Method for preparing caulking gypsum putty powder from flue gas desulfurization gypsum

A technology of desulfurized gypsum and putty powder, applied in the direction of filling slurry, etc., can solve the problems of poor product reliability, poor use effect, poor adhesion, etc., and achieve the effects of prolonged hardening time, long-lasting time, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

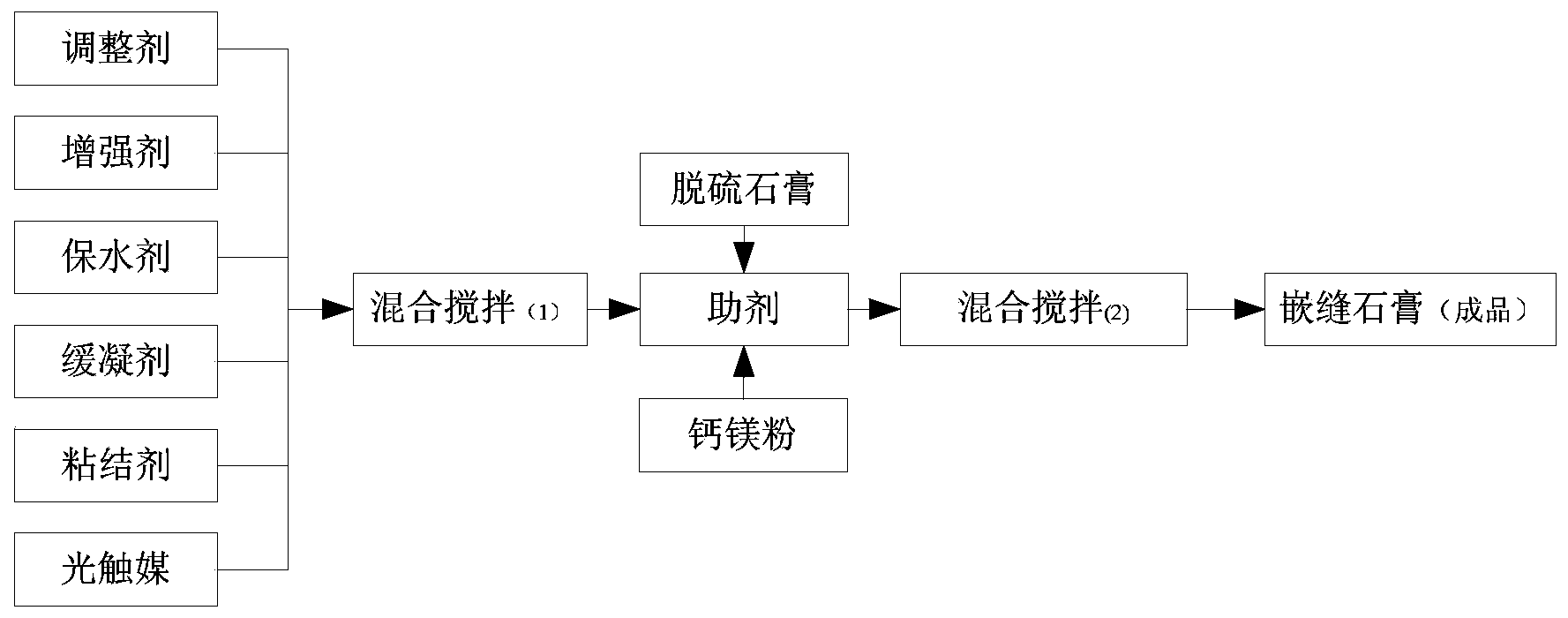

[0030] The preparation process of the present embodiment is as follows:

[0031] 1) Raw material ratio: according to the weight percentage, the adjustment agent is 1.0%, the strengthening agent is 0.5%, the water retention agent is 0.2%, the retarder is 0.3%, the photocatalyst is 0.2%, the binder is 0.2%, the desulfurization gypsum is 87%, and others It is about 10% of calcium magnesium powder.

[0032] 2) Preparation of additives: adjusting agent, reinforcing agent, water retaining agent, retarder, photocatalyst, and binder are mixed according to the weight ratio, and then the above mixed raw materials are sent to the mixer for one stirring and mixed evenly.

[0033] 3) Finished product synthesis: Add 87% of desulfurized gypsum powder and 10% of calcium magnesium powder to the mixture obtained in step 2) according to the weight percentage, perform secondary stirring and mixing, and obtain the finished caulking gypsum putty powder through two times of thorough mixing. can be ...

Embodiment 2

[0036] The preparation process of the present embodiment is as follows:

[0037] 1) Proportion of raw materials: according to the weight percentage, the adjustment agent is 2.0%, the reinforcing agent is 1.0%, the water retention agent is 0.4%, the retarder is 0.4%, the photocatalyst is 0.2%, the binder is 0.25%, the desulfurization gypsum is 80%, calcium Magnesium powder is 15%.

[0038] 2) Preparation of additives: adjusting agent, reinforcing agent, water retaining agent, retarder, photocatalyst, and binder are mixed according to the weight ratio, and then the above mixed raw materials are sent to the mixer for a stirring, fully stirring and mixing;

[0039] 3) Finished product synthesis: Add 80% of desulfurized gypsum powder and 15% of calcium and magnesium powder to the mixture obtained in step 2) according to the weight percentage, carry out secondary stirring and mixing, and obtain the finished caulking gypsum putty powder through two times of thorough mixing. can be u...

Embodiment 3

[0042] 1) Raw material ratio: according to the weight percentage, the adjustment agent is 3.0%, the strengthening agent is 1.5%, the water retention agent is 0.6%, the retarder is 0.5%, the photocatalyst is 0.2%, the binder is 0.2%, the desulfurization gypsum is 85%, calcium Magnesium powder 10%.

[0043] 2) Preparation of additives: adjusting agent, reinforcing agent, water retaining agent, retarder, photocatalyst, and binder are mixed according to the weight ratio, and then the above mixed raw materials are sent to the mixer for one stirring and mixed evenly.

[0044] 3) Finished product synthesis: Add 85% of desulfurized gypsum powder and 10% of calcium magnesium powder to the mixture obtained in step 2) according to the weight percentage, carry out secondary mixing and mixing, and obtain the finished caulking gypsum putty powder through two times of thorough mixing. can be used directly.

[0045] The caulking gypsum powder prepared according to this example meets the buil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com