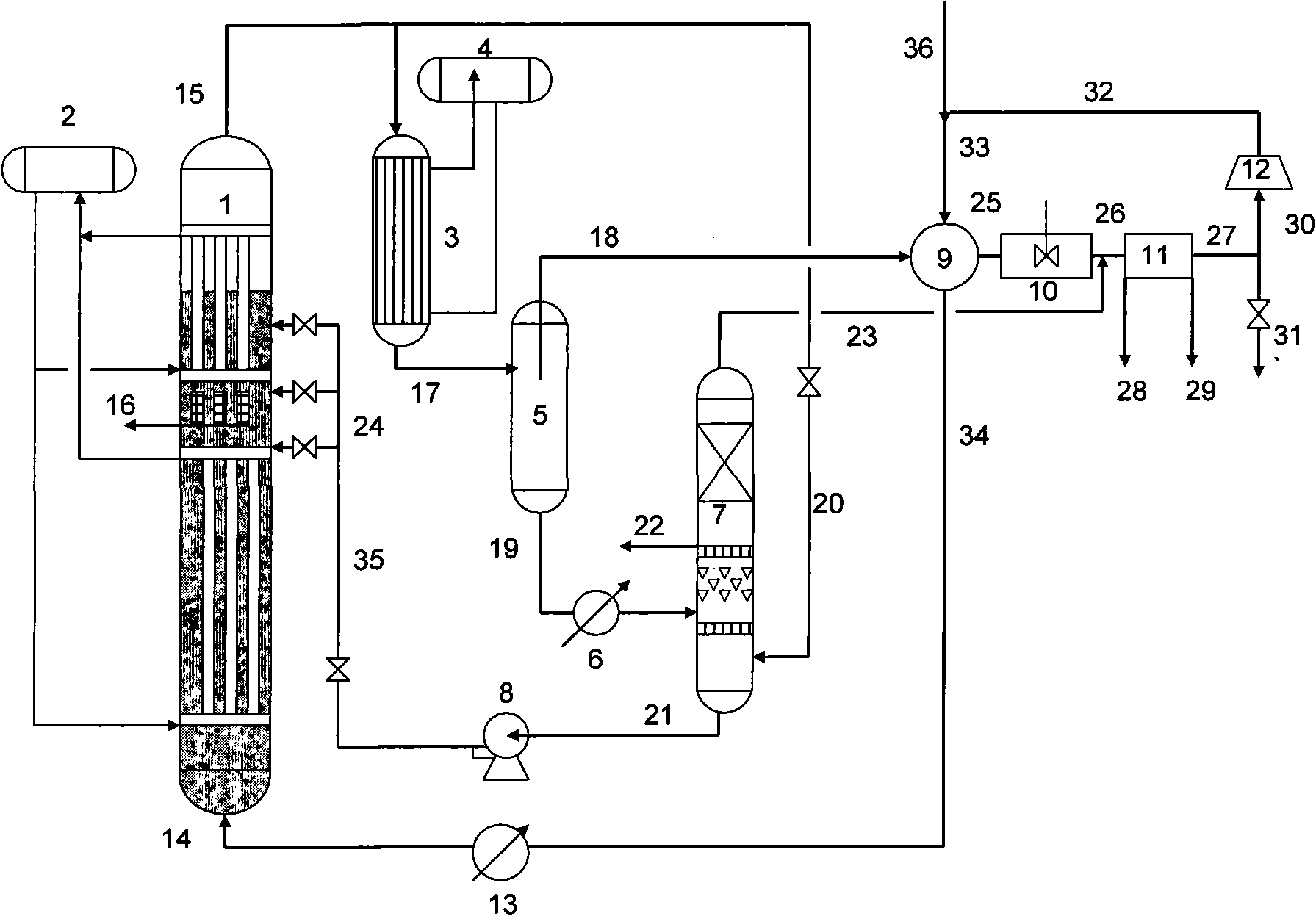

Equipment system for Fischer-Tropsch synthetic reaction and application thereof

A Fischer-Tropsch synthesis and equipment technology, which is applied in the field of Fischer-Tropsch synthesis reaction equipment systems, can solve problems such as acid resistance, large circulation capacity, and large reactor volume of three-phase suspended bed, so as to avoid overheating and increase production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] The inner diameter of the reactor in the industrial demonstration plant is 5.3 meters, and the effective components of fresh syngas (CO+H 2 ) content is 98.5%, fresh air intake volume is 142000Nm 3 / h, the reaction temperature is 260-275°C, the reaction pressure is 30bar, and the loading capacity of the catalyst is 24 tons of iron-based high-temperature slurry bed catalyst at one time. The rate is 94%.

[0072] Production C 3 +26.5t / h, the catalyst performance is 1.1kg C 3 + / kg·h, the reactor generates steam and supplies 28bar superheated steam 100t / h to the main pipe. The waste heat boiler produces 40t / h of 10bar steam. The solid content of liquid phase oil is less than 1ppm, the solid content of crude wax is less than 100ppm, and the iron content of refined filter wax is less than 2ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com