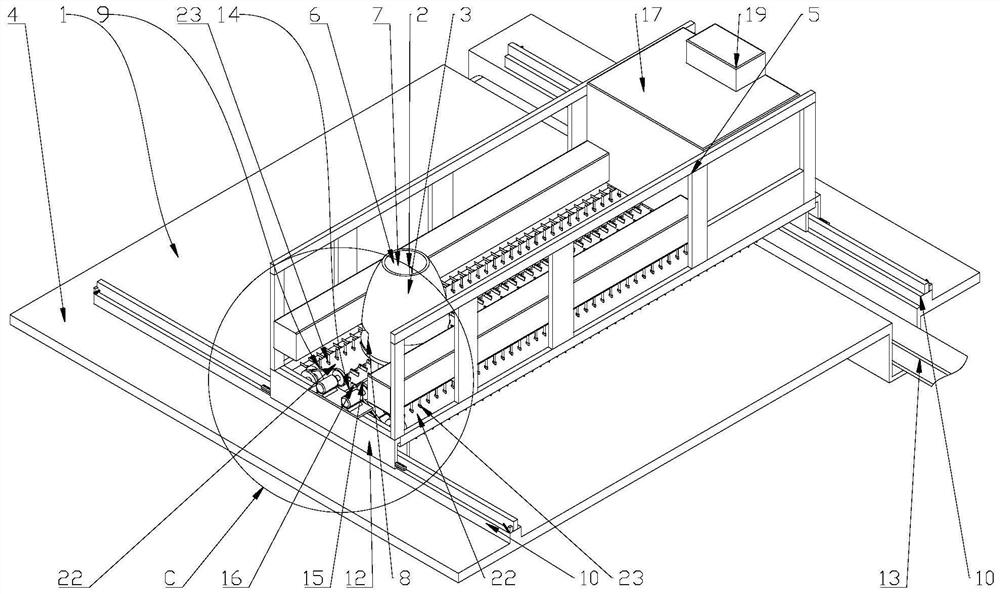

Full-automatic fluorite ball production line

ActiveCN114393873AAvoid affecting productivityAvoid wastingShaping pressVideo monitoringProduction line

The invention relates to the technical field of fluorite ball production, and provides a full-automatic fluorite ball production line which comprises a raw material weighing machine, a material bin, a material spreading machine, a raw material drying bin, a material mixing and stirring machine, a high-pressure ball pressing and forming machine, an electromagnetic microwave drying machine, a cooling barrel and a bagging machine which are sequentially arranged in the conveying direction of raw materials. The video monitors and the fault warning lamps are arranged on the spreading machine, the drying raw material bin, the mixing stirrer, the high-pressure ball pressing forming machine, the electromagnetic microwave drying machine, the cooling barrel and the bagging machine respectively, the video monitors are used for recognizing the fault warning lamps and transmitting signals to the central control room, the central control room is used for controlling equipment operation, and the detection probes are used for detecting whether the equipment operates or not. The weight sensor is used for controlling the quantity of the raw materials conveyed to the mixing stirrer from the drying raw material bin. According to the technical scheme, the problem that in the prior art, all stations of an automatic production line need to be manually monitored is solved.

Owner:唐山明诚矿业有限公司

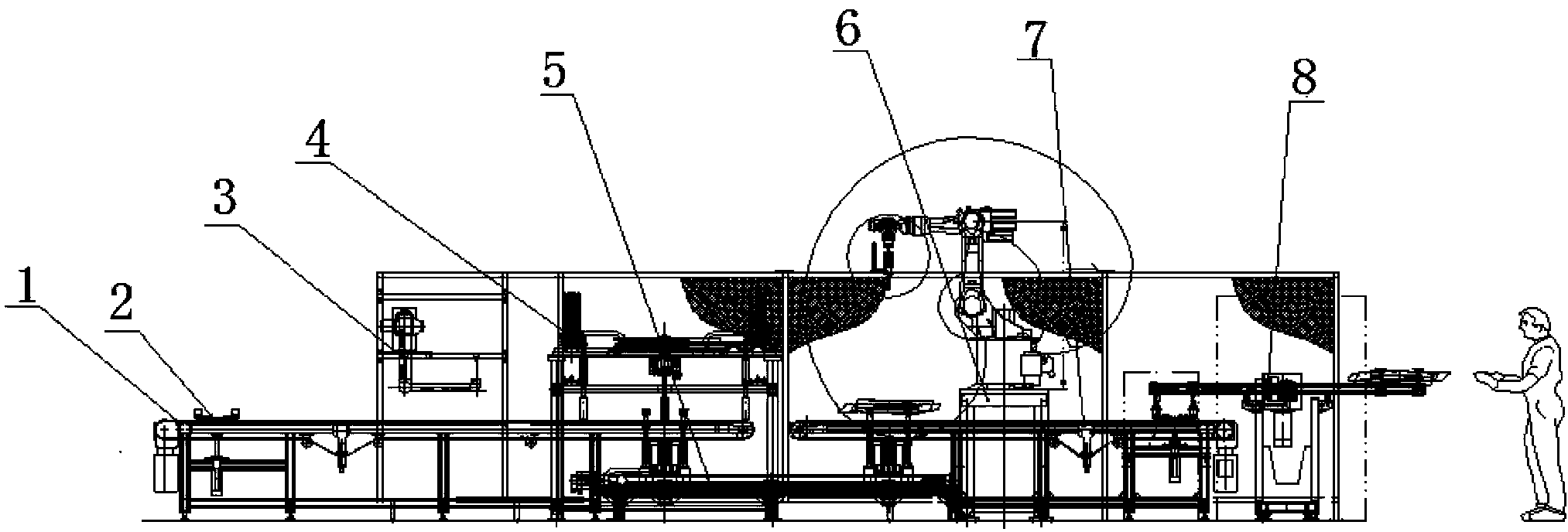

Glue-spraying apparatus for automobile windshield glass and glue-spraying method thereof

The invention discloses a glue-spraying apparatus for automobile windshield glass and a glue-spraying method thereof. The apparatus comprises a robot glue-spraying machine and a tilting machine, a base coating glue-spraying platform, a heat air-drying device and a centering positioning device, wherein the base coating glue-spraying platform is disposed at a first station; the heat air-drying device is disposed at a second station; the centering positioning device is disposed at a third station; the robot glue-spraying machine is disposed at a fourth station; and the tilting machine is disposes at a fifth station. The apparatus also comprises a first transfer line for transferring the bottom-coated windshield glass of the first station to the second station and the third station; a transplanting machine for transferring the centering-positioned glass of the third station to the fourth station; a second transfer line for transferring the glue-sprayed windshield glass from the fourth station to the fifth station; and the base coating glue-spraying platform, the heat air-drying machine, the centering positioning device, the robot glue-spraying machine, the tilting machine, the first transfer line, the transplanting machine and the second transfer line are connected with a controller. The glue-spraying method comprises five steps. The apparatus and the glue-spraying method can improve cycle time and reliability of equipment significantly.

Owner:CHERY AUTOMOBILE CO LTD

A kind of method of golden wasp controlling American white moth

ActiveCN113317282BGuaranteed source of supplyImprove labor productivityInvasive species monitoringAnimal husbandryAnimal scienceCotton bollworm

The invention relates to a method for preventing and controlling the American white moth by the golden wasp, which is characterized in that: the golden wasp is the cotton bollworm golden bee, and the control method comprises the following steps: (1) rearing the golden cotton bollworm adult; ( 2) Cultivate the yellow-pink beetle pupae, transfer the yellow-pink beetle larvae into an insect-raising box with ventilation holes, and then carry out a gradient cooling treatment, and place the treated yellow-pink beetle pupae in a 4°C incubator for protection from light to obtain a bee-receiving use. The yellow-pink beetle pupa; (3) receiving the bees, the step (2) the yellow-pink beetle pupa is reversely heated to receive the bee, and the ratio of the yellow-pink beetle pupa to the number of female adult bees of Helicoverpa armigera is 1:3; (4) parasitic Management of bee development; (5) release of parasitic wasps. The method adopts the alternative host yellow powder beetle pupae to breed Helicoverpa armigera on a large scale indoors, solves the problems of low success rate of the alternative host and the unstable number of breeding bees, and at the same time enriches the dominant parasitic wasp species in the control of American white moth, which is the most important in the United States. The biological control of white moth adds new means and new methods.

Owner:SHENYANG AGRI UNIV

Ramie high-temperature gas explosion degumming process

InactiveCN106637430AImprove qualityShort degumming timeVegetable materialFibre treatment to obtain bast fibreProcess engineeringGas explosion

The invention relates to a ramie high-temperature gas explosion degumming process. The process applies degumming process, and the degumming process applies alkali solution. The degumming process is characterized in that degumming process includes unpacking and unbinding process, feeding process, first high-temperature gas explosion process, first extruding process, second high-temperature gas explosion process, second extruding process, third high-temperature gas explosion process, and third extruding process, wherein a high-temperature high-pressure flushing method is applied; ramie is flushed under the alkali solution in the first high-temperature gas explosion process, the second high-temperature gas explosion process and the third high-temperature gas explosion process; the alkali solution temperature is kept at 80-90 DEG C or 95-100 DEG C; the alkali solution pressure is kept at 0.8-1.0 MPa or 1.0-1.2 MPa; the heat preservation and pressure maintaining times of the alkali solution are 3-5 minutes or 5-10 minutes. The process cancels the binding, packing, softening, and loosening processes, shortens the technical flow, promotes quality of the degummed ramie, improves production efficiency, decreases cost and reduces environmental pollution.

Owner:WUHAN TEXTILE UNIV

Ramee degumming process

InactiveCN100494522CIncrease productivityImprove equipment usage efficiencyFibre treatment to obtain bast fibreOxalateBoiling process

The invention relates to a degumming technology for ramie, comprising unpacking and untying braches, loading cage, boiling, softening, bleaching and washing by acid, supplying oil, deoiling and drying. The boiling process is that the original fiber is put into the mixed solution, of which the weight is nine to twelve times of the weight of original fiber; the pressure is maintained in 0.1-0.2MPa and the maintaining time is for 1-1.5 hours. The mixed solution comprises sodium hydroxide, oxidant, oxalate and scouring agent. Thereinto, the content of sodium hydroxide is 5-8g / l, the content of oxidant is 5-10g / l, the content of oxalate is 3-8g / l and the content of scouring agent is 3-5g / l. By adopting the degumming technology for ramie, the scouring time for ramie is decreased, the manufacturing efficiency is improved, the circumstance pollution is decreased and the quality of ramie after degumming is improved.

Owner:CHONGQING FULING KINGLONG

A kind of fast-setting corrosion-resistant cement using fly ash as raw material and preparation method thereof

ActiveCN104556909BIncrease profitRapid responseSolid waste managementSynthetic materialsWater reducer

The invention discloses a fast-setting anti-corrosion cement using coal ash as a raw material and a preparation method thereof. The fast-setting anti-corrosion cement is prepared from the following components in parts by mass: 60-75 parts of coal ash, 25-40 parts of slaked lime, 0.5-1.5 parts of alkaline excitant, and 1-2 parts of sulfate excitant; the preparation method comprises the following steps: ball-milling the raw materials to obtain a batch mixture with 80-micron screen residue content less than 5%, adding 20-25 parts of water, uniformly stirring to prepare a raw material ball, hydro-thermally treating the raw material ball at 95-98 DEG.C for 10-16 hours to obtain a steamed material, calcining the steamed material at 750-900 DEG.C for 15-90 minutes, and cooling to obtain a synthetic material; and commonly ball-milling 75-85 parts of the synthetic material and 10-20 parts of Portland cement together with 5-8 parts of gypsum, 0.2-1.0 part of thickening time control agent and 0.3-0.7 part of water reducing agent until the 80-micron screen residue content is less than 4%. The cement is low in calcining temperature and thermal loss, high in coal ash utilization rate, fast-setting and fast-hardening, high in strength, and goon in sulfate attack resistance.

Owner:吴忠赛马新型建材有限公司

Connection terminals between wires and components

ActiveCN104134874BAvoid corrosionPrevent theftClamped/spring connectionsConnection contact member materialEngineeringCopper

The invention provides a connecting end between a wire and a component. The connecting end comprises a connecting plate, a connecting column, a clamping column, a spring and a driving mechanism, wherein the connecting plate is made of copper and is of a flat rectangular plate-like structure, and the front segment of the connecting plate is connected with the component; the connecting column is made of aluminum and is of a cylindrical shape, the front segment of the connecting column is connected with the rear segment of the connecting plate, a cylinder cavity is formed inside the rear segment of the connecting column and extends along the length direction of the connecting column, the rear segment of the connecting column is provided with at least one through hole, and the through hole passes through the cavity and is used for the wire to be inserted; the clamping column is of a cylindrical shape and is slidingly arranged in the cavity along the axial direction of the cavity; the spring is arranged between the rear end wall of the cavity and the clamping column and used for driving the clamping column to tightly clamp the wire inserted into the through hole; and the driving mechanism is connected with the clamping column, extends outside the cavity and is used for driving the clamping column to backwards move. With the adoption of the connecting end, the wire can be prevented from being stolen, connecting quality is improved, the risk of heating and burning a connecting part is reduced, and the working efficiency of an electrician and the application efficiency of equipment can be obviously improved.

Owner:STATE GRID CORP OF CHINA +2

Busbar automatic machining machine

InactiveCN107042262AImprove equipment usage efficiencyReduce waste of resourcesContact member manufacturingBusbarControl system

The invention provides a busbar automatic machining machine which comprises an operation table, a control system, a shearing mechanism, a bending mechanism, a punching mechanism, a shearing motor, a bending motor and a punching motor. A vertical rod and a cross beam are arranged on the operation table, and an upper guide rail is arranged on the cross beam. A lower guide rail is arranged at the position, below the cross beam, of the operation table, and the control system comprises a controller and a control panel. The controller is connected with the control panel, and a rotary button and a switch are arranged on the control panel. The controller is connected with the shearing motor, the bending motor and the punching motor through a driving circuit. A locating device is arranged, and therefore the locating precision of a mold is guaranteed. In addition, a transverse dividing ruler and a longitudinal dividing ruler are arranged to guarantee discharging precision. The busbar automatic machining machine is novel in design, simple in structure, convenient to use, high in work efficiency and easy to popularize and implement and has good economic benefits.

Owner:苏州龙兴线缆有限公司

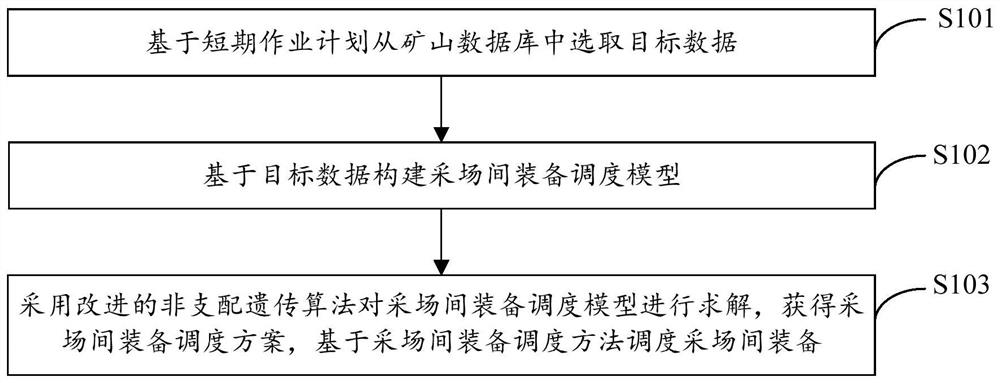

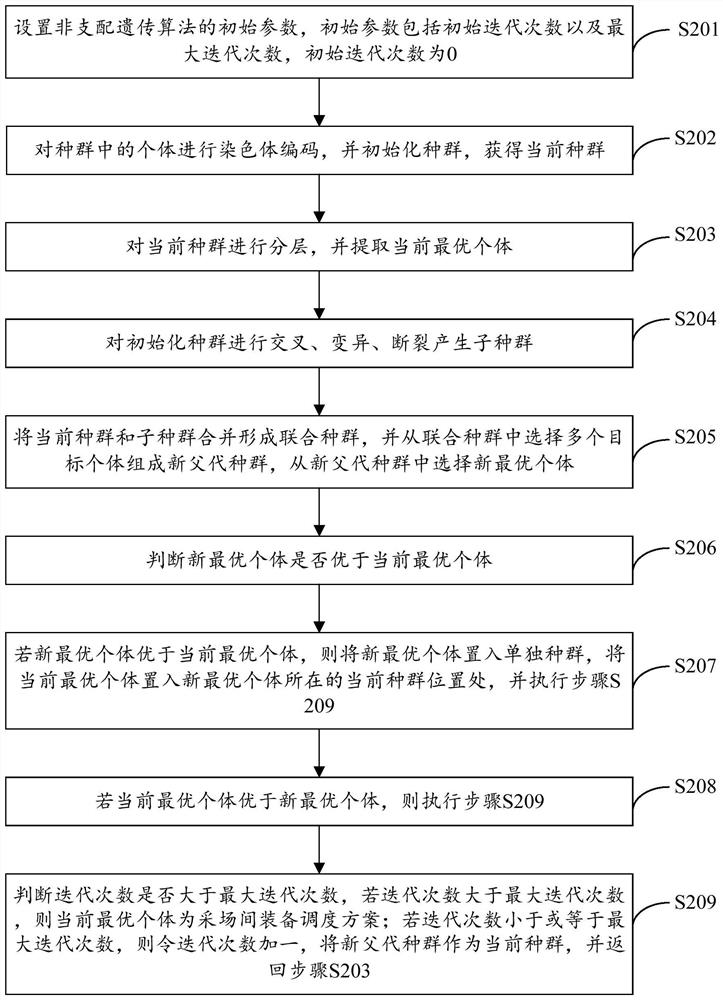

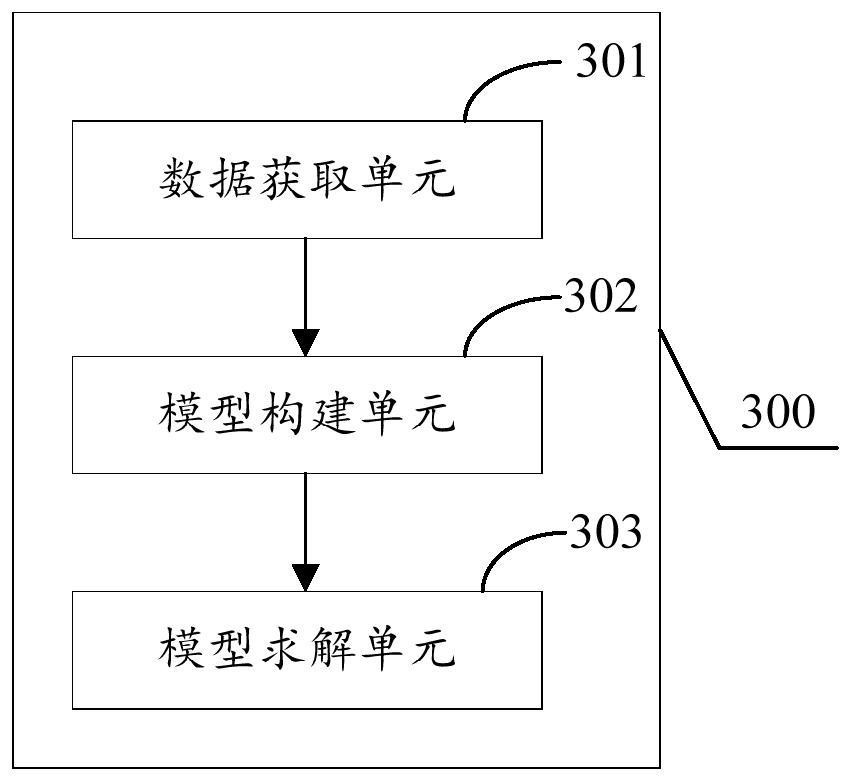

Inter-stope equipment scheduling method and device based on short-term operation plan

PendingCN114511198AImprove acquisition efficiencyImprove production efficiencyUnderground miningForecastingGenetics algorithmsEquipment use

The invention provides an inter-stope equipment scheduling method and device based on a short-term operation plan. The method comprises the following steps: selecting target data from a mine database based on the short-term operation plan; constructing an inter-stope equipment scheduling model based on the target data; and solving the inter-stope equipment scheduling model by adopting an improved non-dominated genetic algorithm to obtain an inter-stope equipment scheduling scheme, and scheduling inter-stope equipment based on the inter-stope equipment scheduling method. The production benefit of a mine and the use efficiency of equipment are improved.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com