Glue-spraying apparatus for automobile windshield glass and glue-spraying method thereof

A windshield and gluing device technology, which is applied to the surface coating liquid device, coating, surface pretreatment, etc., can solve the problem of not being able to meet the needs of primer coating and air drying at the same time, space and cost disadvantageous to corporate interests, increasing space and Problems such as the number of personnel, to achieve the effect of benefiting production interests, reducing equipment downtime, and reducing transshipment procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

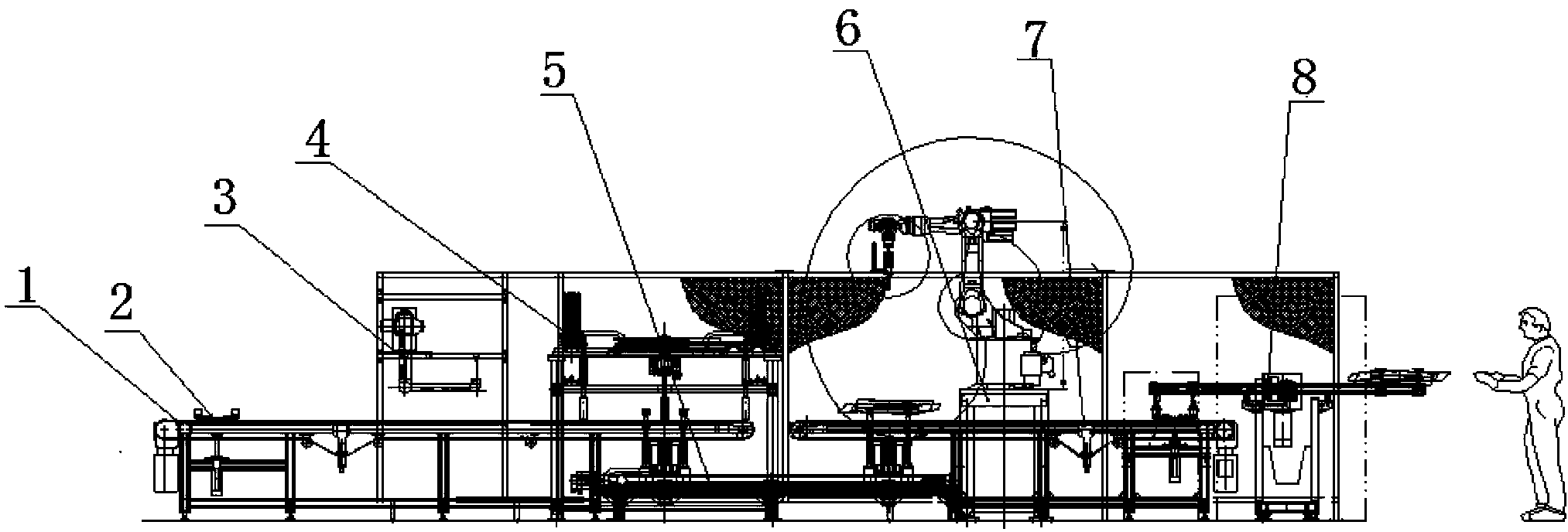

[0028] Such as figure 1 As shown, the automobile windshield gluing device includes a robot gluing machine 6 for gluing the windshield and a turning machine 8 located at the rear station of the robot gluing machine 6 for picking up the windshield; it also includes Primer glue coating station 2 for primer coating of windshield glass, hot air drying device 3 for air-drying the glass after primer coating, and centering positioning device 4 for positioning the air-dried glass; wherein the primer glue station 2 is located in The first station, the hot air drying device 3 is arranged at the second station, the centering positioning device 4 is arranged at the third station, the robot glue applicator 6 is arranged at the fourth station, and the turning machine 8 is arranged at the fifth station; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com