Patents

Literature

58results about How to "Effective removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

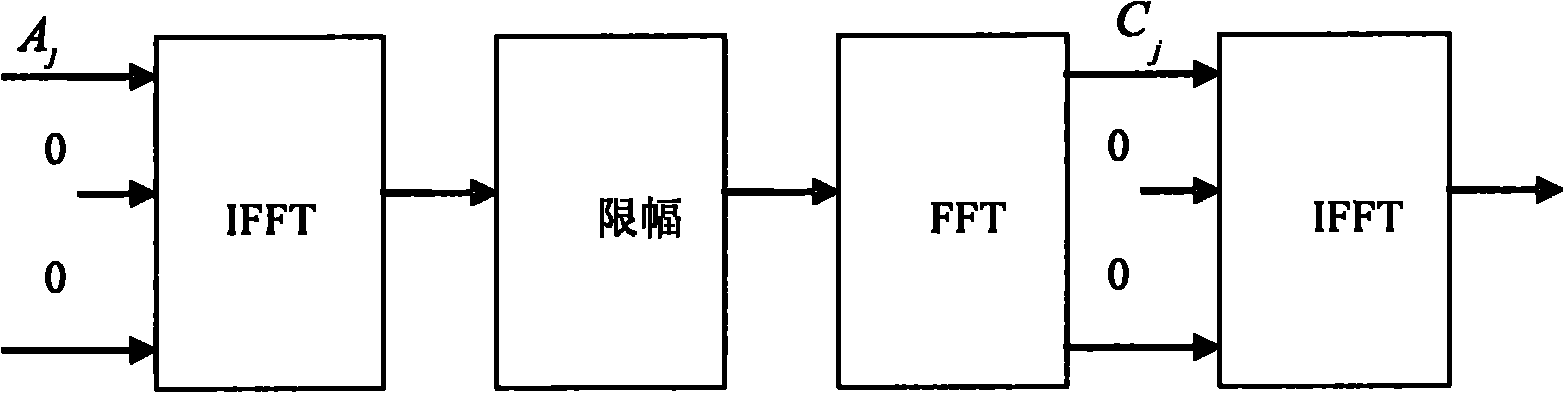

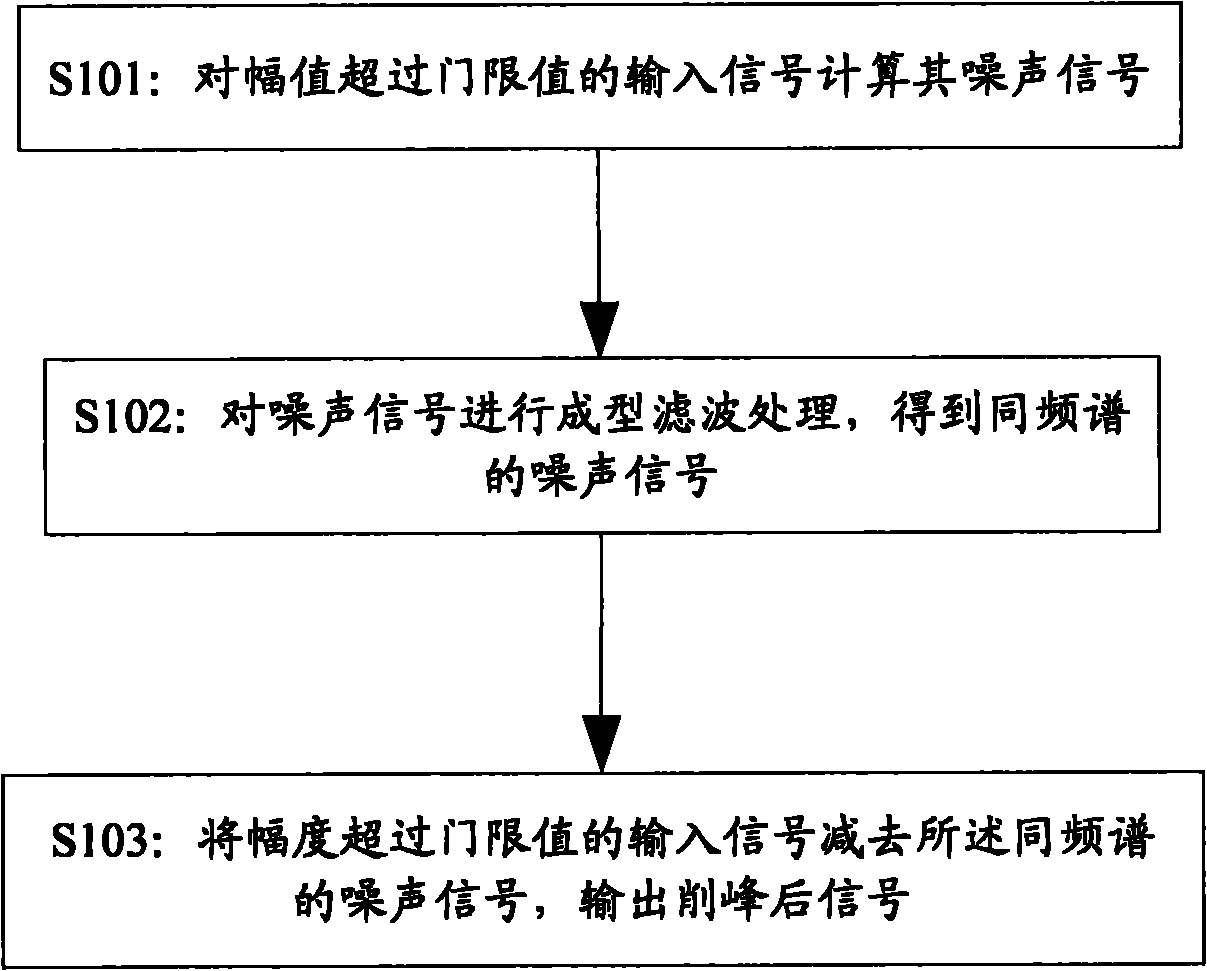

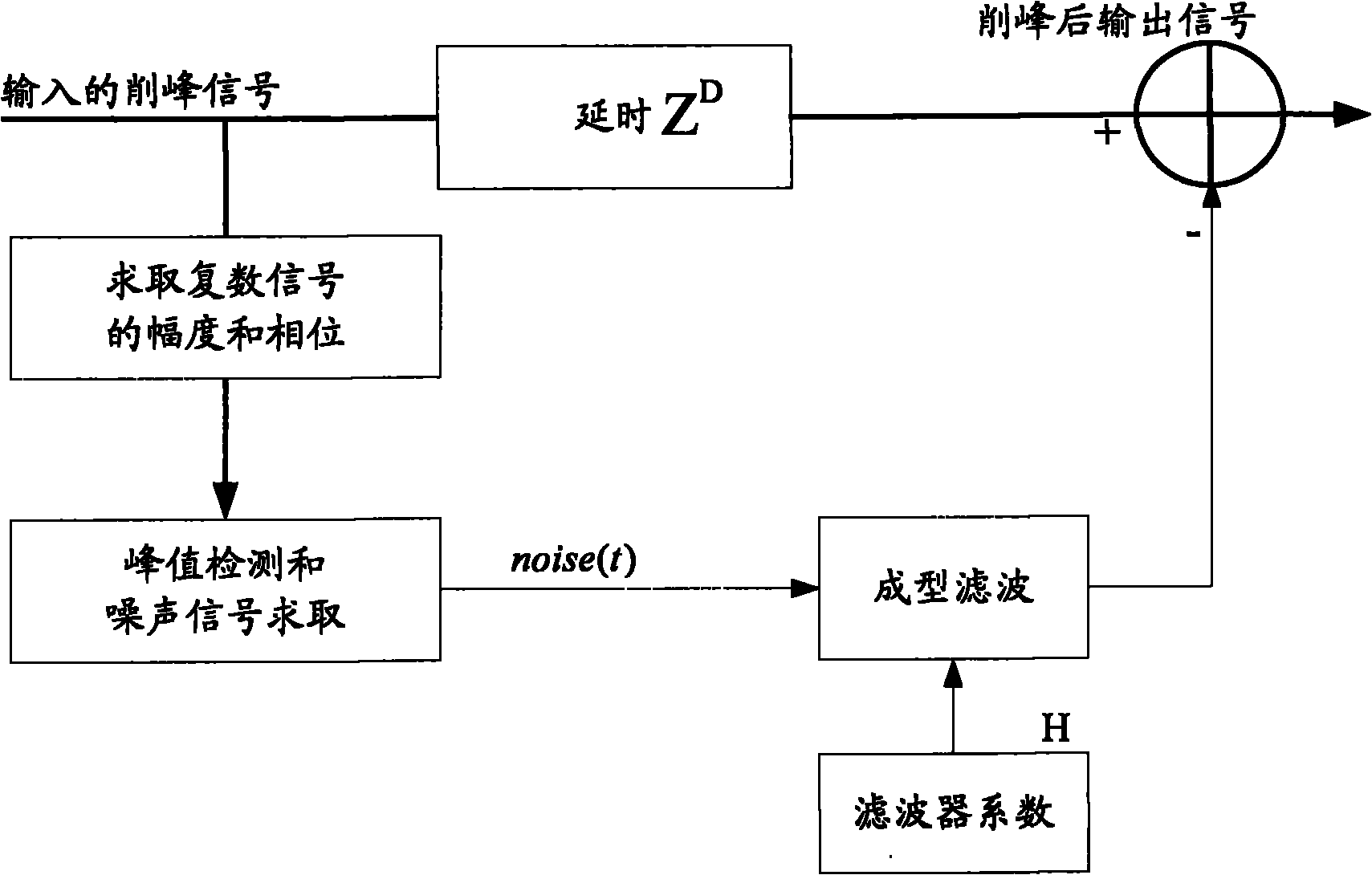

Signal crest trimming method and equipment

ActiveCN101867541ALower peak-to-average ratioEffective removalMulti-frequency code systemsFrequency spectrumFiltration

The invention discloses a signal crest trimming method, which comprises the following steps of: computing the amplitude and phase of an input signal x(t), and if the amplitude, which is represented as the absolute value of x(t), of the input signal x(t) exceeds a threshold, subtracting the threshold from the signal to obtain a noise signal; performing molding filtration on the noise signal to obtain a same-frequency spectrum noise signal; and subtracting the same-frequency spectrum noise signal from the input signal x(t) of which the amplitude exceeds the threshold, and outputting the crest-trimmed signal. The technical scheme of the invention has the advantages of simplicity, high efficiency, relatively lower hardware equipment resource consumption in particular realization, short processing time delay, and the capacity of effectively performing crest trimming on randomly appearing signal peaks exceeding the threshold so as to reduce the peak-to-average power ratio of the signal.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Membrane adsorbent for recycling nitrogen and phosphorus resources from waste water as well as preparation method and application thereof

InactiveCN102211018AImprove adsorption performanceEffective removalOther chemical processesClimate change adaptationFertilizerIon

The invention relates to a membrane adsorbent for recycling nitrogen and phosphorus resources from waste water. A doping method is adopted to uniformly distribute resin capable of selectively adsorbing nitrogen and phosphorous into a casting film solution, a wet phase separation method is adopted for preparation, the casting film solution comprises 10-30wt% of polymer, 10-35wt% of resin, 4-30wt% of additive and the balance of solvent; the membrane adsorbent comprises a flat membrane adsorbent and a hollow fiber membrane adsorbent; and the membrane adsorbent can be used for preparing magnesium ammonium phosphate as a slow release fertilizer, thus the recycling of nitrogen and phosphorus resources is realized. The invention has the advantages that: the surface of the membrane adsorbent is provided with an open pore structure, the water flux is higher, and the adsorption and desorption performances of nitrogen and phosphorous ions are good; the preparation method of the membrane adsorbent is simple, easy to implement, low in cost, environmentally-friendly, safe and reliable as well as easy for realization of large-scale application and popularization, thus the preparation method has practical industrial application significance.

Owner:天津森诺过滤技术有限公司

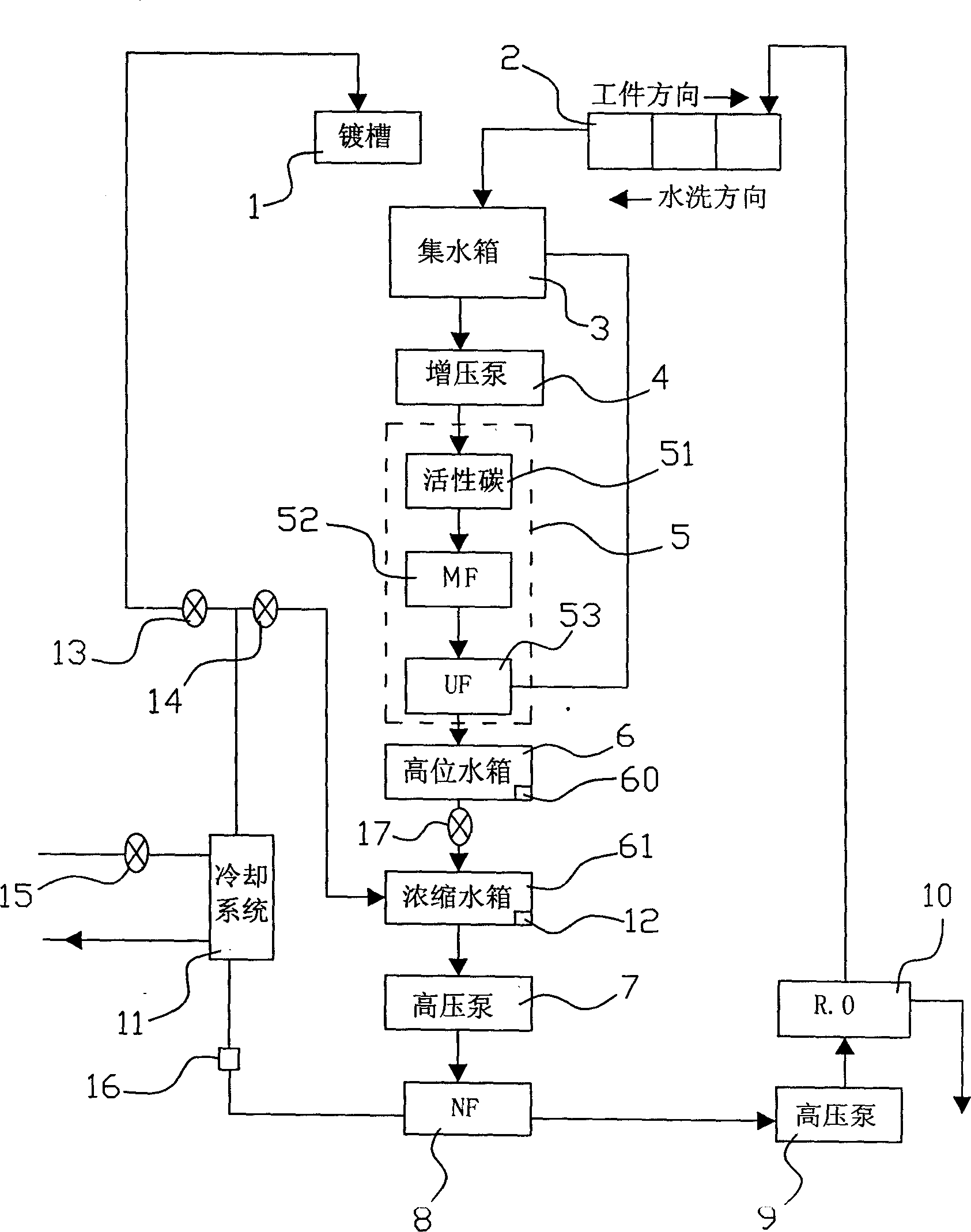

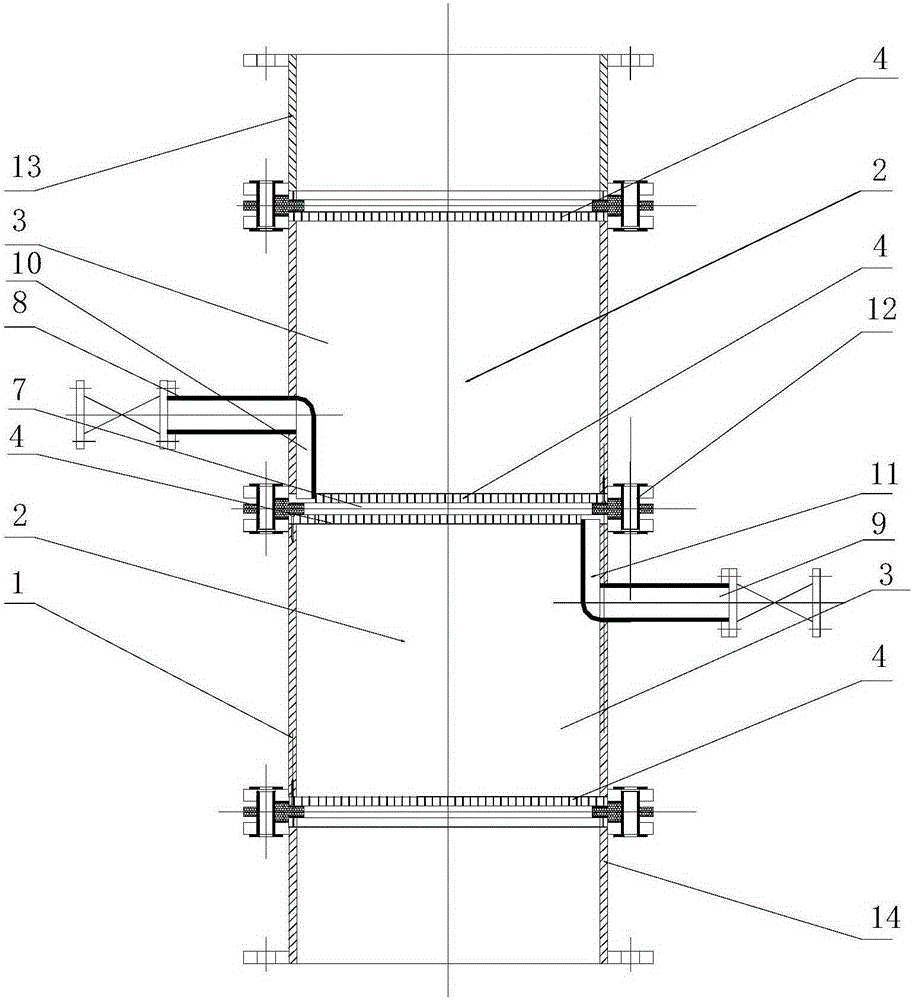

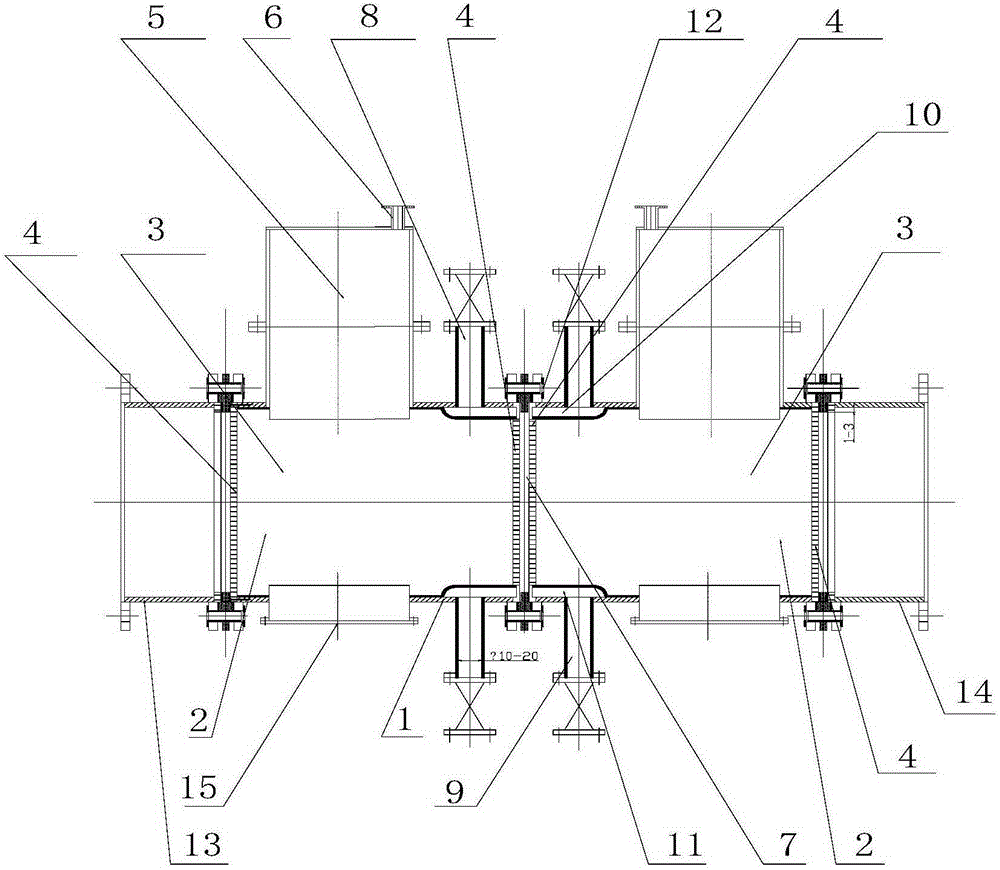

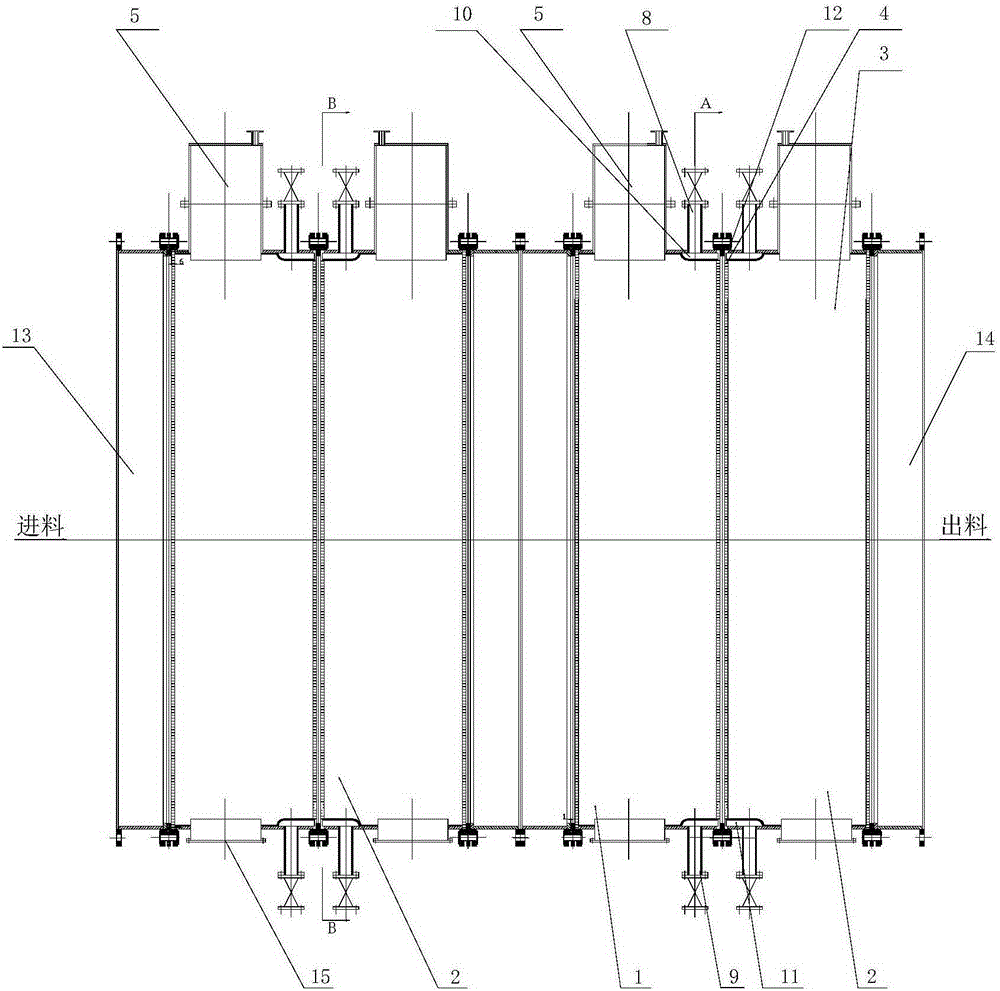

Circulation utilization technology and equipment for electroplating waste water separated by integrated membrane

InactiveCN1868925AEffective removalReduce manufacturing costWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemistryHeavy metals

An integrated membrane separating process for cyclic use of the electroplating sewage includes such steps as pre-treating for removing the micro-molecular organic substances and suspended substance, class-one separation by using nano-class membrane filter to intercept the concentrated liquid containing heavy metal and reuse it in electroplating bath, and class-two separation by using the reverse osmosis membrane to reuse the transmission liquid in rinsing bath and draining the concentrated liquid containing one-valence cations. Its apparatus is composed of water collecting tank, pre-treating module, nano-filter membrane module and membrane module.

Owner:XIAMEN LEEBAM MEMBRANE TECH

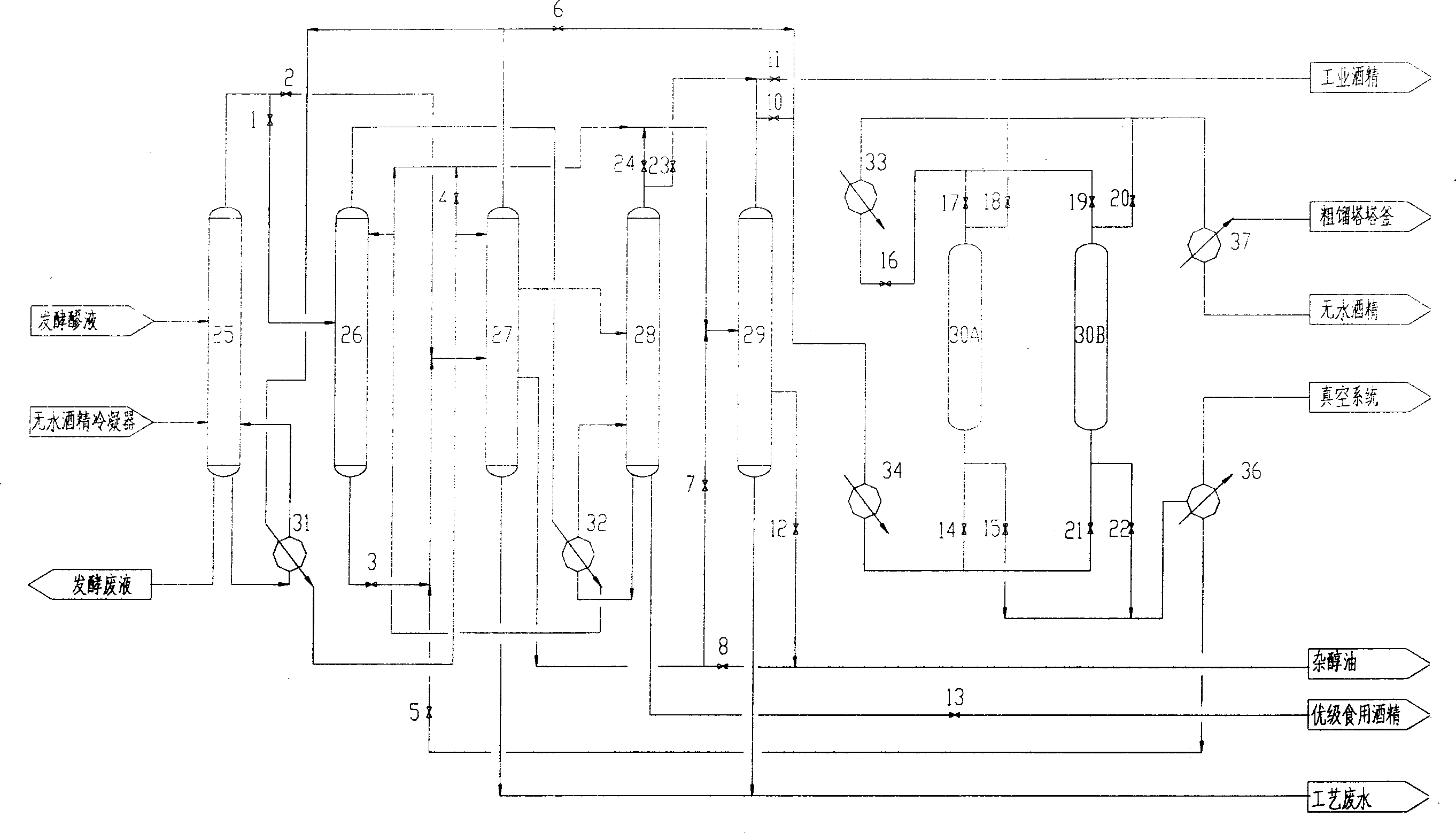

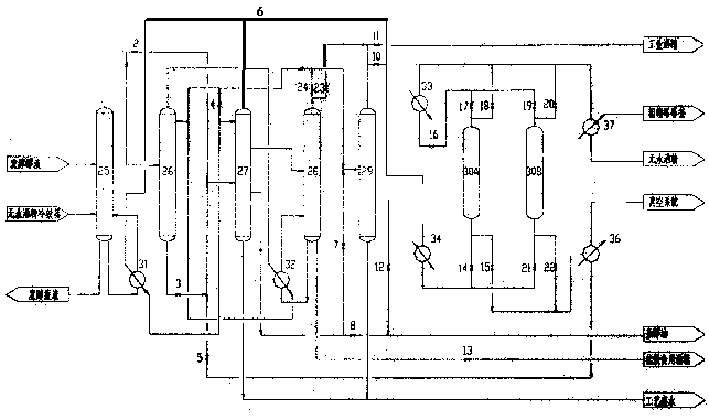

Alcohol refining process for producing several products

InactiveCN1380274AEasy to separateEffective removalOrganic compound preparationHydroxy compound separation/purificationAlcoholTower

The anhydrous alcohol and edible alcohol simultaneous production equipment includes fractionating rectification tower, aldehyde-removing tower, refining tower, methanol-removing tower, recovering tower and adsorption tower, between all the towers there are valves and correspondent pipelines, also includes condenser, reboiling device and preheater. Said ivnention utilizes the raw material liquor containing 5-30 percent alcohol to produce required alcohol by means of opening required tower and controlling required valve according to the requirements. Said technological process can respectively and simultaneously produce various alcohols.

Owner:TIANJIN UNIV

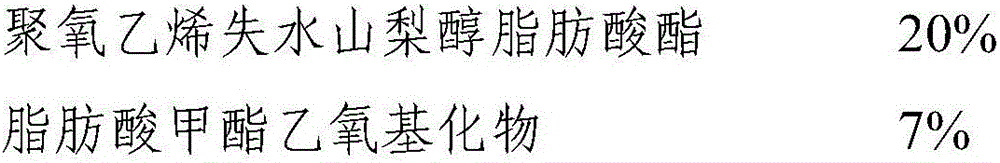

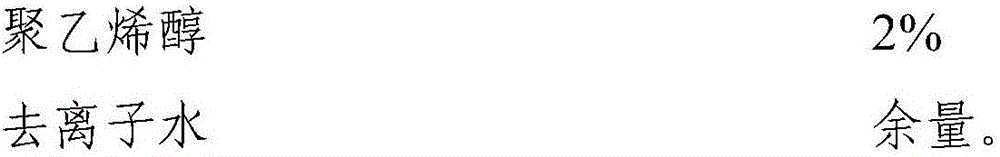

Dewaxing cleaning liquid as well as preparation method and application thereof

InactiveCN105779151AEffective removalGood cleaning performanceNon-ionic surface-active compoundsOrganic detergent compounding agentsWaxSolvent

The invention relates to a dewaxing cleaning liquid as well as a preparation method and application thereof. The dewaxing cleaning liquid comprises the following active components in parts by weight: 5-70 parts of an efficientnonionic surfactant, 0.1-20 parts of a low-foam foam-inhibiting type surfactant and 1-20 parts of a dispersion stabilizer. The dewaxing cleaning liquid provided by the invention is obtained by compounding the efficientnonionic surfactant, the low-foam foam-inhibiting type surfactant and the dispersion stabilizer, and has the following propertyadvantages when being compared with a conventionalindustrial product: 1, the cleaning property is good, and the service life is prolonged by more than 20% when being compared with that of a conventional dewaxing liquid (generally the requirement is 60 pieces / L); 2, the dewaxing cleaning liquid is environmentally friendly and free of pollution, small in volatilization loss when being compared with a solvent dewaxing liquid, and is harmless for human bodies and environments; 3, the cleaning effect is good, the wax can be stably retained in dewaxing cleaning liquid for a long time and is not easy to be layered or separated, and granular muddy matters which can interfere the cleaning effect can be avoided; 4, the dewaxing cleaning liquid has no or a small amount of foams, when being filled into a cleaning tank or mechanically stirred, the dewaxing cleaning liquid does not generate a great amount of foam, and thus convenience can be brought to manual operation.

Owner:BEIJING POLYSTAR HITECH CO LTD

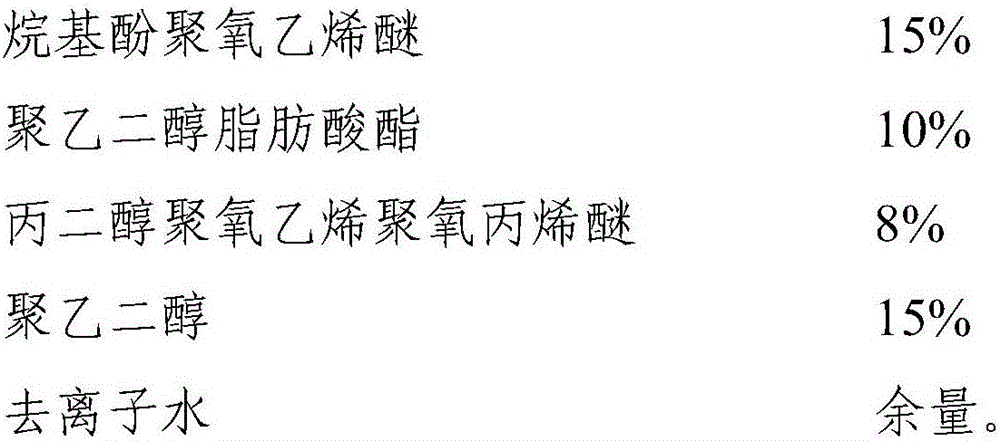

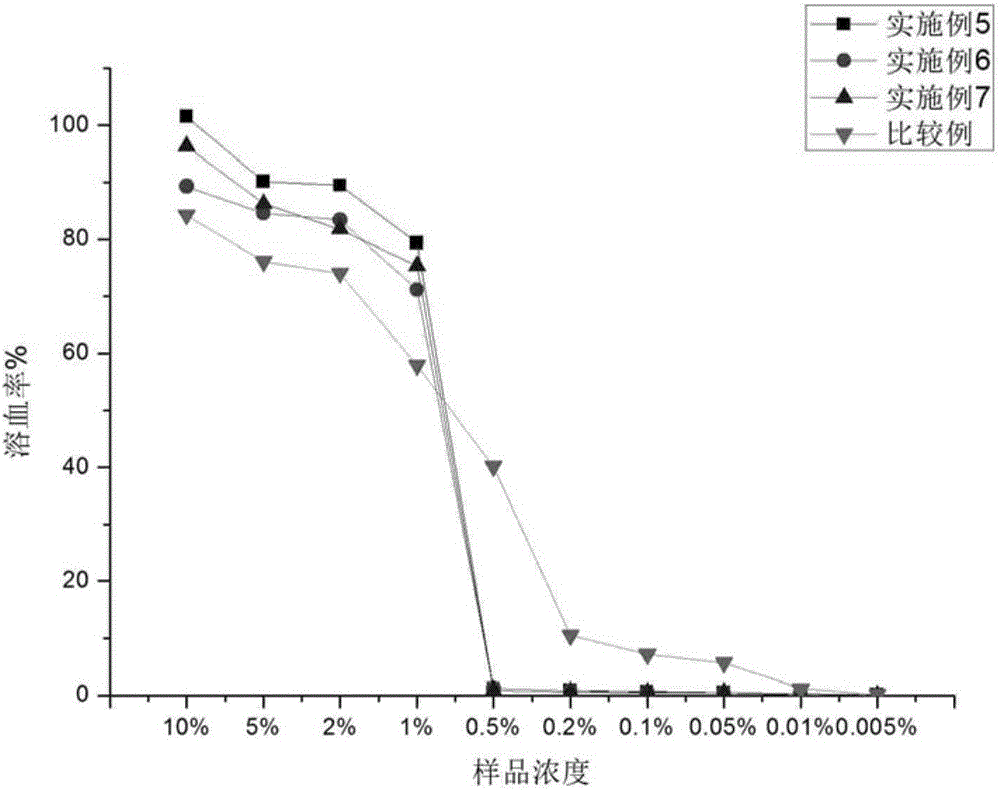

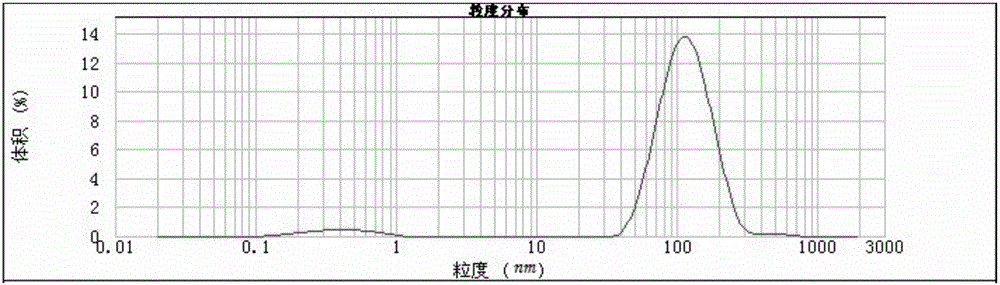

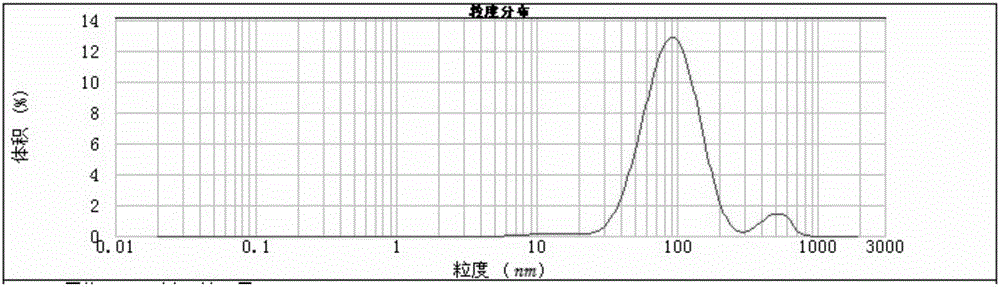

Make up removal micelle composition and preparing method and application in cleansing water thereof

InactiveCN106726770AGood makeup removerEffective removalCosmetic preparationsMake-upChemistryDipropylene glycol

The invention discloses a make up removal micelle composition. The make up removal micelle composition is prepared, by mass, 0.1-20 % of modified fat containing polyethylene glycol chain segments, 0.1-20 % of nonionic surfactant, 0.1-10 % of dipropylene glycol and the balance water. The preparing method of the make up removal micelle composition comprises the steps of mixing polyethylene glycol modified fat with the nonionic surfactant and dipropylene glycol in a water medium according to the ratio to form the micelle composition on the condition of normal temperature. The make up removal micelle composition has the advantages that a micelle solution with a certain partical size range is formed, the using quantity of the modified fat is reduced, make up removal is conducted effectively, and meanwhile stimulation generated by the modified fat to the skin caused by infiltration is reduced; the micelle composition can be used for preparing wild and non-irritant cleansing water, can be used for make up removal of the eye and lip, is good in make up removal effect and convenient to use, and does not need to be washed with water, and the skin is not dry and tight after using the micelle composition.

Owner:GUANGZHOU HUANYA COSMETIC SCI & TECH CO LTD

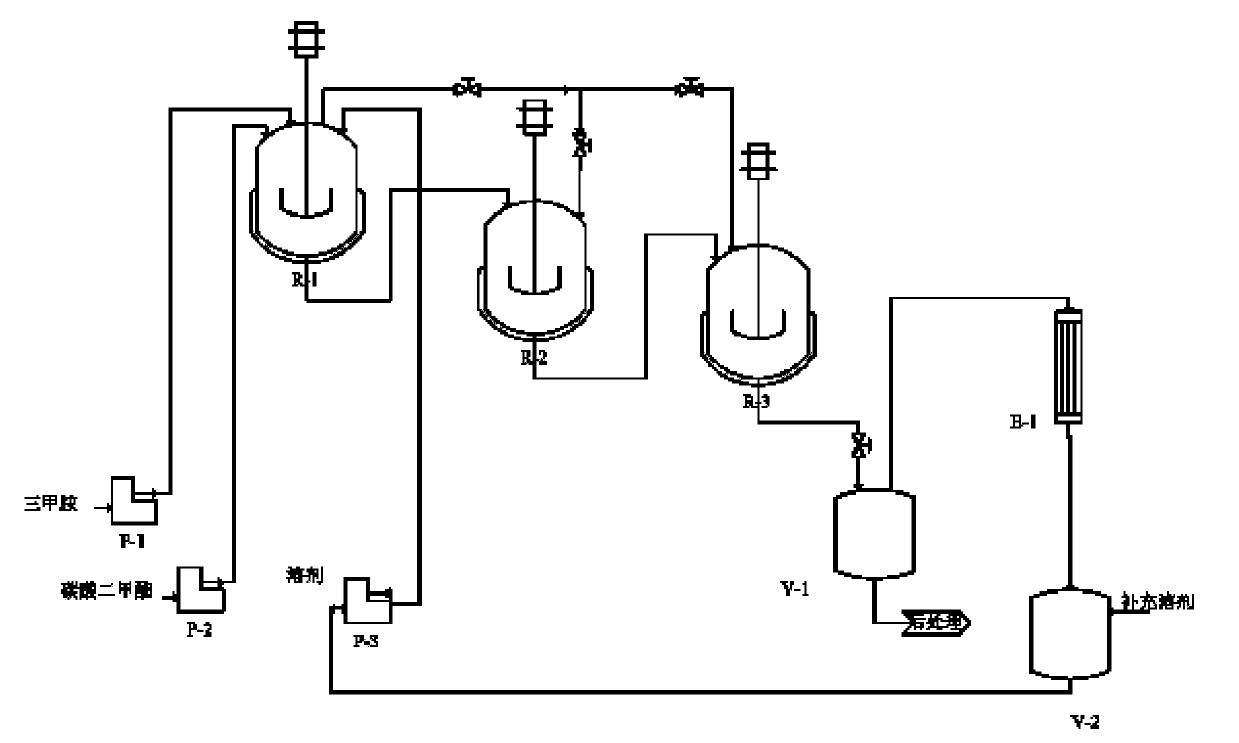

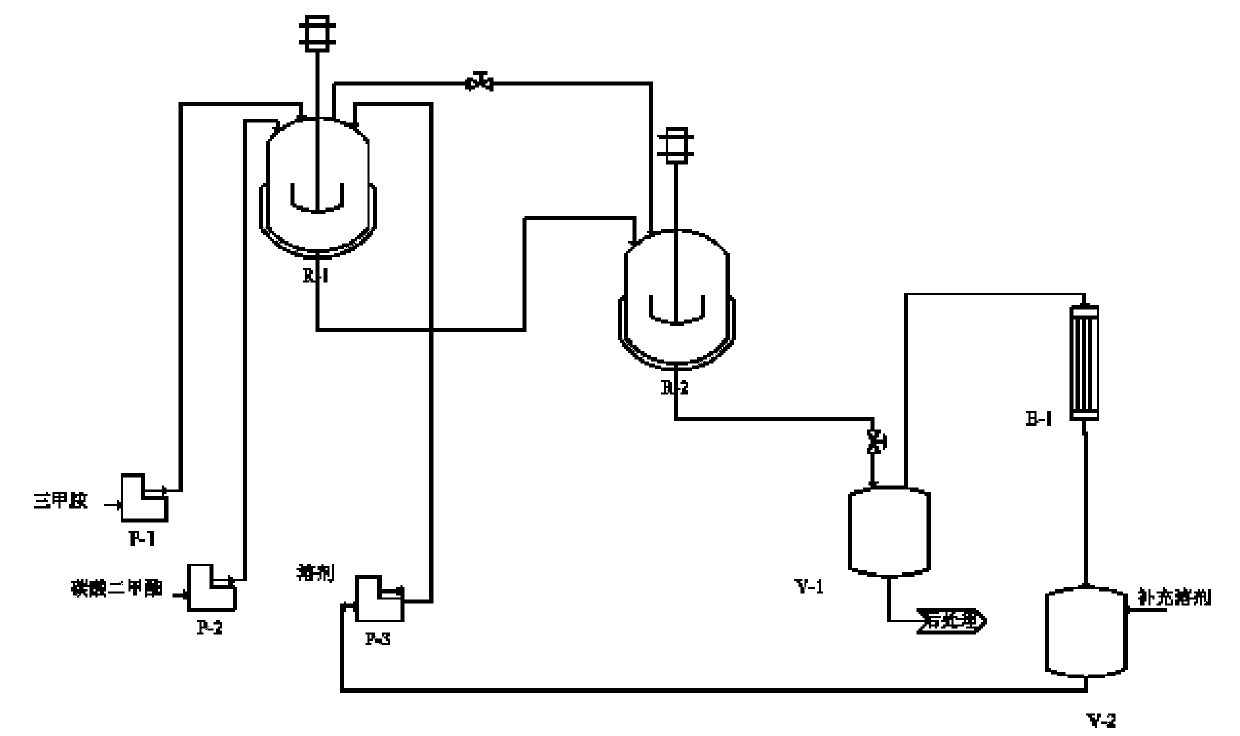

Method and device of continuously synthesizing tetramethyl ammonium carbonate by multi-reactors in series

InactiveCN101992055ASimple designMild reaction conditionsAmino preparation from aminesChemical/physical/physico-chemical stationary reactorsAutomatic controlGas phase

The invention discloses a method and a device of continuously synthesizing tetramethyl ammonium carbonate by multi-reactors in series. Liquid-phase reaction materials in each reactor are connected in series through a pipeline. Gas-phase reaction materials are connected in parallel to keep the pressure between reactors balanced. The reaction materials flow into a next stage reactor from a previousstage reactor through the difference of liquid level in the reactors. The two stage reactors have a difference of liquid level of 0.5-1.0 m. The tetramethyl ammonium carbonate is prepared by continuously adding raw materials including dimethyl carbonate, trimethylamine and solvent methanol to a first stage tank reactor in a mole ratio of 1:0.8:3-1:1.5:8, leading a reaction mixture to continuouslyflow out from the last stage tank reactor, recycling a reaction solvent and an unconverted reactant by flash evaporation, then re-adding to the first stage tank reactor for recycling, and finally removing the solvent and the unconverted reactant. The operation pressure of the invention is the lowest, the reaction is stable, and continuous operation and automatic control are realized. Simultaneously, the reaction materials are heated to a reaction temperature by reaction heat, so the energy is saved and the production cost is reduced.

Owner:CANGZHOU SUNHEAT CHEM

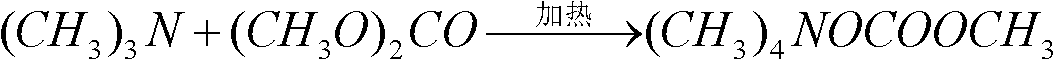

Anti-eavesdropping anti-monitoring device

InactiveCN105162941AGuaranteed to workEnsure safetyEavesdropping prevention circuitsTelevision systemsMonitor equipmentEavesdropping

The invention brings forward an anti-eavesdropping anti-monitoring device. The anti-eavesdropping anti-monitoring device comprises a central processor, a controller, a liquid crystal screen, a wireless signal detector, an electronic signal jammer, a signal detection switch, a signal interference switch and an equipment total switch. The signal detection switch, the signal interference switch and the equipment total switch are respectively connected with the input end of the controller; the controller is in bidirectional connection with the central processor; the wireless signal detector is in bidirectional connection with the central processor; the electronic signal jammer is connected with the output end of the central processor; and the liquid crystal screen is connected with the output end of the controller. The anti-eavesdropping anti-monitoring device has the following advantages: the position of eavesdropping and monitoring equipment can be accurately found and effectively removed, and environmental safety of a space area requiring inspection is guaranteed; and for the eavesdropping and monitoring equipment which cannot be removed, operation of the equipment can be interfered, recordings and videos of the equipment are enabled to be invalid, and the security of highly confidential conference content, file data and the like of enterprises and the like is ensured.

Owner:品晖(河北)人力资源服务有限公司

Sterilization and disinfection preparation for pigsty

InactiveCN105211131AEffective removalGuarantee the living environmentBiocideDisinfectantsTheophyllineDandelion

A sterilization and disinfection preparation for pigsty is made from the following weight components by weight: 5 parts of tourmaline powder, 5 parts of glyceryl behenate, 10 parts of quick lime, 3 parts of theophylline, 3 parts of curcumin, 3 parts of citric acid, 10 parts of persimmon leaf, 15 parts of camphor, 20 parts of crowndaisy chrysanthemum, 15 parts of loquat leaf, 10 parts of licorice, 5 parts of setose abelmoschus leaf, 15 parts of willow leaf, 5 parts of pepper leaves, 5 parts of dandelion, 5 parts of pomegranate seed, 10 parts of Zizania latifolia leaves, 25 parts of Linden peel, 5 parts of garlic, 5 parts of chestnut leaf, 5 parts of Cymbopogon citratus., 5 parts of India canna flower, 5 parts of mint leaves, 5 parts of seaweed, 5 parts of lily, 5 parts of Schizonepeta and 500 parts of distilled water. The deodorant can effectively eliminate smelly substances of pig feces, and has the sterilization function; besides the removal of fecal odor, the preparation preserves the survival environment to some extent, and keeps fresh air. The preparation uses easily available raw materials, and has low production and usage cost.

Owner:郎溪县凌达养猪专业合作社

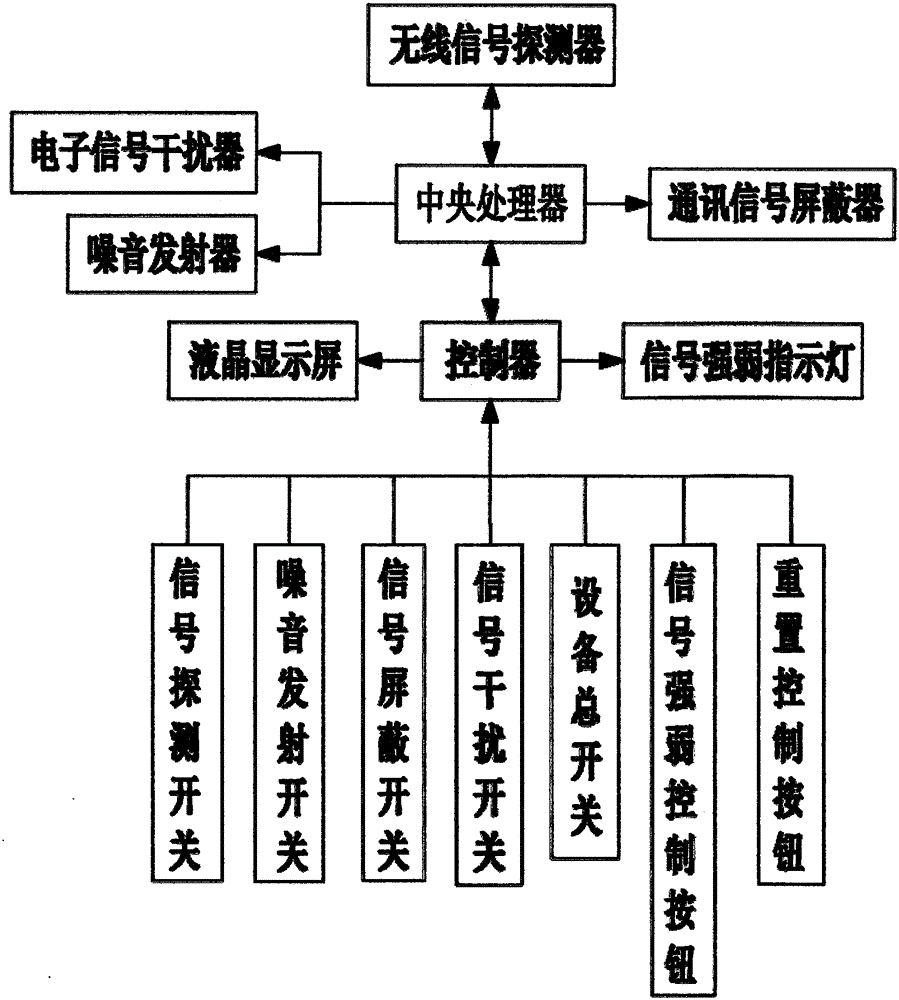

Steel rail profile outlier detection and effective profile recognition method

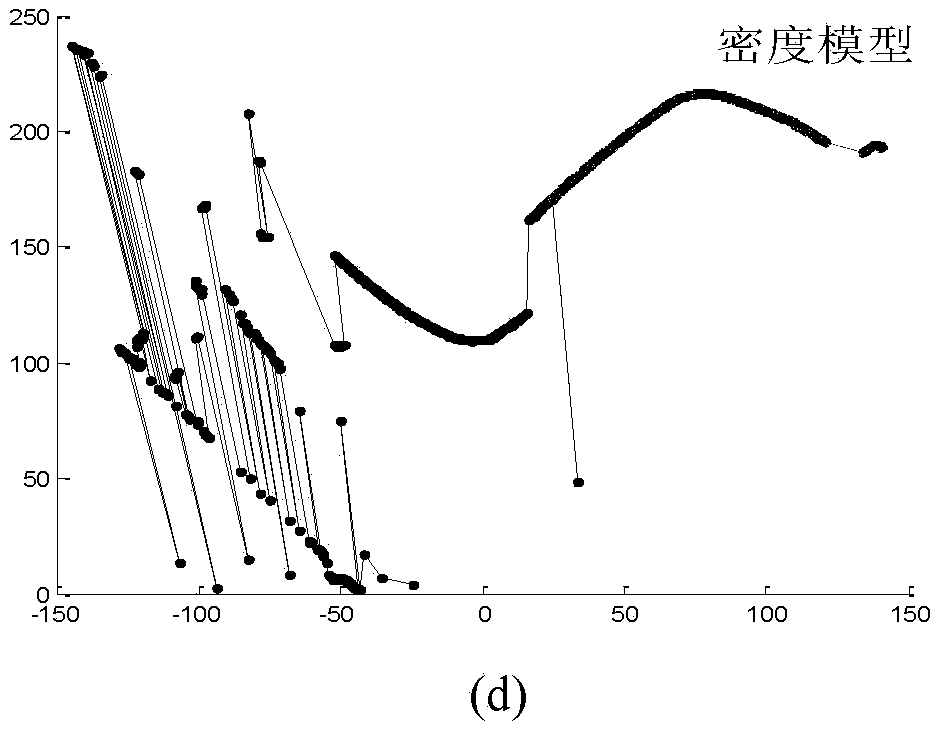

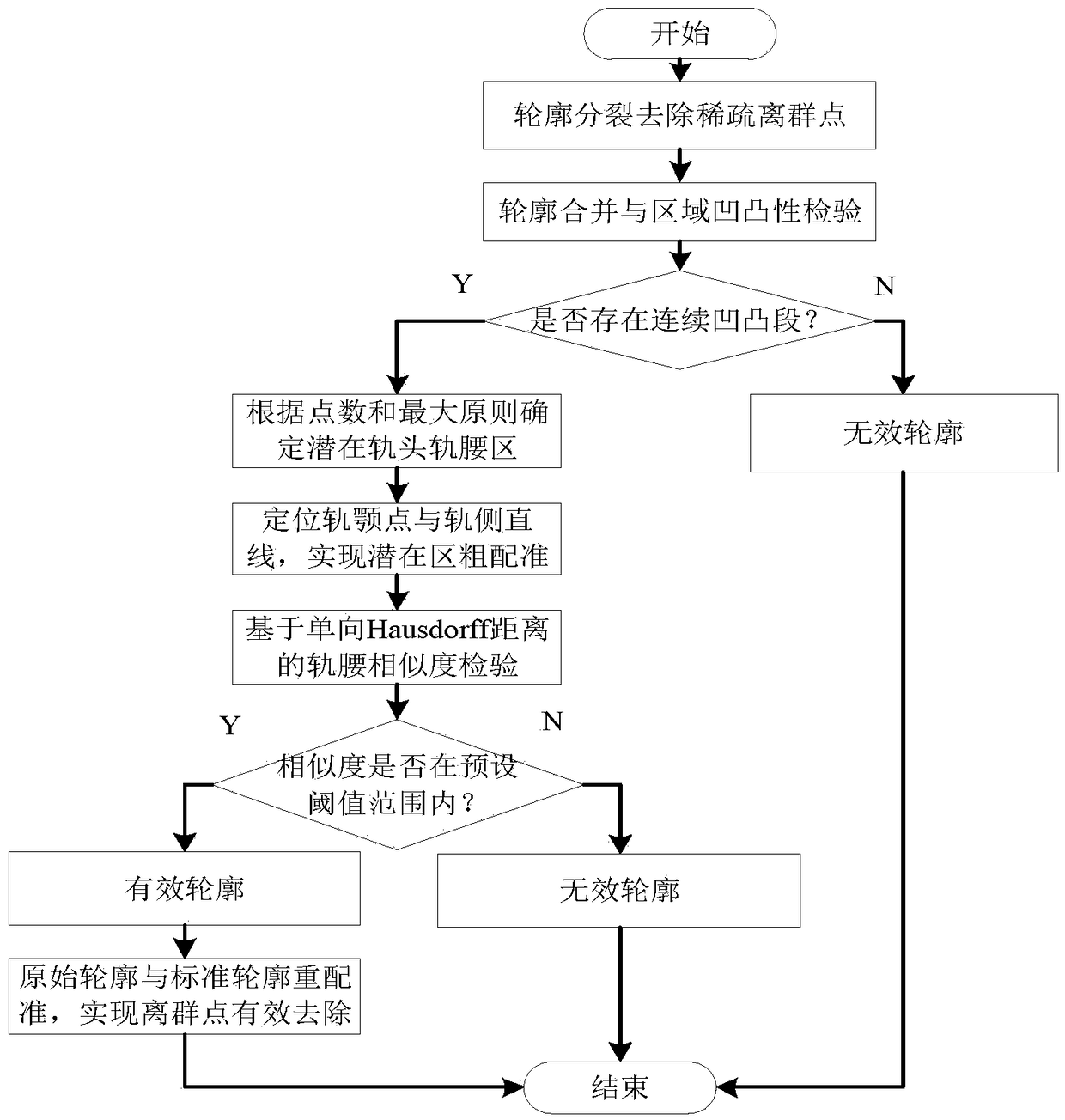

ActiveCN108931206AEffective removalEfficient removalUsing optical meansRailway auxillary equipmentRecognition algorithmOutlier

The invention discloses a steel rail profile outlier detection and effective profile recognition method. In view of a problem that seriously erroneous abrasion calculation is caused by the mismatch between a measured profile and a standard profile due to the outlier and profile diversity in an actual test in a railway line, an outlier detection and fast effective profile recognition algorithm based on profile coarse registration is provided. The algorithm comprises first splitting a profile curve, and eliminating most of sparse outliers in the curve; merging the remaining profile segments andmerging the profile segments belonging to the same region into one segment; performing a regional convexity-concavity test, determining a potential rail-head rail-web area according to continuous convexity-concavity and a maximum point number principle, and realizing the coarse registration of the potential area and the standard profile; finally recognizing the effective profile according to the rail web similarity between the two profiles after registration. On this basis, the method re-registers the original measured profile with the standard profile, and removes the outliers according to the relative distance between the profiles.

Owner:HUNAN UNIV

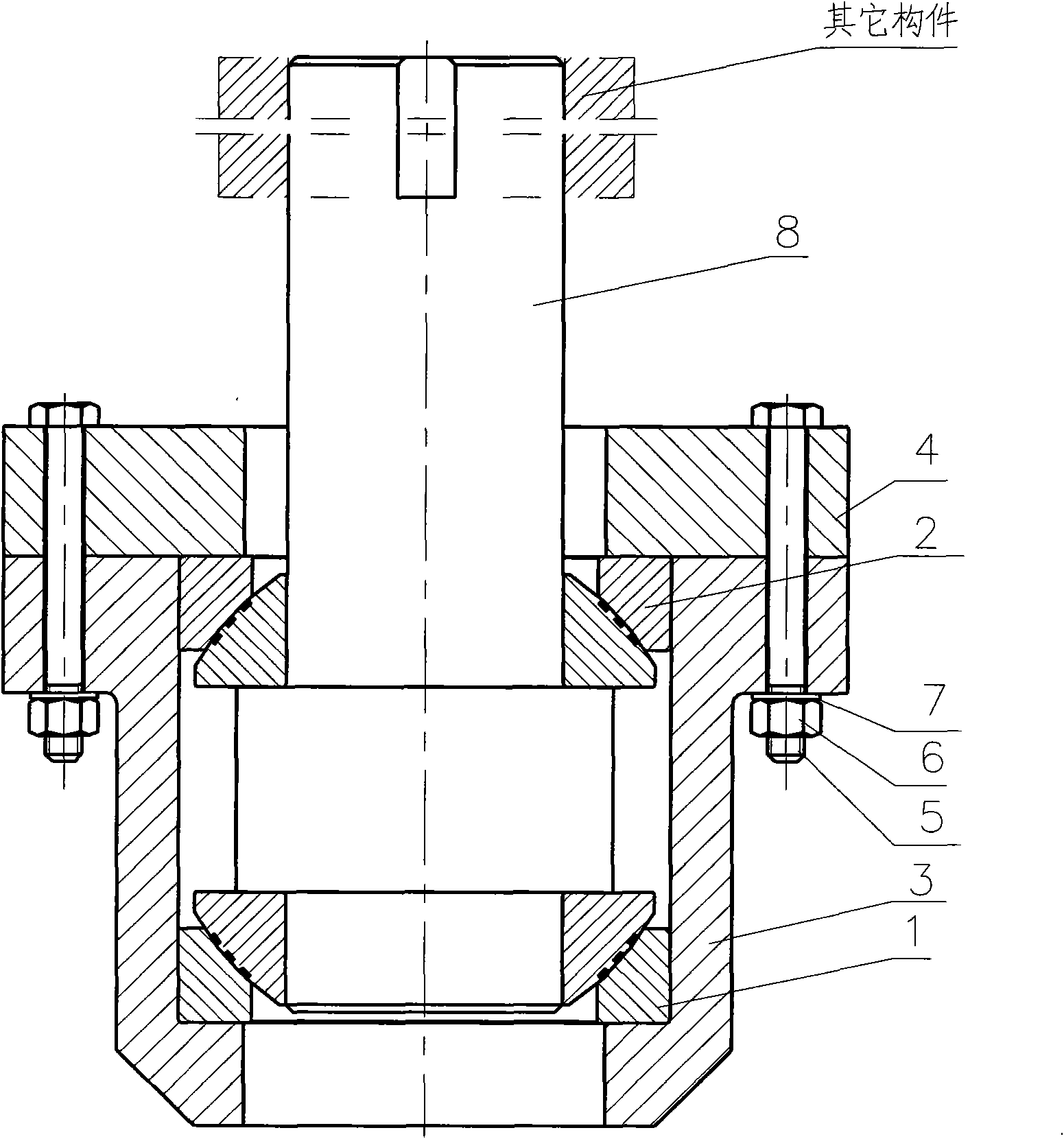

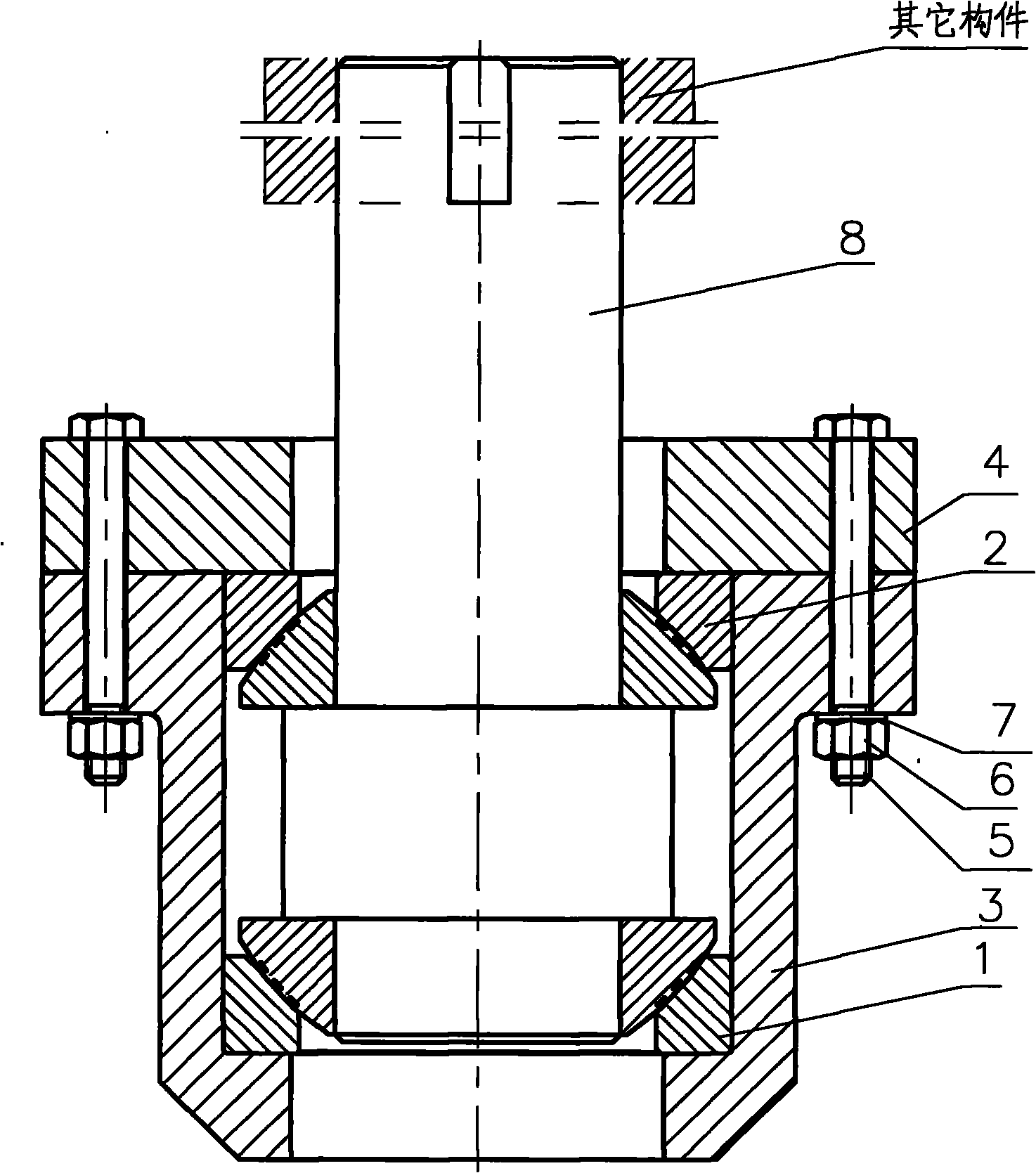

Hardware universal hinging unit

InactiveCN101806325AWith anti-rust functionEffective removalYielding couplingShear forceBending moment

The invention discloses a hardware universal hinging unit, which consists of a pair of thrust articulated bearings, a mandrel, a fixed base, a fixed cover plate, a bolt, a nut and a washer. The pair of thrust articulated bearings are matched and connected with the mandrel; housing washer excircles of the pair of thrust articulated bearings are matched with an inner bore of the fixed base; the fixed cover plate is pressed on the housing washer of one of the thrust articulated bearings and locked with each other through the bolt, the nut and the washer to form the hinging unit; a fitting surface between the thrust articulated bearings and the housing washer is a spherical surface and the two can be relatively rotated, so a member connected with the other end of the mandrel and a member connected with the end of the fixed base can be rotated in all directions in the circumference; a hinging function node with multi-direction rotation is realized, surface outer shearing force or additional bending moment loaded on the hardware can be effectively unloaded, and the safety of a building element is ensured; and the thrust articulated bearings are made of stainless steel, so the hardware universal hinging unit has a rust-proof function.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

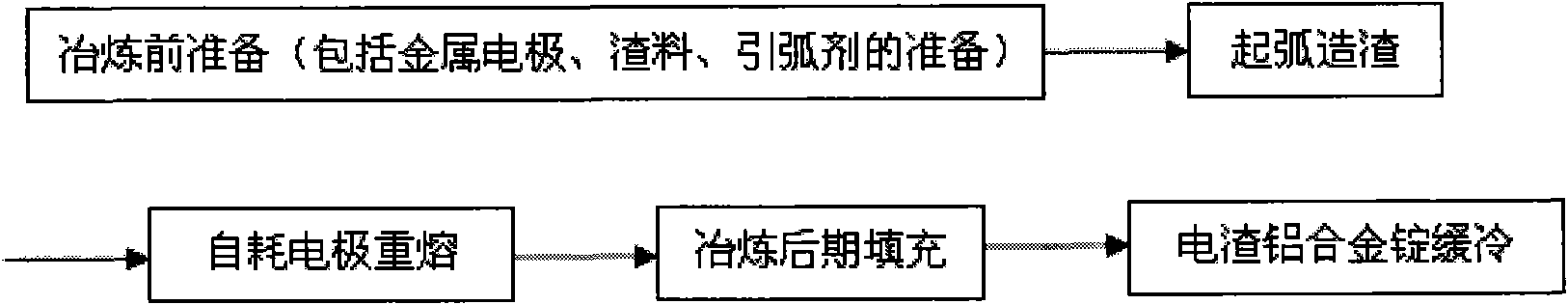

Method for removing silicon out of aluminium alloy

The invention relates to a method for removing silicon out of aluminium alloys, which belongs to the technical field of metal materials. The method comprises the following steps: pouring aluminium alloys into consumable electrode bars; putting the consumable electrode bars into an electroslag furnace, and adding slag into the electoslag furnace for remelting; cutting off the power supply after melting, and cooling the mixture to obtain aluminium alloys. The slag is one of the following compounds in percentage by weight: 5 to 30 percent of MgF2 plus 30 to 40 percent of KCl plus 30 to 60 percent of MgCl2, 5 to 30 percent of MgF2 plus 30 to 40 percent of KCl plus 30 to 60 percent of NaCl, 100 percent of Na3AlF6, 10 to 30 percent of Na3AlF6 plus 30 to 40 percent of KCl plus 30 to 60 percent of NaCl, 10 to 30 percent of Na3AlF6 plus 30 to 40 percent of KCl plus 30 to 60 percent of MgCl2, 5 to 30 percent of CaF2 plus 30 to 40 percent of KCl plus 30 to 60 percent of CaCl2 and 5 to 30 percent of CaF2 plus 30 to 40 percent of KCl plus 30 to 60 percent of NaCl. The method is simple, and can effectively remove the low-consistency impurity silicon out of aluminium alloys without introducing new impurities.

Owner:SHANGHAI JIAO TONG UNIV

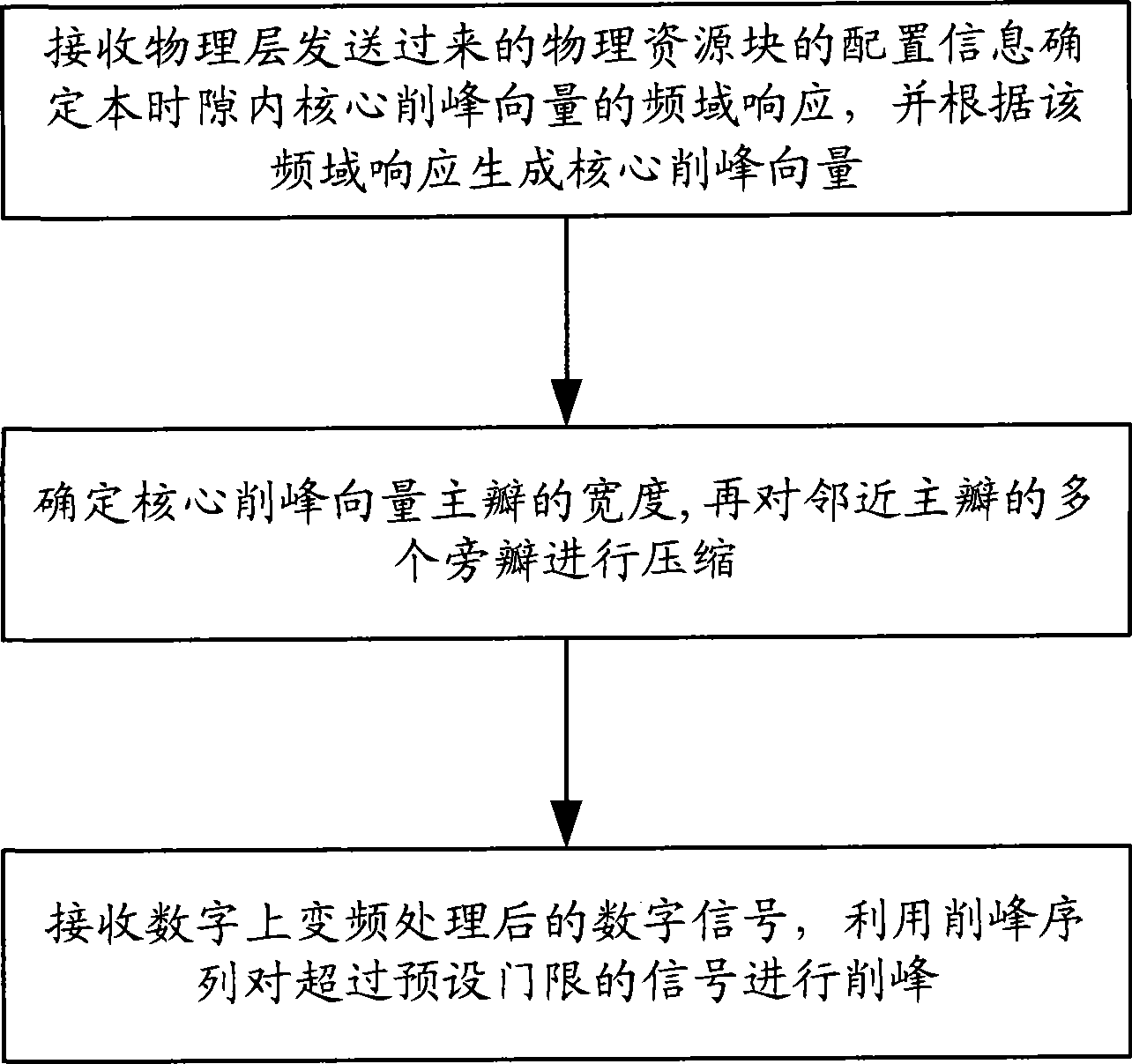

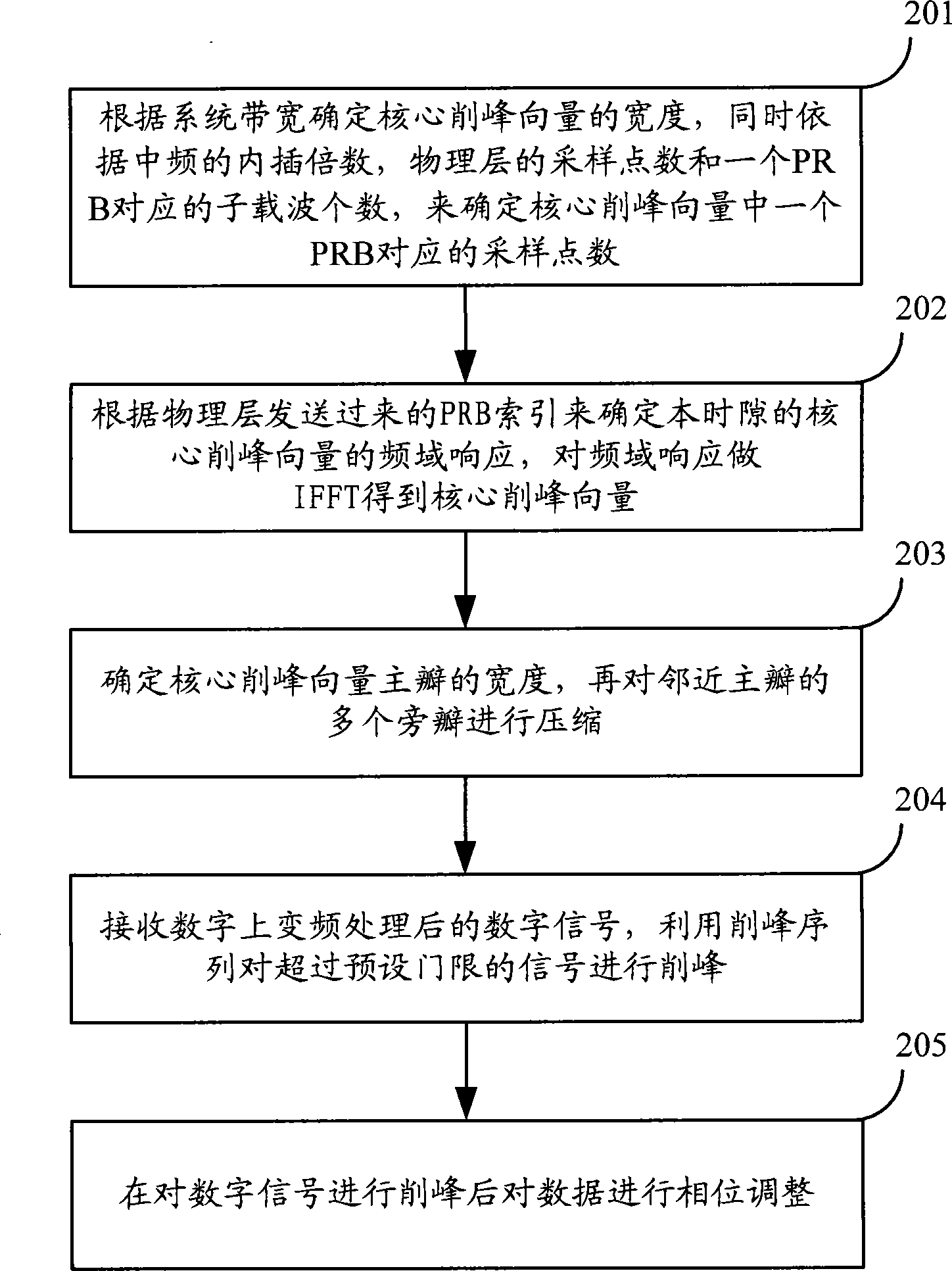

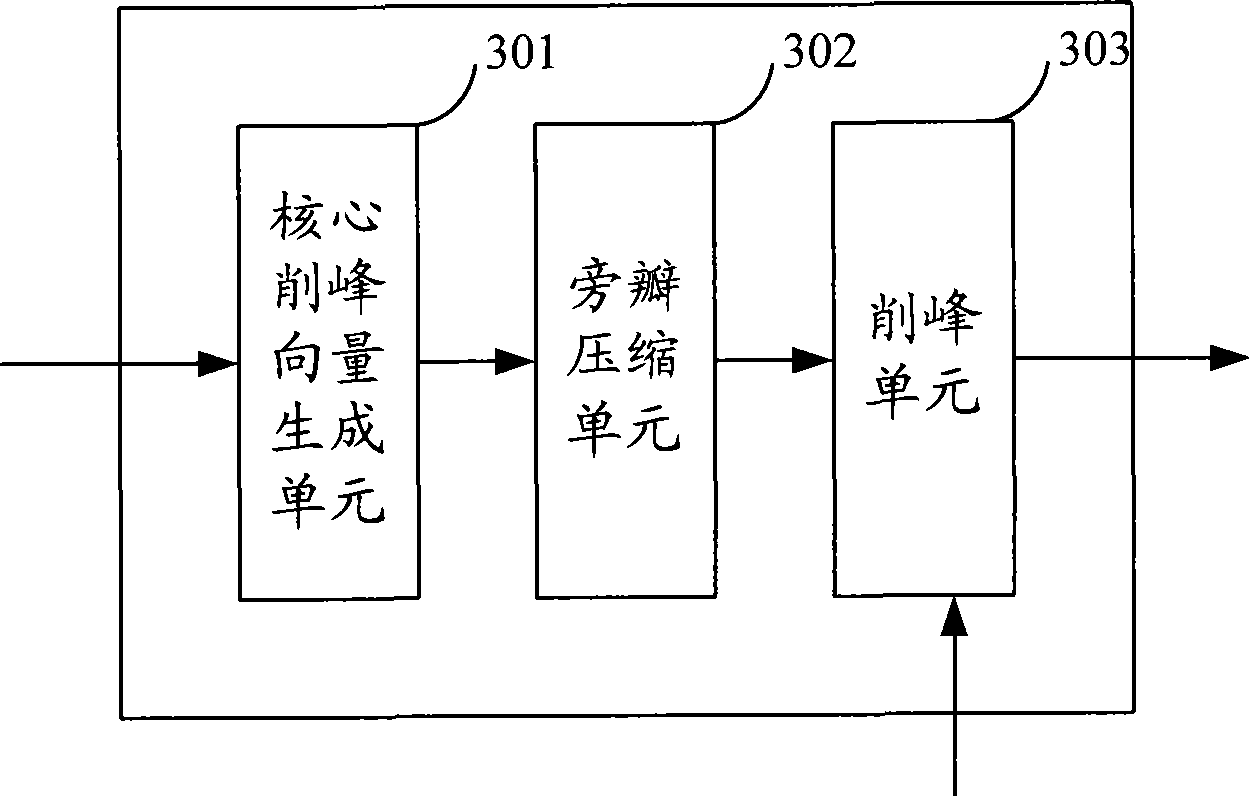

Digital despicking method and device

ActiveCN101369998AEffective removalAvoid BER deteriorationMulti-frequency code systemsResource blockFrequency conversion

The invention provides a digital peak clipping method which comprises: receiving configuration information of physical resource block transmitted by physical layer, determining frequency domain response of core peak clipping vector in present time slot, generating core peak clipping vector according to frequency domain response, determining main lobe width of core peak clipping vector, then compressing multiple side lobes adjacent to main lobe, receiving digital signal after frequency conversion processing, performing peak clipping to signal exceeding in preset threshold utilizing peak clipping sequence. The invention also provides a digital peak clipping device. The inventive method and device utilize physical resource block index for determining core peak clipping vector and compress side lobe of core peak clipping sequence, perform peak clipping for digital signal using compressed core peak clipping vector and preset threshold and then effectively removes all peak point above threshold and can not result in peak resurge, compress side lobe to limit the BER deterioration in a certain degree after peak clipping.

Owner:DATANG MOBILE COMM EQUIP CO LTD +1

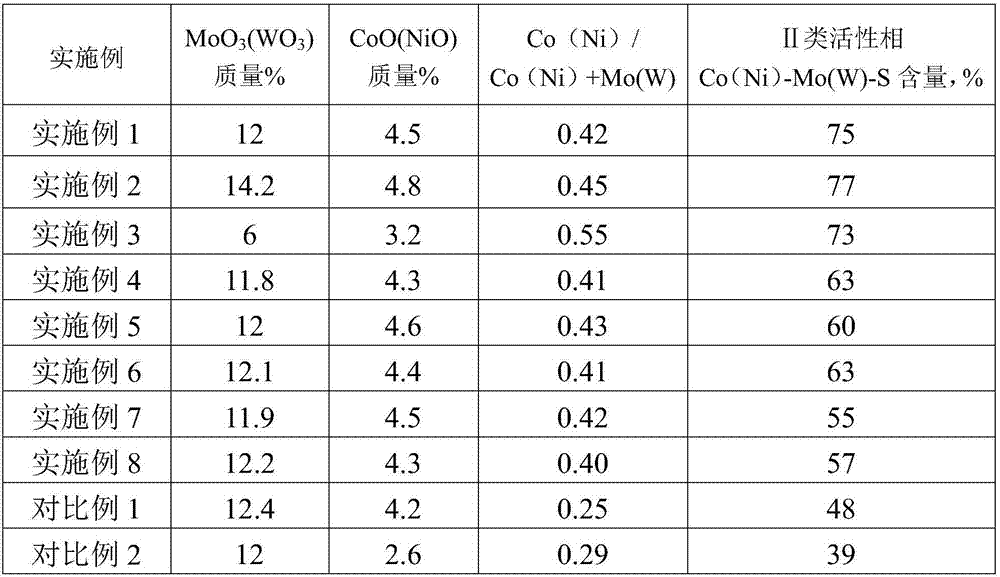

Vulcanization type hydrogenation catalyst and preparation method thereof, and gasoline hydrodesulfurization method

ActiveCN107999092AEffective removalPhysical/chemical process catalystsHydrocarbon oils treatment productsActive phaseAmmonium

The invention relates to the field of hydrofining, and discloses a vulcanization type hydrogenation catalyst and a preparation method thereof, and a gasoline hydrodesulfurization method, wherein an atom ratio of the active metal component A to the sum of the active metal component A and the active metal component B is more than 0.3, and the II-type active phase A-B-S content is more than 55%. According to the preparation method, a molar ratio of the precursor of the active metal component A to the precursor of the active metal component B is 0.6-2.3:1, and the precursor of the active metal component B is an ammonium thioate. According to the present invention, with the application of the vulcanization type hydrogenation catalyst in the gasoline hydrodesulfurization, the mercaptan can be effectively removed at the low reaction temperature under the low reaction pressure in the case of the low octane number loss.

Owner:CHINA PETROLEUM & CHEM CORP +1

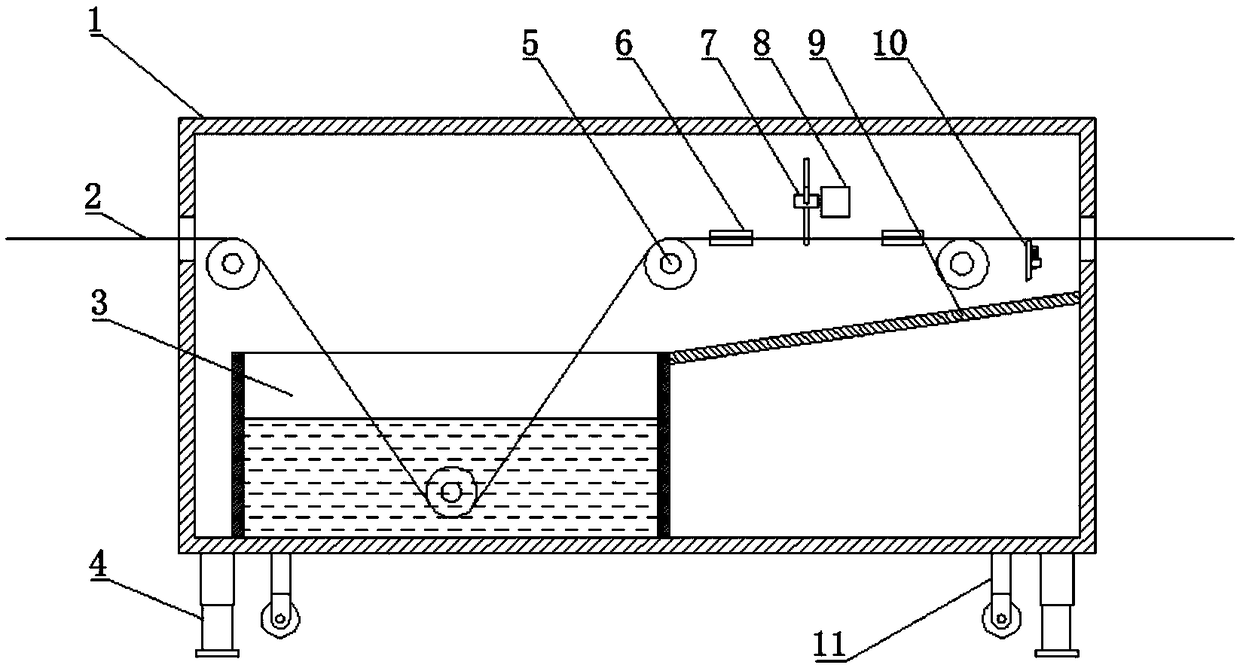

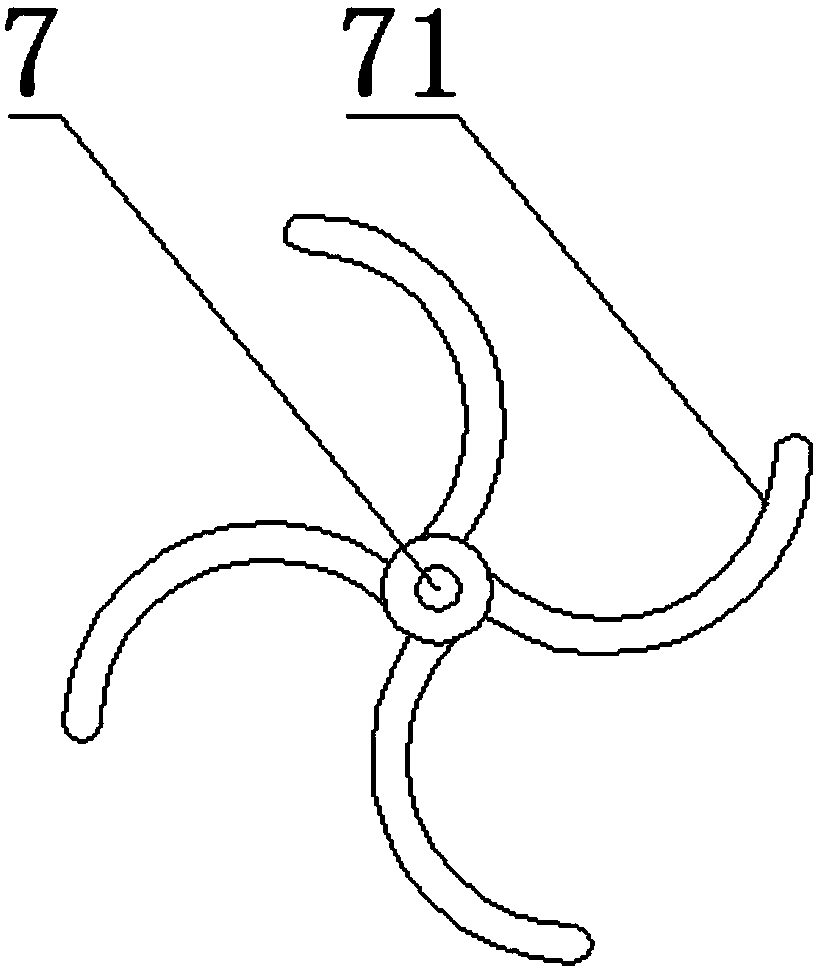

Oiling device for sewing thread production

PendingCN108708106ASimple structureEffective removalTextile treatment machine partsLiquid/gas/vapor removal by scrapingPetroleum engineering

The invention discloses an oiling device for sewing thread production, comprising a box body, a sewing thread, an oil basin, a plurality of guide wheels, and a motor. The guide wheels are arranged inside the box body from left to right. The sewing thread is passed around the guide wheels in sequence. The oil basin is arranged, close to the left end, inside the box body; a return oil plate inclinedto the upper right corner is arranged on the right side of the oil basin; the sewing thread is passed through the oil basin in V form. A stir wheel is arranged at the horizontal part of the sewing thread, a stir rod in arc shape is arranged on the stir wheel, the sewing thread can be stirred, and therefore, the sewing thread vibrates severely to throw off surplus oil from the sewing thread. An oil scraping mechanism scrapes oil for the sewing thread so that environment pollution due to oil that is brought out and resource waste due to the same cause are avoided. The surplus oil on the sewingthread is effectively removed via the simple structure; the height of the oiling device is adjusted via adjusting support feet; the adjusting support feet can be retracted so that the oiling device ismoved via moving support feet; the oiling device is flexible and convenient to use.

Owner:浙江三和线业科技有限公司

Ultrasonic circulating soaping method used for dyeing by adopting isatis root plant dye

The invention relates to an ultrasonic circulating soaping method used for dyeing by adopting isatis root plant dye. In soaping equipment, ultrasonic waves are adopted, and ozone is introduced; beforefabrics and clothes which are dyed by the isatis root plant dye are put in the soaping equipment, hydrogen peroxide is added into an aqueous solution, and a natural soaping agent HO is added for soaping for 2-20 minutes; a soaping solution is recyclied, and hydrogen peroxide and a natural soaping agent HO are supplemented. The method has the advantages that surface dyeing of dyed textile by adopting the plant dye can be greatly removed, all plant pigments are thoroughly oxidized, parts of water-soluble pigments can be degraded and mineralized, the soaping fastness of the textile dyed by the isatis root plant dye is improved to reach 1-2 grade, and the dry-wet color fastness to rubbing is improved to above 1 grade.

Owner:祝洪哲 +1

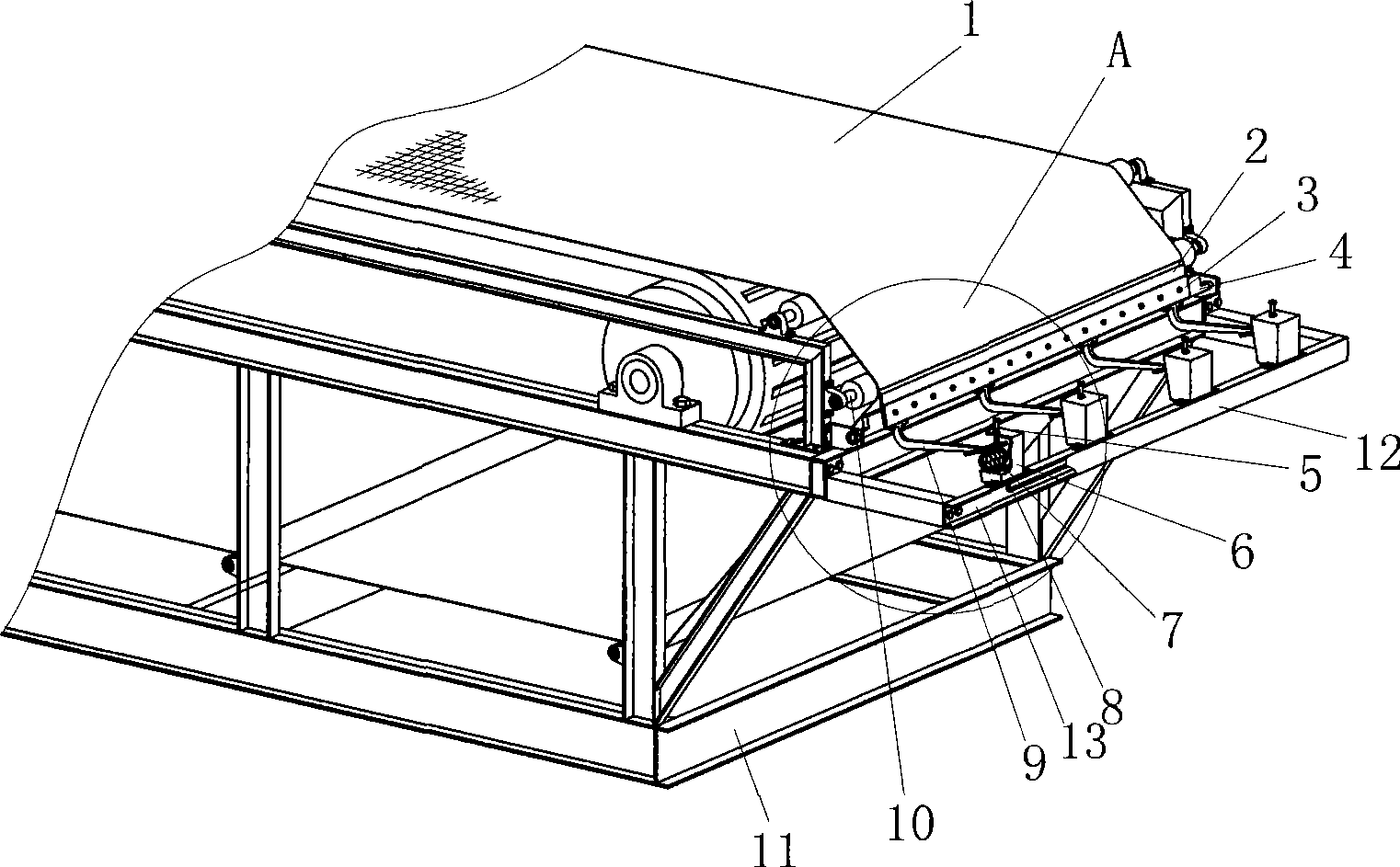

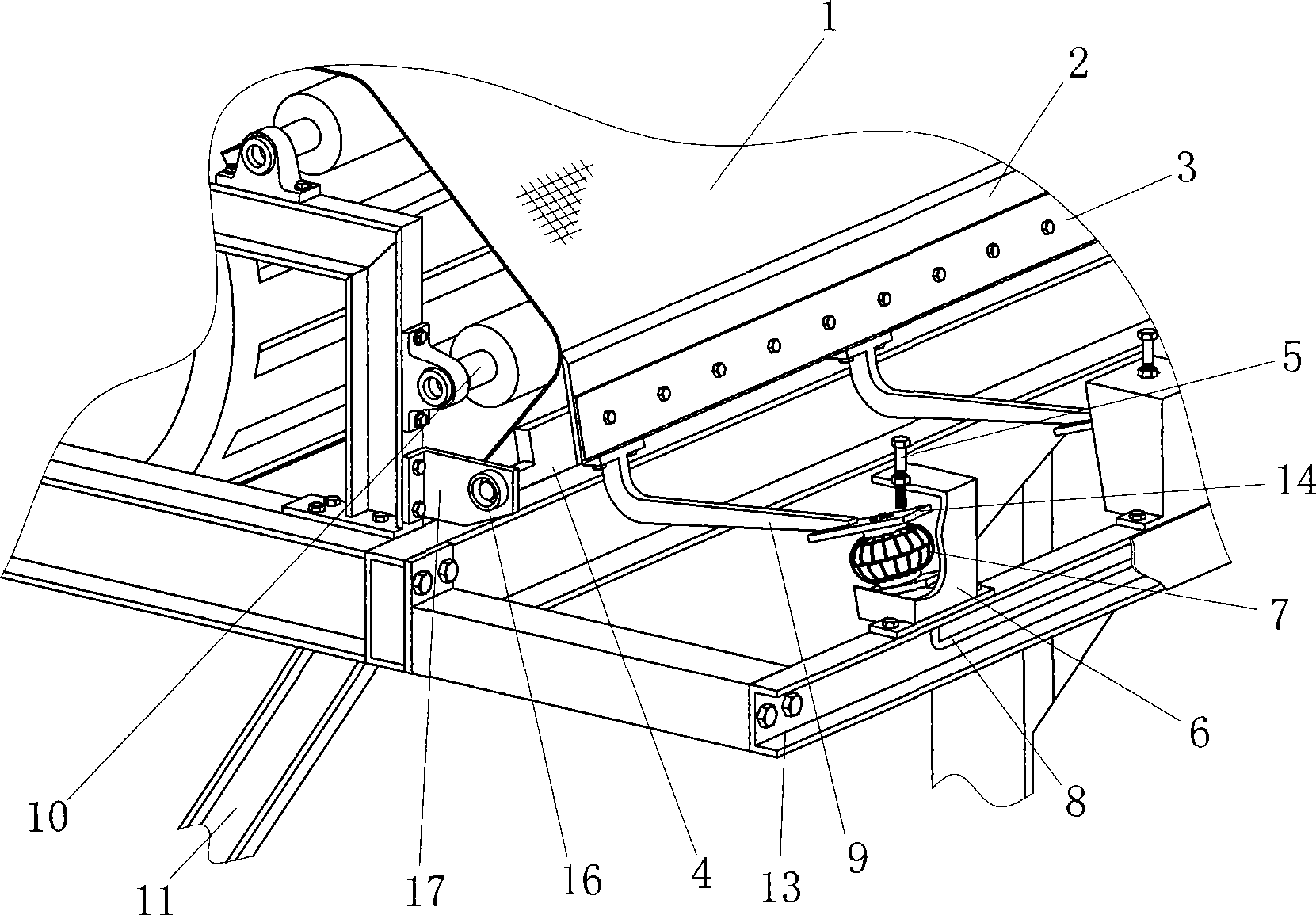

Rubber belt type vacuum filter discharge device

InactiveCN101485943AApplicable dischargeAdaptableMoving filtering element filtersFiltrationInlet pressure

The invention relates to a scraper discharging device, in particular to the scraper discharging device of filtration fabric of a rubber belt type vacuum filter. The scraper discharging device comprises a scraper support saddle and a scraper bracket arranged on the scraper support saddle, wherein the scraper bracket is pivoted with a scraper by a bearing; the scraper comprises a scraper body and a squeeze plate for squeezing the scraper body; the scraper body and the squeeze plate are positioned at the two sides of the bearing respectively; one ends of a plurality of bent levers are fixedly connected with the squeeze plate of the scraper; and the other ends of the bend levers are linked with an air bag. The output force of the air bag can be controlled by adjusting inlet pressure through a pressure regulating valve so as to conveniently adjust condition of the action of the scraper and a discharging roll and avoid damage to the filtration fabric.

Owner:湖州旺能环保科技有限公司

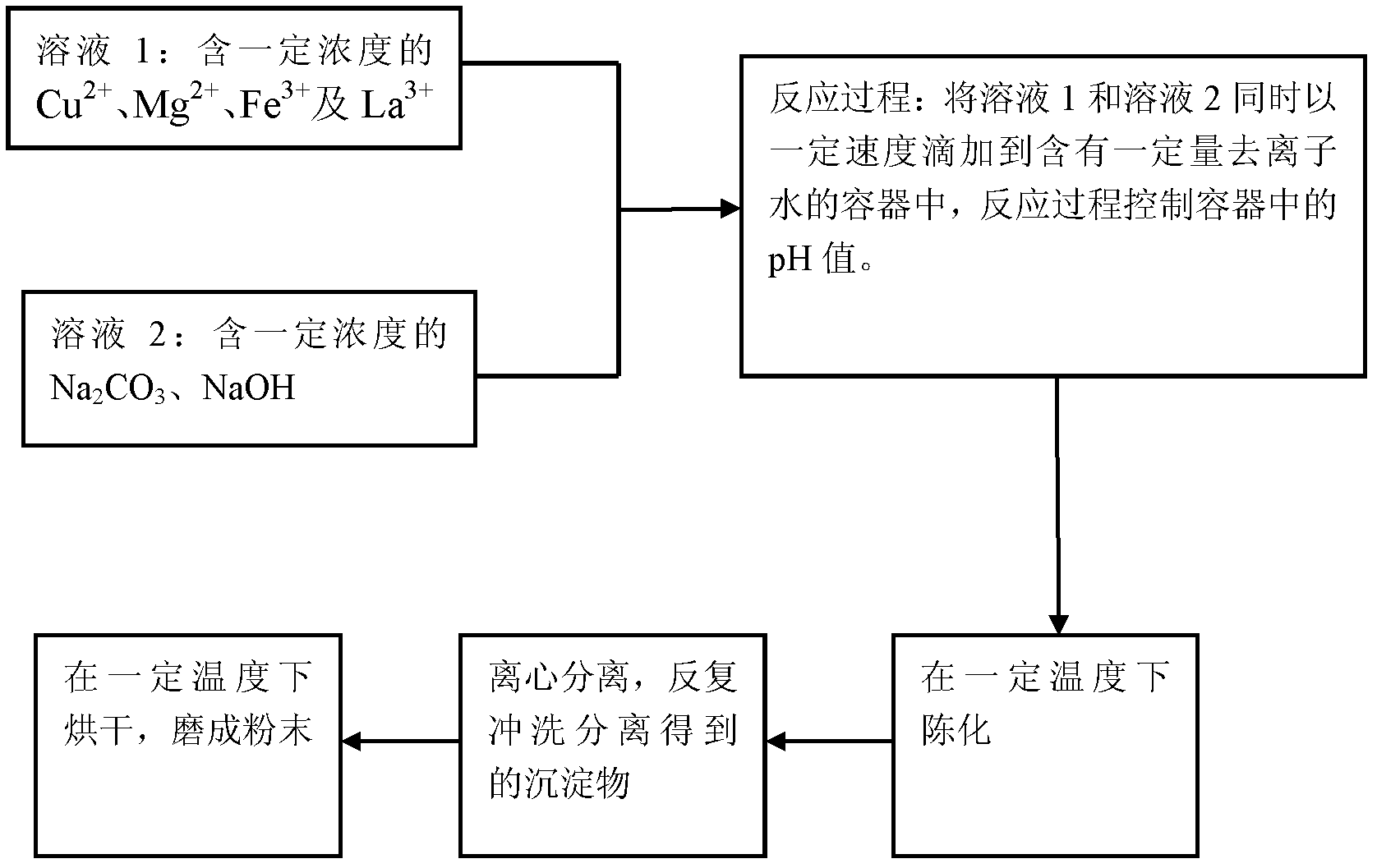

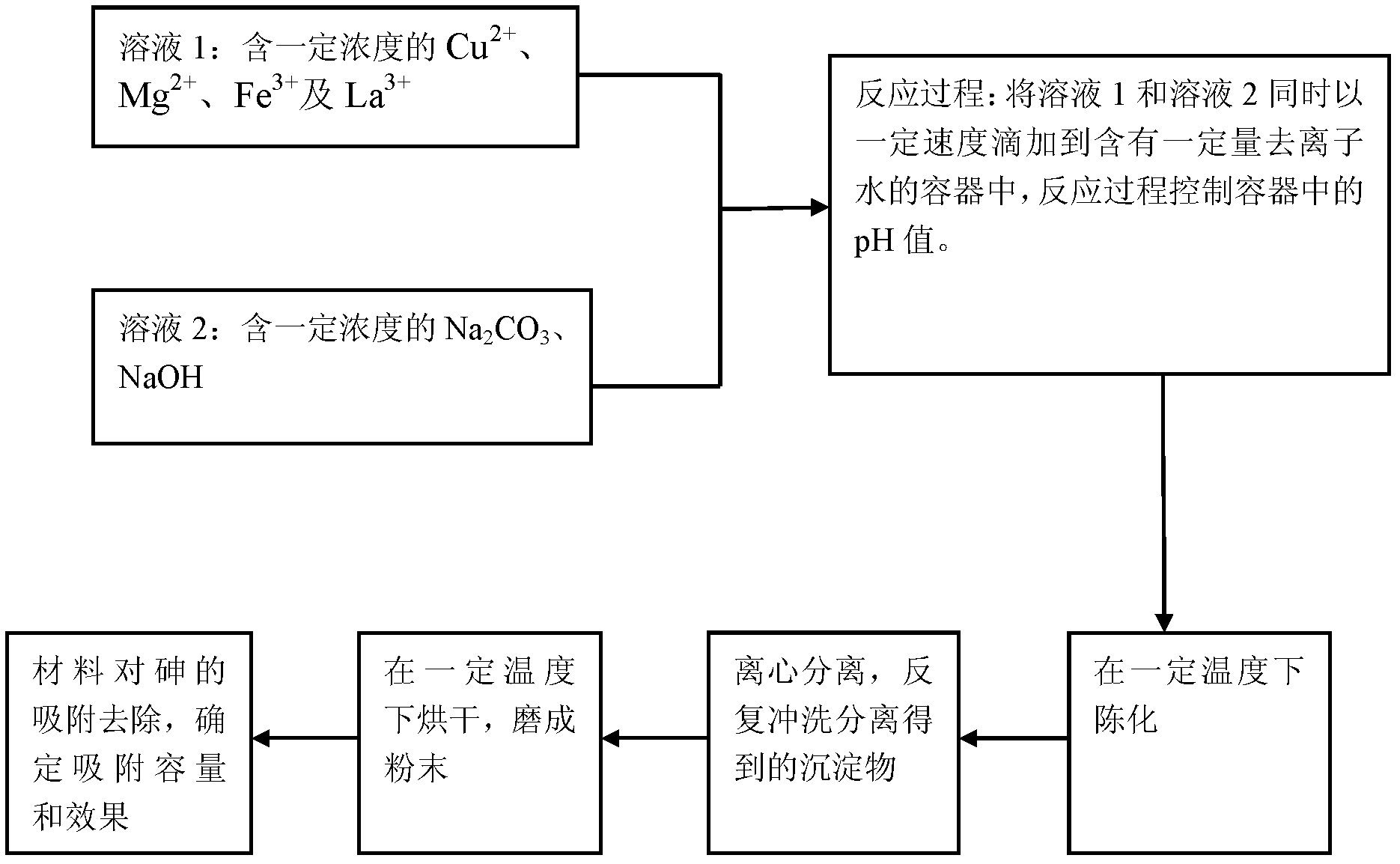

Rare earth elements contained laminated dihydroxy composite metal oxide, and preparation method and application thereof

InactiveCN102923754AEffective removalEasy to prepareOther chemical processesWater contaminantsIonRare-earth element

The invention relates to a rare earth elements contained laminated dihydroxy composite metal oxide, and a preparation method and an application thereof. The rare earth elements contained laminated dihydroxy composite metal oxide is synthesized through treating a salt containing metal elements comprising La, Cu, Mg and Fe as a raw material, and is used for adsorbing and removing As in water. The preparation method comprises the following technological steps: preparing a solution 1 containing certain concentrations of La, Cu, Mg and Fe, and preparing a solution 2 containing certain concentrations of sodium hydroxide and sodium carbonate; adding the solution 1 and the solution 2 into a beaker containing a certain amount of deionized water at certain speeds in a dropwise manner while stirring; and ageing a solution obtained after a reaction and containing a precipitate at a certain temperature for a period of time, centrifuging, repeatedly flushing the precipitate with deionized water until the supernatant is neutral, and drying to obtain the rare earth element contained laminated dihydroxy composite metal oxide which is an adsorbent product. Compared with products in the prior art, the product provided by the invention can realize the effective treatment and purification of the water polluted by As, and has the advantages of high utilization rate, low cost and the like.

Owner:TONGJI UNIV

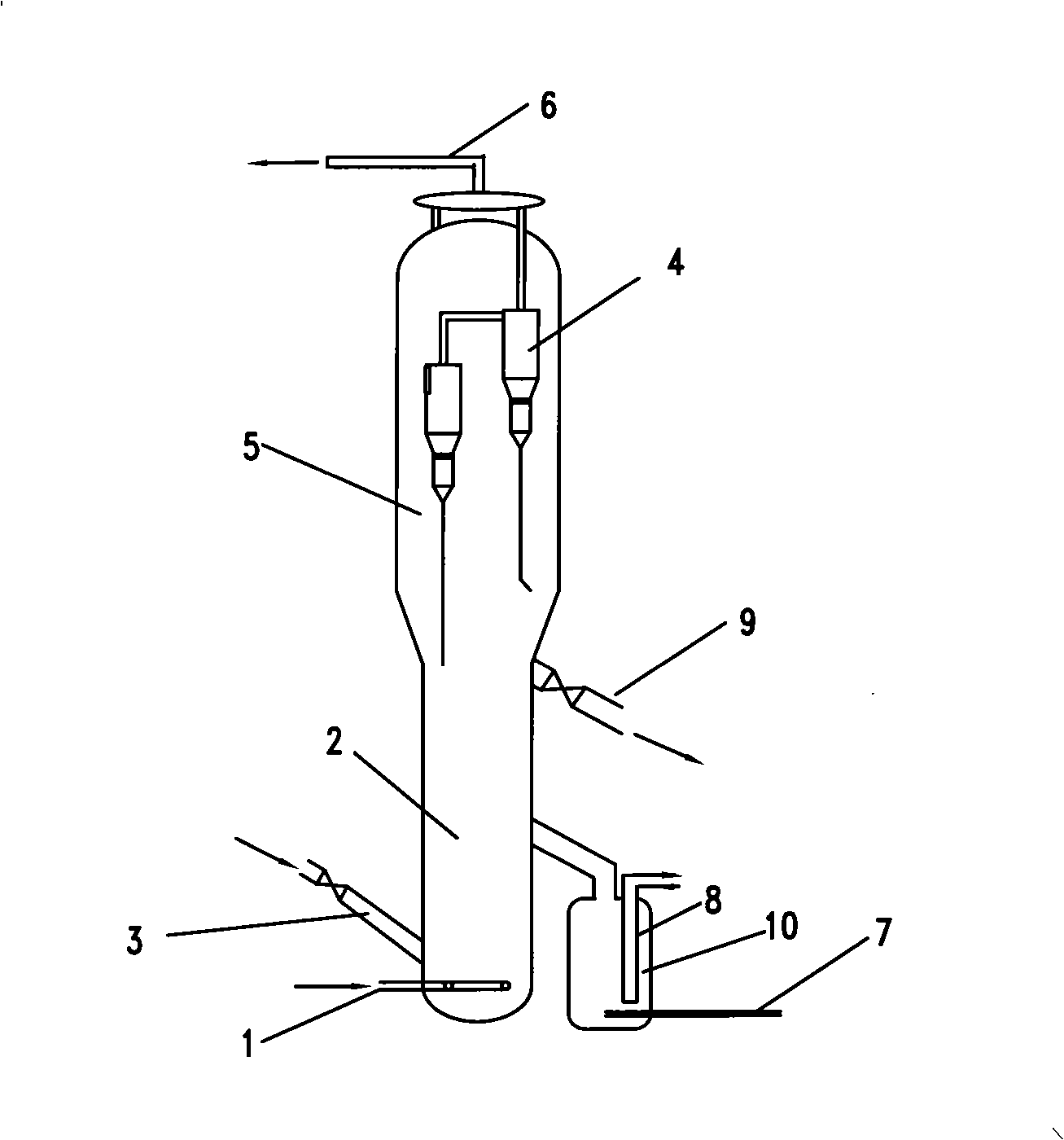

Regeneration method for preparing light olefins catalyst from oxygen-containing compounds

InactiveCN101402050AEffective removalFlexible temperature controlMolecular sieve catalystsCatalyst regeneration/reactivationMolecular sieveFluidized bed

The invention relates to a method for regenerating a catalyst for preparing low-carbon olefin from an oxygen-containing compound, which mainly solves the problem that the temperature of a regenerator is difficult to control in the prior art. The method adopts a technical proposal which comprises the following steps: putting a regenerating medium of which the temperature is between 100 and 300 DEG C into a regeneration dense phase zone of a fluidized bed regenerator to be contacted with a catalyst which is to be regenerated and contains an aluminosilicophosphate molecular sieve with 0.5 to 7.5 weight percent of coke, performing an oxidation reaction on the mixture at a regeneration temperature of between 600 and 700 DEG C to generate large amount of heat while generating a gas phase material flow which contains O2, CO, and CO2, and delivering removing the heat out of the regeneration dense phase zone through an external heat-removing device of the regenerator, wherein the external heat-removing device of the regenerator is a full back mixing type external heat-removing device, and the distance between the connecting position of the external heat-removing device of the regenerator and the regeneration dense phase zone and a feed distributor for bottom regeneration media is less than or equal to 0.5 of the height of a bed layer in the regeneration dense phase zone. The technical proposal better solves the problem and can be used for the industrial production of the low-carbon olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

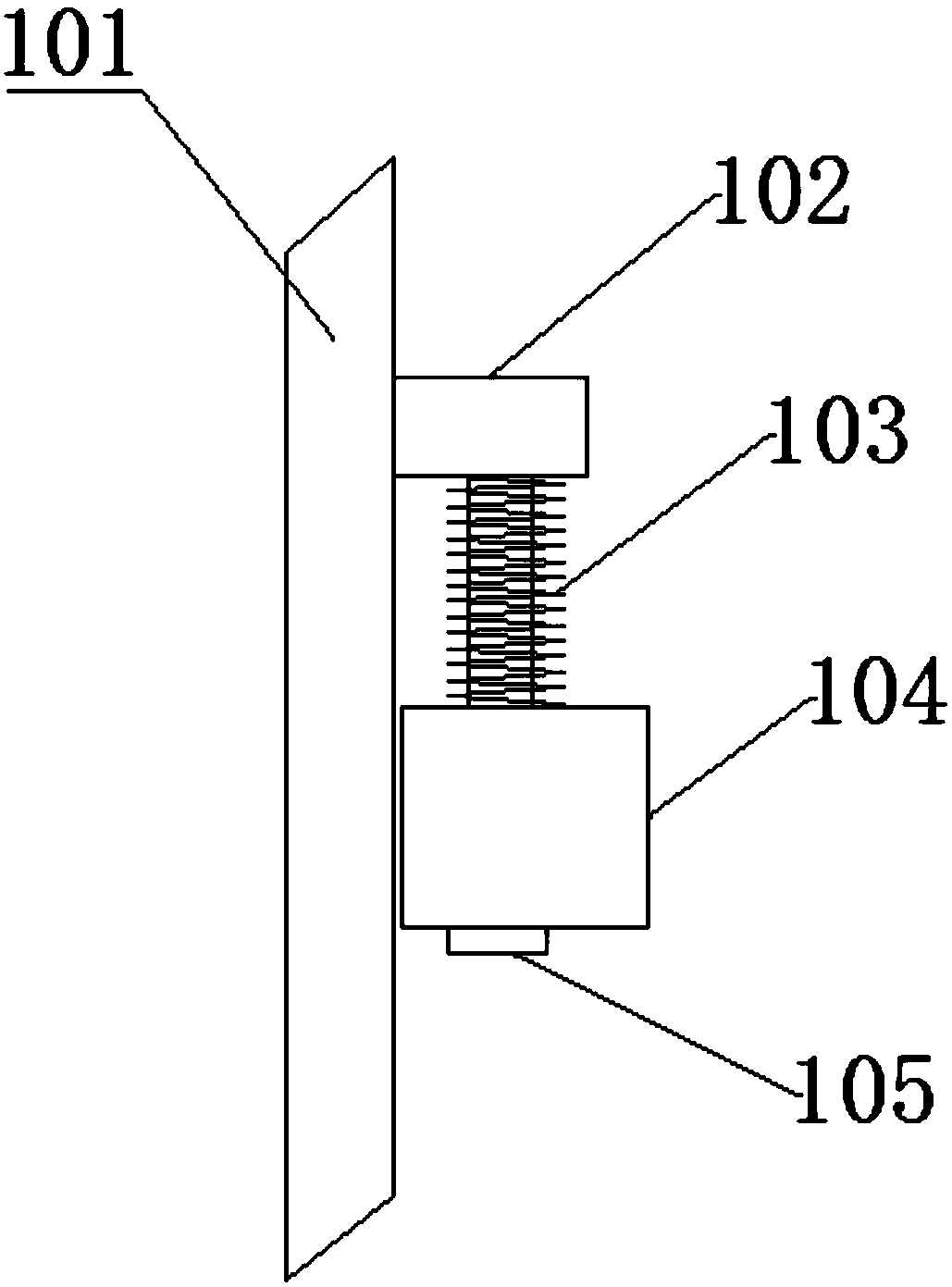

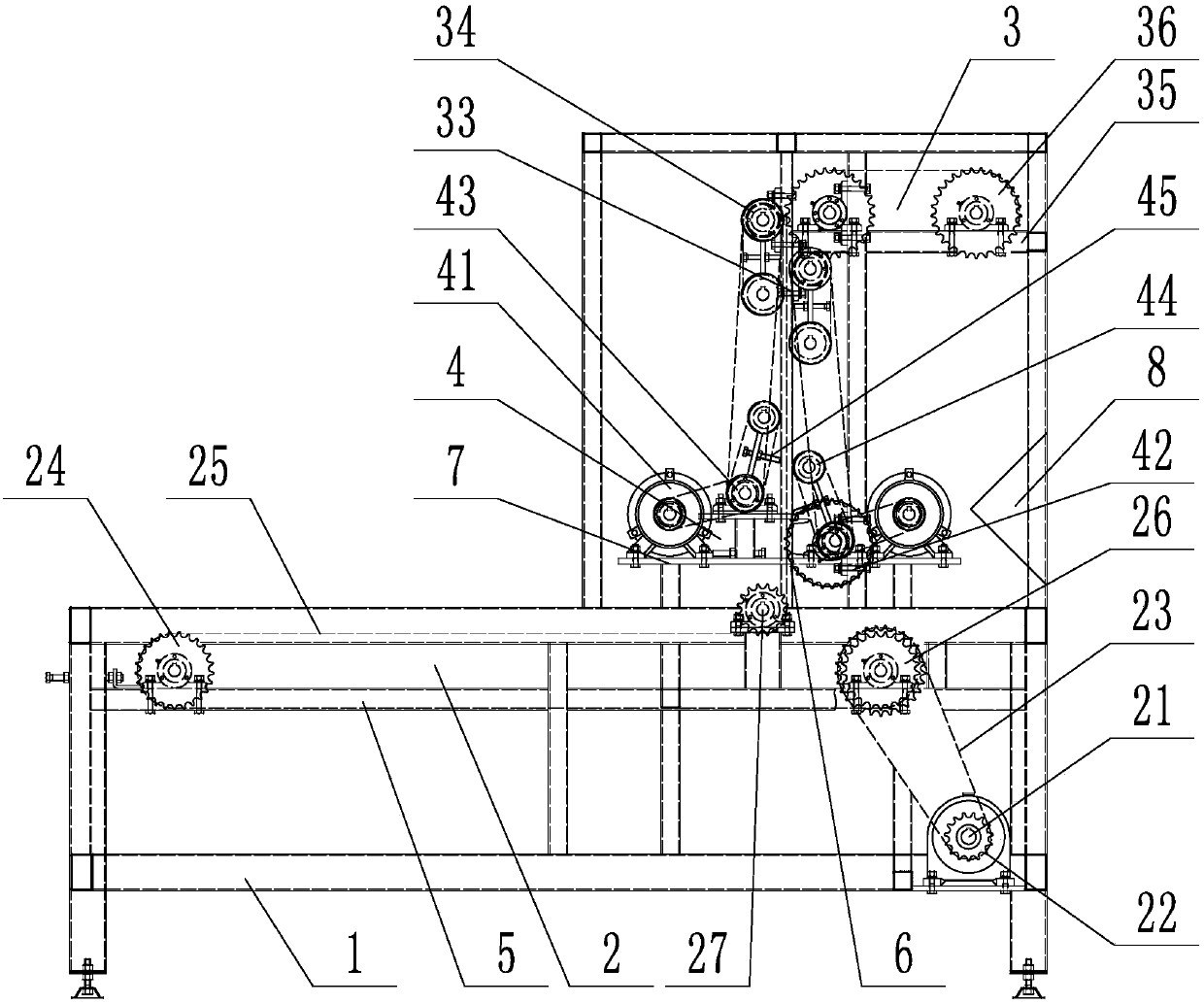

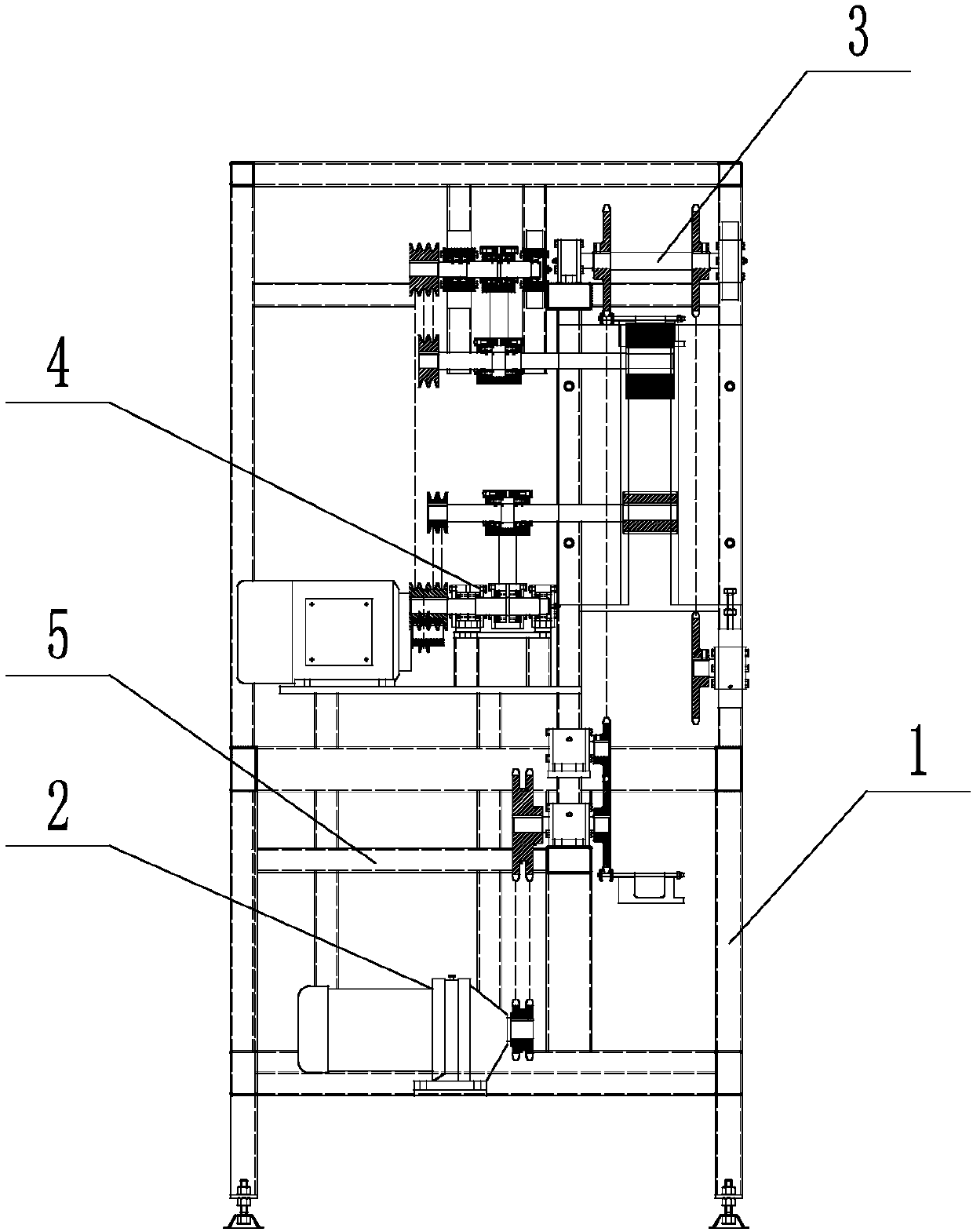

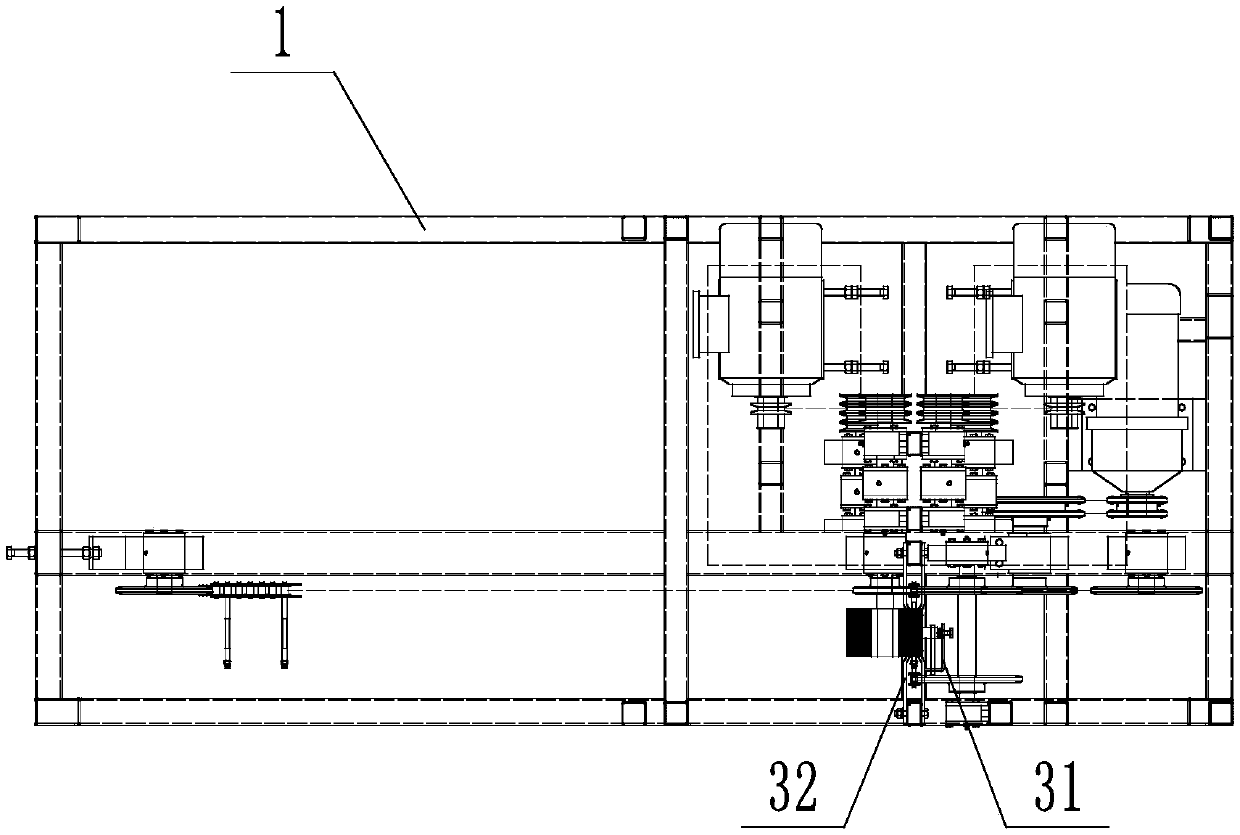

Duck gizzard peeling machine

The invention discloses a duck gizzard peeling machine. The machine comprises a frame assembly, a duck gizzard conveying system, a gizzard-skin separation system and a tension system. The machine is characterized in that a supporting beam is arranged near the upper end of the frame assembly; the duck gizzard conveying system is mounted on the supporting beam; a gizzard-skin separation stand columnis longitudinally arranged in the left middle of the right upper end of the frame assembly; a tensioning system frame is transversely arranged near the bottom end position of the gizzard-skin separation stand column; the gizzard-skin separation system is arranged on the gizzard-skin separation stand column; the tension system is arranged on the tensioning system frame; and the right end of the tension system frame is provided with a discharge port. According to the invention, two independent transmission modes are arranged to control the cooperative operation between the duck gizzard conveying system, the gizzard-skin separation system and the tension system so as to realize the effective removal of yellow skins of duck gizzards, and production efficiency can be freely adjusted accordingto requirements. The machine has the advantages of high work efficiency, low labor investment and low labor intensity.

Owner:SHANDONG BAOXING MACHINERY

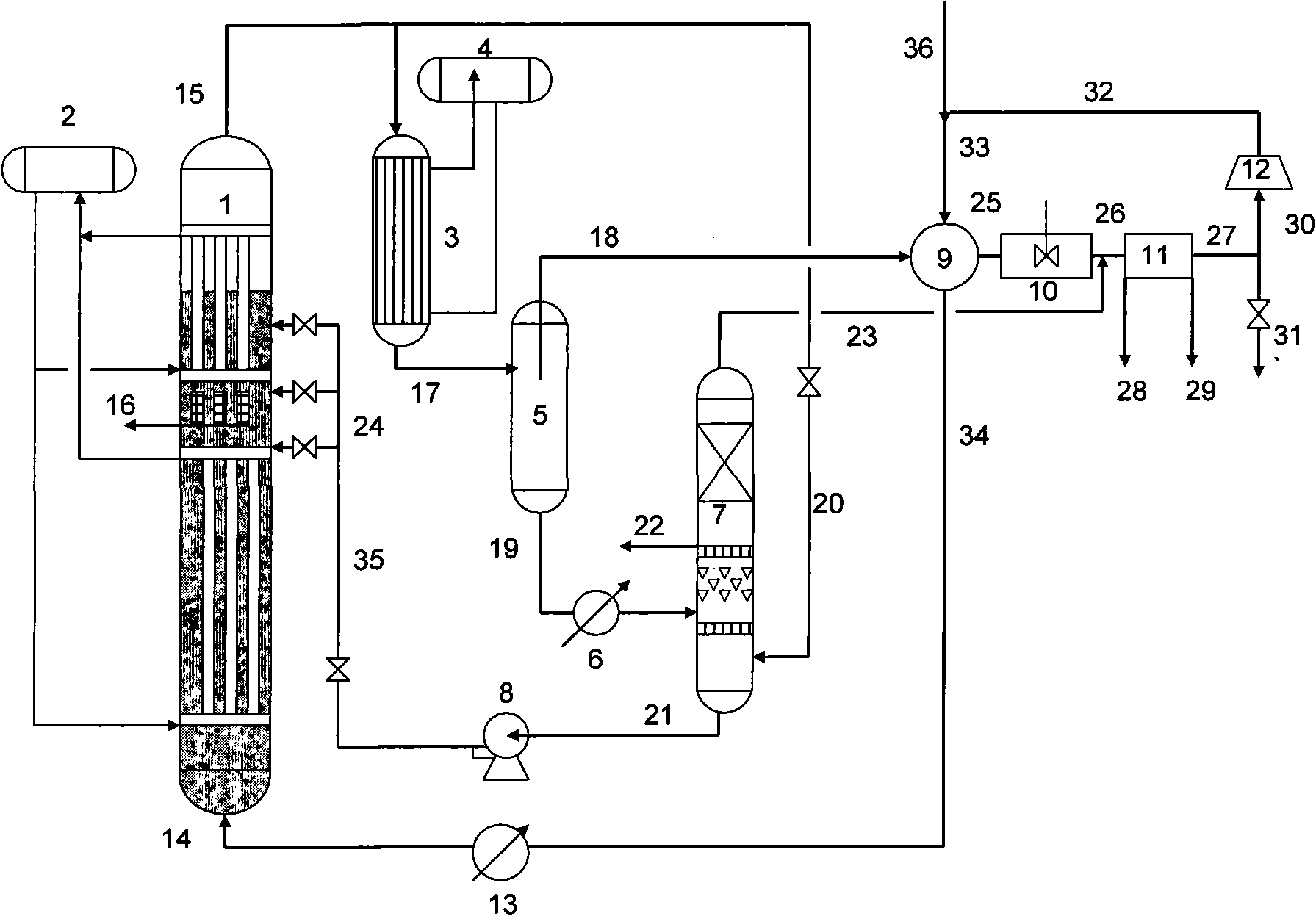

Equipment system for Fischer-Tropsch synthetic reaction and application thereof

ActiveCN102212381BAvoid overall overheatingEffective removalLiquid hydrocarbon mixture productionChemical/physical processesThree-phaseProcess engineering

The invention discloses an equipment system for Fischer-Tropsch synthetic reaction and the system contains a three-phase suspension bed Fischer-Tropsch synthetic reactor and an auxiliary system thereof. The equipment system is characterized in that the three-phase suspension bed Fischer-Tropsch synthetic reactor is provided with a chilling distributor which is used for injecting a circulated condensation product back into the reactor and performing forced heat removing on the filter area of the reactor; the equipment system is also provided with a waste-heat boiler to ensure that the hot air stream of the high temperature light reaction product discharged from the outlet of the reactor first passes through the waste-heat boiler to exchange heat, recycle partial heat and remove less solid catalysts carried by the air stream, thus the downstream condensation product does not contain catalysts. The invention also discloses a method for performing Fischer-Tropsch synthesis by using the equipment system. In the method, tail gas circulation and partial condensation product circulation are adopted, thus the removal of reaction heat can be strengthened, the production capability of the reactor can be increased, the level of the energy recycled from reaction heat can be increased, and the problems that the catalyst is overheated to deactivate and form carbon can be effectively solved.

Owner:SYNFUELS CHINA TECH CO LTD

Rust removing method for steel plates

The invention discloses a rust removing method for steel plates. The rust removing method specifically comprises the following steps that 1), a rust removing agent is prepared, and the rust removing agent is prepared by uniformly mixing the following components in parts by mass: 150-200 parts of sulfuric acid, 55-75 parts of phosphoric acid, 200-300 parts of hydrochloric acid, 15-35 parts of urotropine and 10-30 parts of distilled water; 2), the rust removing agent is poured into a high-pressure spraying machine spraying can; 3) the steel plates are placed orderly; 4), the rust removing agentis uniformly sprayed on the surface of each steel plate by using a high-pressure spraying machine, and then the steel plate is overturned so that the rust removing agent is sprayed on the other side;5), the steel plate on which the rust removing agent is sprayed is dried; and 6) the steel plates are conveyed indoors for storage. The rust removing method provided by the invention is simple and easy to implement; surface rust stains can be rapidly and effectively removed; no corrosion is generated to utensils; the raw materials are simple; and cost is low.

Owner:徐州市博威机械制造有限公司

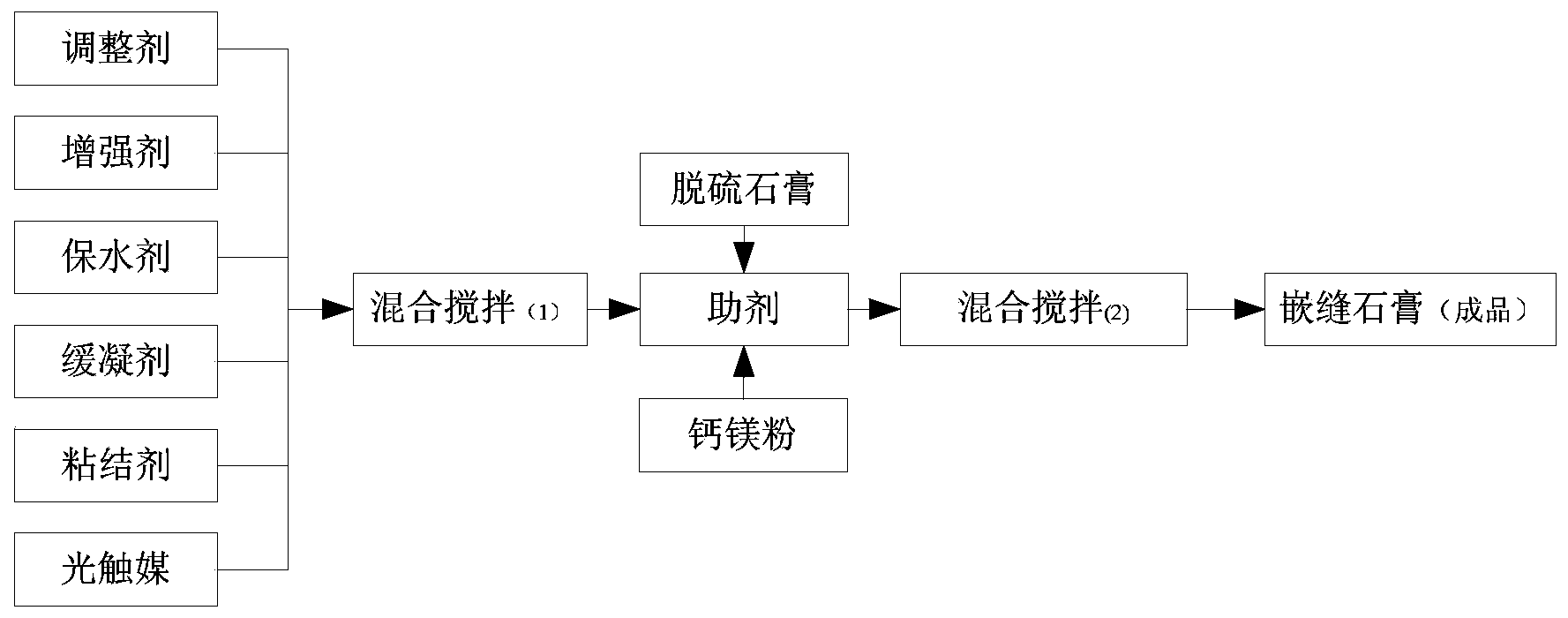

Method for preparing caulking gypsum putty powder from flue gas desulfurization gypsum

The invention discloses a method for preparing caulking gypsum putty powder from flue gas desulfurization gypsum. The method comprises the following steps: crushing the waste desulfurization gypsum till the particles with granularity of 25-35um are over 80 percent, and performing high-temperature calcining, so that CaSO4.2H2O loses crystal water to form CaSO4.1 / 2H2O or CaSO4; uniformly stirring and mixing the following components at one time in percentage by weight: 0.5-3 percent of regulator, 0.5-1.5 percent of enhancer, 0.1-0.6 percent of water-retaining agent, 0.3-0.5 percent of retarder, 0.2-0.5 percent of photocatalyst and 0.2-0.25 percent of adhesive; adding 80-87wt% of desulfurization gypsum powder and 10-20wt% of calcium magnesium powder into the obtained mixture, and performing secondary stirring and mixing, thus obtaining the caulking gypsum putty powder. The prepared product has the advantages of environment friendliness, cracking resistance, availability and low cost, and more importantly has the characteristic of degrading formaldehyde and other volatile organic compounds.

Owner:浙江固德优科技有限公司

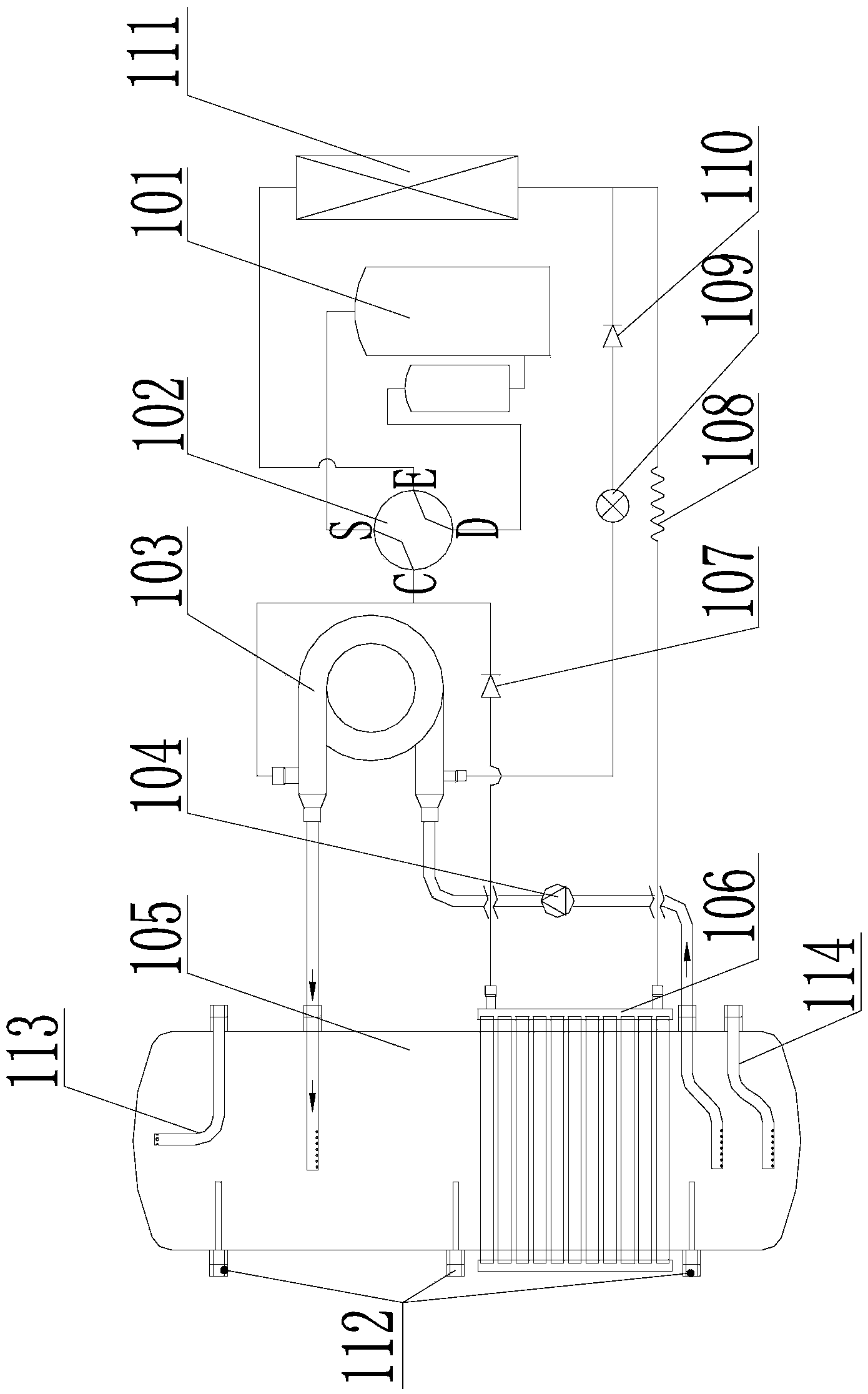

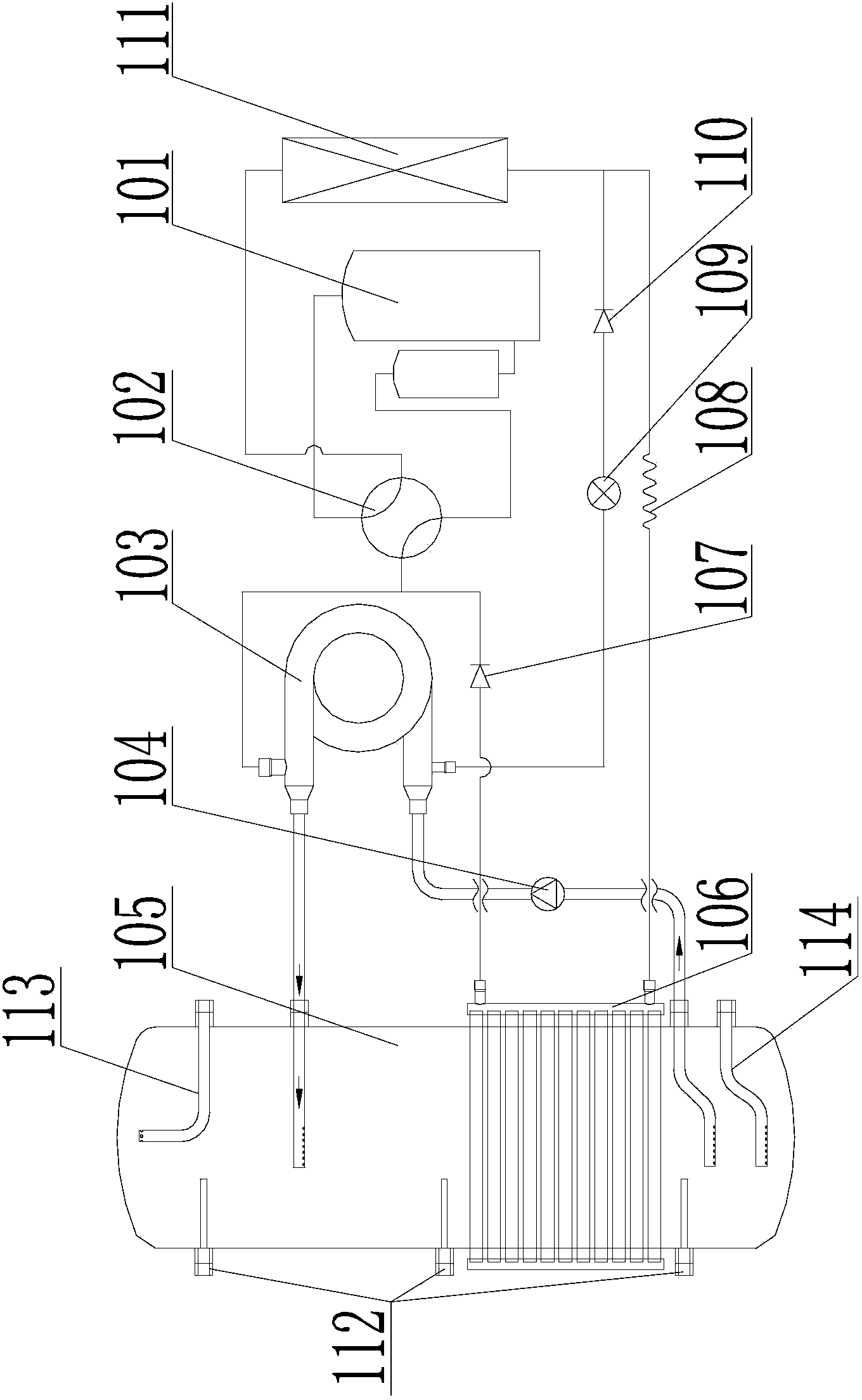

Hot-water system of heat pump

InactiveCN104296433AReduce the impactEffective removalFluid heatersMechanical apparatusRefrigerantEngineering

The invention discloses a hot-water system of a heat pump. The hot-water system comprises a compressor, a four-way valve, an outdoor heat exchanger, a throttling device and a water tank, and further comprises a bushing heat exchanger and a coil heat exchanger, wherein the bushing heat exchanger and the coil heat exchanger are arranged in parallel; in the heating operation of the system, refrigerant flowing out from the compressor flows through the four-way valve to enter the bushing heat exchanger for condensation heat release; after the pressure of the refrigerant is reduced by the throttling device, the refrigerant is fed in the outdoor heat exchanger for evaporation heat absorption; and finally, the refrigerant enters the compressor by the four-way valve; in the defrosting operation of the system, the refrigerant flowing out from the compressor enters the outdoor heat exchanger by the four-way valve for condensation heat release; after the pressure of the refrigerant is reduced by the throttling device, the refrigerant is fed in the coil heat exchanger for evaporation heat absorption; and finally, the refrigerant is fed in the compressor through the four-way valve. The system directly supplies heat to heated water through the bushing heat exchanger in the heating process, so that the purpose of quick water heating can be realized; the heat is supplied through the coil heat exchanger in the defrosting process; and the influence on the water temperature in the water tank and the use comfort of users from the heat absorption of the coil heat exchanger in the defrosting process is little.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Compound type efficient microorganism deodorant for waste blood of flocks and herds and preparation method thereof

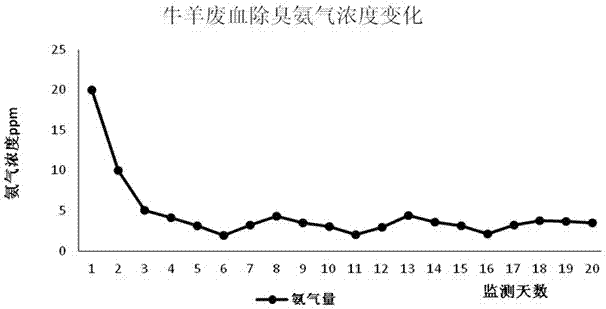

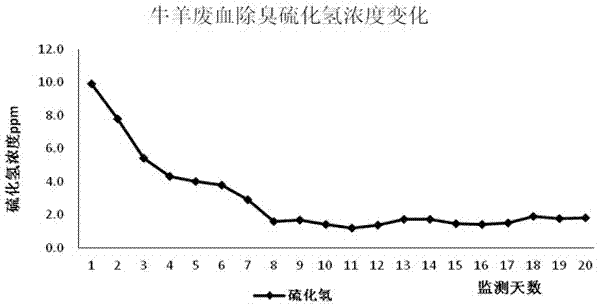

InactiveCN107345214AReduce odor concentrationEffective removalBacteriaDispersed particle separationChemistryEnterococcus

The invention discloses a compound type efficient microorganism deodorant for waste blood of flocks and herds and a preparation method thereof. The deodorant can effectively decompose the repugnant substances in the waste blood of flocks and herds and can overcome the defects of insufficient and incomplete effects and unsatisfactory deodorizing effect of various deodorants. The production fermentation technology of the deodorant is simple and the microbial community can be easily cultured and acquired. The compound type efficient microorganism deodorant for waste blood of flocks and herds comprises the following components in parts by weight: 25-40 parts of bacillus coagulans, 20-35 parts of bacillus subtilis, 10-25 parts of bacillus natto and 20-35 parts of enterococcus faecalis, wherein the viable count is 3.0*10<10>-5.0*10<10>cfu / g.

Owner:江苏远山生物技术有限公司

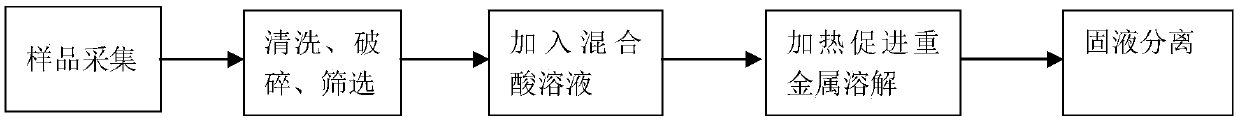

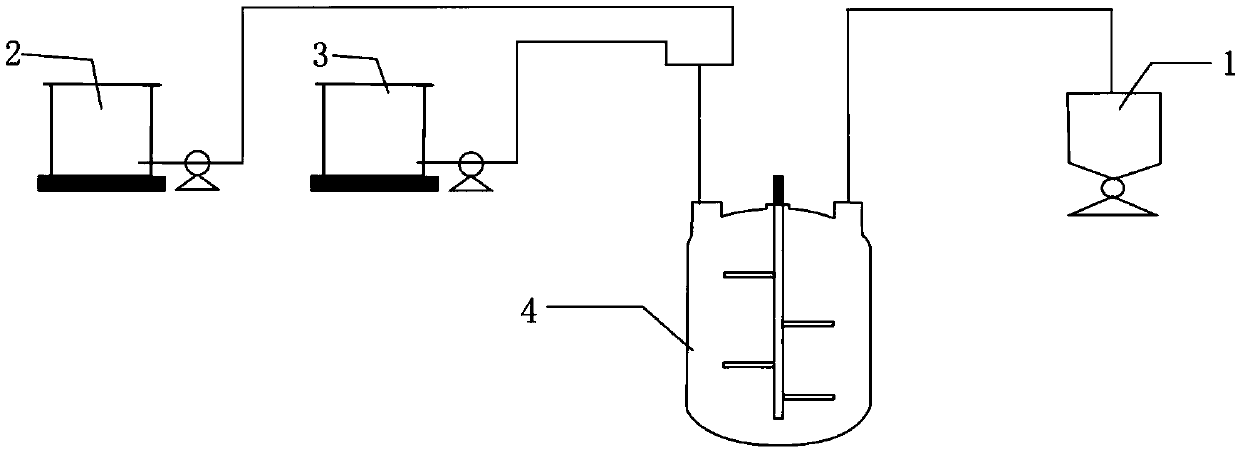

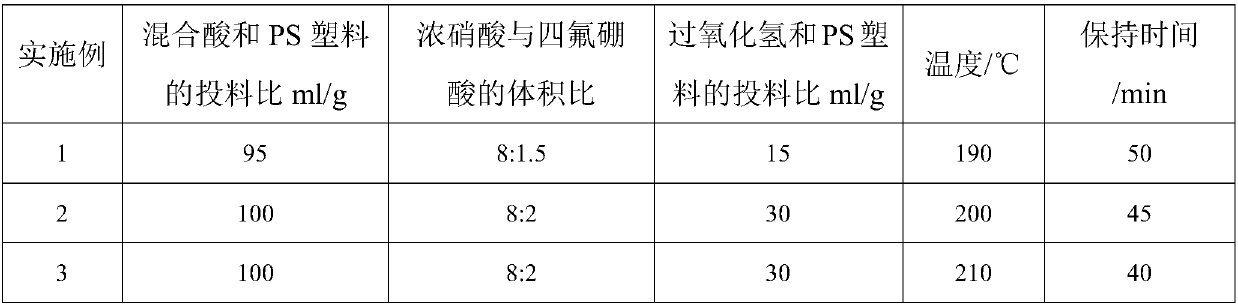

Method for removing heavy metals from electronic waste outer shell PS plastic

The invention discloses a method for removing heavy metals from an electronic waste outer shell PS plastic. The method mainly comprises three steps of pretreatment, soaking and heating, wherein a hydrogen peroxide-containing mixed acid solution (formed by mixing concentrated nitric acid and tetrafluoroboric acid) is heated to dissolve the plastic additive attached to the waste plastic so as to remove heavy metals from the PS plastic, such that the separation of heavy metals Pb, Cd, Cr and Sb from the plastic is achieved, and the heavy metal content in the waste plastic is reduced. With the method of the present invention, the heavy metals in the PS plastic can be effectively removed, the maximum removal efficiency can reach 95%, the removal efficiency is high, and the cost is low.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

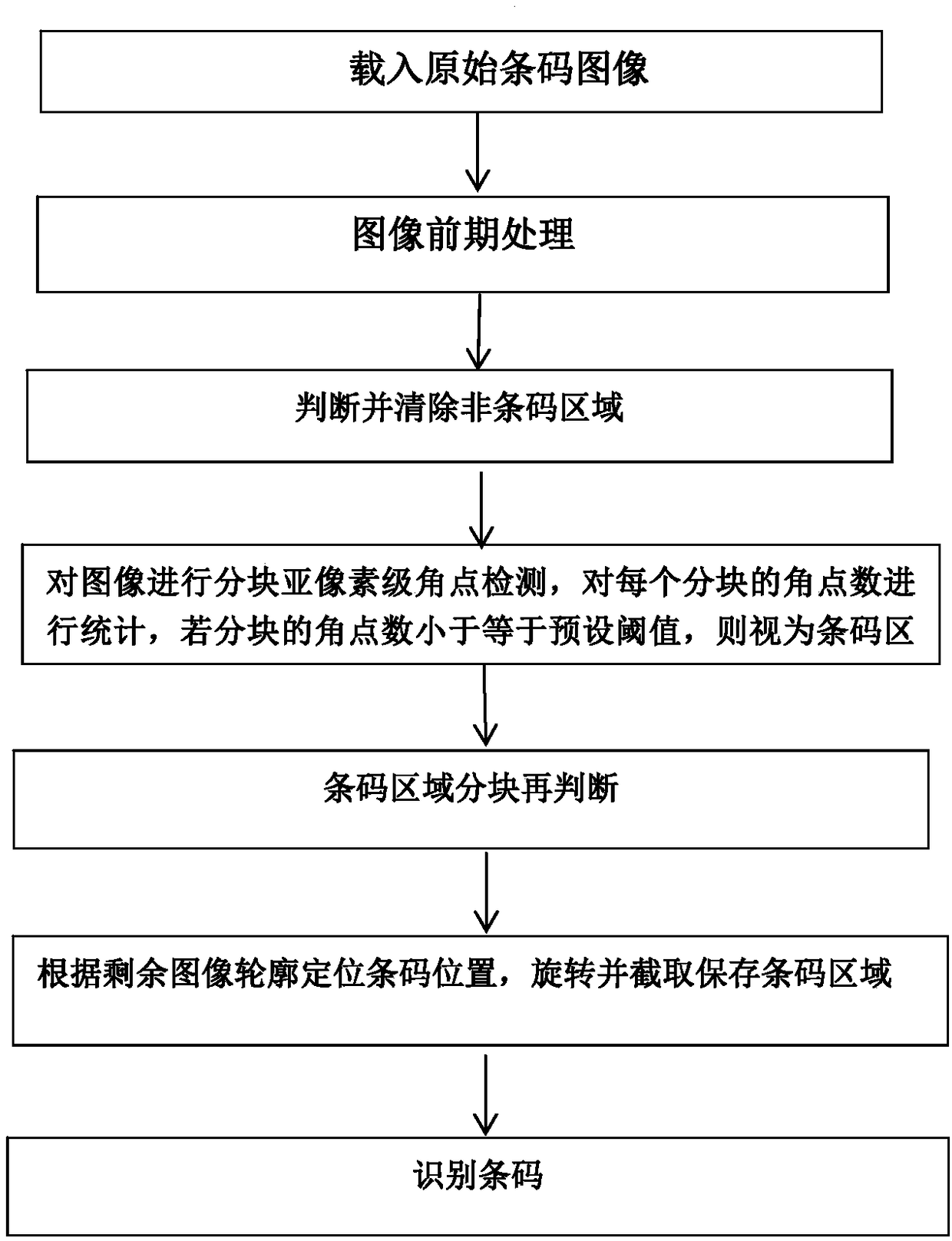

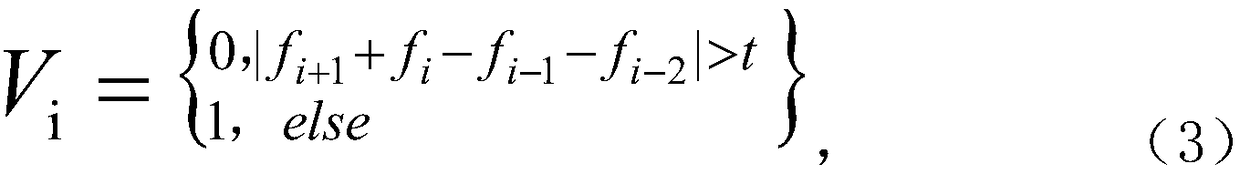

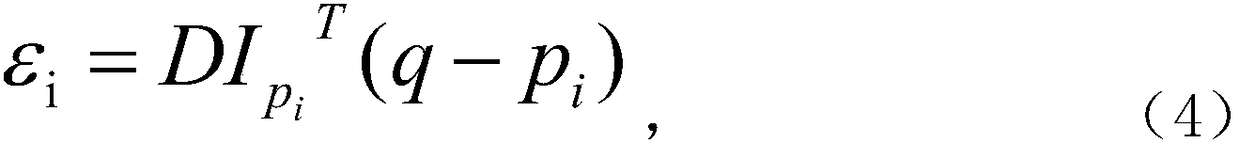

A barcode recognition algorithm based on sub-pixel corner detection

ActiveCN109190434AImprove processing speed and accuracyEffective removalImage enhancementImage analysisRecognition algorithmBarcode

The invention discloses a bar code recognition algorithm based on sub-pixel level corner detection, comprising the following steps: S1, loading an original bar code image; S2, pre-processing the original barcode image; S3, judging and clearing that non-bar code area image, the specific steps being as follows: a block scan mode is performed first, the number of blocks selected is 6, BlockSize= (minimum of image width and height) / 6, the block size is calculated by dividing the minimum number of rows and columns of the original barcode image by the number of blocks, and the number of blocks per row and the number of blocks per column of the image are block_cols and block_rows, respectively. The invention effectively improves the image processing speed and accuracy, clears the non-bar code area more effectively, the image processing and analysis result is closer to the reality, and finally achieves a relatively satisfactory identification effect.

Owner:GUANGDONG UNIV OF TECH

Technology of synchronous desulfurization and denitration through flue gas ammonia method based on electrolytic regeneration iron removal

ActiveCN105251330AEasy to fillGuaranteed reliabilityDispersed particle separationAmmonium sulfatesComing outCrystal system

The invention discloses a technology of synchronous desulfurization and denitration through a flue gas ammonia method based on electrolytic regeneration iron removal. The problem that for an existing desulfurization and denitration technology, the regeneration efficiency of an absorption solution is not high is solved. According to the technical scheme, the technology comprises the steps that pressurizing is conducted on flue gas, the flue gas is sent to a concentration tower to be reacted with a concentrated solution in the tower in a contacting mode, the flue gas coming out of the concentration tower is sent to an absorption tower to be reacted with the circulation absorption solution in the tower in a contacting mode, the concentrated solution reacted at the tower bottom part of the concentration tower is sent into an ammonium sulfate crystal system after iron is removed through a first electrolytic reactor, the absorption solution reacted at the tower bottom part of the absorption tower is sent back to the upper portion of the absorption tower to serve as the circulation absorption solution through regeneration, and the concentration solution enters an anode chamber in a reaction unit of the first electrolytic reactor to conduct an oxidation reaction and then enters a cathode chamber to conduct a reduction reaction; a reacted electrolyte is discharged from an outlet connection short pipe and sent into the ammonium sulfate crystal system. The technology of synchronous desulfurization and denitration through the flue gas ammonia method based on electrolytic regeneration iron removal has the advantages of being simple in method, low in investment cost and operating cost, high in conversion efficiency, good in iron removing effect and good in desulfurization and denitration effect.

Owner:武汉武钢绿色城市技术发展有限公司

Dirt scavenging agent for kitchen exhaust ventilator

InactiveCN102408954AGood cleaning effectEffective removalOrganic detergent compounding agentsSurface-active detergent compositionsSodium carbonateCorrosion

The invention provides a dirt scavenging agent for a kitchen exhaust ventilator. The components of the scavenging agent comprise fatty alcohol polyoxyethylene (9) ether, polyoxyethylene (20) sorbitan monolaurate, triethanolamine, peptization complexing agent Th, sodium carbonate, blue pigment and water. The dirt scavenging agent for the kitchen exhaust ventilator provided by the invention not only can effectively scavenge dirt of the exhaust ventilator but also generate damage and corrosion effects on the exhaust ventilator.

Owner:陈瑜

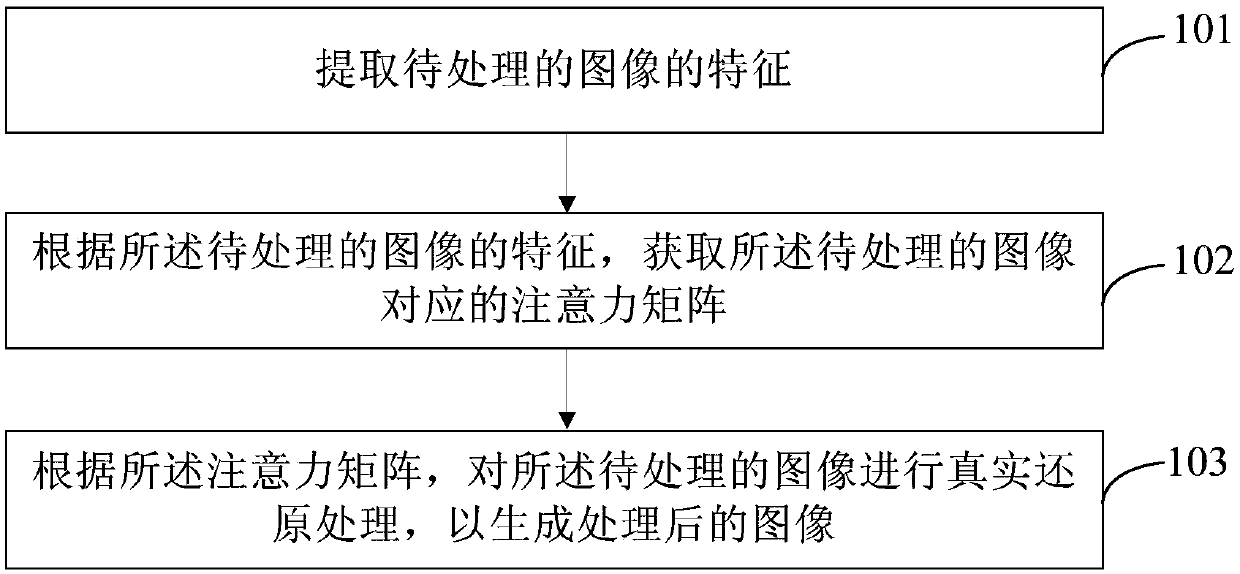

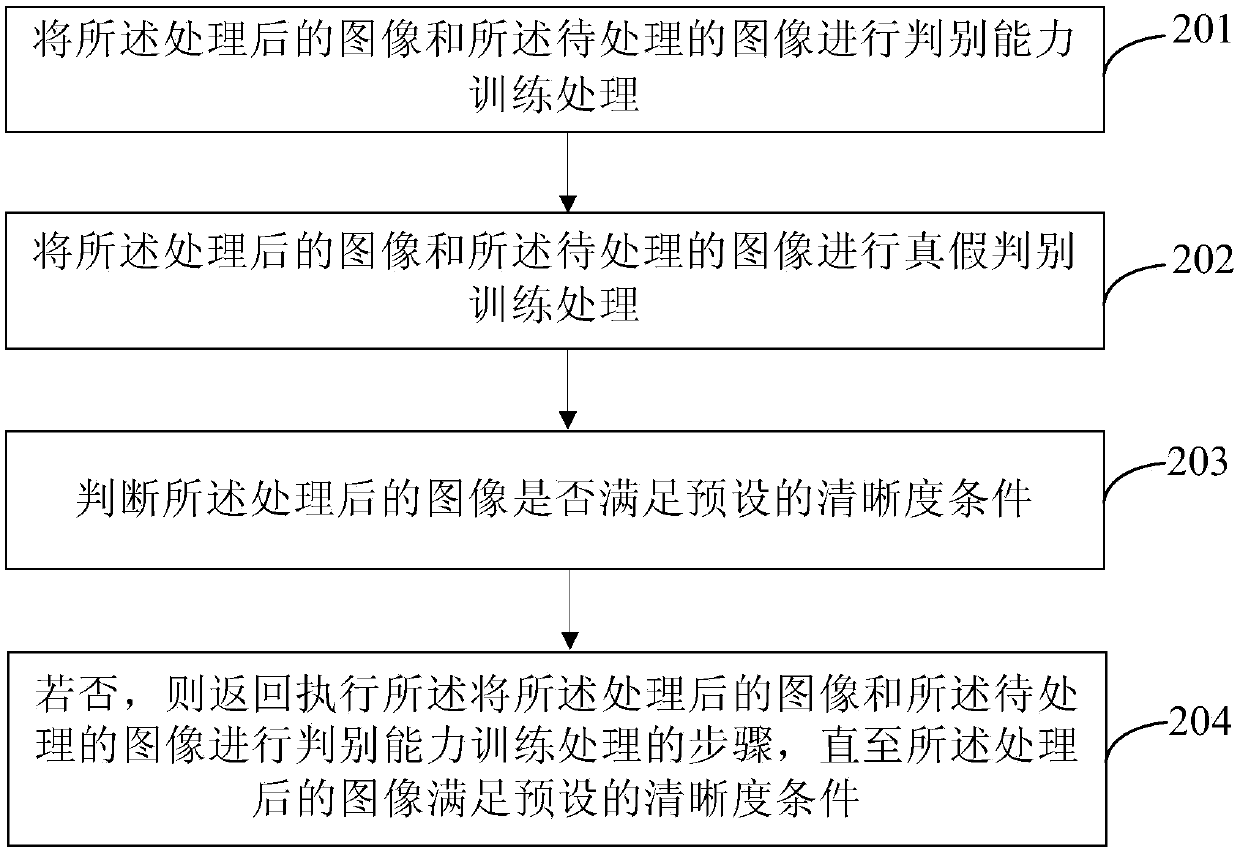

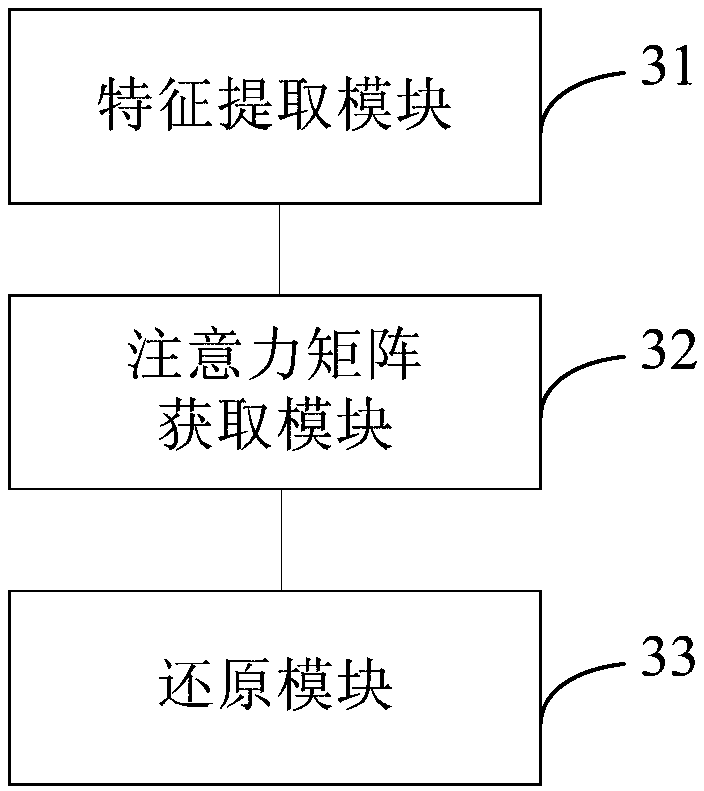

Image processing method, device and equipment and computer readable storage medium

PendingCN110930441AEffective removalAccurate removalImage analysisEngineeringComputer graphics (images)

The embodiment of the invention discloses an image processing method, device and equipment, and a computer readable storage medium. The method comprises the steps of extracting features of a to-be-processed image; obtaining an attention matrix corresponding to the to-be-processed image according to the features of the to-be-processed image; and according to the attention matrix, performing real restoration processing on the to-be-processed image to generate a processed image. Therefore, the water drops and the fog on the image with the water drops and the fog can be accurately removed, and thereal image is restored.

Owner:PEKING UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com